Patents

Literature

65results about How to "Solve the problem of "white pollution"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of biodegradable thermoplastic starch plastic having high starch content

The invention relates to a production technology of a completely bio-degradable plastic with high starch content. In the technology, natural starch, a plasticizer and other addition agents are blended together, squeezed by a double-screw squeezing machine and manufactured into thermoplastic starch particles. The thermoplastic starch particles are mixed with a blended resin, a compatibilizer, a chemical initiation agent and other addition agents. In the double-screw squeezing machine, the completely bio-degradable plastic with high starch content is manufactured by reactive squeezing. The content of the thermoplastic starch in the prepared completely bio-degradable plastic can achieve 80 percent; the material cost is low; the processing performance is good; the mechanical performance is excellent; in addition, the invention is provided with the completely bio-degradable performance and can be directly used for manufacturing various packaging materials, films, shopping bags and tableware, etc.

Owner:SICHUAN UNIV

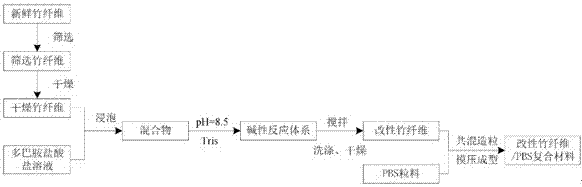

Technique for improving interfacial compatibility of bamboo fiber and polybutylene succinate based on polydopamine bionic interfacial modification modifier

InactiveCN107459830ALow priceGood dimensional stabilityBiocompatibility TestingPoly(butylene succinate)

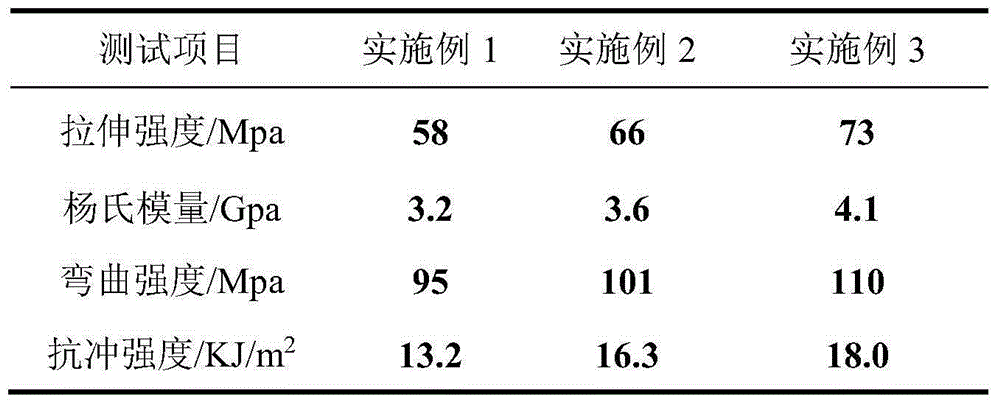

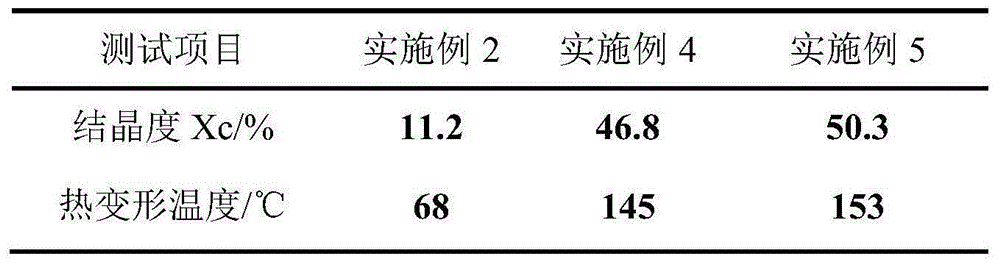

The invention discloses a method for preparing a bionic modified bamboo fiber reinforced polybutylene succinate (PBS) composite material. The method comprises the following steps: (1) screening a bamboo fiber, keeping the length less than 380mu m, and performing soaking treatment with a dopamine hydrochloride solution; 2) putting trismetyl aminomethane (Tris) into the soaked mixed system to adjust the pH value to alkalescence, stirring at normal temperature and normal pressure, filtering, and drying so as to obtain a polydopamine modified bamboo fiber of which the water content is less than 1%; and 3) uniformly mixing the modified bamboo fiber with PBS granules in a mass ratio of 1:1 in a high-speed mixing machine, pelletizing in a double-screw extruder, performing compression molding on mixed granules in a hot press, naturally cooling in a cold press, and demolding, thereby obtaining a modified bamboo fiber / PBS composite material. According to the method disclosed by the invention, dopamine has biocompatibility, the fiber is slightly damaged, no complex container is needed in the modification process, the production method is simple and convenient and safe and environmentally friendly, and the mechanical properties of the composite material are remarkably improved.

Owner:BEIJING FORESTRY UNIVERSITY

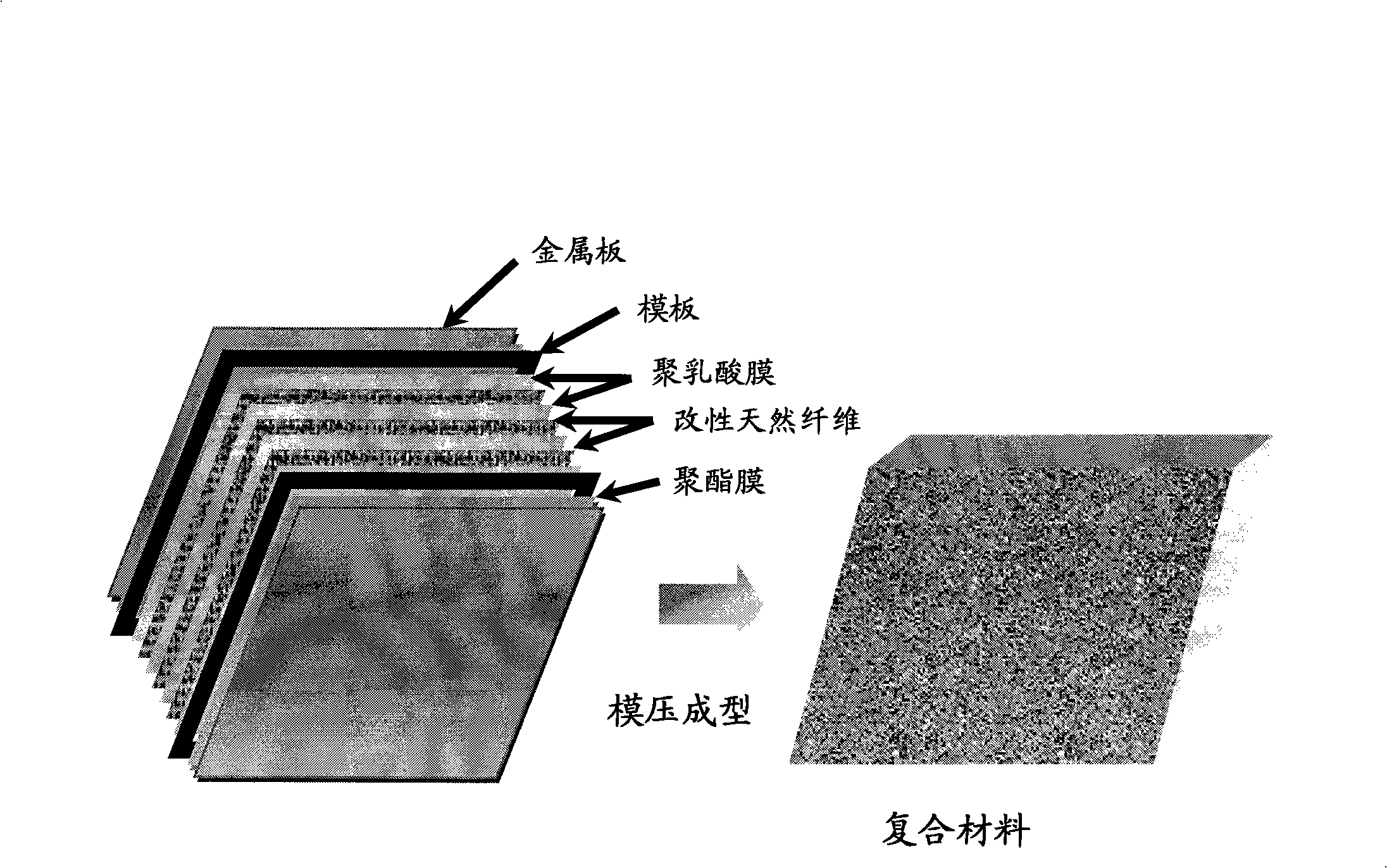

Complete biodegradable polylactic acid composite material and method for preparing same

InactiveCN101333330ASolve the problem of "white pollution"Easy to operateFlat articlesVulcanizationNatural fiber

The invention provides totally biologically degradable polylactic acid composite material and a preparation method thereof, belonging to the technical filed of macromolecule composite material. The composite material is composed of knitted or unknitted natural fiber which is modified at the surface, polylactic acid and silane coupling agent. The method includes the following steps: getting specific amount of knitted or unknitted natural fiber and dipping the natural fiber in the aqueous solution of silane coupling agent for 1-100min, taking out and drying the natural fiber, thus producing natural fiber with modified surface; then pressing the polylactic acid into sheet in a plate vulcanization machine; disposing 2-10 polylactic acid sheets into a die and arranging one modified natural fiber sheet between every two polylactic acid sheets; pressing and molding the sheets; in this way totally biologically degradable polylactic acid composite material can be made. Compared with pure polylactic acid, the polylactic acid composite material is improved in both mechanical property and thermal property. The composite material after use can be totally degraded in natural environment; therefore the composite material is environment-friendly.

