Activated carbon composite melt-blown fabric, preparation method thereof and mask

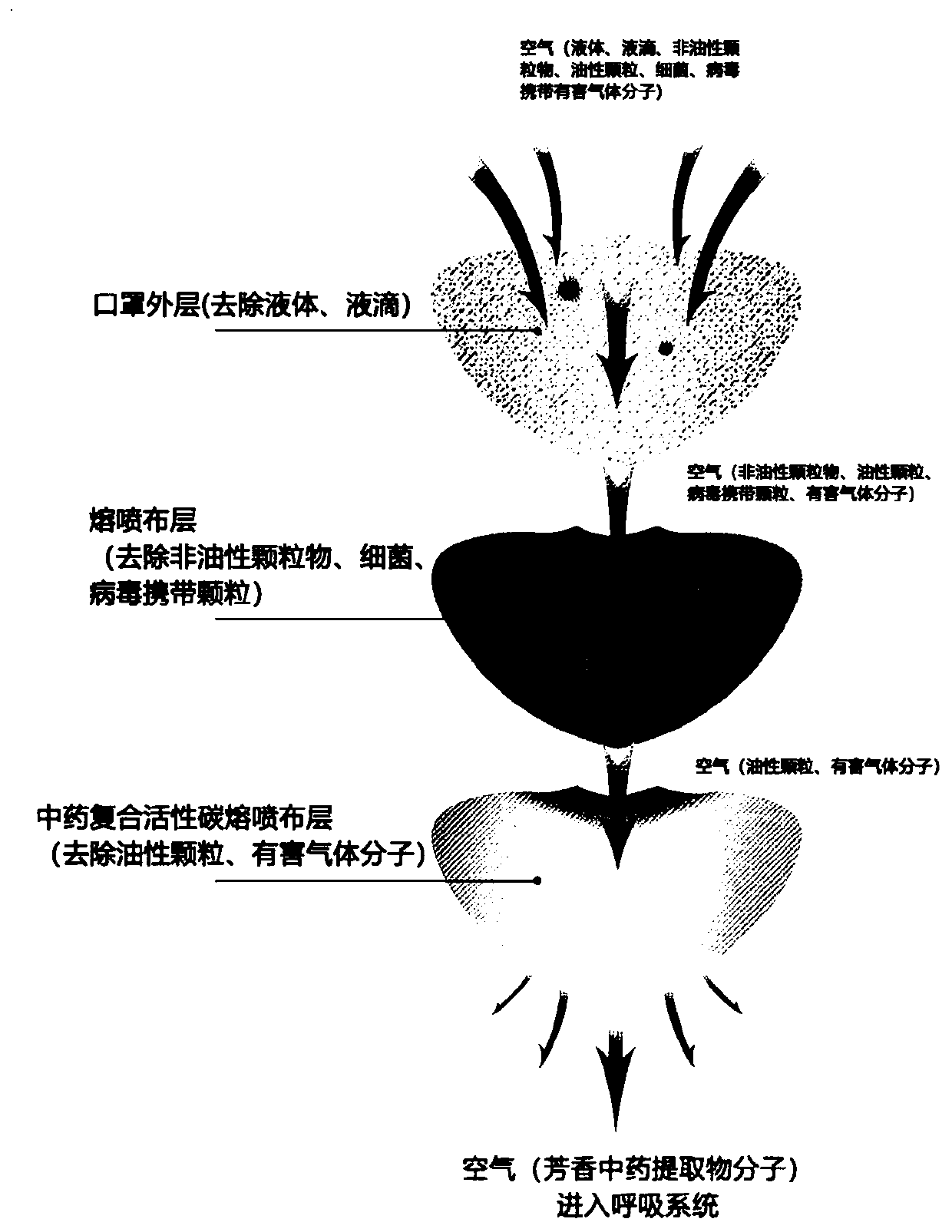

A technology of activated carbon and melt-blown cloth, which is applied in the direction of separation methods, chemical instruments and methods, non-woven fabrics, etc., can solve the problems of easy detachment of activated carbon, poor cohesive force, uneven spraying of activated carbon, etc., and achieve good filtering effect and reduce The effect of peeling off and uniform adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

