Patents

Literature

52results about How to "Solve interface compatibility issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal wear resistant repairing composite coating material and preparation method of metal wear resistant repairing composite coating material

InactiveCN102585746ASimple preparation conditionsGood dispersionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyWear resistant

The invention discloses a metal wear resistant repairing composite coating material and a preparation method of the metal wear resistant repairing composite coating material, wherein the metal wear resistant repairing composite coating material comprises a main agent which is prepared by mixing a silane coupling agent, epoxy resin, diisoamyl naphthalene, silicon carbide particles, aluminium oxide powder and fumed silica, and a curing agent which is prepared by mixing a silane coupling agent, triethylenetetramine, N-aminoethyl piperazine, aluminium oxide powder and fumed silica. A two-component room temperature curing composite coating with good anti-corrosion performance and abrasive resistance is prepared by optimizing the performance of epoxy coating inorganic powder filled and modified with inorganic powder, the prepared wear-resistant coating has good bonding effect to the metal, the cured coating has excellent abrasive resistance and can be applied for building and repairing the inner layer of a liquid slurry delivery pump, and an anti-corrosion wear-resistant coating of blades, and building an anti-corrosion wear-resistant coating of the inner surface of a gas transmission pipeline, a powder transmission pipeline and a liquid transmission pipeline.

Owner:依工聚合工业(吴江)有限公司

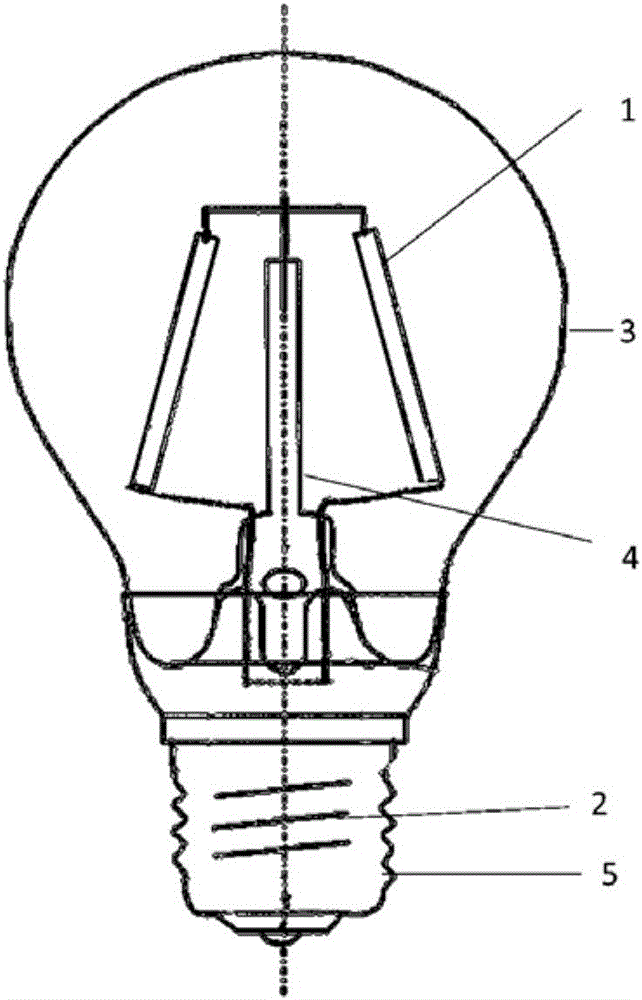

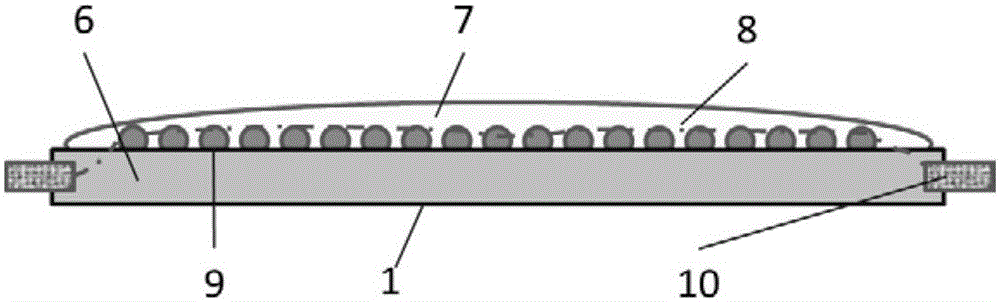

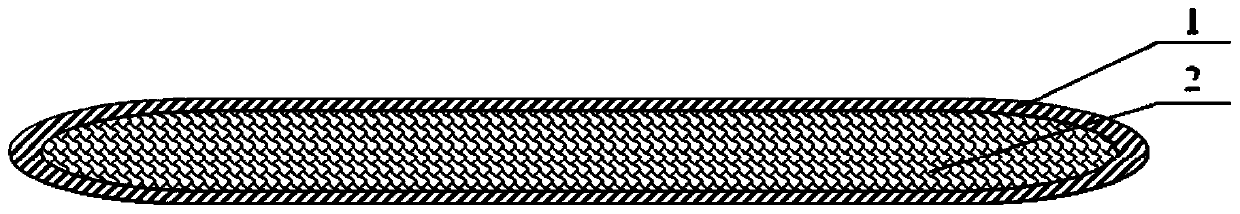

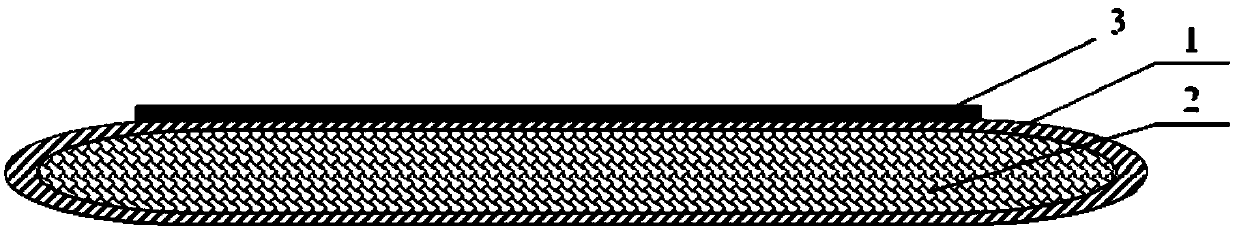

LED-chip shining-light-bar base plate material and LED bulb lamp

InactiveCN106190124AExtended service lifeImprove use reliabilityElectric circuit arrangementsChemical industryColor rendering indexOptical transmittance

The invention relates to an LED-chip shining-light-bar base plate material and an LED bulb lamp. The LED-chip shining-light-bar base plate material and the LED bulb lamp are characterized in that the LED bulb lamp is composed of shining strips (1), a driving power source (2), a glass bulb shell (3), a glass support core column (4) and an electric connector (5); the glass bulb shell (3) and the glass support core column (4) are subjected to vacuum sealing to a cavity to be filled with high thermal conduction gas, the glass support core column (4) and the shining strips (1) fixed on the glass support core column (4) are contained in the sealed cavity; the shining strips (1) are sequentially electrically connected with the driving power source (2) and the electric connector (5); the LED-chip shining strips (1) are composed of YAG, wherein Ce raw material powder and nitride red fluorescence powder are fired to achieve the effect that one face of the base plate material (6) comprises LED blue light chips (9), and the surfaces of the blue light chips (9) are coated with a fluorescent powder layer (7). According to the LED-chip shining-light-bar base plate material and the LED bulb lamp, low-cost preparing of the high-quality transparent fluorescence polycrystal base plate material is achieved with the novel environment-friendly aqueous tape-casting technology. The fluorescence polycrystal base plate material which is high in lighting efficiency, color rendering index and optical transmittance and the bulb lamp which is good in color-temperature consistency heat dissipation, high in reliability and long in service life are obtained.

Owner:张伯文

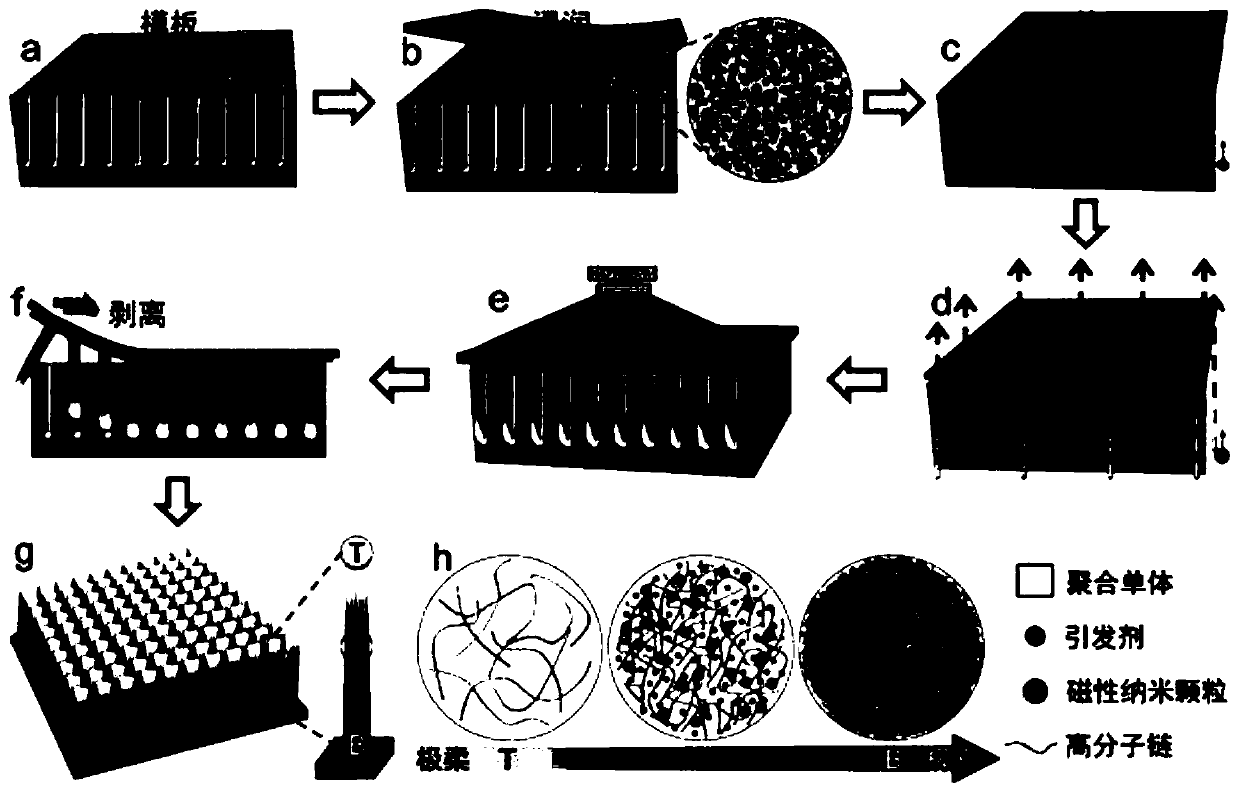

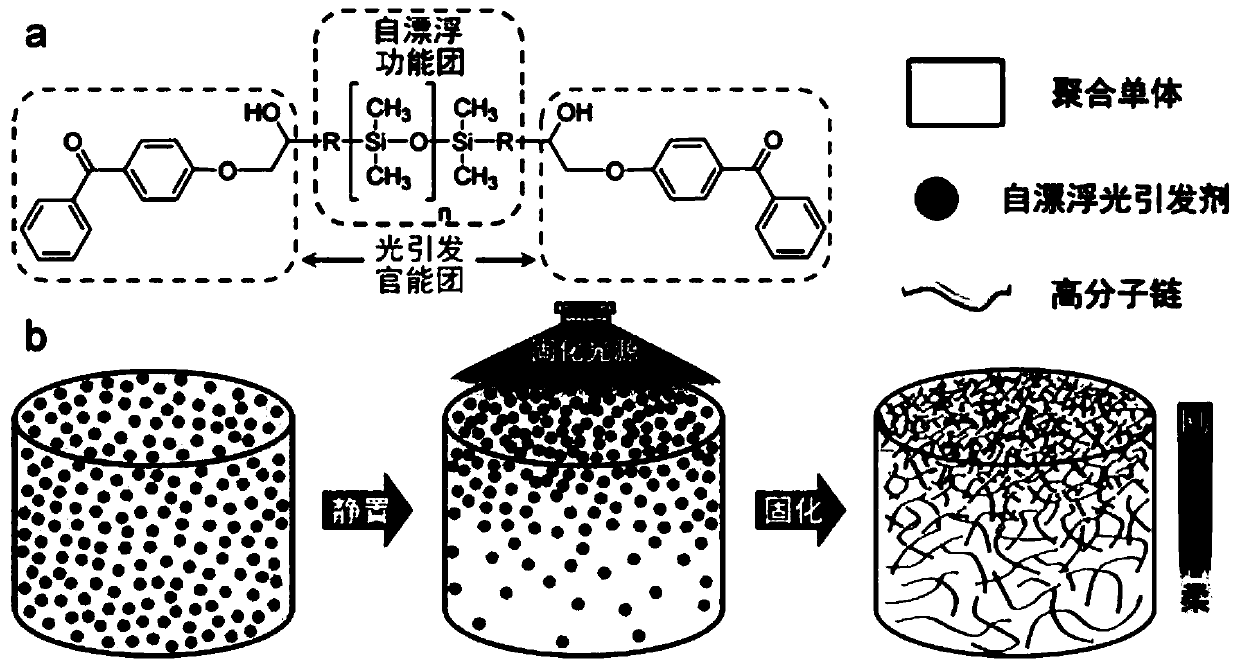

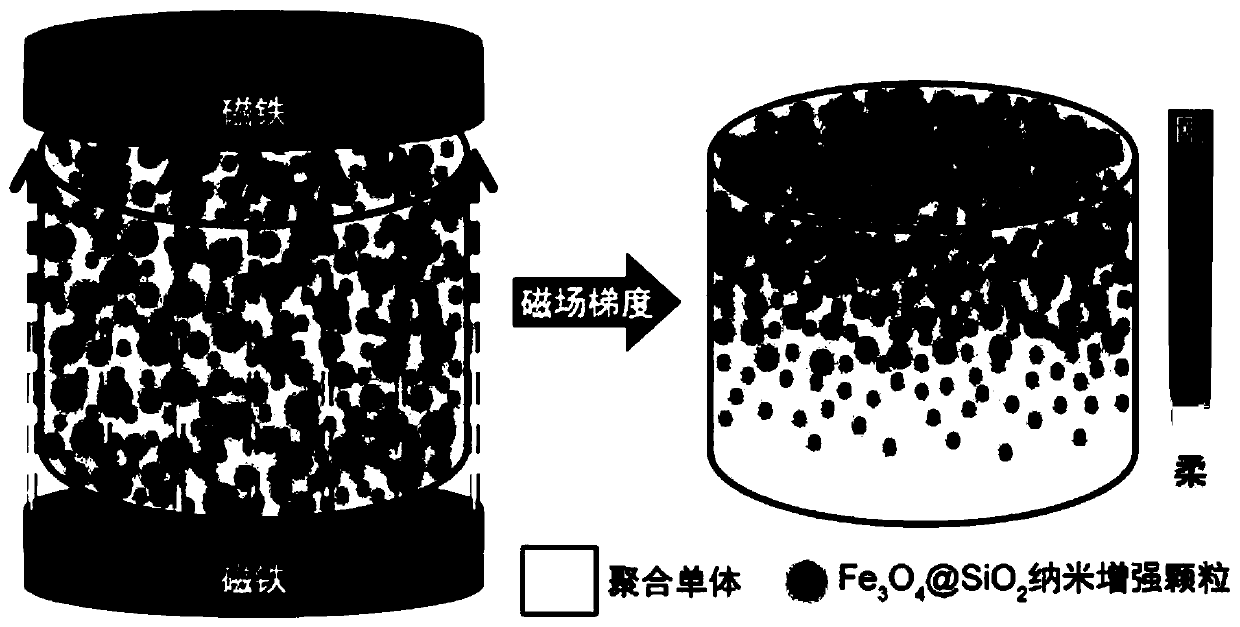

Preparation method and application of bionic gecko extremely progressive rigid-flexible gradient micro-column structure

ActiveCN110668398ASolve interface compatibility issuesSolve matching problemsDecorative surface effectsNanotechnologyPhysicsPhotoinitiator

The invention belongs to the technical field of biomimetic materials, and particularly relates to a preparation method and application of a bionic gecko extremely progressive rigid-flexible gradient micro-column structure. According to the preparation method disclosed by the invention, a self-floating photoinitiator technology and gradient distribution of magnetic enhanced particles driven by a magnetic field are utilized, so that the preparation of a micro-column structure with an extreme mechanical gradient (the local elastic modulus is changed by more than three orders of magnitudes: (10MPa-10GPa) can be realized; meanwhile, one end of the micro-column array is a pure matrix, the other end of the micro-column array is highly mixed and filled with particles of different sizes, the middleof the micro-column array is gradually distributed according to particle sizes and concentration levels, the progressive gradient structure solves the problems of interface compatibility and matchingof rigid and flexible materials in the combining process, and the maximum length-diameter ratio of the composite micro-column with the stable structure is greatly increased.

