Low-temperature phase-change heat accumulator

A low-temperature phase change and regenerator technology, which is applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of poor operating performance, low heat storage and slow heat storage and discharge speed of phase change regenerators and other problems, to achieve the effect of good material stability, elimination of supercooling phenomenon, and improvement of COP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the invention is not limited thereto.

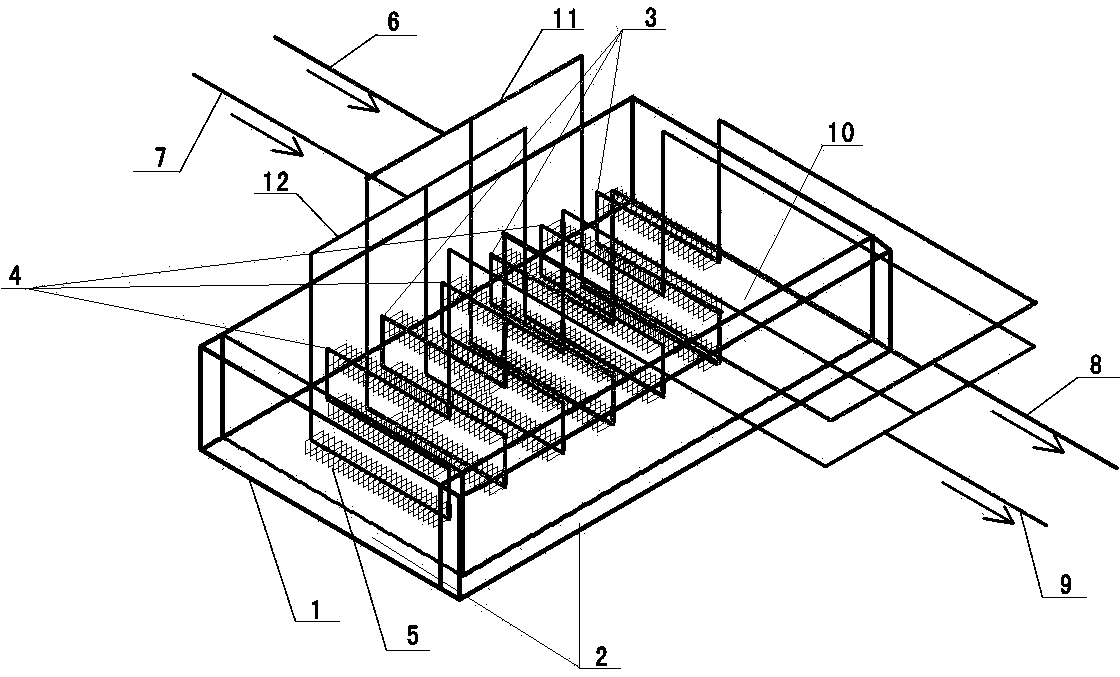

[0019] Such as figure 1 As shown, a low-temperature phase change heat accumulator provided by the present invention includes a box body, which can be made of steel, polyurethane foam insulation material is arranged in the interlayer of the box body, and serpentine metal pipe rows are arranged inside the box body, including storage The heat pipe row and the heat release pipe row, the working medium in the tube is refrigerant fluid. The two tube rows are arranged alternately, and metal fins are set at intervals on the two metal tube rows. In this embodiment, it is preferably a rectangular structure with a size of 55×26×0.3mm and a fin pitch of 5mm. The structure and size layout greatly increase the heat storage area and heat release area, increase the heat storage, and enhance the heat storage and heat release p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com