High-efficiency liquid cooling server

A technology for servers and server cabinets, applied in the fields of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of low efficiency, single air-cooling and heat-dissipating method of servers, slow cooling rate of cooling liquid, etc., to improve heat-dissipating efficiency , Improve the heat dissipation effect, the effect of accelerating the convection circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] As a basic example:

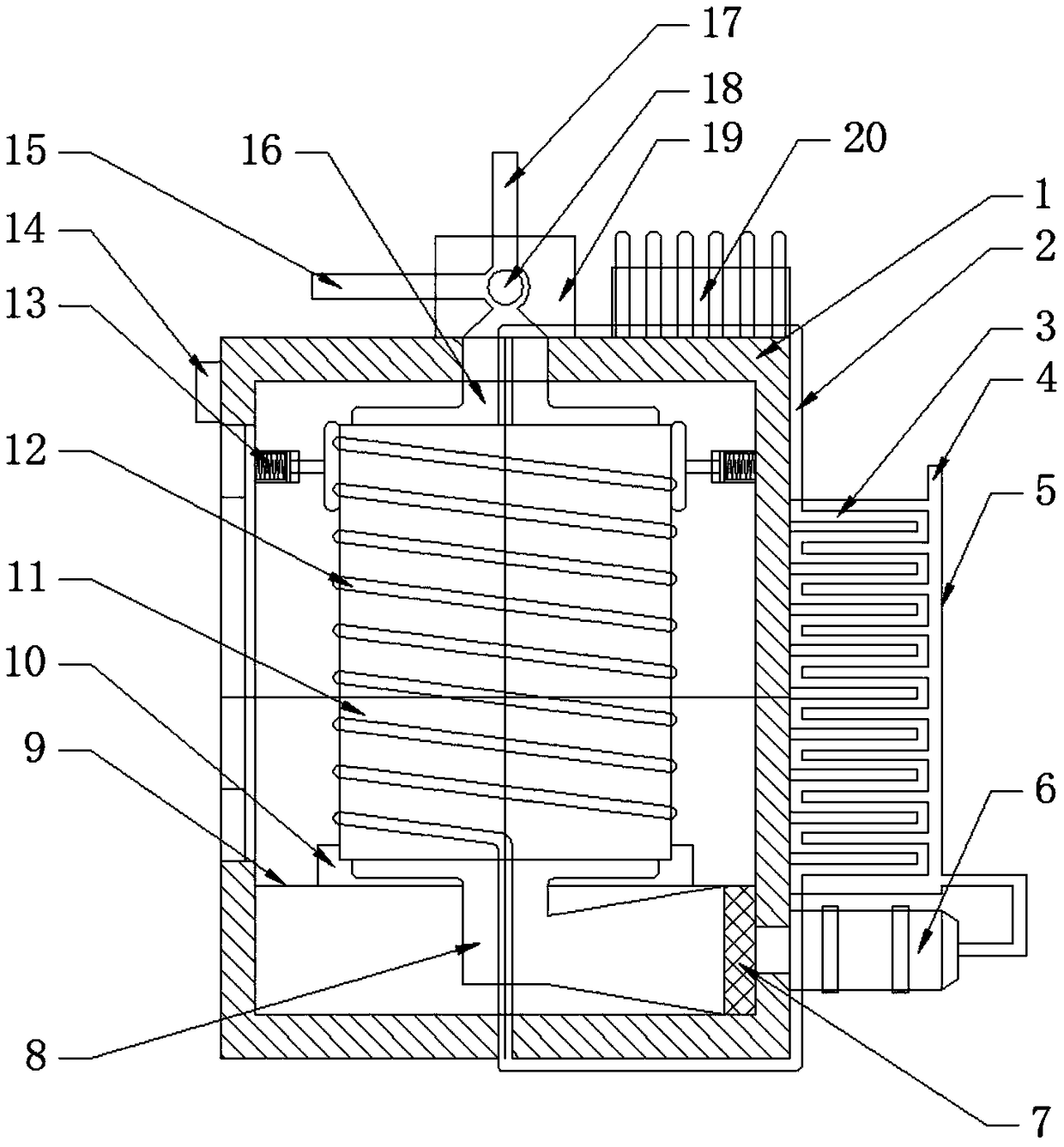

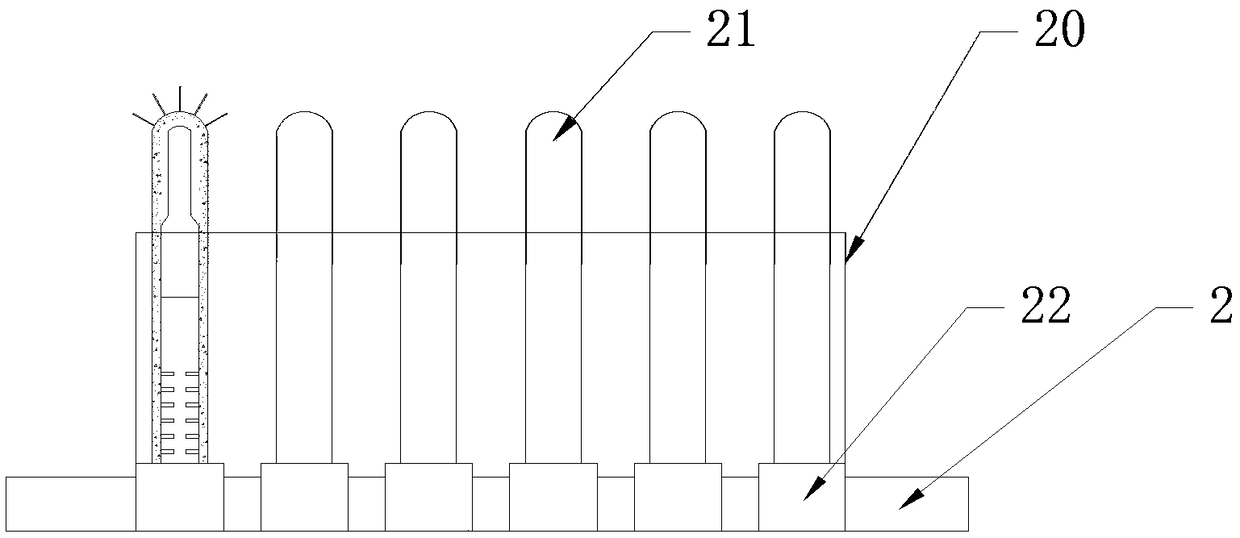

[0042] A high-efficiency liquid-cooled server, including a casing 1, a horizontal partition 9 is installed inside the casing 1, and a mounting base 10 is connected to the partition 9, and a server cabinet 11 is mounted on the mounting base 10. Its features That is, an upper ventilation hood 16 is connected above the server cabinet 11, and a ventilation device 19 located on the top surface of the casing 1 is connected above the upper ventilation hood 16. The outer surface of the server cabinet 11 is also connected with a spiral liquid cooling pipe 12, and the spiral The upper and lower ends of the liquid cooling pipe 12 are connected with a cooling pipe 2, and the cooling pipe 2 at the upper end is connected with a cooling box 20, and the cooling box 20 is provided with a plurality of contact ports 22 connected with the cooling pipe 2. Convection heat pipes 21 are connected above the ports 22 , and a heat-absorbing evaporation section 26 is provided...