Owner:WUHAN UNIV

A composite piezoelectric material prepared from piezoceramic powder, carbon black and asphalt and a preparing method thereof

InactiveCN104891867ASolve interface compatibility issuesSolve the difficult problem of polarization processElectricityAging resistance

A composite piezoelectric material prepared from piezoceramic powder, carbon black and asphalt and a preparing method thereof are provided. The composite piezoelectric material is prepared from 25-60 parts by weight of the asphalt, 2-5 parts by weight of the carbon black, 320-630 parts by weight of the piezoceramic powder and 1-10 parts by weight of an asphalt modifier. The problems of interfacial compatibility and difficult polarization processes are overcome. The composite piezoelectric material can provide electricity for monitoring systems, can be used as sensors, and is good in compatibility with road surfaces. Natural asphalt and petroleum asphalt have good compatibility and durable ageing resistance, thus largely improving pavement performance of the substrate asphalt. The piezoceramic-carbon black-asphalt composite material improves interfacial compatibility of the piezoceramic and the asphalt, reduces the polarization voltage of the composite piezoelectric material, and improves piezoceramic properties of the composite piezoelectric material.

Owner:HARBIN ENG UNIV

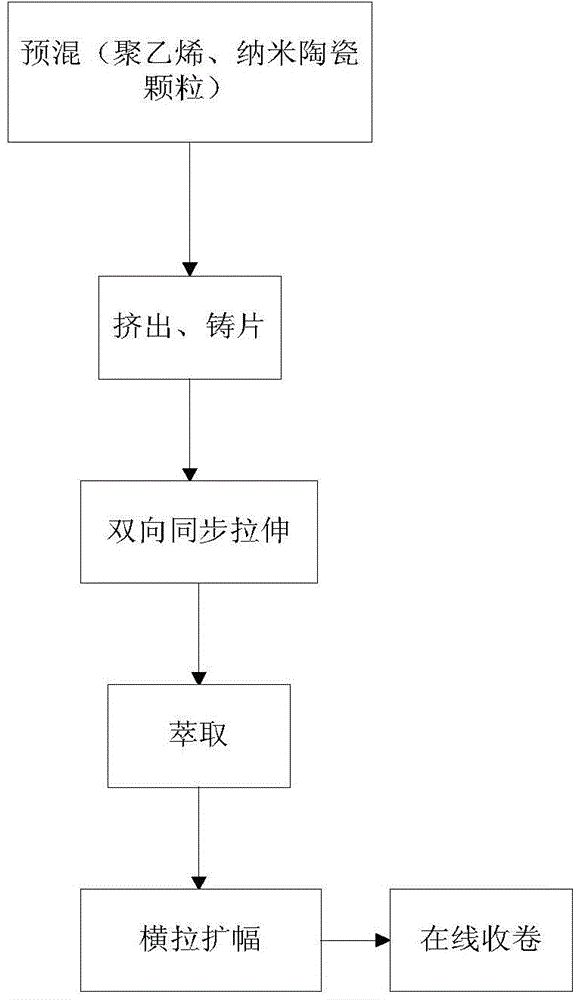

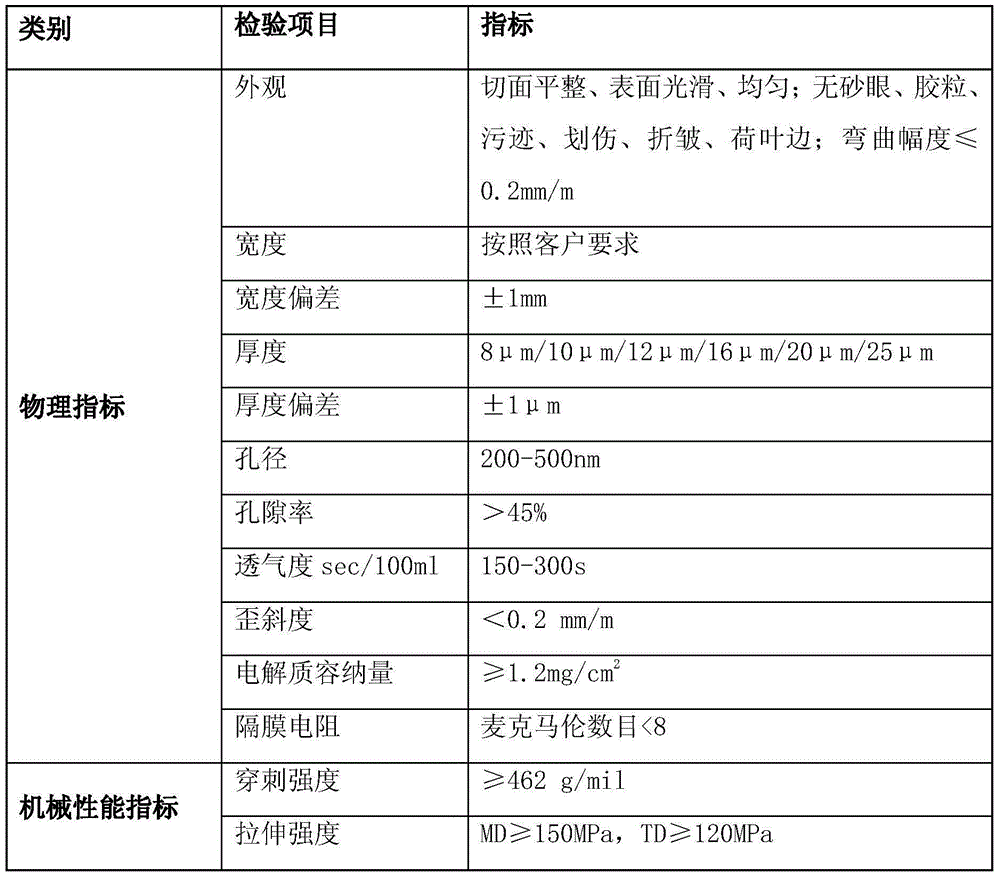

Method for preparing nanometer ceramic particle doped PE diaphragm

InactiveCN104617248AReduce production processReduce energy consumptionCell component detailsTemperature resistanceHigh rate

The invention provides a method for preparing a nanometer ceramic particle doped PE diaphragm, belonging to the technical field of high-property membrane materials. The method for preparing the nanometer ceramic particle doped PE diaphragm comprises the steps of proportioning materials, extruding cast strips, synchronously drawing towards two directions, extracting, transversely stretching for enlarging and the like; as electrochemical inactive inorganic ceramic particles are added in a skeleton material of the PE diaphragm, the PE diaphragm has better compatibility with the electrodes of a lithium ion battery than the common battery diaphragm, the high-temperature resistance and the safety of the battery can be greatly improved, the absorbability of liquid electrolytes is good, the electrolyte filling time of the battery can be shortened,the internal resistance of the battery can be reduced, and the high-rate charging-discharging properties of the batteries can be improved, so that the charging-discharging cycle properties of the battery can be greatly improved.

Owner:刘会会

Composite solid electrolyte, all-solid-state lithium ion battery and preparation method of all-solid-state lithium ion battery

InactiveCN111697262ASolve interface compatibility issuesReduce interface impedanceFinal product manufactureElectrolyte accumulators manufactureLithium electrodeInterface impedance

The invention discloses a composite solid-state electrolyte, an all-solid-state lithium ion battery and a preparation method thereof. The composite solid-state electrolyte is composed of three layersof solid-state electrolytes with different components, and the composite solid-state electrolyte comprises an electrolyte coated on the negative electrode side, an electrolyte coated on the positive electrode side and a composite solid-state electrolyte located between the positive electrode electrolyte and the negative electrode electrolyte. In addition, an all-solid-state lithium ion battery isprepared through the solid electrolyte. Electrolyte which is not prone to electrochemical reduction and good in electrode interface compatibility is adopted to coat one side of the negative electrode,and electrolyte resistant to high voltage is selected to coat one side of the positive electrode, so the interface compatibility of the electrolyte and an electrode material is effectively improved,and the interface impedance is reduced; the solid electrolyte between the positive electrolyte and the negative electrolyte has relatively high ionic conductivity, so the ionic conductivity of the whole composite solid electrolyte is improved; meanwhile, the prepared all-solid-state lithium ion battery has excellent cycling stability and high safety.

Owner:SHENZHEN GPC ENERGY GRP CO LTD

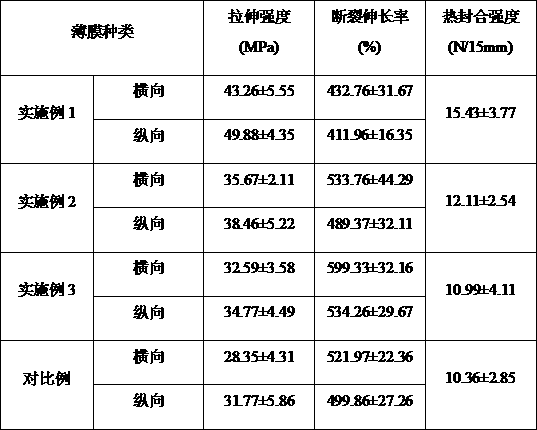

Low-cost high-biology-base full-biodegradable multi-layer coextrusion film for waistcoat pocket and preparation method of coextrusion film

InactiveCN109367173ALow costSolve the problem of "white pollution"Synthetic resin layered productsLaminationBlow moldingThermoplastic

A polylactic acid / polyadipate-butylene terephthalate (PLA / PBAT) modified material and a polyadipate-butylene terephthalate / thermoplastic starch (PBAT / TPS) modified material which can meet the blow molding requirement are prepared through melting reaction in a blending manner based on a multi-element blending modification technique of fully biodegradable materials; and a full-biodegrade three-layercoextrusion film is prepared by virtue of a multilayer coextrusion technique, the upper and lower layers are PLA / PBAT modified films, and the middle layer is a PBAT / TPS modifying film. The biology base content of the film can reach up to over 50%, the tensile strength is higher than that of a traditional PE film, the cost is relatively low, and the film has very important significances to the solving of ''white pollution'' problem and the promotion of the application of a full-biodegrade material in the field of waistcoat pockets.

Owner:束建军

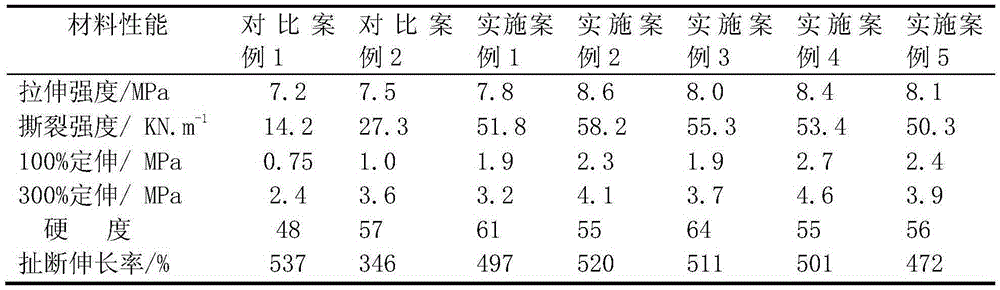

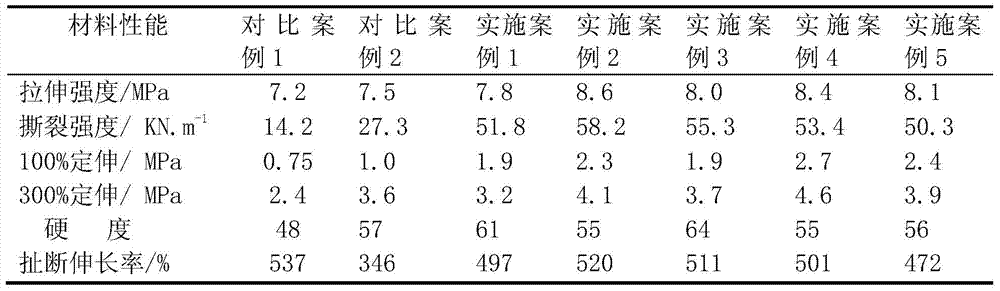

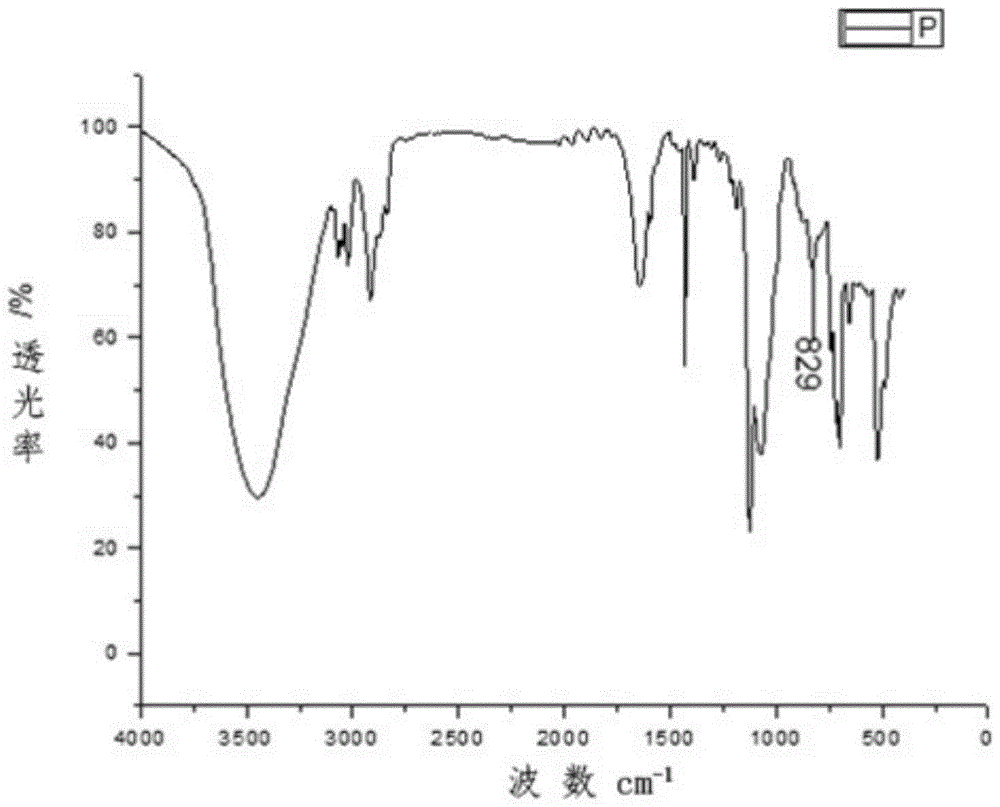

Silicone rubber nano composite with high tear resistance and preparation method thereof

The invention discloses a preparation method of a silicone rubber nano composite with the high tear resistance. The composite is prepared from, by weight, 100 parts of silicone rubber, 3-10 parts of carbon nano tubes, 30-50 parts of fumed silica, 3-6 parts of hydroxyl silicone oil, 0.5-3.5 parts of vulcanizing agents and 0.2-0.8 part of interface agents. According to the silicone rubber nano composite with the high tear resistance and the preparation method thereof, by selecting and using the interface agents, the problems that when the carbon nano tubes serve as reinforcing fillers, the carbon nano tubes are unevenly dispersed in the silicone rubber, and the interfacial action of the carbon nano tubes and the silicone rubber is weak are solved, and the tearing property of the silicone rubber nano composite is significantly improved.

