Patents

Literature

85results about How to "Uniform heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

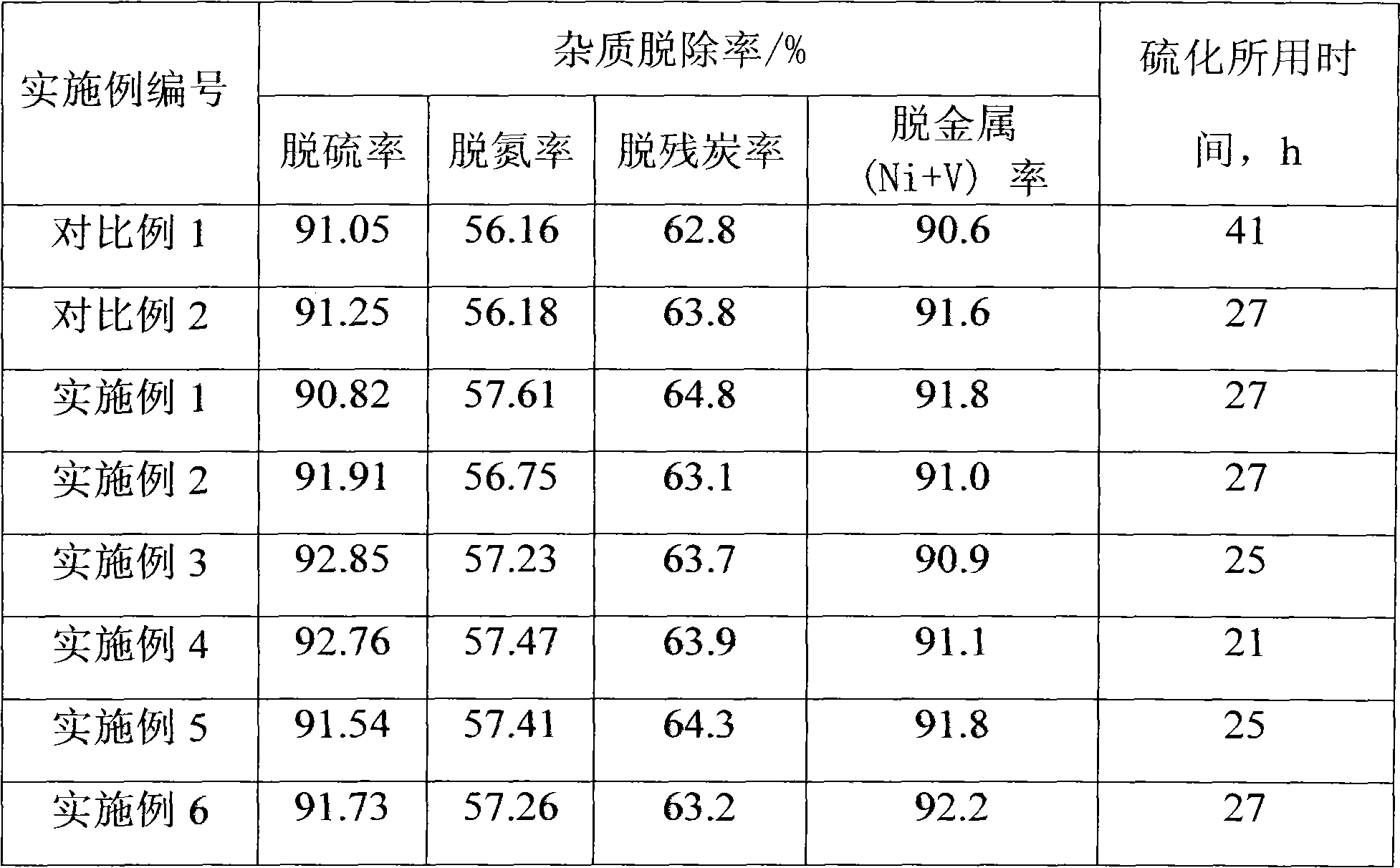

Start working method for hydrocracking process

ActiveCN101492613AHigh vulcanization rateHigh Sulfur Utilization EfficiencyHydrocarbon oil crackingSulfurEconomic benefits

The invention discloses a hydrocracking process operation method. Hydrocracking pre-refining catalyst is treated by precuring outside a reactor while hydrocracking catalyst is not treated or is partially treated by precuring outside the reactor. Curing ingredient introduced by the hydrocracking pre-refining catalyst and the hydrocracking catalyst precured outside the reactor accounts for 90-120% of the theoretical sulfur demand for all the catalyst. The hydro cracking pre-refining catalyst and the hydro cracking catalyst are layered in the reactor and then activated by heating, so that all the catalyst is sulfurated effectively. The method of the invention can precure the hydrocracking pre-refining catalyst outside the reactor or precure the hydrocracking pre-refining catalyst and partial hydrocracking catalyst outside the reactor, thus reducing the catalyst requiring precuring outside the reactor, reducing the production period and production cost of the precuring catalyst and improving the economic benefit and production security.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfurized hydrogenation catalyst, prepn. method

ActiveCN1861260AGood pre-vulcanization effectEasy to useCatalyst activation/preparationRefining to eliminate hetero atomsHydrodesulfurizationSulfur

A process for preparing the sulfurizing hydrocatalyst used for the hydrodesulfurizing and hydrodenitrifying reactions of light fractional oil and the hydrosaturating of arylhydrocarbon includes such steps as carrying a certain part of the precursor compound of the metal in VI and VIII families, introducing sulfur to it, heat treating, introducing the rest of said precursor compound, and drying.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for regenerating and pre-vulcanizing hydrogenation catalyst