Owner:SHANGHAI UNIV

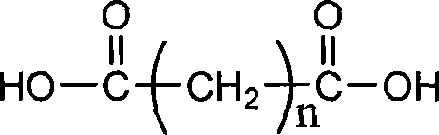

Preparation method of full biodegradation polyester copolymer

The invention belongs to the technological field of the polymer material, particularly relating to a preparation method of the completely biodegradable polyester copolymer. The invention uses the method of the fusion and direct polymerization to prepare the carboxyl-terminated lactic acid prepolymer and then copolymerize with the aliphatic polycarbonate; then the reaction is done in the twin-screw extruder to screw out the extension chain and the good polylactic acid copolymer is made. The concrete steps are: the lactic acid and small-molecule dicarboxylic acid react under the condition with the presence of the catalyst to directly polymerize the carboxyl-terminated lactic acid prepolymer; then the aliphatic polycarbonate diol and the catalyst are added; with the presence of the N2, the reaction is kept for 1 to 10 hours at the temperature of 150 to 200 Celsius system to get the poly lactic acid and polycarbonate copolymer of the low molecular weight; then the reaction is done in the twin-screw extruder at the temperature of 150 to 190 Celsius system to screw out the extension chain; finally the polylactic copolymer of the high molecular weight, toughness and heat resistance is made. The process of the method of the invention is simple and easy in the industrialized production; the copolymer resin product produced by the method is completely biodegradable and the application scope is wide.

Owner:TONGJI UNIV

Degradable polyurethane and preparation method thereof

The invention provides degradable polyurethane. The degradable polyurethane comprises the following raw materials by mass: 5.30 to 38.00% of poly(propylene carbonate) polyol, 0 to 31.00% of polyester dihydric alcohol, 0 to 15.50% of polyether dihydric alcohol, 9.20 to 13.50% of diisocyanate, 0.02 to 0.04% of a catalyst, 1.80 to 3.10% of a chain extender and 50.00% of an organic solvent, wherein the contents of the above-mentioned raw materials sum to 100%. The invention further discloses a preparation method for the polyurethane. The method comprises the following steps: preparing three precursors from weighed raw materials, selecting one of the three precursors, putting the selected precursor in a reaction vessel, subjecting the precursor to vacuum-pumping and dehydration so as to obtain a dehydrated precursor and then mixing diisocyanate, the catalyst and the dehydrated precursor so as to obtain a prepolymer; and mixing the organic solvent, the chain extender and the prepolymer so as to obtain the degradable polyurethane. The degradable polyurethane provided by the invention has good storage stability, excellent film properties and good degradability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

A highly filled fully biodegradable packaging material

InactiveCN102277005AIncrease contentSolve the problem of "white pollution"Flexible coversWrappersEnvironmental resistanceBiodegradable polymer

A highly-filled fully-biodegradable packaging material is obtained by mixing and extruding the following components on a weight basis: 70-90 parts of fillers, 10-30 parts of biodegradable polymer, 0.5-3 parts of coupling agents, and 2-5 parts of plasticizers. The fillers are dried at 100-200 DEG C to obtain a water content of not more than 0.5%; the coupling agent is mixed and stirred with the dried fillers according to a certain ratio in a high-speed mixing machine; the biodegradable polymer and the plasticizer are added proportionally, and well mixed; the mixture is extruded and granulated in an extruder to obtain a material for packaging; and the a material for packaging can be processed into various packaging materials by blow molding, injection molding, molding, and the like. When the packaging plastic of the invention becomes waste, the material can degrade into carbon dioxide, water and inorganic mineral in natural environment, which solves the problem of white pollution, and the material is a green and environment-friendly packaging material; the content of the inorganic filler is high, and reaches above 70%, which greatly decreases the production cost. The production cost is low; the preparation process is simple; and the economic practicality is strong.

Owner:宋旭

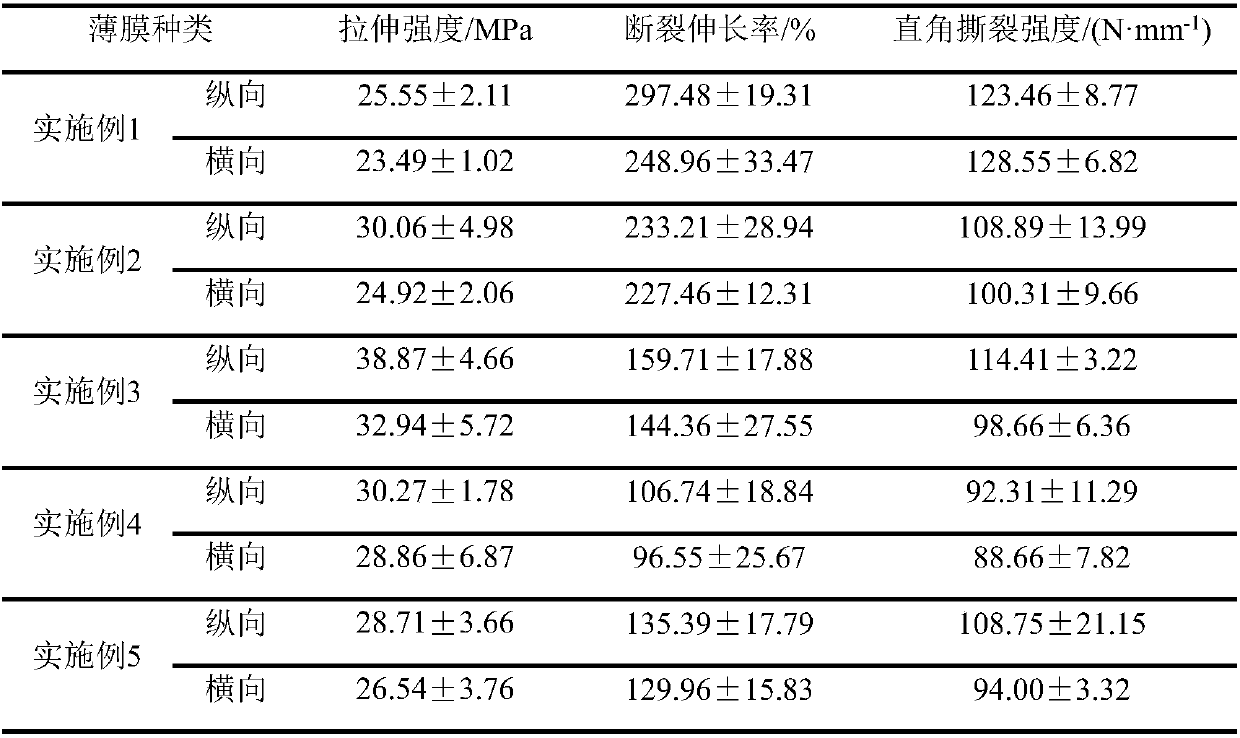

Low-cost biology base full degradation thin film and preparation method thereof

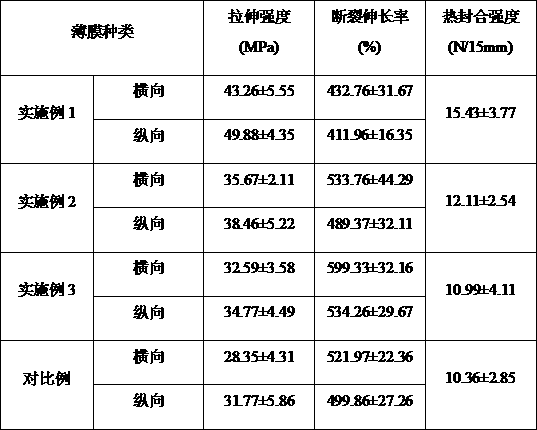

The invention discloses a low-cost biology base full degradation thin film and a preparation method thereof. The thin film is prepared from the following ingredients in parts by mass: 15 to 25 parts of polyglycollide, 25 to 35 parts of corn starch, 35 to 55 parts of poly(butyleneadipate-co-terephthalate), 5 parts of compatilizers, 3.75 to 12.25 parts of starch plasticizers, 0.5 to 0.7 part of citric acid, 0.75 to 1.25 parts of acetyl tributyl citrate, 0.3 to 0.5 part of maleic anhydride, 0.2 part of antioxidants 164 and 0.2 part of 2-(2'-hydroxyl-5'-methyl phenyl)benzotriazole. The low-cost biology base full degradation thin film provided by the invention has the advantages that the biology base content can reach 30 percent or higher; the cost is lower; the stretching intensity exceeds that of a conventional PE thin film; very important significance is realized on solving the problem of white pollution and promoting the popularization and the application of a full biodegrade material.

Owner:JIANGSU JINJU ALLOY MATERIAL

Biodegradable plastic with high starch content and preparation method of biodegradable plastic

The invention discloses a biodegradable plastic with high starch content and a preparation method of the biodegradable plastic. The preparation method comprises the steps: with corn starch, potato starch and other natural plant starches as main raw materials, completely biodegradable polyvinyl alcohol as a main toughening agent and polyethylene glycol as an auxiliary toughening agent, adding an environment-friendly composite plasticizer and a processing acid, and mixing all the components to obtain the biodegradable plastic with high starch content. The biodegradable plastic with high starch content, prepared by the invention, contains at most 90wt% of starch, has favorable plasticity and machinability, and can be prepared into products such as pipes, sheets, profiles, films, vessels, foamed base materials and the like with various shapes by using the traditional polymer forming and machining method.

Owner:宋旭

Method and system for improving metallurgical coke strength by utilizing waste plastics

The present invention relates to a method for raising strength of metallurgical coke and its system. Said invention adopts traditional coking process and equipment, and adds waste plastics in the course of coking process, and is characterized by that after the waste plastics and additive are processed, they are added into coking furnace to implement co-coking with coking coal, at the same time of that the waste plastics are charred at high temp., and converted into coke, tar and gas the coke quality can be improved, crushing strength of coke M40 can be raised, abrasive resistance index of coke M10 is reduced, coke reactivity CPI is reduced and coke postreaction strength can be raised. Said system includes waste plastics processing system, additive and waste plastics mixing system, waste plastics and additive mixture and coking coal mixing system and traditional coking system.