Owner:BEIJING UNIV OF CHEM TECH

Heat-conducting and heat-storing phase-change plate and preparation method thereof

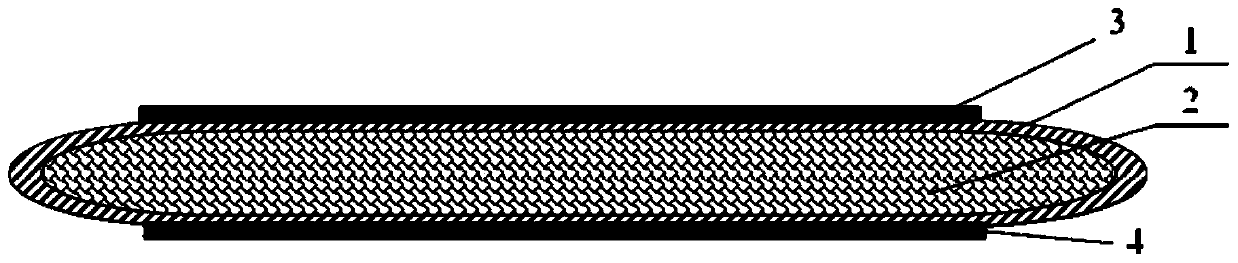

InactiveCN111234781ALarge latent heat of phase changeImprove heat storage capacityHeat-exchange elementsElectronic componentPhase-change material

The invention relates to the technical field of heat dissipation. The invention provides a heat-conducting and heat-storing phase-change plate and a preparation method thereof. The heat-conducting andheat-storing phase-change plate comprises a phase change plate shell and a phase change composite material. A closed containing cavity is defined by the phase change plate shell. The phase-change composite material is filled in the containing cavity, the phase change plate shell is made of a heat conduction material, and the phase change composite material comprises the following raw material components in parts by weight: 300-600 parts of a phase change material, 100-250 parts of a heat conduction filler, 0-80 parts of a base material, 0-15 parts of a coupling agent and 0-3 parts of a heat stabilizer. The heat-conducting and heat-storing phase-change plate is high in phase change latent heat, large in heat conduction coefficient, good in durability, free of toxicity and corrosion to electronic components, easier to clean and repair, good in interface compatibility, low in manufacturing cost, simple in formula and convenient to use.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

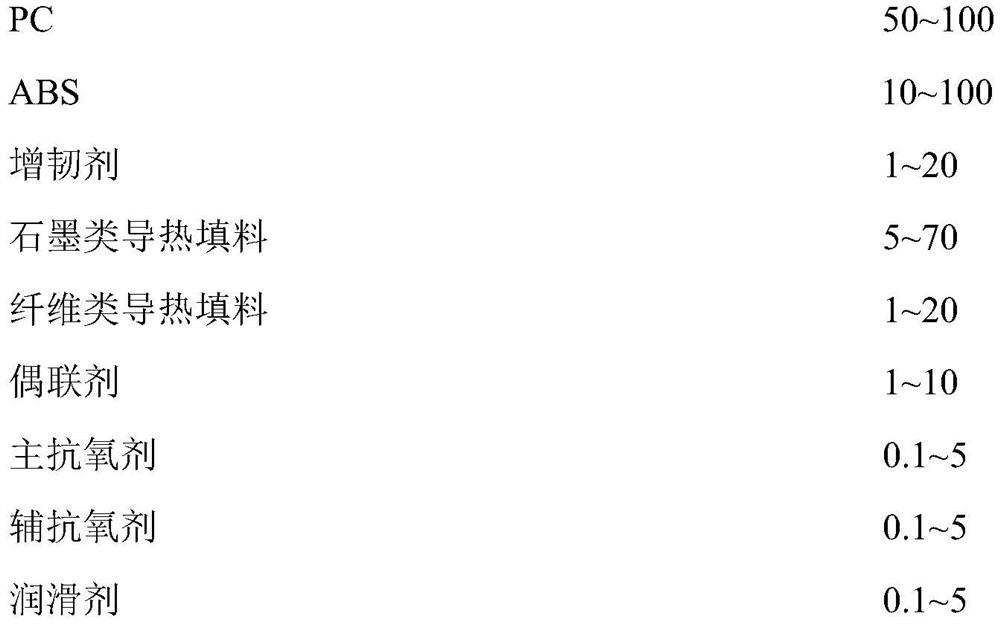

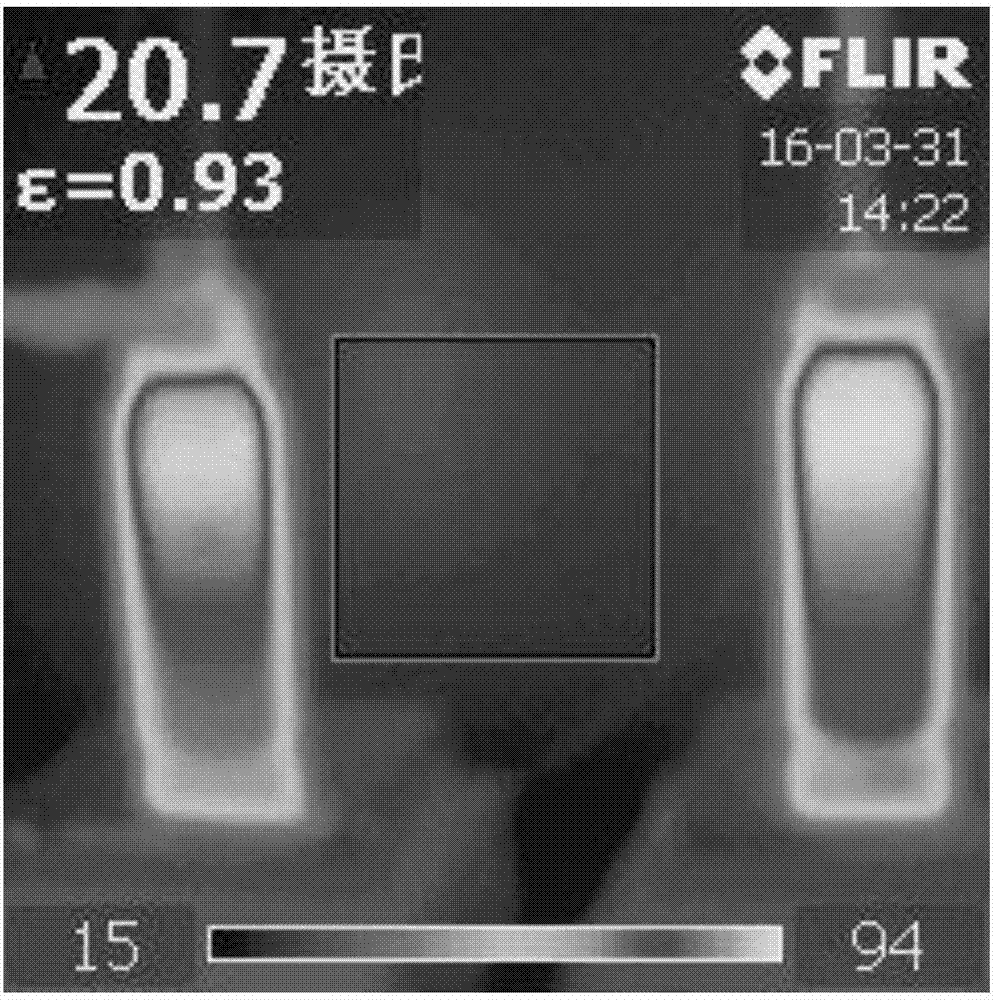

High-thermal-conductivity and high-electric-conductivity PC/ABS composite material and preparation method thereof

The invention relates to a high-thermal-conductivity and high-electric-conductivity PC / ABS composite material and a preparation method thereof. The high-heat-conductivity and high-electric-conductivity PC / ABS comprises PC, ABS, a toughening agent, a graphite heat-conducting filler, a cellulose heat-conducting filler, a coupling agent, a main antioxidant, an auxiliary antioxidant and a lubricatingagent, wherein the graphite heat-conducting filler and the fiber heat-conducting filler are respectively subjected to polyvinyl alcohol coating modification and coupling agent modification treatment in advance; and blending, melting and extruding are carried out to obtain heat-conducting filler master batch, and the heat-conducting filler master batch is compounded with other raw material components. According to the high-heat-conductivity and high-electric-conductivity PC / ABS composite material, a multi-heat-conductivity and multi-electric-conductivity percolation network is constructed by compounding the graphite heat-conducting filler and the fiber heat-conducting filler, and the graphite heat-conducting filler and the fiber heat-conducting filler are subjected to surface chemical modification in combination with pretreatment of polyvinyl alcohol coating and coupling agent treatment; The electric conduction and heat conduction performance is effectively improved, and the impact resistance of the material can be enhanced.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

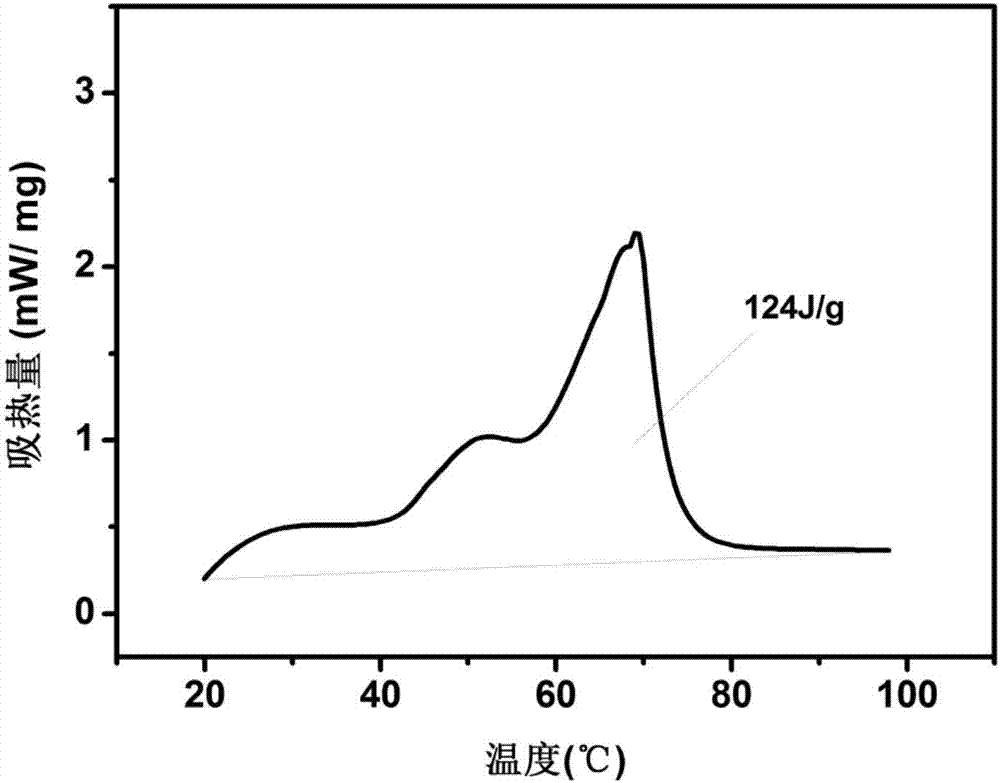

Heat-dissipation coating with phase-changing temperature adjusting function and preparing method of heat-dissipation coating

ActiveCN107337985AIncreased strength and heat resistanceReduce the internal temperature of the deviceHeat-exchange elementsRadiation-absorbing paintsEnvironmental resistancePhase change temperature

The invention relates to a heat-dissipation coating with a phase-changing temperature adjusting function and a preparing method of the heat-dissipation coating. The heat-dissipation coating comprises phase-changing microcapsules, high thermal-radiation materials, epoxy resin and a curing agent, wherein the phase-changing microcapsules account for, by mass, 1%-10% of the epoxy resin, the high thermal-radiation materials account for, by mass, 3%-6% of epoxy resin, and the curing agent accounts for, by mass, 35%-45% of the epoxy resin. The heat-dissipation coating is constituted by the phase-changing microcapsules, the high thermal-radiation materials and epoxy resin, wherein the phase-changing microcapsules are large in latent heat of phase change, resistant to high temperature, environmentally friendly and free of pollution; meanwhile, silicon carbide, beryllium oxide, aluminum nitride and the like have the advantages of being high in thermal radiation capability and good in thermal conductivity, through the combination of both parties, the heat dissipation effect of the epoxy-resin-based heat-dissipation coating can be remarkably improved, and the internal temperature of coated equipment is lowered greatly.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

