Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

A magnesium alloy blood vessel and degradation rate technology is applied in the field of surface coating preparation for reducing the degradation rate of a fully degradable magnesium alloy blood vessel stent, and can solve the problem of excessively fast degradation of the coating, loss of protective effect, and adhesion between the coating and the magnesium alloy substrate Weakness and other problems, to reduce the corrosion rate, inhibit the degradation of the substrate, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of silane coupling agent coating, mixing silane coupling agent and organic solvent to form silane coupling grafting agent, using dip coating method to graft silane coupling grafting agent to the surface of magnesium alloy for biodegradable vascular stents , forming a cross-linked silane coupling agent layer after heating and curing;

[0041] The preparation of the polymer coating, the granular polymer is dissolved in an organic solvent and mixed to form a polymer spin coating solvent, and the polymer spin coating solvent is coated with the above steps by using a spin coating method The surface of the sample coated with the silane coupling grafting agent was vacuum-dried, and the polymer coating was formed after the polymer spin-coating solvent evaporated.

[0042] As an optimization, the silane coupling agent is γ-aminopropyltriethoxysilane KH550, N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane KH602, γ-aminoethyl Any one of aminopropyltrimethoxysi...

Embodiment 1

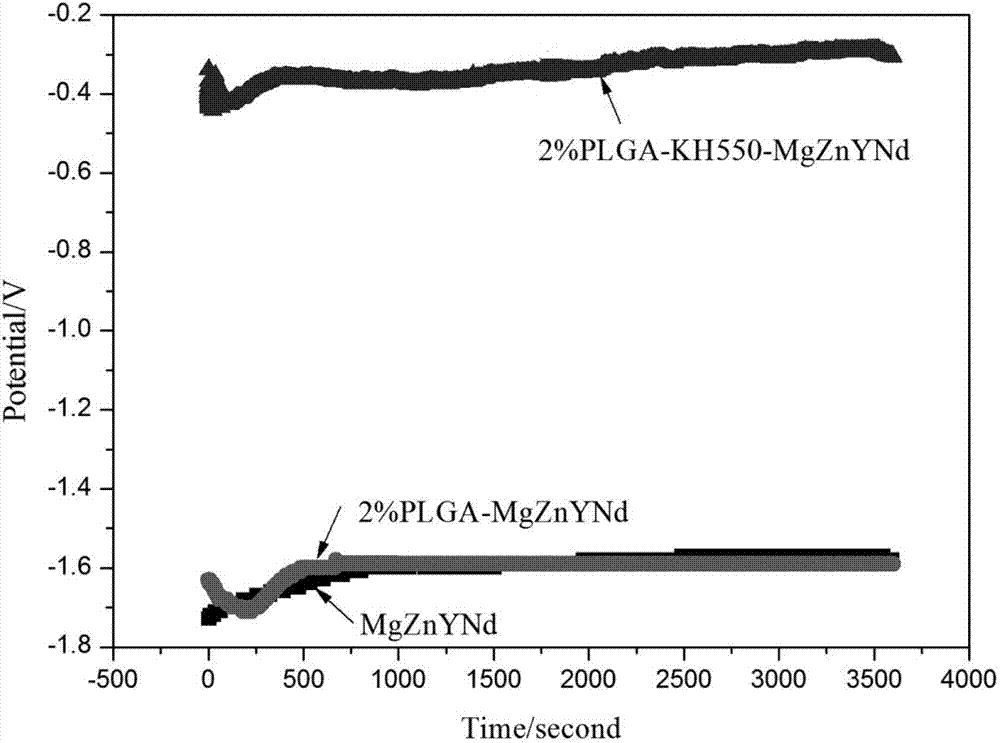

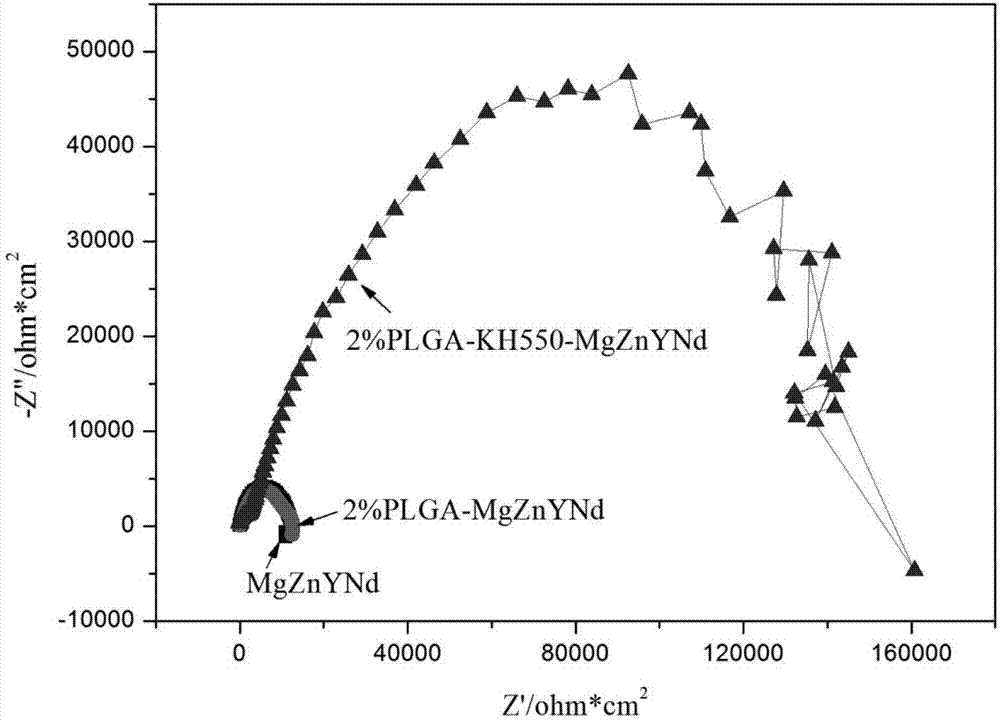

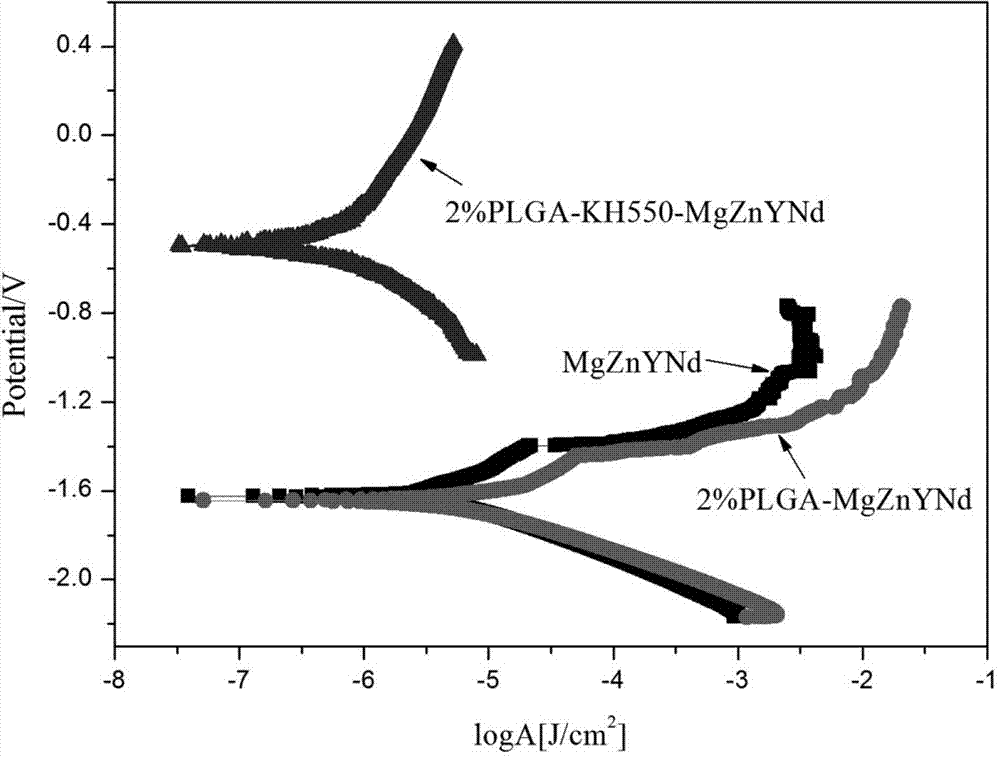

