Mixed fit device for biomass fuel, paper sludge and coals

A biomass fuel and papermaking sludge technology, applied in the direction of fuel supply, combustion method, combustion type, etc., can solve the problems of complex equipment composition, large coal treatment system, complex equipment installation, etc., and achieve the purpose of inhibiting ash deposition, corrosion, and The effect of low calorific value and good burnout characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

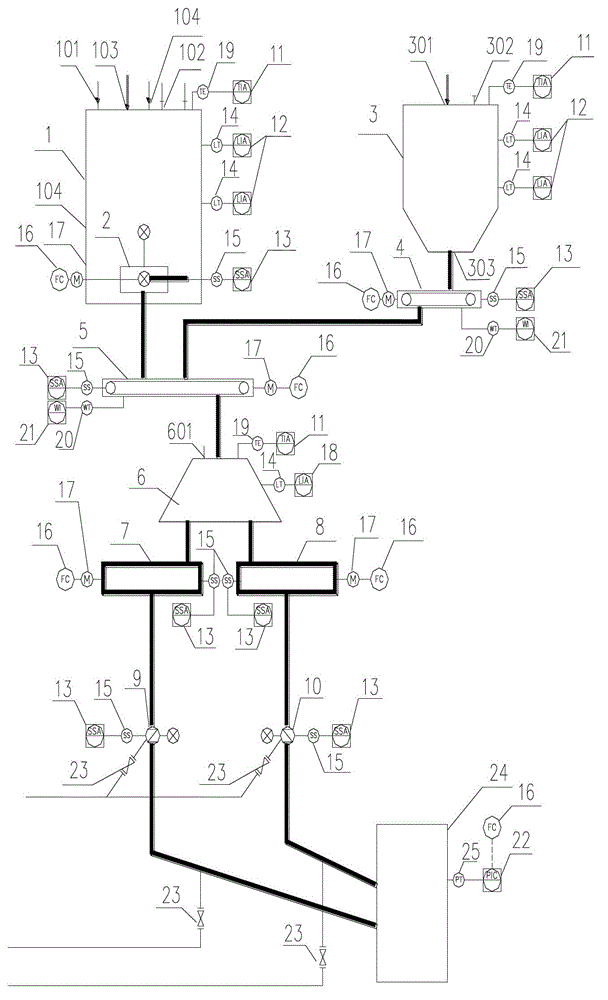

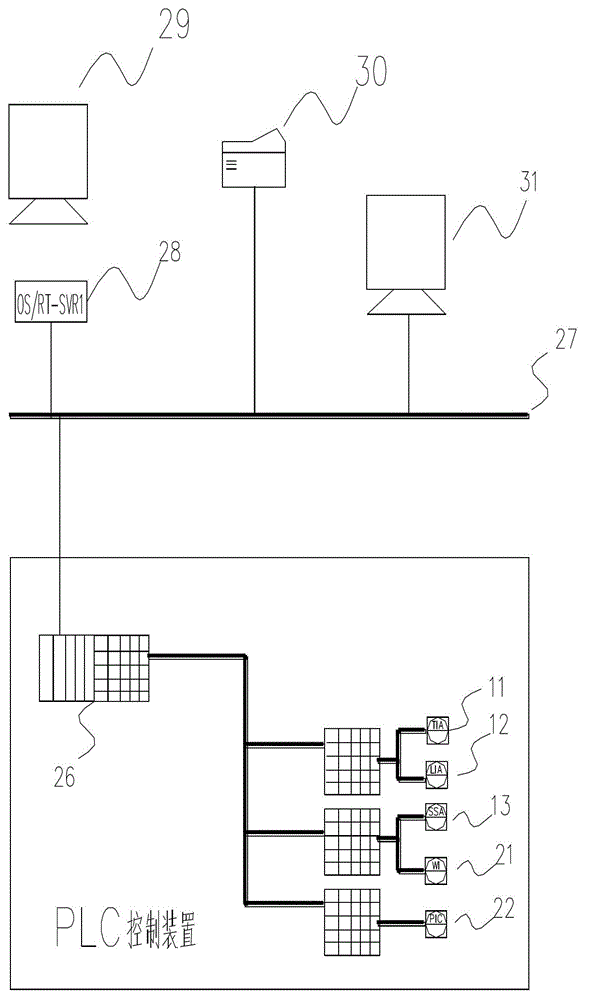

[0028] Such as figure 1 as shown,

[0029] A biomass fuel, papermaking sludge and coal mixing device, including a biomass material bin 1, a biomass bin screw conveyor 2, a coal bin 3, a frequency conversion coal screw conveyor 4, a frequency conversion scraper conveyor 5, and a furnace mixing Device 6, the first screw distributor 7, the second screw distributor 8, the first screw feeder 9, the second screw feeder 10 and the boiler 24, the biomass in the biomass material bin 1 is conveyed by the screw of the biomass material bin The machine 2 is sent to the frequency conversion scraper conveyor 5, the coal in the coal bunker 3 is sent to the frequency conversion scraper conveyor 5 through the frequency conversion coal screw conveyor 4, and the output end of the frequency conversion scraper conveyor 5 passes through the coal sliding pipe and the mixing device in front of the furnace 6 is connected to the input end, and the output end of the mixing device 6 in front of the furna...

Embodiment 2

[0036]Biomass silo 1 is located on the third floor (15-20 meters high), and the feed port of biomass silo 1 is connected to the feed slide pipe to connect with the feeding equipment; the fire hose is connected to the biomass through the fire outlet of the silo Bin 1; the inspection port is set at the manhole 104, and the top of the biomass bin 1 is provided with a bin exhaust port 102. The biomass bin screw conveyor 2 is connected to the outlet of the biomass bin 1 . The screw conveyor 2 of the biomass material bin is connected to the inlet of the variable frequency scraper conveyor 5 through a drop pipe; The outlet is connected to the inlet of the frequency conversion scraper conveyor 5 through the coal sliding pipe, the outlet of the frequency conversion scraper conveyor 5 is connected to the inlet of the mixing device 6 in front of the furnace through the discharge pipe, and the fire water pipe passes through the front of the mixing device 6 in front of the furnace The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com