Owner:SHOUGANG CORPORATION

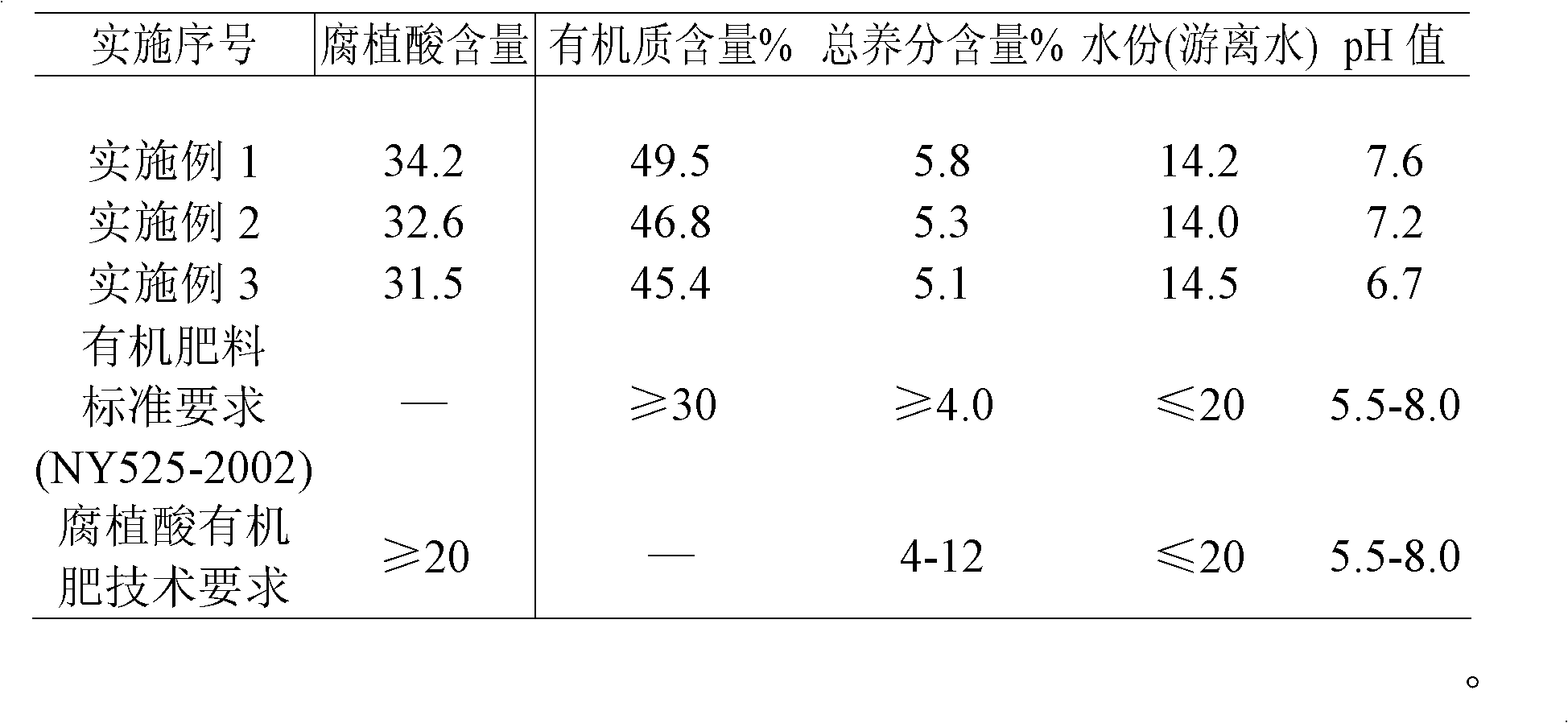

Method for producing humic acid organic fertilizer by adopting tobacco waste

InactiveCN102219582AAvoid dependenceSimple production methodBio-organic fraction processingOrganic fertiliser preparationAlcoholFermentation

The invention discloses a method for producing humic acid organic fertilizer by adopting tobacco waste, which is characterized in that the organic fertilizer is prepared by tobacco waste, alcohol waste and biological bactericide, wherein the tobacco waste is smashed and then is mixed with the alcohol waste and the biological bactericide is added, the three are subjected to solid spontaneous fermentation for 10-25 days after being stirred and blended to be uniform, and the tobacco waste humic acid organic fertilizer can be produced after curing treatment; the method has wide source of raw materials and simple process, and the produced product, humic acid, is a novel microbial organic fertilizer with excellent performance and can be used as an environment-friendly fertilizer to replace inorganic fertilizer.

Owner:昆明春叶塑料制成品有限公司

Degradable polyurethane rigid foam material and manufacture method thereof

InactiveCN101245130ASolve the problem of "white pollution"Good landfill degradation performancePolyolFoaming agent

The invention discloses a degradable rigid polyurethane foam material which is prepared by A and B components in the ratio of 1:1-1:1.1; wherein, the component A consists of materials with the following parts by weight: 50-100 portions of biomass polyols, 0-50 portions of general polyols, 0.3-5 portions of catalyst, 0.5-5 portions of water, 1-4 portions of silicone surfactant oil, 0-30 portions of physical foaming agent; the component B is pure industrial diphenyl-methane-diisocyanate. The invention also discloses a preparation method for the rigid polyurethane foam material. The method is that the component A is prepared by biomass polyols, general polyols, catalyst, water, silicone surfactant oil, and physical foaming agent in the ratio, the component A and component B are mixed and sprayed out for solidification by a polyurethane spray gun according to the proportion of 1:1-1.1. The degradable rigid polyurethane foam material is characterized by good soil burial degradability, thus solving the problem of 'white pollution' caused by using the traditional rigid polyurethane foam material.

Owner:JIANGMEN KELI NEW MATERIAL CO LTD

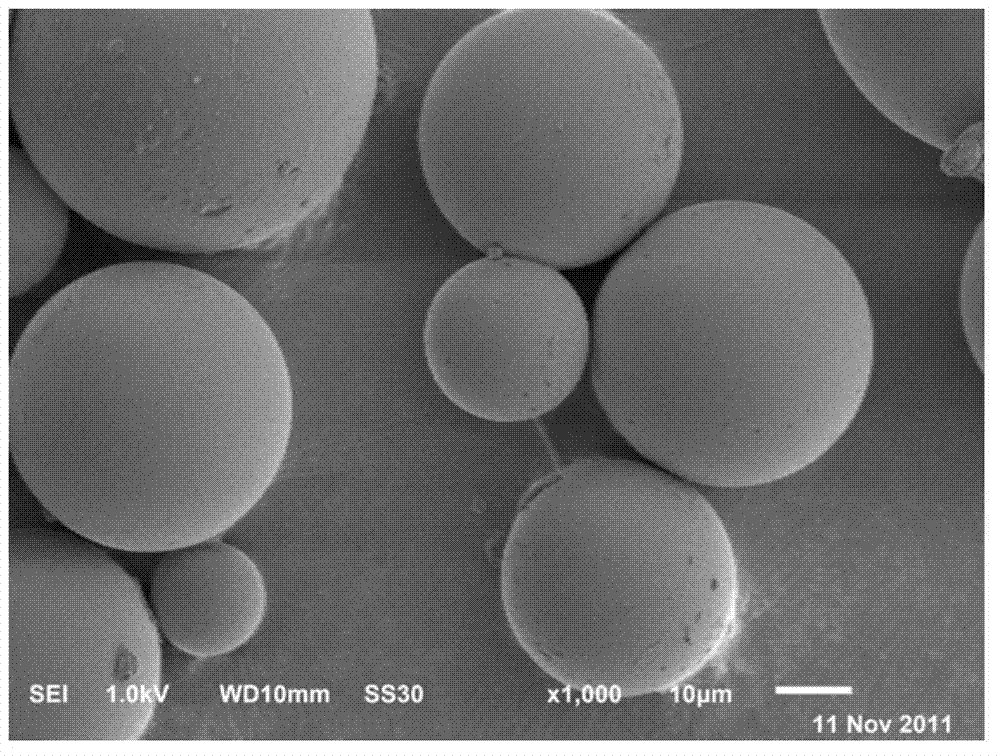

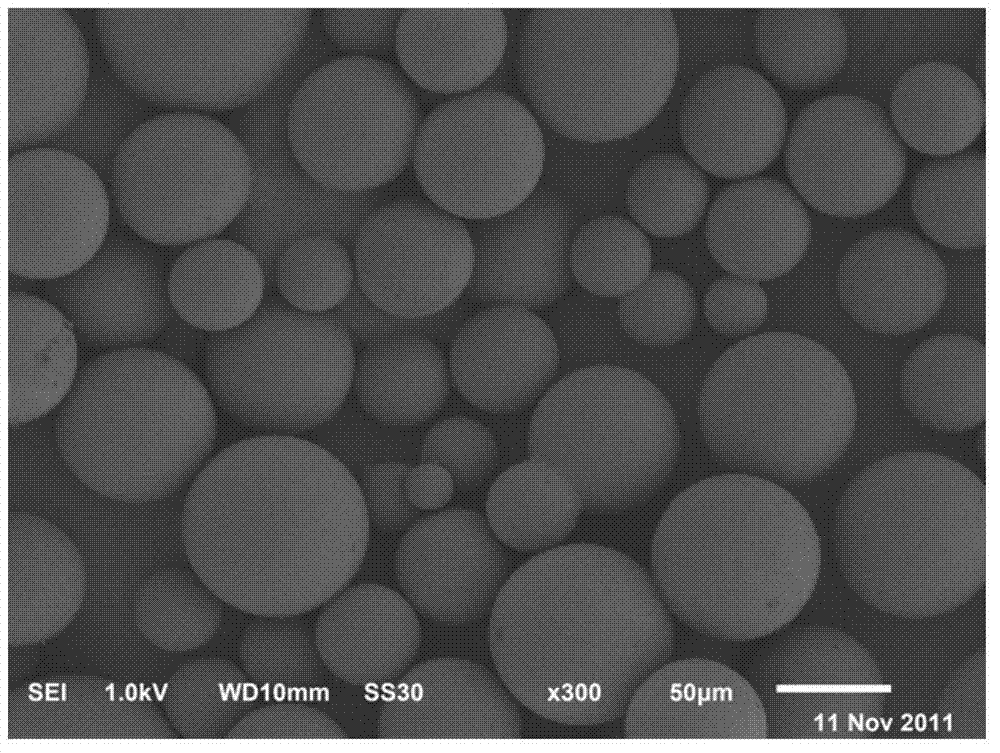

Hollow polystyrene plastic spheres, and preparation method and application thereof

ActiveCN103387691AUniform particle sizeProduct circularity is goodDrilling compositionSolid phasesPetroleum

The invention provides a preparation method for hollow polystyrene plastic spheres, and spheres prepared by the method, and an application of the spheres, and relates to the plastic field. The preparation method for the hollow polystyrene plastic spheres comprises the steps of dissolving an oil-phase solute in an organic solvent, adding a foaming agent, mixing uniformly to obtain an oil phase, wherein the oil-phase solute is polystyrene or a mixture of polystyrene and styrene monomers; dissolving a dispersing agent or the dispersing agent and an emulsifying agent in water to obtain a water phase; mixing the oil phase and the water phase uniformly, so as to make the oil phase dispersed uniformly in the water phase to obtain an emulsion; heating to evaporate the organic solvent while curing and foaming the oil-phase droplets; then separating a solid phase from the emulsion; and drying to obtain the hollow polystyrene plastic spheres. The hollow polystyrene plastic spheres have an internal hollow-core structure, are small in particles and controllable in particle size distribution, and can be well applied in the fields of petroleum drilling fluids, cosmetics, coatings, etc. The preparation method is simple in process and short in preparation time and can be easily industrialized.