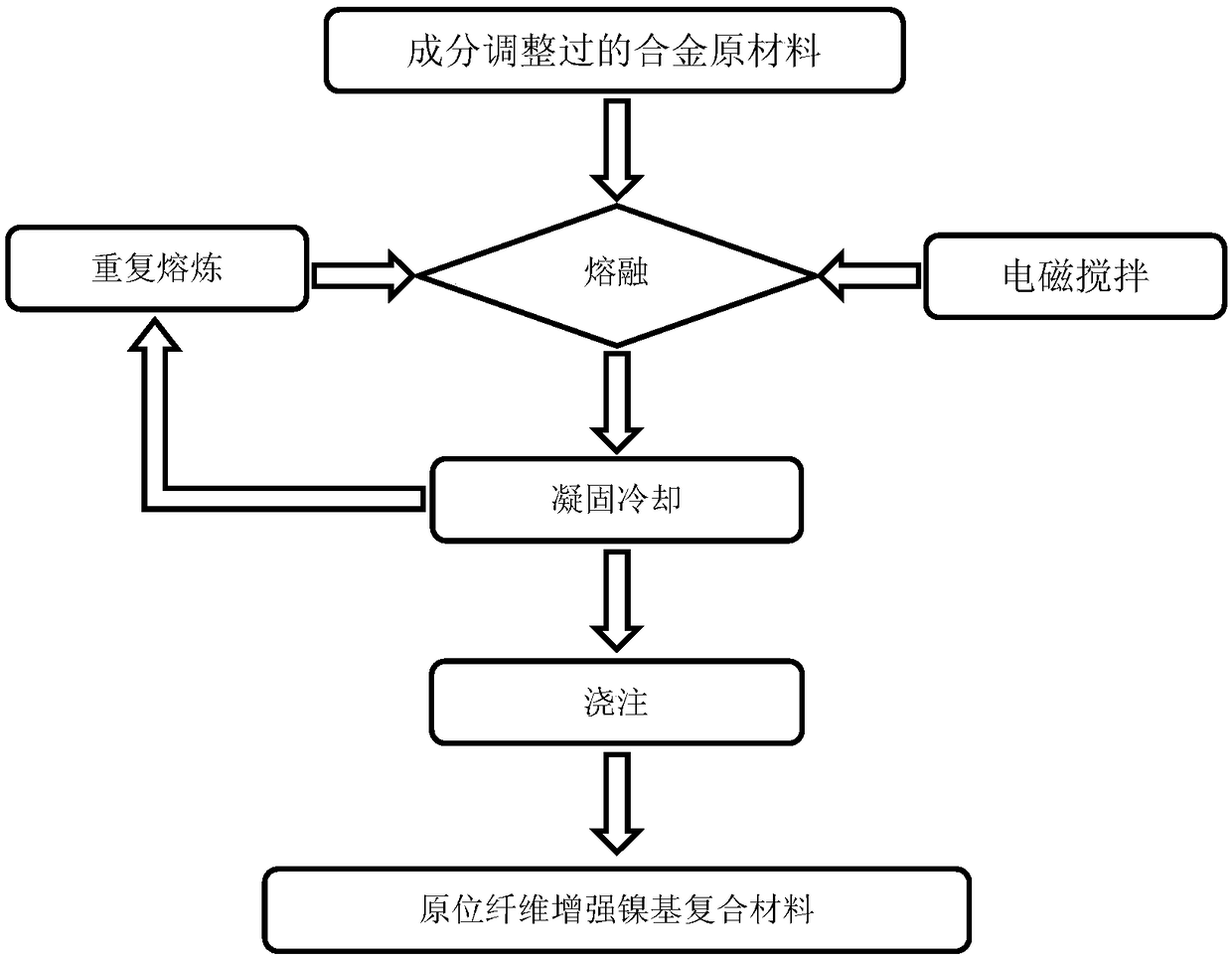

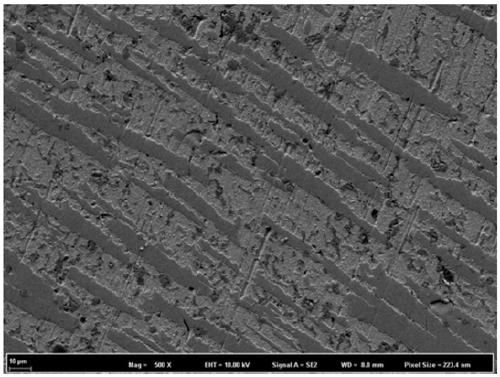

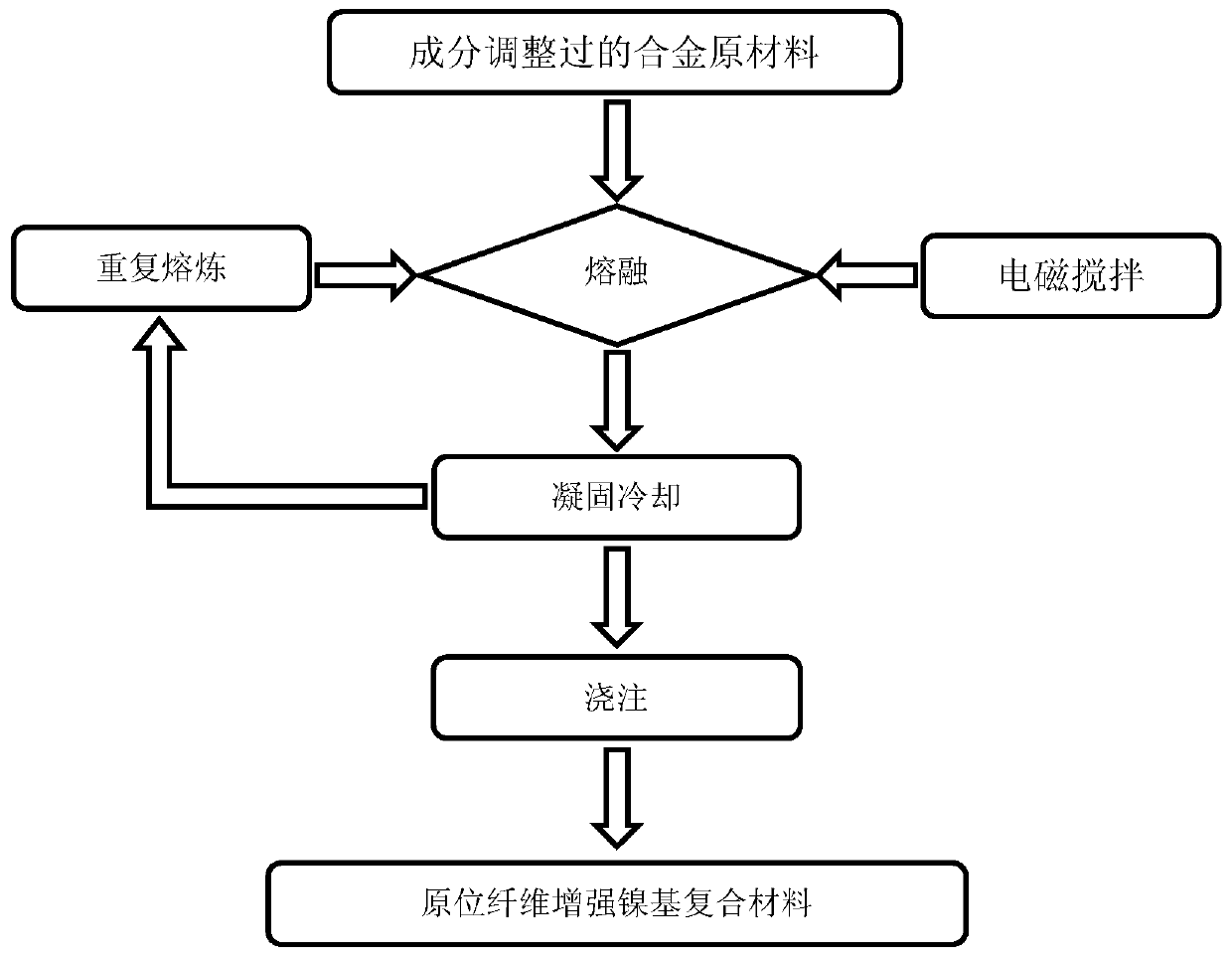

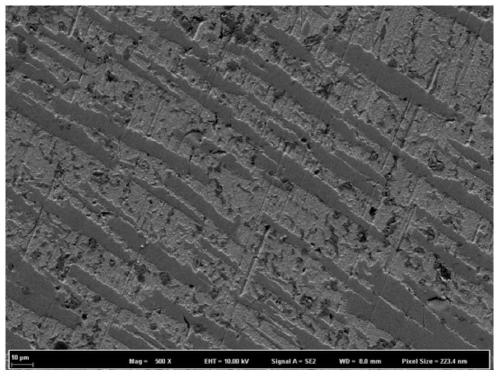

Preparation method of fiber-enhanced high temperature alloy composite material via in-situ generation

ActiveCN109112436ASolve interface compatibility issuesImprove stabilityAlloy compositeFiber reinforcement

The invention discloses a preparation method of a fiber-enhanced high temperature alloy composite material via in-situ generation, and belongs to the technical field of preparation of materials. The preparation method comprises the following steps of preparing the materials according to typical high temperature alloy components, and increasing the content of carbon element in proportioning, so asto increase the content of carbon; smelting by a vacuum electric arc furnace, so as to form fiber-shaped carbide, thereby obtaining the fiber-enhanced high temperature alloy composite material via in-situ generation. The preparation method has the advantage that the enhancing fibers directly grow in a high temperature alloy matrix, so as to obtain the composite material with a stable interface, thereby solving the problem of poor interface compatibility of the fiber-enhanced high temperature alloy composite material.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of polylactic acid-based nanocomposite film with high strength and barrier property

The invention relates to a preparation method of a polylactic acid-based nanocomposite film with high strength and barrier property. The raw materials of the composite film comprise polylactic acid, carbon nanotubes, a KH-550 silane coupling agent, nanofibrillated cellulose and ethanol. The polylactic acid-based nano composite film with high strength and barrier property is obtained through the preparation of a silane modifier, silanization modification of the nanofibrillated cellulose and solution casting and shaping of the polylactic acid-based nanocomposite film. The polylactic acid-based nanocomposite film has wide sources of raw materials and a simple preparation process, the production cost can be effectively reduced, and economic benefits can be effectively increased. More importantly, the agglomeration effect is improved after the modification of the carbon nanotubes and coating of the nanofibrillated cellulose, the interfacial compatibility between the polylactic acid, the carbon nanotubes and the nanofibrillated cellulose is better improved, and correspondingly the enhancement effect of the carbon nanotubes and the nanofibrillated cellulose on the polylactic acid is improved. Not only is the mechanical performance of the polylactic acid-based nanocomposite film improved significantly, but also the barrier property is greatly enhanced.

Owner:ZHEJIANG SCI-TECH UNIV

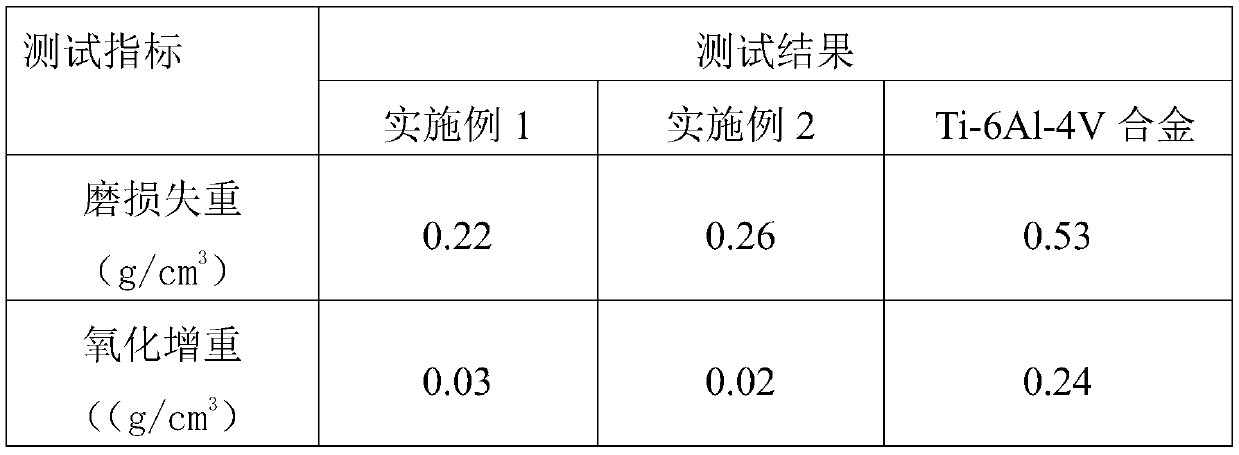

Method of forming TiB2 particle-reinforced high-entropy alloy coating on titanium alloy

ActiveCN111020579AImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingHigh entropy alloysOxidation resistant

The invention discloses a method of forming a TiB2 particle-reinforced high-entropy alloy coating on titanium alloy. The method comprises the steps that a Co film, an Ni film and a Cr film are formedon the surface of a titanium alloy substrate in advance in sequence, then Co, Cr, Cu, Fe, Ni, Mo, Mn and TiB2 mixed powder covers the titanium alloy substrate with the pre-formed film in a fusion mode, and therefore the TiB2 particle-reinforced CoCrCuFeNiMoMn high-entropy alloy coating can be obtained. The coating which is obtained according to the method has the advantages of being high in wear resistance and high in oxidation resistance.

