Low-cost high-biology-base full-biodegradable multi-layer coextrusion film for waistcoat pocket and preparation method of coextrusion film

A multi-layer co-extrusion, low-cost technology, applied in the field of fully biodegradable materials, can solve the problems of too soft film texture, high film cost, limited wide application, etc., achieve low cost, obvious cost advantage, and make up for the effect of being too soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

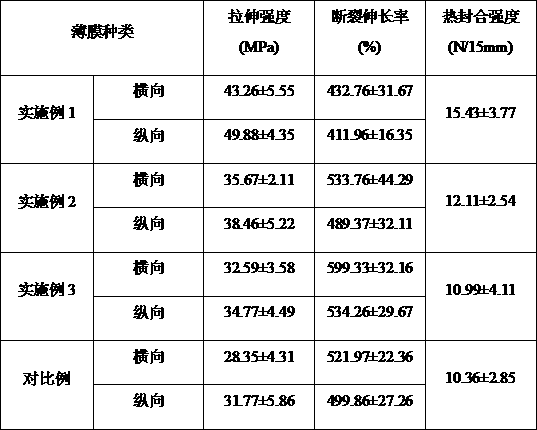

Examples

Embodiment 1

[0025] The upper and lower layers of the low-cost high bio-based fully degradable multi-layer co-extrusion film for vest bags are composed of the following mass fractions of raw materials:

[0026] 70 parts of PLA, 30 parts of PBAT, 0.2 parts of ethylene-maleic anhydride copolymer, 5 parts of ethylene-vinyl acetate copolymer, 0.2 parts of erucamide, 0.15 parts of nano silicon dioxide, 0.1 part of antioxidant 1010, antioxidant 168 0.2 parts.

[0027] The middle layer is composed of raw materials with the following mass fractions:

[0028] 50 parts of PBAT, 40 parts of corn starch, 0.4 parts of zinc stearate, 4.8 parts of glycerin, 2.8 parts of diethylene glycol, 2 parts of sorbitol, 0.8 parts of citric acid, 3.2 parts of ethylene-acrylic acid copolymer, dibenzoyl peroxide 0.05 part, 0.1 part of oleic acid amide.

[0029] The preparation method of the vest bag with low cost and high bio-based fully degradable multi-layer co-extruded film comprises the following steps:

[0030...

Embodiment 2

[0035] The upper and lower layers of the low-cost high bio-based fully degradable multi-layer co-extrusion film for vest bags are composed of the following mass fractions of raw materials:

[0036] 60 parts of PLA, 40 parts of PBAT, 0.2 parts of ethylene-maleic anhydride copolymer, 5 parts of ethylene-vinyl acetate copolymer, 0.2 parts of erucamide, 0.15 parts of nano silicon dioxide, 0.1 part of antioxidant 1010, antioxidant 168 0.2 parts.

[0037] The middle layer is composed of raw materials with the following mass fractions:

[0038] 55 parts of PBAT, 35 parts of corn starch, 0.4 parts of zinc stearate, 4.8 parts of glycerin, 2.8 parts of diethylene glycol, 2 parts of sorbitol, 0.8 parts of citric acid, 3.2 parts of ethylene-acrylic acid copolymer, dibenzoyl peroxide 0.05 part, 0.1 part of oleic acid amide.

[0039] The preparation method of the vest bag with low cost and high bio-based fully degradable multi-layer co-extruded film comprises the following steps:

[0040...

Embodiment 3

[0045] The upper and lower layers of the low-cost high bio-based fully degradable multi-layer co-extrusion film for vest bags are composed of the following mass fractions of raw materials:

[0046] 55 parts of PLA, 45 parts of PBAT, 0.1 part of ethylene-maleic anhydride copolymer, 3 parts of ethylene-vinyl acetate copolymer, 0.2 part of erucamide, 0.15 part of nano silicon dioxide, 0.1 part of antioxidant 1010, antioxidant 168 0.2 parts.

[0047] The middle layer is composed of raw materials with the following mass fractions:

[0048] 60 parts of PBAT, 30 parts of corn starch, 0.3 parts of zinc stearate, 3.6 parts of glycerin, 2.1 parts of diethylene glycol, 1.5 parts of sorbitol, 0.6 parts of citric acid, 2.4 parts of ethylene-acrylic acid copolymer, dibenzoyl peroxide 0.05 part, 0.1 part of oleic acid amide.

[0049] The preparation method of the vest bag with low cost and high bio-based fully degradable multi-layer co-extruded film comprises the following steps:

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com