Preparation of spherical silicon dioxide

A technology of spherical silica and silicon dioxide, which is applied in the direction of silica and silicon oxide, can solve the problems of high cost, high equipment requirements, and unstable product quality, and achieve high ball forming rate, good dispersibility, The effect of engineering stability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

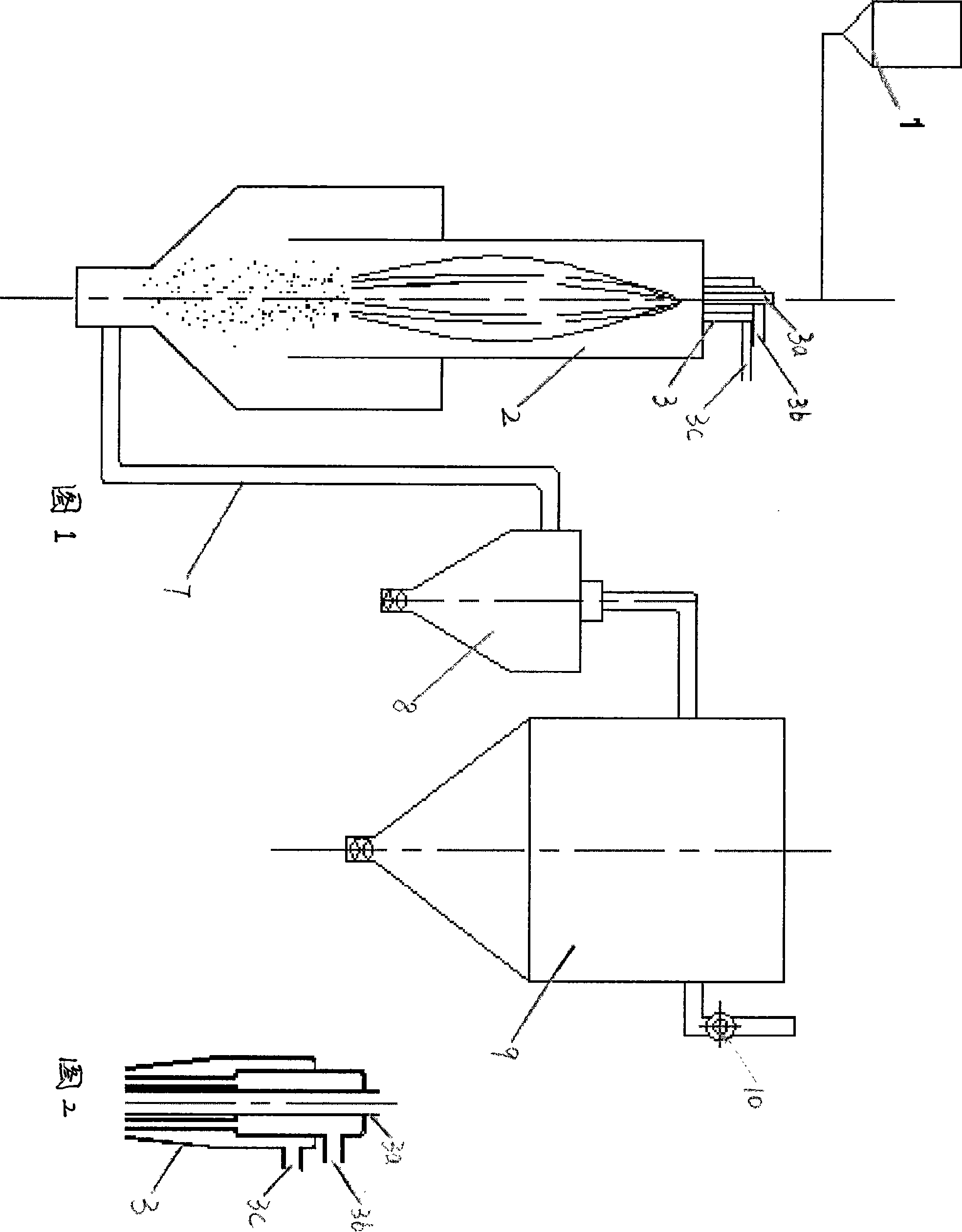

[0037]Example 1: Choose silica raw materials and grind them to obtain angular silica particles through physical actions such as mutual collision and shearing. The obtained angular silica granules are put into the silica granule hopper 1 . As shown in Figures 1 and 2, the pipelines of natural gas, oxygen, and silica particles are connected to the combustion furnace 2, and the oxygen, natural gas, and silica particles used for combustion enter the combustion furnace through the same nozzle 3, and the nozzle 3 has an internal Layer 3a, middle layer 3b, and outer layer 3c are composed of three layers, wherein the inner layer 3a is connected to the silica particle hopper 1, the middle layer 3b is connected to natural gas, and the outer layer 3c is connected to oxygen. In this embodiment, the feed rate of oxygen is 2.3 times that of natural gas (the ratio of the amount of substances). The internal space of the combustion furnace 2 is a cylinder with a diameter of 3m and a height of...