Owner:GUIZHOU INST OF TECH

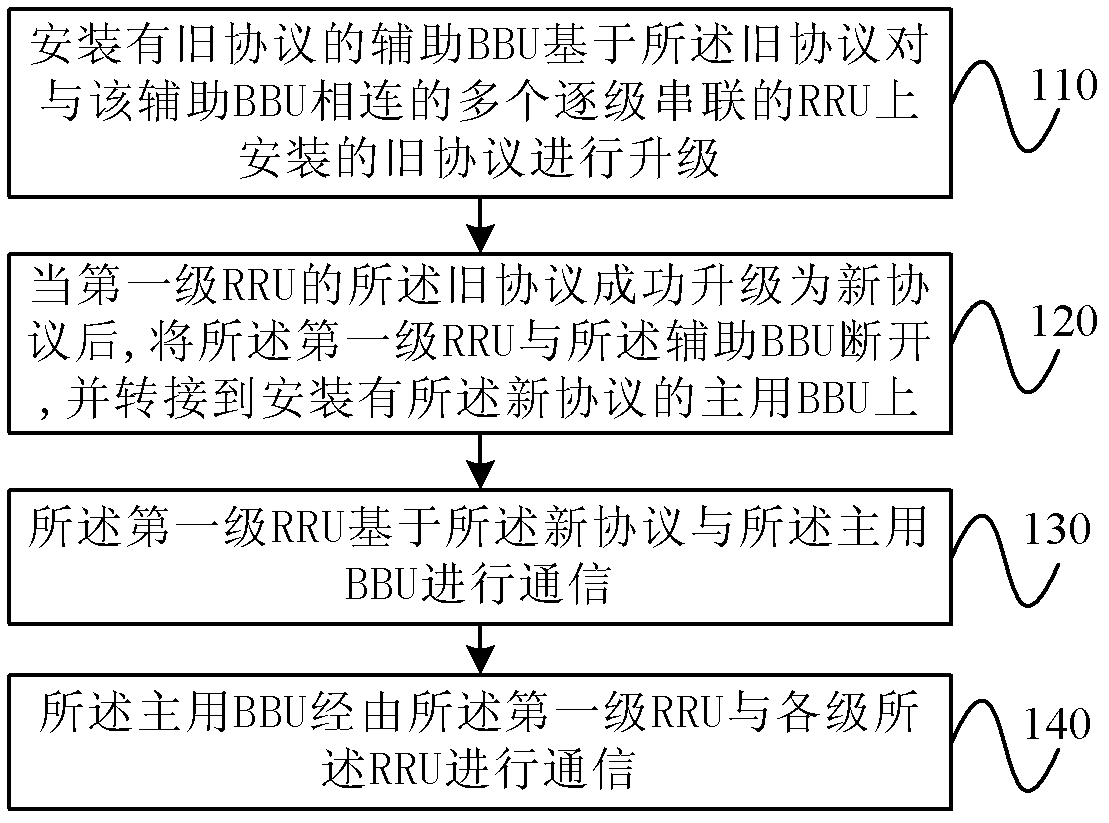

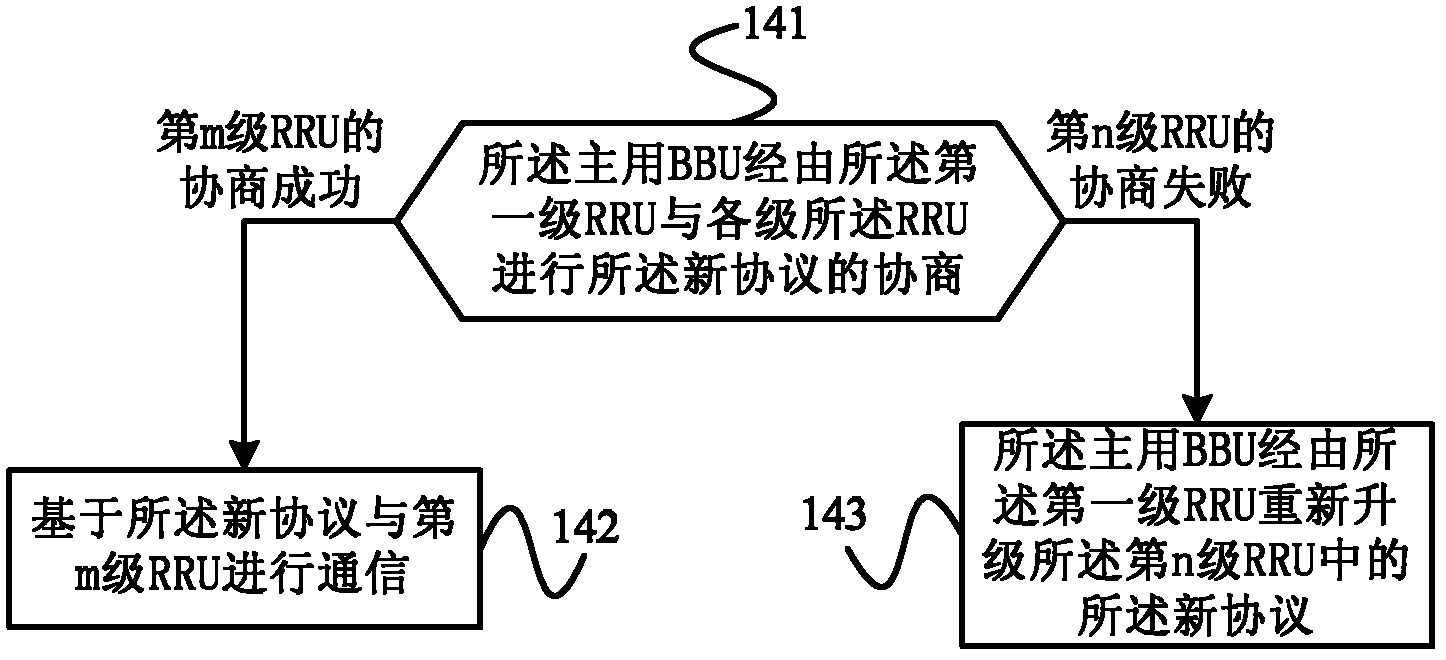

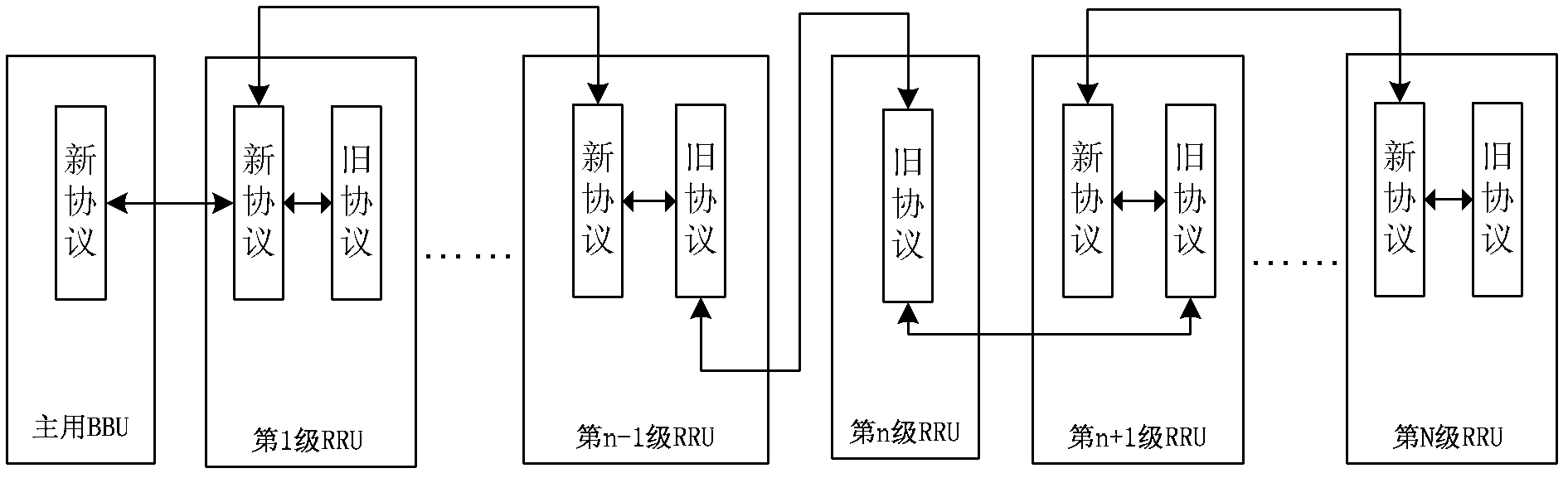

Communication method of BBU (Building Base band Unit) and RRU (Radio Remote Unit) and base station

ActiveCN102843707ASolve interface compatibility issuesWide range of optionsWireless communicationComputer scienceUpgrade

The invention provides a communication method of a BBU (Building Base band Unit) and an RRU (Radio Remote Unit) and a base station. The communication method comprises the following steps of upgrading an old protocol installed on multiple RRUs, which are connected in series step by step and are connected with an auxiliary BBU based on the old protocol by the auxiliary BBU which is provided with the old protocol; disconnecting a first state RRU and the auxiliary BBU after the old protocol of the first state RRU is upgraded into a new protocol, and connecting the first state RRU to a main BBU which is provided with the new protocol; carrying out communication between the first stage RRU and the main BBU basing on the new protocol; and carrying out the communication between the main BBU and RRUs at different stages through the first RRU. According to the communication method and the base station, provided by the invention, through the upgrade, the interface compatibility problem between the main BBU and the RRUs is effectively solved, and the selectable range of the RRU is enlarged.

Owner:TD TECH COMM TECH LTD

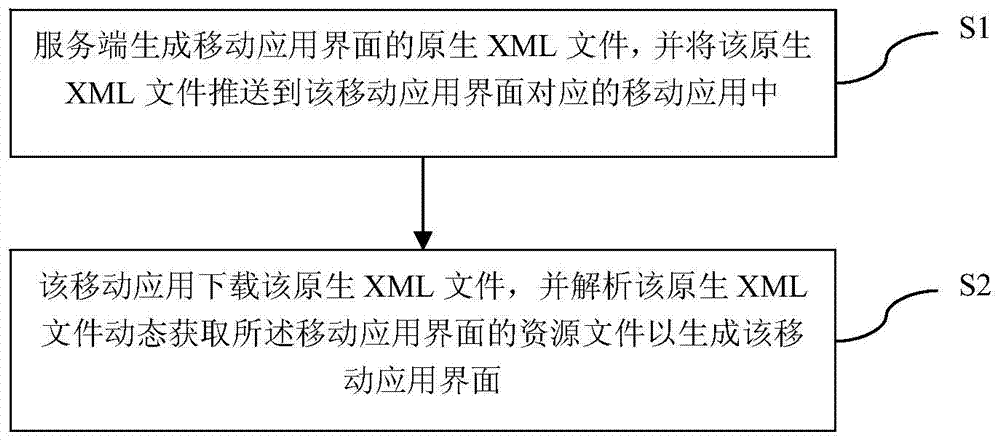

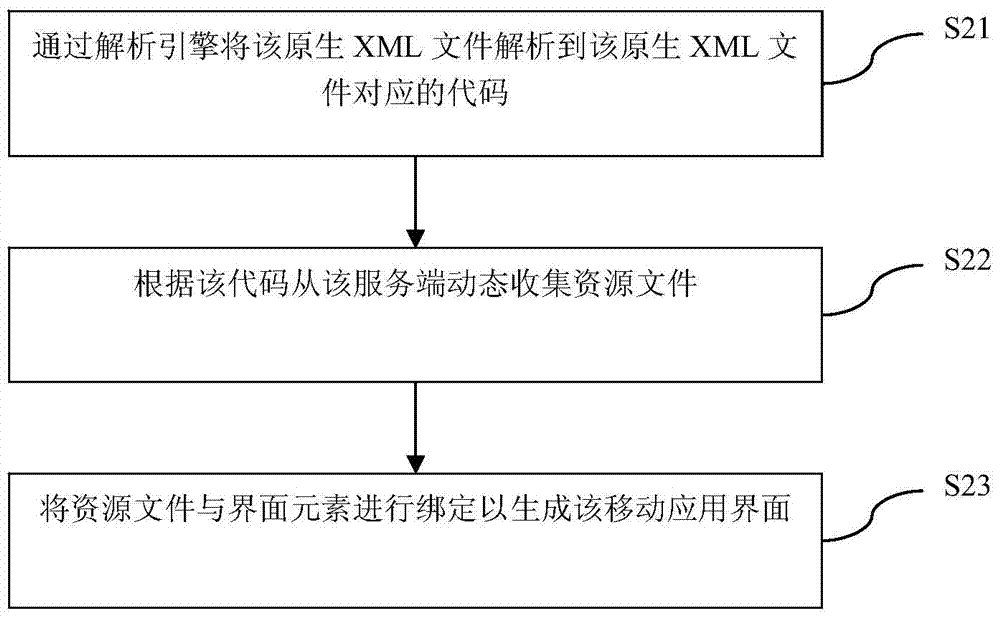

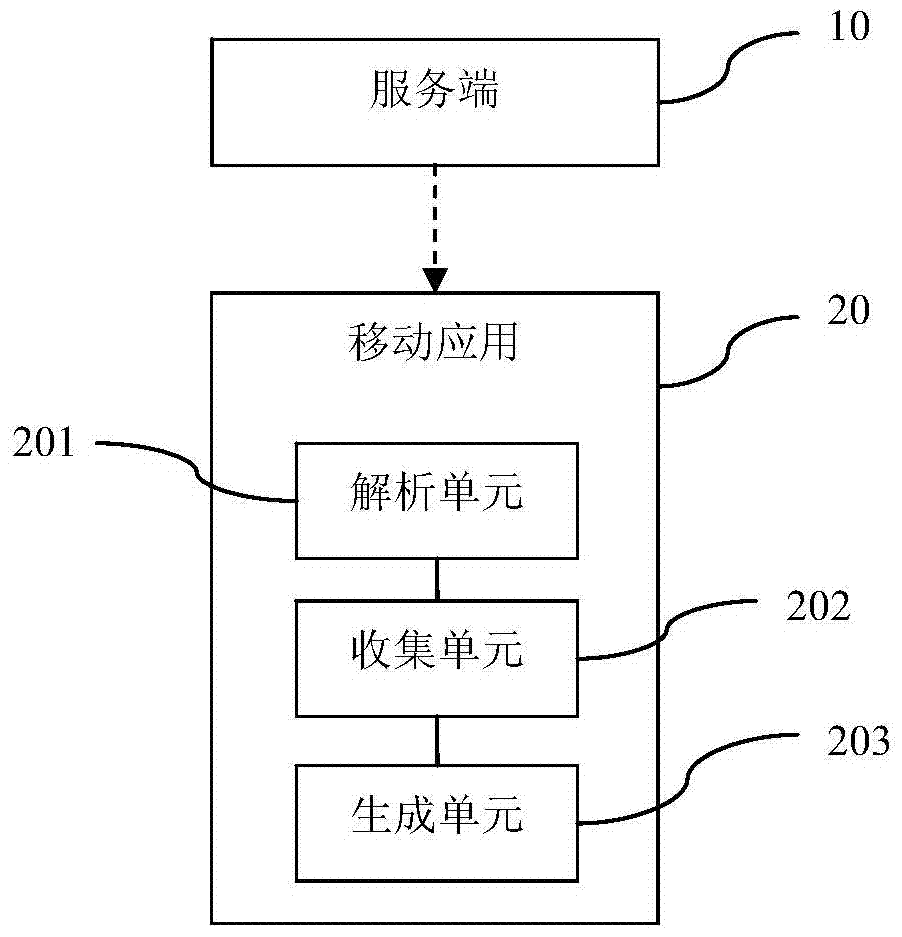

Method and system for dynamically generating mobile application interface

InactiveCN106970926ASolve interface compatibility issuesImplement dynamic loadingWebsite content managementSpecial data processing applicationsSoftware engineeringExtensible markup

The invention provides a method for dynamically generating a mobile application interface. The method comprises the following steps: a server generates a native XML (Extensible Markup Language) file of the mobile application interface and pushes the native XML file to a mobile application corresponding to the mobile application interface; and the mobile application downloads the native XML file, analyzes the native XML file, and dynamically acquires a resource file of the mobile application interface so as to generate the mobile application interface. The invention also provides a corresponding system. By implementation of the method and the system, the mobile application interface is dynamically loaded in operation of the mobile application, an ARK (Android Package) does not need to be updated, thus the trouble of recompilation is eliminated when updating is needed on a UI (user interface) every time; furthermore, once an update exists, the mobile application interface changes instantly, a code does not need to be complied into an app (Application) package again to be released to an application store for updating.

Owner:卓望数码技术(深圳)有限公司

Preparation method of polymer/cement composite material structure electrolyte based on synchronous reaction

ActiveCN112951621ABroaden the field of applicationSolve interface compatibility issuesHybrid capacitor electrolytesHybrid/EDL manufactureAqueous solutionCement Material

The invention relates to a synchronous reaction-based polymer / cement composite material structure electrolyte preparation method, and the method comprises: (1) weighing an organic polymer monomer, dissolving the organic polymer monomer in deionized water, and performing complete stirring to obtain an organic polymer monomer aqueous solution; (2) weighing an ionic electrolyte, adding the ionic electrolyte into the organic polymer monomer aqueous solution, and performing full stirring to obtain an organic polymer monomer electrolyte; (3) adding cement powder and an initiator into the organic polymer monomer electrolyte, and performing full stirring to obtain uniform slurry; (4) pouring the uniform slurry into a mold, performing hardening, molding, curing and demolding to obtain the solid block structure electrolyte, namely the target product. Compared with the prior art, the polymer / cement composite material structure electrolyte has the advantages that the good interface compatibility of a structure phase and a conductive phase in the structure electrolyte is improved, and meanwhile, the comprehensive balance of mechanical properties and electrical properties is also realized.