Owner:CHINA PETROLEUM & CHEM CORP +1

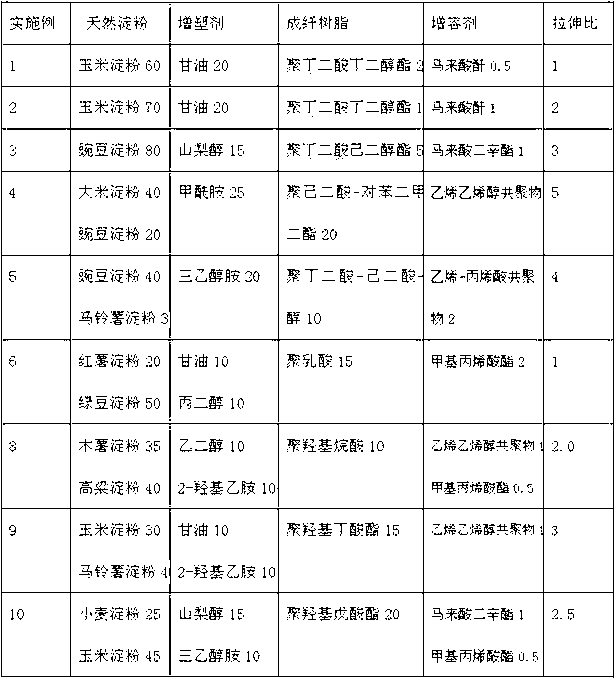

Full-biodegradable starch-base in-situ fiber reinforced composite material and preparation method thereof

InactiveCN102702580ALow costGood processing performance and application performancePlasticizerFiber-reinforced composite

The invention discloses a full-biodegradable starch-based in-situ fiber reinforced composite material and a preparation method thereof. The starch-based full-biodegradable in-situ fiber reinforced composite material comprises the components in parts by weight: 60-80 parts of natural starch, 15-25 parts of plasticizer, 5-20 parts of fiber-forming resin and 0.5-2 parts of compatibilizer. The preparation method comprises the three steps of: mixing the natural starch, the plasticizer and the fiber-forming resin with the compatibilizer for 20-30 minutes at high speed according to a certain ratio; carrying out melt blending and extrusion in a double-screw extruder with an extrusion temperature of 145-190 DEG C, an extrusion die temperature of 130-170 DEG C and a screw rotation speed of 20-40 r / min; and cooling in natural air; and pelletizing to prepare the starch-based in-situ fiber reinforced composite material. The full-biodegradable starch-based in-situ fiber reinforced composite material contains thermoplastic starch as high as over 80% and has good processing property and application performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

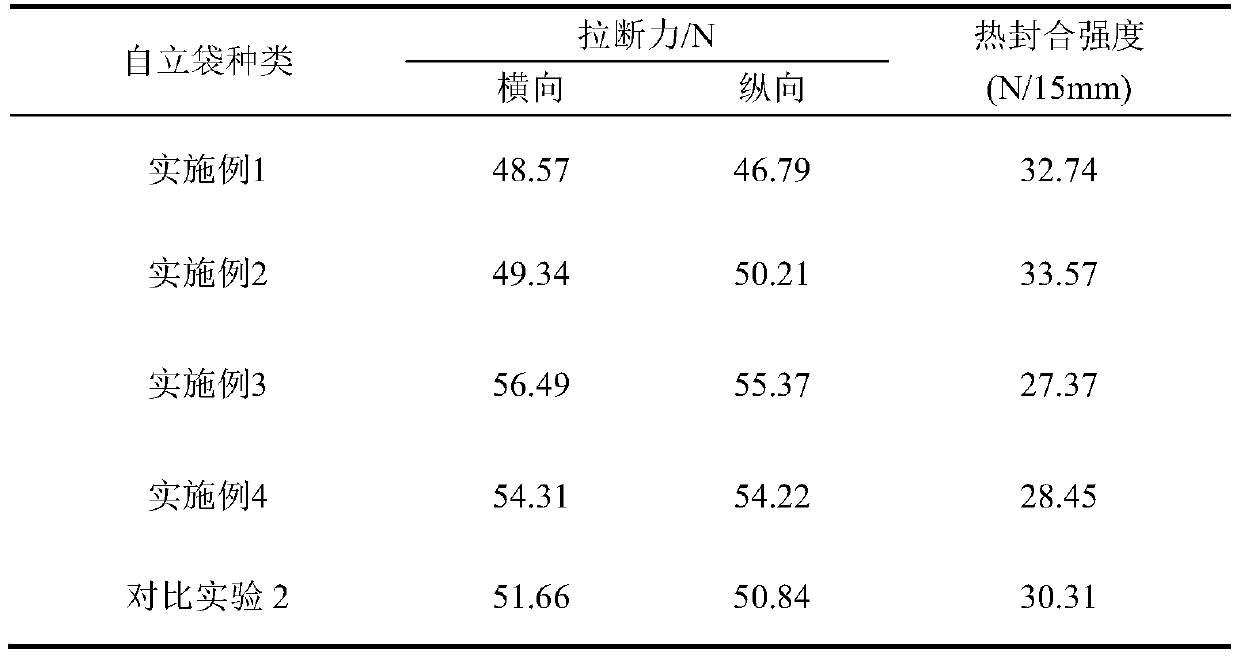

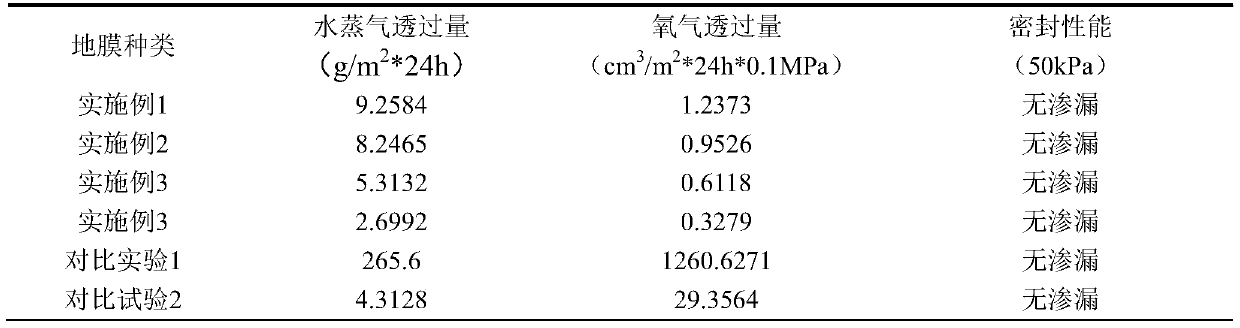

High-barrier biodegradable free-standing bag and preparation method thereof

ActiveCN110921099ALow oxygen transmission rateLow water vapor transmission rateFlexible coversWrappersPolymer scienceBiodegradable bag

The invention discloses a high-barrier biodegradable free-standing bag and a preparation method thereof. The free-standing bag is composed of two parts of a high-barrier biodegradable self-sealing strip and a five-layer composite high-barrier biodegradable bag body, the main substrate of the high-barrier biodegradable self-sealing strip is PLGA and PPC with excellent barrier property, the five-layer composite high-barrier biodegradable bag body is composed of single-light white kraft paper, a bonding layer, a first barrier layer, a second barrier layer and a heat seal layer, and is integrallyformed by adopting the four-layer co-extrusion and film-coating combined process. Compared with a traditional non-degradable free-standing bag, the prepared high-barrier biodegradable free-standing bag has the advantages that the physical mechanical property and the heat sealing performance are substantially equivalent, the barrier property is more excellent, biodegradation can be achieved, the problem of "white pollution" caused by waste of traditional free-standing bags is solved, and the application of the biodegradable plastic in the field of high-barrier food packaging is expanded, so that the high-barrier biodegradable free-standing bag has very important significance.

Owner:JIANGSU GOLDEN RAINBOW NEW MATERIAL CO LTD

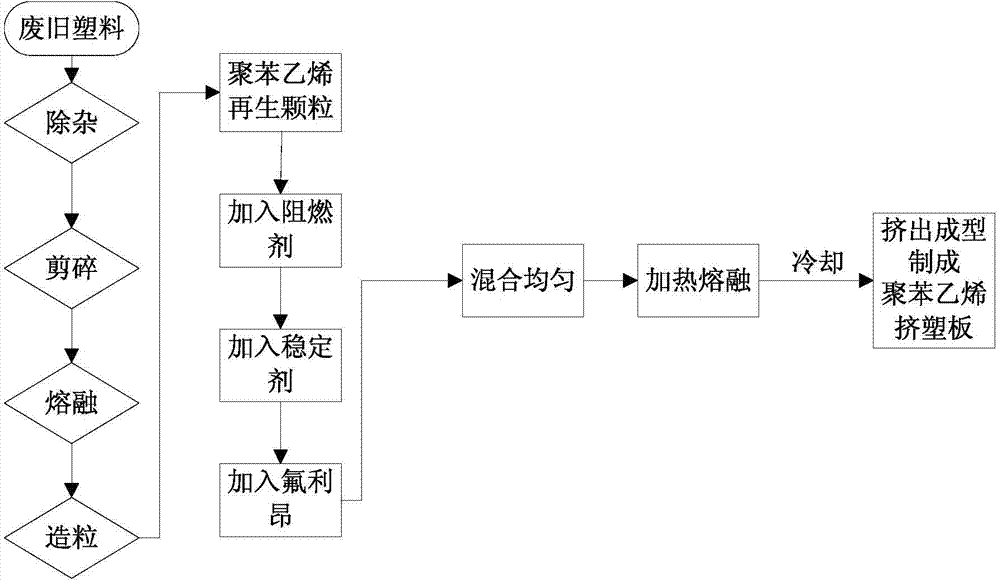

Method for preparing polystyrene extruded sheet from waste plastics

The invention belongs to the field of material science and specifically relates to a method for preparing a polystyrene extruded sheet from waste plastics. The method comprises the following steps: step 1, preparing polystyrene regenerated particles from the waste plastics; and step 2, preparing the polystyrene extruded sheet. The method for preparing the polystyrene extruded sheet from the waste plastics has the advantages of low cost, energy source conservation and simple preparation process; the problem of white pollution bothering the state is effectively solved; and meanwhile, the prepared polystyrene extruded sheet is high in mechanical strength and good in heat resistance.

