Patents

Literature

96results about How to "Fast heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

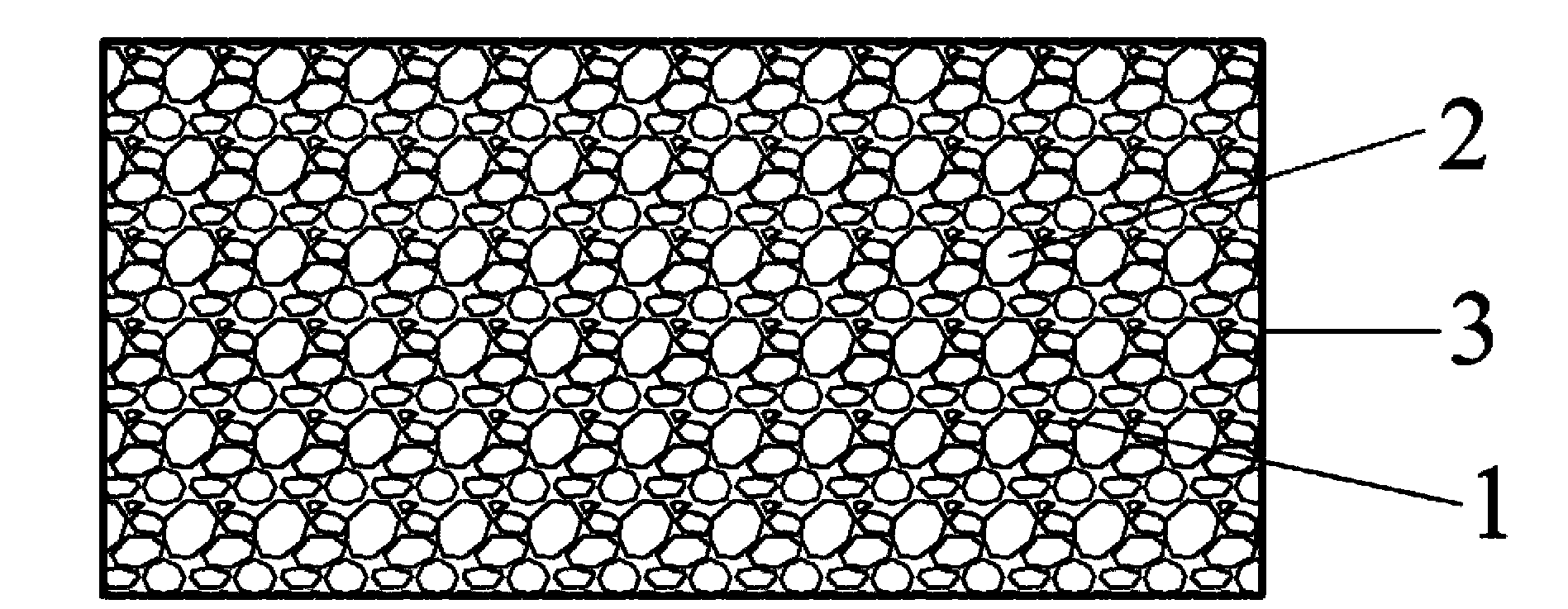

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

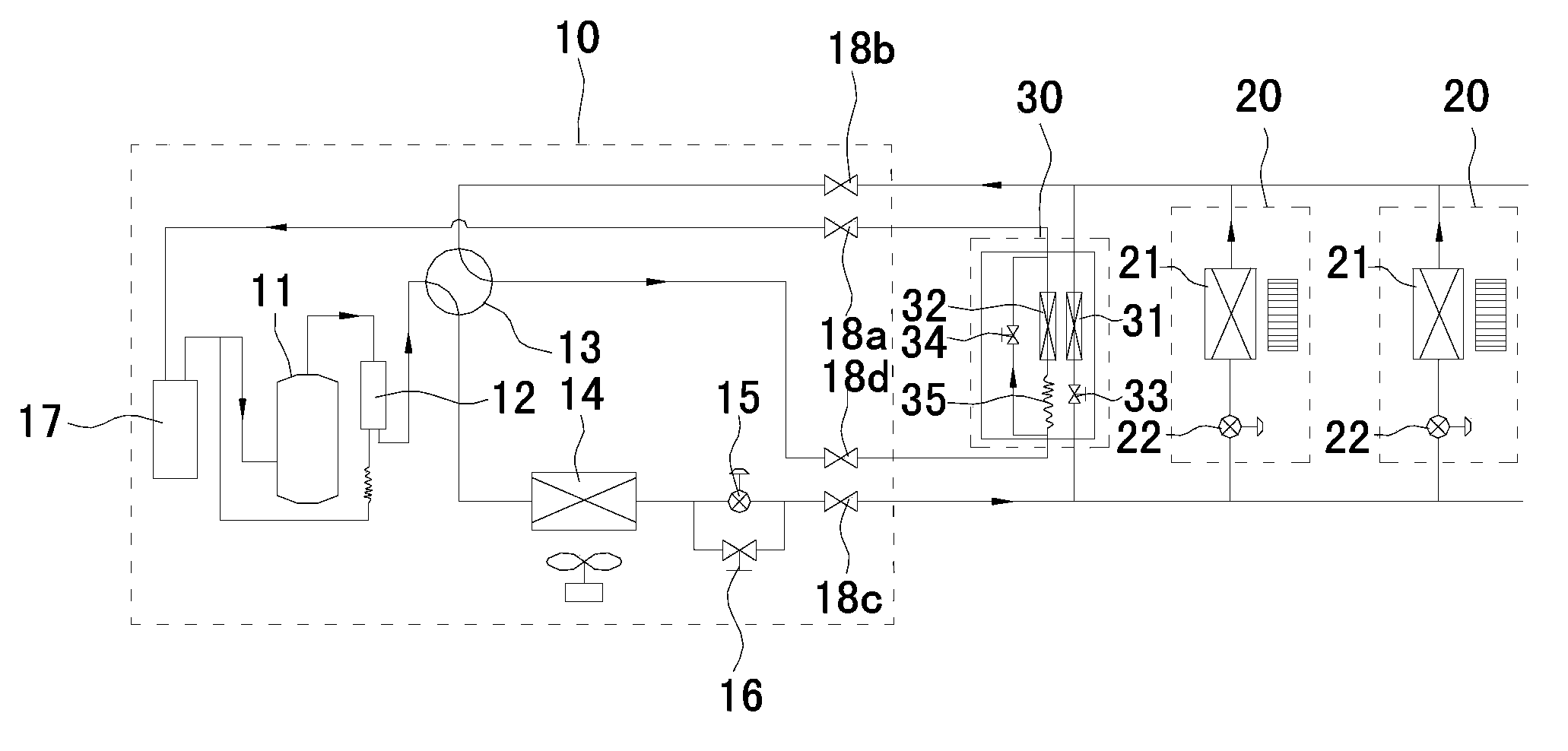

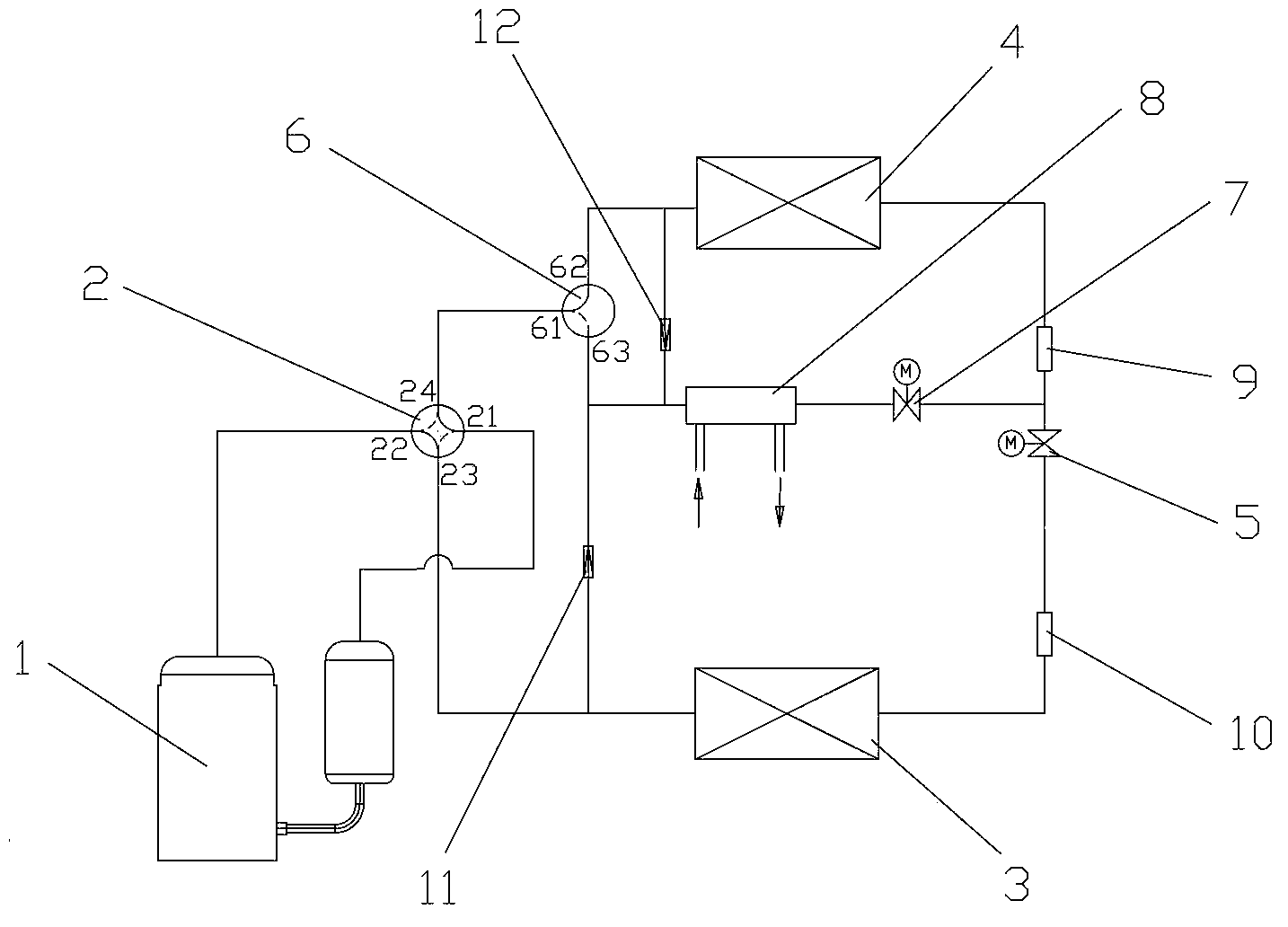

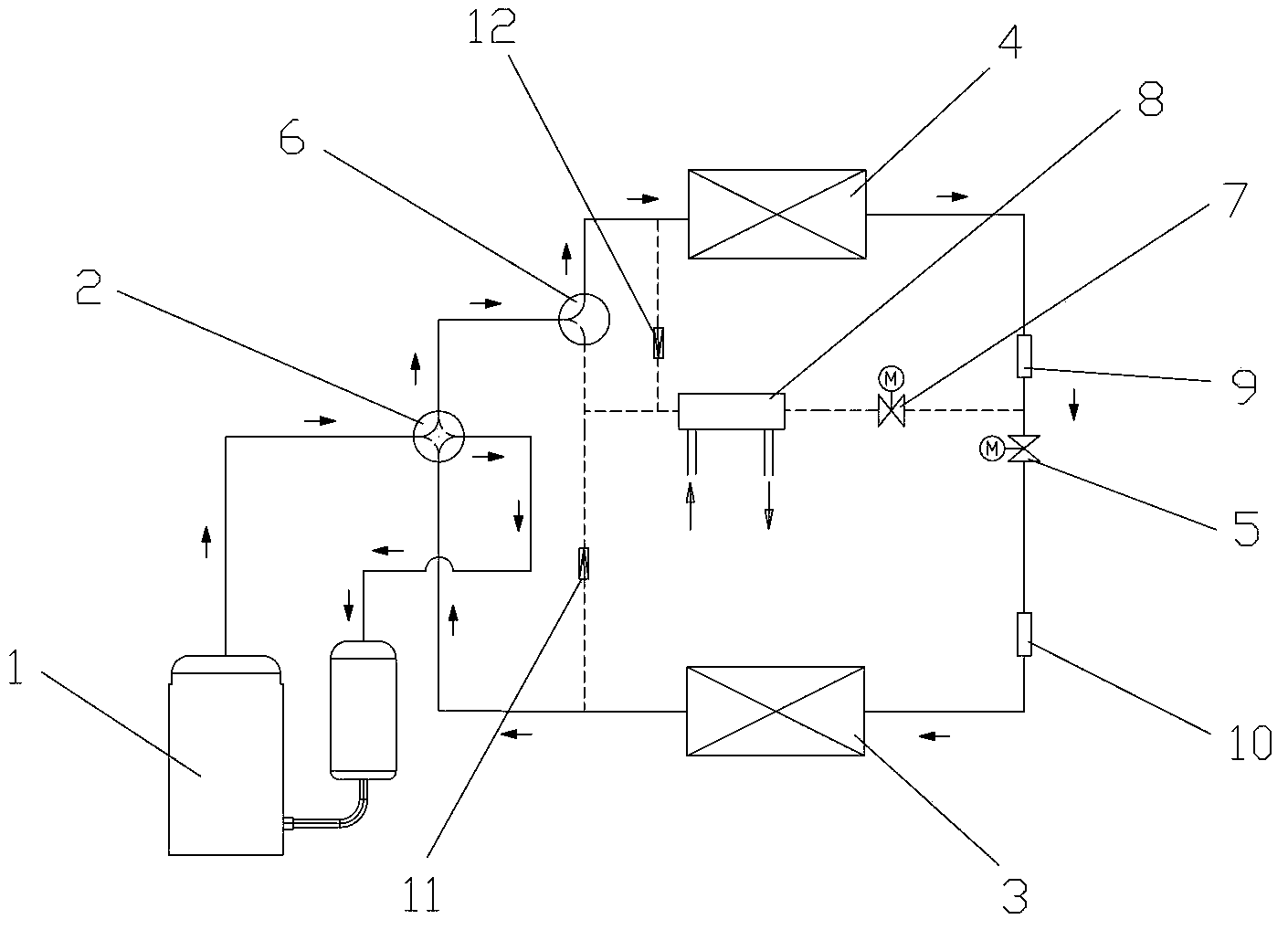

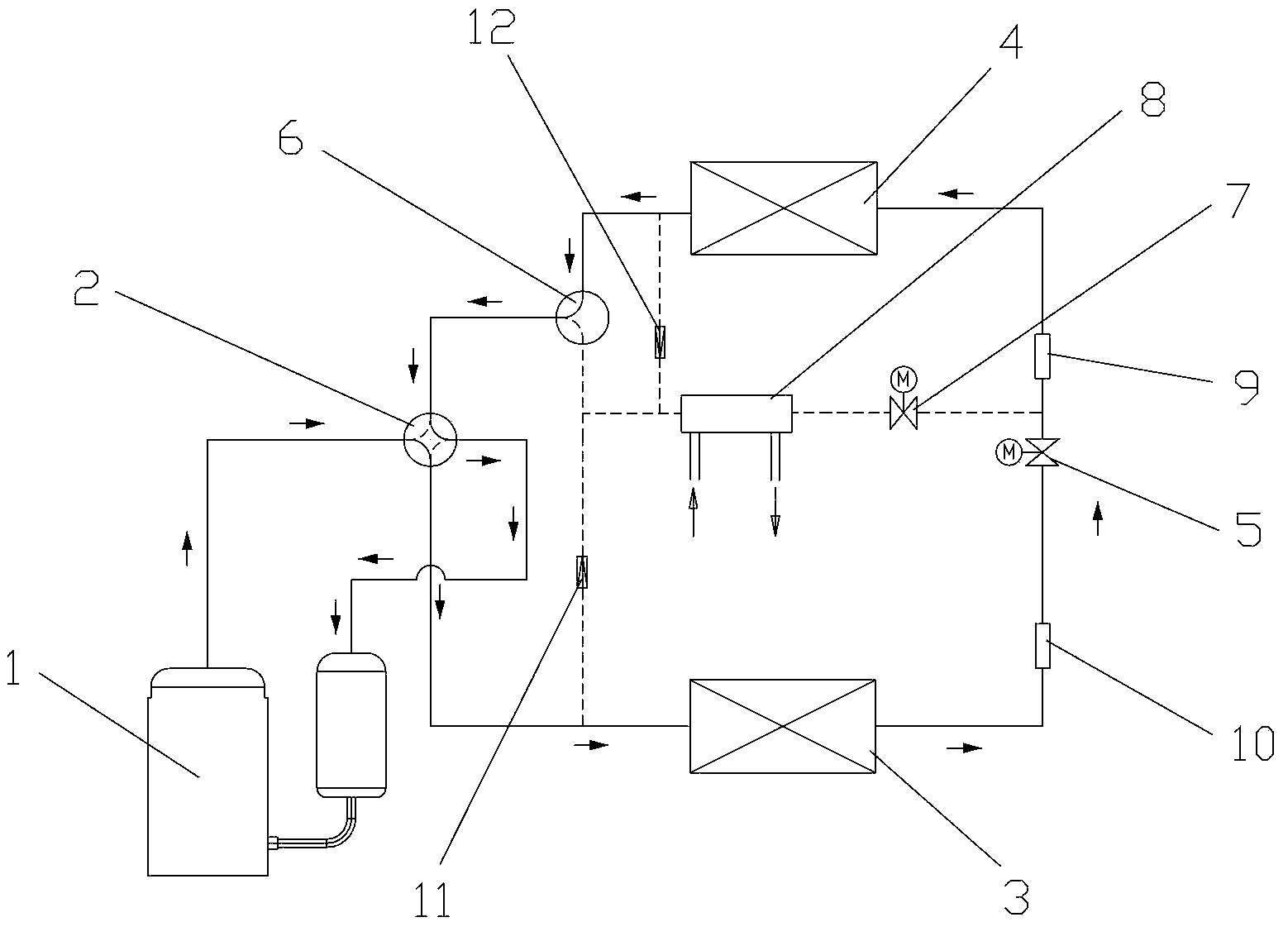

Air conditioner system and control method thereof

ActiveCN103807997AFlexible settingsSmall sizeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorPlate heat exchanger

The invention discloses an air conditioner system and a control method thereof. The air conditioner system comprises an outdoor unit and one or more indoor units connected in parallel; the outdoor unit comprises a compressor, a gas-liquid separator, an oil separator, a four-way valve, an outdoor heat exchanger, an outdoor throttling element and a first cutoff valve; each indoor unit comprises an indoor heat exchanger; the first cutoff valve and the outdoor throttling element are connected in parallel; the air conditioner system also comprises a heat storing heat exchanger provided with a heat absorption heat exchange pipe, a heat releasing heat exchange pipe, a regulation valve and a second cutoff valve; the heat absorption heat exchange pipe and the regulation valve are connected in series to form a serial connection pipeline which is connected with the indoor unit in parallel; the heat releasing heat exchange pipe and the second cutoff valve are connected in parallel and form a parallel connection pipeline which is serially connected onto the pipeline between the gas-liquid separator and the four-way valve. The heat storing heat exchanger of the air conditioner system is flexible in arrangement, fast in defrosting speed, high in comfort level and capable of effectively avoiding the liquid slugging condition during the defrosting operation.

