Enhanced TiNi layered composite material and preparation method thereof

A layered composite material and matrix technology, applied in the direction of metal layered products, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as unsatisfactory bonding state and reduced bonding performance, and achieve broad application prospects and markets. Improved interfacial bonding strength and uniform heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: This example provides a kind of reinforced Ti / Ni layered composite material, is to obtain through the following steps:

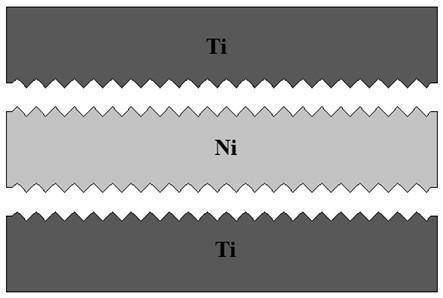

[0024] (1) Take 2 pure titanium plates and 1 nickel plate with dimensions of 0.7mm(h)×75mm(b)×100mm(l). Surface pretreatment is carried out, and the contact surface of titanium and nickel plates is made serrated with a milling machine or a lathe (see figure 2 ), then put it in a beaker filled with acetone and ultrasonically clean it for 30 minutes, then use the chemical soaking method to remove the metal oxide on the surface, then use absolute ethanol to clean the surface, wait for the absolute ethanol to volatilize, and then use the Ti / Ni / Ti structure Stacked together in order.

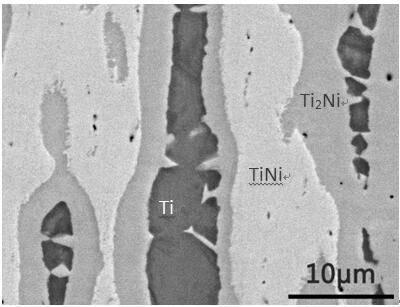

[0025] (2) Put the above-mentioned stacked samples into a heat treatment furnace protected by argon gas at 500°C for 10 minutes, and then immediately carry out single-pass rolling and compounding at a reduction of 50%. After rolling, the heterogeneous The thick...

example 2

[0027] Example 2: Cut the 6th pass composite board obtained in step 2 into such Figure 4 The tensile sample shown is then kept at 650°C for 4 hours in a heat treatment furnace protected by argon gas, and the tensile test is carried out by air-cooling, and the stress-strain curve is measured as follows: Figure 6 shown.

[0028] From Figure 5 , Figure 6 From the above, the mechanical properties of the Ti / Ni layered composite material prepared by the present invention are obviously better than those of the product not using this example, which shows that the present invention can significantly enhance the interfacial bonding performance of the layered composite material and then improve its mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com