Patents

Literature

955results about How to "Aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

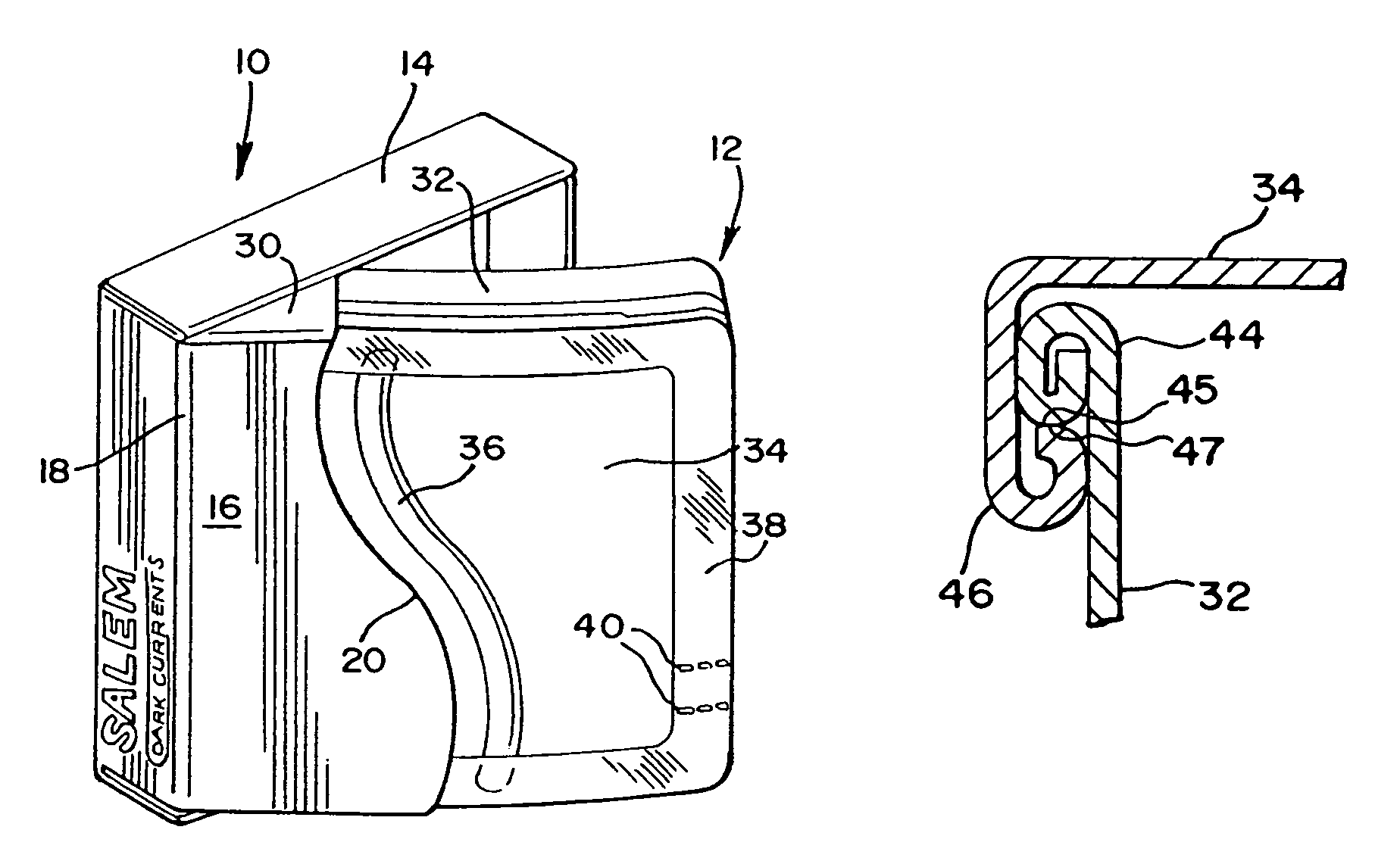

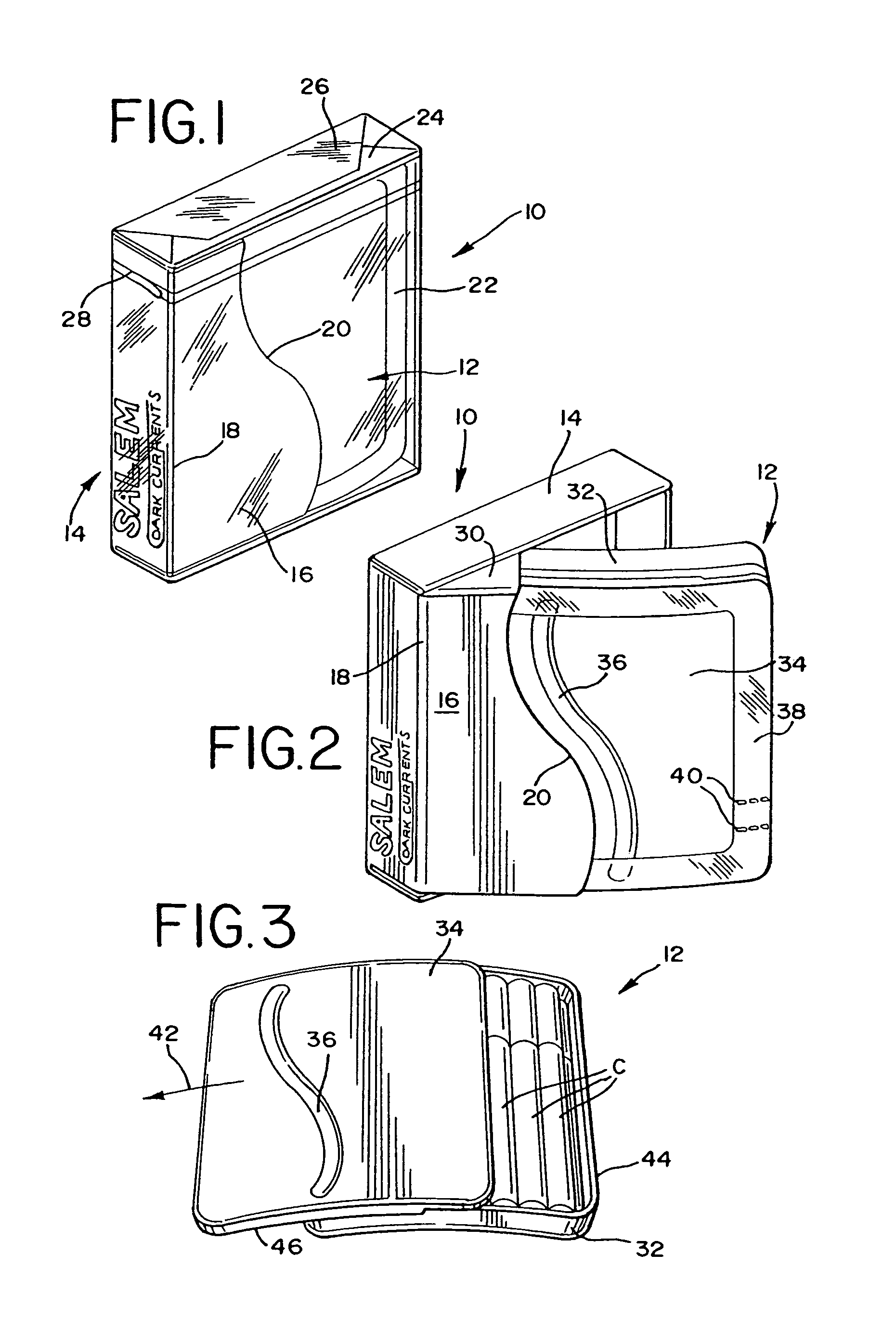

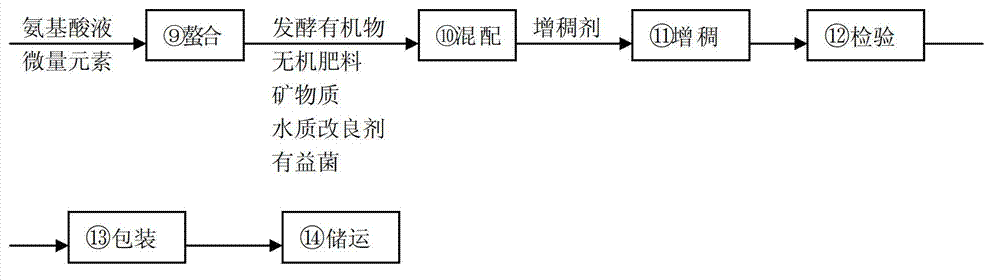

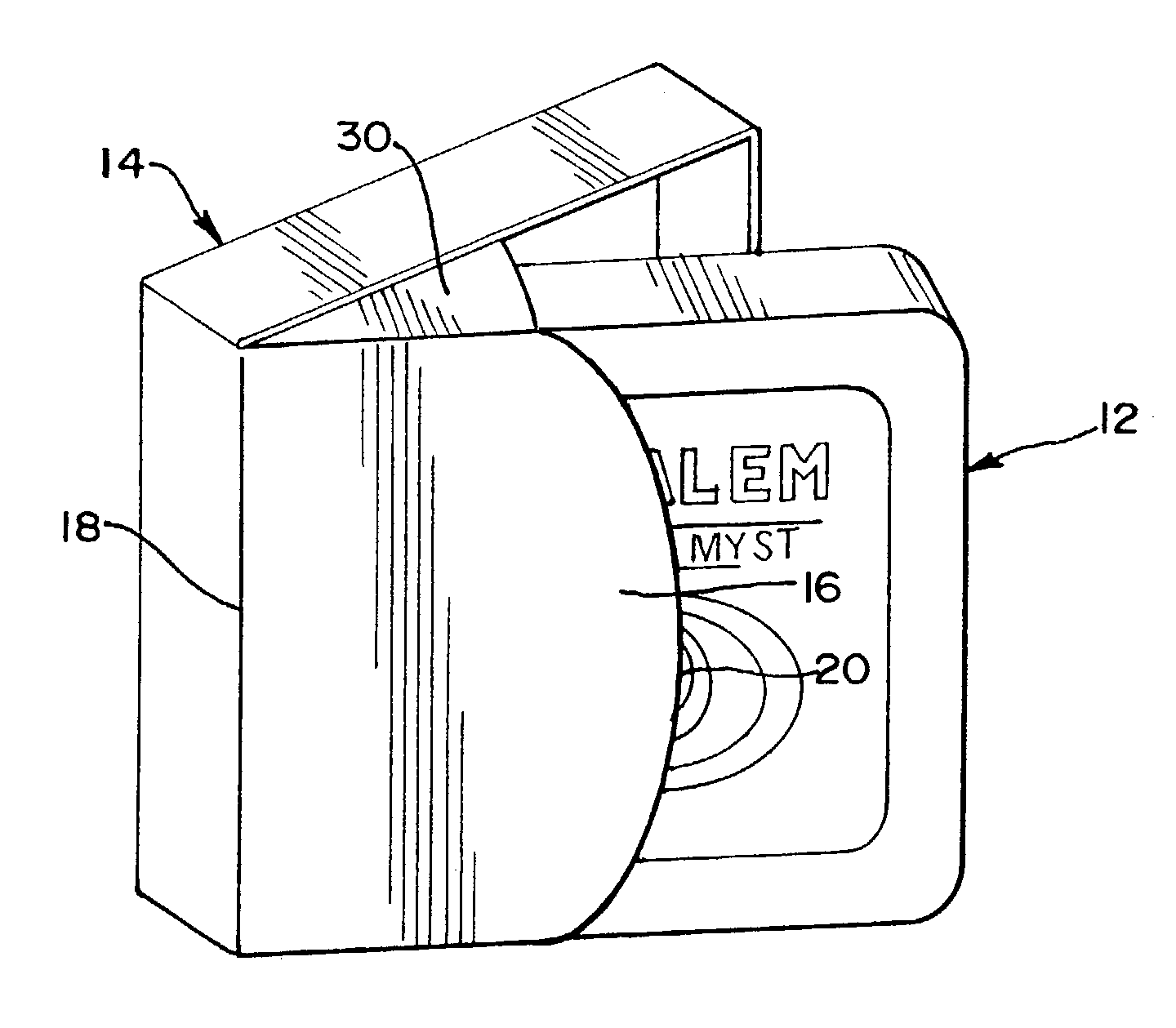

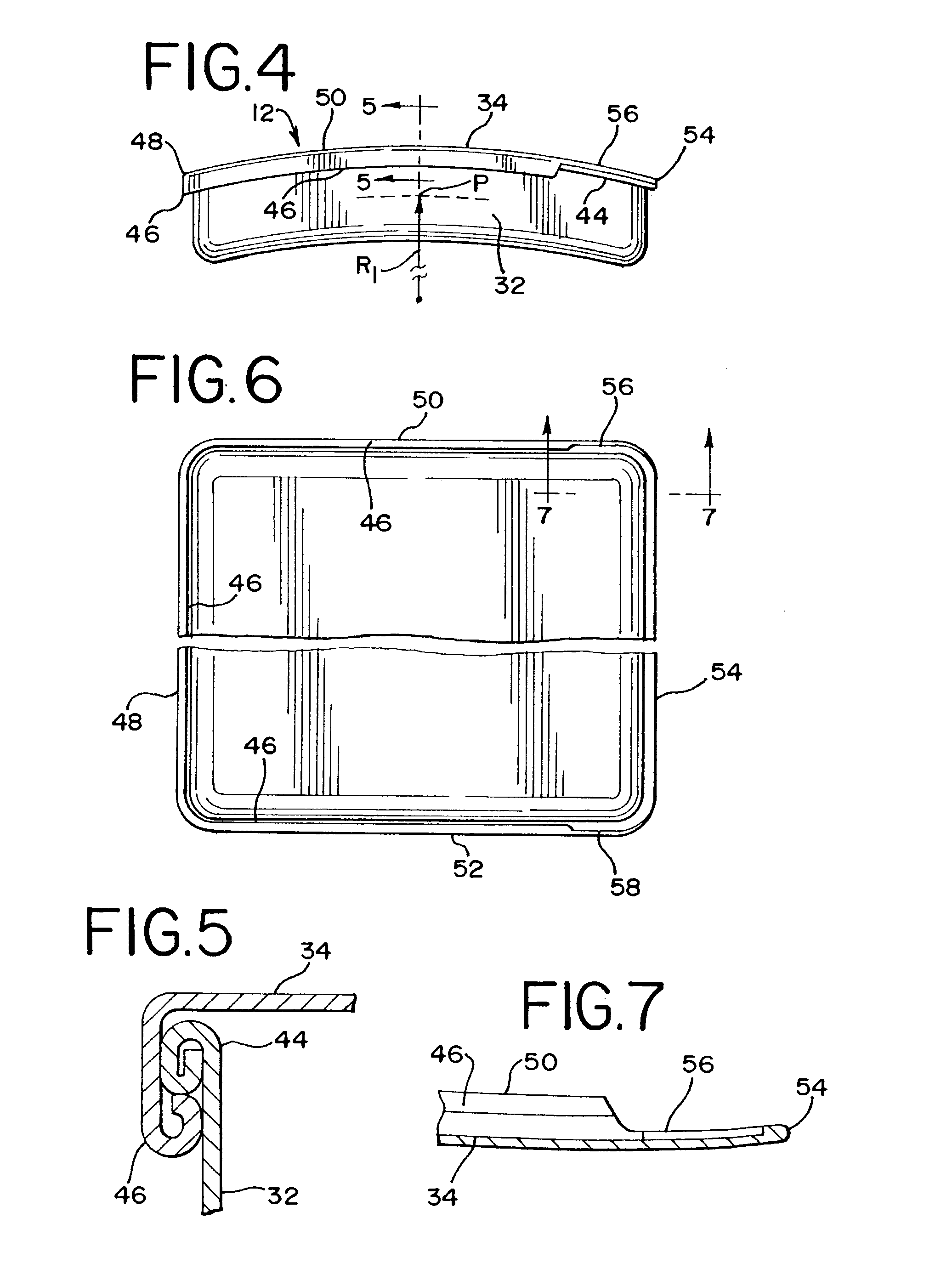

Sliding shell package for smoking articles

InactiveUS7014039B2Increase stiffnessMaximum engagementContainers for flexible articlesPackaging cigaretteAbutmentBiomedical engineering

Smoking articles, such as filter cigarettes, are packaged in a metal box which is curved to a shape that conforms to the curvature of the human body so that the box can be comfortably carried in a shirt or pant pocket. The metal box comprises a lid and a four sided tray. The lid and the tray have rolled lips which interengage to mechanically and slidably retain the lid to the tray. The lid covers the open front of the tray and is slidable along an arcuate path corresponding to the radius of curvature of the lid to selectively open or close the front of the tray. The lid of the box includes an abutment that prevents the lid of the box from being completely removed unless additional force is applied to push the abutment past the rear wall of the tray.

Owner:R J REYNOLDS TOBACCO COMPANY

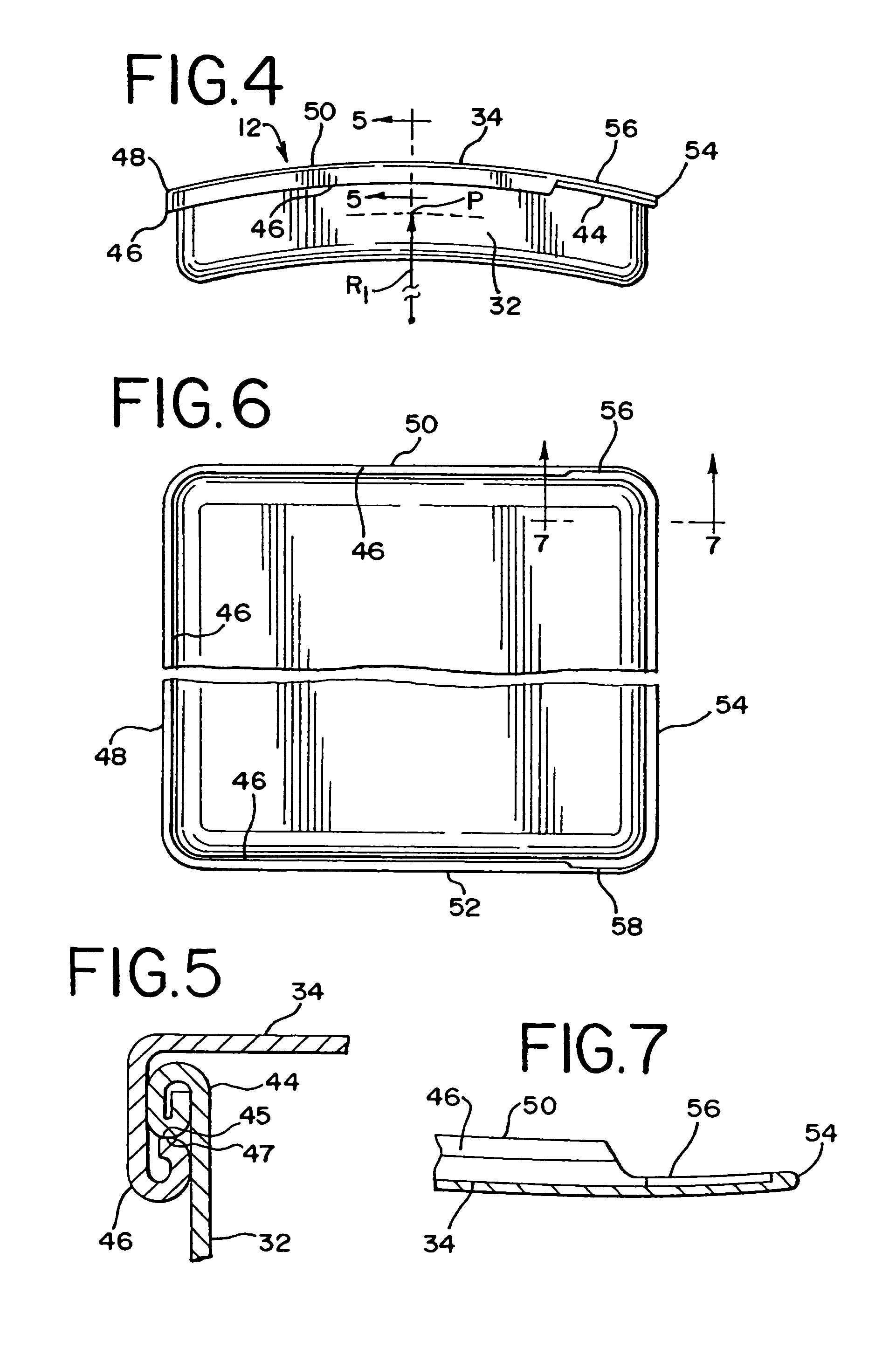

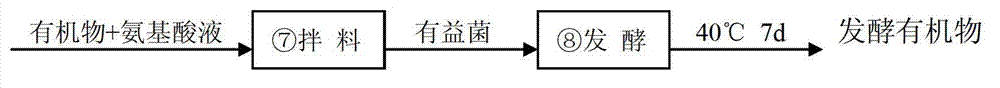

Special amino acid fertilizer-water paste for aquiculture and preparation method thereof

The invention discloses a special amino acid fertilizer-water paste for aquiculture and a preparation method thereof. The special amino acid fertilizer-water paste for aquiculture is prepared from the following raw materials in certain proportion: an amino acid solution, microelements, fermentation organic substances, inorganic fertilizers, minerals, a water quality improver, beneficial bacteria and a thickening agent. The preparation method