Owner:GREE ELECTRIC APPLIANCES INC

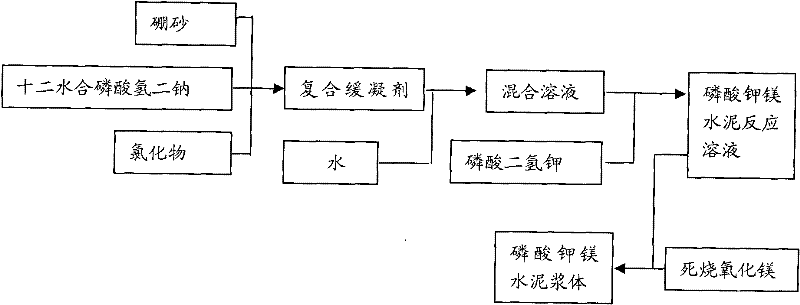

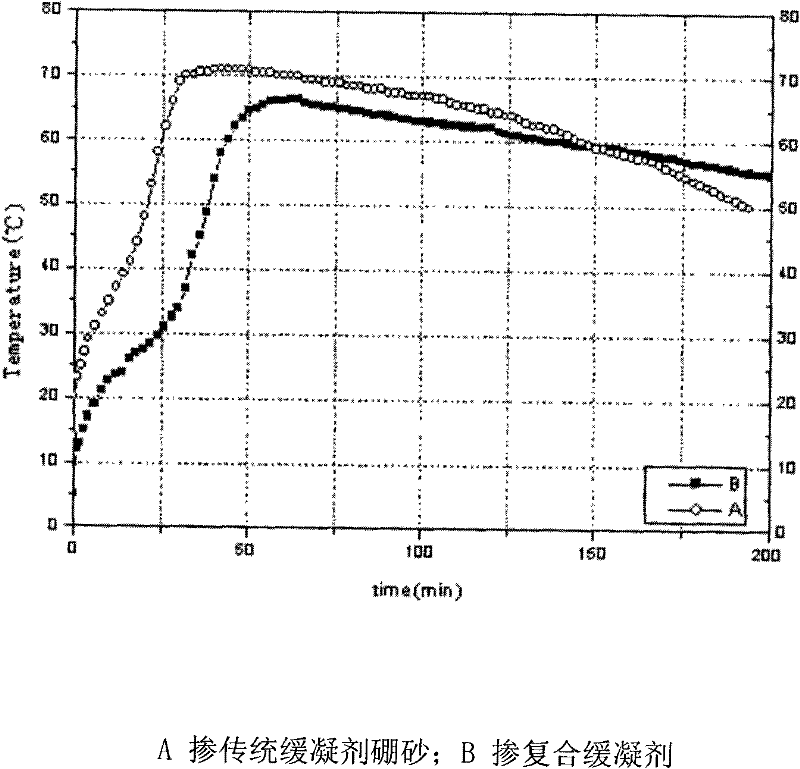

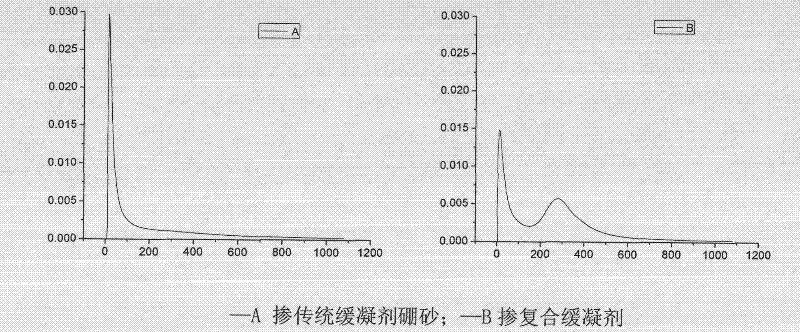

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

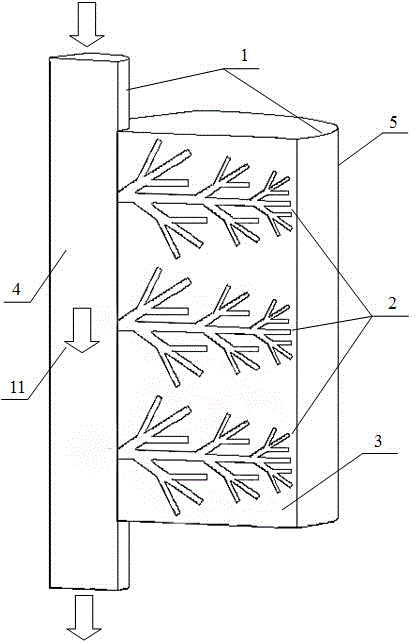

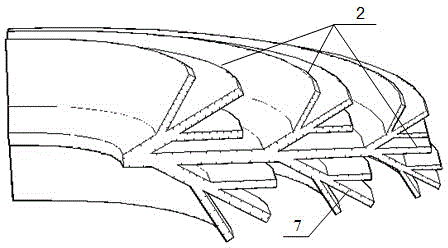

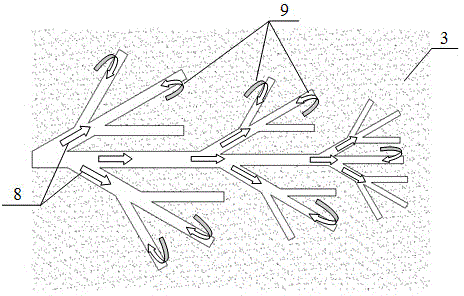

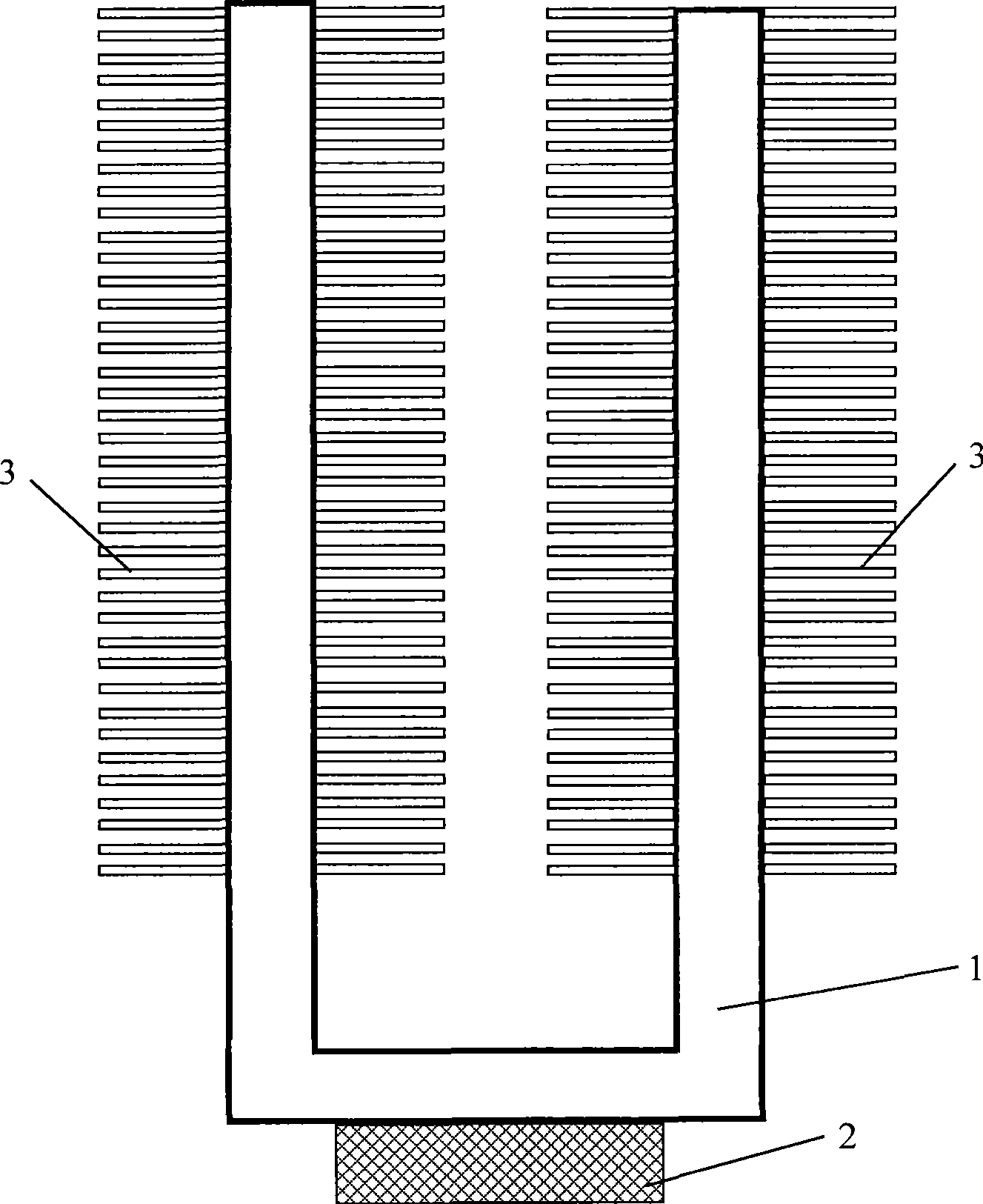

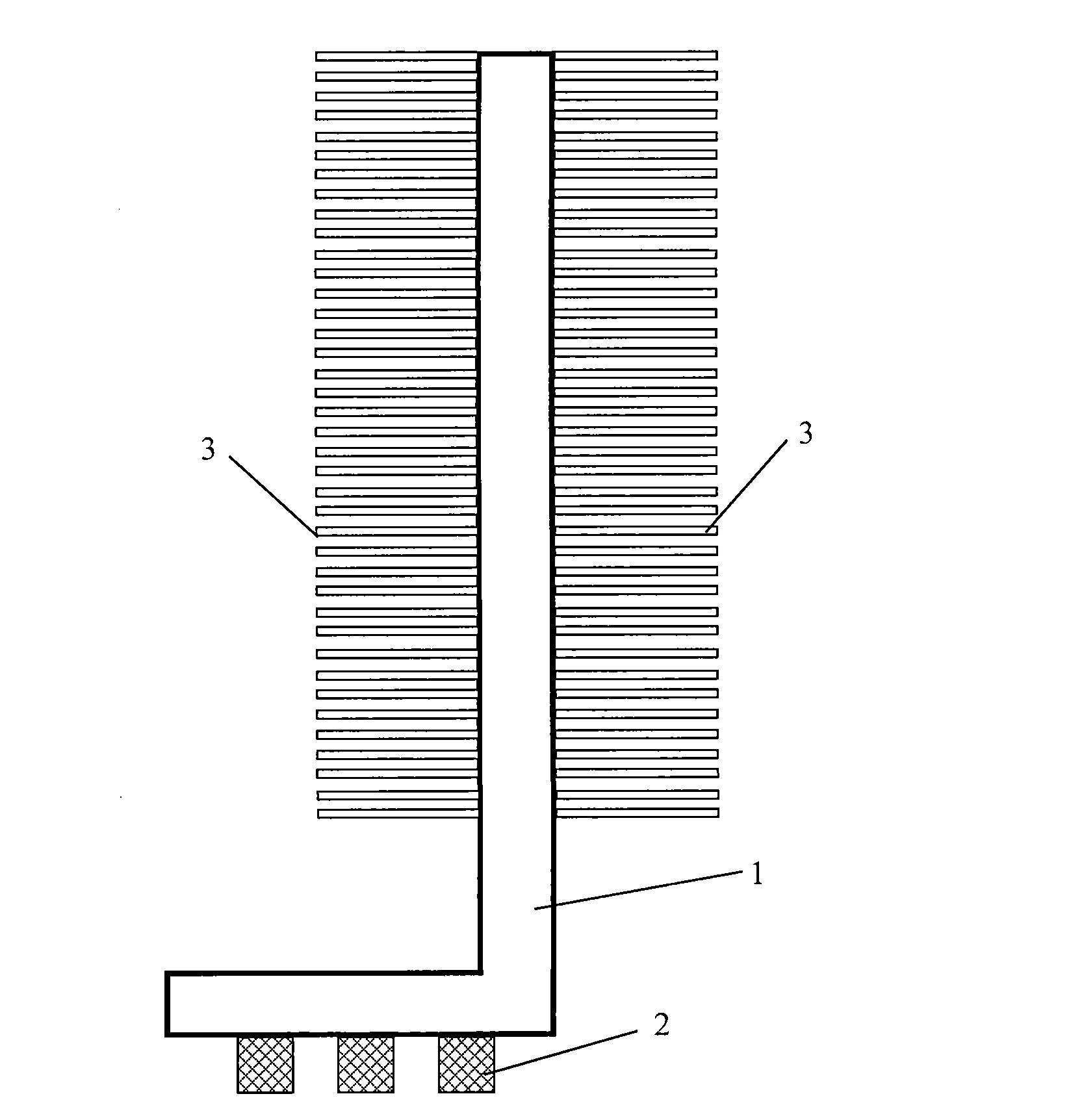

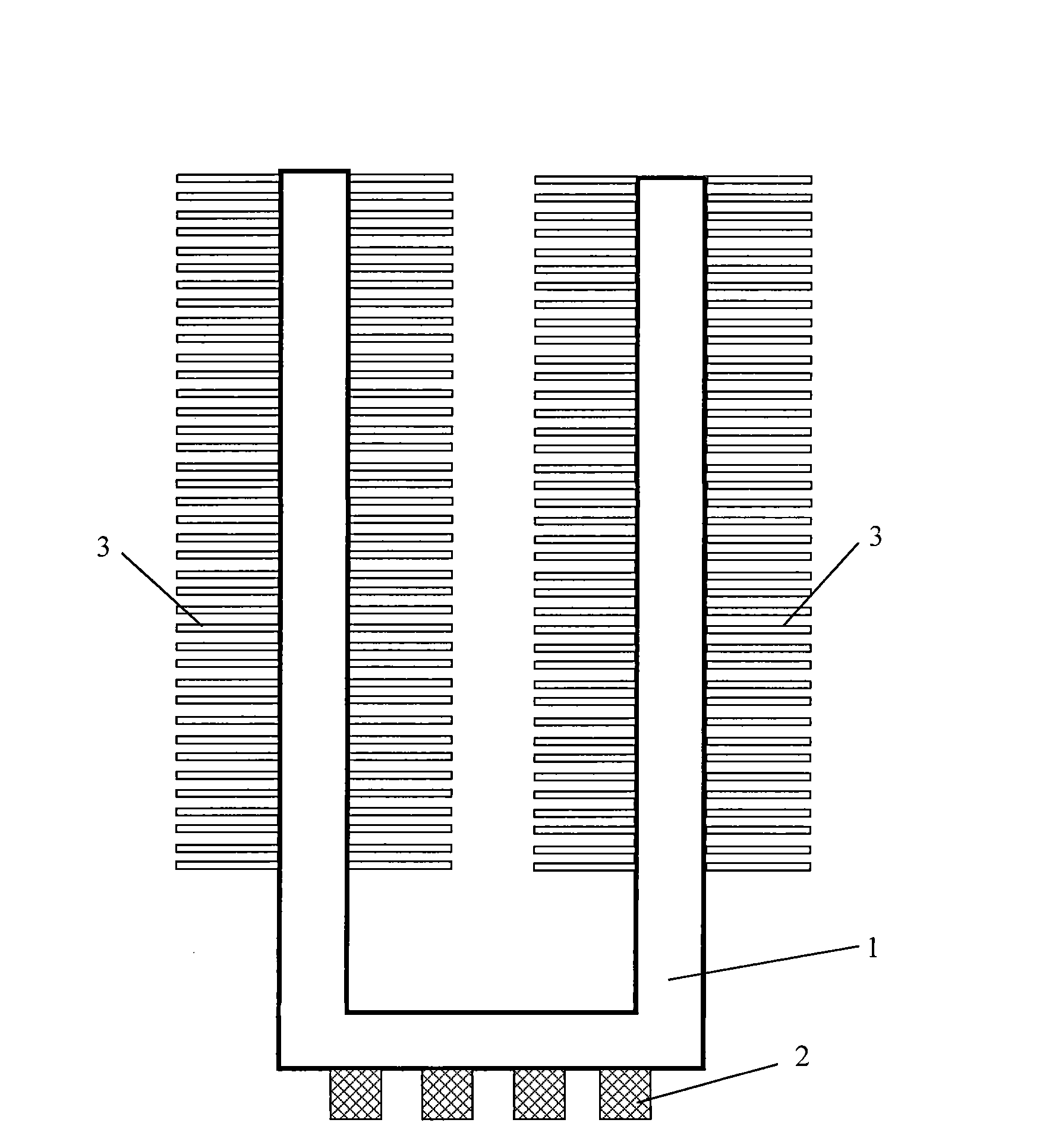

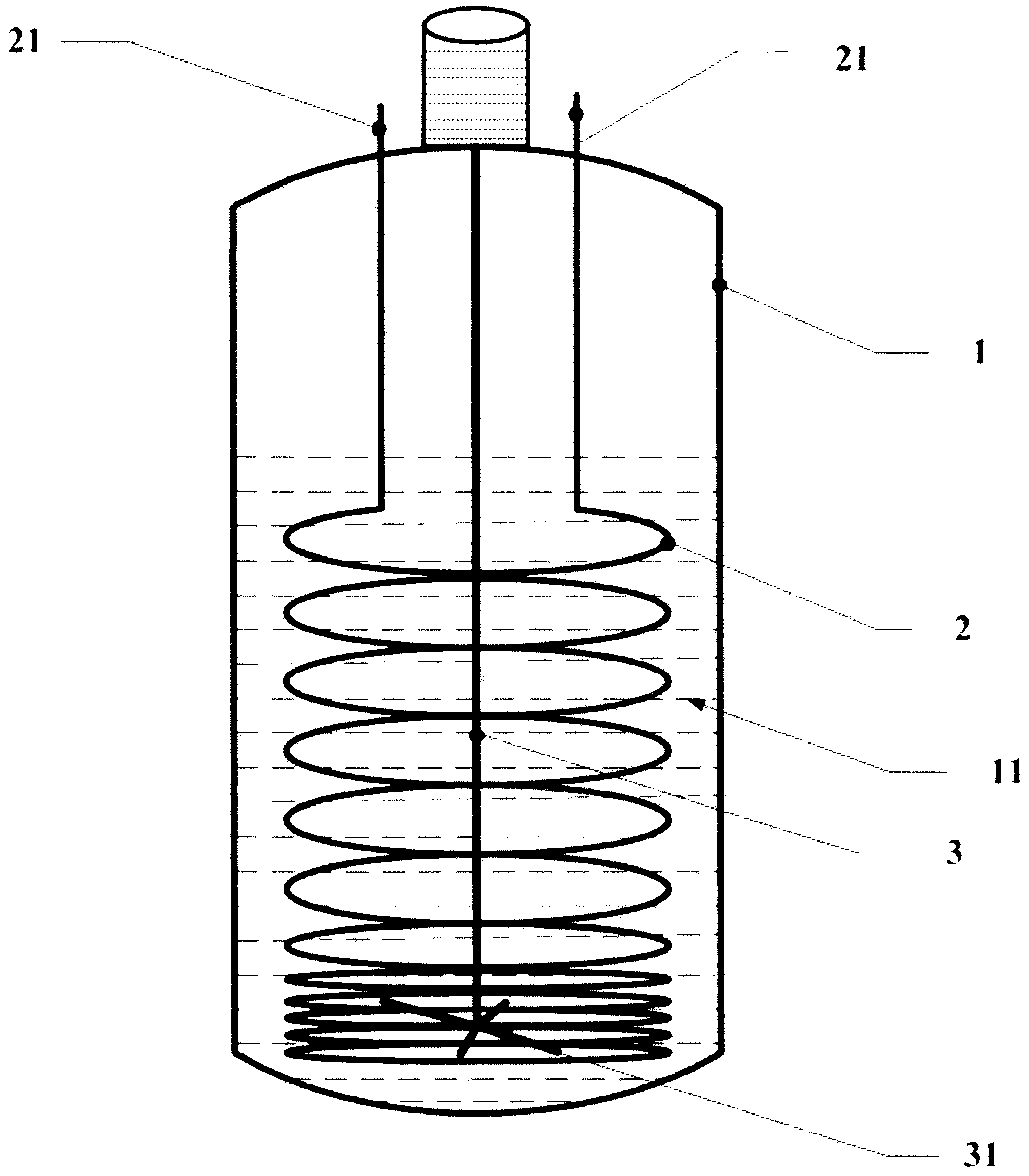

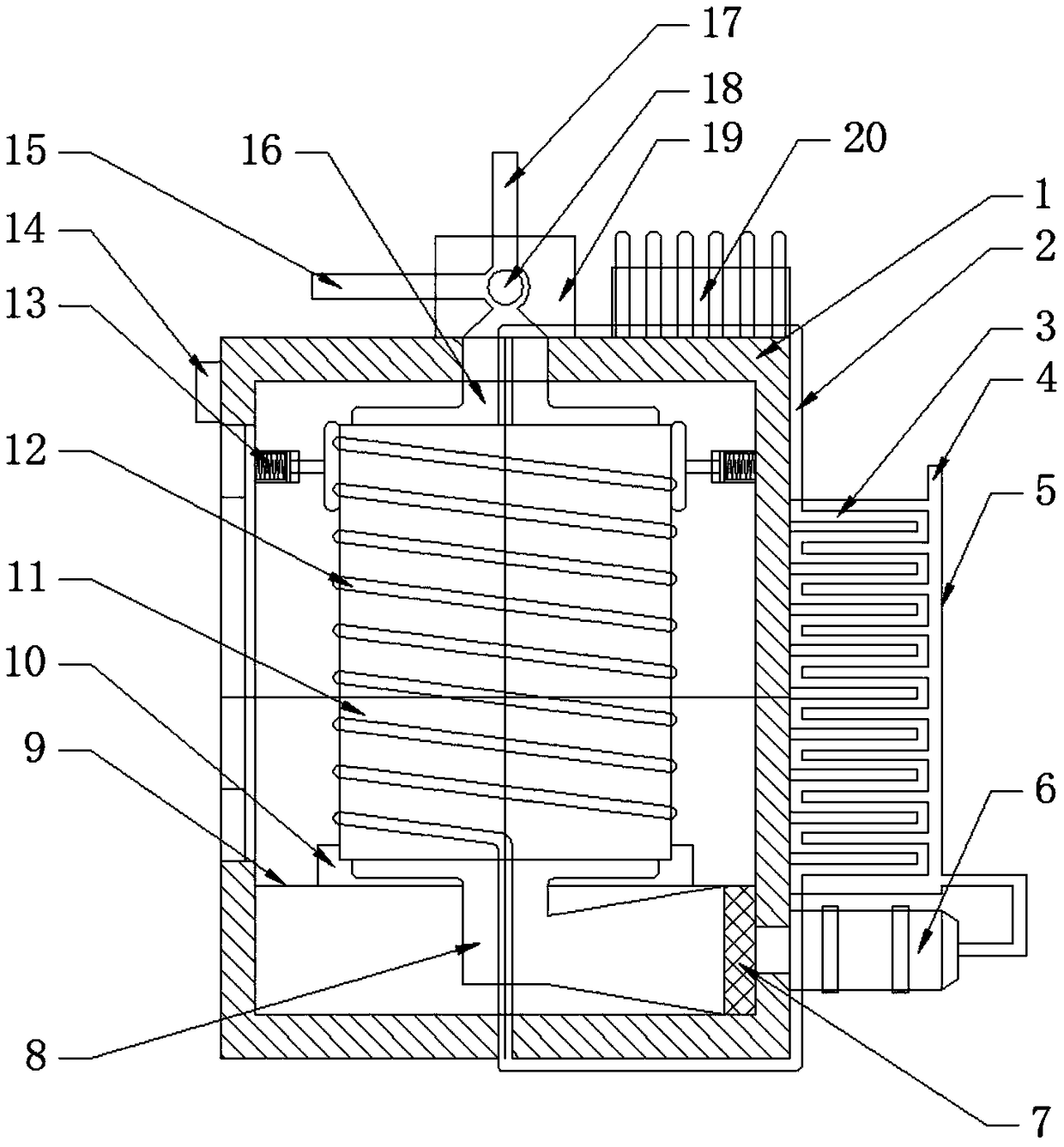

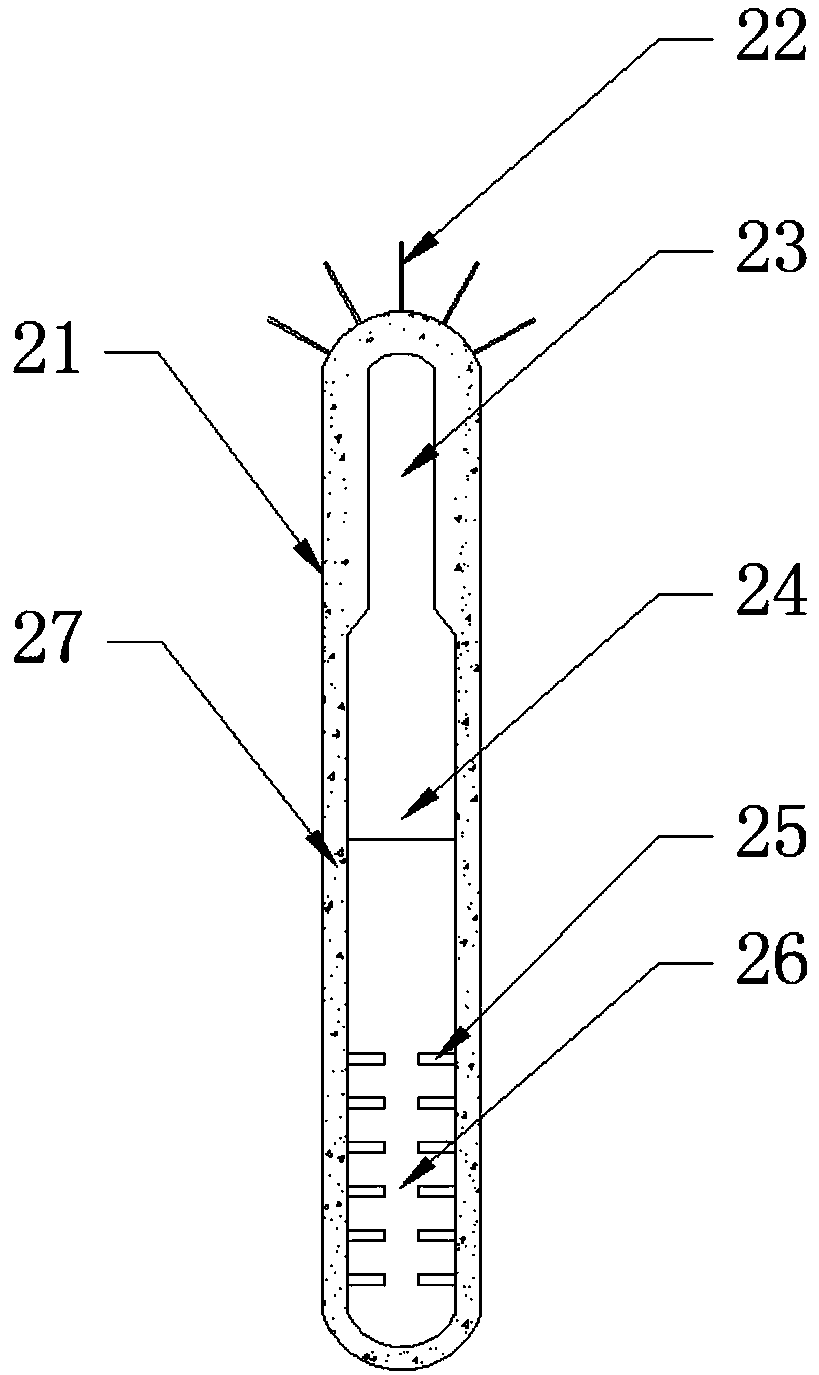

Heat pipe type solid-liquid phase transition heat accumulator

InactiveCN104154788AHigh working reliabilityImprove work efficiencyHeat storage plantsFluid phaseEngineering

The invention discloses a heat pipe type solid-liquid phase transition heat accumulator which comprises a box body, fins, liquid absorbing cores, phase transition heat accumulating materials and working media. The box body comprises a shell and a main channel formed in the shell, the two ends of the main channel are opened, the main channel is not communicated with the shell, the shell is internally provided with the fins and the phase transition heat accumulating materials, the fins are fixed to the main channel, the fins are annularly arranged about a center shaft of the main channel, and are arranged in the axial direction of the main channel in multiple layers, the ribs are of hollow structures, the liquid absorbing cores are attached to the inner walls of the hollow structures, and the spaces in the fins are filled with the working media for heat transferring between heat or cold sources and the phase transition heat accumulating materials through evaporating and condensing. According to the heat pipe type heat accumulator, the fins achieve heat exchange between the heat or cold sources and the solid and liquid phase transition heat accumulating materials through evaporating and condensing of the internal working media, and the working efficiency of the heat accumulator is improved.

