SCR system automatic control method based on ammonia spraying sensitive valve locking

A technology of SCR system and sensitive valve, which is applied in the field of air pollutant control of coal-fired boilers, can solve the problems of increased ammonia escape, high ammonia injection volume, and large hysteresis, so as to improve reaction efficiency, save ammonia consumption, and reduce ammonia escape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of this technical solution. It should be understood that the embodiment is to illustrate the present invention, but the protection scope of the present invention is not limited to the embodiment.

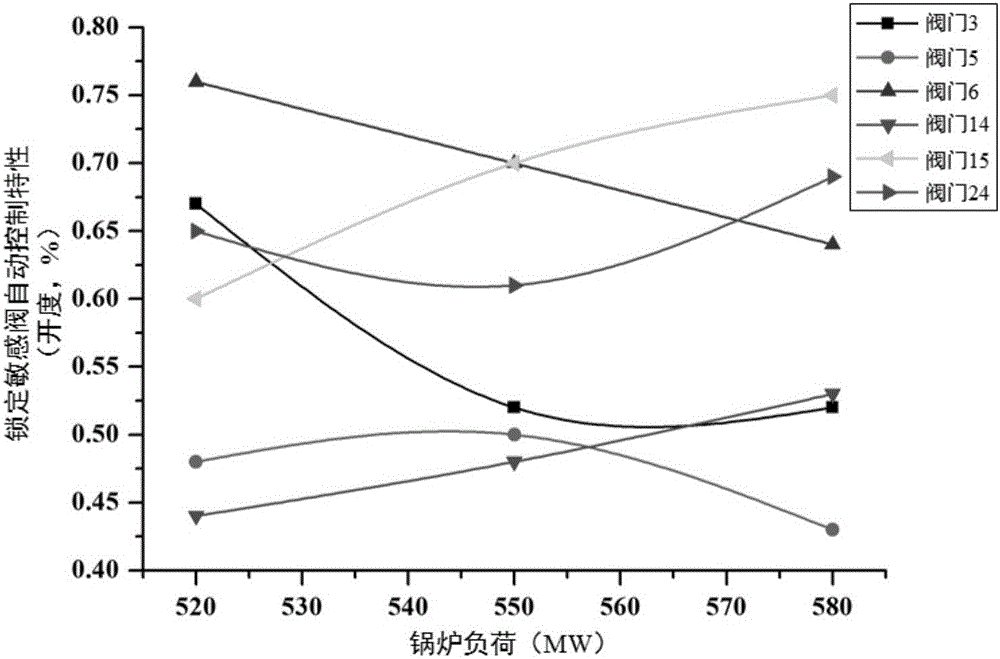

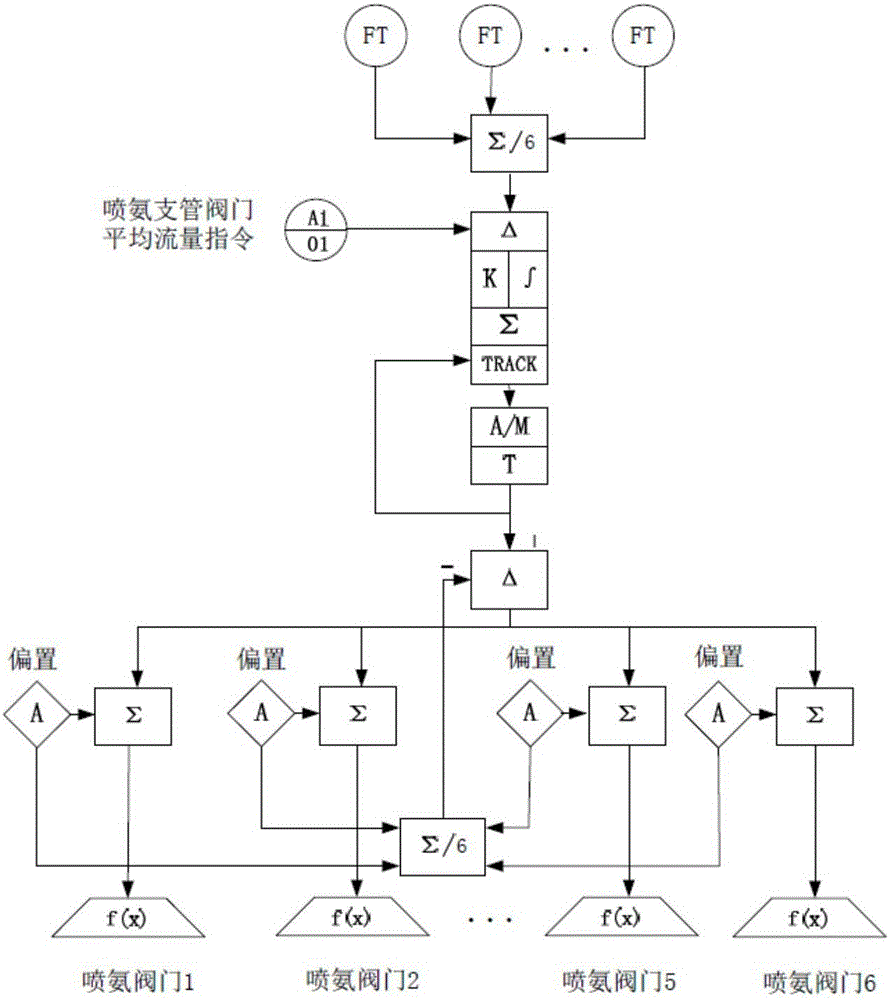

[0052] This implementation case is aimed at the development of AIG automatic control of SCR system for a 660MW coal-fired unit. The SCR ammonia injection system consists of 1 main valve, 2 main automatic regulating valves, 48 ammonia injection branch pipe valves (24 on each side), etc. The components coordinate to control the amount of ammonia injected. The following takes the development of AIG automatic control on the A side of the SCR system as an example to describe, and the specific implementation steps are as follows:

[0053] 1. Comprehensive analysis of operating characteristics of SCR system under variable load conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com