Magnetic control melting electrode welding method, and its developed application, and its universal equipment

A welding method and welding equipment technology, which are applied to the magnetron melting pole welding method and its extended application and general equipment field, can solve the problems of continuous high current droplet transition stability and other problems, and achieve rich basic theory and technical practical ability. , The effect of reducing welding cost and overcoming use limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

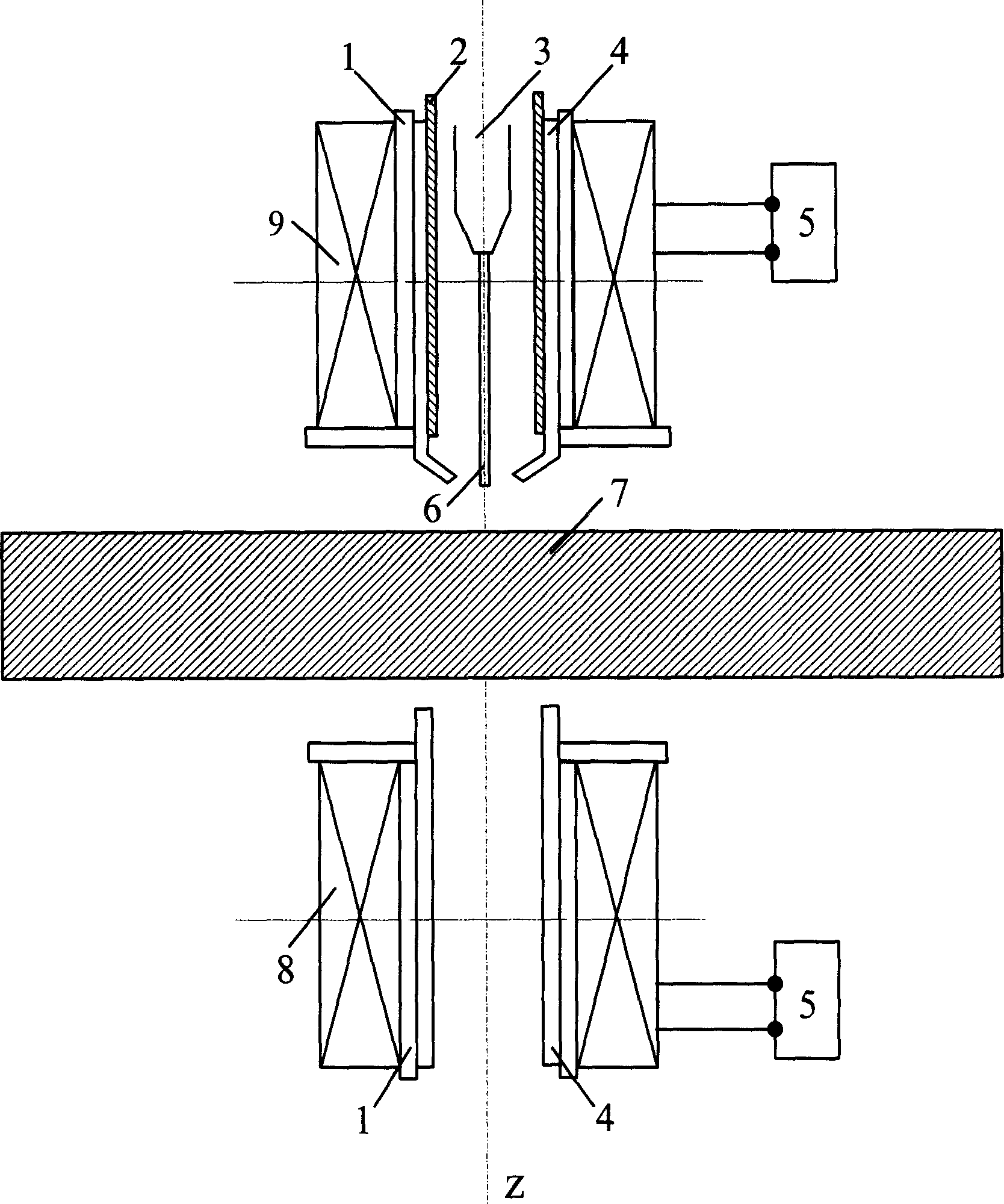

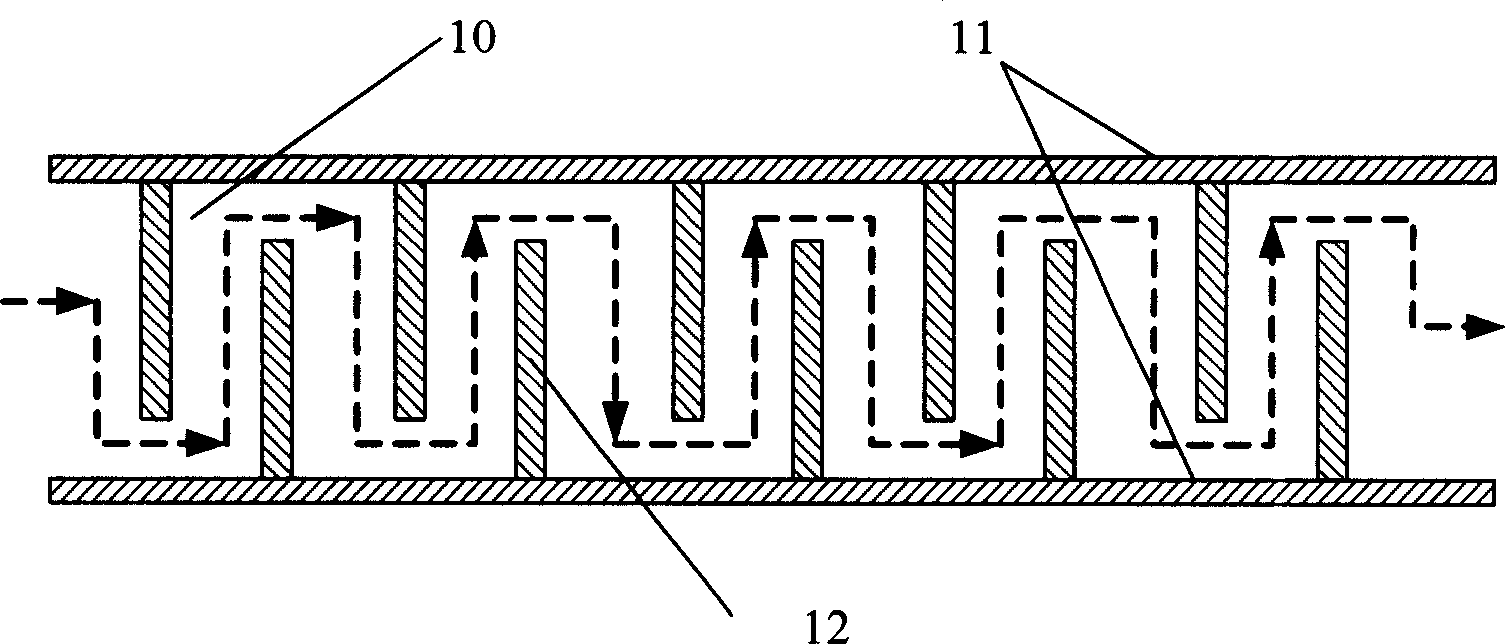

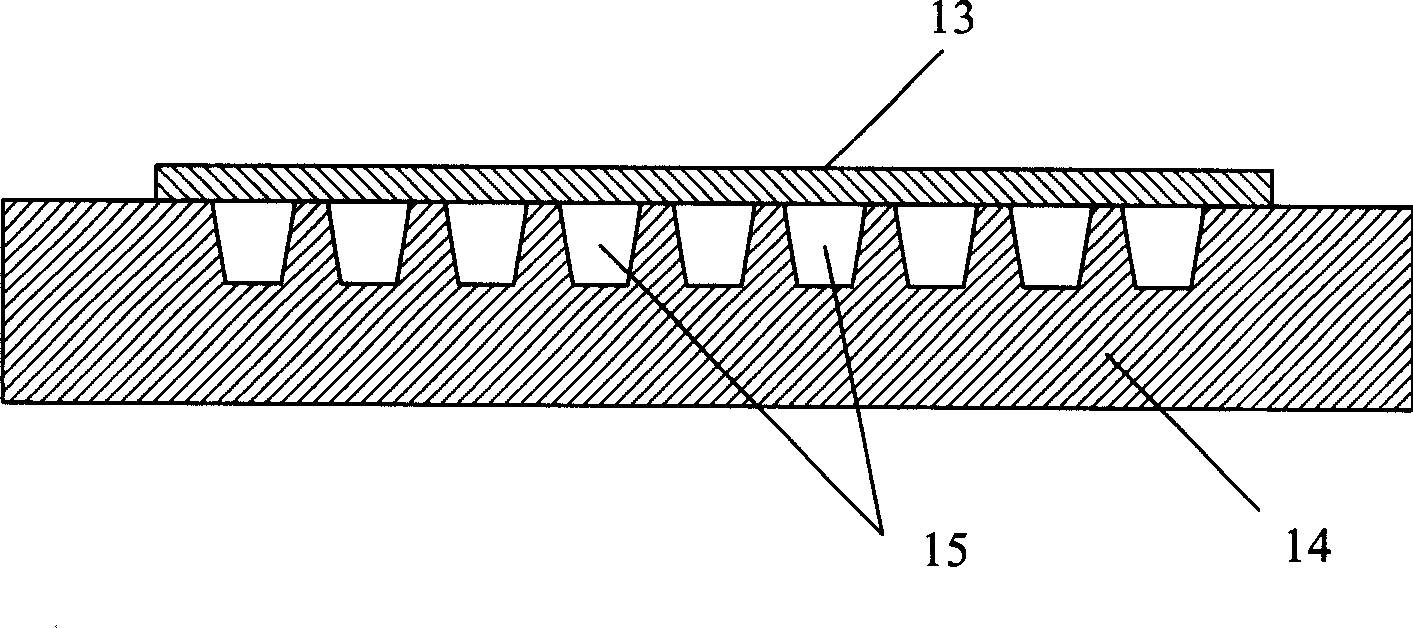

Method used

Image

Examples

example 1