Owner:SOUTHEAST UNIV

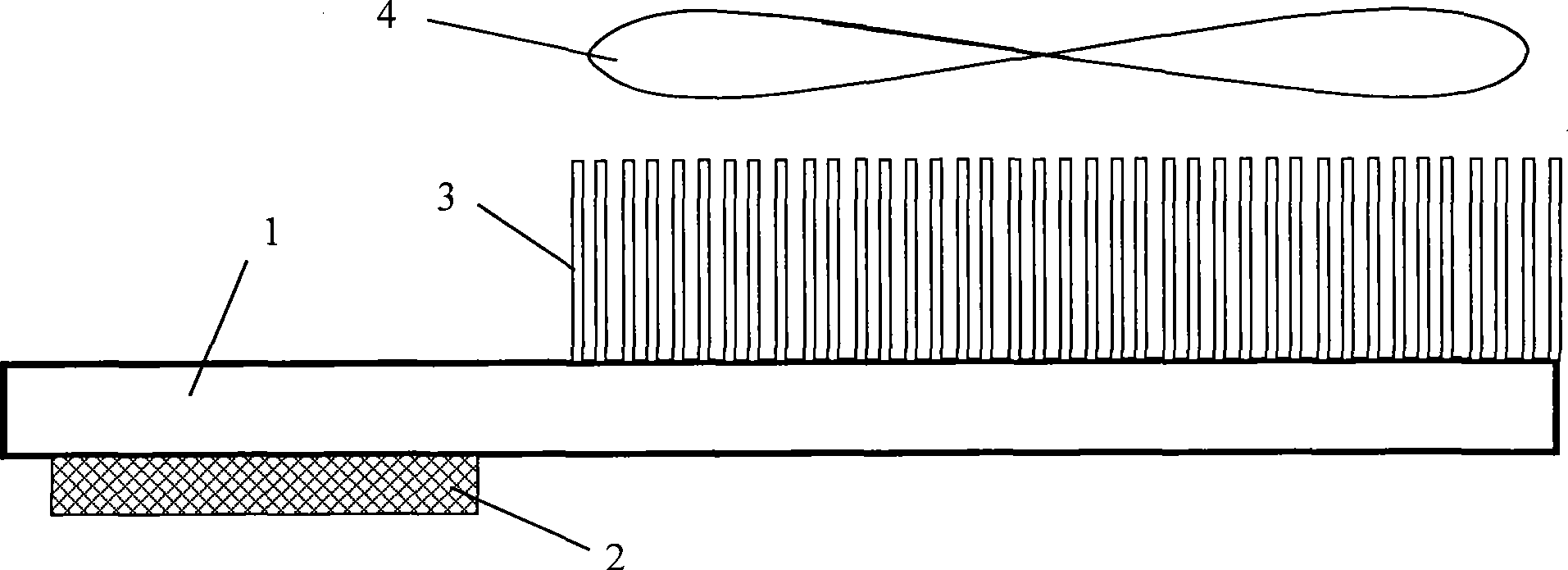

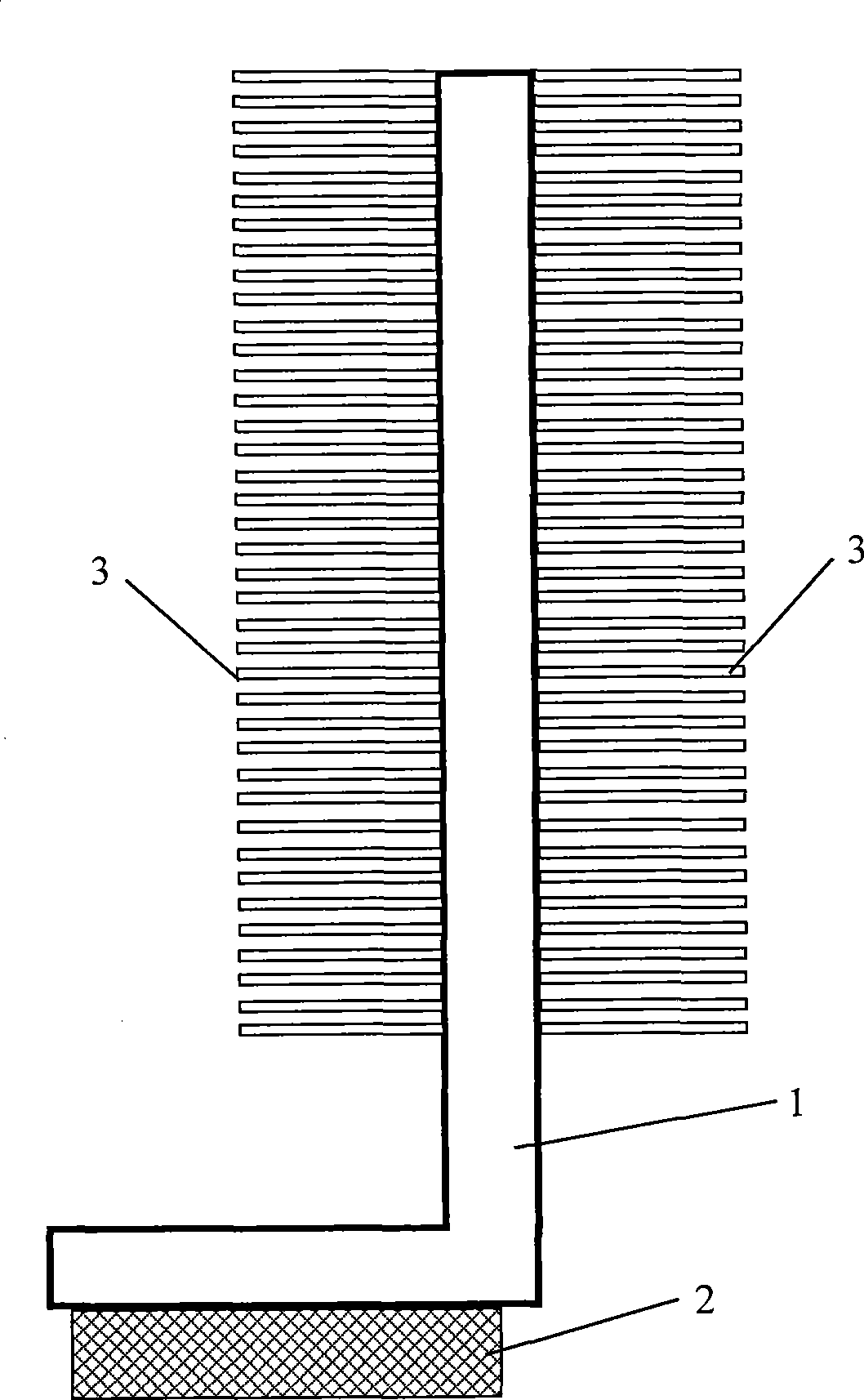

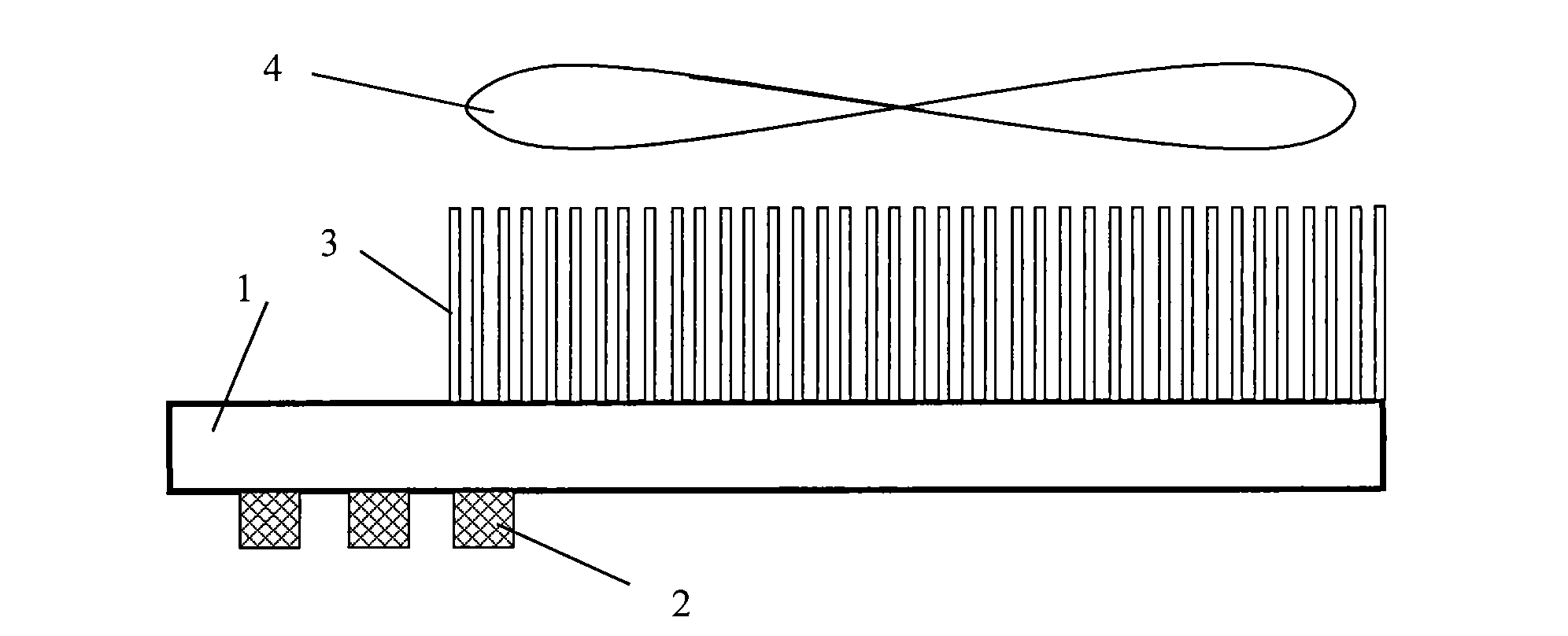

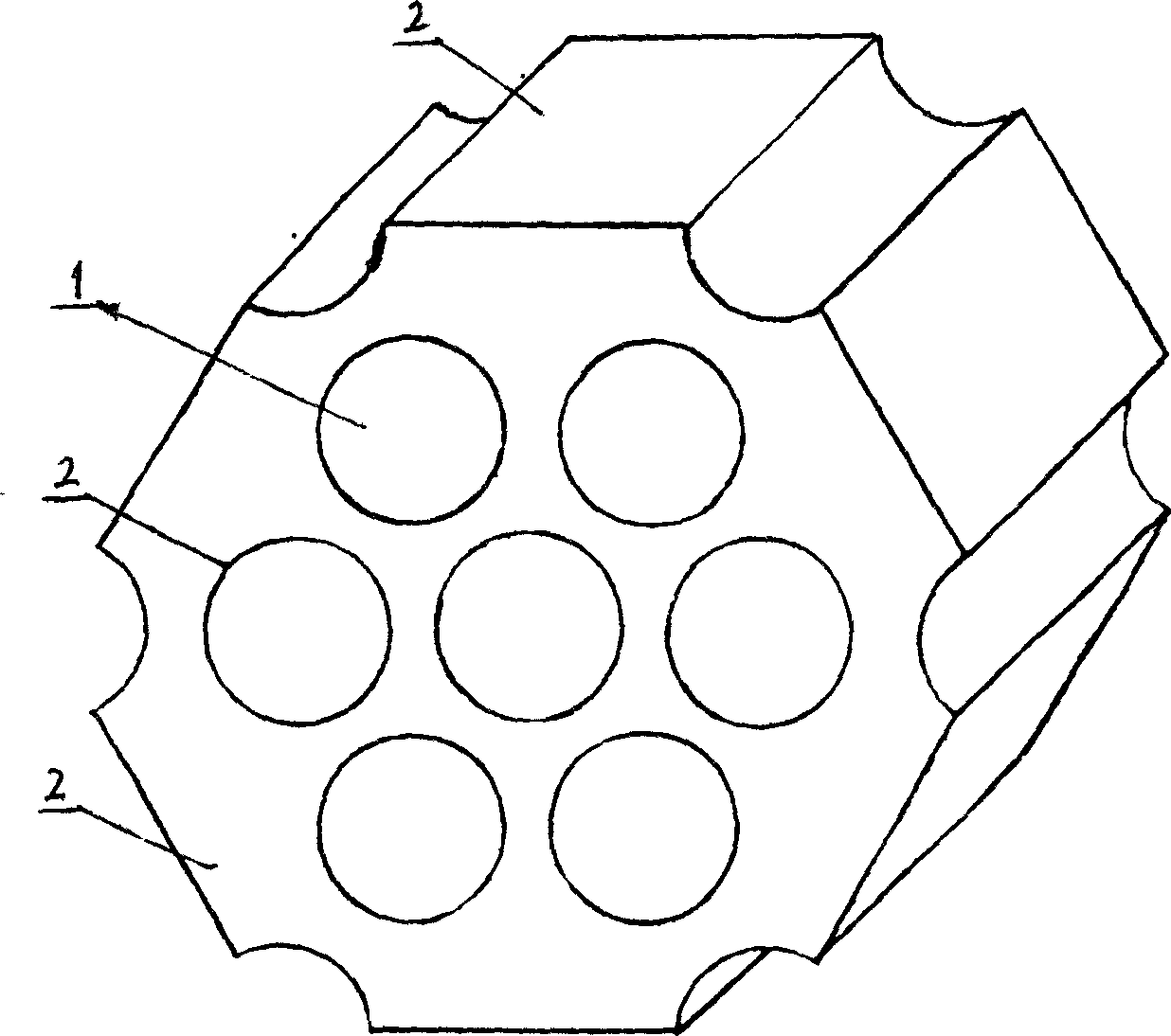

Novel microelectronic device radiator

ActiveCN101510533AImprove heat transfer effectImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesMetalThermal conduction

The invention relates to a novel microelectronic device radiator which comprises a planar heat pipe being two or more through hole array flat plate structures arranged side by side and formed by extrusion or punching of metal materials and the equivalent diameters of through holes range from 0.2mm to 6mm. The through holes are filled with liquid working substance and two ends of the planar heat pipe are encapsulated in a sealing manner; an evaporation section of the planar heat pipe is in surface contact with a heating surface of a microelectronic device and a condensation section of the planar heat pipe eliminates heat through a heat elimination component. The novel microelectronic device radiator overcomes the defects of small contact area between the current round heat pipe and the heating surface of the microelectronic device, large equivalent resistance of heat conduction and complex manufacture technology, and has the advantages of high heat elimination efficiency and simple technology.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

