Anode plate for lithium ionic cell and preparation thereof

A technology for lithium ion batteries and negative electrode sheets, which is applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve problems such as poor cycle performance of lithium ion batteries, and achieve the effect of alleviating shedding and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example illustrates the preparation method of the lithium ion secondary battery negative electrode provided by the present invention.

[0036] (1) Preparation of negative electrode active material

[0037] The raw material silicon of 100 parts by weight (Zhongzhang International Co., Ltd., 5 microns in average particle diameter, purity is 90%) and the raw material copper of 200 parts by weight (Zhongzhang International Co., Ltd., 10 microns in average particle diameter) are added to the planetary ball mill (ND7-2L type Nanjing Nanda Tianzun Electronics Co., Ltd.) ball mill tank, wherein the ratio of the weight of the ball to the total weight of the raw material is 10:1. After sealing the ball mill jar, vacuumize it and fill it with argon as a protective gas, and perform ball milling. The rotating speed of the ball milling is 400 rpm, and the milling time is 30 hours, so as to obtain the negative electrode active material.

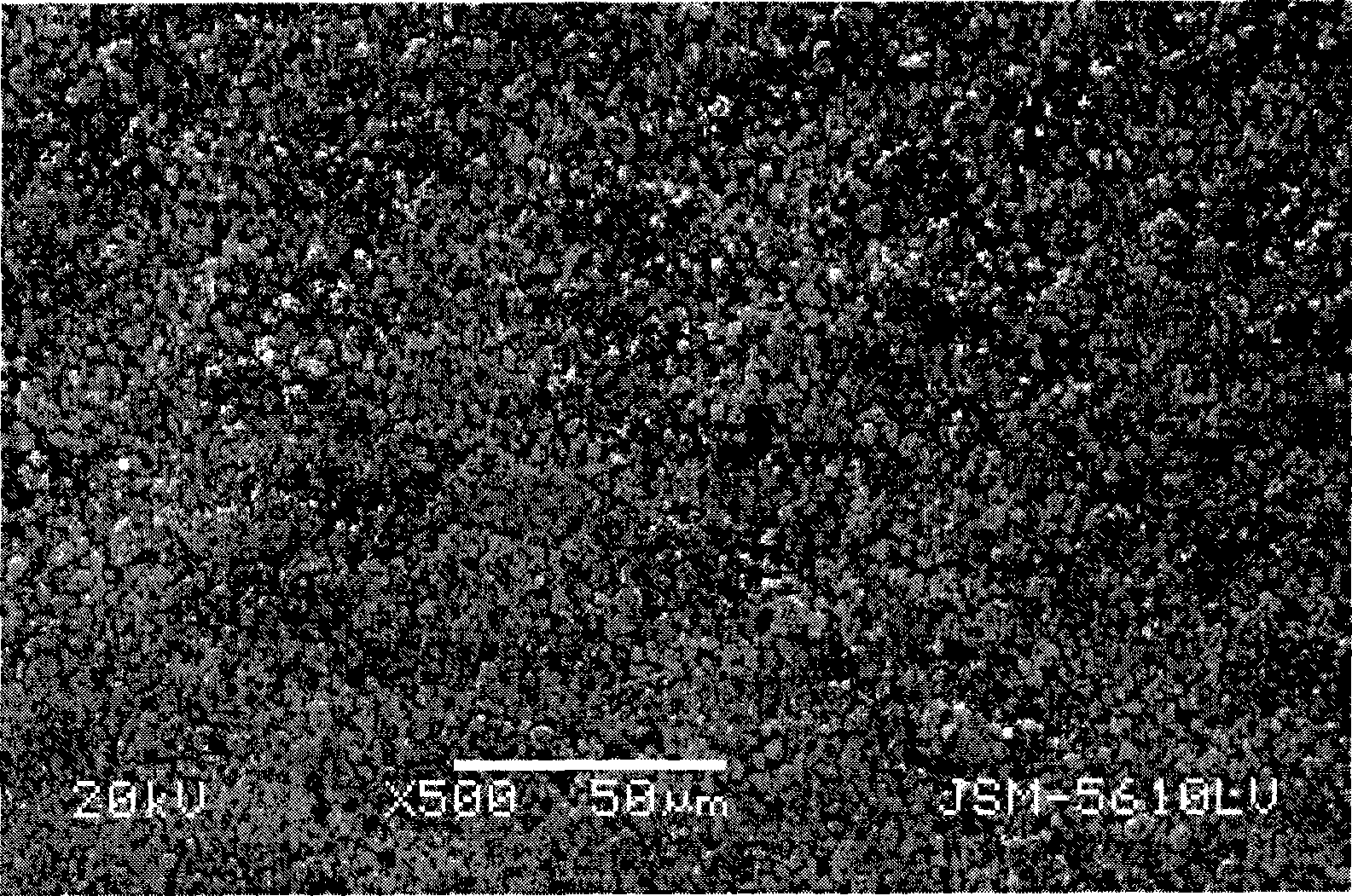

[0038] The average particle diameter of ...

Embodiment 2

[0059] This example illustrates the preparation method of the lithium ion secondary battery negative electrode provided by the present invention.

[0060] (1) Preparation of negative electrode active material

[0061] 100 parts by weight of raw material silicon (Zhongzhang International Co., Ltd., 5 microns in average particle diameter, 92% purity) and 60 parts by weight of raw material aluminum (Zhongzhang International Co., Ltd., 20 microns in average particle diameter) are added to the planetary ball mill (ND7-2L Nanjing Nanda Tianzun Electronics Co., Ltd.) ball mill tank, wherein the ratio of the weight of the ball to the total weight of the raw material is 5:1. After sealing the ball mill jar, vacuumize it and fill it with argon as a protective gas, and perform ball milling. The rotating speed of the ball milling is 400 rpm, and the milling time is 30 hours, so as to obtain the negative electrode active material.

[0062] The average particle diameter of the negative ele...

Embodiment 3

[0071] This example illustrates the preparation method of the lithium ion secondary battery negative electrode provided by the present invention.

[0072] (1) Preparation of negative electrode active material

[0073] With 100 parts by weight of raw material silicon (Zhongzhang International Co., Ltd., 5 microns in average particle diameter, the purity is 95%), 50 parts by weight of raw material zinc (Zhongzhang International Co., Ltd., 10 microns in average particle diameter) and 50 parts by weight of Raw material copper (Zhongzhang International Co., Ltd., with an average particle diameter of 10 microns) is added to the ball mill tank of a planetary ball mill (ND7-2L Nanjing Nanda Tianzun Electronics Co., Ltd.), wherein the ratio of the weight of the ball to the total weight of the raw material It is 20:1. After sealing the ball mill jar, vacuumize it and fill it with argon as a protective gas, and perform ball milling. The rotating speed of the ball milling is 400 rpm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com