Owner:青岛欧克斯新型建材有限公司

Process for producing environmentally-friendly full-degradable liquid mulch film capable of turning into fertilizer by using coal humic acid

ActiveCN102239794ANo pollutionIncrease fertilizer and water retention performanceAgriculture tools and machinesOrganic fertilisersCross-linkPotassium

The invention provides a method for producing an environmentally-friendly full-degradable liquid mulch film capable of turning into a fertilizer by using coal humic acid. The process comprises the following steps: finely selecting weathered coal, brown coal, peat or rogued turf, removing impurities, and then adding the coal into a crusher and crushing the coal into coal powder with the grain size of 100-150 meshes; adding raw materials into a reaction kettle in a raw material weight ratio of coal powder to potassium hydroxide to potassium carbonate to water equal to (100-120):(0.2-0.7):(0.2-0.6):(200-320), stirring, heating the mixture, standing for settling, and then taking liquid supernatant, thereby acquiring a potassium humate solution; and enabling raw materials to react in a raw material weight ratio of potassium humate solution to boric acid to potassium silicate to cellulose to cross-linking agent to water to propylene glycol monomethyl etheracetate to ammonium nitrate equal to (10-12):(1.8-2.5):(1.2-1.7):(0.15-0.17):(0.25-0.27):(20-30):(0.2-0.3):(0.1-0.2), thereby generating the environmentally-friendly full-degradable liquid mulch film capable of turning into the fertilizer. The process provided by the invention is used for producing the environmentally-friendly full-degradable liquid mulch film by using coal humic acid. After being used, the liquid mulch film is free from being cleared away and is turned into the fertilizer which is absorbed by crops, thereby solving the 'plastic pollution' problem of plastic mulch films.

Owner:方宁

High-performance wood-plastic composite material and preparation method thereof

The invention discloses a high-performance wood-plastic composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 60 to 80 parts of peanut hull powder, 30 to 50 parts of bamboo powder, 60 to 90 parts of abandoned plastics, 15 to 25 parts of epoxy resin, 4 to 6 parts of mineral fibers, 5 to 7 parts of magnesium carbonate whiskers, 4 to 6 parts of nano calcium carbonate, 6 to 9 parts of maleic anhydride, 3 to 5 parts of an organosilicone water-proofing agent, 2 to 4 parts of an 168 antioxidant, 3 to 5 parts of a red phosphorus fire-retardant and 3 to 5 parts of a 788 light stabilizer. The preparation method comprises the processing steps of modified pre-treatment, mixing at high speed, hot press molding, cooling setting and the like. The wood-plastic composite material obtained through the method has the advantages of high compressive strength, high abrasive resistance, low cost, high distortion temperature and the like, and the material and the method, provided by the invention, also have the advantages of simple processing technique, short processing time, low cost and the like, and are suitable for industrial production.

Owner:许超群

Special pbs modified biological fully-degradable film material

The present invention relates to the technical field of biodegradable plastic films, particularly to a special pbs modified biological fully-degradable film material, which comprises the following raw materials by weight: 5-30 parts of polylactic acid, 20-40 parts of starch, 40-60 parts of polyadipic acid / butylene terephthalate, 0-20 parts of lignocellulose, 0-1 part of an antioxidant, 2-10 parts of a melt reinforcing agent, 5-20 parts of a starch modified plasticizer, and 0.1-10 parts of a coupling agent. According to the present invention, the special pbs modified biological fully-degradable film material is disclosed, the film prepared from the special pbs modified biological fully-degradable film material has advantages of excellent mechanical property, excellent thermal stability and excellent film uniformity, the prepared special pbs modified biological fully-degradable film material belongs to the completely biodegradable material, can solve the white pollution problem caused by the plastic, and belongs to the environmentally friendly material, and the prepared plastic film has the high bio-base content, has advantages of low cost and environmental protection, and has great industrialization advantages at home and abroad.

Owner:新疆蓝山屯河型材有限公司 +1

Low-cost high-biology-base full-biodegradable multi-layer coextrusion film for waistcoat pocket and preparation method of coextrusion film

InactiveCN109367173ALow costSolve the problem of "white pollution"Synthetic resin layered productsLaminationBlow moldingThermoplastic

A polylactic acid / polyadipate-butylene terephthalate (PLA / PBAT) modified material and a polyadipate-butylene terephthalate / thermoplastic starch (PBAT / TPS) modified material which can meet the blow molding requirement are prepared through melting reaction in a blending manner based on a multi-element blending modification technique of fully biodegradable materials; and a full-biodegrade three-layercoextrusion film is prepared by virtue of a multilayer coextrusion technique, the upper and lower layers are PLA / PBAT modified films, and the middle layer is a PBAT / TPS modifying film. The biology base content of the film can reach up to over 50%, the tensile strength is higher than that of a traditional PE film, the cost is relatively low, and the film has very important significances to the solving of ''white pollution'' problem and the promotion of the application of a full-biodegrade material in the field of waistcoat pockets.

Owner:束建军

Method for preparing polymer oil absorption material

InactiveCN102534830ASimple structureCause economic pressureWater cleaningFatty/oily/floating substances removal devicesChemical industryPolymer science

The invention relates to the field of chemical industry, and discloses a method for preparing a polymer oil absorption material. The method comprises the following steps of: heating to melt raw materials so as to obtain a melt by a horizontal disc rotary centrifugal spinning method, and slowly putting the melt into the center of a turntable of a horizontal disc rotary centrifuge, which rotates at high speed, to generate silk, namely the polymer oil absorption material. By the method, low-cost raw materials are adopted, the preparation process is simple, and the prepared oil absorption material has high selectivity and oil absorption efficiency and a wide industrial application prospect.

Owner:EAST CHINA NORMAL UNIV

Low-cost wood-plastic composite material and preparation method thereof

The invention discloses a low-cost wood-plastic composite material and a preparation method thereof. The low-cost wood-plastic composite material comprises, by weight, 40-60 parts of corn stalks, 25-40 parts of sisal dregs, 35-50 parts of abandoned plastics, 15-20 parts of polyvinyl chloride, 3-5 parts of aramid fibers, 5-7 parts of cotton fibers, 6-9 parts of calcium stearate, 2-3 parts of antioxidant, 2-4 parts of light stabilizer and 3-5 parts of magnesium hydroxide fire retardant. The preparation method includes the processing steps of modified pretreatment, high-speed material mixing, hot press molding, cooling and shaping. According to the low-cost wood-plastic composite material and the preparation method thereof, the corn stalks, the sisal dregs and the abandoned plastics are comprehensively used as main raw materials, so that cost is lowered, and the environmental pollution problem of waste is further solved. The obtained wood-plastic composite material has the advantages of being high in compressive strength, high in abrasion resistance and the like. The wood-plastic composite material further has the advantages of being simple in processing technology, short in processing time, low in cost and the like, thereby being suitable for industrial production.

Owner:许超群

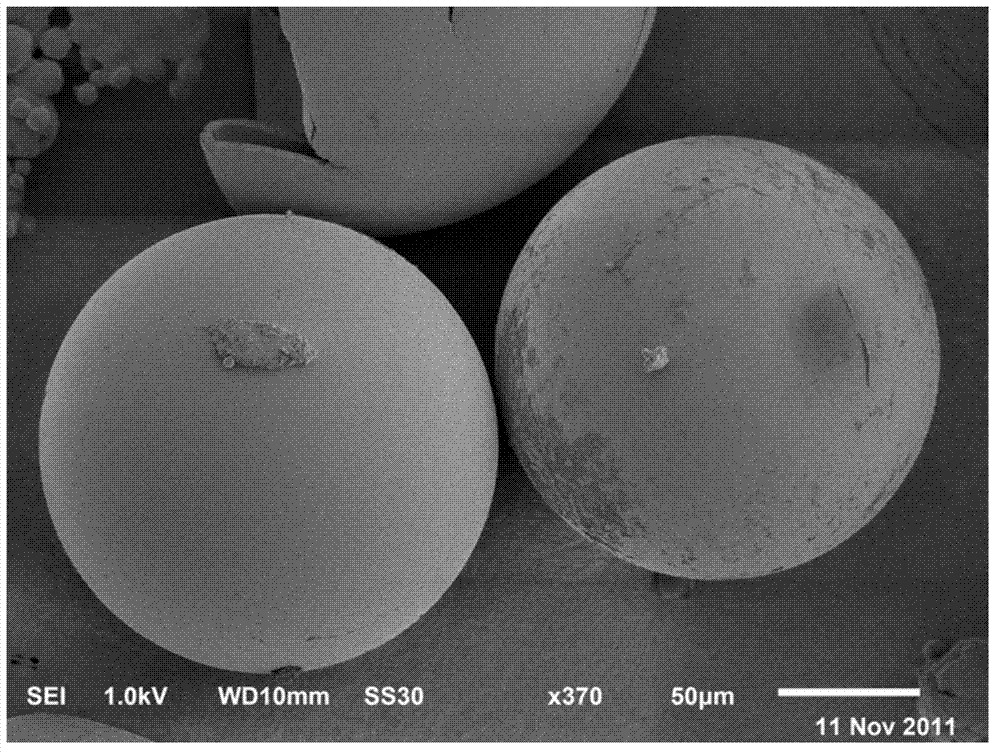

Preparation method for plastic hollow globule, and prepared product and application thereof

ActiveCN103585936AUniform particle sizeImprove circularityMicroballoon preparationMicrocapsule preparationSolid phasesPolycarbonate

The invention provides a preparation method for a plastic hollow globule and the prepared plastic hollow globule and application thereof. The preparation method comprises the following steps: dissolving an oil phase solute in an organic solvent to obtain an oil phase, wherein the oil phase solute is polycarbonate or a mixture of polystyrene and / or a styrene monomer and polycarbonate; adding an emulsifier into water to obtain a first water phase; adding a dispersant or a mixture of the dispersant and the emulsifier into water to obtain a second water phase; fully emulsifying the oil phase and the first water phase to prepare a first emulsion; adding the second water phase into the first emulsion for complete emulsification so as to obtain a second emulsion and heating the second emulsion to allow the organic solvent to evaporate and an oil phase liquid drop to be cured and foamed; and carrying out liquid-solid separation, separating out a solid phase and drying the solid phase to prepare the plastic hollow globule with a hollow structure inside and an average particle size of 1 to 300 mu. The plastic hollow globule has a small and controllable particle size and can be used in fields like oil drilling fluids, cosmetics and paints.