Owner:TONGJI UNIV

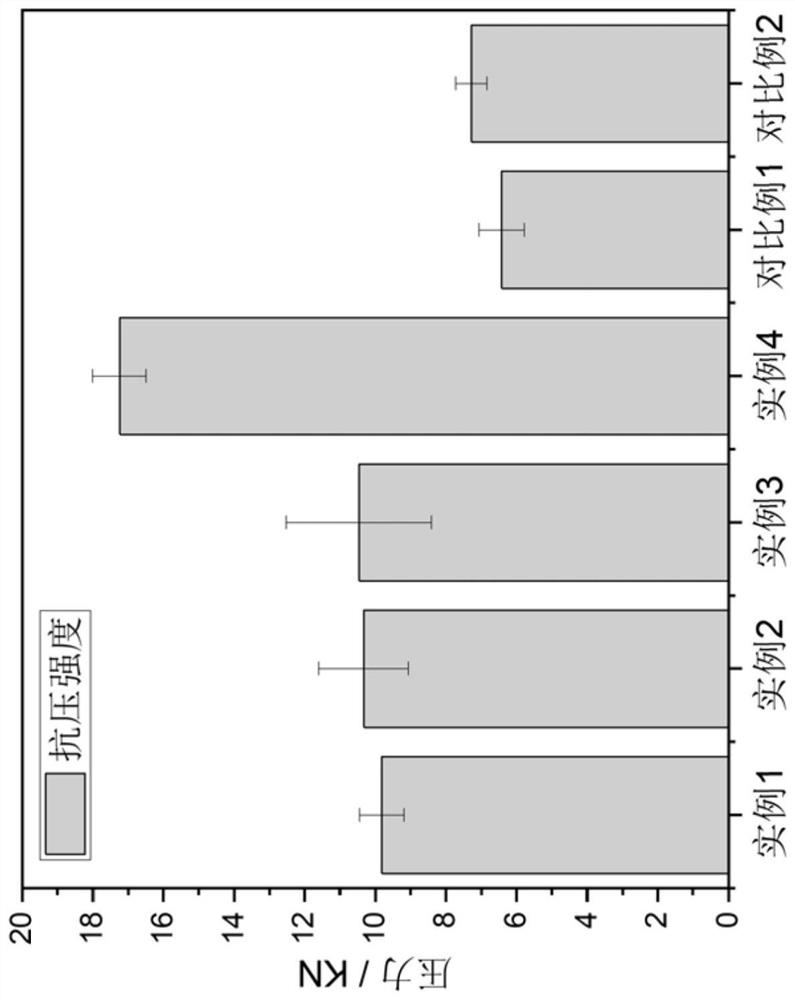

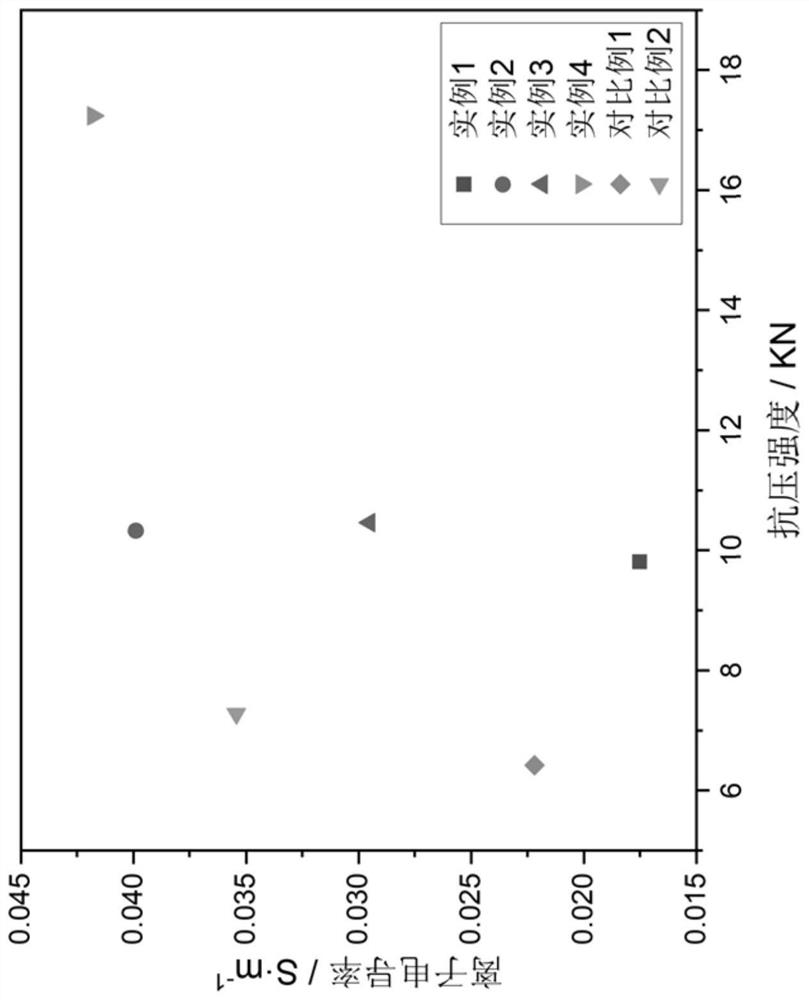

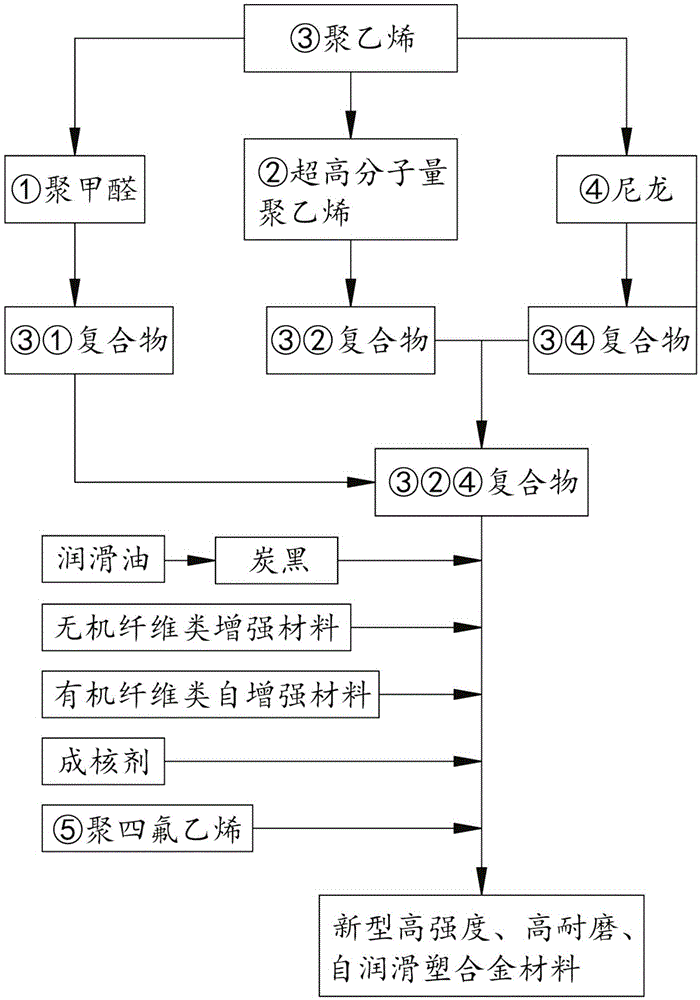

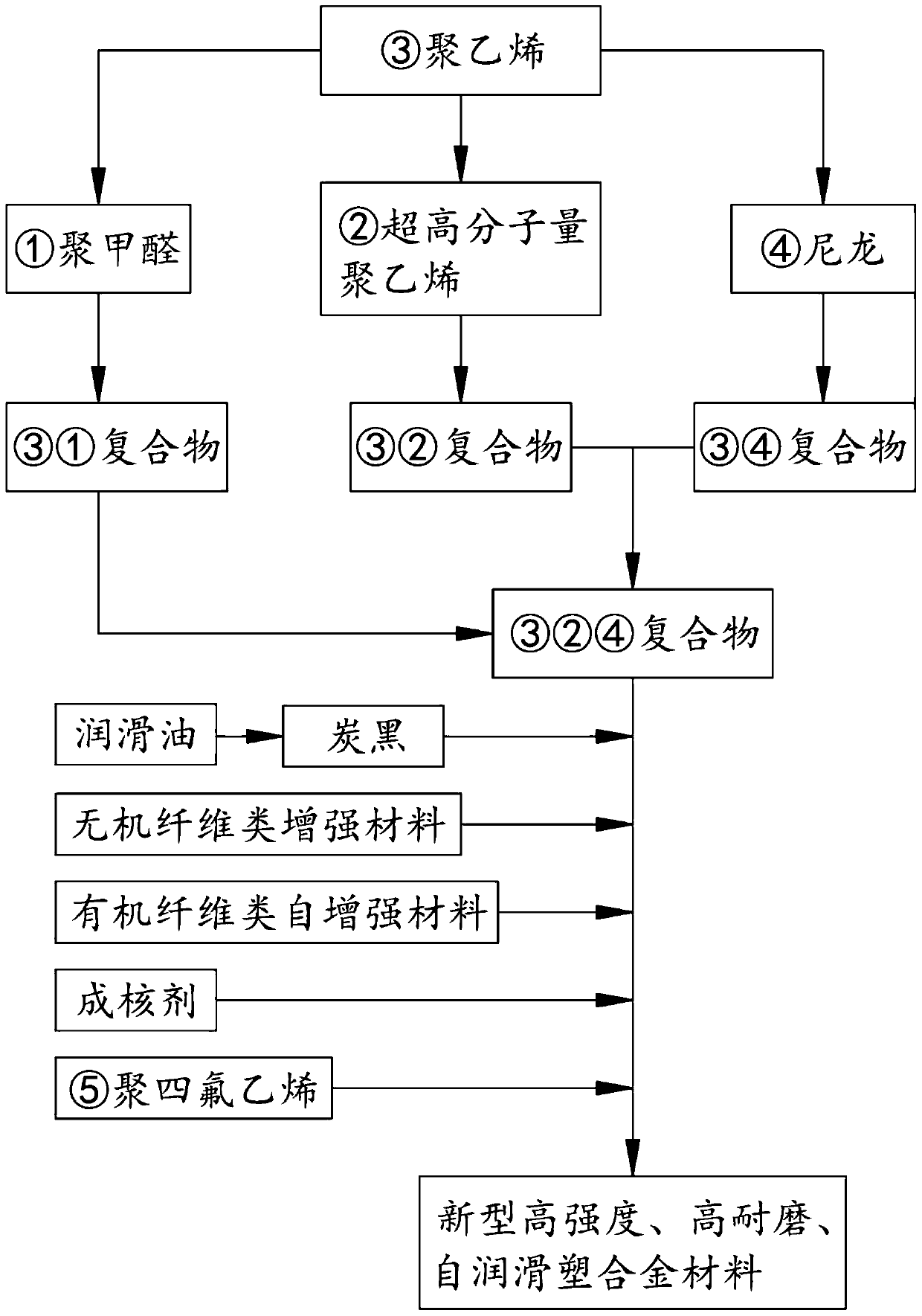

Novel plastic alloy material and preparation method thereof

The invention relates to a novel plastic alloy material, which comprises a variety of polymer materials and an additive, wherein the main polymer materials comprise, by mass, 30-90 parts of polyformaldehyde (short for material 1), 20-50 parts of ultra-high molecular weight polyethylene (short for material 2), 10-50 parts of polyethylene (short for material 3), 20-50 parts of nylon (short for material 4), and 10-40 parts of polytetrafluoroethylene (short for material 5). The preparation method comprises: carrying out a grafting treatment or surface polar treatment on the material 3 by using a grafting material alpha, compounding the treated material 3 respectively with the material 1, the material 2 and the material 4 to prepare composite materials 3-1, 3-2 and 3-4, compounding the composite materials 3-2 and 3-4 to obtain a new composite material, compounding the new composite material and the composite material 3-1 while adding an additive, and carrying out a wear resistance enhancement treatment. The novel plastic alloy material of the present invention has advantages of high strength, high wear-resistance, and strong adaptability.

Owner:洛阳摩丁塑业有限公司

Modified halloysite nanotube / biodegradable polyester composite material and preparation method thereof

InactiveCN102952385BSpecial nanotubular structureGood biocompatibilitySurgeryPharmaceutical non-active ingredientsHalloysiteElectrospinning

Owner:JINAN UNIVERSITY

Biodegradable plastic as well as preparation method and application thereof

PendingCN114276656AEfficient fusionReduce tensionProtective garmentSpecial outerwear garmentsPolyesterPolymer science

The invention provides a biodegradable plastic. The biodegradable plastic comprises the following components: 30-50 parts of PBAT modified polyester; and 8-15 parts of polylactic acid (PLA). 4 to 10 parts of a hydroxyl modifier; 0.3-1 part of a chain extender; 0.5 to 1 part of a plasticizer; and the balance of starch. The invention further provides a preparation method of the biodegradable plastic and application of the biodegradable plastic in medical protective clothing and sanitary towels. The chain extender is added, so that the chain extender can be subjected to chain extension reaction with the PLA and the PBAT in the processing process, tension between two phase interfaces is reduced, efficient fusion of the PLA and the PBAT is achieved, the problem of interfacial compatibility of the PLA and the PBAT is solved, overall molecules of the polymer are more regular, and water molecules can pass through easily; the treated starch and the hydroxyl modifier are added to increase the permeability of water vapor, so that the water absorption of the whole plastic material is enhanced, the plastic material can be better suitable for the fields of medical protective clothing, sanitary towels and the like, and the environmental protection performance is also improved.

Owner:CHONGQING HETAI PLASTIC

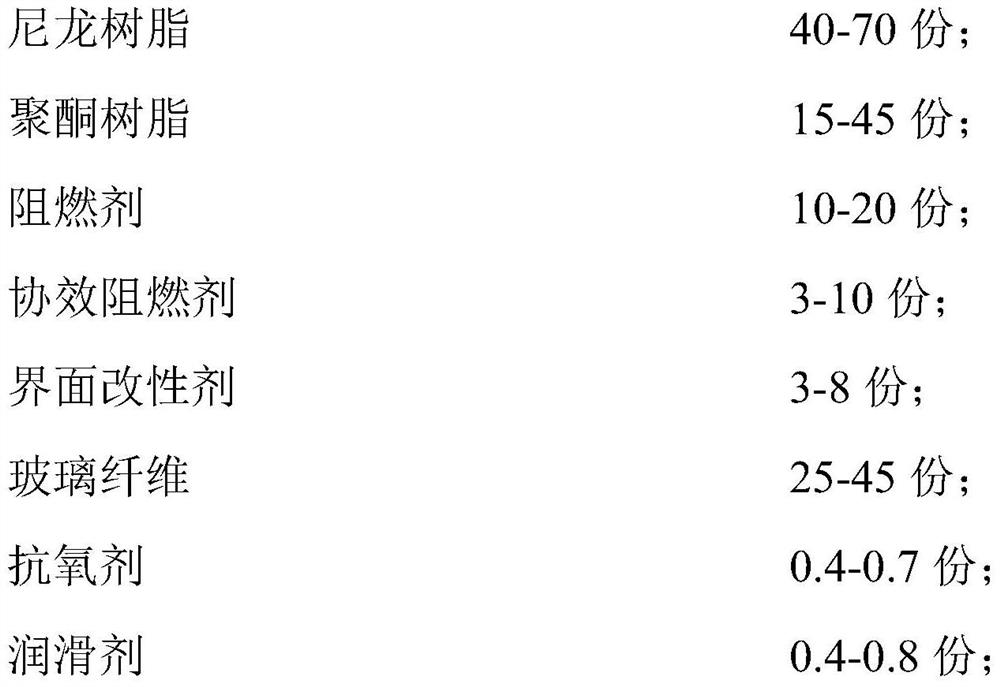

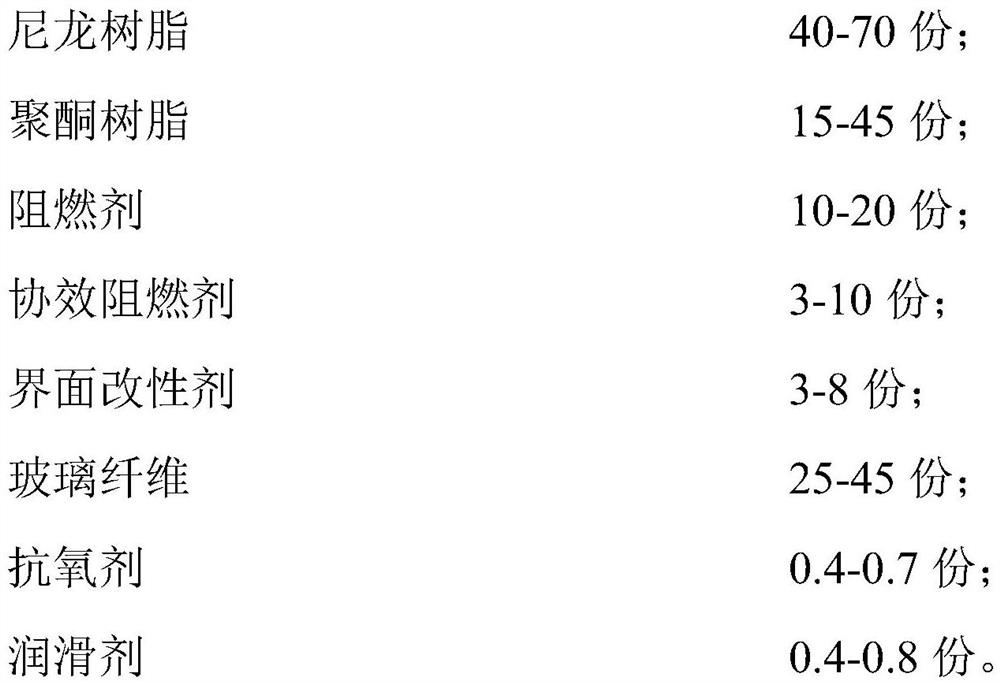

Hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material and preparation method thereof