comprises the following steps: A. production of amino acid solution namely, a. hydrolyzing; b. neutralizing; c. filtering; d. concentrating; B. production of fermentation organic substances: a. mixing: evenly mixing organic raw materials with the amino acid solution; b. inoculation: evenly mixing the organic raw materials with beneficial bacteria; c. fermentation; and C. production of amino acid fertilizer-water paste: a. chelation: heating the amino acid solution, adding microelements while stirring to perform chelation; b. mixing: sequentially adding the fermentation organic substances, inorganic fertilizer, minerals, water quality improver and beneficial bacteria, and evenly mixing; c. thickening: adding a thickening agent, and evenly mixing; d. inspection. The invention enhances the immunity of fish, reduces the occurrence of diseases, increases the culture yield of bighead, lowers the fish culture cost, and improves the fish quality.

Owner:武汉市洪山吕墩氨基酸厂

Sliding shell package for smoking articles

InactiveUS20040256253A1Increase stiffnessMaximum engagementContainers for flexible articlesPackaging cigaretteAbutmentBiomedical engineering

Smoking articles, such as filter cigarettes, are packaged in a metal box which is curved to a shape that conforms to the curvature of the human body so that the box can be comfortably carried in a shirt or pant pocket. The metal box comprises a lid and a four sided tray. The lid and the tray have rolled lips which interengage to mechanically and slidably retain the lid to the tray. The lid covers the open front of the tray and is slidable along an arcuate path corresponding to the radius of curvature of the lid to selectively open or close the front of the tray. The lid of the box includes an abutment that prevents the lid of the box from being completely removed unless additional force is applied to push the abutment past the rear wall of the tray.