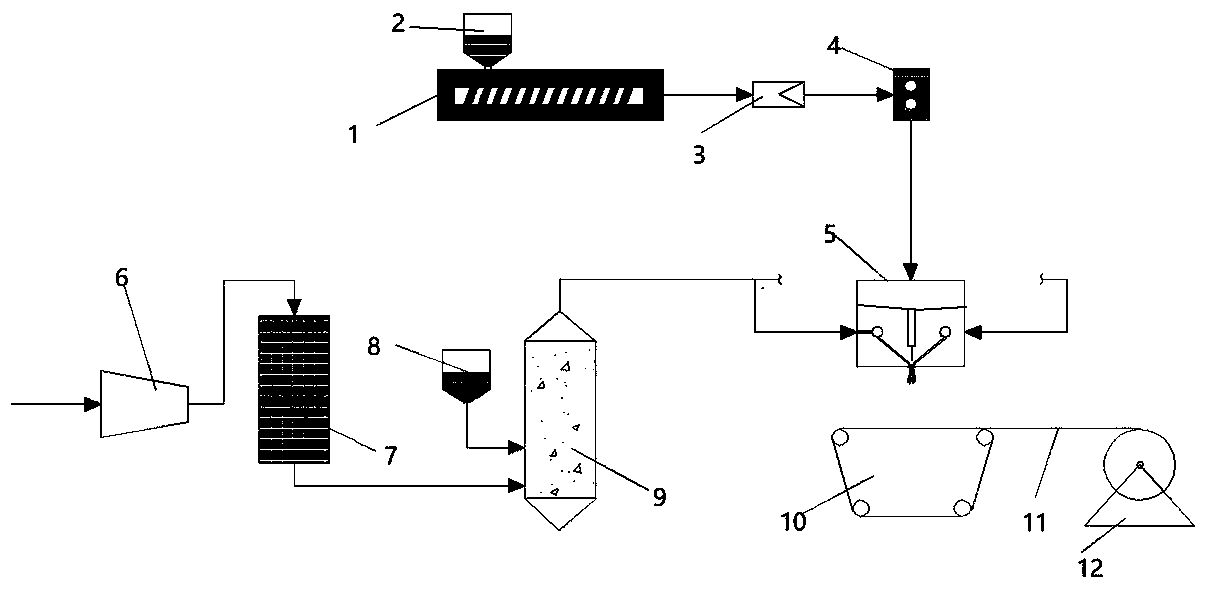

[0032] Such as figure 1 and figure 2 As shown, this embodiment discloses a manufacturing device for melt-blown cloth, which includes a screw extruder 1 and a spinning box 5, and the screw extruder 1 is equipped with a polypropylene raw material feeding bin 2. A filter 3 and a metering pump 4 are arranged between the screw extruder 1 and the spinning box 5, and the spinning box 5 includes a spinneret. Of course, the metering pump 4 can also be arranged in the spinning box 5, And the preferred gear metering pump of metering pump 4; Also comprise receiving device, described receiving device is curtain net 11, and it realizes receiving melt blown cloth by mesh belt receiver 10 and winder 12, and above-mentioned structure can adopt prior art Melt blown cloth manufacturing equipment.