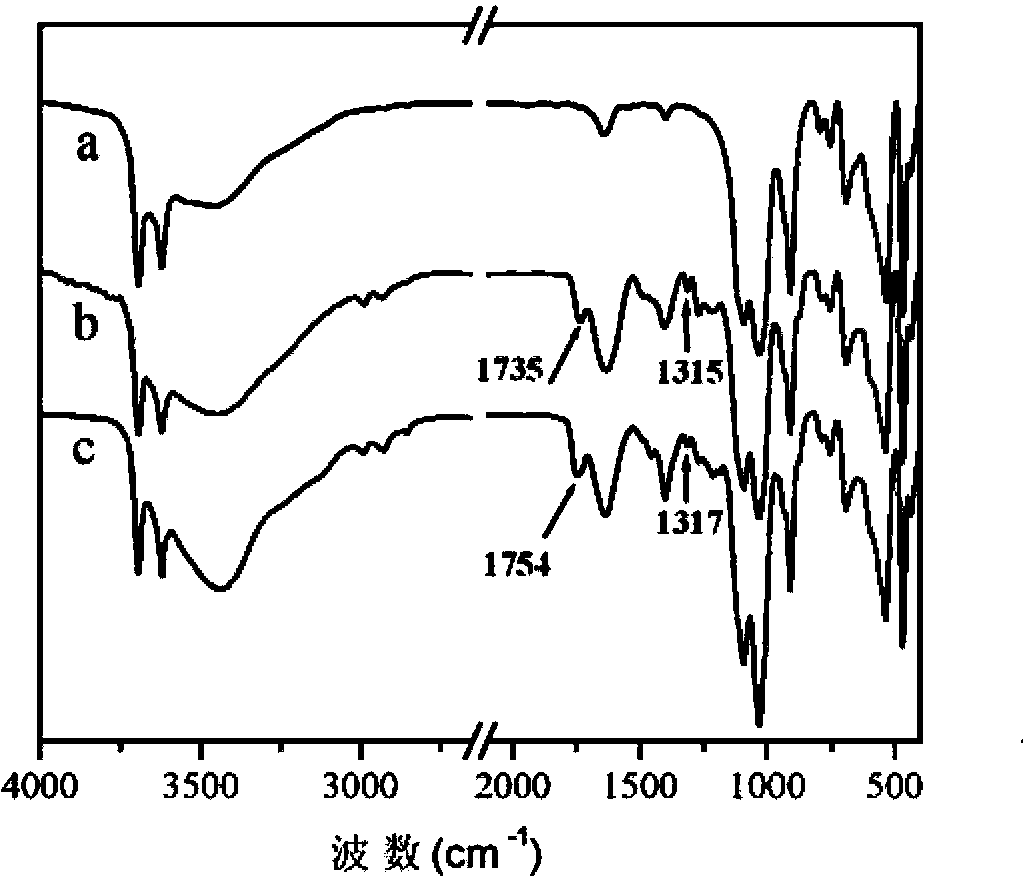

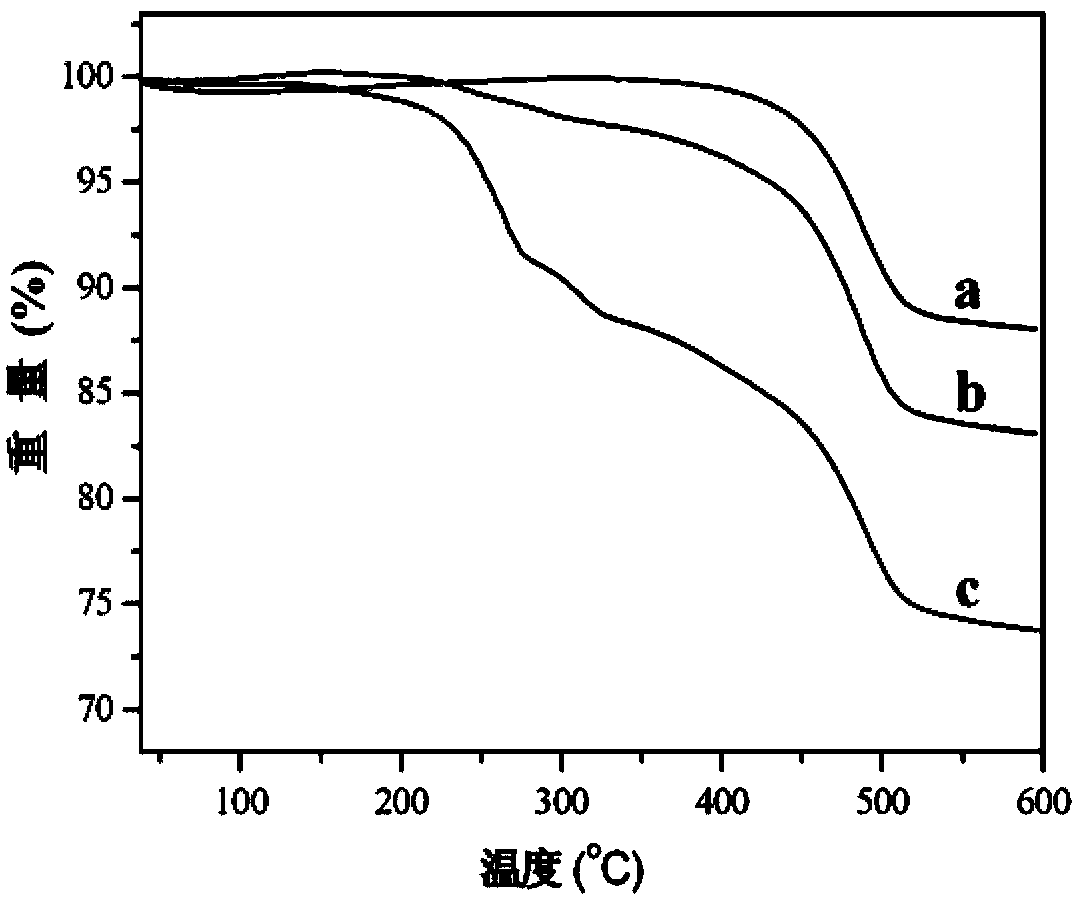

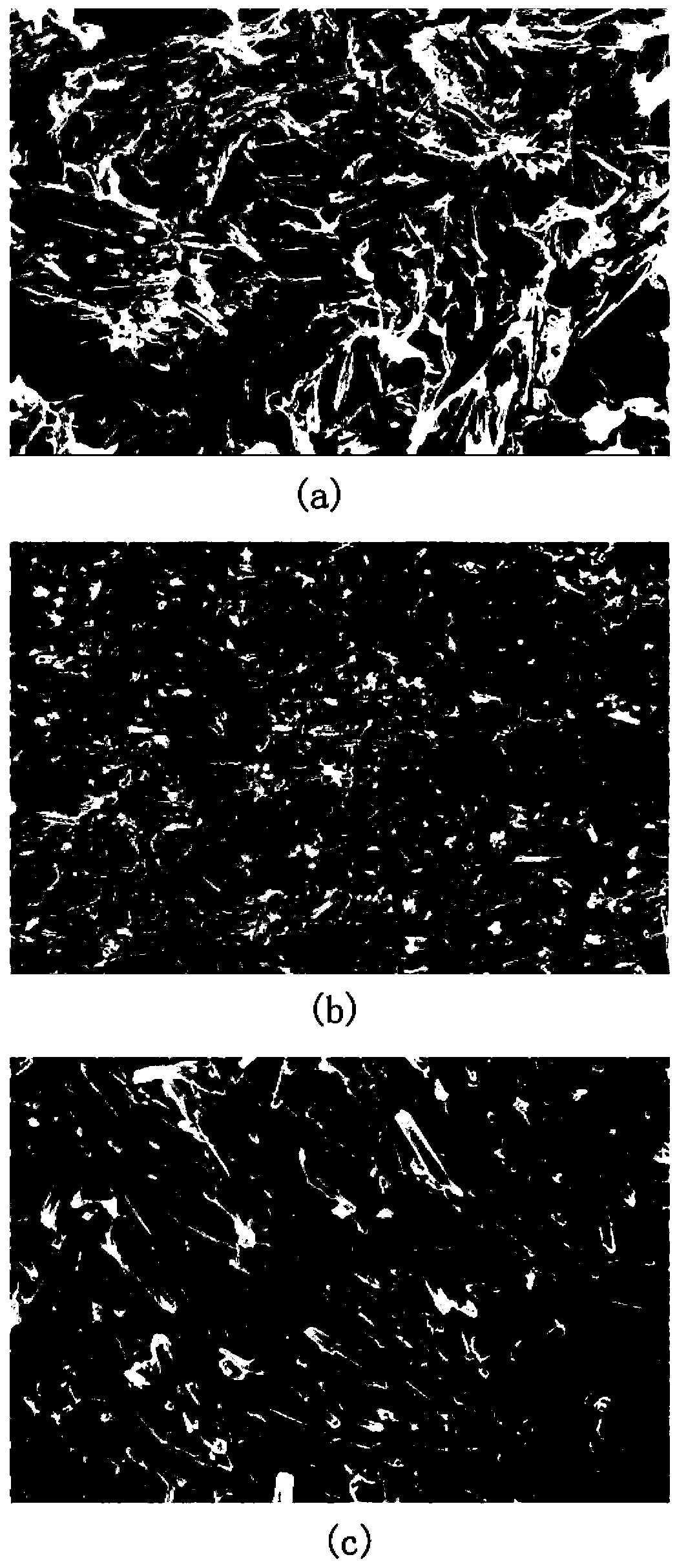

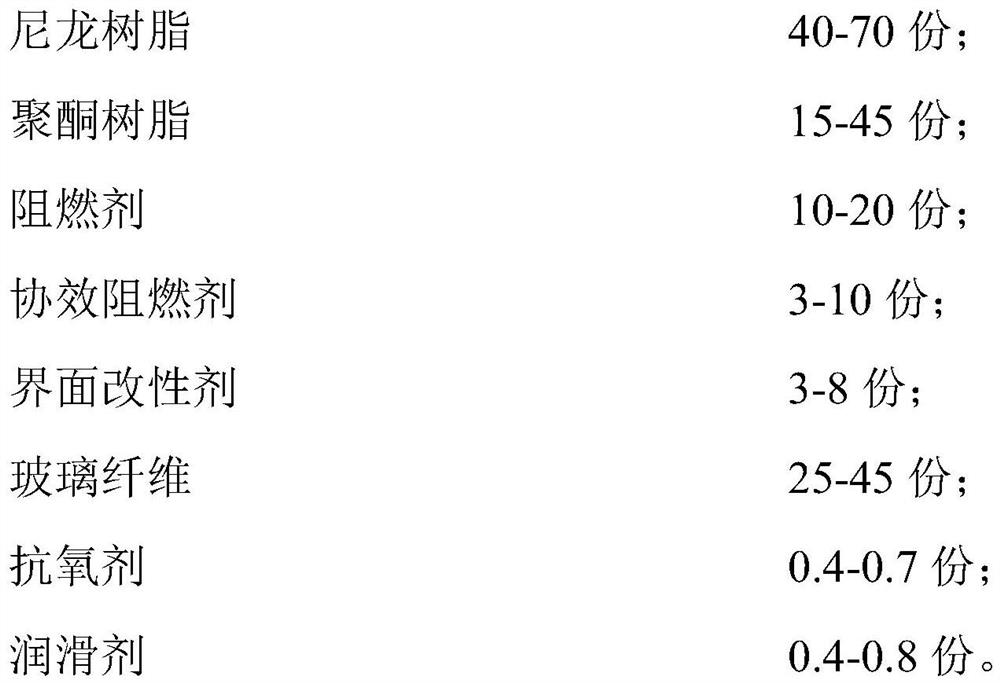

The invention belongs to the technical field of high polymer materials, and discloses a hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material and a preparation method thereof. The hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material comprises the following components in parts by weight: 40-70 parts of nylon resin, 15-45 parts of polyketone resin, 10-20 parts of aflame retardant, 3-10 parts of a synergistic flame retardant, 3-8 parts of an interface modifier, 25-45 parts of glass fibers, 0.4-0.7 part of an antioxidant and 0.4-0.8 part of a lubricant. Comparedwith the prior art, the PA6-POK alloy material has the characteristics of low water absorption, high wet volume resistivity, small warping, excellent water resistance and the like, and the mechanicalproperties of the PA6-POK alloy material can be comparable with those of reinforced flame-retardant PA6, so that the PA6-POK alloy material has wider application fields than reinforced flame-retardant PA6, and can be used for electronic and electrical parts in high-temperature and high-humidity environments.

Owner:横店集团得邦工程塑料有限公司

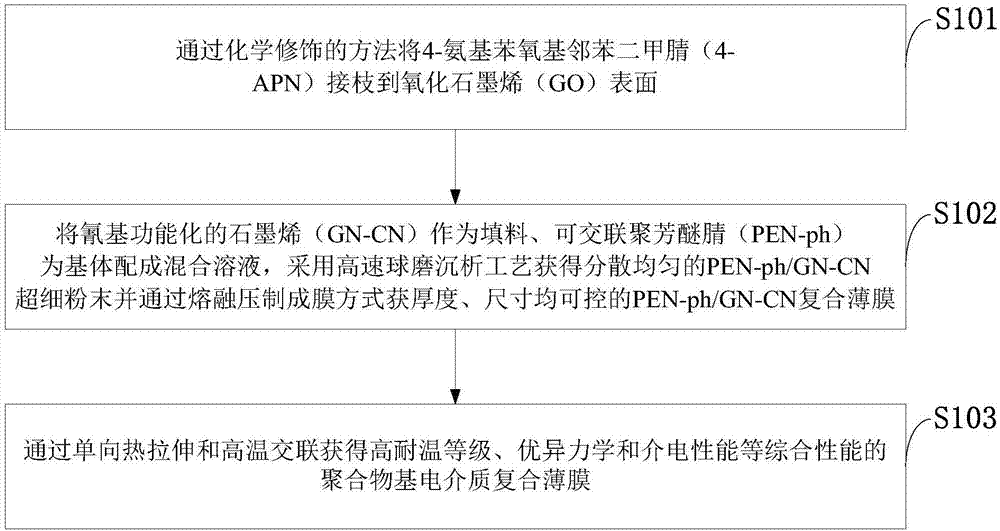

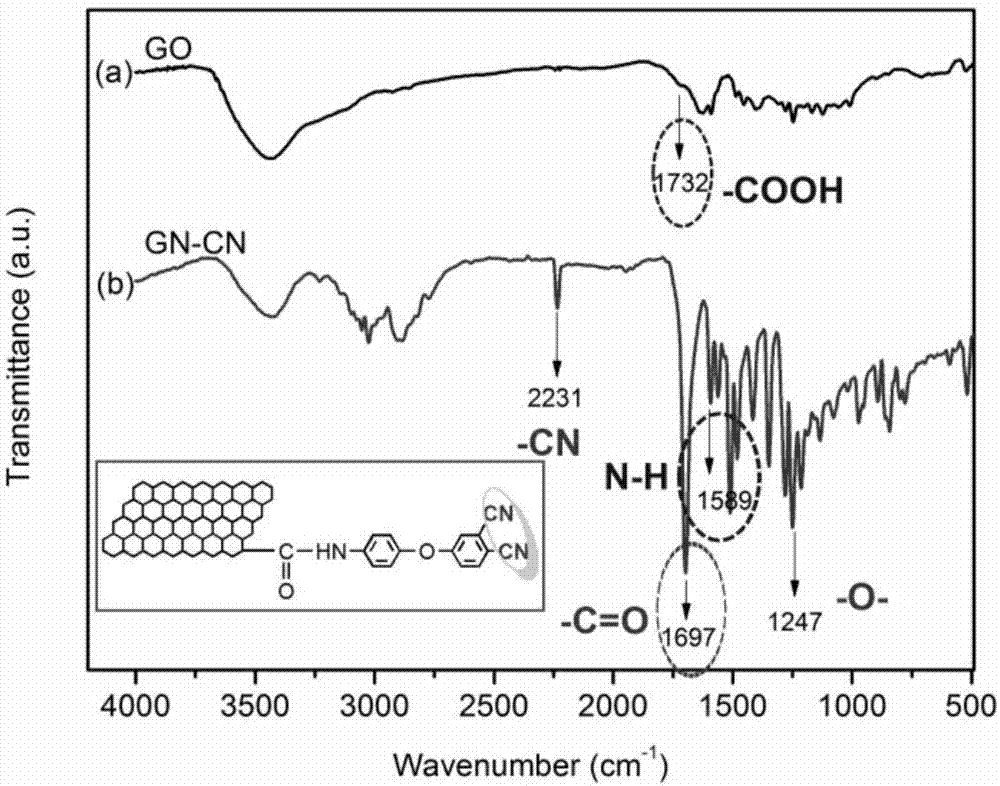

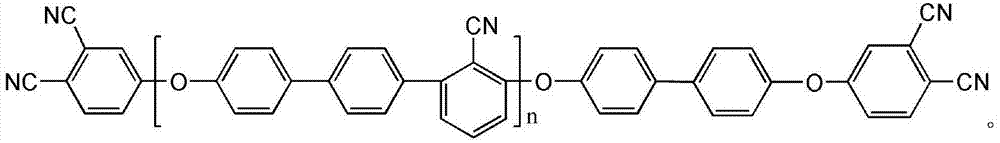

High-intensity high-temperature-resistant polymer-based dielectric thin film and preparation method thereof

InactiveCN107474517AImprove mechanical strengthExcellent flexibility and dielectric propertiesFlat articlesPhthalonitrileEther

The invention belongs to the technical field of a macromolecular dielectric material, and discloses a high-intensity high-temperature-resistant polymer-based dielectric thin film and a preparation method thereof. Graphene oxide is subjected to chemical grafting by 4-aminophenoxyl-o-phthalonitrile; cyan functional graphene is obtained; the continuous ultrasonic and high-speed ball milling precipitation technology is used for obtaining the uniformly dispersed crosslinking poly (arylene ether nitrile) / cyan functional graphene ultrafine powder; a composite thin film with the controllable thickness and dimension is obtained in a fusion pressing film forming mode. The composite thin film provided by the invention has ultrahigh heat-resistant performance (Tg is higher than 360 DEG C), high mechanical strength (the stretch intensity is higher than 450 MPa, and the modulus is higher than 4.5GPa) and excellent toughness; the dielectric constant is 11 to 28.5; the dielectric loss is 0.02 to 0.045. The composite material belongs to a polymer-based composite dielectric material and can be applied to the technical field of dielectric energy storage as a dielectric thin film.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Green biomass packaging material and preparation method thereof

The invention discloses a green biomass packaging material and a preparation method thereof. The biomass packaging material is prepared from the following components in parts by mass: degradable resin, ramie fiber, reed fiber, orange peel powder, silk, micro Crystalline Cellulose PH‑105, Graphite Fluoride, Urea, Sodium Ascorbate, Magnesium Stearate, Tall Oil, Pentaerythritol Esters, Polyethylene Oxide, Beta‑Diketone. The biomass packaging material prepared by the present invention is not only green and environmentally friendly, but also solves the problem of interfacial compatibility between materials to a certain extent through reasonable material selection and proportioning, and the test results show that the prepared packaging material has mechanical properties and The degradation properties are good and have good market application prospects.