Owner:R J REYNOLDS TOBACCO COMPANY

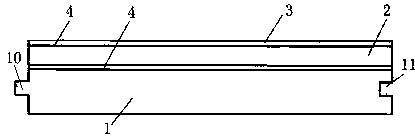

Anion anti-microbial mildew-proof floor

InactiveCN104234368AGood for healthFresh smellBiocideNon-macromolecular adhesive additivesWear resistantAdhesive

The invention discloses an anion anti-microbial mildew-proof floor. The mildew-proof floor is composed of a damp-proof layer, a TCM (Traditional Chinese Medicine) board layer, an anion adhesive layer and a wear-resistant layer, wherein the damp-proof layer, the TCM board layer, the anion adhesive layer and the wear-resistant layer are sequentially arranged from down to up, and the upper and lower surfaces of the TCM board layer are respectively glued with the damp-proof layer and the wear-resistant layer through the anion adhesive layer; the anion adhesive layer consists of a soy protein adhesive and anion natural mineral substance powder, wherein the mass ratio of the soy protein adhesive to the anion natural mineral substance powder is 4:1, the anion natural mineral substance powder is a mixture of tourmaline, lanthanide rare earth compound salt and titanium dioxide in accordance with the weight ratio of 4:3:3, therefore anions can be continuously released to remove formaldehyde, other hazardous substances and indoor peculiar smell, and realize bacteria resistance and bacteriostasis and purify indoor air, so health efficacy is achieved; furthermore, Chinese herbal medicinal ingredients contained in the anion anti-microbial mildew-proof floor can play a role in mosquito repellent, bacteria resistance, bacteriostasis and multiple functions, therefore the anti-microbial mildew-proof floor has an extensive application prospect.

Owner:ZHONGSHAN YIZHAN DECORATION ENGINEERING CO LTD

Preserved meat and pickling method thereof

ActiveCN103610088AGuarantee the traditional qualityRich cured meatFood ingredient as flavour affecting agentFood preparationLean meatAdditive ingredient

The invention relates to the technical field of animal product processing and in particular relates to preserved meat and a pickling method of the preserved meat. The preserved meat is obtained by pickling pork by using edible salt, white spirit, peppers, anises, cloves, tea, white sugar and nitrate. The pickling method comprises the steps of (1) pretreatment; (2) immersing;(3) salt frying and pickling; (4) air-drying; (5) fumigation-drying; (6) cooling; and (7) package. According to the preserved meat and the pickling method of the preserved meat, the using amount of pickling ingredients is small, so that the conventional flavor and the color of the preserved meat are guaranteed; the preserved meat is brown, transparent and shiny, is the same in reality as in appearance and smells delicious; the good smell can be kept for a long time; the preserved meat is tender and fat but not greasy; furthermore, the pickling flavor is strong; lean is kermesinus, and fat is milk white; meanwhile, the salt content is only 1.6-2 percent; people do not feel seriously thirsty after eating the preserved meat. The preserved meat is immersed in boiled tea water, so that the meat has natural, fresh, cool and pleasant tea flavor; fumigation is executed by combusting tea tree branches, so that the natural tea fragrance of the preserved meat is enhanced.

Owner:重庆渝旺食品股份有限公司

Tea making technology using light microwaves

InactiveCN102754707AShorten the production cycleReduce lossesPre-extraction tea treatmentMicroorganismMicrowave applications

The invention discloses a tea making technology using light microwaves. The technology comprises the following steps of: sunning with light waves; putting fresh tea leaves in light wave equipment; turning on a power supply, wherein the wavelength of the light waves is 250-800nm, the power is 400-3,000W, and the illumination time is 1-10min; removing green with light microwaves, drying and sterilizing; extracting aroma with light waves; and performing tea screening, check and vacuum packing to obtain a tea product. The light microwaves are applied to the tea processing; and due to the non-thermal effect of the light microwave electric field in the green removing and drying processes, the processing time is greatly shortened, and the tea quality is maintained. Meanwhile, the light microwaves have a sterilization function and can effectively kill microorganisms in tea. Through the tea making technology using light microwaves, the fresh leaves can be collected and processed on the site, and the processes of sunning, green removing, drying, aroma extraction and sterilization are finished in one step, thus the efficiency is high, the operation is simple and the production cost is effectively reduced. Through the invention, the prepared tea has high and stable quality.

Owner:FUZHOU HUAINANZI BIOLOGICAL TECH

Feed for crabs

InactiveCN103284016AMeet the needs of growthIncrease appetiteAnimal feeding stuffBiotechnologyAnimal science

The invention belongs to the technical field of feeds and particularly relates to a feed for crabs. The feed for crabs is characterized by comprising the following materials in parts by weight: 30-60 parts of pork skin, 20-50 parts of fat pork, 5-15 parts of lean pork, 6-9 parts of corn meal, 3-5 parts of soybean meal, 1-5 parts of edible oil, 0.1-1 part of garlic cloves, 1-2 parts of fish scale powder and 0.5-1.5 parts of rape seed cakes. The main problems that since the feed for crabs is difficult to absorb, the crabs grow slowly and the water quality is contaminated in the prior art are solved; the feed disclosed by the invention has the beneficial effects of being rich in nutrition and aromatic in smell, containing antiviral components, and enabling the crabs to grow fast after the feed is eaten; the feed is simple to prepare and all the materials of the feed are rich in supply.

Owner:陈瑜 +7

Method for preparing Tujia cured meat

The invention relates to a method for preparing Tujia cured meat. The method comprises the following 10 processes of: preparing a meat blank raw material, stirring and mixing the raw material, pickling, soaking, airing, baking, smudging, mixing colors, protecting the colors and taste and packaging. The method has the advantages that pricklyash peel and table salt are used only in pickled ingredients, so that the conventional distinctive character of pickling the Tujia cured meat is kept; the operation of baking for dehydration and the operation of smudging for flavoring is separated in the smoke curing process, so that the cured meat can be controlled; the taste of the cured meat is fragrant and diffused by using smoke generated by fresh pine and cypress branches and oriental oak wood; the colors are mixed by utilizing the concentration of the smoke, so that the natural color of the cured meat is kept and an effect of brown color can also be achieved under the condition that pigments are not used; and by the processes of protecting the colors and taste and packaging, the specific color of the cured meat is constant for a long time, and the cured meat can be stored for a long time without deterioration. The Tujia cured meat is brown in color, transparent, bright, consistent in outside and inside, diffused in fragrance, soft in mellow taste, tender in meat and fat but not greasy.

Owner:重庆敦康农业发展股份合作社

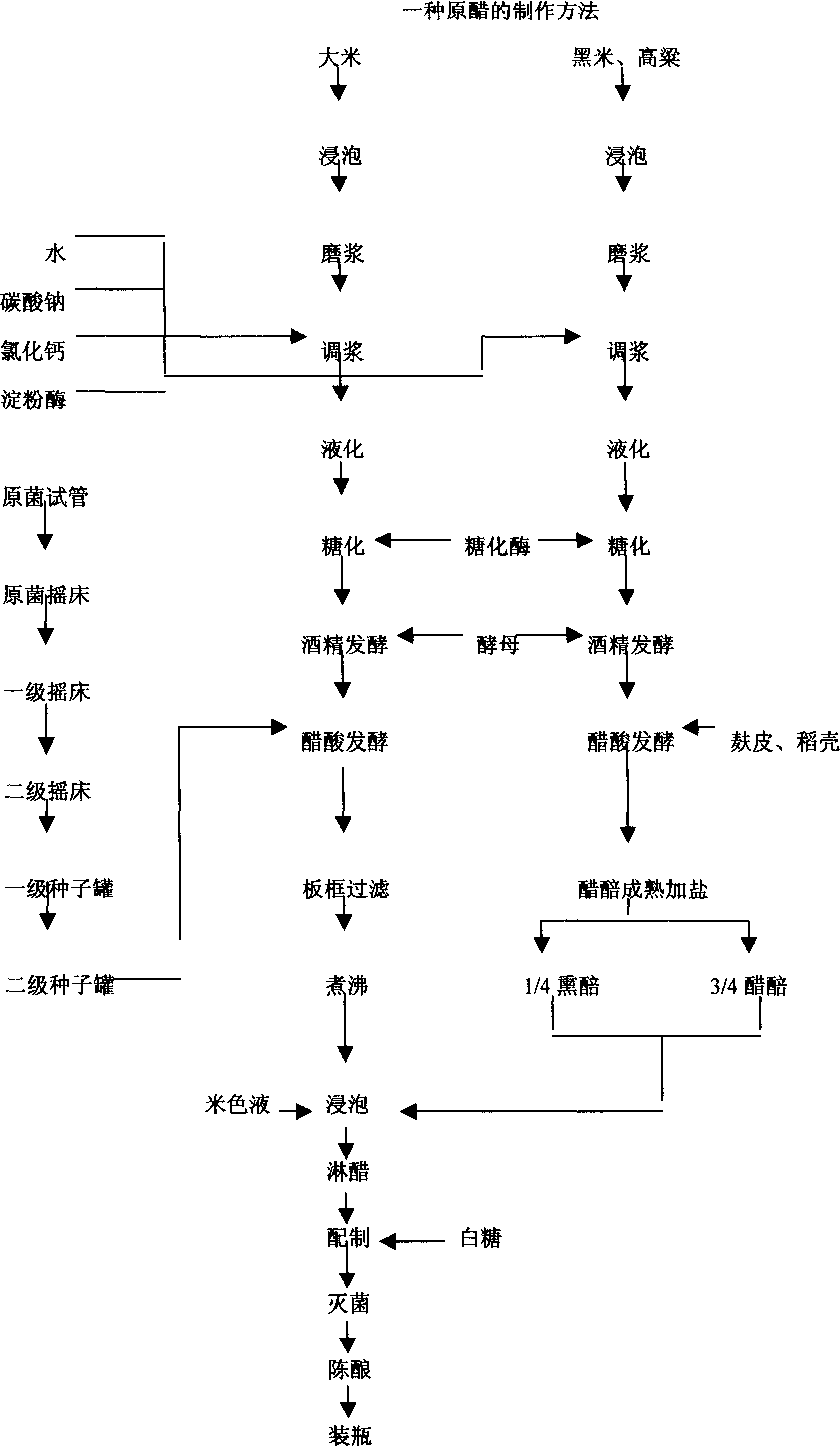

Vinegar making process

The present invention discloses vinegar making process, in which rice, sodium carbonate, salt, calcium chloride, alpha-amylase, sugar, saccharifying enzyme, yeast, water and rice hull or wheat bran in certain weight proportion are used as material. The made vinegar is brown, bight, fragrant, mildly sour and slightly sweet, and has total acid amount account with acetic acid not less than 4.0 g each 100 ml.

Owner:陈松

Health-care type floor material with anion releasing function

InactiveCN104295055AGood for healthFresh smellBiocideNon-macromolecular adhesive additivesAdhesiveNatural mineral

A health-care type floor material with an anion releasing function comprises a damp-proof layer, a traditional Chinese medicine material plate layer, an anion adhesive layer and an anti-abrasion layer. The anion adhesive layer is composed of a soy protein adhesive and anion natural mineral powder, wherein the mass ratio of the soy protein adhesive and the anion natural mineral powder is 4:1, the anion natural mineral powder is a mixture of tourmaline, lanthanide rare earth composite salt and titanium dioxide, the mass ratio of the tourmaline, the lanthanide rare earth composite salt and the titanium dioxide is 3:3:4, and the tourmaline is a mixture of dravite and elbaite in the mass ratio of 6:4. Anions can be released continuously, harmful matter such as formaldehyde and indoor odors are removed, an anti-bacterial effect is achieved, indoor air is purified, and a health-care effect is achieved. Besides, the floor contains natural traditional Chinese medicine components so that mosquito-repellent and anti-bacterial functions can be achieved, and the floor is multifunctional and has very wide application prospects.