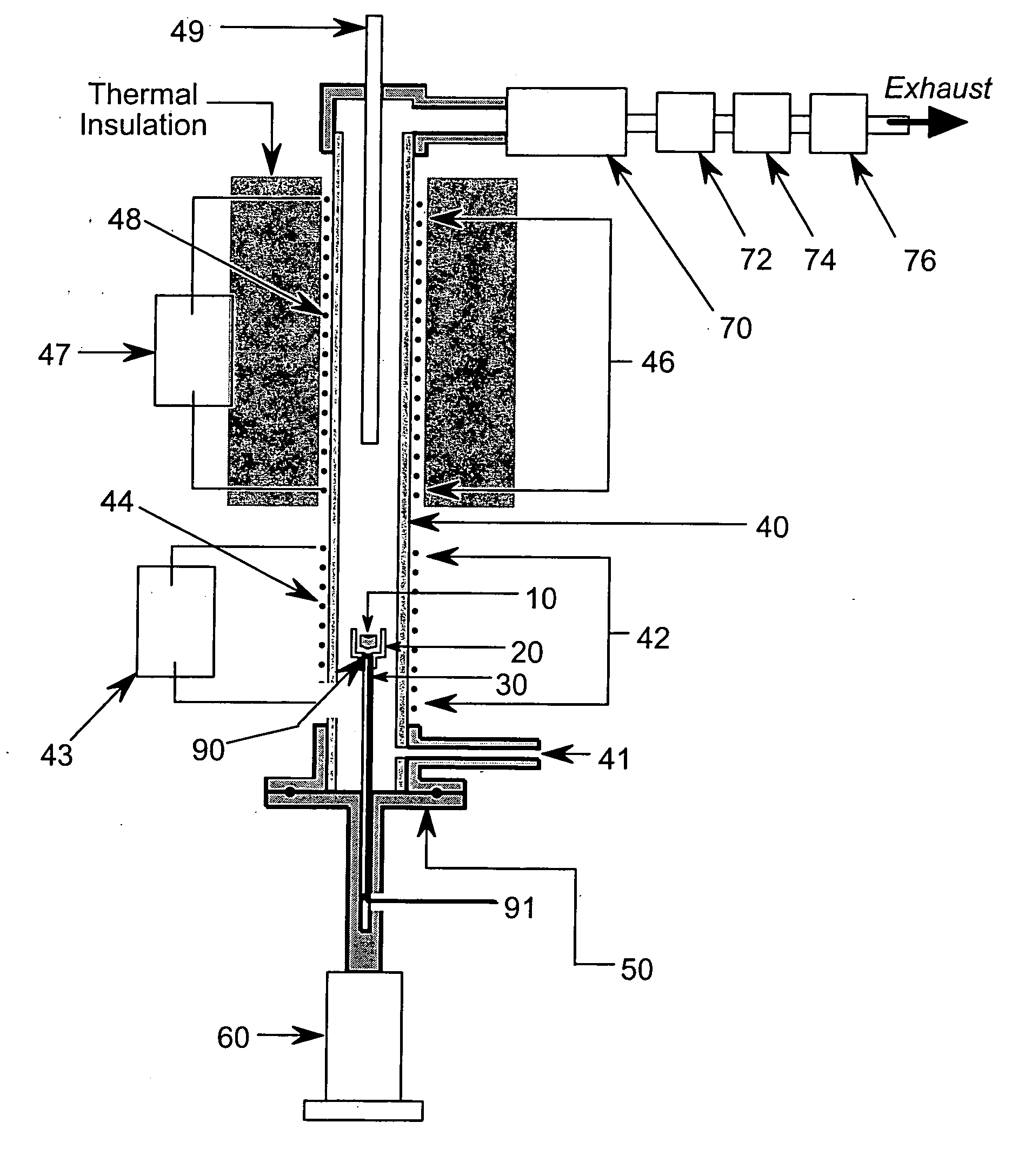

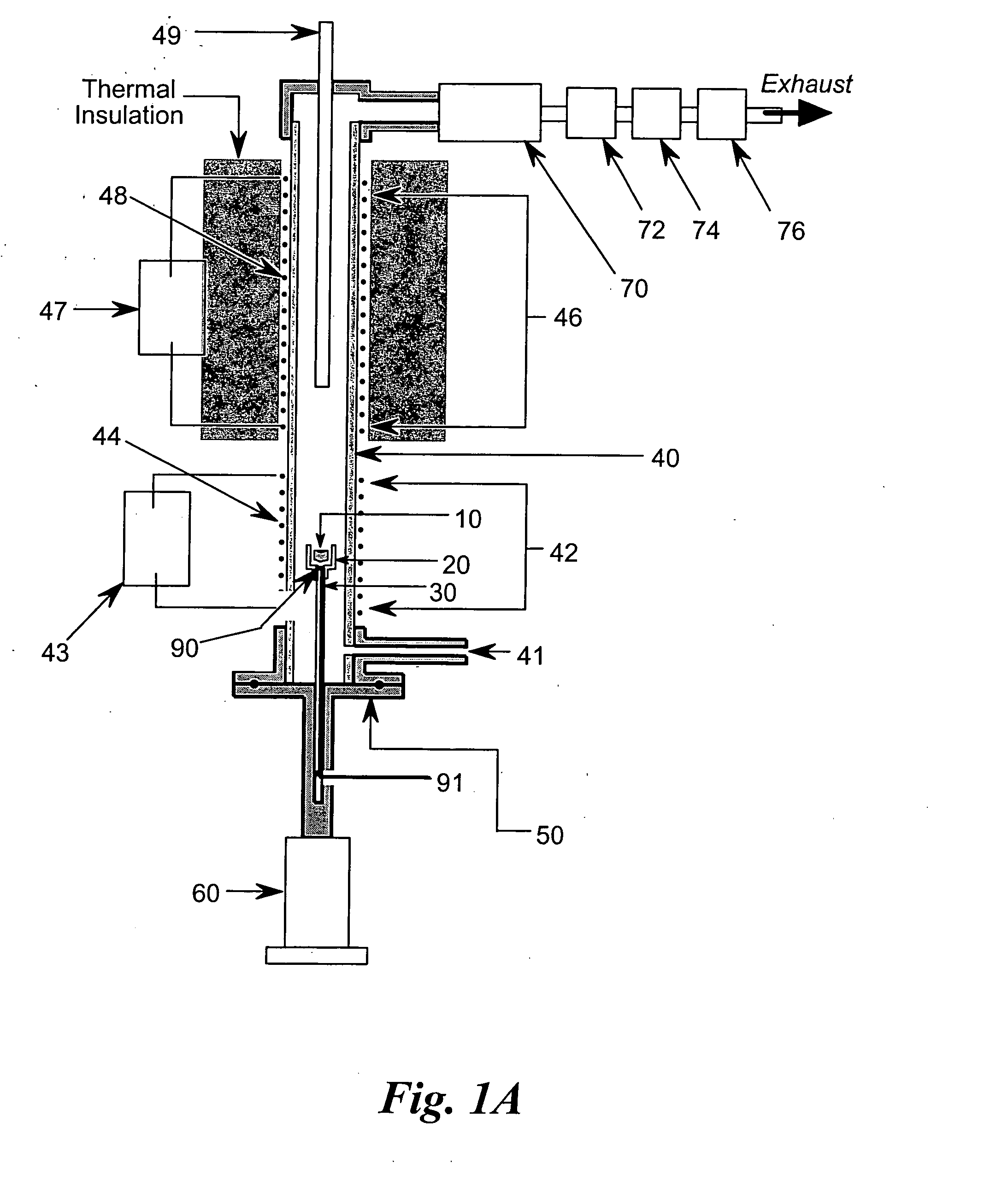

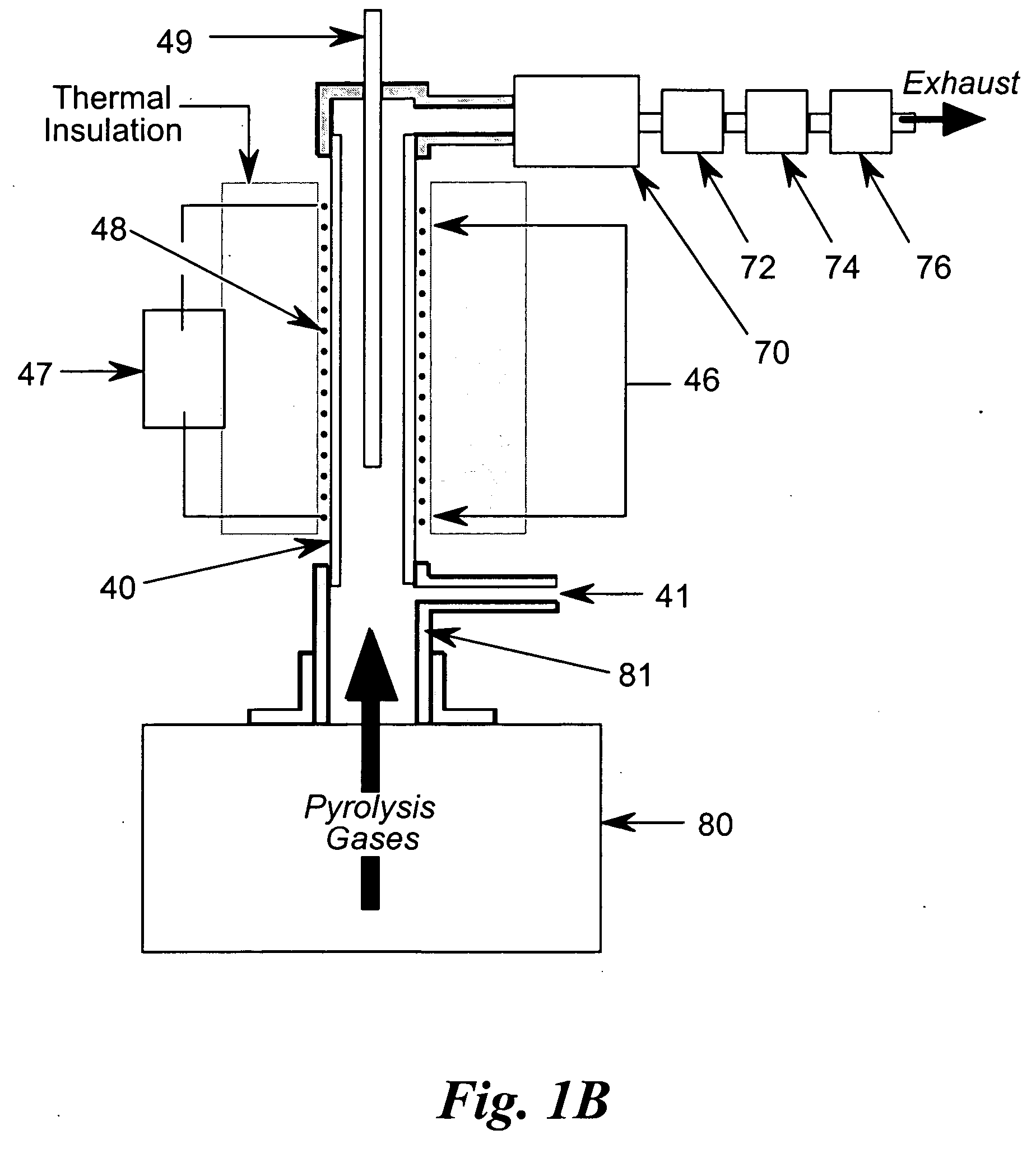

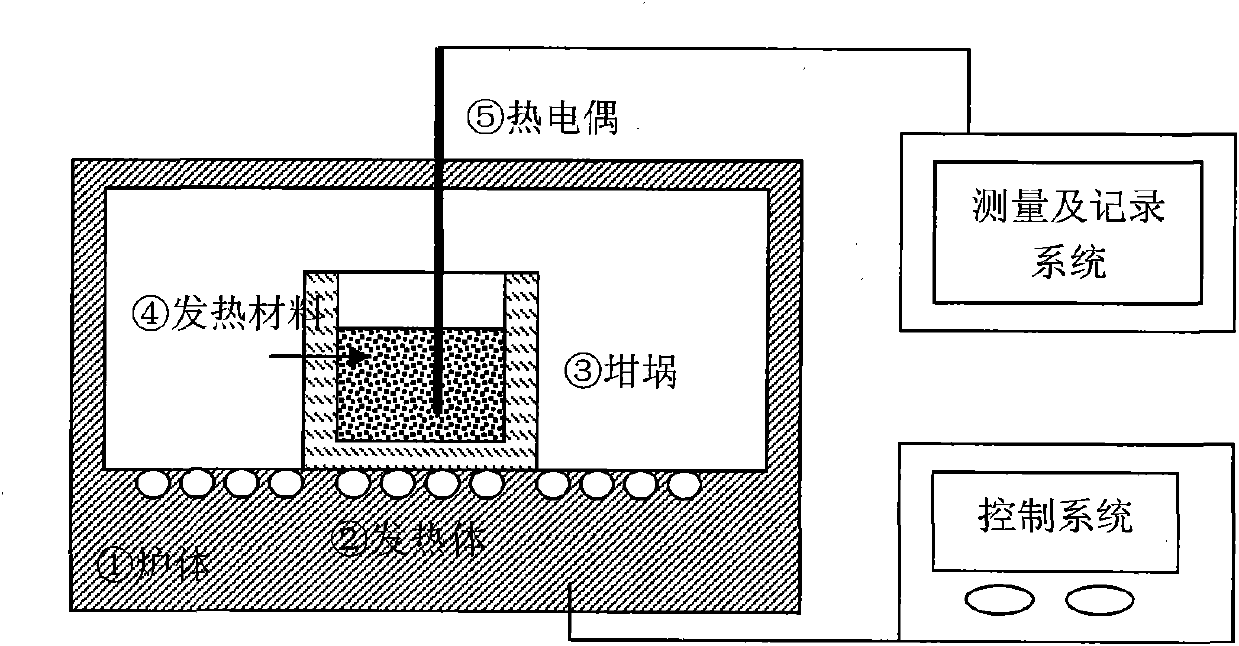

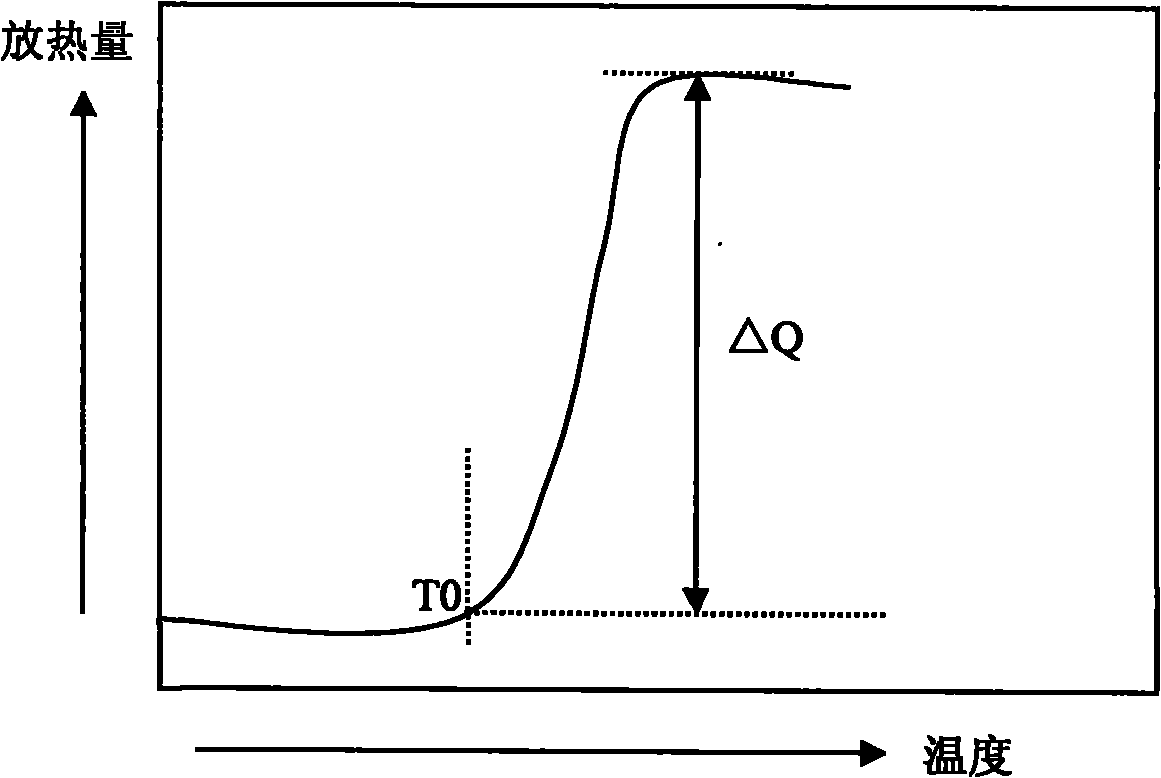

Flammability tester

InactiveUS20060133445A1Measure quickly and accuratelyReduce time availableMaterial thermal analysisLoss rateCombustor

A flammability tester for samples in the milligram range. A tube with a lower pyrolyzing region, or pyrolyzer, contains a sample that is heated to thermally degrade in the absence of oxygen, or pyrolyzed, to produce fuel gases. An inert gas carries the fuel gases to an upper combustion region, or combustor, where oxygen is measured into the gas flow containing the inert gas and fuel gases. Combustion of the fuel gases occurs at a temperature where the reaction time for almost all of the fuel gases is at or below 10 seconds. Under these conditions, the combustor volume need for complete combustion is small, permitting the fuel gases to be oxidized as they are liberated and travel from the pyrolyzer into the combustor in what is essentially sequential flow. Complete combustion in such a small volume produces a large decrease in the oxygen content of the gases emerging from the combustor, allowing the use of a simple inexpensive oxygen analyzer to measure the oxygen content of the gases emerging from the combustor. Oxygen depletion can be used to determine flammability parameters of the sample. The tester can be fitted with a thermometer to measure the combustion temperature of the pyrolyzed sample. The tester may also be configured to use a carbon dioxide analyzer to measure additional flammability parameters. The tester may also be combined with a separate thermogravimetric analyzer to yield further flammability parameters where the mass loss rate of the pyrolyzing sample is needed.

Owner:US DEPT OF TRANSPORTATION

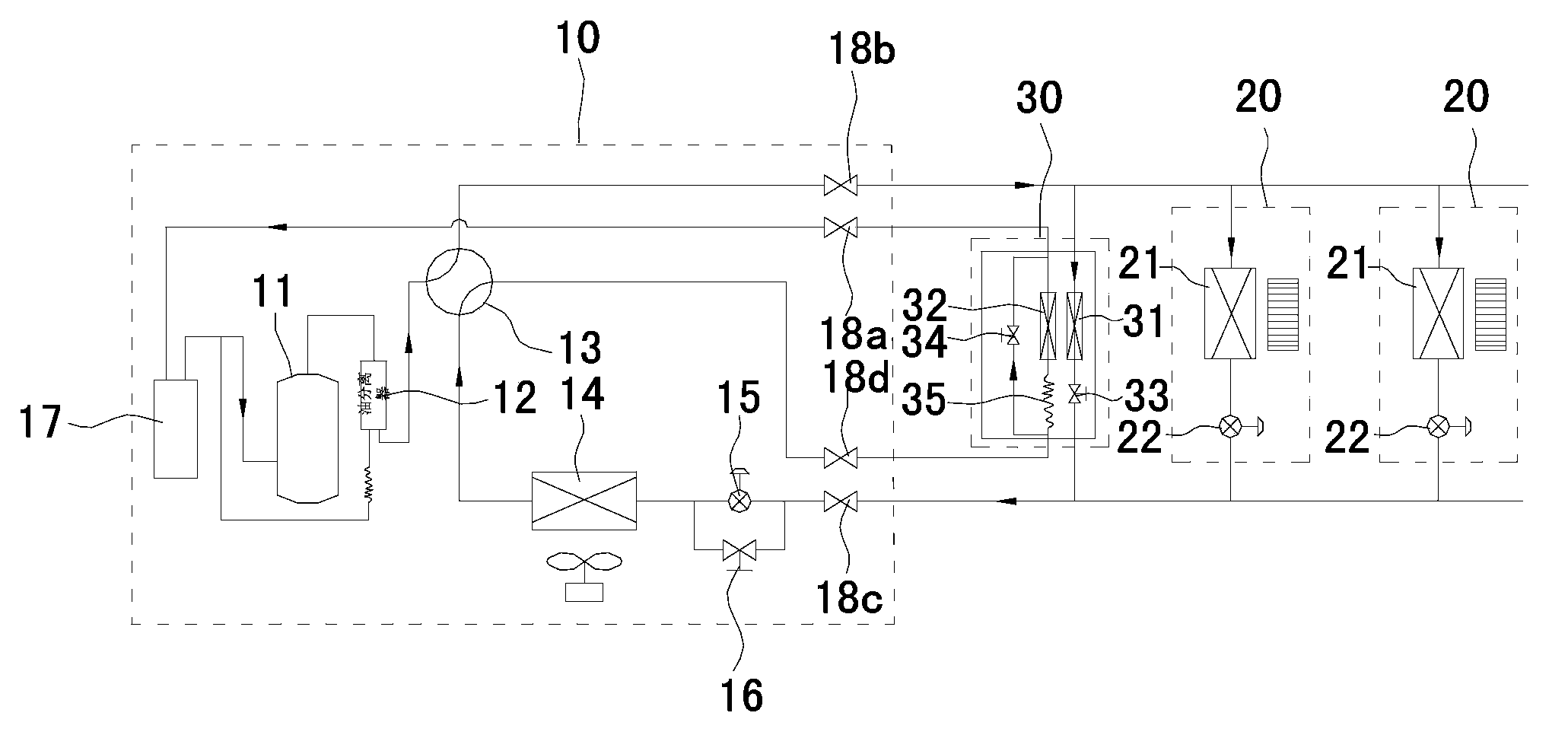

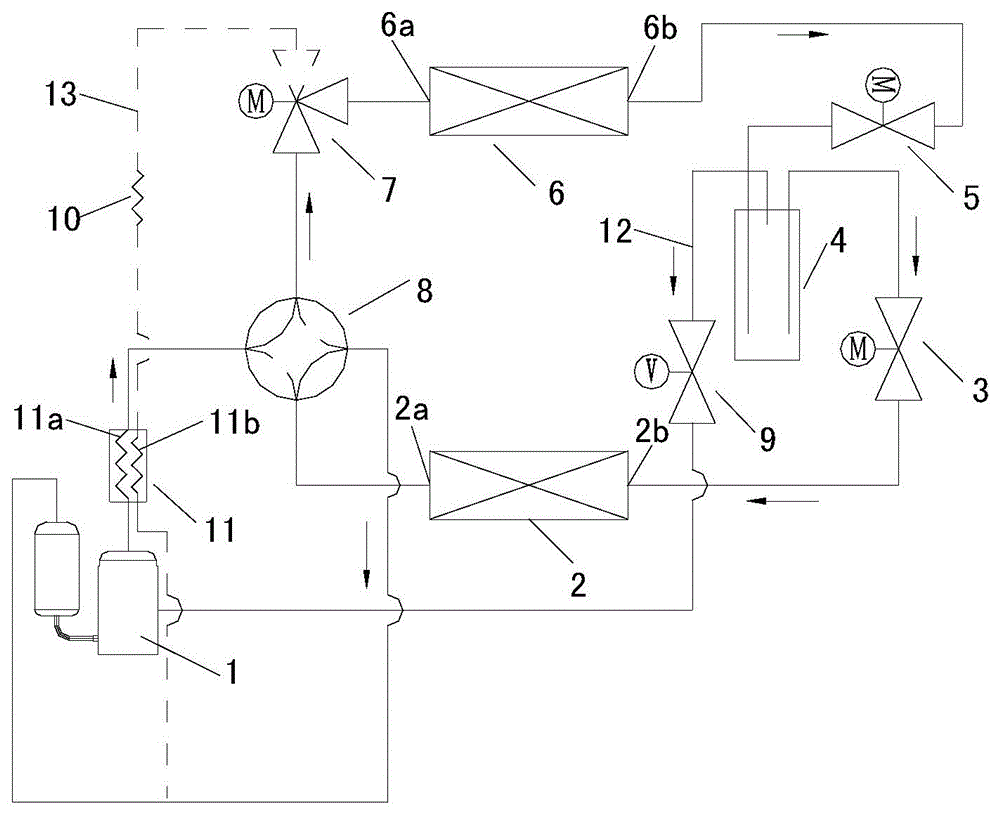

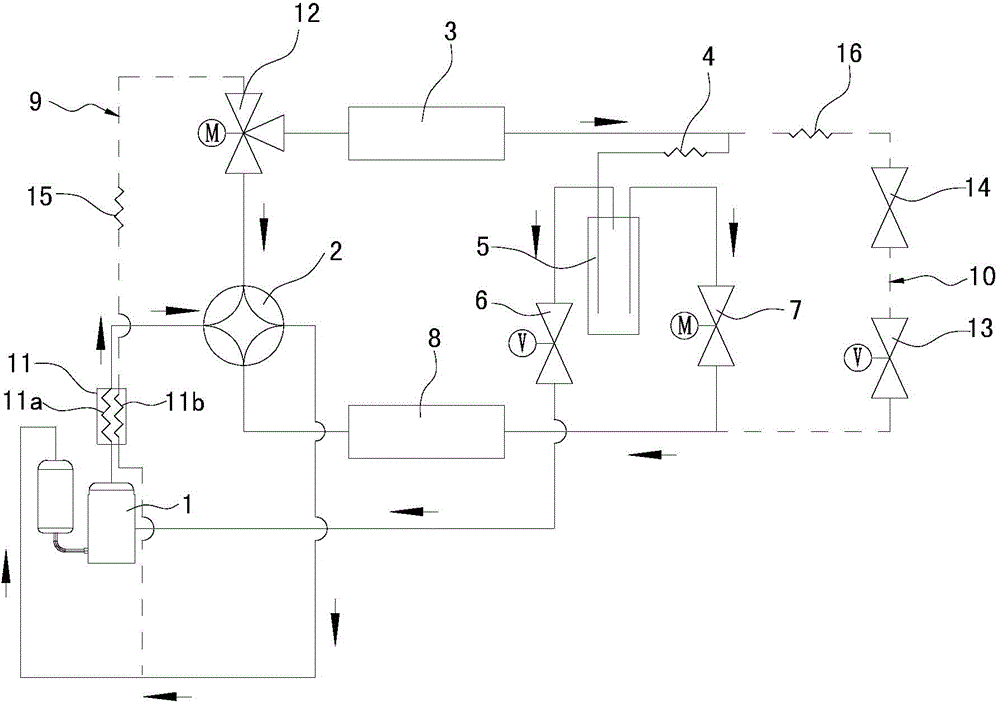

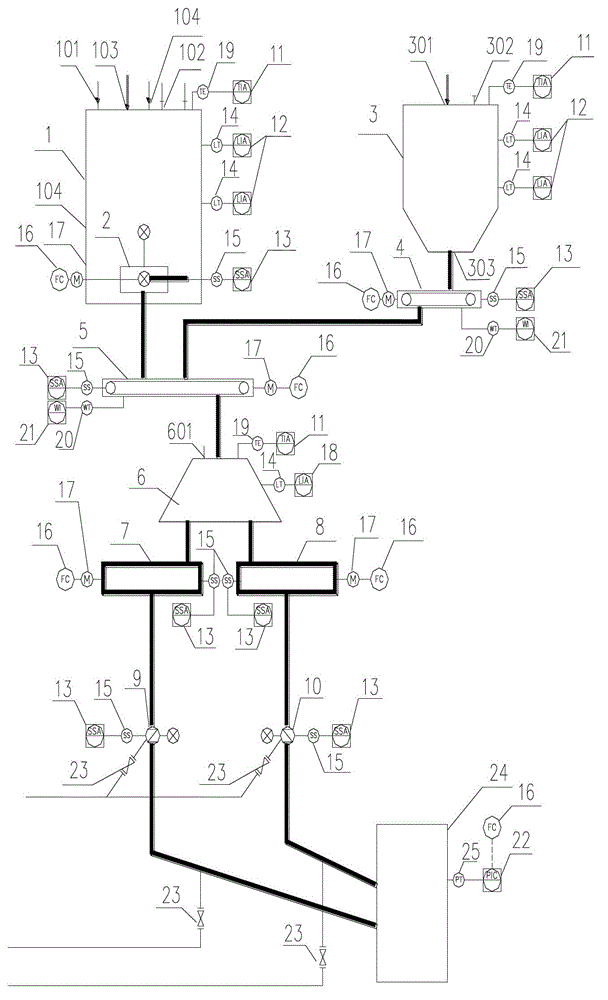

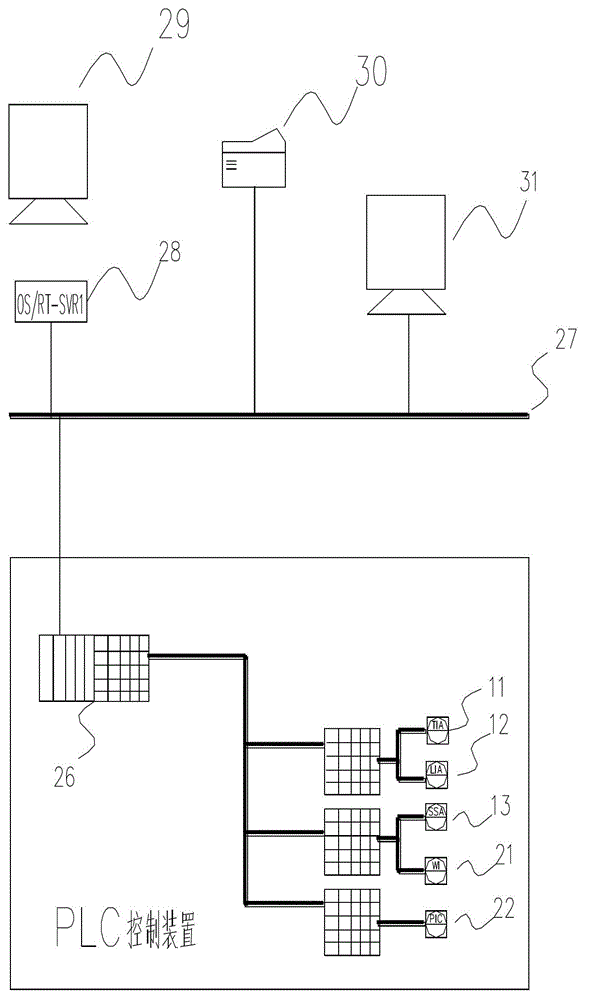

Two-stage compression air conditioner system and control method thereof

ActiveCN104061705AFast heat releaseGuaranteed comfortCorrosion preventionFluid circulation arrangementRefrigerantEvaporator