Owner:苏州倍力特物流设备有限公司

High-temperature-resisting Y containing lead-lithium alloy with extremely low machining hardening rate

The invention discloses a high-temperature-resisting Y containing lead-lithium alloy with an extremely low machining hardening rate and a machining technology of the high-temperature-resisting Y containing lead-lithium alloy. The high-temperature-resisting Y containing lead-lithium alloy comprises components including, by weight percent, 0.8 wt.%-1.5 wt.% of Li, 0.3 wt.%-0.5 wt.% of Y, 0.2 wt.%-0.4 wt.% of Nb, 0.5 wt.%-0.8 wt.% of Ge, 0.3 wt.%-0.5 wt.% of W, 0.2 wt.%-0.3 wt.% of Te and the balance lead. The lead-lithium alloy has the extremely low machining hardening rate and excellent high-temperature performance. The performance exceeds a traditional shielding material lead alloy, and the high-temperature-resisting Y containing lead-lithium alloy is widely applied to the military and civil fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

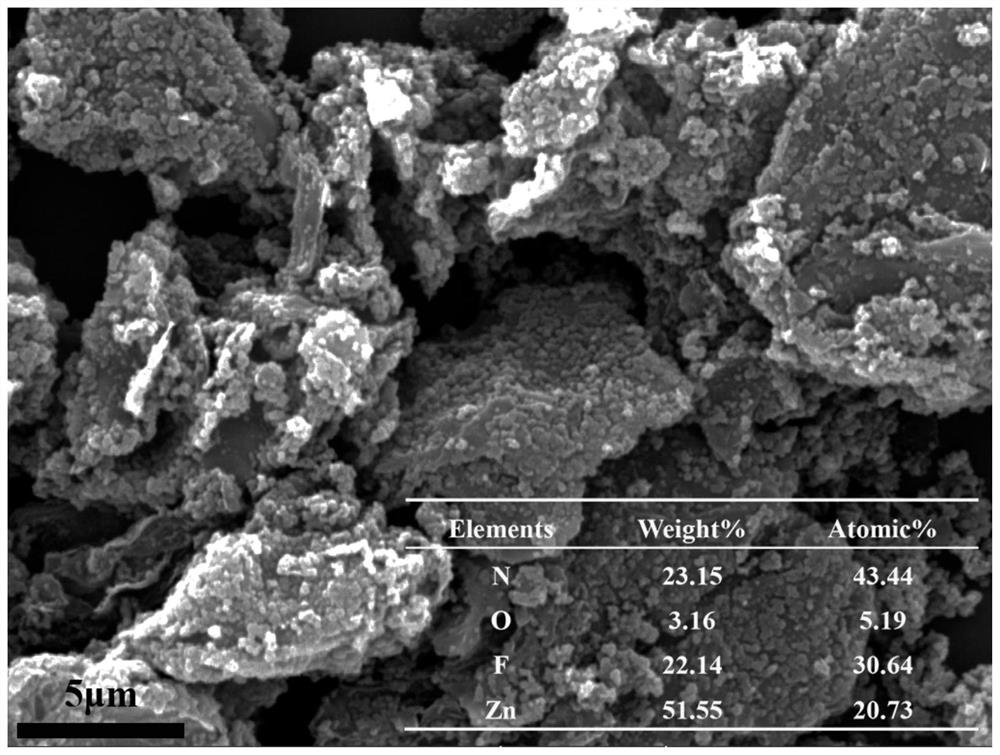

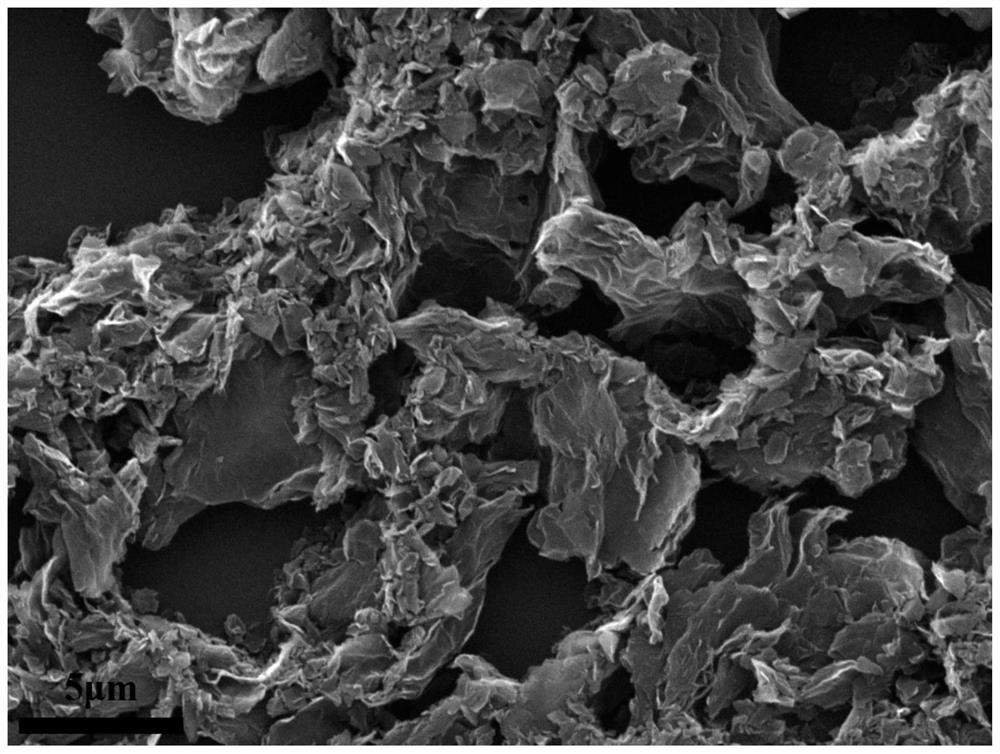

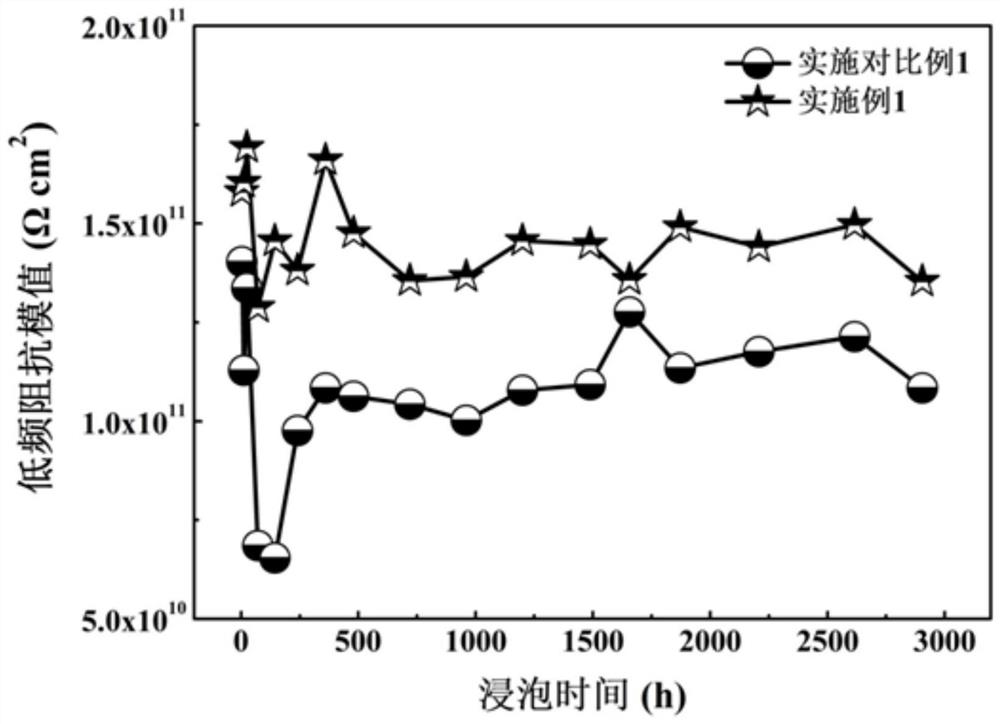

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

PendingCN112442187AImprove protection performanceRegulatory loadAnti-corrosive paintsEpoxy resin coatingsEpoxy resin compositeUltrasonic oscillation

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Whisker reinforced polyether ether ketone composite material and preparation method thereof

ActiveCN105504763BImprove mechanical propertiesImprove wear resistancePoly ether ether ketonePotassium

The present invention discloses a crystal whisker reinforced poly(ether-ether-ketone) composite material and a preparation method thereof. The composite material comprises, by mass, 50-80% of poly(ether-ether-ketone), 4-20% of polytetrafluoroethylene, 5-20% of modified potassium hexatitanate crystal whisker, 5-10% modified zinc oxide crystal whisker, and 1-4% of a processing aid. The preparation method comprises: drying various raw materials, carrying out mixing stirring, carrying out mixing extrusion on the obtained mixture, pelletizing to obtain composite material particles, drying the composite material particles, carrying out injection molding, and carrying out an annealing treatment on the obtained composite material molded material to obtain the crystal whisker reinforced poly(ether-ether-ketone) composite material. The crystal whisker reinforced poly(ether-ether-ketone) composite material of the present invention has advantages of high strength, high wear resistance, wide application range, simple preparation method, and good effect.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A kind of high tear-resistant silicone rubber nanocomposite and preparation method thereof

The invention discloses a preparation method of a silicone rubber nano composite with the high tear resistance. The composite is prepared from, by weight, 100 parts of silicone rubber, 3-10 parts of carbon nano tubes, 30-50 parts of fumed silica, 3-6 parts of hydroxyl silicone oil, 0.5-3.5 parts of vulcanizing agents and 0.2-0.8 part of interface agents. According to the silicone rubber nano composite with the high tear resistance and the preparation method thereof, by selecting and using the interface agents, the problems that when the carbon nano tubes serve as reinforcing fillers, the carbon nano tubes are unevenly dispersed in the silicone rubber, and the interfacial action of the carbon nano tubes and the silicone rubber is weak are solved, and the tearing property of the silicone rubber nano composite is significantly improved.

Owner:BEIJING UNIV OF CHEM TECH

A method for in-situ generation of fiber-reinforced superalloy composites

The invention discloses a preparation method of a fiber-enhanced high temperature alloy composite material via in-situ generation, and belongs to the technical field of preparation of materials. The preparation method comprises the following steps of preparing the materials according to typical high temperature alloy components, and increasing the content of carbon element in proportioning, so asto increase the content of carbon; smelting by a vacuum electric arc furnace, so as to form fiber-shaped carbide, thereby obtaining the fiber-enhanced high temperature alloy composite material via in-situ generation. The preparation method has the advantage that the enhancing fibers directly grow in a high temperature alloy matrix, so as to obtain the composite material with a stable interface, thereby solving the problem of poor interface compatibility of the fiber-enhanced high temperature alloy composite material.

Owner:UNIV OF SCI & TECH BEIJING

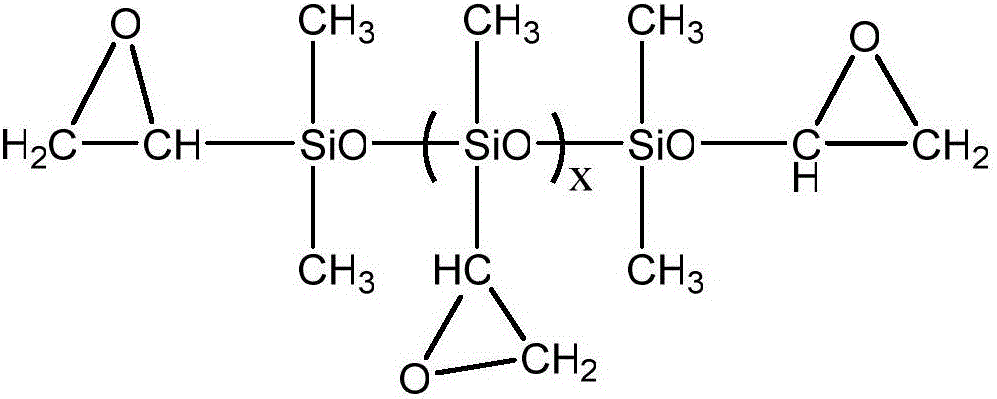

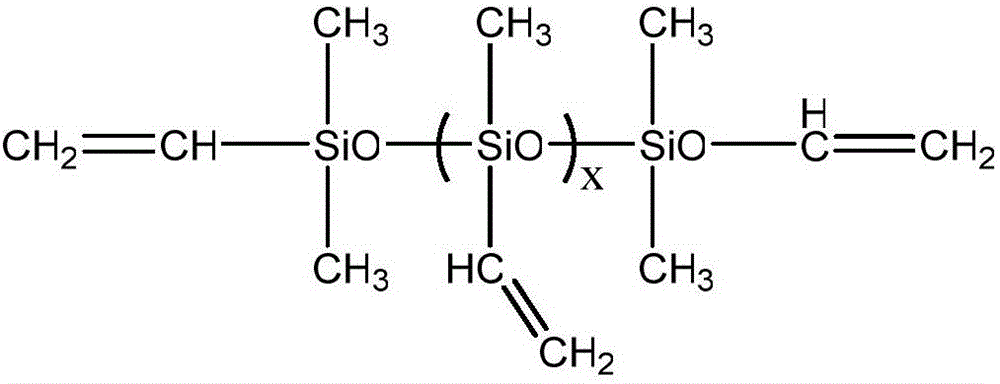

A kind of epoxy polysiloxane and epoxidation preparation method

The invention discloses an epoxy polysiloxane and an epoxidation preparation method thereof. The present invention prepares the base by first using octamethylcyclotetrasiloxane, tetramethyltetravinylcyclotetrasiloxane and vinyl double-capped anion ring-opening under alkaline conditions, and then in the presence of ethyl acetate Next, the mixture obtained by mixing tetracarboxylic metal phthalocyanine complex and H2O2 is used as a catalyst to obtain epoxy polysiloxane compound. The preparation method of the invention is simple, and avoids the problems of interfacial compatibility caused by blending modification, many side reactions of copolymerization modification, difficult removal of catalysts and the like, and the prepared compound can be used in the technical field of LED lighting lamps.

Owner:SHANGHAI RESIN FACTORY

A kind of plastic alloy material and preparation method thereof

A plastic alloy material, which is composed of various polymer materials and additives. The main polymer materials and their mass parts are: polyoxymethylene (referred to as material ①): 30-90 parts, ultra-high molecular weight polyethylene (referred to as material ②): 20-50 parts, polyethylene (material ③ for short): 10-50 parts, nylon (material ④ for short): 20-50 parts, polytetrafluoroethylene (material ⑤ for short): 10-40 parts. First, use graft α to do graft treatment or surface polarity treatment on material ③; compound the treated material ③ with material ①, material ②, and material ④ respectively to obtain composite materials ③‑①, ③‑②, ③ ‑④; compound the composite materials ③‑②, ③‑④ to obtain a new composite material; then compound the aforementioned new composite material with the composite material ③‑①, and at the same time add additives for wear-resistant enhancement treatment. The plastic alloy material proposed by the invention has the advantages of high strength, high wear resistance and strong adaptability.

Owner:洛阳摩丁塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com