Heat-conducting and heat-storing phase-change plate and preparation method thereof

A phase change and heat storage technology, applied in the field of heat dissipation, can solve the problems of electronic components such as difficult repair, difficult removal, leakage, etc., and achieve the effect of avoiding interface compatibility problems, increasing weight percentage, and enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

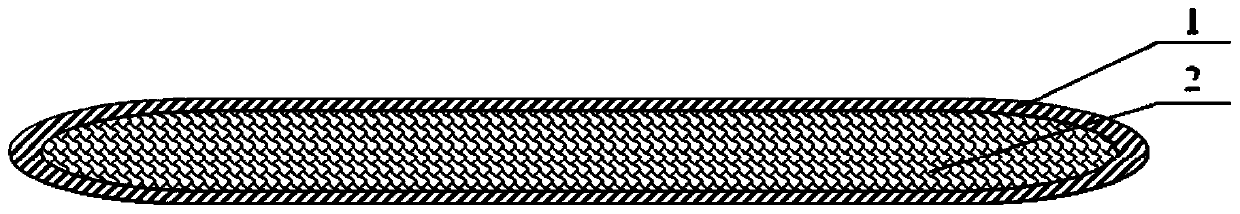

[0040] The heat conduction heat storage phase change plate of this embodiment, such as figure 1As shown, it includes a phase change plate shell 1 and a phase change composite material 2. The phase change plate shell 1 encloses a closed cavity, and the phase change composite material 2 is filled in the cavity. The phase change plate shell 1 The material is copper, and the phase-change composite material 2 is composed of the following raw materials in parts by weight: 500 parts of refined paraffin wax for phase-change materials, and 100 parts of a mixture of alumina and graphene at a weight ratio of 30:1 as a heat-conducting filler.

Embodiment 2

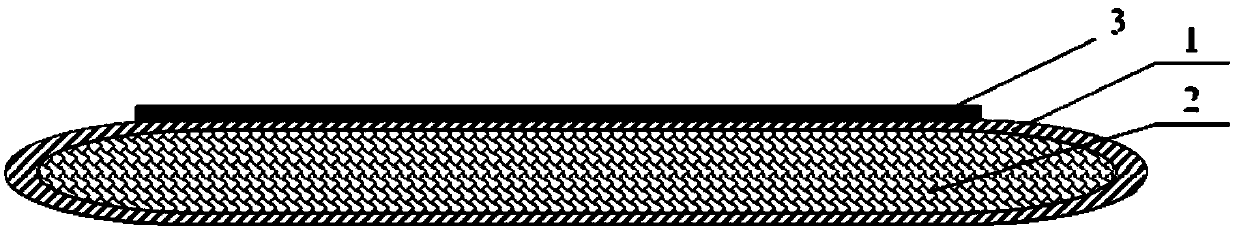

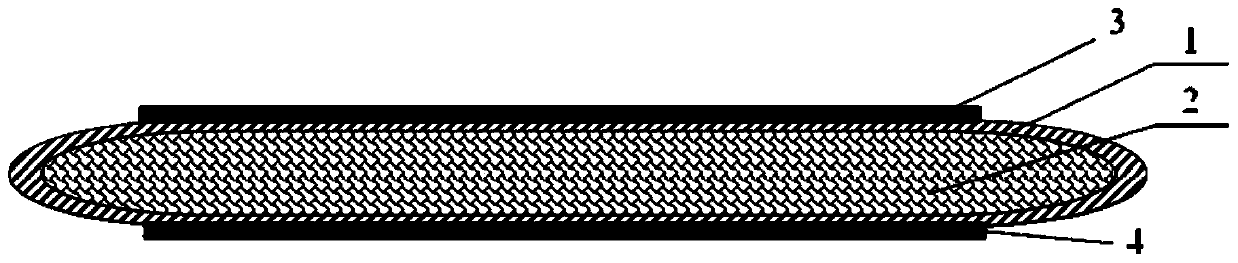

[0042] The heat conduction heat storage phase change plate of this embodiment, such as figure 2 As shown, it includes a phase change plate shell 1 and a phase change composite material 2. The phase change plate shell 1 encloses a closed cavity, and the phase change composite material 2 is filled in the cavity. The phase change plate shell 1 An adhesive layer 3 is arranged on one surface of the phase change plate shell 1, and the material of the phase change plate shell 1 is copper, and the phase change composite material is composed of the following raw materials in parts by weight: 600 parts of refined paraffin wax for the phase change material, aluminum oxide for thermal conductivity, The mixture of graphene and carbon nanotubes in a weight ratio of 30:1:1 is 100 parts in total.

Embodiment 3

[0044] The heat conduction heat storage phase change plate of this embodiment, such as figure 2 As shown, it includes a phase change plate shell 1 and a phase change composite material 2. The phase change plate shell 1 encloses a closed cavity, and the phase change composite material 2 is filled in the cavity. The phase change plate shell 1 An adhesive layer 3 is arranged on one surface of the phase change plate, the shell material of the phase change plate is copper, and the phase change composite material is composed of the following raw materials in parts by weight: 60 parts of silicon rubber for the base material, 400 parts of refined paraffin wax for the phase change material, The thermally conductive filler is 150 parts of a mixture of alumina and graphene at a weight ratio of 30:1, 8 parts of a silane coupling agent, and 2 parts of a thermal stabilizer calcium stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com