The invention discloses a two-stage compression air conditioner system and a control method thereof. The air conditioner system comprises a two-stage compressor, a four-way reversing valve, an outdoor heat exchanger, a first throttling device, a flash evaporator, a second throttling device and an indoor heat exchanger, wherein the opening of the first throttling device and the second throttling device is adjustable. The air conditioner system further comprises a bypass pipeline, a heat accumulator and a control valve, wherein the bypass pipeline is connected between a first end interface of the outdoor heat exchanger and an air suction port of the two-stage compressor, a first heat exchange pipe of the heat accumulator is serially connected onto a pipeline between an air exhaust port of the two-stage compressor and a first end interface of the indoor heat exchanger, a second heat exchange pipe of the heat accumulator is serially connected onto the bypass pipeline, and the control valve is used for selectively opening or closing the pipeline between the first end interface of the outdoor heat exchanger and the air suction port of the two-stage compressor and the bypass pipeline. The two-stage compression air conditioner system disclosed by the invention has the advantages that the operating efficiency of the system can be improved; the defrosting speed is fast and refrigerant which is not fully evaporated can be prevented from entering the compressor during defrosting.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

Novel LED and a high-power radiator of a radiating element

ActiveCN101515572AIncrease contact areaImprove heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEvaporation

The invention relates to a novel LED and a high-power radiator of a radiating element, comprising flat plate heat pipes which are of two or more via-hole array flat plate structures arranged side by side; the via-hole array flat plate structures are formed by carrying out extrusion or punch forming on metal materials; the equivalent diameter of the via hole is 0.5-3mm; the via hole is filled with liquid propellant and both ends of the flat plate heat pipes are packaged by sealing; an evaporation section of the flat plate heat pipe contacts heating surfaces of the LED and the high-power radiating element and a condensation section thereof radiates through the radiating element. The novel LED and the high-power radiator of a radiating element overcome the disadvantages that the contact area of the existing circular heat pipes and the heating surfaces of the LED and the high-power radiating element is small, the equivalent resistance of heat conduction is large and the manufacturing process is complex, which have the advantages of high radiating efficiency and simple process.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

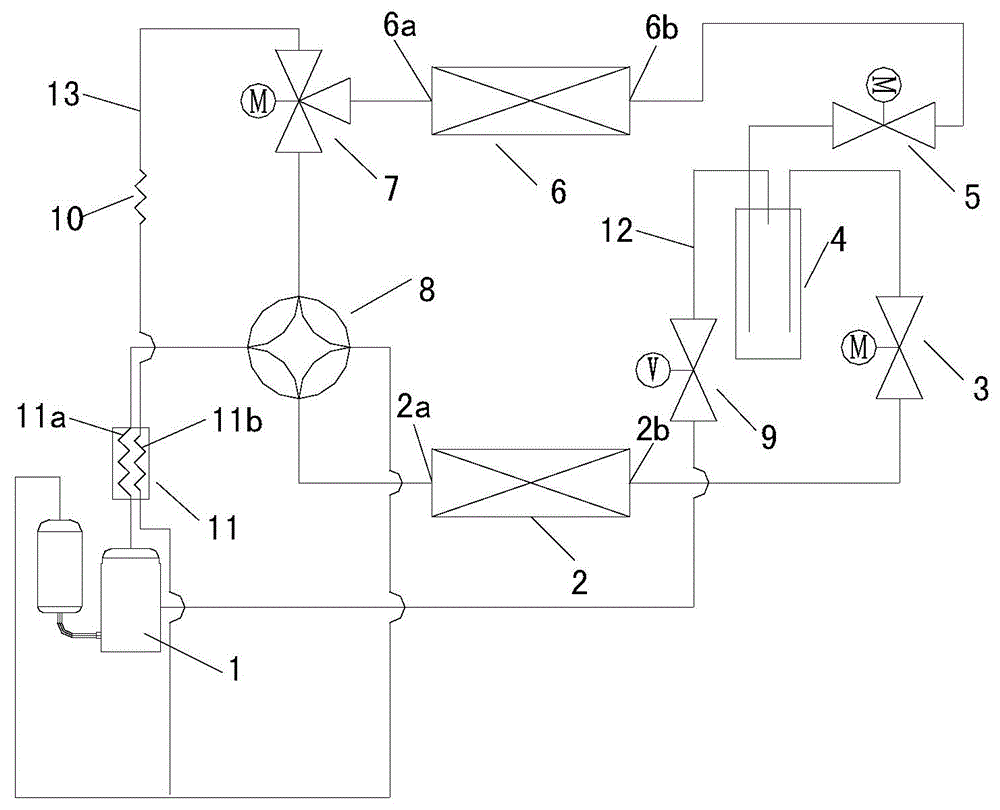

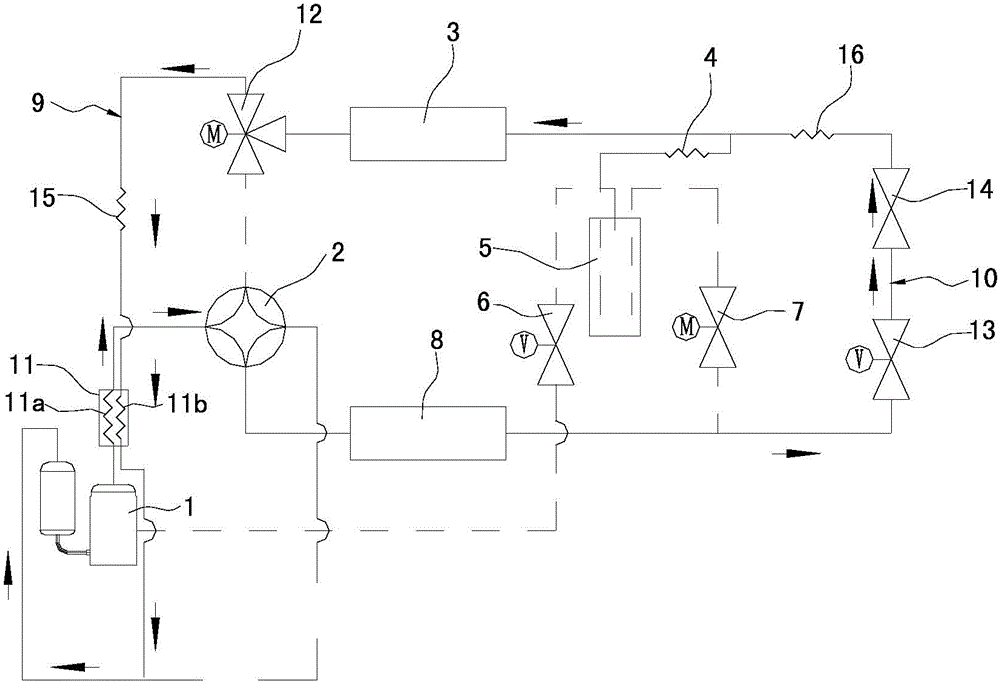

Multifunctional air-conditioning system

ActiveCN103574968AFast heat releaseSimple structureMechanical apparatusCorrosion preventionFour-way valveEngineering

The invention provides a multifunctional air-conditioning system which comprises a main air-conditioning loop, wherein the main air-conditioning loop is composed of a compressor, a four-way valve, an indoor heat exchanger, a first expansion device and an outdoor heat exchanger which are connected in turn through a coolant pipeline; the multifunctional air-conditioning system is characterized by further comprising a thermal storage loop and a switching control valve set which is used for controlling the switch-on / off of the coolant pipeline between the four-way valve and the indoor heat exchanger and between the outdoor heat exchanger and the thermal storage loop; the thermal storage loop comprises a thermal storage box; the thermal storage box comprises a shell, a thermal storage material arranged in the shell, a cold water inlet and a hot water outlet. The multifunctional air-conditioning system has a simple structure, can easily achieve a high-efficient hot water making effect, is easily applied and popularized in the domestic field and can reduce the space occupation.

Owner:GREE ELECTRIC APPLIANCES INC

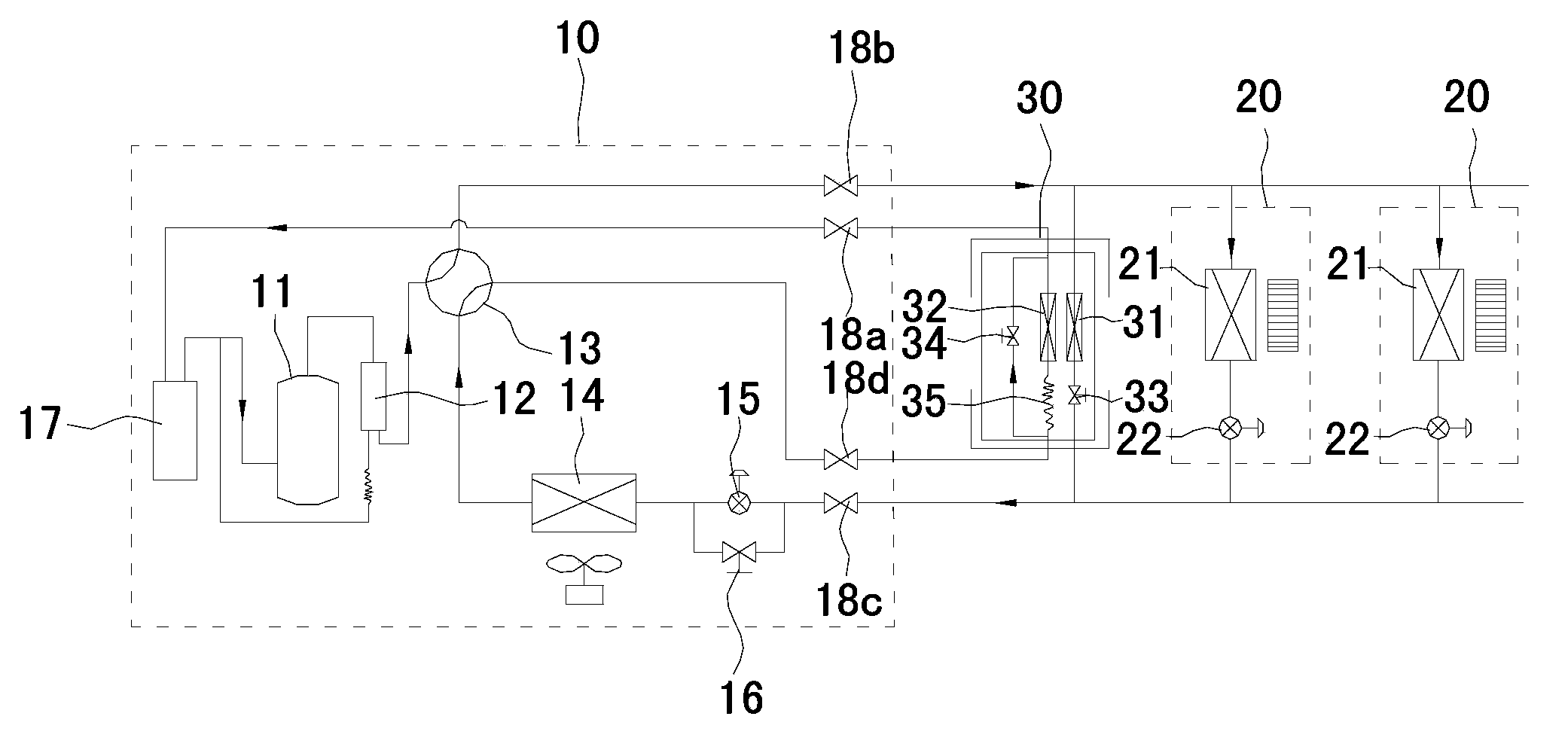

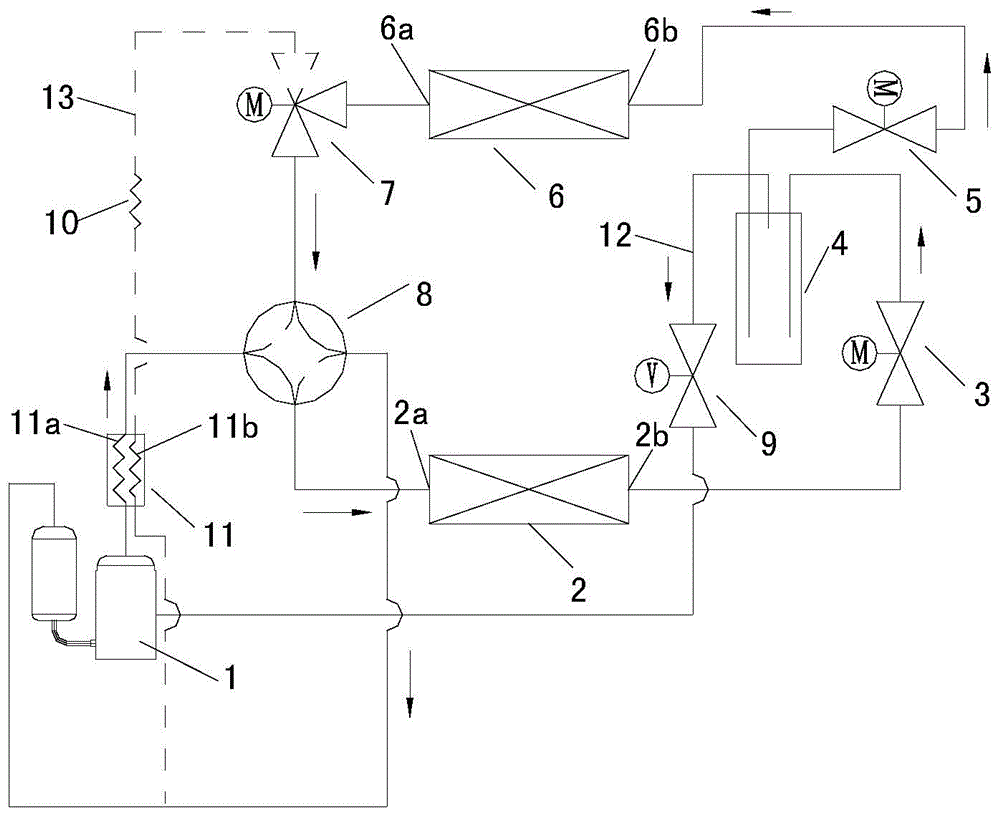

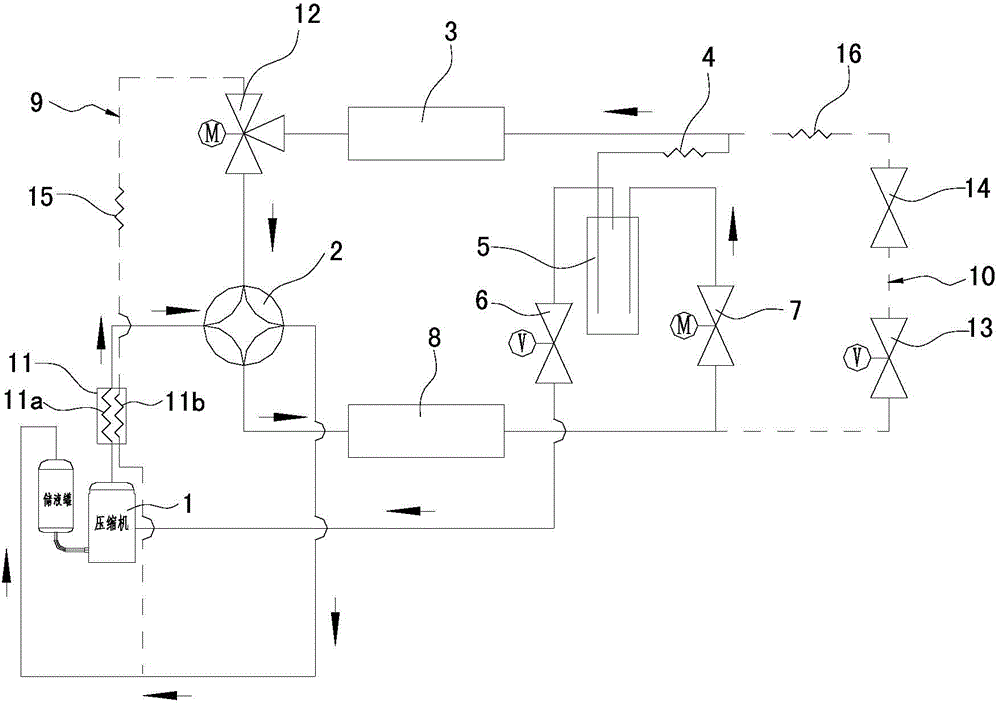

Two-stage compression air conditioning system with defrosting function

ActiveCN103983037AFast heat releaseGuaranteed comfortCorrosion preventionFluid circulation arrangementEngineeringControl valves

The invention relates to a two-stage compression air conditioning system with a defrosting function. The two-stage compression air conditioning system with the defrosting function comprises a two-stage compressor, a four-way reversing valve, an outdoor heat exchanger, a first throttling device, a flash evaporator, a second throttling device and an indoor heat exchanger, and also comprises a first bypass pipeline, a heat accumulator and a control valve, wherein the first bypass pipeline is connected between the first end of the outdoor heat exchanger and an air suction opening of the two-stage compressor, the heat accumulator is provided with a first heat exchange pipe and a second heat exchange pipe, the first heat exchange pipe is connected in series onto a pipeline arranged between an exhaust opening of the two-stage compressor and the first end of the indoor heat exchanger, the second heat exchange pipe is connected in series onto the first bypass pipeline, and the control valve is used for controlling coolants to flow back to the air suction opening of the two-stage compressor through the first bypass pipeline or a pipeline arranged between the first end of the outdoor heat exchanger and the air suction opening of the two-stage compressor. The two-stage compression air conditioning system with the defrosting function has the advantages that the defrosting speed is high, the defrosting time is short, the use comfort of users can be ensured, and in addition, the adverse influence on the compressor caused during the defrosting can be avoided.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

Efficiency and emissions improvements for natural gas conversions of emd 2-cycle medium speed engines

InactiveUS20160003117A1Avoid excessive distanceReduce the impactLiquid coolingInternal combustion piston enginesCylinder headEngineering

A prechamber assembly includes a cylinder head including a coolant cavity, a prechamber body located within the cylinder head, the prechamber body including a nozzle, and an annular sleeve radially surrounding a portion of the prechamber body. The sleeve includes a plurality of coolant inlet holes. A portion of the prechamber body is radially spaced from the sleeve to form a coolant sleeve annulus extending along a length of the prechamber body above the coolant inlet holes. The coolant cavity and the coolant sleeve annulus are in fluid communication through the plurality of coolant inlet holes.

Owner:RAIL PROPULSION SYSTEMS LLC

Deep desulfurizer for refining ultra-low-carbon steel and manufacturing method thereof

The invention discloses an ultralow carbon steel refining deep-desulfurizer and making method, which comprises the following parts: 60%-69% CaO, 11%-20% Al, 5%-10% MgO, 5%-10% SiO2, 1%-5% Al2O3, 0.5%-1.2% Fe2O3, 1%-3% CaF2, 1%-3% B2O3, 1%-3% BaO and impurity. The making technique comprises the following steps: blending; grinding the material with grain size not more than 1mm; inactivating the material; drying; draining the trace element of water; packing.

Owner:ANGANG STEEL CO LTD

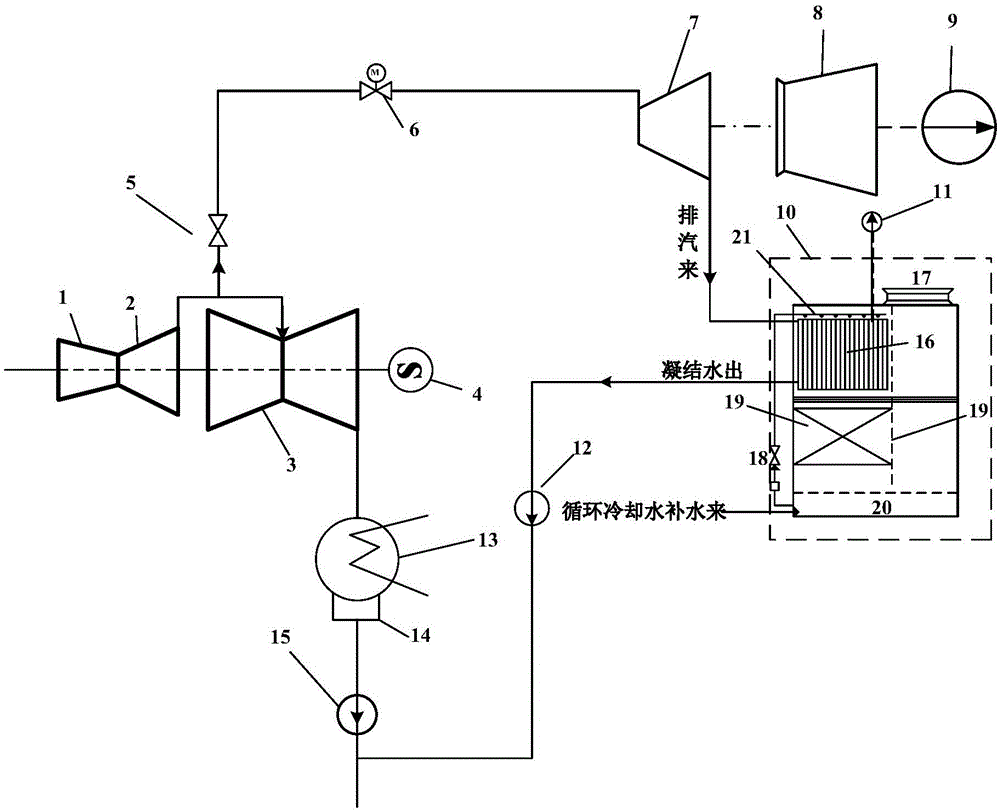

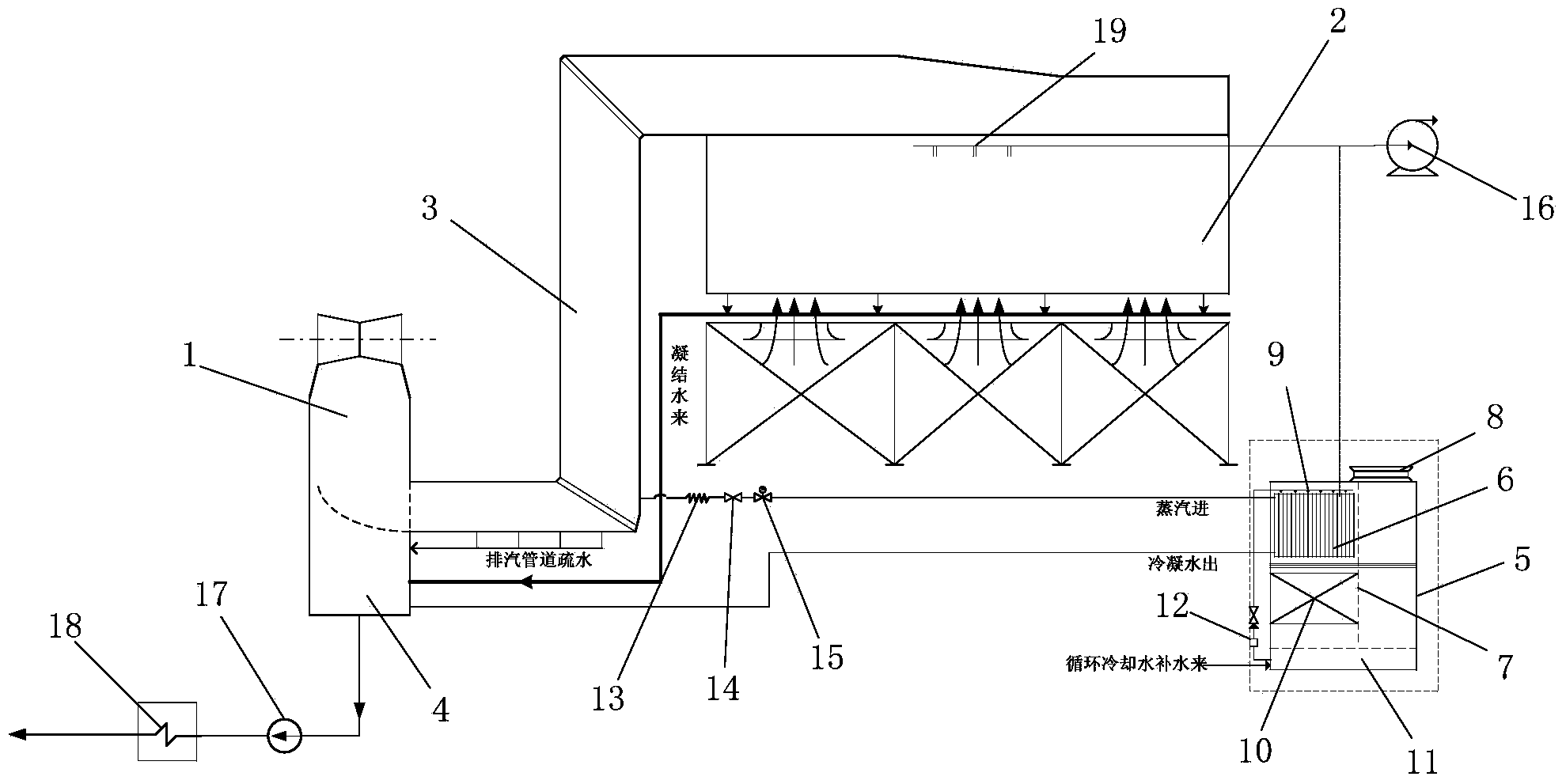

Evaporation type condenser system used for thermal power plant small steam turbine steam exhaust condensing

InactiveCN104864732ASmall footprintLess investmentSteam regenerationSteam/vapor condensersSmall footprintMotor drive

The invention discloses an evaporation type condenser system used for thermal power plant small steam turbine steam exhaust condensing. The system comprises a high-pressure cylinder, a medium-pressure cylinder, a low-pressure cylinder, a drive steam turbine and a condenser of a direct air-cooled unit. A steam exhaust opening of a small steam turbine is connected with an evaporation type condenser through a pipeline, and the evaporation type condenser is used for condensing exhausted steam of the small turbine. A condensed water outlet of the evaporation type condenser is connected with a condensed water main pipe, and condensed water flows back to a main machine backheating system through a booster pump. The evaporation type condenser system is simple, small in occupied area and particularly suitable for exhausted steam condensing of a water feed pump or a draught fan of a unit in use, and a motor drive mode is changed into a small steam turbine drive mode. Early investment is small, environment adaptability is high, the heat transfer coefficient is large, and the heat exchange effect is good. When temperature is low in winter, the system can be used as a direct air-cooled condenser, and the water consumption is zero.