Owner:ZHONGSHAN YIZHAN DECORATION ENGINEERING CO LTD

Method for preparing camellia oil

InactiveCN101831352AColor light yellowClear and transparent colorFatty-oils/fats refiningWater dischargeWastewater

The invention discloses a method for preparing camellia oil. The method is implemented by the following steps of: physically de-acidifying degummed crude tea seed oil from which impurities are removed to keep free fatty acid in the crude oil less than 0.4 percent, wherein peroxide and odoriferous substances in the crude oil, in particular the free fatty acid are removed in a physical de-acidifying process; performing alkaline refining and deacidification for ensuring the color and luster of physically de-acidified oil; adding sodium silicate and alkali into the oil in turn respectively; washing and standing the mixture; washing the mixture with water; drying the washed mixture; and de-coloring and deodorizing the dried mixture to obtain refined camellia oil. The method has the characteristics of low consumption of needed auxiliary materials, little waste water discharge, less produced soapstock, short deodorizing time and low production cost.

Owner:黄崇芳

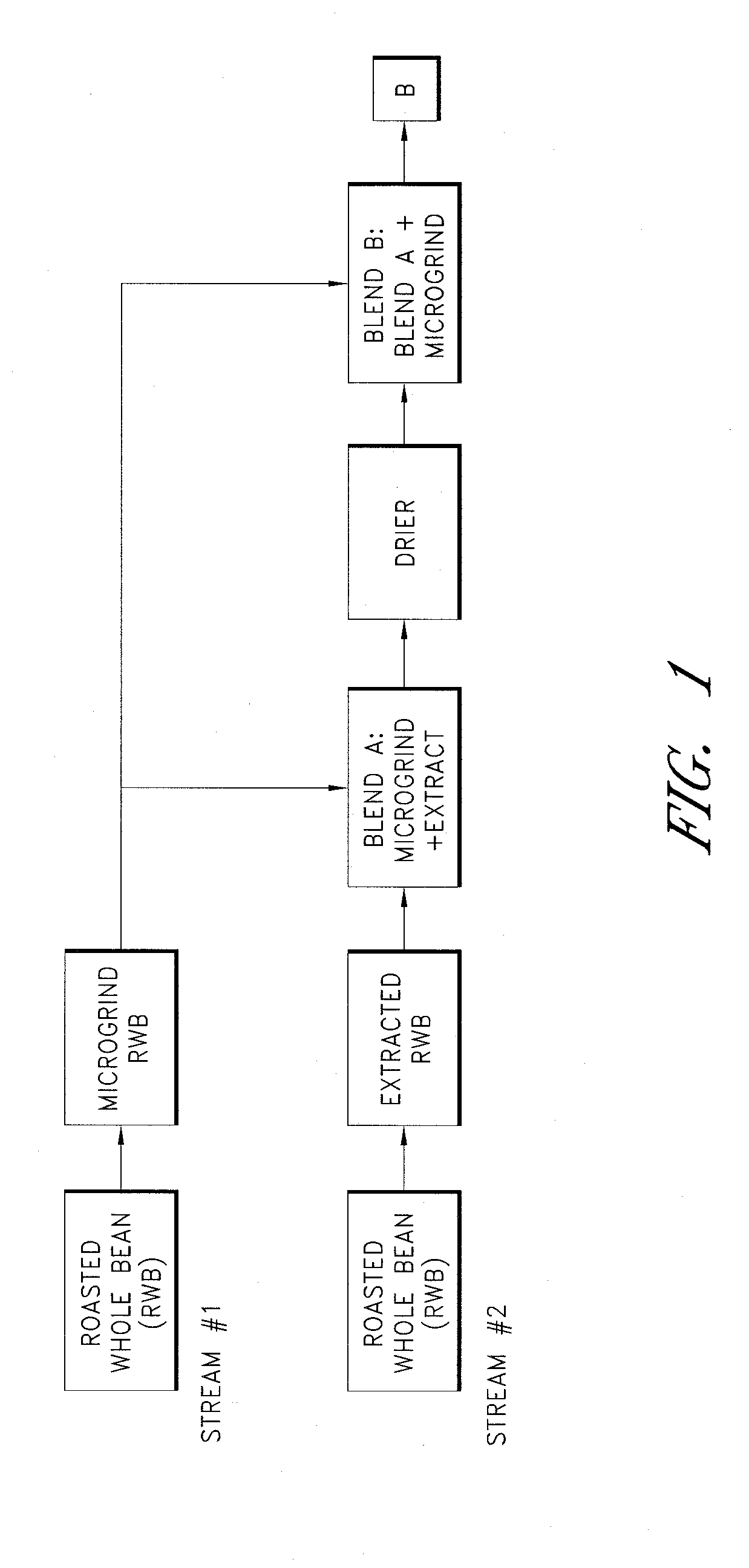

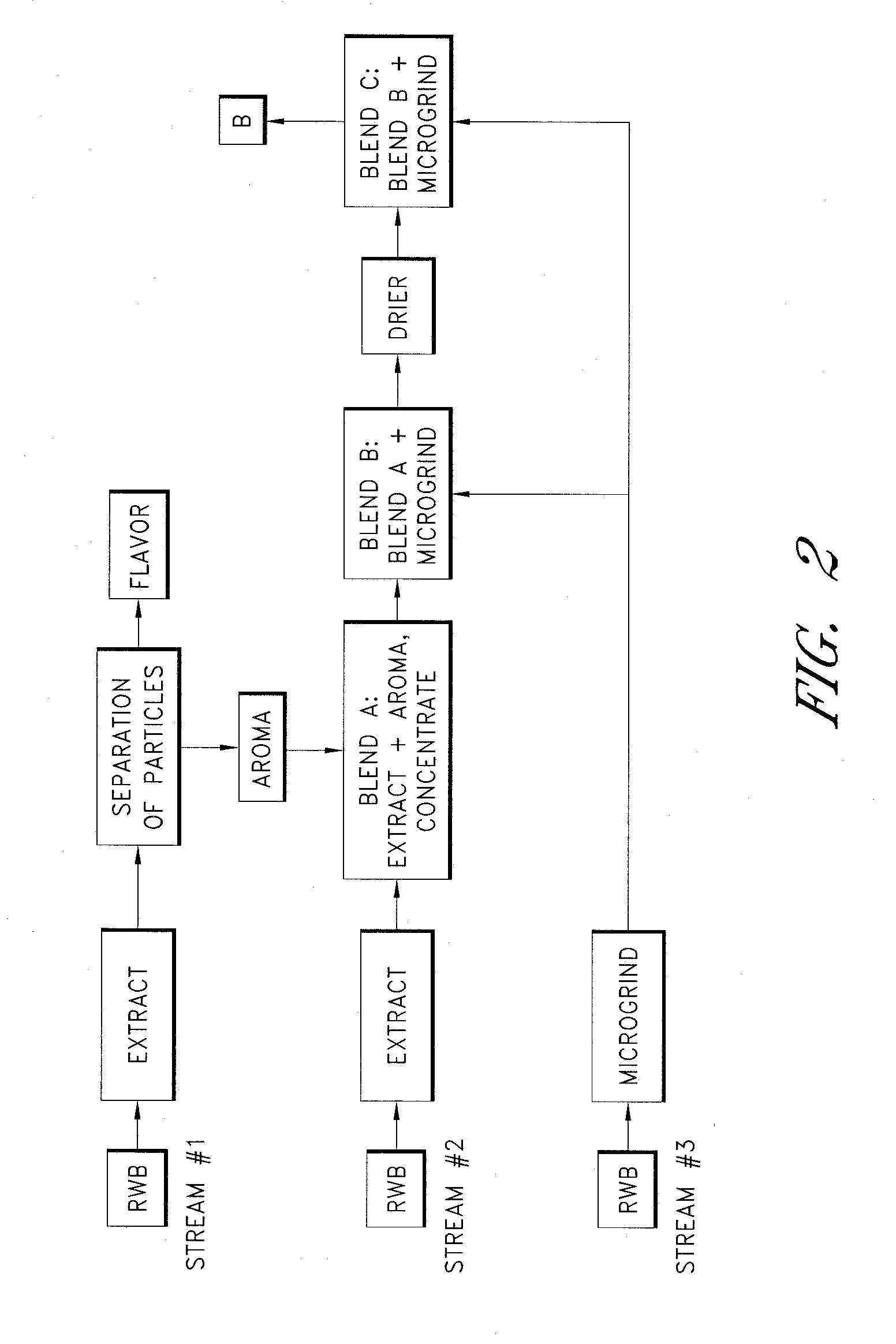

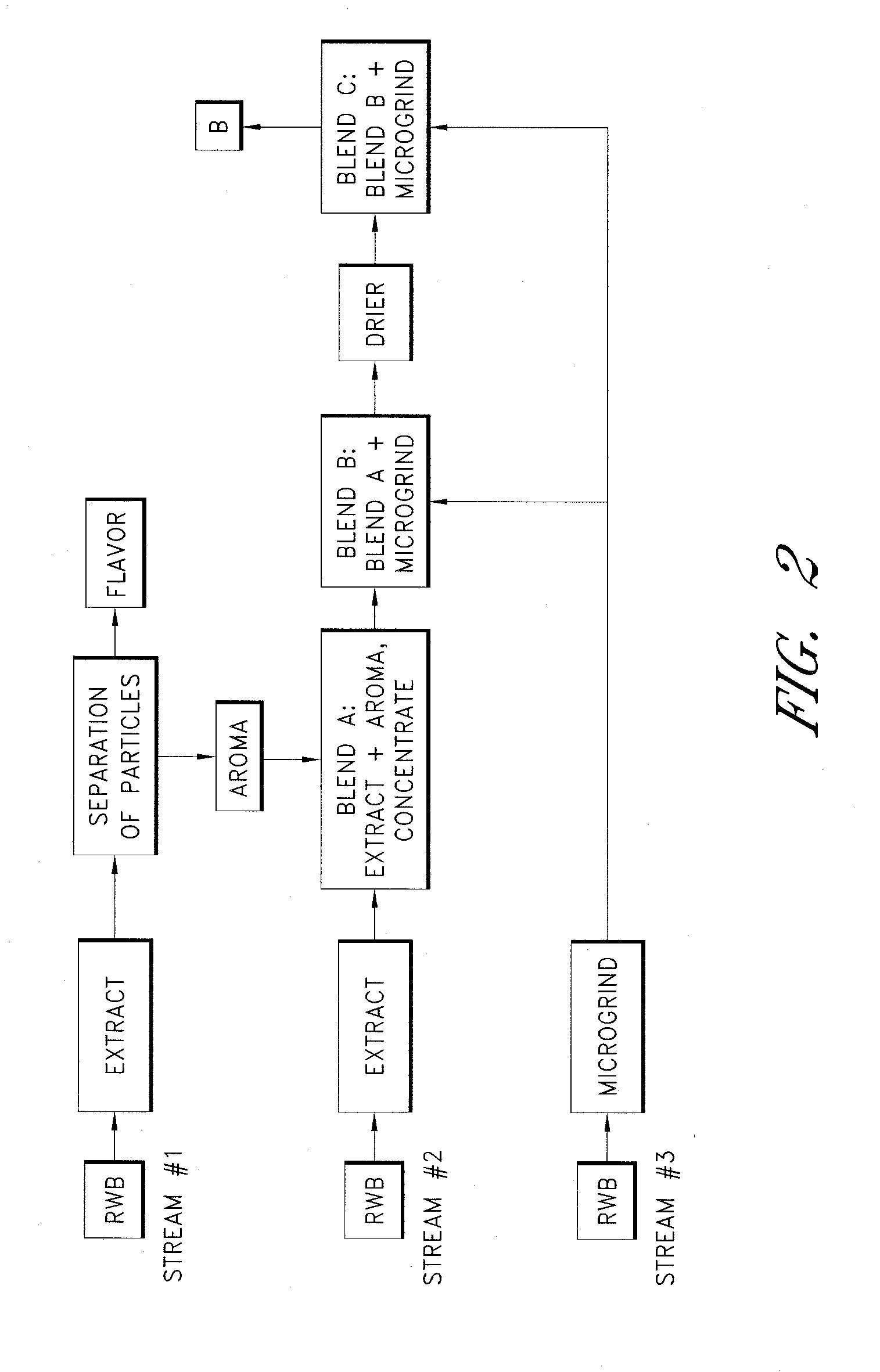

Dairy containing beverages with enhanced flavors and textures and methods of making same