Embodiment 2

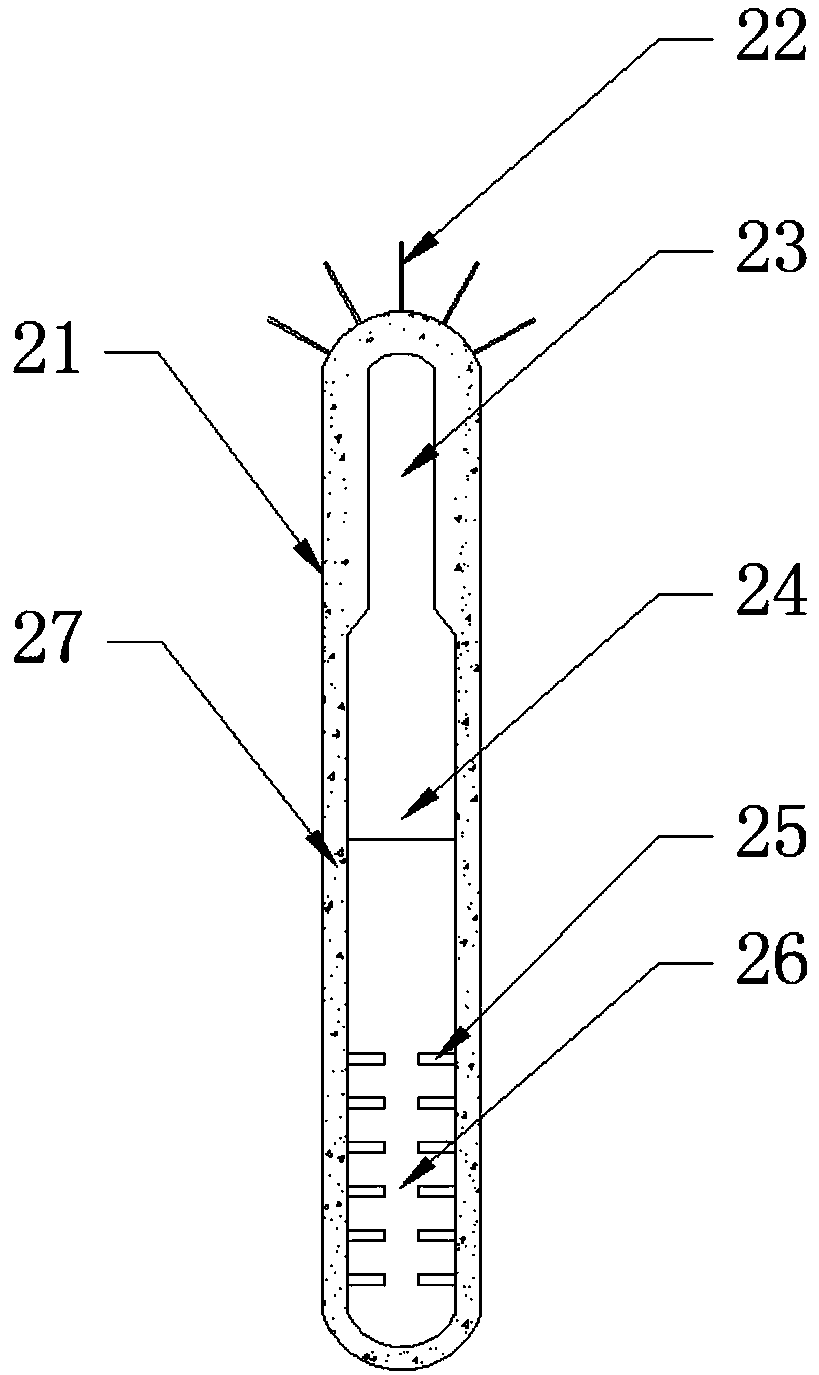

[0045] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the upper part of the convection heat pipe 21 is provided with an exothermic condensation section 23, and an exothermic condensation section 23 A recirculation layer 27 thicker than that of the endothermic evaporation section 26 is provided, and the recirculation layer 27 is attached to the inner wall of the convection heat pipe 21 , and the top of the convection heat pipe 21 is connected with a cooling fin 28 .

[0046] Further, the return layer 27 is a capillary layer, and the capillary layer is provided with a plurality of capillary holes.

Embodiment 3

[0048] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, a lower ventilation hood 8 is connected below the server cabinet 11, and the lower ventilation hood 8 is connected with a fitting The dust removal net 7 on the inner wall of the housing 1 is connected with an electrostatic precipitator 6 on the outer wall of the housing 1 corresponding to the position of the dust removal net 7, and the electrostatic precipitator 6 is connected with an air drying device 5, and the cooling pipe 2 is respectively connected with the drying device is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com