Combusting device for low nitrogen combustion of classification pre-mixed swirling flow

A combustion device and low-nitrogen combustion technology, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve problems such as incomplete combustion, technical effects that cannot achieve environmental protection, and uneven mixing of gas and air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

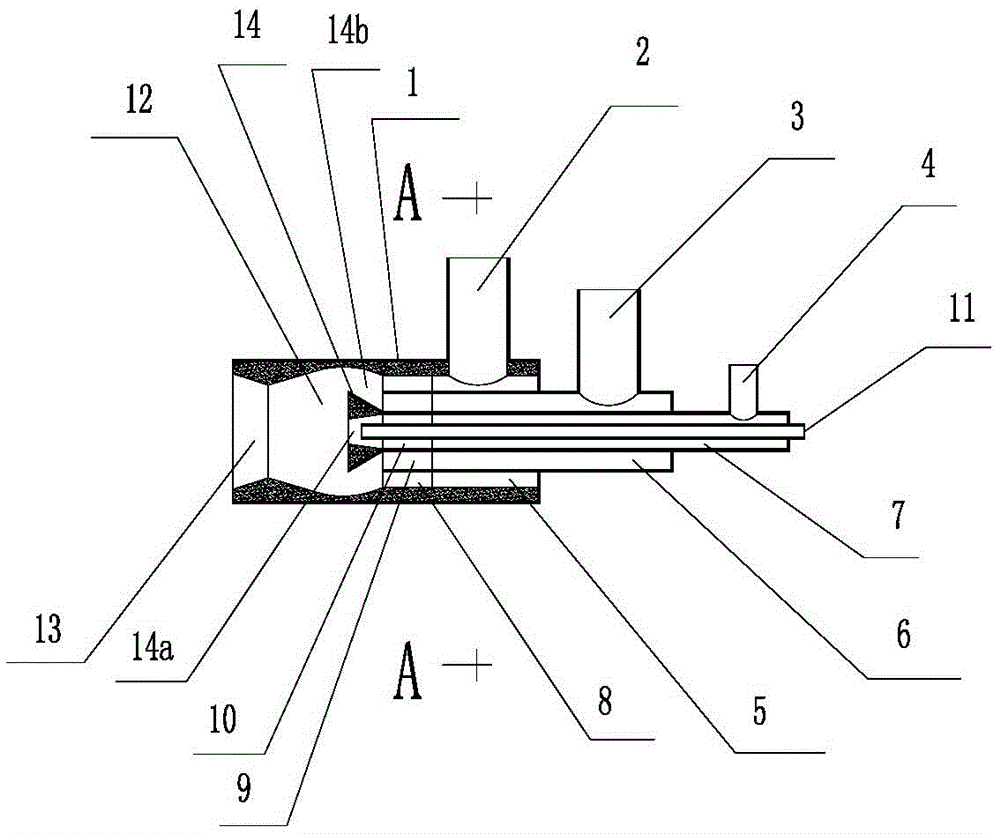

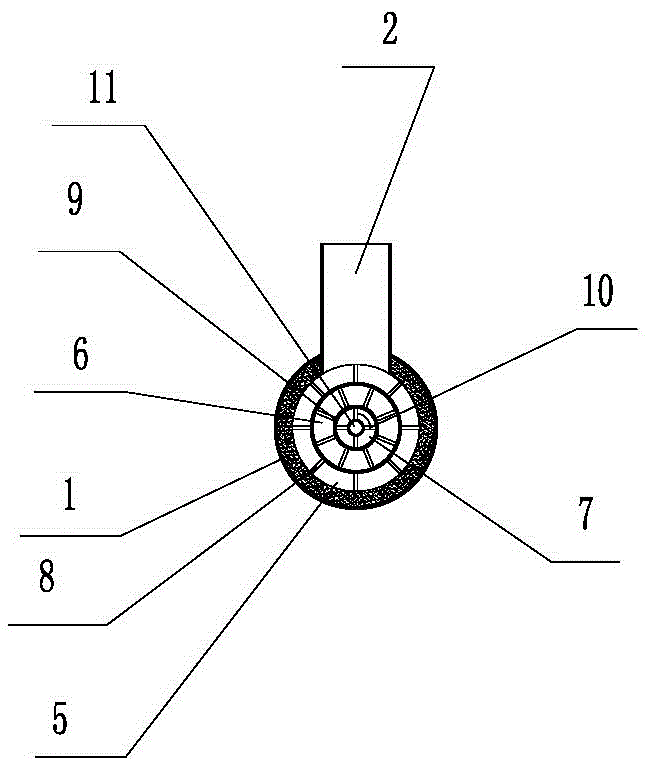

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] like figure 1 and figure 2 As shown, the structure of the present invention is that the cylinder body 1 of the combustion device is composed of four tube bodies that are concentrically set together in a stepped shape from the inside to the outside, forming a central channel and three annular channel structures. Outside the center of the central tube, the outer ends of the other three tubes are closed. The outermost annular channel among the three annular channels is the air annular channel 5, and there is a connected air channel on the outer wall near the closed end of the air annular channel. Inlet pipe 2, an air swirl support sheet 8 is arranged in the outlet section of the air annular channel; the innermost annular channel among the three annular channels is the auxiliary air ring channel 7, and there is a wall near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com