InactiveUS20120164277A1Increase heatAvoid overall overheatingMilk preparationMilk treatmentFood flavorMilk products

Owner:STARBUCKS

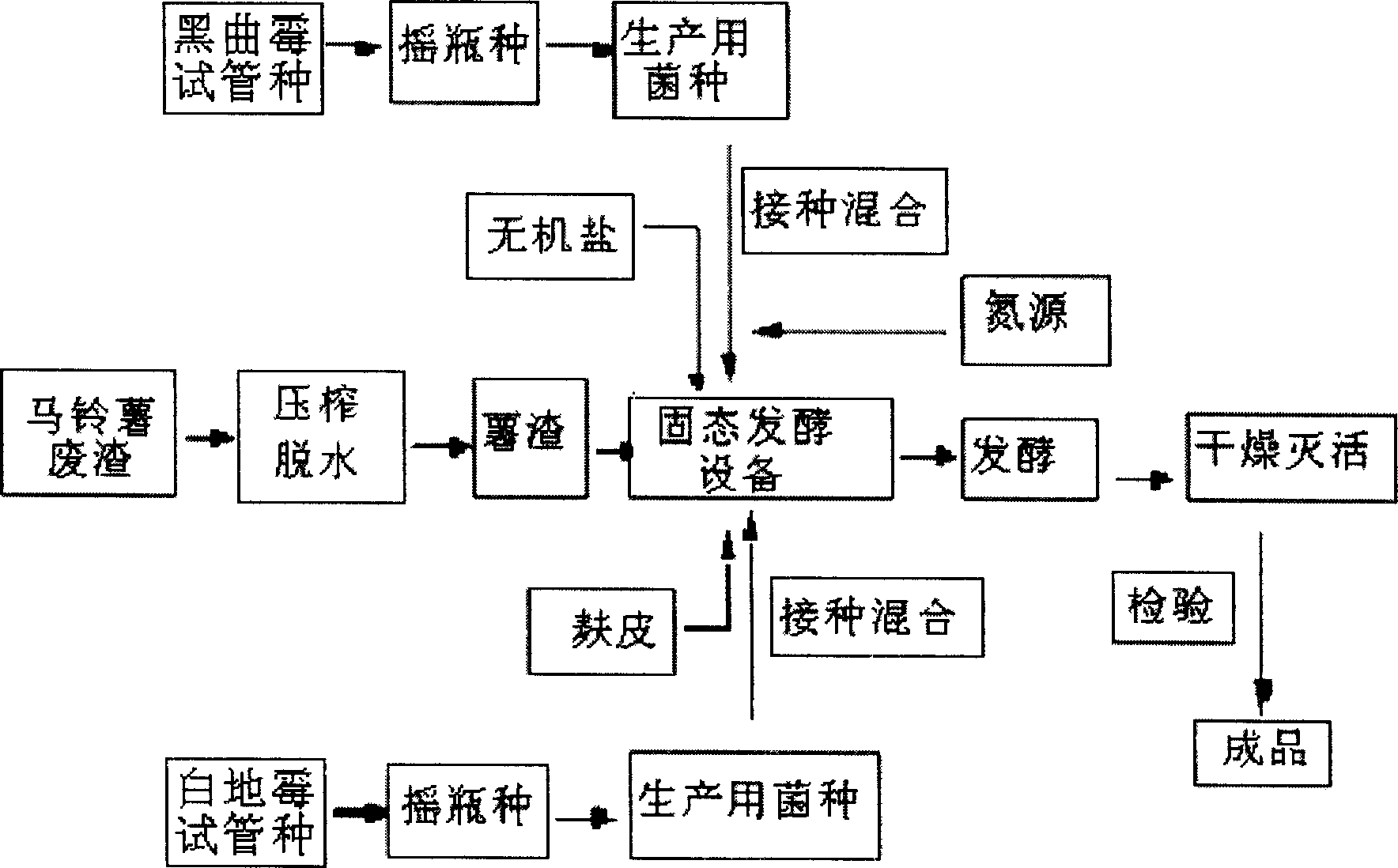

Method for preparing protein feed by solid fermenting potato slag

ActiveCN1899079ALow degree of mechanizationLess investmentAnimal feeding stuffVegetable proteins working-upMetabolitePotato starch

The present invention is protein feed and its preparation process with potato slag. Protein feed is prepared with waste potato slag from starch production, and through squeezing to dewater, adding certain amount of supplementary material, inoculating certain amount of microbe seed and solid fermentation. The said preparation process is simple, and has high yield, low investment, low power consumption and other advantages. Thus obtained feed product has the fermented product, including microbe, metabolite and substrate utilized fully, and possesses the active components maintained, high amino acid content and high nutritious value.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

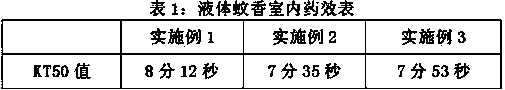

Electric-heating liquid mosquito-repellent incense with natural plant fragrance of agilawood and preparation method of electric-heating liquid mosquito-repellent incense

InactiveCN104186565AEnhance immune functionPrevent Respiratory DiseasesBiocideFungicidesBottleFatty alcohol

The invention discloses electric-heating liquid mosquito-repellent incense with natural plant fragrance of agilawood and a preparation method of the electric-heating liquid mosquito-repellent incense. The preparation method comprises the following steps: after uniformly stirring and dispersing 40-60 parts of ethanol, 10-30 parts of butyric acid butylester, 10-15 parts of a traditional Chinese medicine mosquito-repellent purified liquid, 18-19 parts of eucalyptus oil, 1-2 parts of isopropyl myristate, 10-15 parts of fatty alcohol polyoxyethylene ether sodium sulfate and 0.1-0.3 part of sodium benzoate in parts by weight, feeding the raw materials into a bottle, inserting a volatilizing bar made from fiber into the bottle, and heating, so as to volatilize the electric-heating liquid mosquito-repellent incense to repel mosquitoes. The electric-heating liquid mosquito-repellent incense has high safety performance, can be used for effectively repelling the mosquitoes and further has certain inhibiting and killing effects on multiple germs and fungi such as staphylococcus, mycobacterium tuberculosis, pseudomonas aeruginosa, gram-negative bacteria and gram-positive bacteria; meanwhile, the electric-heating liquid mosquito-repellent incense has fragrance and mild properties, can refresh mind, has the effects of relieving pressure and effectively improving sleep quality and is suitable for crowds of all ages.

Owner:中山市品匠电子科技有限公司

Processing method of special type wild boar bacon

The invention discloses a processing method of special type wild boar bacon. The processing method comprises the ten major steps of: selecting a material; placing under a cold environment; trimming; tumbling; pickling; cleaning; soaking; drying; fire-curing; and air-drying. The processing method has the beneficial effects that the special type wild boar meat is used as the raw material, the special flavor of the bacon is substantially guaranteed, meanwhile various natural Chinese traditional medicine raw materials are used as spices for pickling, not only the natural quality of the bacon can be guaranteed, but also the bacon has a health-care function, grease of the bacon can be effectively removed through multiple cleaning and soaking, finally the meat is subjected to fire-curing by using cinnamomum hupehanum branches and leaves, branches and leaves of pine and cypress trees and ailanthus bark, smoke is directly used for fire-curing of the bacon after being filtered by active silicon oxide, harmful components in the smoke can be filtered off, and the bacon is subjected to fire-curing of bamboo leaves on the last day. The special type wild boar bacon pickled by using the method has rich and delicious flavor, yellow color, diffusing aroma, lasting pure taste, no greasiness and long storage period and can meet the diverse requirements of people on material and cultural life.

Owner:重庆市黔江区嘉佳畜禽养殖专业合作社

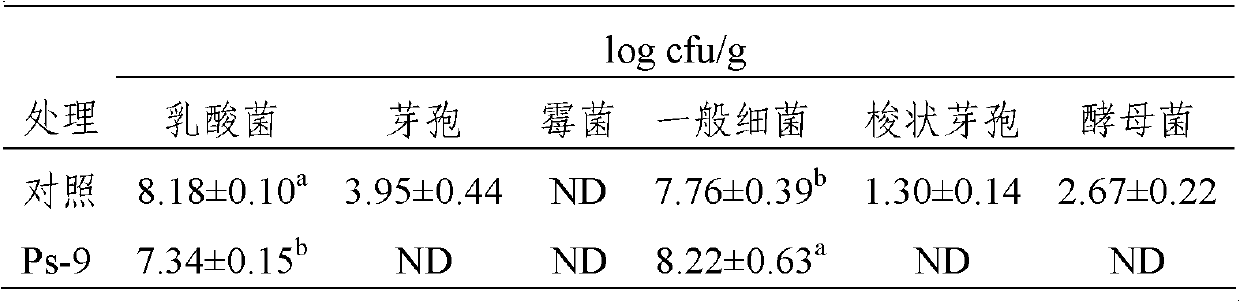

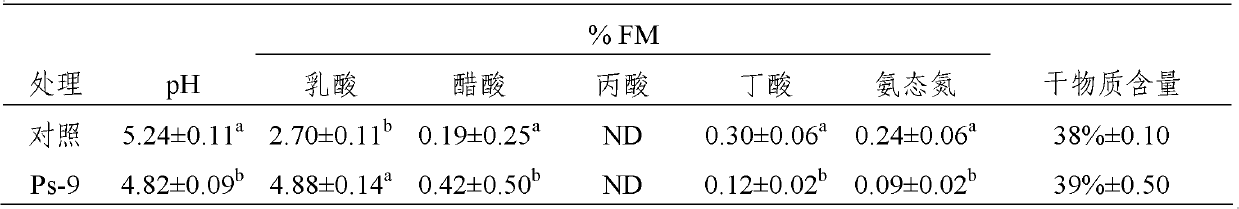

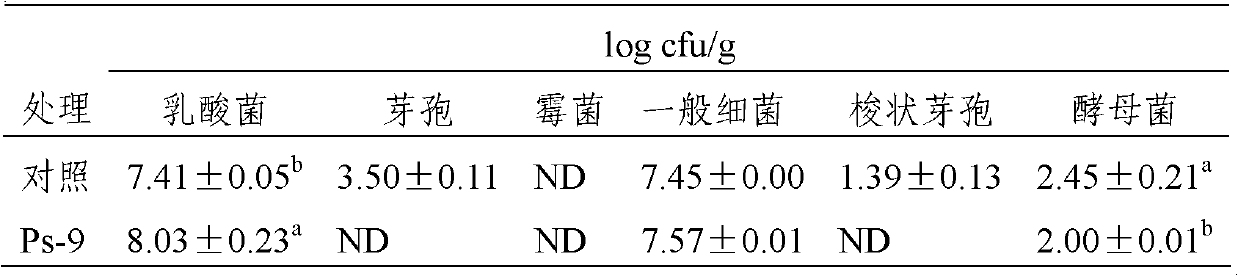

Lactobacillus plantarum used for silage alfalfa and use method thereof

ActiveCN102864095AImprove qualityAromaBacteriaMicroorganism based processesBacterial strainMicrobiological culture

The invention discloses a lactobacillus plantarum used for the silage alfalfa, which can improve the quality of the alfalfa silage feed. The lactobacillus plantarum used for the silage alfalfa has the technical scheme that the lactobacillus plantarum (L. plantarum Ps-9) is lactic acid bacteria which is screened from 100 plants of lactobacillus plantarum and has the advantages of favorable acid resistance, strong growth capability and high acid production speed. The bacterial strain of the bacteria is collected in the China general microbiological culture collection center with the collection number of CGMCC (China general microbiological culture collection center) No. 5489, and the collection data is 23rd, Nov., 2011. The invention also discloses a use method for the lactobacillus plantarum.