Owner:XIAN THERMAL POWER RES INST CO LTD

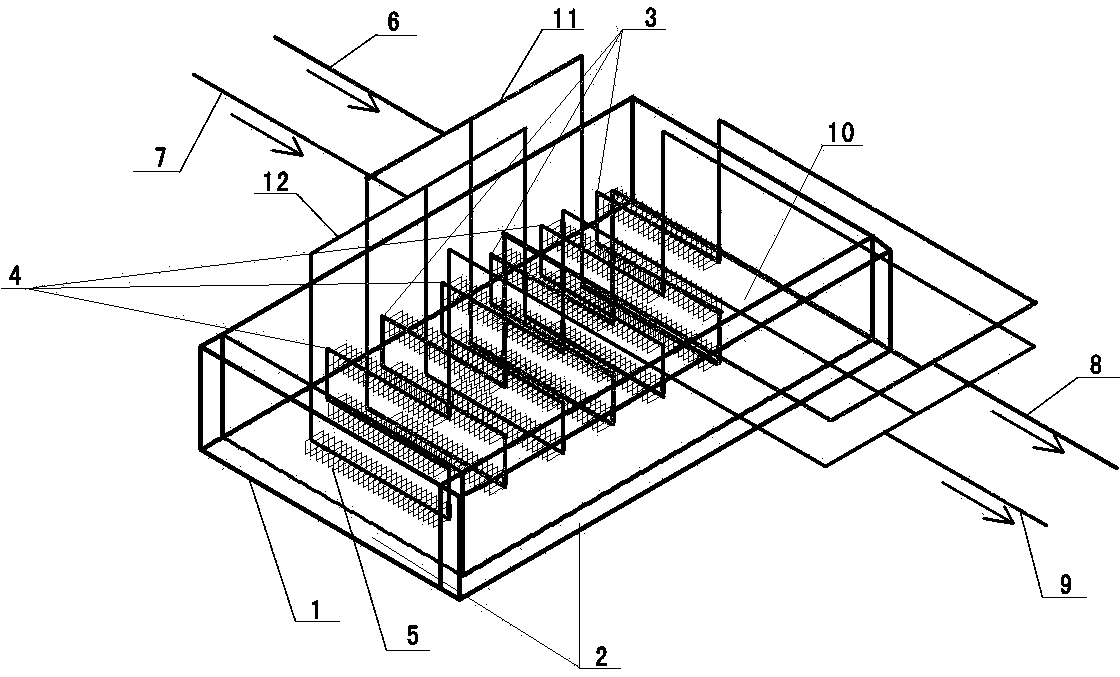

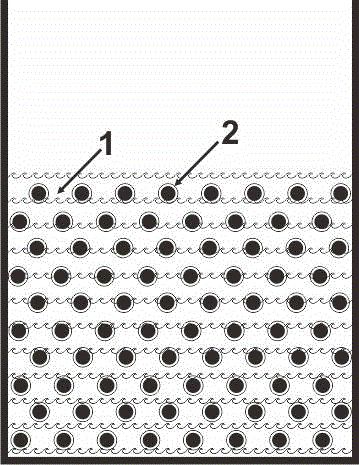

Inorganic phase change heat storage device capable of reducing phase separation

InactiveCN103913087AExtended service lifePrevent subsidenceHeat storage plantsExothermic processHeat storage material

The invention provides an inorganic phase change heat storage device capable of reducing phase separation. The inorganic phase change heat storage device comprises a container (1), an inorganic phase change heat storage material (11), heat exchange tubes (2) and a stirrer (3); the inorganic phase change heat storage device is so structured that the heat exchange tubes (2) and the stirrer (3) are mounted in the container (1), the stirrer (3) is arranged between the heat exchange tubes (2), and the rest space part of the container (1) is filled with the inorganic phase change heat storage material (11). The phase separation generated by the inorganic phase change heat storage material (11) in the repeated heat storage and release process by virtue of stirring of the stirrer (3), and the service life of the heat storage device is prolonged; meanwhile, heat exchange can be strengthened and the heat release speed can be increased.

Owner:杨春花

Method for preparing high-performance heat-generating agent

The invention relates to a method for preparing a heat-generating agent. The technical scheme is that: the heat-generating agent is prepared from the following raw materials in percentage by mass: 10 to 60 percent of aluminum metal powder, 10 to 60 percent of silicon / calcium oxides, 5 to 30 percent of graphite, 2 to 20 percent of ferric oxide and 1 to 10 percent of rare earth oxides, wherein the purity of the aluminum metal powder is over 90 percent; the particle diameter of silicon / calcium oxide micro powder is less than 0.074mm; the mol ratio of calcium oxide to silicon oxide is 1 to 5; the silicon / calcium oxide micro powder contains 0.5 to 9 mass percent of impurities, such as magnesium oxide and the like; the purity of the expanded graphite is over 90 percent; the purity of the ferric oxide is over 60 percent; and the rare earth oxides contain more than 30 mass percent of cerium oxide. The heat-generating agent with high performance can be prepared by uniformly mixing the raw materials according to the proportion in mixing equipment. The heat-generating agent has the characteristics of low combustion starting temperature, high heat productivity, good heat-preservation effect. Moreover, the process is simple, and the method is applicable for large-scale production.

Owner:沈阳东大高温材料有限公司

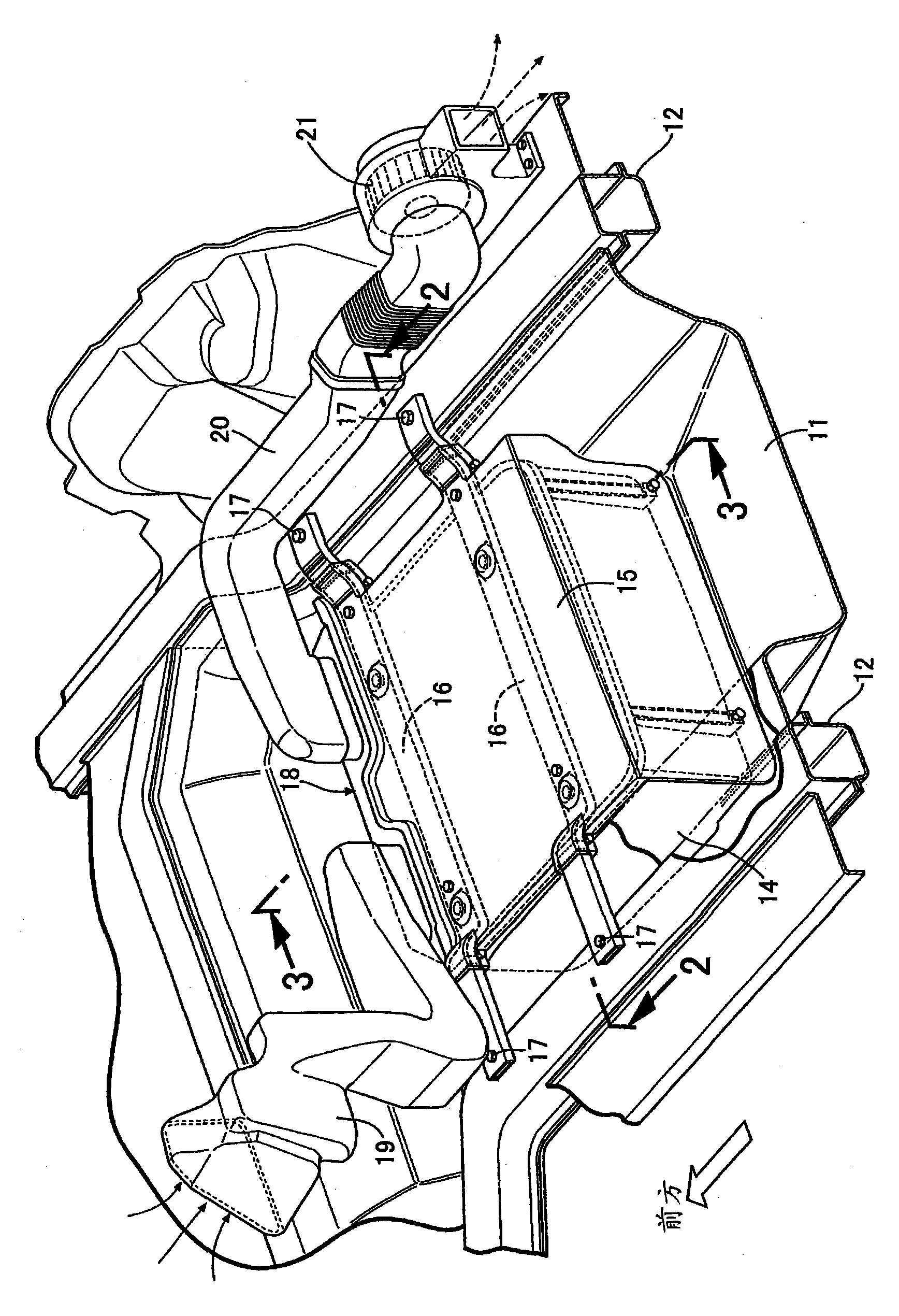

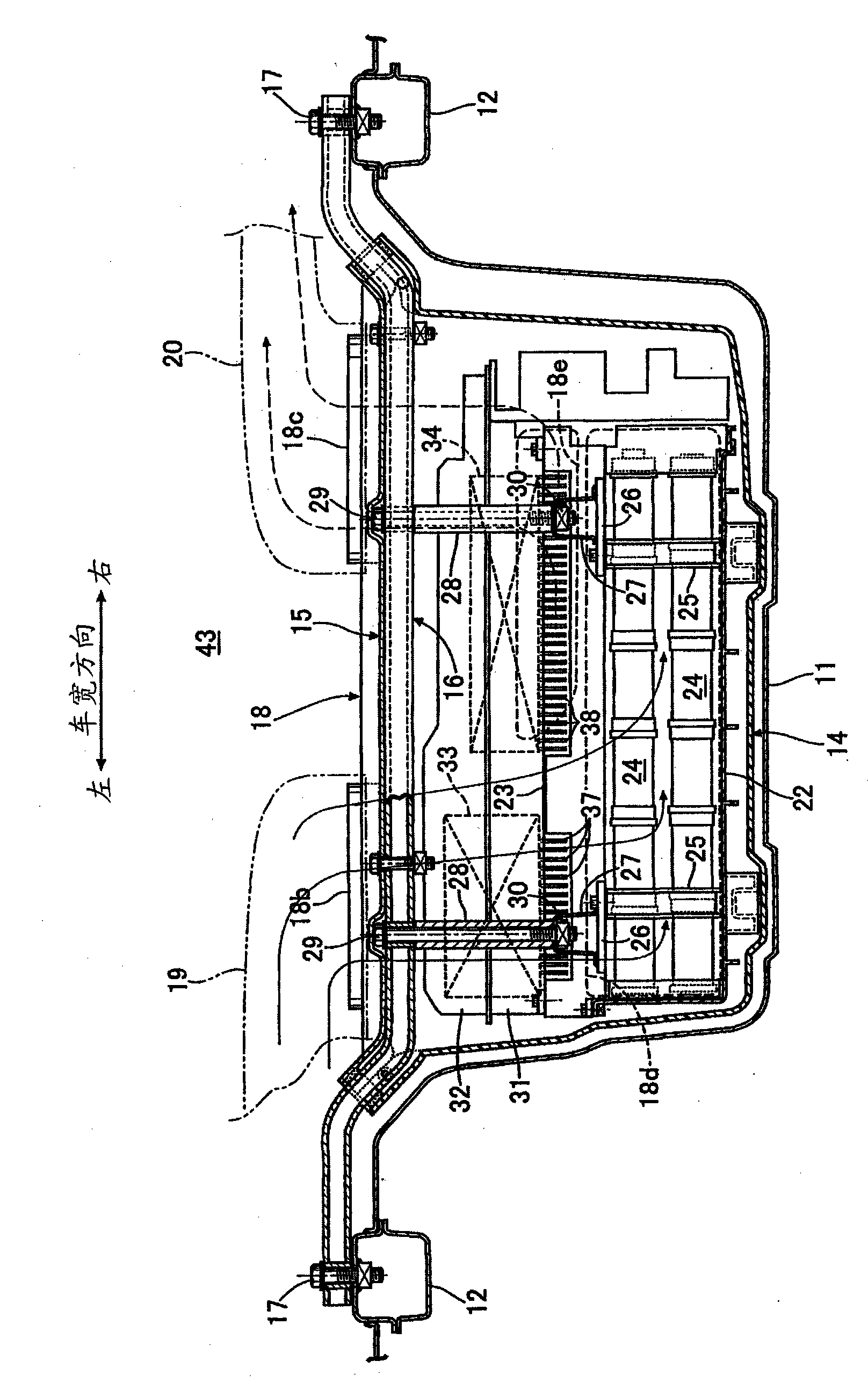

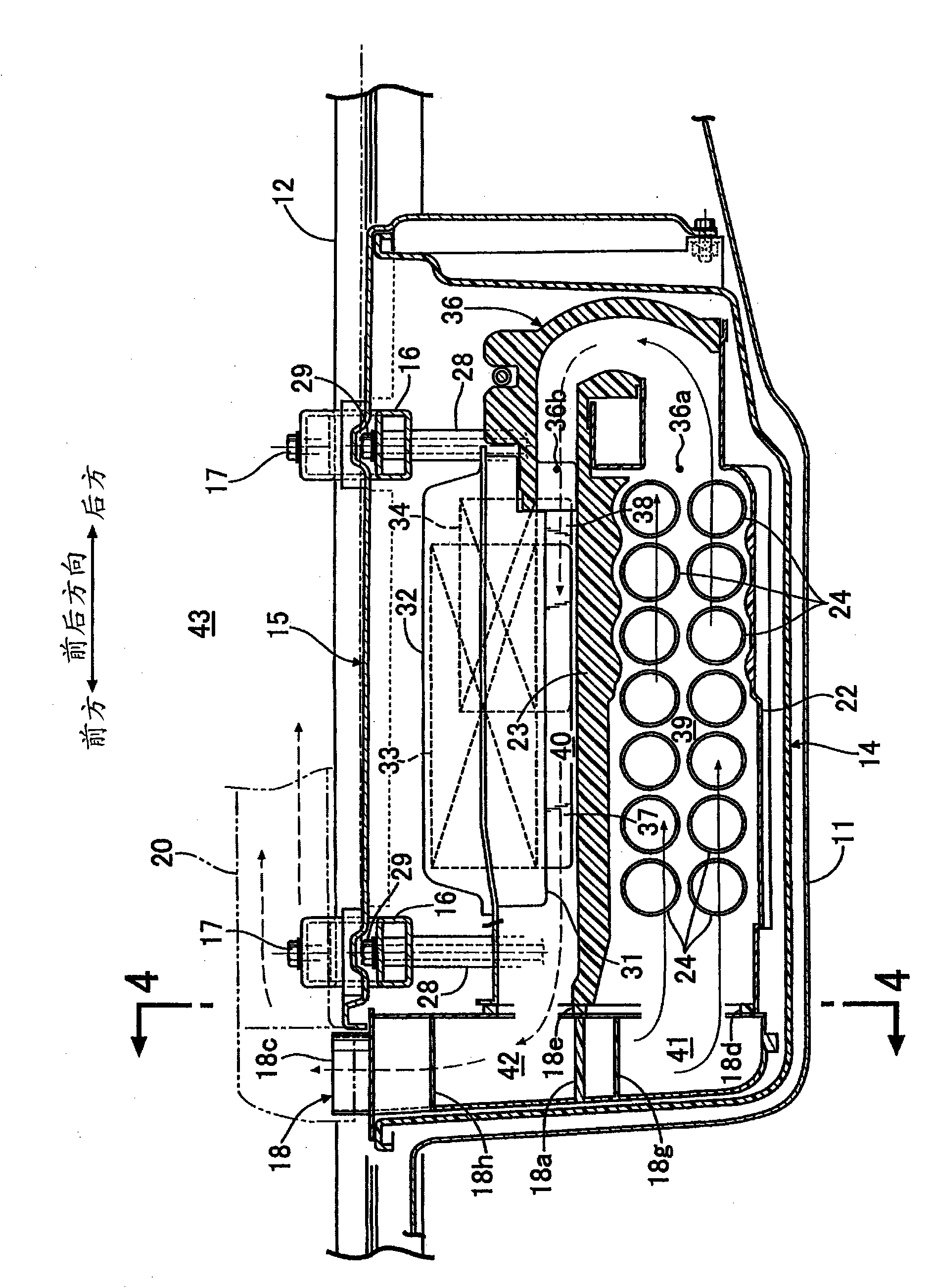

Electric power supply device

InactiveCN101925482AReduced durabilityFast heat releaseCell temperature controlElectric propulsion mountingElectrical batteryMiniaturization

An electric power supply device in which the inside of a waterproof case (14) is partitioned into a lower first cooling air flow path (39) and an upper second cooling air flow path (40), cooling air introduced from an intake air flow path (41) of a duct (18) and flowing through the lower first cooling air flow path (39) cools a battery module (24), and after that, the cooling air is introduced into the upper second cooling air flow path (40) by an intermediate duct (36) to cool high-voltage electrical components (33, 34). Air heated by the high-temperature electrical components (33, 34) aftera cooling fan is stopped is discharged from a discharge air flow path (42) of the duct (18) without contact with the battery module (24) located below the components. Further, because the intake air flow path (41) and the discharge air flow path (42) are provided integrally in the duct (18) which is provided on one end side of the waterproof case (14), the electric power supply device is more compact than in the case where the intake air flow path (41) and the discharge air flow path (42) are separately provided at opposite ends of the waterproof case (14).