[0084] Example 1: When LD10CS aluminum alloy (US brand 2014-T6) is controlled by intermittent alternating longitudinal magnetic field for TIG welding, the welding process parameters are as follows to obtain good weld formation: the applied magnetic field strength is 0.01-0.05T, and the magnetic field frequency is 1-4Hz , The welding current is 100-140A, the welding speed is 300-400mm / min, and the arc length is 1-1.5mm.

example 2

[0085] Example 2: When 1Cr16Ni9Ti (American brand AISI 340) is controlled by intermittent alternating longitudinal magnetic field for TIG welding, the welding process parameters are as follows to obtain a good weld shape: the applied magnetic field strength is 0.01T, the magnetic field frequency is 1.5Hz, and the welding current is 140A. The welding speed is 150mm / min, and the arc length is 1mm.

[0086] Example 3: When Q235 steel (old national standard A3 steel) is welded with intermittent alternating longitudinal magnetic field to control high cladding rate MAG welding, a good weld shape can be obtained under the following welding process parameters: the shielding gas is Ar+20% CO 2 Components, gas flow rate 20-30L / min, excitation current 10-30A, excitation frequency 1-10Hz, welding current 500-800A, arc voltage 30-50V, wire diameter 0.8-1.6mm, wire feeding speed 20~35m / min.

[0087] Example 4. When 20G boiler steel (US brand SA414D) is controlled by intermittent alternatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com