Owner:BEIJING SCITOP BIO TECH CO LTD

Chicken soup and preparation method thereof

The invention discloses a chicken soup and a preparation method thereof. The soup is prepared by boiling raw materials which comprise tender chicken, ginseng, red dates and medlar together with Astragalus mongholicus, Poria cocos, shallot, ginger, pepper, anise, cayenne pepper and salt. The preparation method comprises the steps of washing ginseng, red dates and medlar, soaking in hot water, pre-treating the tender chicken, putting the dosing and the pre-treated tender chicken into a pan, adding water to boil, taking out the boiled tender chicken and cooling, taking out the raw materials, filtering, packing the boiled tender chicken, soup and soaked ginseng, red dates and medlar, sterilizing in three sections, checking and enchasing the qualified packaged soup. The soup of the invention tastes fresh and is convenient to eat, is full of nutriments, and has the functions of benefiting the five internal organs, tonifying spleen and stomach, tonifying heart and soothing the nerves.

Owner:河北美客多食品集团股份有限公司

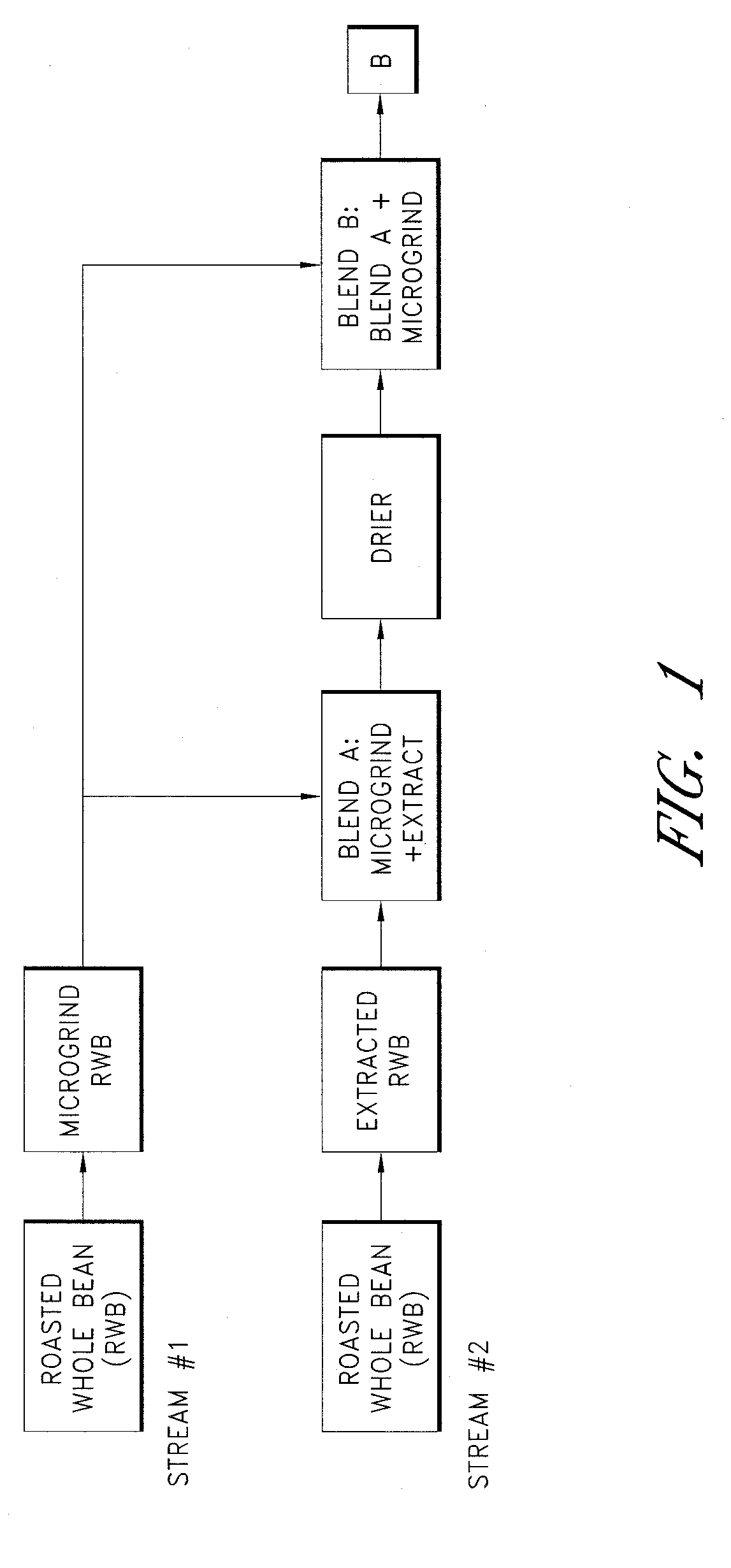

Dairy containing beverages with enhanced flavors and method of making same

InactiveUS20110135803A1Preserve the tastePreserve mouthfeelMilk preparationRoasted coffee treatmentFood flavorMilk products

Owner:STARBUCKS

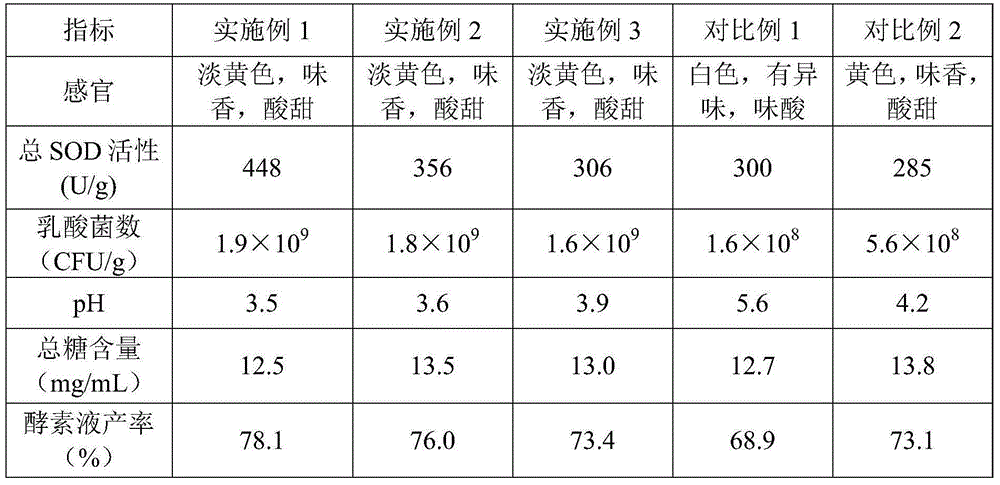

Preparation method of high-SOD-activity fruit and vegetable enzyme solution and fruit and vegetable enzyme powder

ActiveCN105054054ACover up the smellImprove coordinationFood ingredient functionsFood preparationFlavorHansenula anomala

The present invention discloses a preparation method of high-SOD-activity fruit and vegetable enzyme powder. The enzyme powder is prepared by squeezing Chinese watermelon flesh and apple flesh into pulp, respectively fermenting filtrate using saccharomyces cerevisiae and hansenula anomala and streptococcus thermophilus and lactobacillus plantarum, fermenting filter residues with rhizopus oryzae suspension, mixing the three fermentation liquor, conducting secondary fermentation on the mixture, and finally spray-drying the mixture. The prepared enzyme powder is good in mouthfeel and flavor, high in SOD activity and high in lactic acid bacteria content.

Owner:HUAZHONG AGRI UNIV

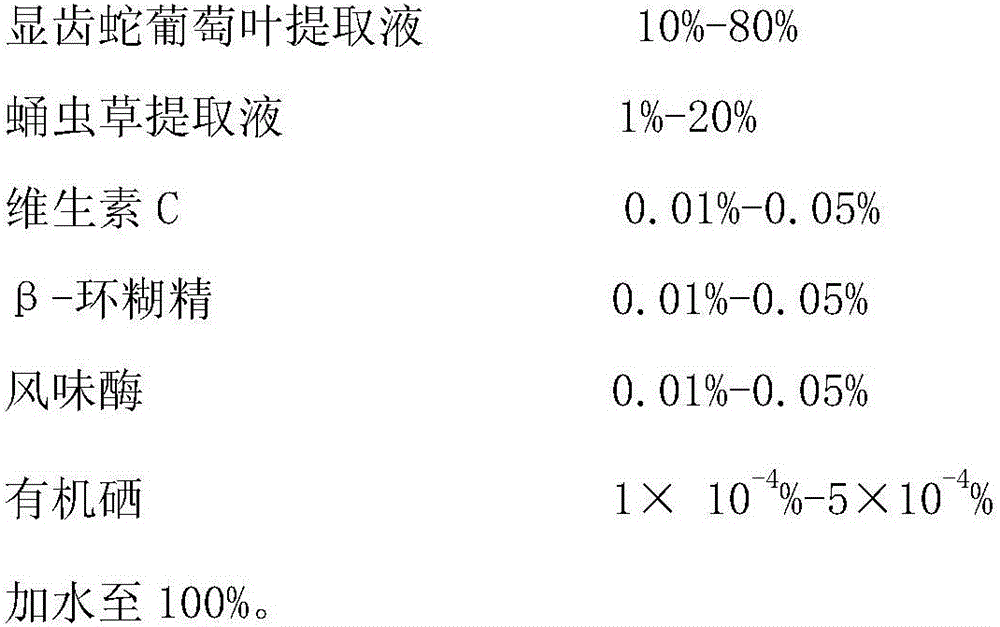

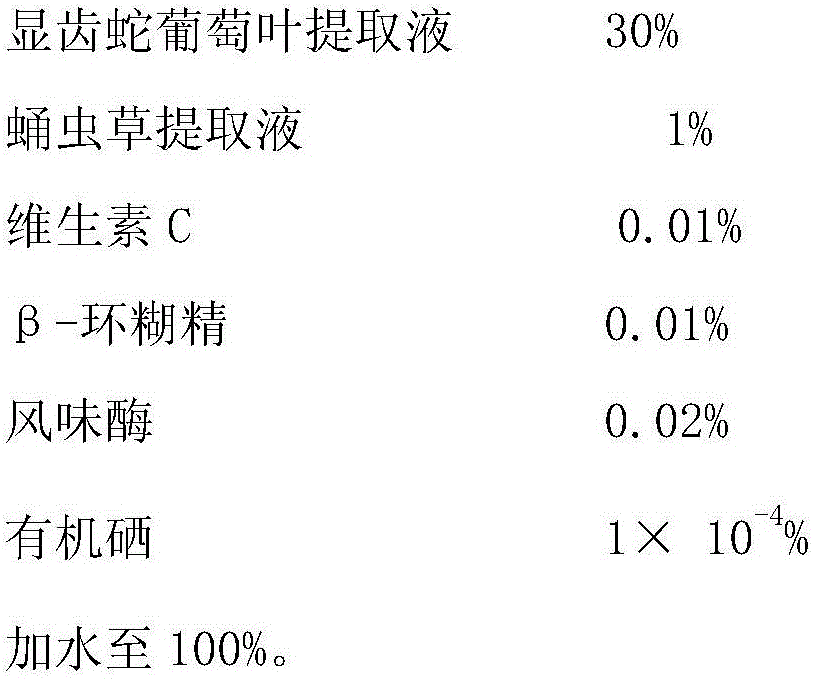

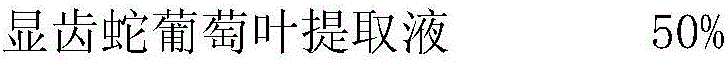

Ampelopsis grossedentata selenium-enriched functional drink and preparation method thereof

InactiveCN105995340AEasy to be popularAcceptableTea extractionFood ingredient functionsVitamin CPreservative

The invention discloses ampelopsis grossedentata selenium-enriched functional drink and a preparation method thereof and relates to natural health functional drink added with no preservative. The ampelopsis grossedentata selenium-enriched functional drink is prepared from the following components in percentage by weight: 10-80% of ampelopsis grossedentata extracting solution, 1-20% of cordyceps militaris extracting solution, 0.01-0.05% of vitamin C, 0.2-0.8% of beta-cyclodextrin, 0.01-0.05% of flavoured enzyme, (1-5)*10<-4>% of plant organic selenium and the balance of water. The prepared drink has the health effects of resisting to oxidation, protecting liver, helping digestion and improving immunity and can meet market diversification demand of drink.