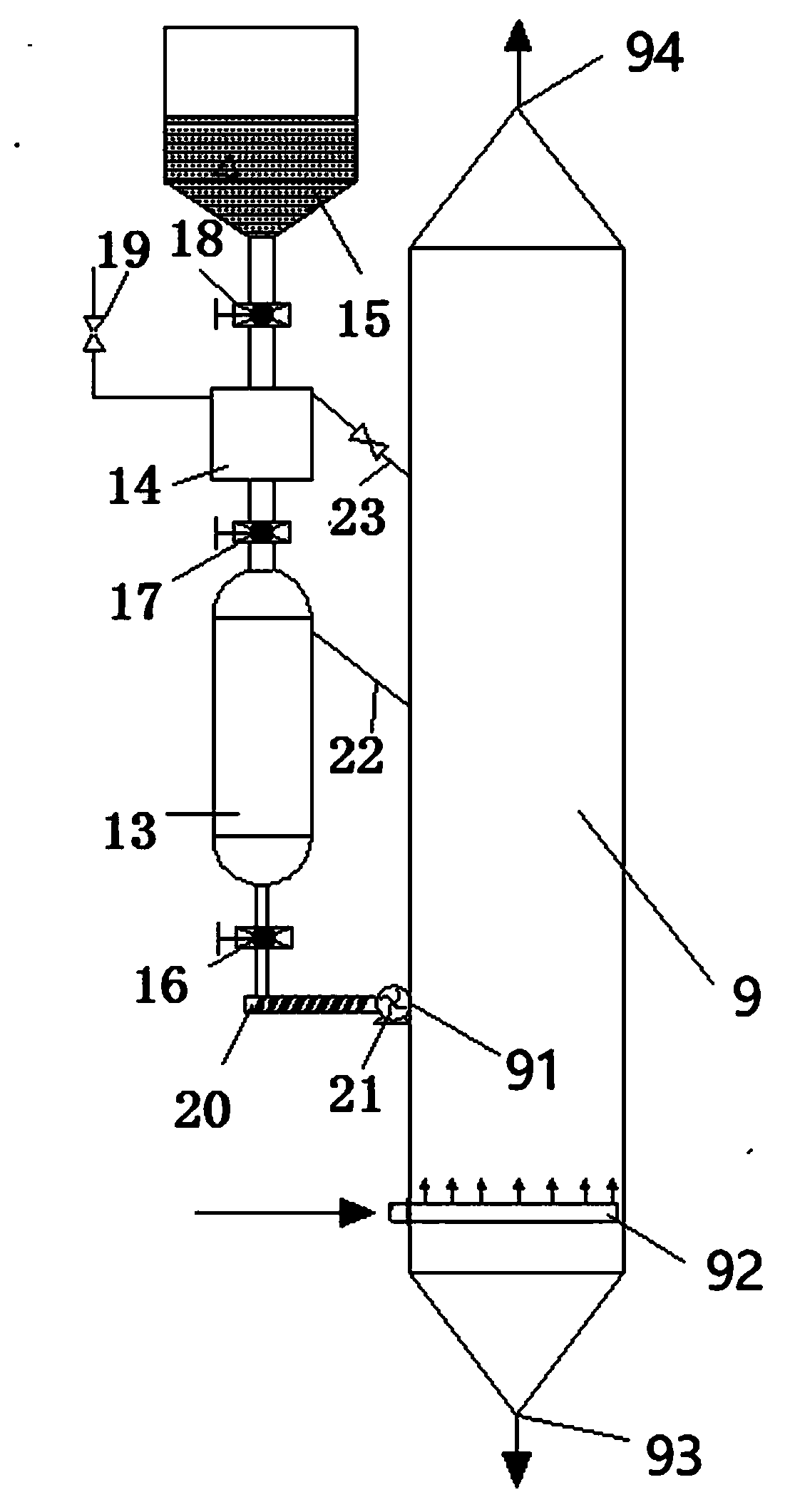

[0033] Further, it also includes a fluidized bed 9, and the structure of the fluidized bed 9 is not specifically limited. In this embodiment, the fluidized bed 9 is a cylindrical empty tower struct...

Embodiment 2

[0042] Feed polypropylene granules with a melt index of 800g / min into the screw extruder 1, the polypropylene granules are melted and extruded at 180°C, and the extruded melt passes through the filter 3 and the metering pump 4 and then enters the spinning box 5 The spinneret is ejected, and the fluidized gas-solid mixture mixed with activated carbon particles from the fluidized bed 9 passes through the airflow channels on both sides of the spinneret as a draft airflow, and is sprayed on the melt by both sides of the spinneret; here , the mixed flow of activated carbon and hot air pulls, stirs and cools the melt, forming a gas-liquid-solid three-phase mixed flow field and jetting forward, the melt is drawn into filaments by high-temperature and high-speed airflow, and the melt is gradually cooled and finally solidified Activated carbon composite melt-blown cloth is formed on the screen 11; wherein, the airflow velocity of the traction airflow is 10000m / min, the airflow temperatu...

Embodiment 3

[0044] Feed polypropylene granules with a melt index of 1000g / min into the screw extruder 1, the polypropylene granules are heated and melted at 200°C and extruded, and the extruded melt passes through the filter 3 and the metering pump 4 and then enters the spinning box 5 The spinneret is ejected, and the fluidized gas-solid mixture mixed with activated carbon particles from the fluidized bed 9 passes through the airflow channels on both sides of the spinneret as a draft airflow, and is sprayed on the melt by both sides of the spinneret; here , the mixed flow of activated carbon and hot air pulls, stirs and cools the melt, forming a gas-liquid-solid three-phase mixed flow field and jetting forward, the melt is drawn into filaments by high-temperature and high-speed airflow, and the melt is gradually cooled and finally solidified Activated carbon composite melt-blown cloth is formed on the screen 11; wherein, the airflow velocity of the traction airflow is 12000m / min, the airfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com