Method for preparing polystyrene extruded sheet from waste plastics

A technology of polystyrene and waste plastics, applied in the field of material science, can solve problems such as white pollution, and achieve the effects of saving energy, solving white pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

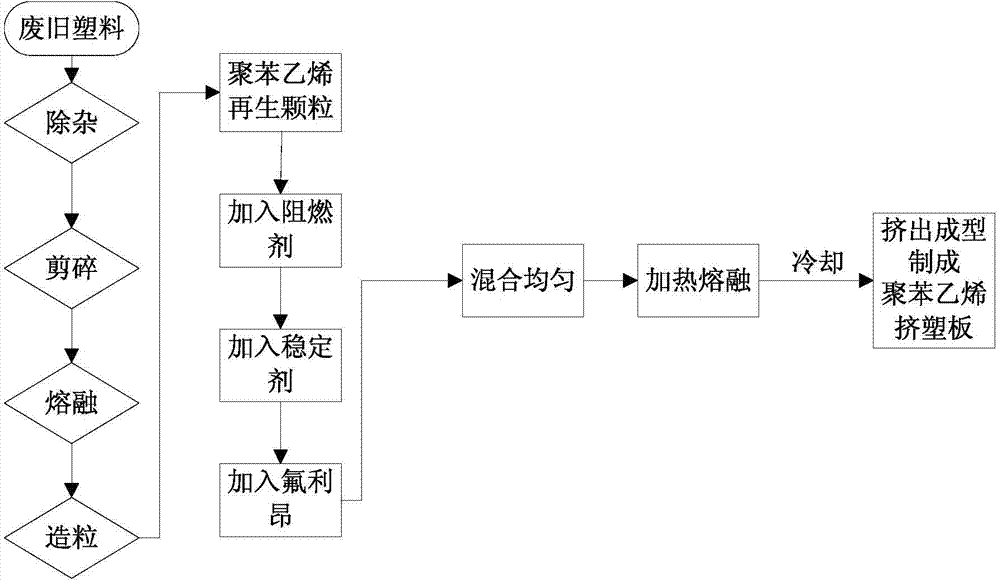

[0022] A method for preparing polystyrene extruded board by using waste plastics includes the following steps:

[0023] Step 1: Use waste plastics to prepare polystyrene recycled particles: remove waste plastics, cut, melt, and pelletize to prepare polystyrene recycled particles, and then cool them for use;

[0024] Step 2: Prepare the polystyrene extruded board: take 45 parts by weight of the polystyrene regenerated particles prepared in step 1, 5 parts of hexabromocyclododecane, and 2 parts of calcium-zinc composite stabilizer into the mixing tank and mix evenly , Heat to 200℃, melt and mix the materials to form a polymer melt, then add 5 parts of Freon; cool the melt to 100℃, then send it to the extruder for extrusion molding.

[0025] According to the test in Example 1, the compressive strength is ≥280kPa, the thermal conductivity is ≤0.03W / mk, the water absorption is ≤1% (V / V), and the water vapor transmission coefficient is ≤3ng / m.s.Pa.

Embodiment 2

[0027] A method for preparing polystyrene extruded board by using waste plastics includes the following steps:

[0028] Step 1: Use waste plastics to prepare polystyrene recycled particles: remove waste plastics, cut, melt, and pelletize to prepare polystyrene recycled particles, and then cool them for use;

[0029] Step 2: Prepare polystyrene extruded board: take 75 parts by weight of the polystyrene regenerated particles prepared in step 1, 15 parts of tetrabromobisphenol A bisallyl ether, and 13 parts of dibasic lead sulfate into the stirring Mix uniformly in the kettle, heat to 350°C to melt and mix the materials to form a polymer melt, then add 15 parts of Freon; cool the melt to 125°C, then send it to the extruder for extrusion molding.

[0030] According to the test in Example 2, the compressive strength is ≥280kPa, the thermal conductivity is ≤0.03W / mk, the water absorption is ≤1% (V / V), and the water vapor permeability coefficient is ≤3ng / m.s.Pa.

Embodiment 3

[0032] A method for preparing polystyrene extruded board by using waste plastics includes the following steps:

[0033] Step 1: Use waste plastics to prepare polystyrene recycled particles: remove waste plastics, cut, melt, and pelletize to prepare polystyrene recycled particles, and then cool them for use;

[0034] Step 2: Prepare the polystyrene extruded board: take 60 parts by weight of the polystyrene regenerated particles prepared in Step 1, 8 parts of brominated epoxy oligomer, 8 parts of tribasic lead sulfate, add them to the mixing tank and mix Evenly, heat to 300°C to melt and mix the materials to form a polymer melt, then add 10 parts of Freon; cool the melt to 110°C, then send it to the extruder for extrusion molding.

[0035] According to the test in Example 3, the compressive strength is ≥280kPa, the thermal conductivity is ≤0.03W / mk, the water absorption is ≤1% (V / V), and the water vapor permeability coefficient is ≤3ng / m.s.Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com