Owner:HUBEI GUOJI SELENIUM PROD RES & DEV CO LTD

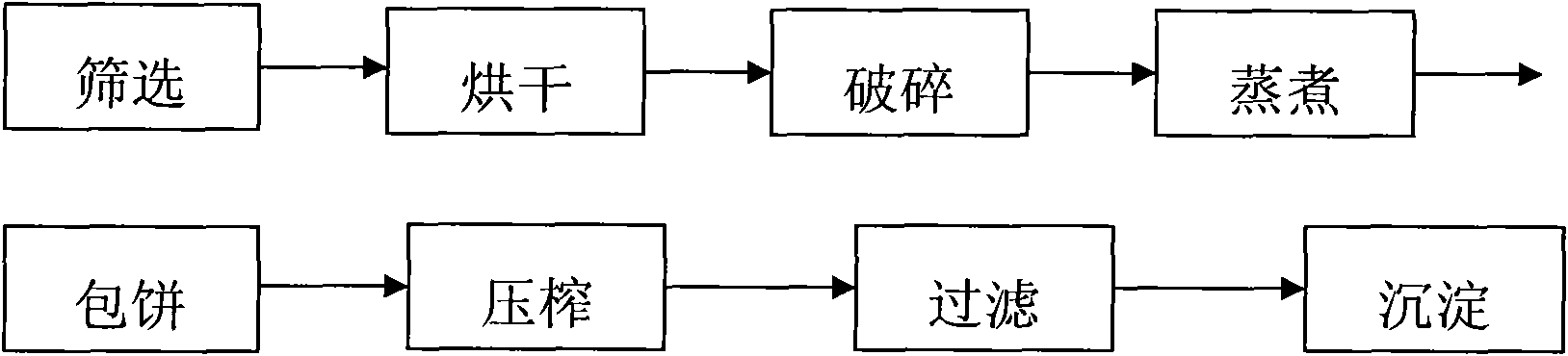

Virgin process method for camellia seed oil

The invention discloses a virgin process method for camellia seed oil, which is characterized by comprising the following steps: detecting the acid value and the water content of tea seeds after drying and cracking tea seeds; then adding dietary alkali into tea seed powder before stewing and boiling according to the proportion; and evenly stirring and carrying out stewing and boiling and squeezing. The camellia seed oil squeezed by the virgin process method can reach the standard of finished products. The camellia seed oil has light yellow and bright oil color, fragrant flavor and special flavor; and the quality of the camellia seed oil can be compared with virgin special olive oil.

Owner:蔡章振

Prepn. contg. composite enzyme for improving quality of tobacco

InactiveCN1692846AAccelerates the natural aging processShorten the natural aging cycleTobacco treatmentAmylaseYeast

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Dairy containing beverages with enhanced flavors and method of making same

InactiveUS20110135802A1Preserve the tastePreserve mouthfeelMilk preparationRoasted coffee treatmentMilk products

Owner:STARBUCKS

Health-care floor made of tourmaline composite natural extractives

InactiveCN104295054ARelieve nasal congestionSoft skinAntibacterial agentsBiocideAdhesiveHazardous substance

A health-care floor made of tourmaline composite natural extractives is composed of a damp-proof layer, a traditional Chinese medicine plate layer, a negative ion adhesive layer and an anti-abrasion layer. The negative ion adhesive layer is composed of a soybean protein adhesive and negative ion natural mineral substance powder by the mass ratio of 4:1, and the negative ion natural mineral substance powder is a mixture of tourmaline, lanthanide rare-earth composite salts and titanium dioxide by the mass ratio of 4:3:3. Negative ions can be released continuously so as to remove formaldehyde and other harmful substance and indoor peculiar smells, achieve bacteria resistance and bacteriostasis and purify indoor air, so that the health-care effect is achieved; contained natural traditional Chinese medicine components can have the functions of mosquito repelling, bacteria resistance and bacteriostasis, and therefore the health-care floor is multipurpose and has wide application prospects.

Owner:ZHONGSHAN YIZHAN DECORATION ENGINEERING CO LTD

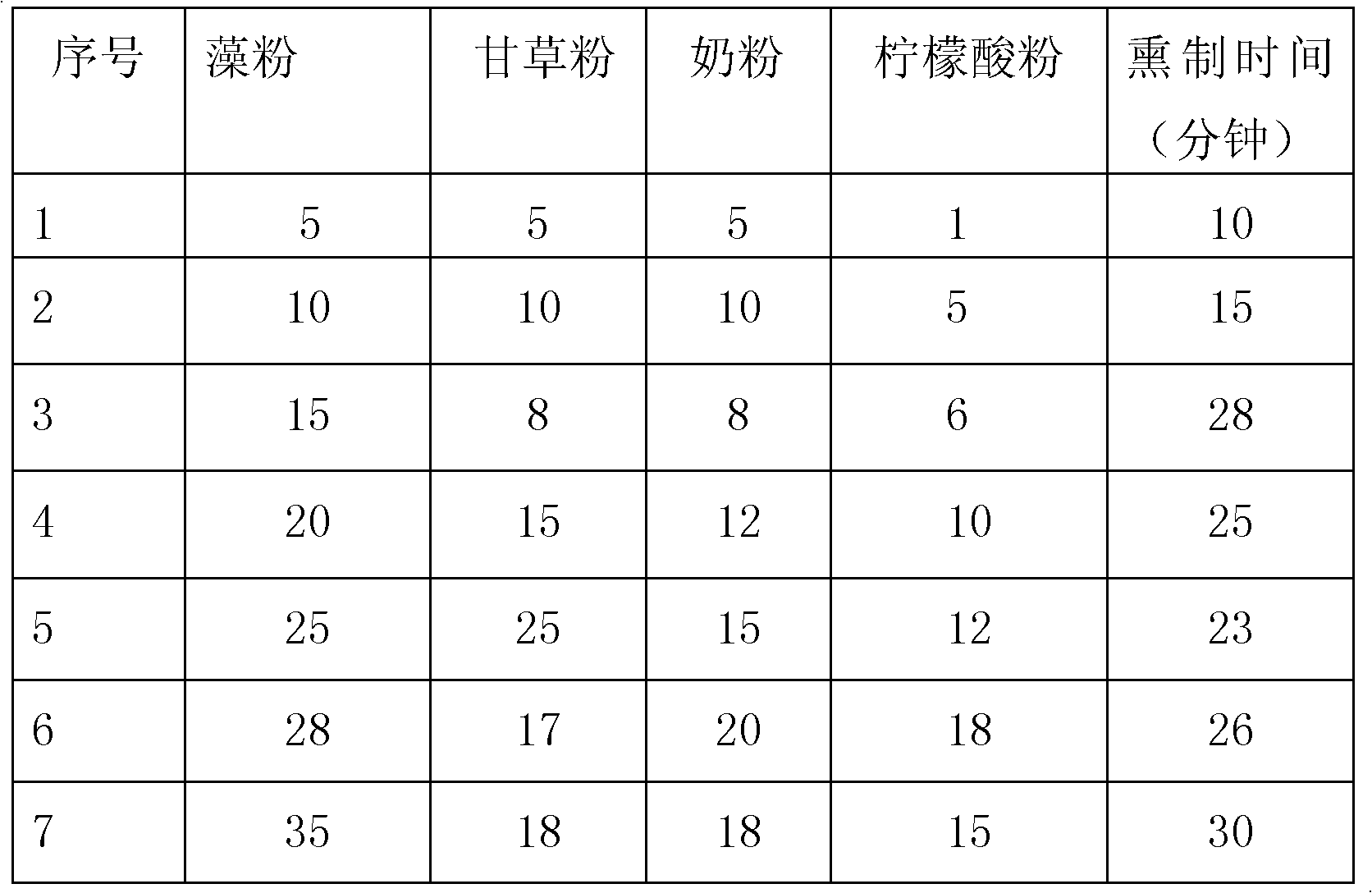

Spirulina/chlorella beverage and preparation method thereof

The invention relates to a spirulina / chlorella beverage and a preparation method thereof. The spirulina / chlorella beverage is characterized by comprising the following substances in part by weight: 5 to 35 parts of powdery spirulina or chlorella (algae powder for short), 5 to 25 parts of liquorice, 5 to 20 parts of milk powder and 5 to 15 parts of citric acid. Compared with the prior art, the invention has the advantages that: the spirulina / chlorella beverage is a natural green beverage, food additives are not added into raw materials in the processing process, and the beverage does not have any fishy smell of algae absolutely, and has an aromatic smell and a long quality guarantee period. The product is rich in various nutrient substances beneficial for a human body, such as plant protein, multivitamin, carotene, linolenic acid and the like, and has the characteristics of fresh and mellow mouthfeel, effects of helping produce saliva, quenching thirst moistening lung, and resisting fatigue, and the like.

Owner:福清市新大泽螺旋藻有限公司

Production technology of lotus seed wine

A production technology of lotus seed wine comprises the steps: crushing dry lotus seeds with or without husks into 1 mesh to 8 meshes, adding 40 Kg-70 Kg of water and mixing to moisten the crushed dry lotus seeds; putting into a container or wrapping with cloth, compacting and pilling up to make water uniformly fully absorbed, then stirring to a fluffy state, steaming until the lotus seeds are thoroughly cooked, spreading and cooling to 26 DEG C-34 DEG C; stirring and mixing with 0.8%-2% of a medicinal liquor, 0.2%-0.6% of glucoamylase and 0.08%-0.15% of dry yeast which are calculated by dry weight of dry lotus seeds; putting in a tank and sealing the mouth of the tank with thin cloth for about 16 h-24 h, then removing the thin cloth and sealing with a thin film, controlling the temperature at 24 DEG C-38 DEG C and fermenting for 25 days -40 days; taking out the wine original blank, squeezing, placing the squeezing liquid at the lower layer of a distiller, introducing steam to make the boiling squeezing liquid evaporated and pass through the squeezed blank to obtain original wine with alcohol degree of 40 degrees to 60 degrees; and filtering the original wine with diatomite to obtain the wine. According to the production technology, pure fruit lotus seeds with or without husks are employed for production of the wine, and the wine is not added with sugar, is not colored and is not perfumed; the production technology is easy to control, special raw material pretreatment and slaking technology is employed; and fermentation is performed at a low temperature, the use amount of the medicinal liquor is reduced, the generation of methanol is reduced, and the quality is improved.