Owner:CHINA PETROLEUM & CHEM CORP +1

Full-biodegradation bacterial cellulose/polylactic acid composite material and preparing method thereof

The invention relates to a full-biodegradation bacterial cellulose / polylactic acid composite material and a preparing method thereof. The composite material is prepared from, by weight, 75 parts to 99 parts of polylactic acid, 1 part to 25 parts of bacterial cellulose and 1 part to 3 parts of coupling agents. The preparing method includes the steps that the polylactic acid and the bacterial cellulose are stirred to be mixed by weight, the coupling agents are added by weight, then the mixture is put into a mixing apparatus, the temperature is controlled to range from 170 DEG C to 220 DEG C, melt mixing is carried out, extruding and prilling are carried out, and premix particles are obtained; the premix particles are added into an injection molding machine or a compression molding machine, the temperature is controlled to range from 170 DEG C to 220 DEG C, the melting time is controlled to range from 2 min to 3 min, melt molding is carried out, and sample strips of the composite material are obtained; then drying treatment and heat treatment are carried out to increase the practical using temperature of the material. Compared with the prior art, the full-biodegradation bacterial cellulose / polylactic acid composite material and the preparing method thereof are simple in preparing technology, good in controllability, wide in raw material source and low in processing cost, and the prepared composite material is excellent in mechanical property, good in heat stability, capable of achieving full biodegradation in the natural environment and is environmentally friendly.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Under-mulch-plastic-film drip irrigation area promoting type corn straw returning-field method

InactiveCN106938963ASolve the problem of "white pollution" caused by overturningSolve the problem of "white pollution"Organic fertilisersUrea compound fertilisersDecompositionPlastic mulch

The present invention provides an under-mulch-plastic-film drip irrigation area promoting type corn straw returning-field method. According to the method, the straw composting rate is regulated by using a straw composite decomposition bacterial agent and an excitant and by covering a under-mulch-plastic-film drip irrigation system with a degradable mulch plastic film, and according to the growth and development requirement law of corn in the under-mulch-plastic-film drip irrigation area on nutrients, the nutrients required by corn are timely supplemented and the soil fertility is improved so as to achieve the scientific management and the efficient use of the straws. In the prior art, the under-mulch-plastic-film drip irrigation area corn straw returning-field causes the soil microorganism action so as to compete the nutrients with the corn seedlings, such that the problems of corn seedling weakening, corn seedling death and yield reducing are caused. With the method of the present invention, the problems in the prior art are solved, the rural environment is improved, and the technical difficulty of the under-mulch-plastic-film drip irrigation area corn straw returning-field is broken through.

Owner:JILIN ACAD OF AGRI SCI

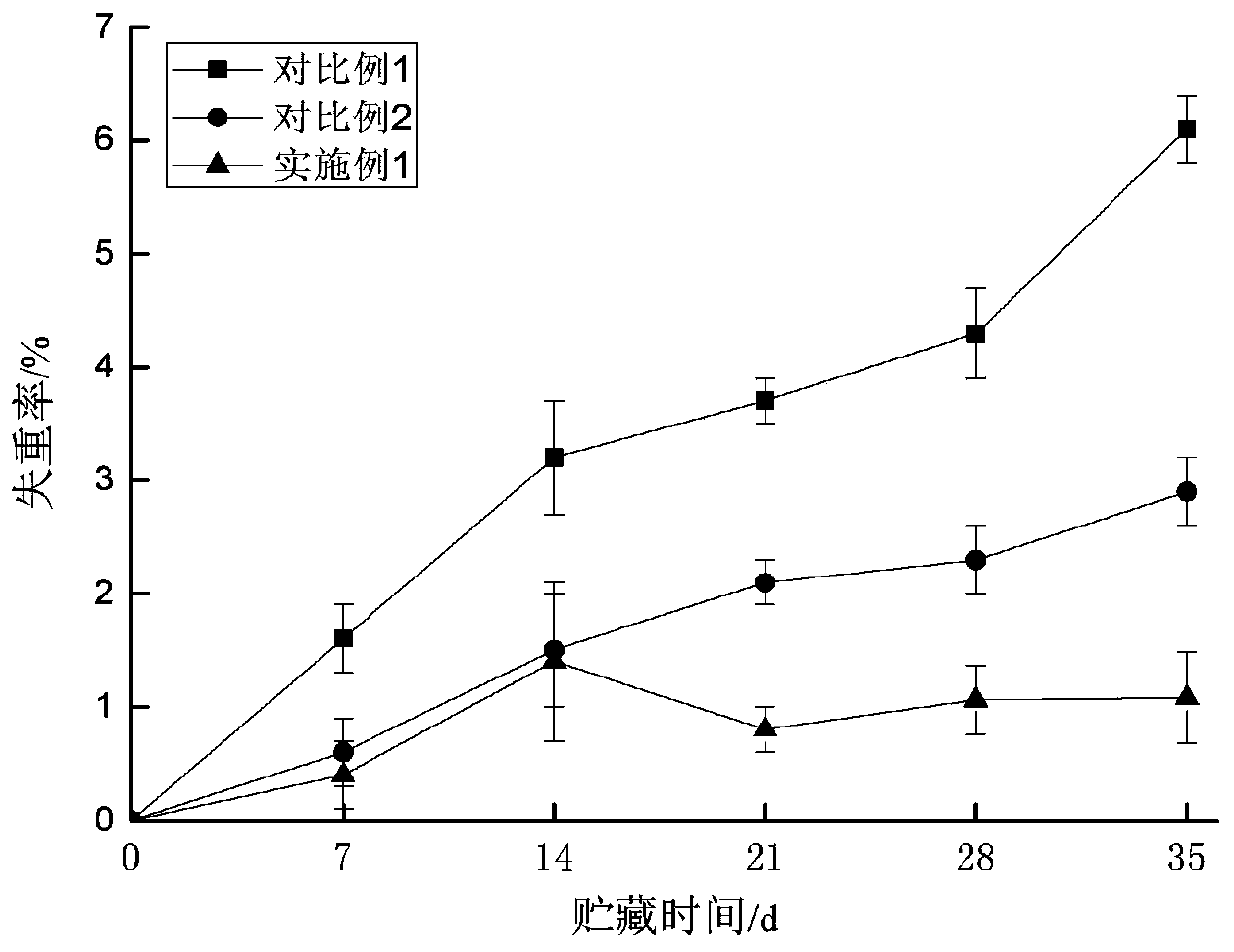

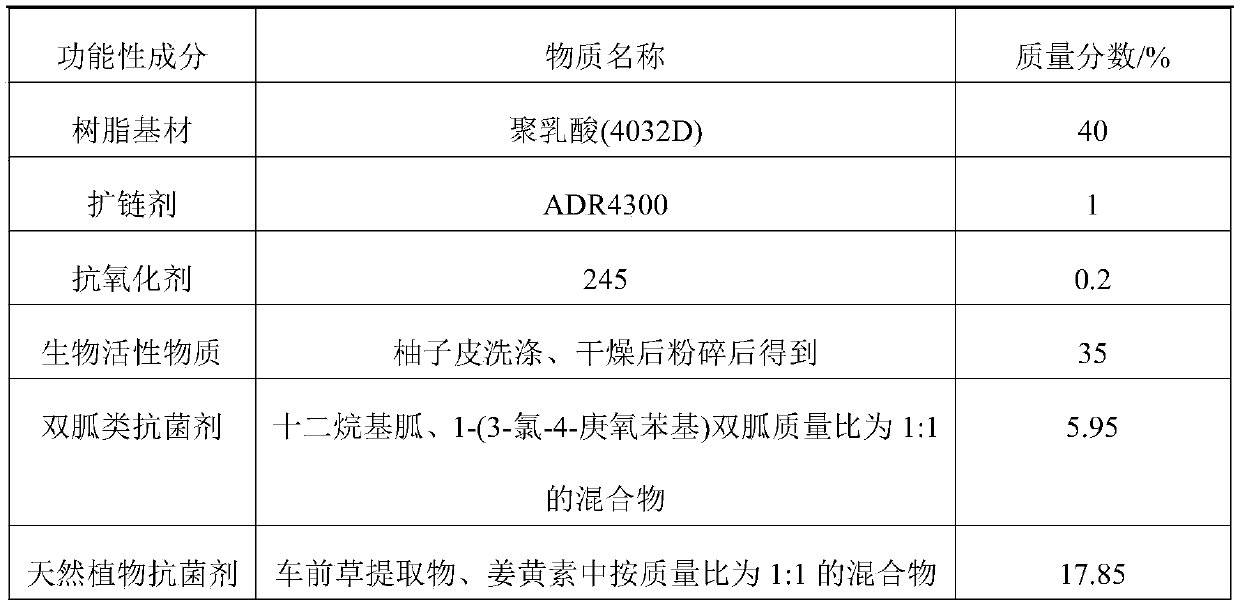

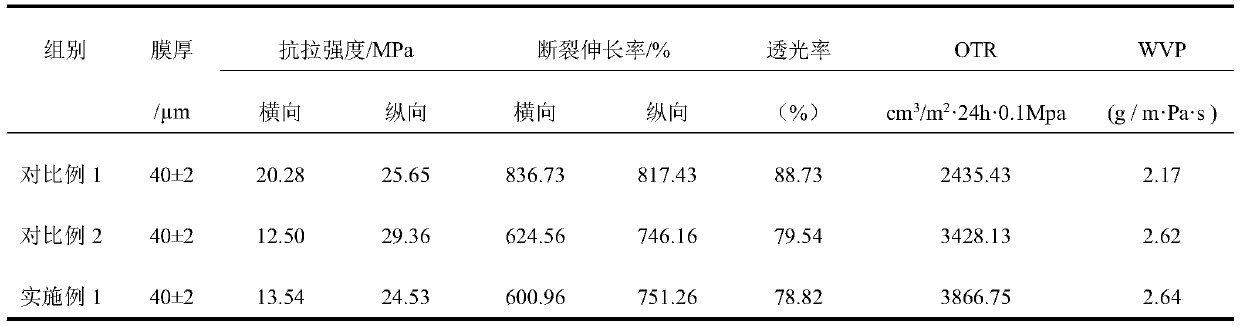

Full-biomass porous material slow-release antibacterial active preservative film and preparation method thereof

InactiveCN110835457AWide variety of sourcesSolve pollutionAntimicrobial actionBiochemical engineering

The invention provides a full-biomass porous material slow-release antibacterial active preservative film and a preparation method thereof. The full-biomass porous material slow-release antibacterialactive preservative film comprises 35-45 wt% of a matrix resin, 30-40 wt% of a biological porous substance, 20-25 wt% of an antibacterial agent and 0.9-1.3 wt% of a processing aid. The preparation method comprises the following steps: mixing the biological porous substance with the antibacterial agent to make the biological porous substance fully adsorb the antibacterial agent, mixing the obtainedmixture with the matrix resin and the processing aid, granulating the obtained mixture, and carrying out tape casting to prepare the film. Hyphae, pomegranate rind, shaddock peel, orange peel, bark and straw are porous substances, and can effectively adsorb the active antibacterial agent so as to achieve the slow release effect of the active antibacterial agent and improve the film performance, so that the long-term antibacterial effect on mutton is achieved; and the raw materials are degradable substances, so the pollution problem of agricultural byproducts and the white pollution problem ofplastic package can be solved, and the additional values of agricultural products can be improved.