Owner:HONDA MOTOR CO LTD

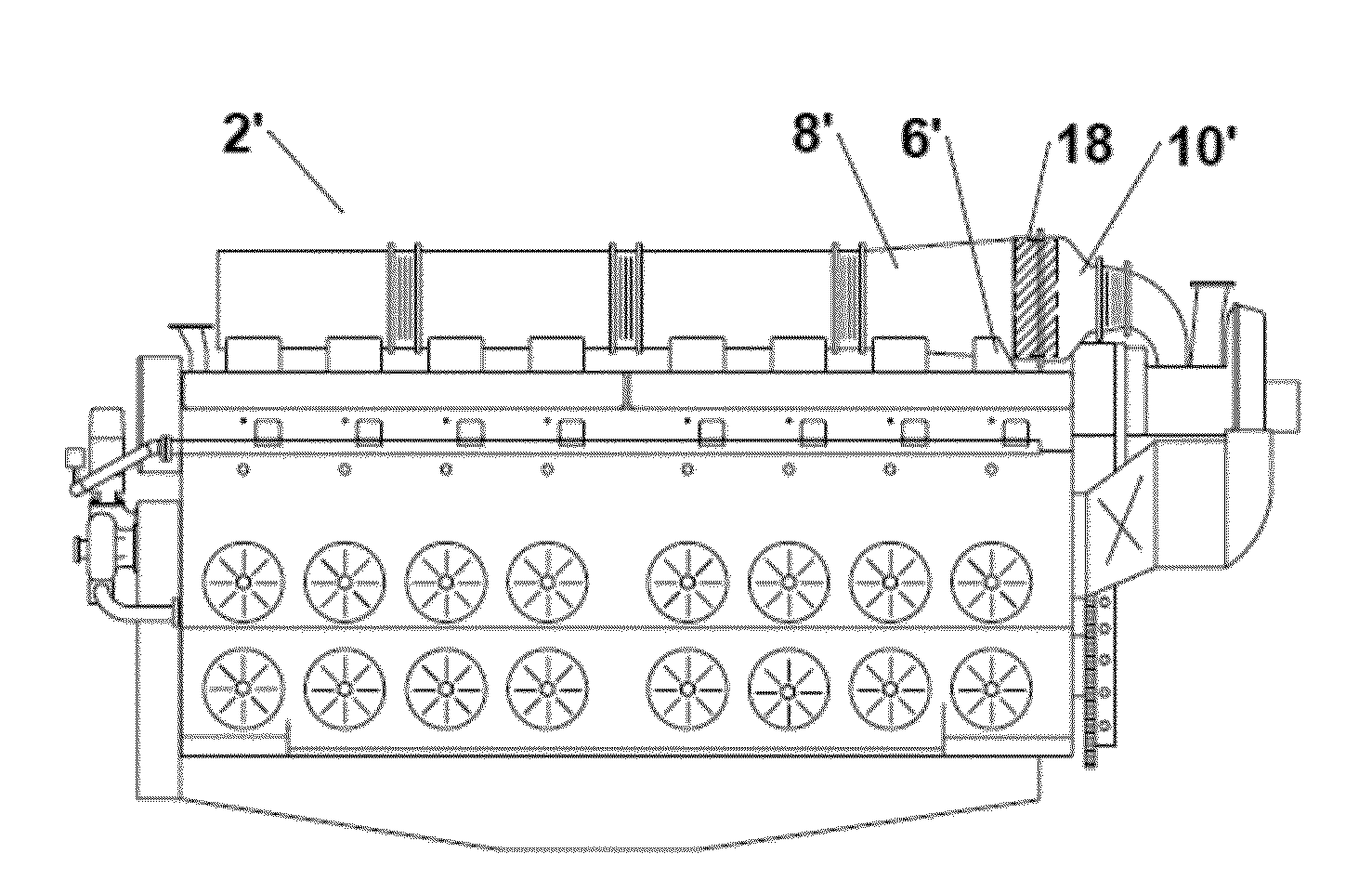

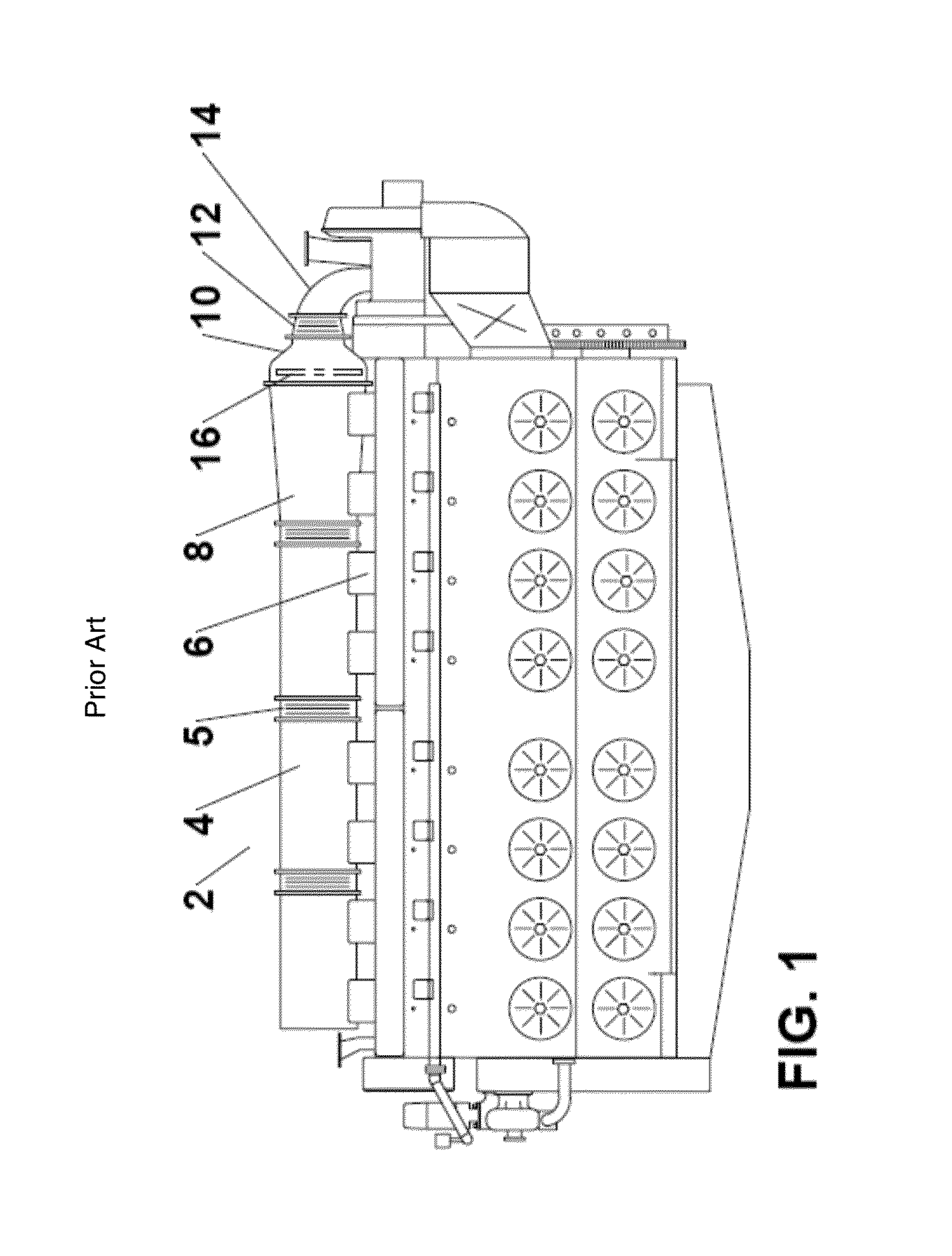

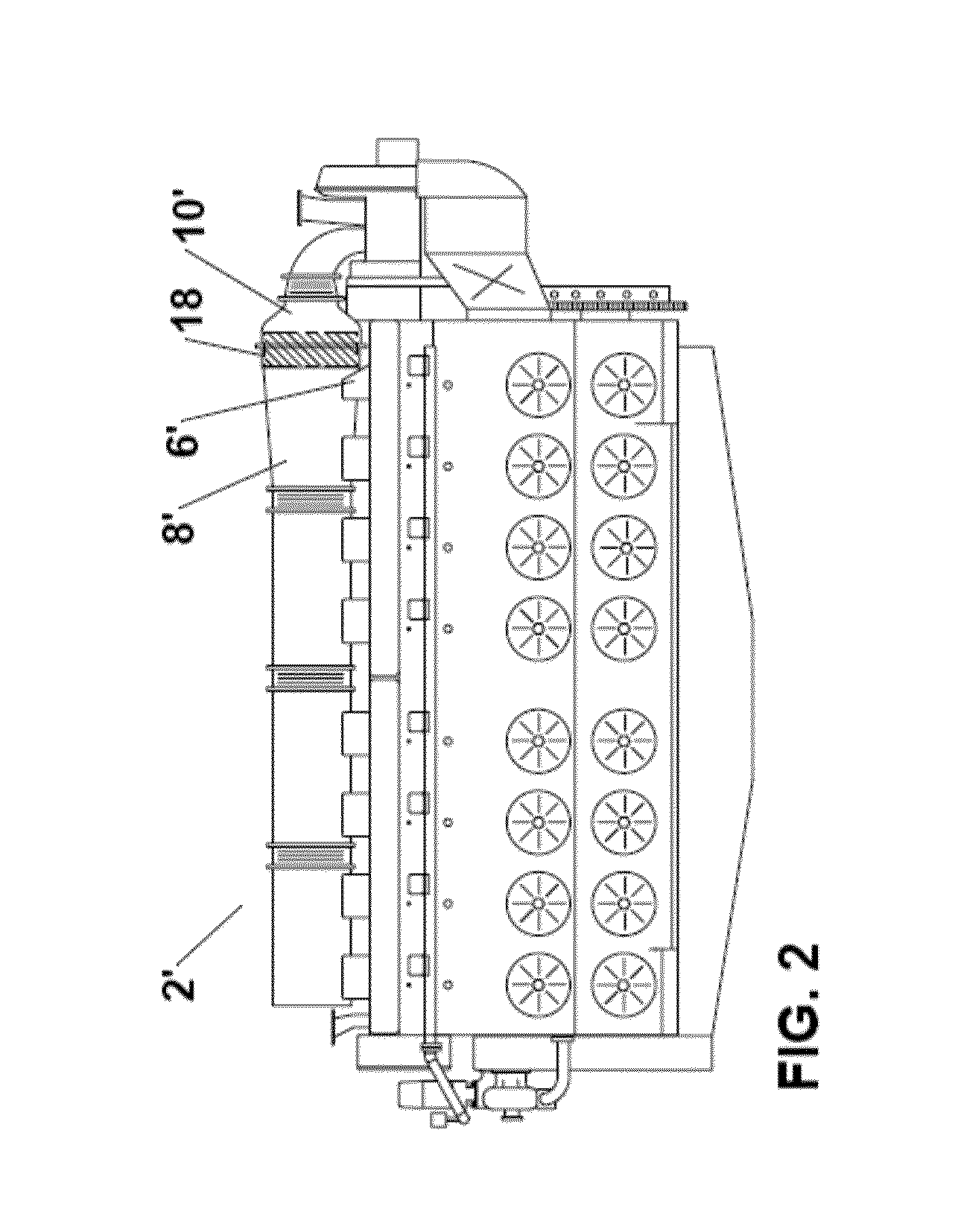

Direct air-cooling unit system with plate-type evaporative condenser unit adopted

ActiveCN103527267AReduce exhaust pressureReduce heat loadSteam/vapor condensersMachines/enginesUnit systemEngineering

The invention discloses a direct air-cooling unit system with a plate-type evaporative condenser unit adopted. The direct air-cooling unit system comprises a low pressure cylinder, an air cooled condenser and the plate-type evaporative condenser unit, wherein an exhaust steam pipe is communicated with a dead steam inlet of the plate-type evaporative condenser unit through a pipeline to send part of dead steam discharged by a turbine to the plate-type evaporative condenser unit to be cooled, and a condensed water outlet of the air cooled condenser and a condensed water outlet of the plate-type evaporative condenser unit are both communicated with a condensed water tank arranged blow the lower pressure cylinder through pipelines. According to the direct air-cooling unit system with the plate-type evaporative condenser unit adopted, steam discharged by the turbine is introduced into the air condense to be condensed through the steal discharging pipeline connected with the lower pressure cylinder, a pipeline communicated with the dead steam inlet of the plate-type evaporative condenser unit is further arranged on the steal discharging pipeline to introduce part of the dead steam discharged by the turbine to the plate-type evaporative condenser unit to be condensed, so that the thermal load entering the air cooled condenser is reduced, and then steam discharging pressure of the turbine is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

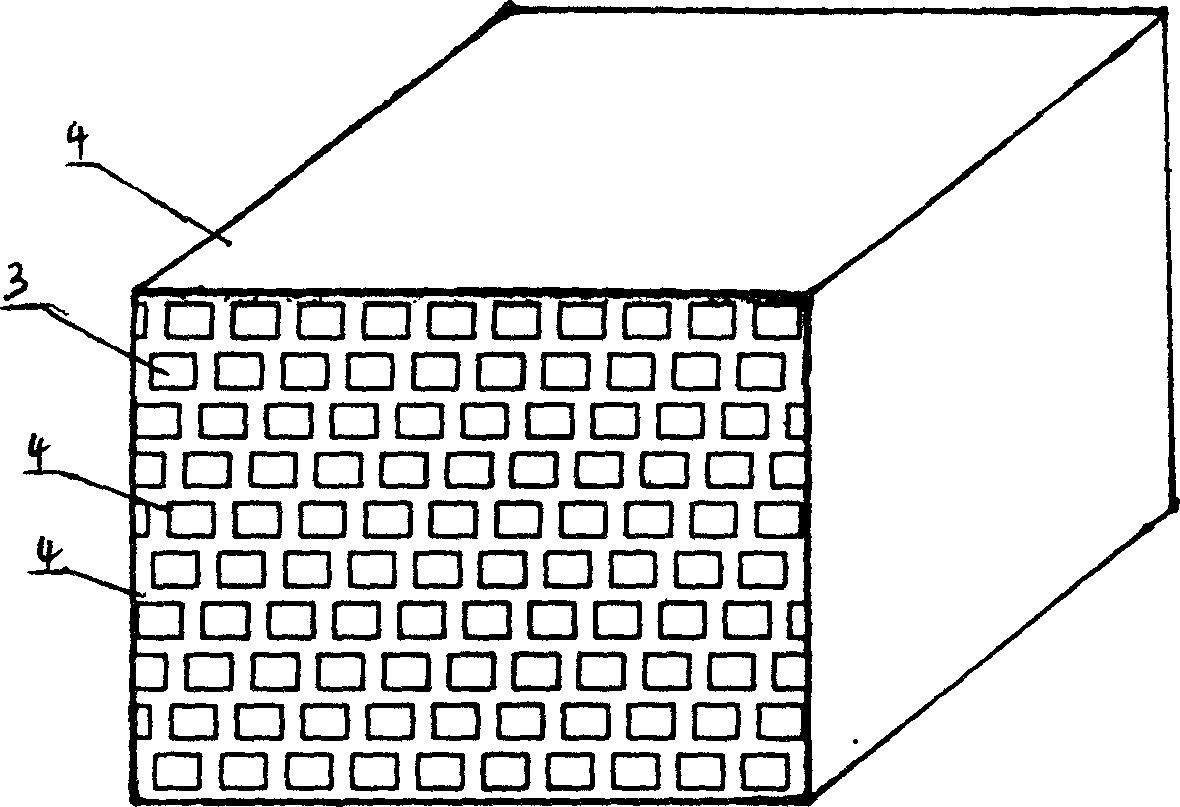

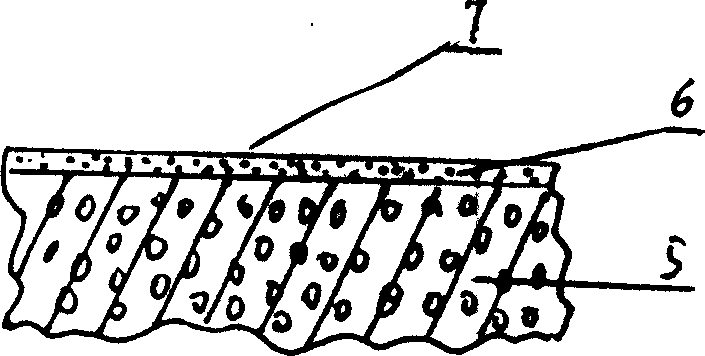

Heat exchanger with covering layer

ActiveCN1696596AIncrease heat absorptionIncrease heat releaseBrick-hot blast stovesFurnace componentsPlate heat exchangerEmissivity

The present invention relates to a heat exchanger with covering layer, belonging to the field of heat exchanger technology. Said heat exchanger is characterized by that one side or several sides of surface of its heat storage body are coated with a layer of high radiation material, whose radiation factor is higher than that of heat storage body base material. The heat storage body form can be honeycomb, fin form, ball form or plate form, and base body of heat storage body is made up by using refractory material, ceramic material or metal material.

Owner:山东慧敏科技开发有限公司

Solar heating and heat preservation curing method for railway concrete prefabricated part

InactiveCN109159270AQuality improvementReasonable designSolar heating energySolar heat storageEngineeringPhase change

The invention discloses a solar heating and heat preservation curing method for a railway concrete prefabricated part. The heat release of the concrete is fully utilized through solar heating, the heat preservation is carried out by virtue of a polyurethane, the purpose that a railway concrete prefabricated part is free of steam curing in winter is achieved. The method mainly comprises the following steps that heating air by utilizing solar energy, bubbling the hot air into a heat preservation space, the prefabricated part concrete with relatively low temperature is heated, heat release is carried out after the concrete is hydrated, heat preservation measures are used for preventing the temperature of the concrete from being lowered, redundant materials are stored in a phase change energystorage material, when the temperature of the concrete is reduced, the phase change energy storage material in a polyurethane heat preservation wall releases heat, the hydration hardening of the concrete is accelerated. The method has the characteristics of energy conservation and environmental protection, environmental friendliness and low carbon, and low economic cost, the quality of the railwayconcrete prefabricated part can be improved, the steam curing of the railway concrete prefabricated part can be replaced, and the non-steam-free effect is achieved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

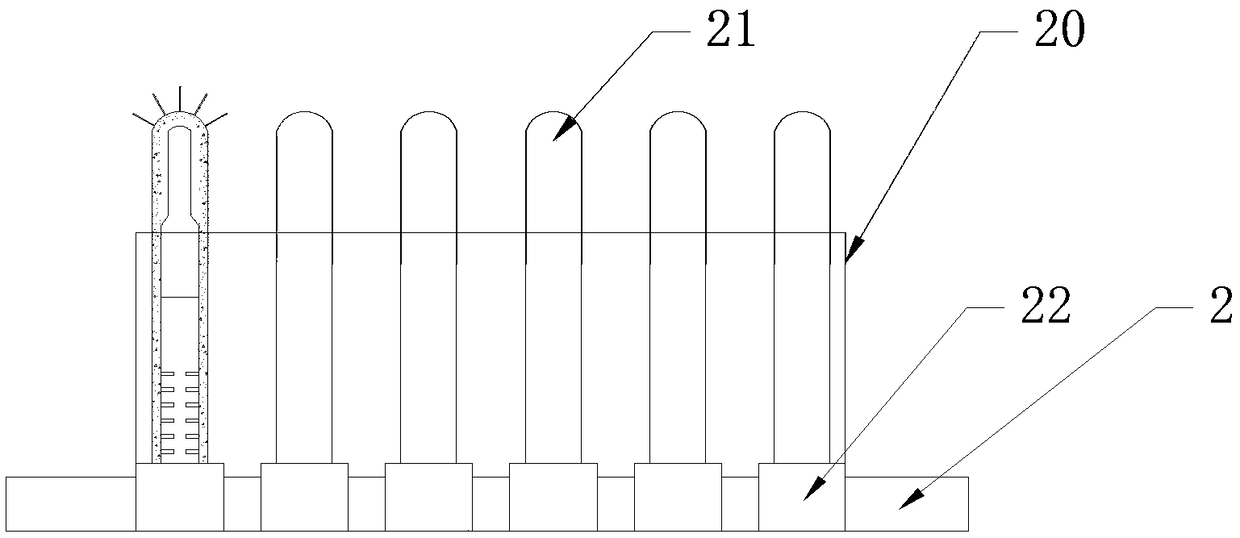

Low-temperature phase-change heat accumulator

InactiveCN103512415ALower phase transition temperatureLarge latent heat of phase changeHeat pumpsHeat storage plantsEvaporationEngineering

The invention provides a low-temperature phase-change heat accumulator which comprises a tank body and a snakelike metal pipe row. The snakelike metal pipe row is arranged in the tank body, metal fins are arranged on the snakelike metal pipe row in a sleeved mode at intervals, the snakelike metal pipe row comprises heat accumulation pipe row bodies and heat releasing pipe row bodies, the heat accumulation pipe row bodies and the heat releasing pipe row bodies are alternatively arranged, the heat accumulation pipe row bodies are connected with a heat accumulation refrigerant loop of a heat accumulation evaporation type air source heat pump through liquid inlet pipes and liquid outlet pipes of the heat accumulation pipe row bodies, the heat releasing pipe row bodies are connected with a heat releasing refrigerant loop of the heat accumulation evaporation type air source heat pump through liquid inlet pipes and liquid outlet pipes of the heat releasing pipe row bodies, the positions between the heat accumulation pipe row bodies and the liquid inlet pipes of the heat releasing pipe row bodies and between the heat accumulation pipe row bodies and the liquid outlet pipes of the heat releasing pipe row bodies are respectively provided with a heat accumulation header, the positions between the heat releasing pipe row bodies and the liquid inlet pipes of the heat releasing pipe row bodies and between the heat releasing pipe row bodies and the liquid outlet pipes of the heat releasing pipe row bodies are respectively provided with a heat releasing header, heat preservation materials are arranged in an interlayer of the tank body, and the interior of the tank body is filled with composite phase-change heat accumulation materials. The low-temperature phase-change heat accumulator is mainly used in an air source heat pump unit technological process, can serve as a heat accumulator or a subcooler or an auxiliary evaporator, and can carry out heat accumulation and heat releasing at the same time. The heat supply coefficients of a heat pump unit can be improved, and the operation performance of the air source heat pump unit in a low-temperature environment is remarkably improved.

Owner:TAIYUAN UNIV OF TECH +2

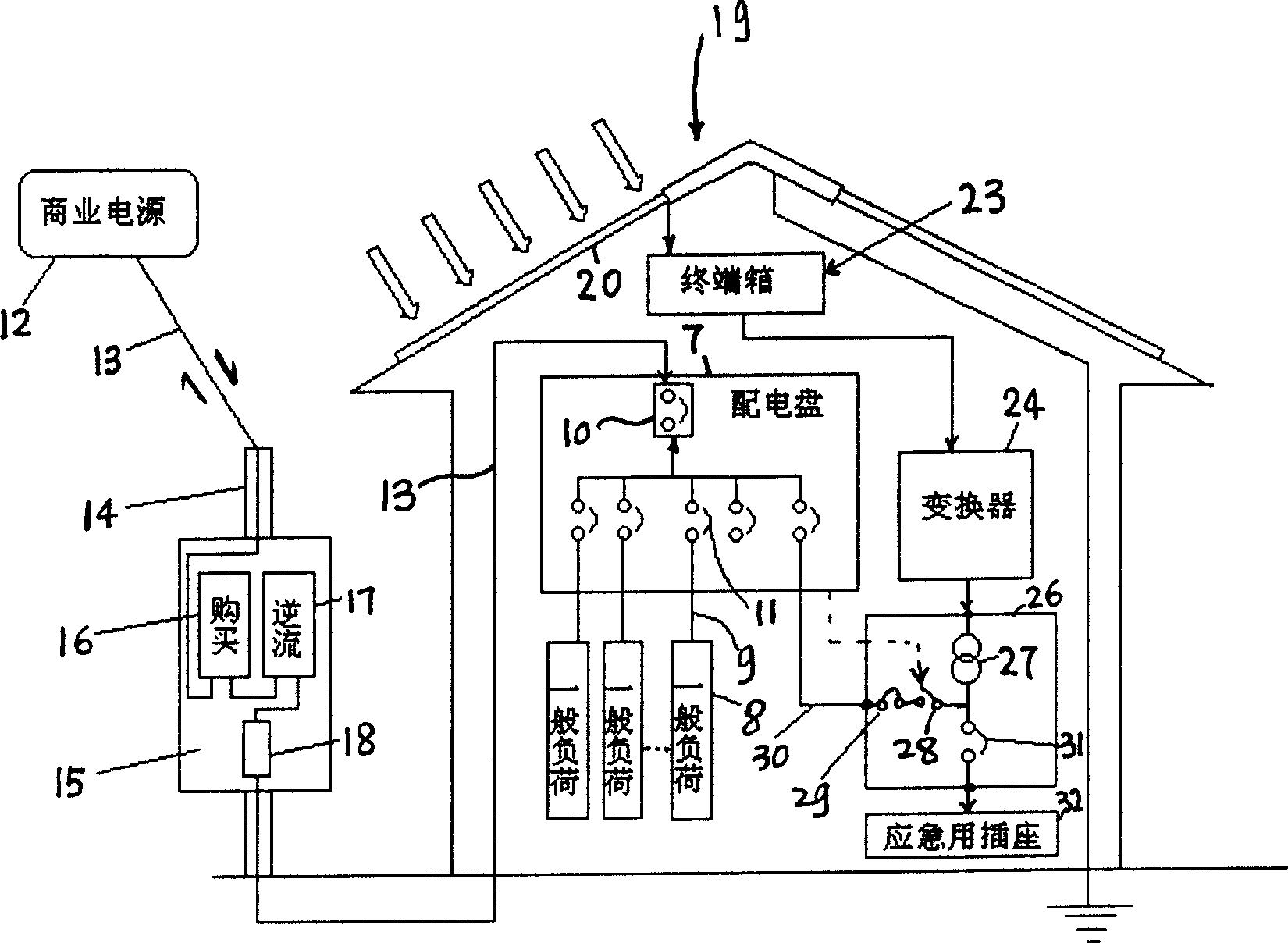

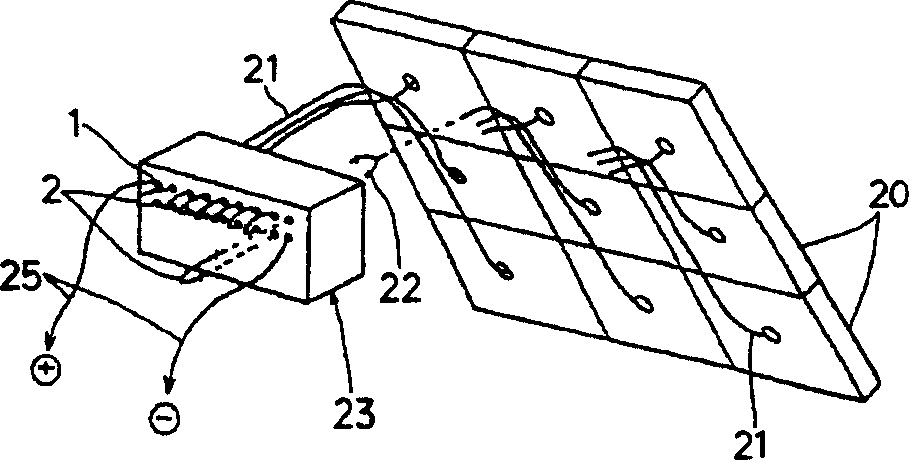

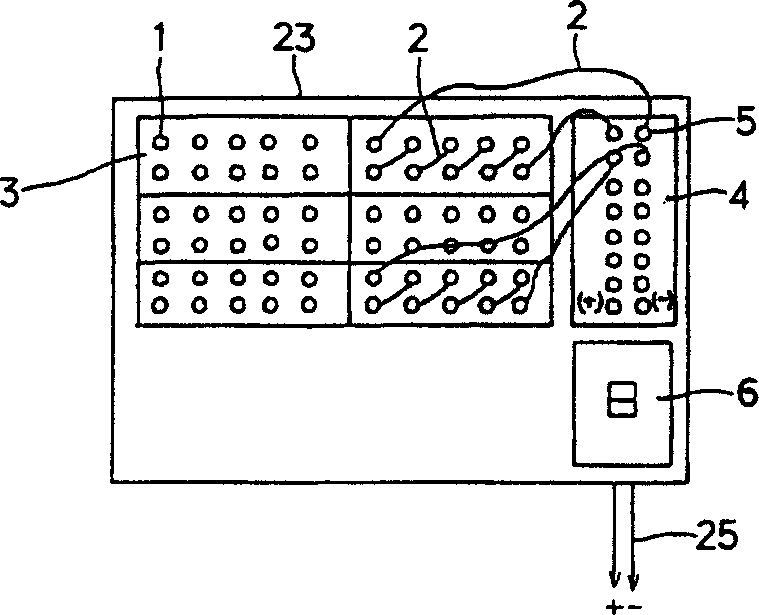

Solar cell generating unit

InactiveCN1627621AIncrease freedomSimple operation and maintenancePhotovoltaicsPhotovoltaic energy generationSolar cellBattery cell

All cable output from solar cell faceplates setup on building roof are led in termination rack connected to output sockets in building. Connection cables are connected to output sockets at backside. Each solar cell faceplate is connected in serial, and cables to convectors are connected to two ends of the said cascaded solar cell faceplate. Thus, connection and operation at backside of solar cell faceplate can be omitted. Zone of aeration for heat release is formed between solar cell faceplates and faceplates of building roof. Cables through the said zone of aeration are collocated to house from roof. House is faced to south within 30 degrees in order to guarantee stable power supply. Advantages are: easy of installation and reconditioning, preventing lowered conversion ratio, not easy influenced by environment and providing stable electrical power.

