Preparation method of heat-conducting wave-absorbing phase-change composite material, and composite material

A technology of phase-change composite materials and wave-absorbing fillers, which can be applied to heat exchange materials, chemical instruments and methods, etc., and can solve the problems of easy rupture of phase-change microcapsules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

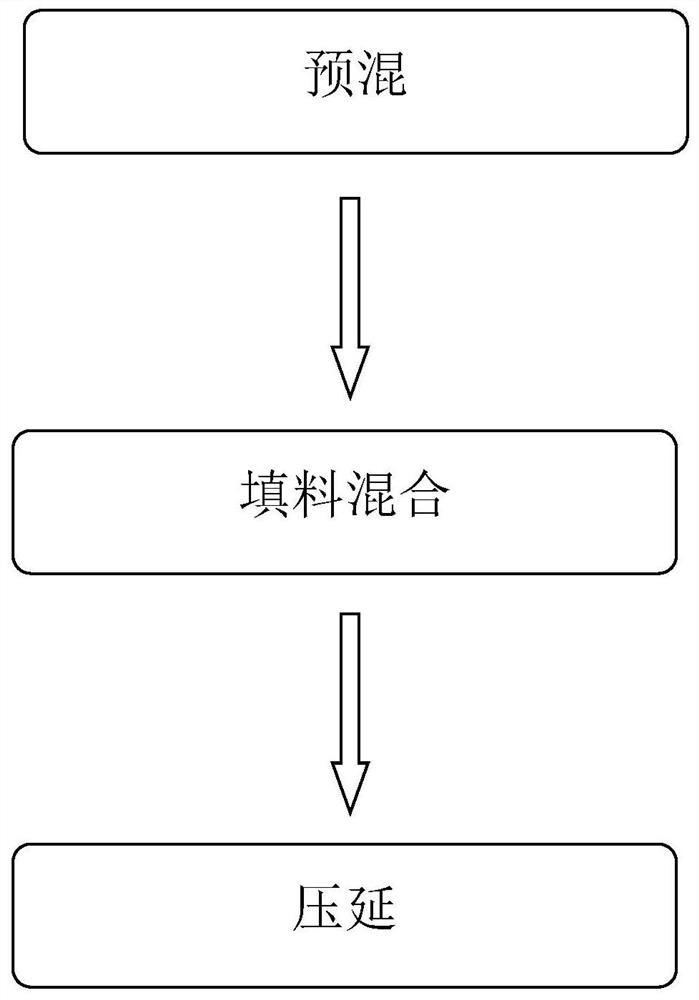

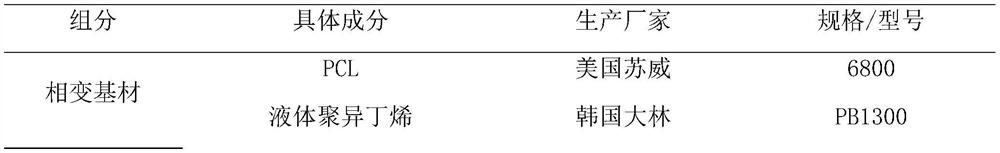

[0040] A preparation method of heat-conducting wave-absorbing phase-change composite material, such as figure 1 As shown, the following preparation steps are included: S1 premixing: add 10 parts of PCL to the stainless steel cup with heating device in the premixing container, add 30 parts of liquid polyisobutylene and 25 parts of phase change microcapsules in turn after melting, and stir well To obtain a uniformly dispersed phase-change premixed substrate, the heating temperature of the heating device is set to 100°C;

[0041] S2 Filler mixing: Add 400 parts of wave-absorbing fillers, 1000 parts of thermally conductive fillers, 3 parts of coupling agents, and 2 parts of antioxidants to the phase change premixed substrate and stir. The heating temperature during stirring is set to 100 ° C. The above components Disperse and mix evenly and then vacuumize and defoam to obtain semi-finished products;

[0042] S3 Calendering: Set the temperature of the rollers of the calender to 80...

Embodiment 2

[0055] This embodiment is provided with 4 groups of experimental groups and 2 groups of control groups. Compared with embodiment 1, the only difference is that the temperature of the calender roller in step S3 in experimental group A is set to 70°C; in experimental group B, step S3 The temperature of the calender roll in the experimental group C is set to 75°C; the temperature of the calender roll in step S3 in the experimental group C is set to 85°C; the temperature of the calender roll in step S3 in the experimental group D is set to 90°C; the control group The temperature of the calender roll in step S3 in A was set to 60°C; the temperature of the calender roll in step S3 in control group B was set to 100°C.

[0056] The composite materials obtained in each group in Example 2 were tested, and the test data are shown in Table 3.

[0057] Table 3: composite material test data in embodiment 2

[0058]

[0059] Combining the data of Example 1 and Example 2 and Table 3, it c...

Embodiment 3

[0061] This embodiment is provided with 4 groups of experimental groups and 2 groups of control groups. Compared with Example 1, the only difference is that the PCL added in step S1 in the experimental group A is 6.5 parts, the liquid polyisobutylene is 32 parts, and the phase change microcapsules 26.5 parts; the PCL that step S1 added in the experimental group B was 8 parts, the liquid polyisobutylene was 31 parts, and the phase change microcapsules were 26 parts; the PCL that step S1 added in the experimental group C was 12 parts, and the liquid polyisobutylene was 29 parts 1, 24 parts of phase-change microcapsules; 13 parts of PCL, 28 parts of liquid polyisobutylene, and 24 parts of phase-change microcapsules in step S1 in the experimental group D; 3 parts of PCL added in step S1 in control group A , 34 parts of liquid polyisobutylene, and 28 parts of phase-change microcapsules; 20 parts of PCL, 25 parts of liquid polyisobutylene, and 20 parts of phase-change microcapsules w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com