Owner:SHANGHAI OCEAN UNIV

Wood plastic floor resistant to acid and alkali corrosion and production technology thereof

The invention discloses a wood plastic floor resistant to acid and alkali corrosion and a production technology thereof, and belongs to the technical field of construction materials. The wood plastic floor is prepared from the following raw materials in parts by weight: 20 to 40 parts of waste and old PVC aggregate, 3 to 8 parts of PVC plastic particle, 40 to 70 parts of waste and old wood powder or fiber powder, 5 to 10 parts of active calcium carbonate, 1 to 3 parts of filler, 5 to 10 parts of processing aid, 1 to 5 parts of anti-aging auxiliary agent, 0.1 to 0.15 part of copper powder, 0.01 to 0.02 part of molybdenum disulfide, and 5 to 10 parts of PTFE pellet. The raw materials mentioned above are subjected to steps of granulating, mixing, extruding, and moulding to produce the wood plastic floor. Compared with the conventional wood plastic floors, the provided wood plastic floor has the advantages of good mechanical properties, strong performance on resisting acid and alkali corrosion, and low manufacturing cost.

Owner:脱德明

Polylactic acid bio-based special material for disposable syringe

The invention discloses a polylactic acid bio-based special material for a disposable syringe. The polylactic acid bio-based special material is prepared from, by weight, 100 parts of polylactic acid (PLA), 5-30 parts of toughening agent, 0.1-2 parts of nucleating agent and 0.1-0.5 part of antioxidant. A degradable material vinyl acetate and vinyl laurate copolymer (VAc-VL) is adopted as the toughening agent, and N,N'-dicyclohexyl-2,6-naphthalenedicarboxamide (TMB-5000) is adopted as the nucleating agent. According to the polylactic acid bio-based special material for the disposable syringe, transparent crystallization nucleation and reaction blending modification technologies are adopted, the polylactic acid bio-based special material which is uniform in microstructure, friendly to environment, high in size stability, good in transparency, resistant to high temperature and capable of meeting the national standard GB15810-2001 for the disposable syringe is developed out, the polylactic acid bio-based special material is suitable for manufacturing the disposable syringes through precise injection molding, and important significance to solving of the white pollution caused by disposable medical products is achieved.

Owner:江苏金扬子包装科技有限公司

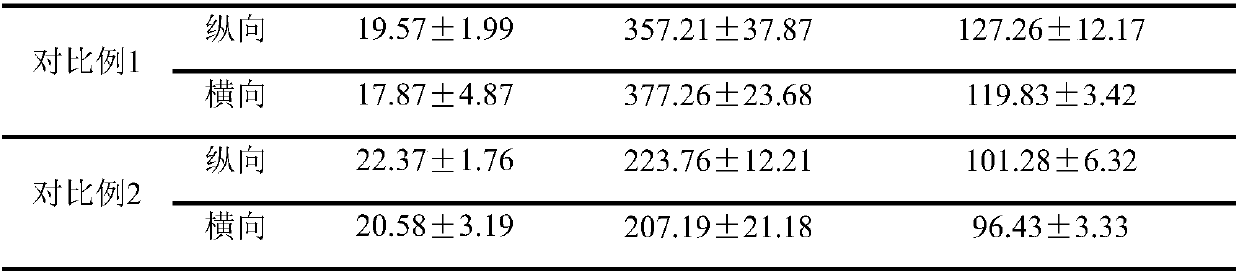

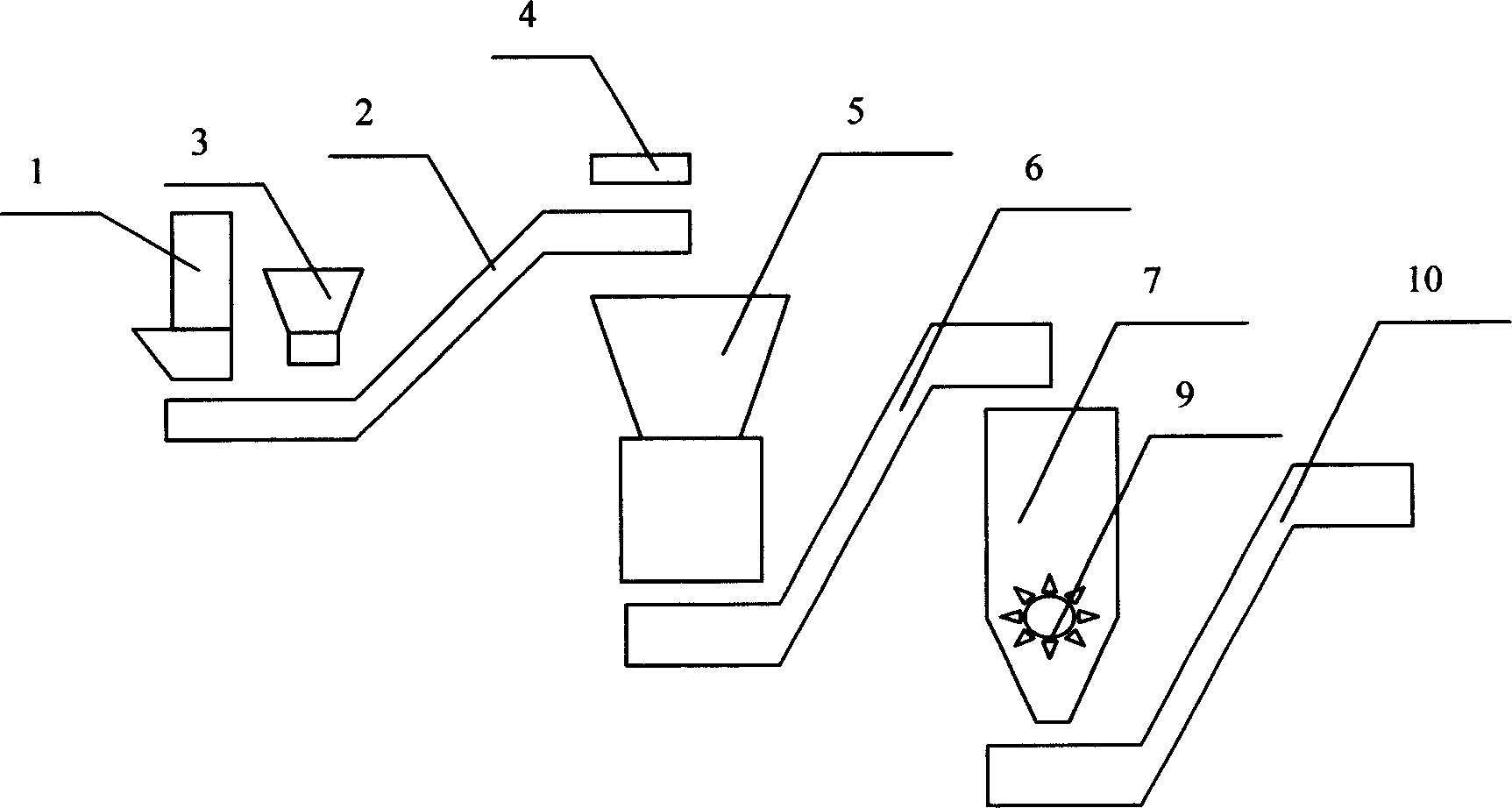

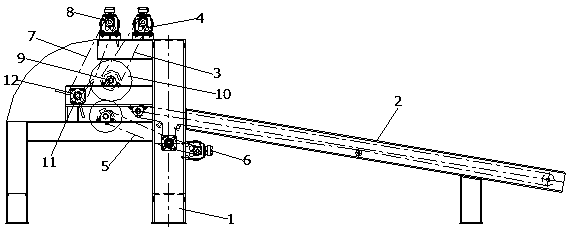

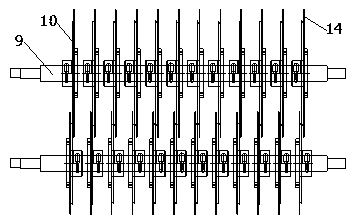

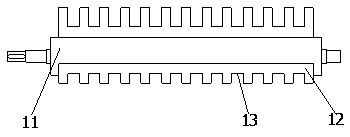

Waste film shredding machine

InactiveCN109513502AAchieve recyclingNovel structurePlastic recyclingGrain treatmentsMechanical engineering

The invention discloses a waste film shredding machine which can effectively shred waste films. The waste film shredding machine comprises a machine frame, a feeding conveyor, a first knife roller assembly, a second knife roller assembly, a shredding roller assembly, a first motor, a second motor and a third motor, wherein the feeding conveyor is arranged on the front side of the machine frame, the first knife roller assembly and the second knife roller assembly are rotatably arranged on the machine frame, the shredding roller assembly is rotatably arranged on the machine frame and located behind the first knife roller assembly and the second knife roller assembly, the first motor is arranged on the machine frame and is in transmission connection with the first knife roller assembly through a first transmission mechanism, the second motor is arranged on the machine frame and is in transmission connection with the second knife roller assembly through a second transmission mechanism, andthe third motor is arranged on the machine frame and is in transmission connection with the shredding roller assembly through a third transmission mechanism. The first knife roller assembly comprisesa rotating shaft rotatably mounted on the machine frame and a plurality of cutters mounted on the rotating shaft at intervals. The second knife roller assembly and the first knife roller assembly arethe same in structure, cutters of the second knife roller assembly and the cutters of the first knife roller assembly are close to each other and partially coincide.