Owner:MISAWA HOMES CO LTD

Preparation method of solvent type cumyl peroxyneodecanoate (CNP)

InactiveCN102443079AOvercoming activityOvercome the disadvantage of high toxicityOrganic compound preparationPeroxy compound preparationAlkaneChloride

The invention relates to a preparation method of an initiator for synthesizing a high polymer, in particular to a preparation method of solvent type cumyl peroxyneodecanoate (CNP). According to the technical scheme of the invention, the preparation method of the solvent type CNP comprises the following steps of: mixing octyl decanoyl chloride with an alkaline solution and cumyl hydroperoxide, stirring and reacting at the temperature of 10-40 DEG C; and washing a reaction product to neutral, and adding an alkane solvent to obtain the solvent type CNP. Due to the adoption of the method for preparing the solvent type CNP provided by the invention, the process flow is simplified, the complex requirements on reaction equipment are eliminated, a reaction can be undergone in a mild and safe condition, the product content and yield can be increased greatly, and the yield can be over 95 percent.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Building material with energy storage and temperature adjusting functions

InactiveCN109650766AHigh specific heat capacityImprove heat storage capacityBiocideChemical industryAir conditioningFire resistance

The invention discloses a building material with energy storage and temperature adjusting functions, and relates to the technical field of energy-saving building materials. The specific heat capacityand the heat storage capacity of the building material prepared by compounding a compound phase change material and a building matrix material are greatly higher than those of a common building matrixmaterial, meanwhile, the anti-aging capability is enhanced, and the flame retardancy is remarkably improved, and the building material can quickly carry out heat storage and heat release at the phasechange temperature so as to improve the heat storage and release efficiency, so that the temperature adjusting capability is improved, and meanwhile, the building heating and air conditioning equipment running time is shortened, the environmental pollution is reduced, and the comfort level is improved; meanwhile, the compound material has sound absorption, sound insulation, water resistance and fire resistance, has the advantages of no toxicity, no odor, light weight, high strength and safety, and is more beneficial to practical large-scale popularization and application.

Owner:蒲连影

High-efficiency liquid cooling server

PendingCN108762439AImprove cooling effectImprove cooling efficiencyDigital data processing detailsEvaporationEngineering

The invention discloses a high-efficiency liquid cooling server, belongs to the technical field of computer hardware, and solves the problems that the air cooling and heat dissipation mode of a serveris single, the efficiency is low, and the cooling speed of the liquid cooling mode cooling liquid is low in the prior art. The high-efficiency liquid cooling server comprises a shell; a transverse partition is installed in the shell; a mounting base is connected to the partition; a server cabinet is installed on the mounting base; an upper ventilation hood is connected above the server cabinet; aventilation device located on the top surface of the shell is connected to the upper part of the upper ventilation hood; the outer surface of the server cabinet is further connected with a spiral liquid cooling pipe, and the upper end and the lower end of the spiral liquid cooling pipe are connected with a cooling pipe respectively; the cooling pipe at the upper end is connected with a cooling box, and a plurality of contact openings connected with the cooling pipe are arranged in the cooling box; a convection heat pipe is connected above each contact opening; a heat-absorbing evaporation section is arranged at the lower part of the convection heat pipe; and a plurality of capillary tubes are connected to the inner wall of the convection heat pipe of the heat-absorbing evaporation section. The high-efficiency liquid cooling server provided by the invention has the advantages of being fast in liquid cooling and good in cyclic heat dissipation effect.

Owner:郑州天点科技有限公司

Underwater anti-dispersion high-strength acrylate grouting material

The invention relates to a novel composite underwater anti-dispersion high-strength acrylate grouting material which comprises a material A, a material B and a material C. The material A is composed of a calcium magnesium acrylate solution, deionized water, a surfactant, a calcium magnesium ion chelating agent, a cross-linking agent and an accelerant. The material B is prepared from an initiator and deionized water; the material C is prepared from superfine cement, a flocculating agent, steel slag microspheres, an active excitant and low-temperature expandable microspheres. According to the underwater anti-dispersion high-strength acrylate grouting material, the calcium-magnesium ion chelating agent is used as a retarder, so that the grouting material is green, environment-friendly, non-toxic and harmless; superfine cement is matched with a flocculating agent, so that the compressive strength and the water dispersion resistance are greatly improved, and meanwhile, heat is provided forexpansion of the low-temperature expandable microspheres; the low-temperature expandable microspheres are adopted, so that the slurry has excellent elasticity and tensile property while maintaining high compressive strength after hardening, and the elongation rate can reach 205%; and the steel slag microspheres are adopted, so that the viscosity of the slurry is sharply reduced to 8Pa. S, and thegrouting performance is excellent.

Owner:常州绿玛特建筑科技有限公司 +2

Mixed fit device for biomass fuel, paper sludge and coals

ActiveCN102980201ALow calorific valueUniform heat releaseIncinerator apparatusLump/pulverulent fuel feeder/distributionBoiler furnaceControl system

The invention relates to a mixed fit device for biomass fuels, paper sludge and coals. Biomasses in a biomass bunker are conveyed to a variable frequency scraper conveyor through a biomass bunker screw conveyor; coals in a coal bunker are conveyed to the variable frequency scraper conveyor through a variable frequency coal screw conveyor; an output end of the variable frequency scraper conveyor is connected with an input end of a boiler-front mixing device through a coal drop pipe; and an output end of the boiler-front mixing device is connected with a boiler through a spiral distributor and a spiral feeder. In order to prevent the boiler-front blockage and tube pulling, the system is provided with a primary hot-air system. The fuel mixing technology adopts paper sludge (absolute dried), wood chips (absolute dried), and fuel coals distributed in normal operation (at most not exceed 20%); and the optimal operation effect is achieved through a PLC control system with high automation degree of the mixed fit of the biomass fuels, the paper sludge and the coals in front of a boiler. The sludge incineration technology has is superior, is combined with a sludge incineration power generation technology, and is a sludge treatment technology popular with paper making enterprises.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG CO LTD

Low-melting metal heat absorption solution

ActiveCN104449588AHigh latent heat of phase changeHigh heat transfer and heat storage capacityHeat-exchange elementsTemperature controlMaterials science

The invention relates to a low-melting metal heat absorption solution. The low-melting metal heat absorption solution is characterized in that the solution is a homogeneous dispersion system, wherein the dispersion phase in the dispersion system is phase-change microcapsules; the dispersion medium is oil, water or alcohol; the phase-change microcapsules are produced in the way that the walls are made from high-molecular polymer and the core material is low-melting metal. The low-melting metal has relatively high phase-change hidden heat and thermal conductivity, so that the low-melting metal heat absorption solution can quickly absorb heat of high-temperature objects (liquids or solids) to enable the high-temperature objects to be quickly cooled down to reach the required temperature. The low-melting metal heat absorption solution is obvious in temperature reduction rate, and can be widely applied in the fields of temperature control, energy utilization, heat exchange and the like.

Owner:BEIJING EMIKON TECH DEV

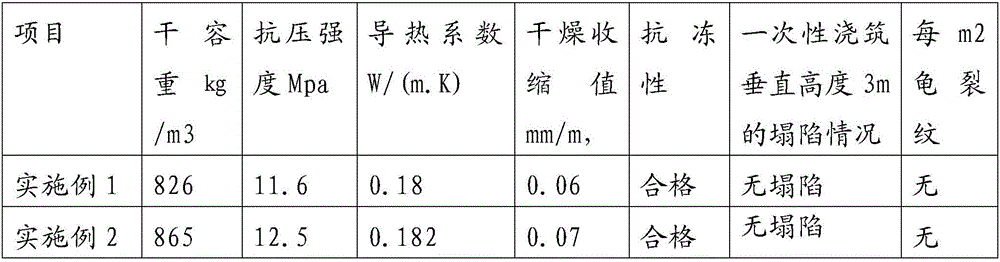

High-strength shrinkage-free cast-in-place foam concrete wall material and wall preparation method

The invention discloses a high-strength shrinkage-free cast-in-place foam concrete wall material and a wall preparation method. The wall material comprises, by weight, 30-50 parts of cement, 10-30 parts of sand, 10-30 parts of water granulated slag, 5-25 parts of coal ash, 0.1-3 parts of silica fume, 0.1-3 parts of quick lime, 0.1-3 parts of water glass, 0.01-0.45 part of sodium fluosilicate, 0.1-3 parts of polypropylene fiber, 0.1-0.5 part of a water reducer, 0.1-1 part of a water-retentive and thickening admixture, water and a foaming agent, wherein the mass ratio of the dry mixed materials to the water is (0.35-0.45):1, and the mass ratio of the dry mixed materials to the foaming agent is (0.0125-0.125):1. The high-strength shrinkage-free cast-in-place foam concrete wall material is applied in the technical field of building walls, a reasonable raw material matching ratio is adopted, quite good fluidity and stability can be achieved, the prepared wall material is high in strength and small in shrinkage rate, and the using requirements for wall portions and the like of living buildings and public buildings are completely met.

Owner:山东亮普建材科技有限公司

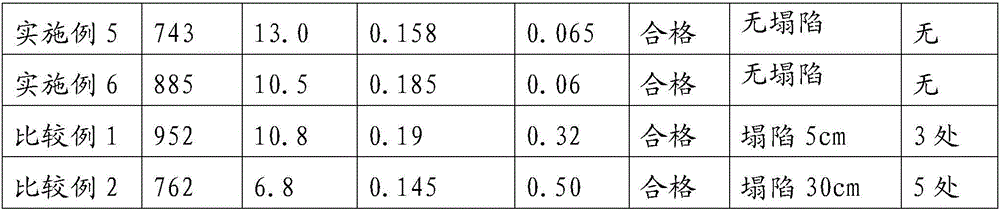

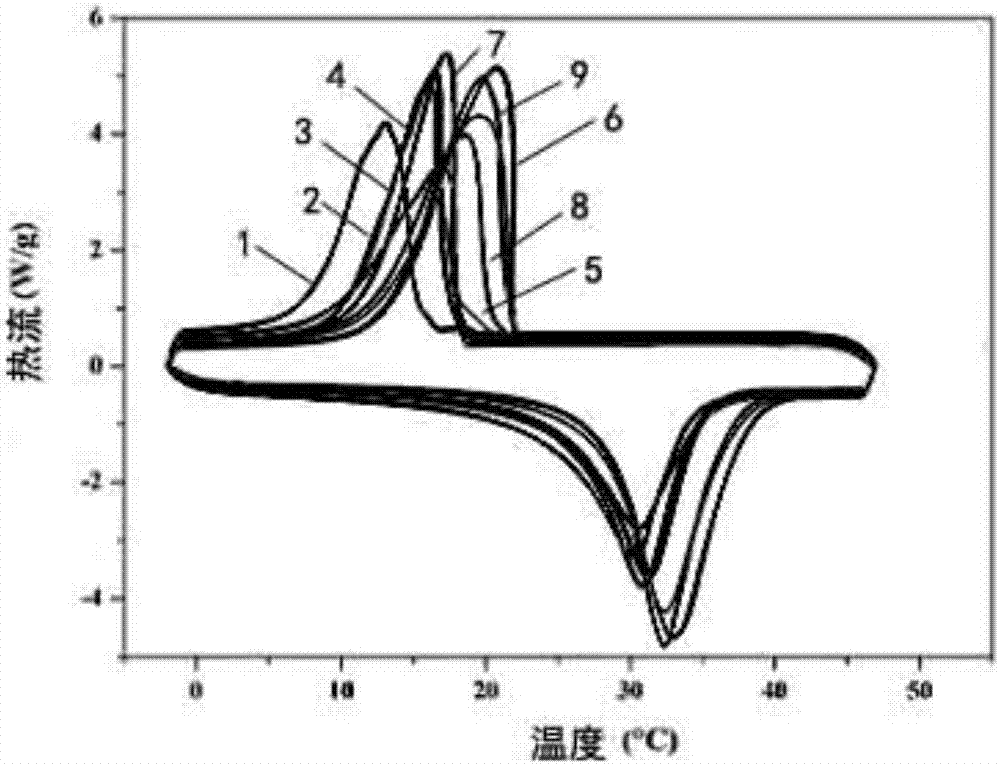

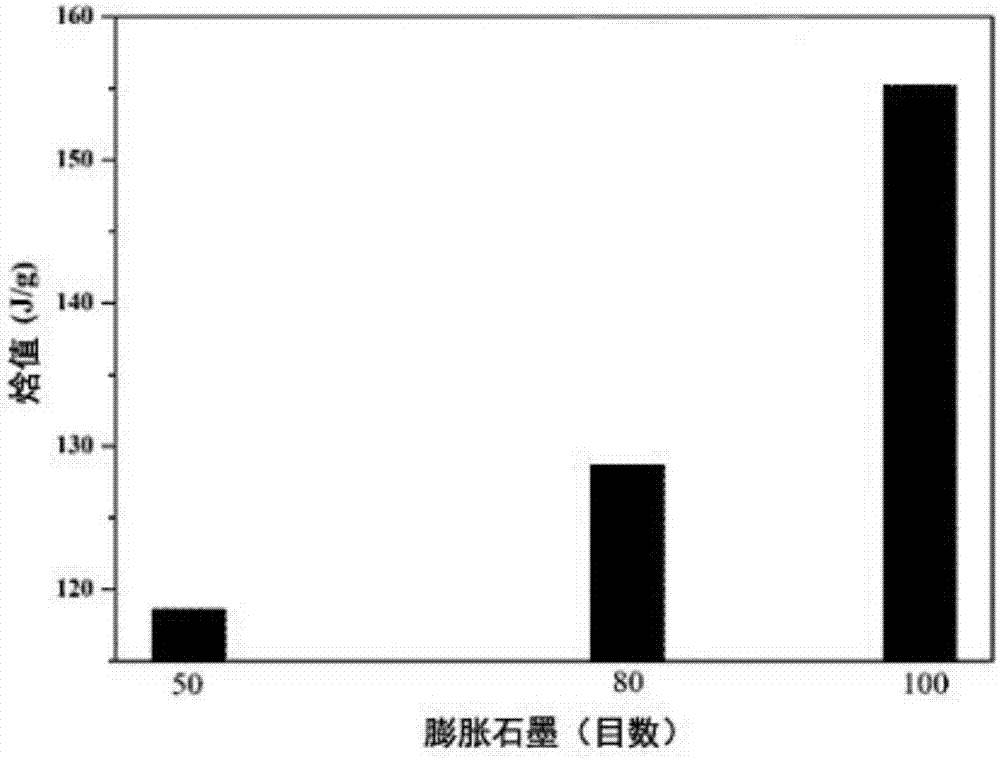

Composite phase change material and its preparation method and building material

The invention relates to the field of phase change materials and particularly relates to a composite phase change material and its preparation method and a building material. The composite phase change material comprises calcium chloride hexahydrate, a subcooling degree reducing agent and a thermal conductivity enhancer. A mass part ratio of the calcium chloride hexahydrate, subcooling degree reducing agent to thermal conductivity enhancer is 100: 1-5: 10-20. The thermal conductivity enhancer is expanded graphite or a carbon fiber. The subcooling degree reducing agent is used for reducing a subcooling degree of calcium chloride hexahydrate. The thermal conductivity enhancer ensures that the thermal conductivity coefficient of the composite phase change material is greater than that of the calcium chloride hexahydrate.

Owner:ENN ENERGY SERVICE

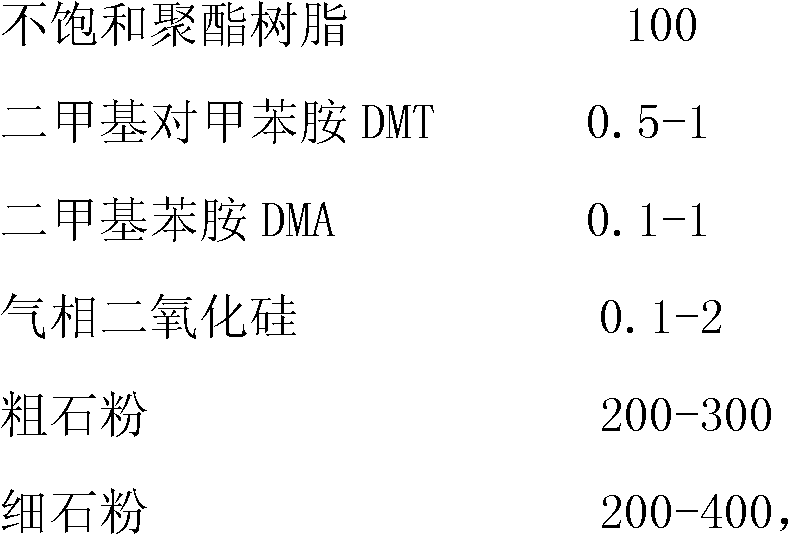

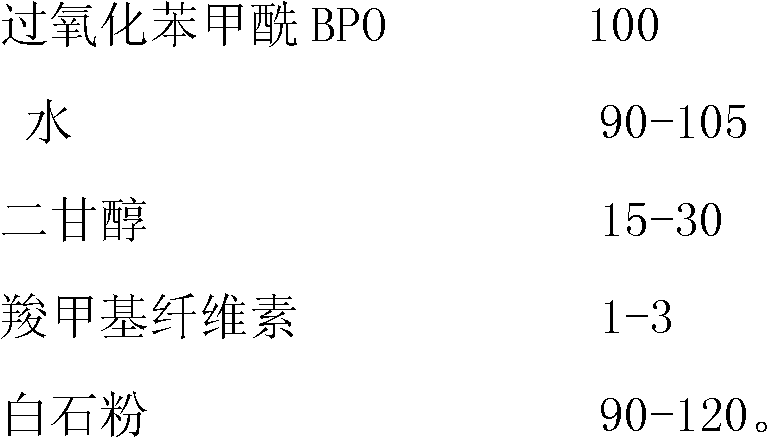

Early-strength CK anchoring agent and application thereof

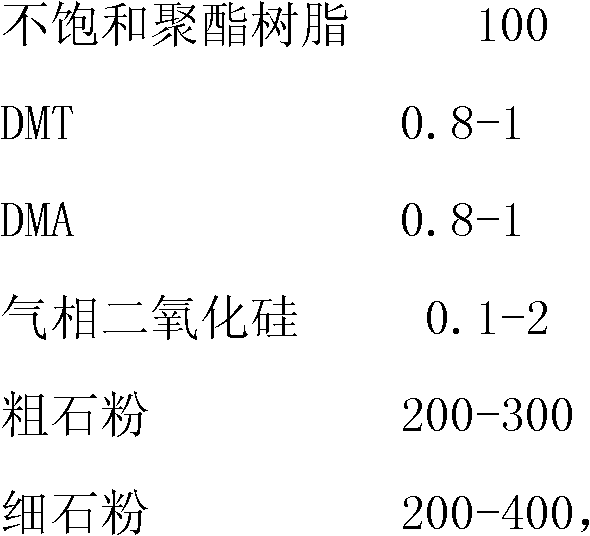

The invention discloses an early-strength CK anchoring agent and is characterized in that the early-strength CK anchoring agent comprises resin mortar and a curing agent, wherein the weight ratio of the resin mortar to the curing agent is 100 : 4 to 6; the resin mortar comprises the following ingredients by part by weight: 100 parts of unsaturated polyester resin, 0.5 to 1 part dimethyl-p-toluidine (DMT), 0.1 to 1 part of dimethyl aniline (DMA), 0.1 to 2 parts of gas phase silicon dioxide, 200 to 300 parts of coarse stone powder, and 200 to 400 parts of fine stone powder; and the curing agent comprises the following ingredients by part by weight: 100 parts of benzoyl peroxide, 90 to 105 parts of water, 15 to 30 parts of diethylene glycol, 1 to 3 parts of carboxymethyl cellulose, and 90 to 120 parts of white stone powder. The early-strength CK anchoring agent is applied to underground roadway supporting and pit shaft equipment installation work in a coal mine. Compared with the traditional CK anchoring agent, the early-strength CK anchoring agent mainly has the advantages that the early strength development and the curing exotherm are quick, the exotherm is large, and the final strength after curing is high.

Owner:美亚高新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com