Owner:杨起根

Mashed potato and preparation process thereof

InactiveCN1961735AIdea novel scienceGood workmanshipCheese manufactureFood preparationFood sectorDry bean

The invention relates to a mashed potatoes and relative production, wherein it comprises that using the potatoes, to be boiled, skin remove, dried, and broken into potato powder; adding chickens' extract, plant oil, iodized salt, dried onion, dried particles, to be mixed; packing into package box; when eating, opening the package, adding boiled water, eating after 3-5mins; the particles are chicken, beef, pork, tomato, bread, and dry bean curd. The invention has high nourishment content.

Owner:金大顺

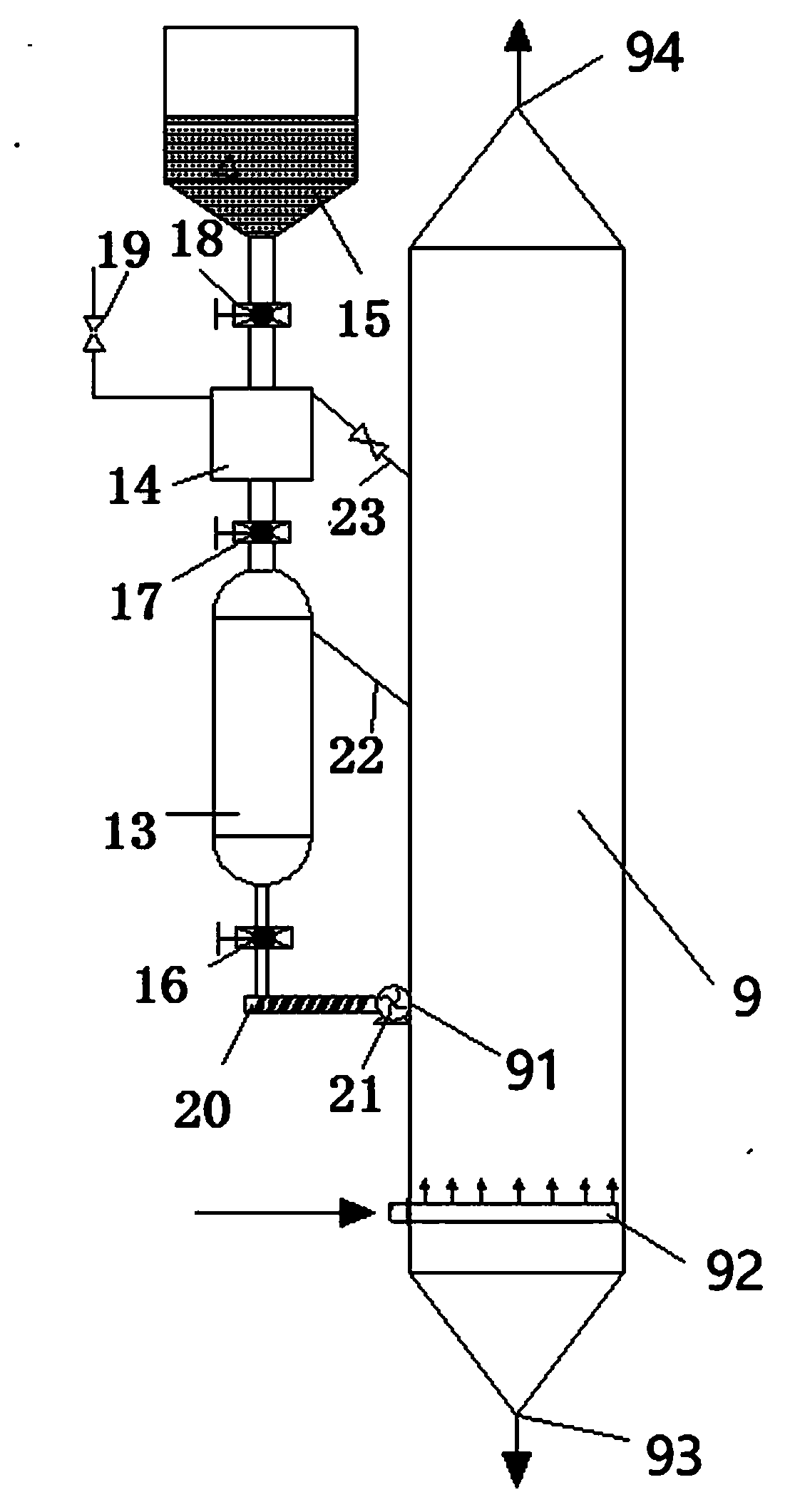

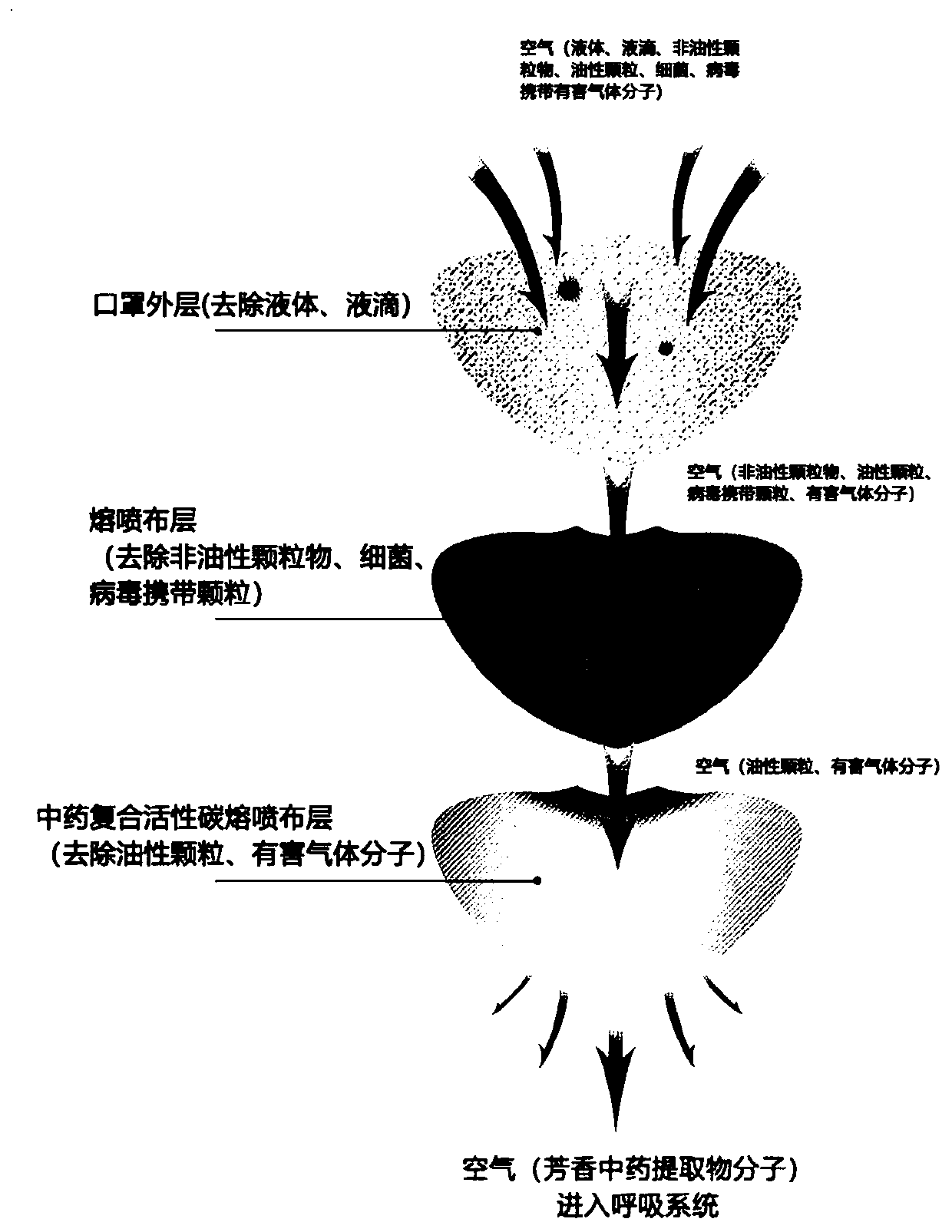

Activated carbon composite melt-blown fabric, preparation method thereof and mask

ActiveCN111424374AReduce sheddingImprove filtering effectDispersed particle filtrationBiochemical fibre treatmentFiberActivated carbon

The invention discloses a preparation method of an activated carbon composite melt-blown fabric. A melt-blown melt is sprayed by using a fluidized state high-temperature high-pressure gas containing activated carbon particles as traction gas, in the process, a gas-liquid-solid three-phase mixed flow field is sprayed forwards, and finally, the melt is cooled and formed and cured in the form of a fiber mesh structure; meanwhile, activated carbon evenly adheres to and is constrained in the fiber mesh structure, and finally the stable activated carbon composite melt-blown fabric is formed. The activated carbon composite melt-blown fabric is soaked in a traditional Chinese medicine extract, so that the melt-blown fabric has the effects of sterilizing, disinfecting, respiratory tract resistanceimprovement, odor freshening and the like. The invention also discloses the activated carbon composite melt-blown fabric obtained through the preparation method and a mask using the activated carbon composite melt-blown fabric. The filtering, sterilizing and protecting effects are good.

Owner:大湾汉唯(广州)医药科技集团有限公司

Traditional Chinese medicine capsule for repairing dysinsulinism function to balance blood sugar

InactiveCN101306171APromote blood circulationImprove nutritional statusMetabolism disorderCapsule deliveryAdditive ingredientRadix Rehmanniae Preparata

The invention relates to a Chinese traditional hypoglycemic medicine, in particular a thirty-ingredient hypoglycemic gelatin capsule, which is prepared from thirty ingredients, including red ginseng, astragali, ganoderma lucidum, magnolia vine fruit, kudzu root, radix salviae miltiorrhizae, hemlock parsley, symbranchoid eels, dodder, black sesame seed, radix rehmanniae, radix rehmanniae preparata, blackfungus and so on, through extraction.

Owner:王跃进

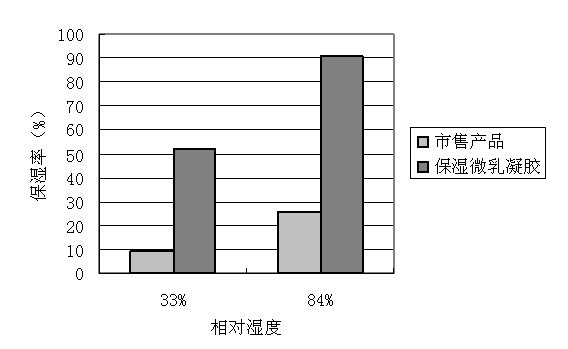

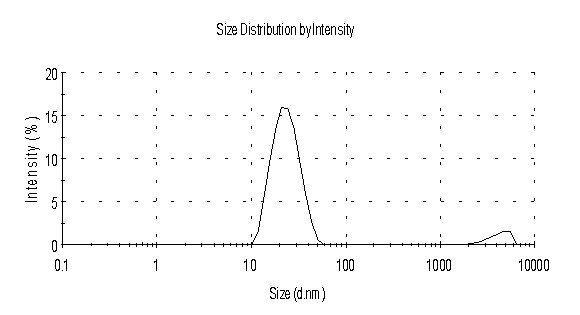

Moisture-retaining micro-emulsion gel containing egg yolk oil, and preparation method thereof

ActiveCN102670466AGood moisturizing effectIn vitro moisturizing test is goodCosmetic preparationsToilet preparationsYolkActive agent

Owner:INST OF CHINESE MATERIA MEDICA CHINA ACAD OF CHINESE MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com