Owner:云南同云科贸有限公司

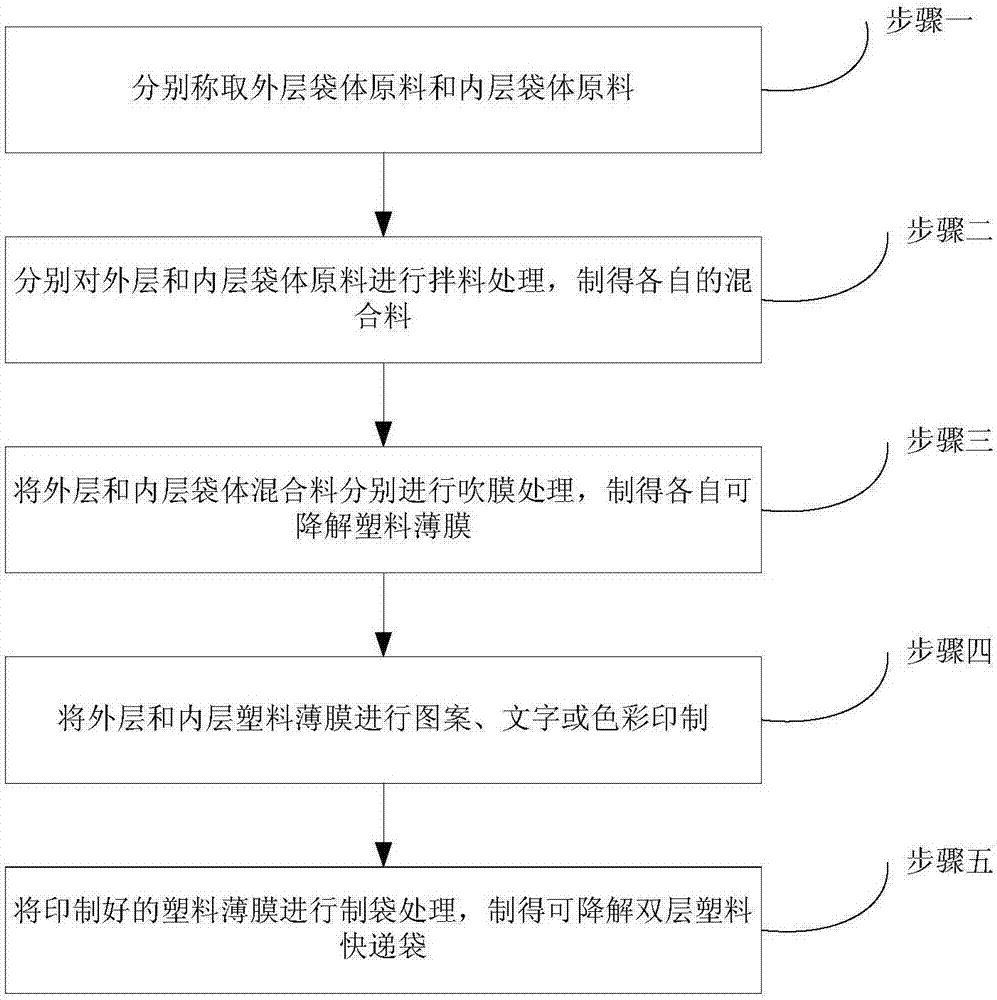

Degradable double-layer plastic express bag and preparation method thereof

InactiveCN107216538ASolve white pollutionDegrade automaticallyBio-packagingBagsBiodegradable plasticEngineering

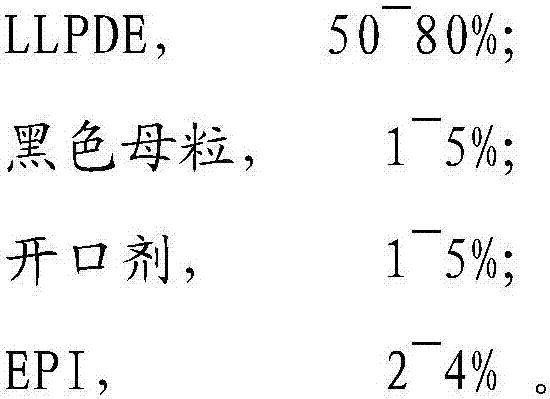

The invention discloses a degradable double-layer plastic express bag and a preparation method thereof. The express bag comprises an outer layer bag body and an inner layer bag body, wherein, in mass percentage, the outer layer bag body comprises the following components: 10-30% of LDPE, 50-80% of LLPDE and 10-30% of white master batches, and the inner bag body comprises the following components: 10-30% of LDPE, 50-80% of LLPDE, 1-5% of black master batches, 1-5% of an anti-block agent, and 2-4% of EPI. In the express bag, the EPI is a completely biodegradable plastic additive, and has a characteristic of oxidizing plastics so as to achieve the function of degrading the plastics and solve the white pollution problem caused by the plastics.

Owner:GUANGDONG TENGEN IND GRP CO LTD

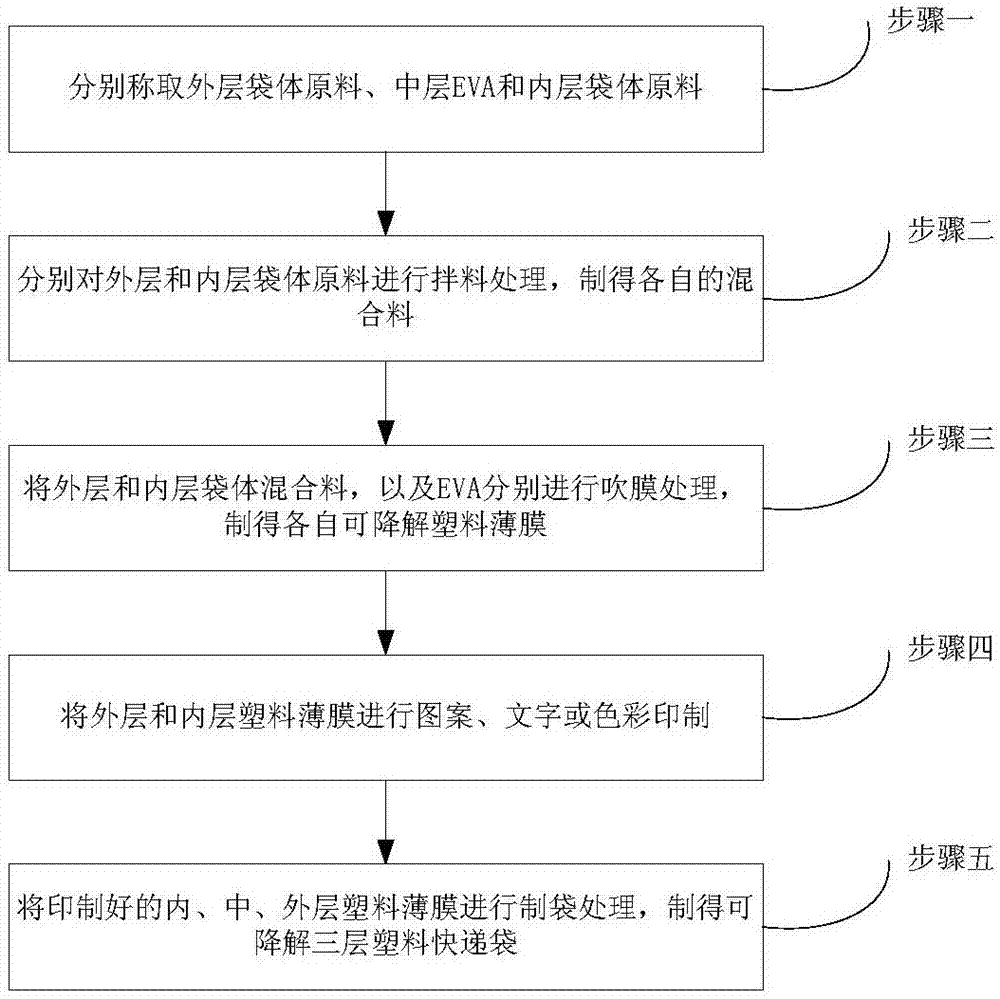

Degradable three-layer plastic express bag and preparation method thereof

InactiveCN107216537ADegrade automaticallyDegradation reachesBio-packagingSynthetic resin layered productsEngineeringMechanical engineering

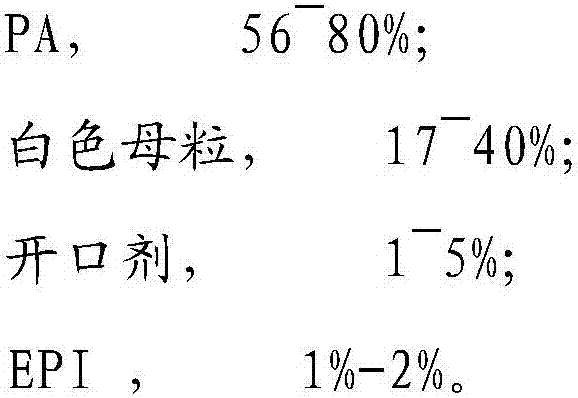

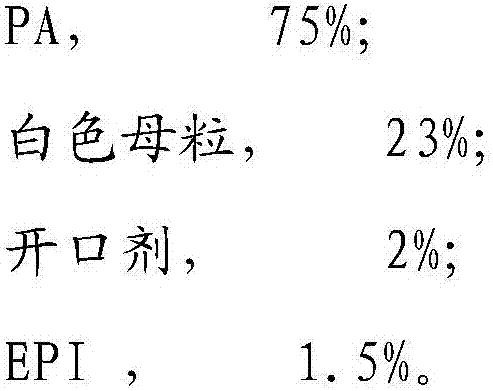

The invention discloses a degradable three-layer plastic express bag and a preparation method thereof. The express bag comprises an outer layer bag body, a middle layer bag body and an inner layer bag body, wherein, in mass percentage, the outer layer bag body comprises the following components: 10-30% of LDPE, 50-80% of LLPDE and 10-30% of white master batches; the middle layer bag body comprises the following component: 100% of EVA; and the inner bag body comprises the following components: 50-80% of PA, 10-40% of the white master batches, 1-5% of an anti-block agent, and 1-2% of EPI. The express bag has super stretching resistance and low-temperature resistant performance, and can bear weight twice heavier than common express bags. After a certain period, the product provided by the invention can be degraded automatically through EPI degradation so as to achieve the function of environmental protection.

Owner:GUANGDONG TENGEN IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com