Embodiment 2

[0039] Embodiment 2: The difference between this embodiment and Example 1 is that the feed rate of the oxygen is 3.2 times of the feed rate of natural gas, and the inside of the combustion furnace is a cylinder with a height of 15 m between 6 m; The residence time of the silica in the flame is 0.6s; the silica particles in this embodiment are sent into the combustion furnace by compressed air.

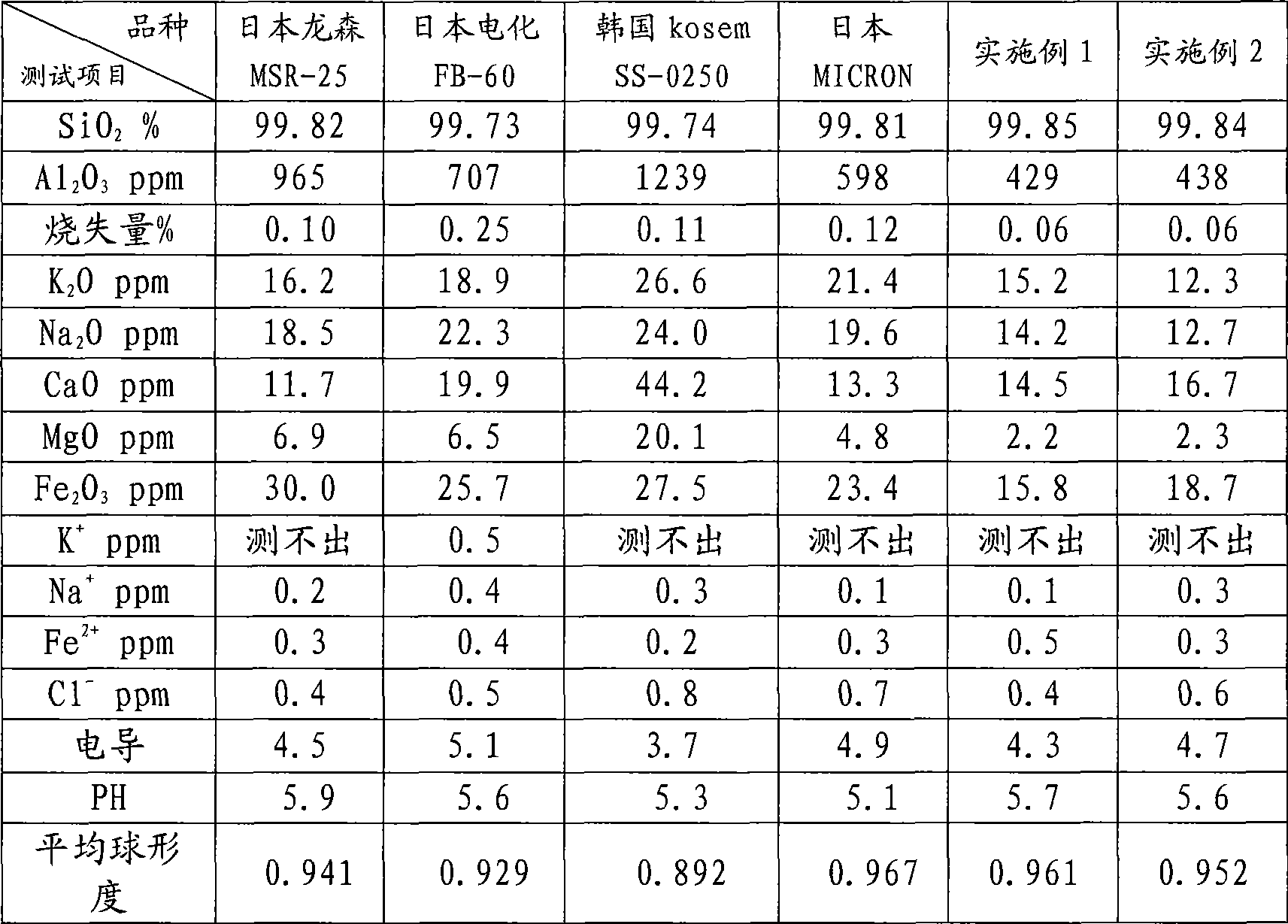

[0040] Table 1

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com