Coal-burning boiler coupling biomass fuel gas combustion device and combustion system arrangement method using same

A biomass gas and combustion device technology, applied in the direction of combustion methods, combustion using gaseous fuels and powder fuels, and controlled combustion, can solve the effects of fuel burnout nitrogen oxide emissions, boiler efficiency, combustion aerodynamic field, Does not have low nitrogen capacity and other issues, and achieves the effect of wide load adaptability, low emission concentration, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

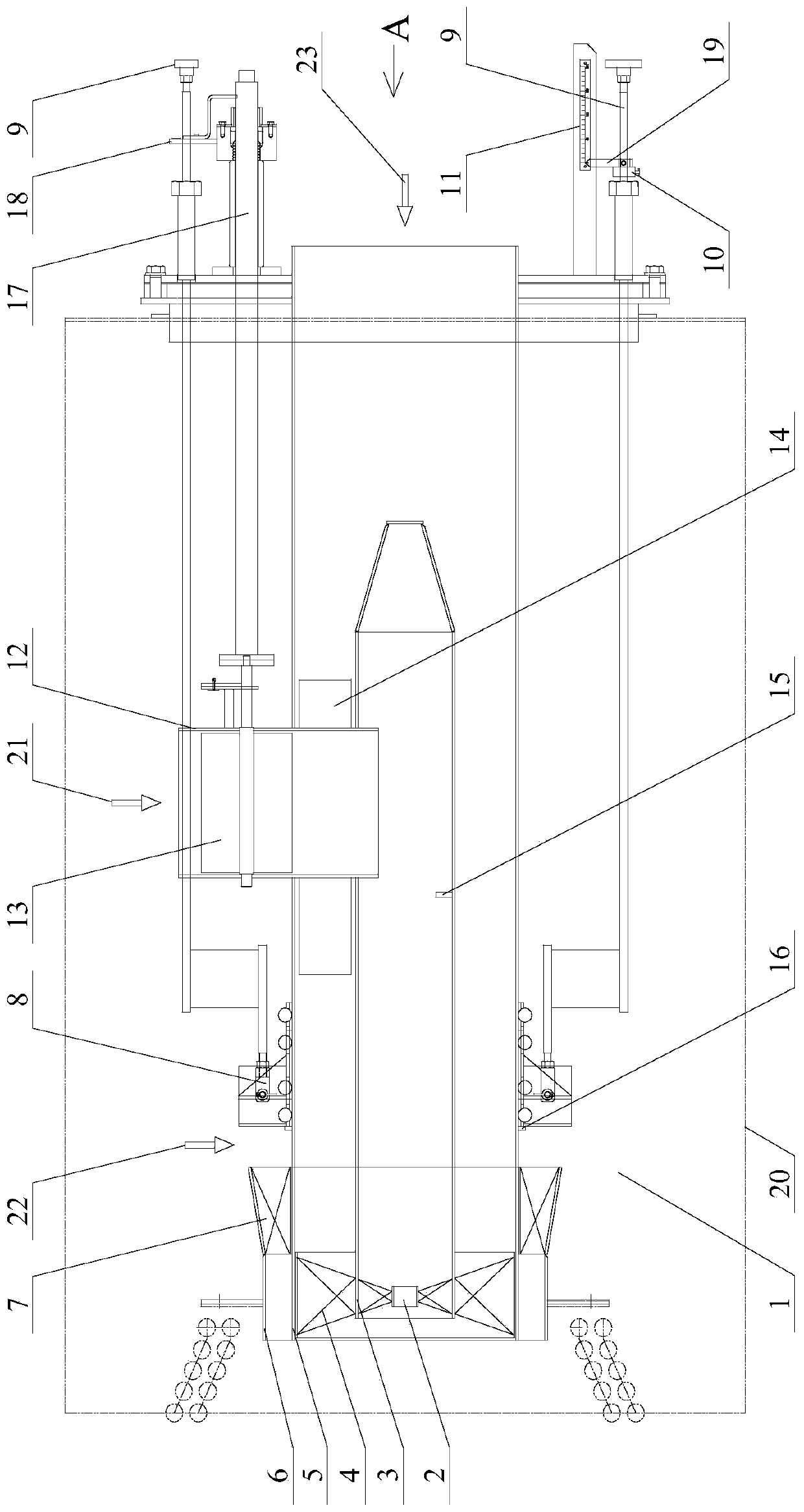

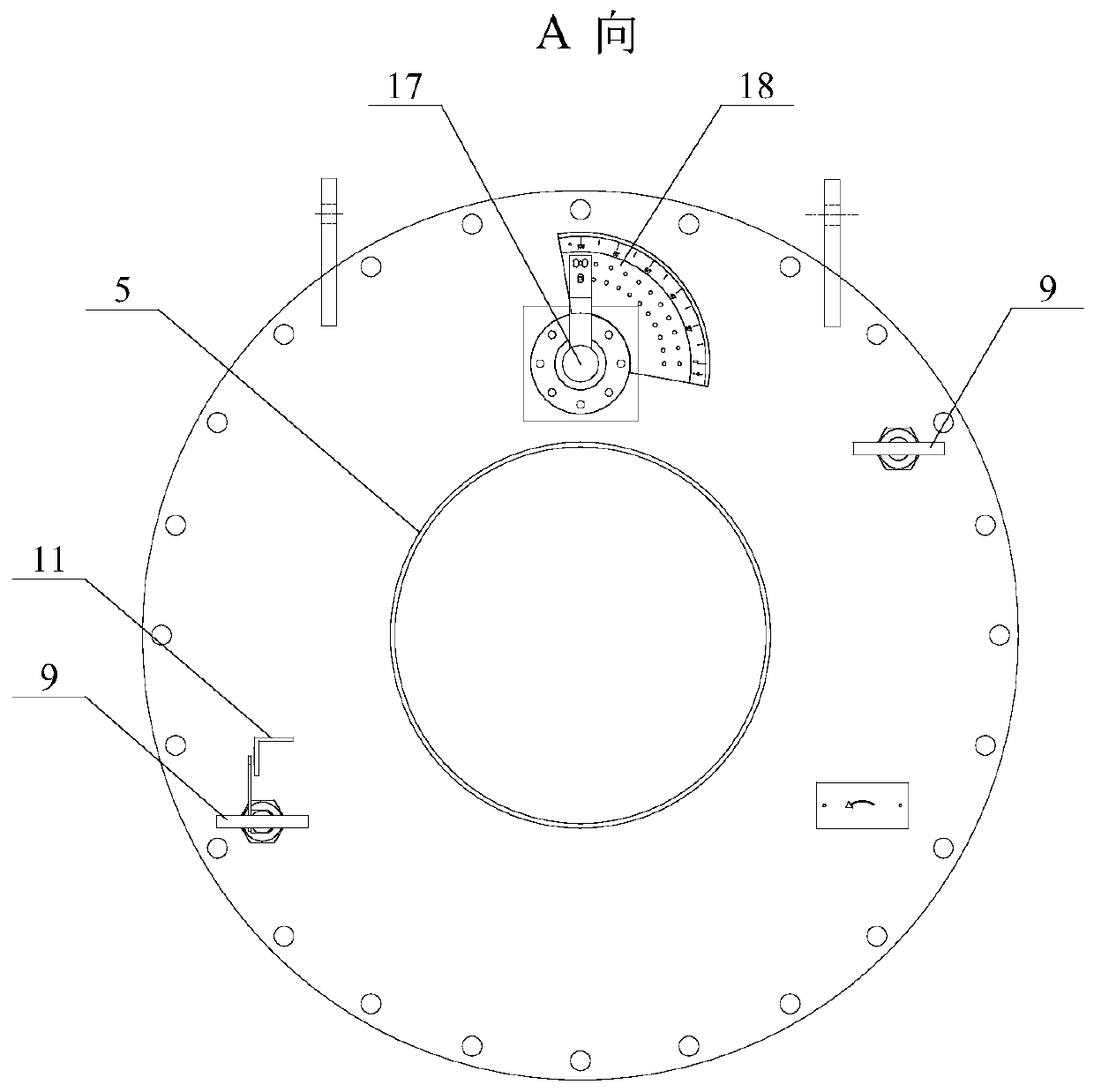

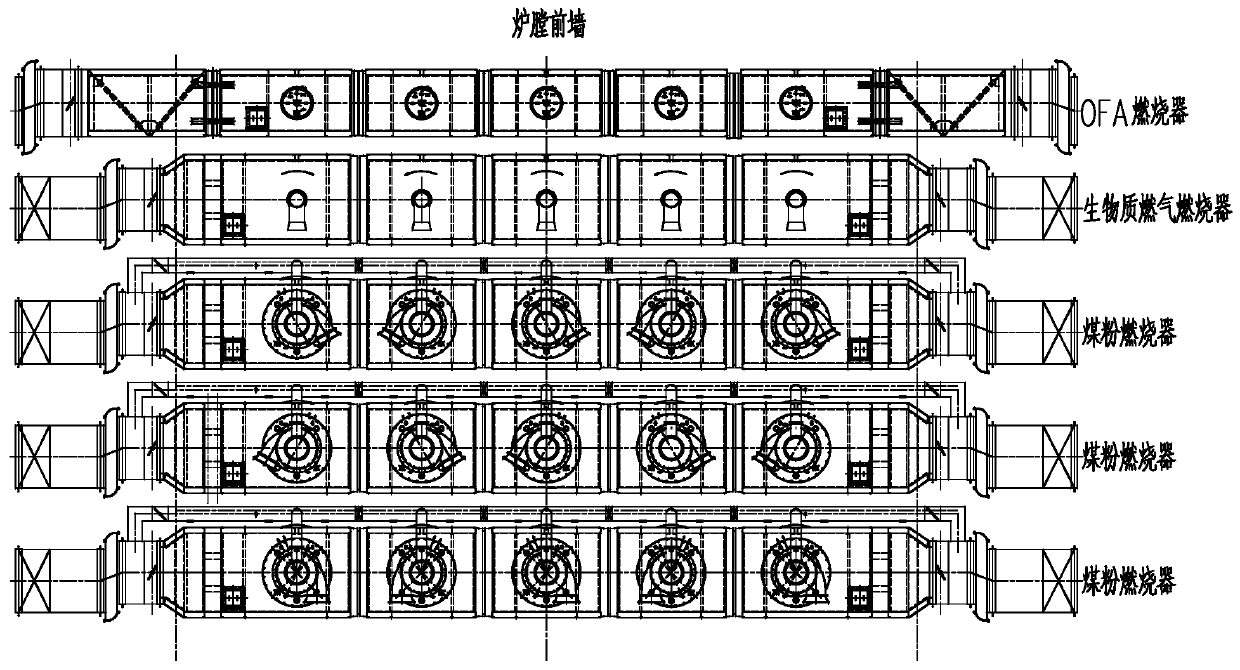

[0015] Such as figure 1 and figure 2 As shown, a coal-fired boiler coupling biomass gas combustion device involved in this embodiment includes: a biomass gas combustion device 1, a central air swirl device 2, a central air cylinder 3, a gas swirl device 4, and a gas channel 5. Secondary air pipe 6. Secondary air swirl device 7. Secondary air door adjustment mechanism 8. Secondary air door adjustment rod 9. Positioner 10. Secondary air door indicator scale 11. Central air introduction channel 12. Central air volume adjustment Baffle plate 13, conical blunt body 14, central wind block 15, secondary air volume adjustment de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com