[0051] In the first embodiment of the surface coating preparation method for reducing the degradation rate of fully degradable magnesium alloy stents involved in the present invention, the magnesium alloy used for biodegradable stents is Mg-Zn-Y-Nd, and the silane coupling agent is γ-Aminopropyltriethoxysilane KH550, the granular polymer is dissolved in 100,000 (LA:PA=75:25) polylactic acid-glycolic acid particles, and the organic solvent is dichloromethane solution. The method includes the following steps:

[0052] Step 1, preparation of silane coupling agent coating: Dissolving silane coupling agent γ-aminopropyltriethoxysilane KH550 in organic solvent dichloromethane to form silane with a volume percentage of 5% (v / v) The dichloromethane solution of the coupling grafting agent KH550 was stirred for 0.5h, and the biodegradable Mg-Zn-Y-Nd magnesium alloy wire cutting was processed into thin slices with a diameter of ?=10mm and a wall thickness of d=0.8mm, and polished to 2000...

Embodiment 2

[0056] In the second embodiment of the surface coating preparation method for reducing the degradation rate of fully degradable magnesium alloy stents involved in the present invention, the method includes the following steps:

[0057] Step 1, preparation of silane coupling agent coating: Dissolving silane coupling agent γ-aminopropyltriethoxysilane KH550 in dichloromethane to form a silane coupling with a volume percentage of 5% (v / v) The dichloromethane solution of grafting agent KH550 was stirred for 0.5h; the biodegradable magnesium alloy was wire-cut into thin slices with a diameter of ?=10mm and a wall thickness of d=0.8mm, and polished to 2000 # , after cleaning with acetone and deionized water, ultrasonic cleaning in absolute ethanol for 30min; soak the sample in 5% (v / v) silane coupling grafting agent KH550 solution for 1.0h, and silane coupling grafting agent KH550 branch to the surface of the magnesium alloy, heat and cure at 100°C for 60 minutes to form a cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com