Method for producing humic acid organic fertilizer by adopting tobacco waste

A tobacco waste and organic fertilizer technology, which is applied to the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, can solve the problems of limited resources and raw material sources, and achieve improved soil structure, simple and practical production methods, and improved The effect of crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

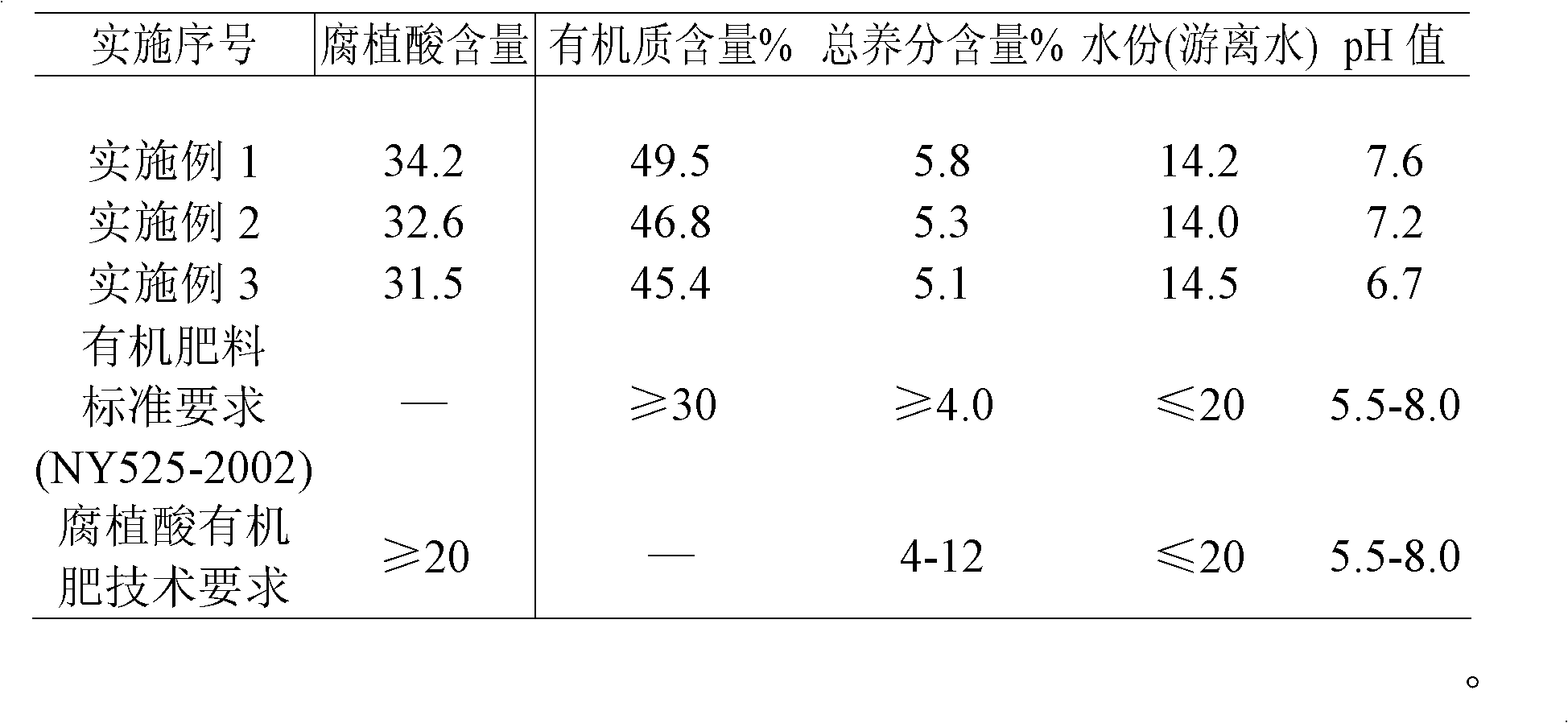

[0017] Tobacco waste from tobacco fields, tobacco re-baking factories and tobacco factories is classified and collected, pulverized to a powder of more than 80 mesh, and mixed according to the mass ratio of 80:20 with the concentrated dry powder of waste liquid from the molasses alcohol factory, and then added to compound 0.6% biological agent, added according to seasonal changes, the three raw materials are further stirred, mixed and sieved evenly, and then stored at room temperature for solid-state fermentation: 10-15 days in summer and 20-25 days in winter. Carry out post-aging treatment until the water content is below 15% to become humic acid organic fertilizer, and its properties are shown in Table 1. Among them, the compound biological agent is a custom-made product of the Institute of Microbiology, Yunnan University.

Embodiment 2

[0019] The concentrate of volume concentration 60% produced by tobacco waste and starch alcohol waste liquid is mixed by mass ratio 60:40 and then added with 0.6% of compound biological bacterial agent. Other conditions are the same as in Example 1. The properties of humic acid organic fertilizer are shown in Table 1 .

Embodiment 3

[0021] Tobacco waste and molasses alcohol plant waste with a volume concentration of 60% were mixed in a mass ratio of 40:60 and then added with 0.6% of compound biological bacterial agent. Other conditions were the same as in Example 1. The performance of humic acid organic fertilizer is shown in Table 1.

[0022] The sources of the above-mentioned examples 2 and 3 are the tobacco wastes of Kunming, the rebaking factory and the tobacco factory. The reconstituted tobacco factory and the tobacco waste can also be used to extract nicotine or solanesol, etc., and the molasses alcohol factory Waste liquid dry powder and concentrated liquid can also be provided by general cassava alcohol factory waste liquid dry powder and concentrated liquid. The compound biological agent is a commercially available or customized compound decomposing agent or compound yeast.

[0023] The tobacco waste humic acid produced by the invention meets the technical requirements of the national organic fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com