High-thermal-conductivity and high-electric-conductivity PC/ABS composite material and preparation method thereof

A composite material and high thermal conductivity technology, which is applied in the field of high thermal conductivity and electrical conductivity PC/ABS composite material and its preparation, can solve problems such as poor compatibility, easy agglomeration of added amount, poor compatibility, etc., to improve thermal and electrical conductivity, solve Difficult heat transfer at the interface and effects of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

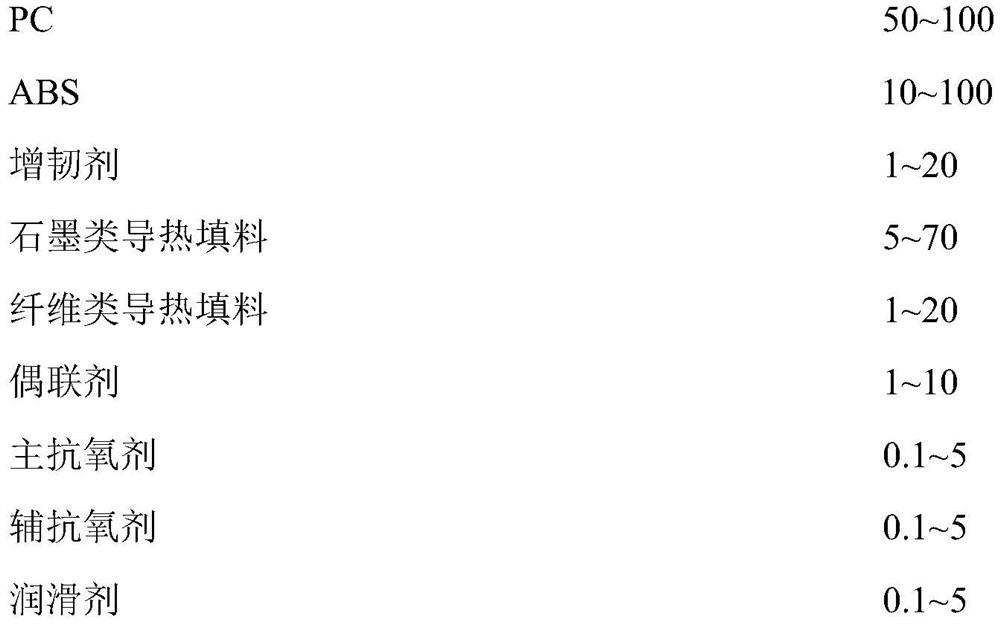

[0034] Embodiment 1 of the present invention provides a high thermal conductivity and electrical conductivity PC / ABS composite material, which comprises the following raw materials in parts by weight: 80 parts of PC, 20 parts of ABS, 8 parts of ABS toughening agent with a particle size of 5 μm or more, 3 parts of ABS toughening agent below 1μm, 8 parts of flake graphite masterbatch with particle size of 3μm, 20 parts of flake graphite masterbatch with particle size of 12μm, 5 parts of spherical graphite masterbatch with particle size of 10μm, length of 5μm 3 parts of carbon nanotube masterbatch, 1.4 parts of silane coupling agent KH570, 2 parts of hindered phenol antioxidant 1010, 1 part of phosphite antioxidant 168, and 3 parts of pentaerythritol stearate lubricant.

Embodiment 2

[0036] Embodiment 2 of the present invention provides a PC / ABS composite material with high thermal conductivity and electrical conductivity, which comprises the following raw materials in parts by weight: 100 parts of PC, 50 parts of ABS, 10 parts of MBS toughening agent with a particle size of 5 μm or more, and a particle size of 4 parts of MBS toughening agent below 1μm, 20 parts of flake graphite masterbatch with particle size of 3μm, 15 parts of flake graphite masterbatch with particle size of 12μm, 10 parts of spherical graphite masterbatch with particle size of 10μm, length of 5μm 8 parts of carbon nanotube masterbatch, 2.65 parts of silane coupling agent KH550, 5 parts of hindered phenol antioxidant 1076, 3 parts of phosphite antioxidant PEP-36, and 4 parts of pentaerythritol stearate lubricant.

Embodiment 3

[0038] Embodiment 3 of the present invention provides a high thermal conductivity and electrical conductivity PC / ABS composite material, which comprises the following raw materials in parts by weight: 120 parts of PC, 30 parts of ABS, 6 parts of acrylate toughening agent with a particle size of 5 μm or more, particle size 12 parts of acrylate toughening agent below 1μm, 30 parts of flake graphite masterbatch with particle size of 3μm, 10 parts of flake graphite masterbatch with particle size of 12μm, 20 parts of spherical graphite masterbatch with particle size of 10μm, length of 5 parts of 5 μm carbon nanotube masterbatch, 3.25 parts of titanate coupling agent NDZ101, 3 parts of hindered phenol antioxidant 245, 2 parts of phosphite antioxidant 168, and 2 parts of polyol lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com