InactiveCN102310006AEasy to useImprove active recovery effectCatalyst regeneration/reactivationCatalyst activation/preparationVulcanizationActive state

The invention discloses a method for regenerating and pre-vulcanizing a hydrogenation catalyst, which comprises the following steps of: after carrying out charcoal burning on the inactivated hydrogenation catalyst, cooling to a certain temperature; and then directly carrying out suitable pre-vulcanizing treatment and passivating treatment outside a device. In the method disclosed by the invention, the regeneration and vulcanization of the inactivated hydrogenation catalyst are organically combined, so that the generated catalyst is directly subjected to pre-vulcanizing and passivating treatment without being cooled, active metal components can be in a certain active state, and at the time, if the pre-vulcanizing is directly carried out, the vulcanizing effect and the utilization rate of a vulcanizer can be improved. A test shows that in the process, the activity recovery effect of the regenerated catalyst can be improved and the service performance of the regenerated catalyst can be improved. Meanwhile, due to the adoption of the method disclosed by the invention, the energy consumption can be reduced, the production cost is reduced and the production period is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

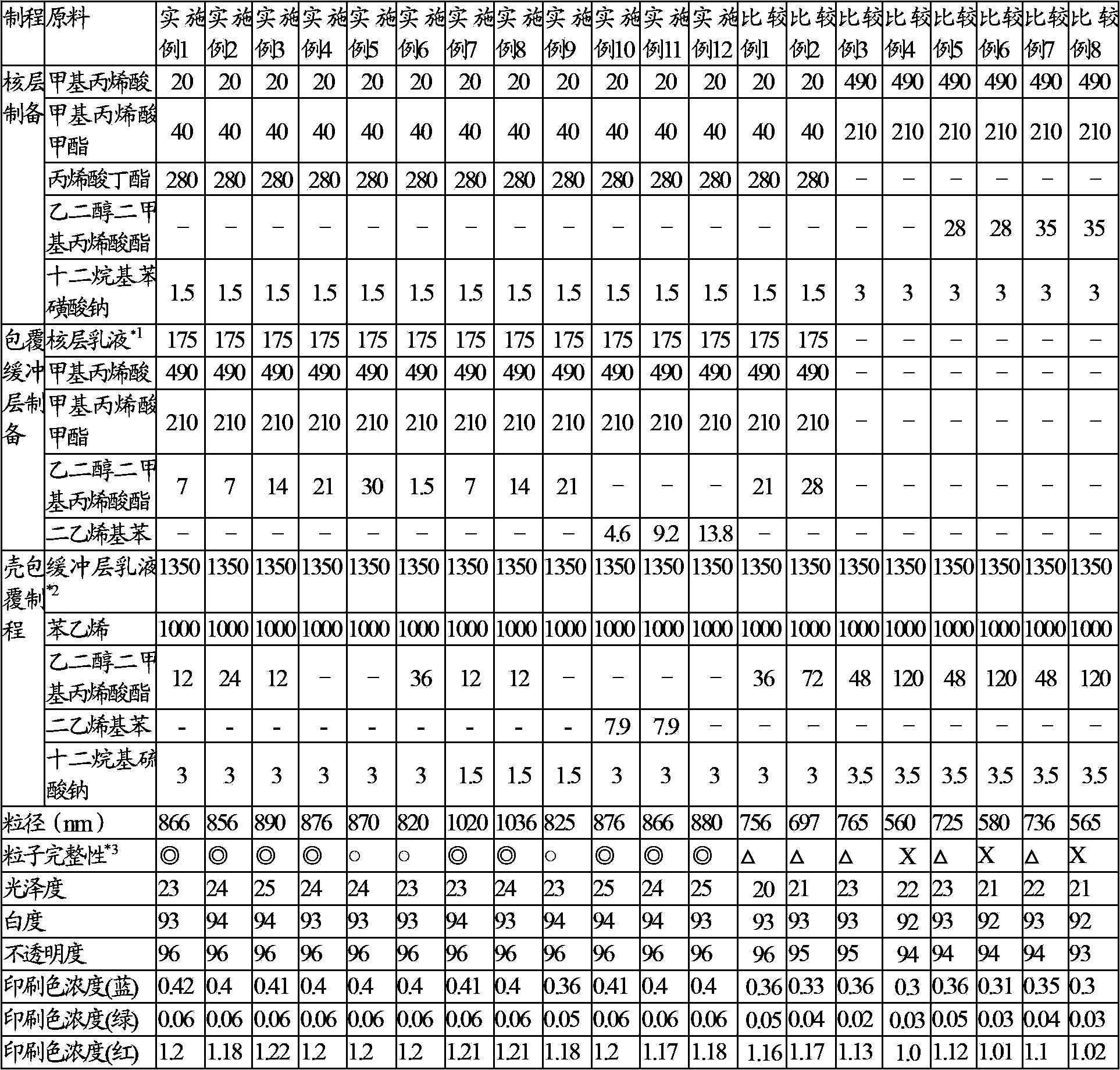

Preparation method of hollow polymer microspheres

ActiveCN103524653AImprove stabilityWell mixedPowdery paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a preparation method of hollow polymer microspheres. Hollow particles with buffer layers are prepared by a three-stage reaction process; the hollow particles are complete in structure, uniform in particle diameter, applied to a plastic or a paper coating, high in gloss, whiteness and non-transparency, and have characteristics of good printing color concentration and printing water resistance.

Owner:NANYA PLASTICS CORP

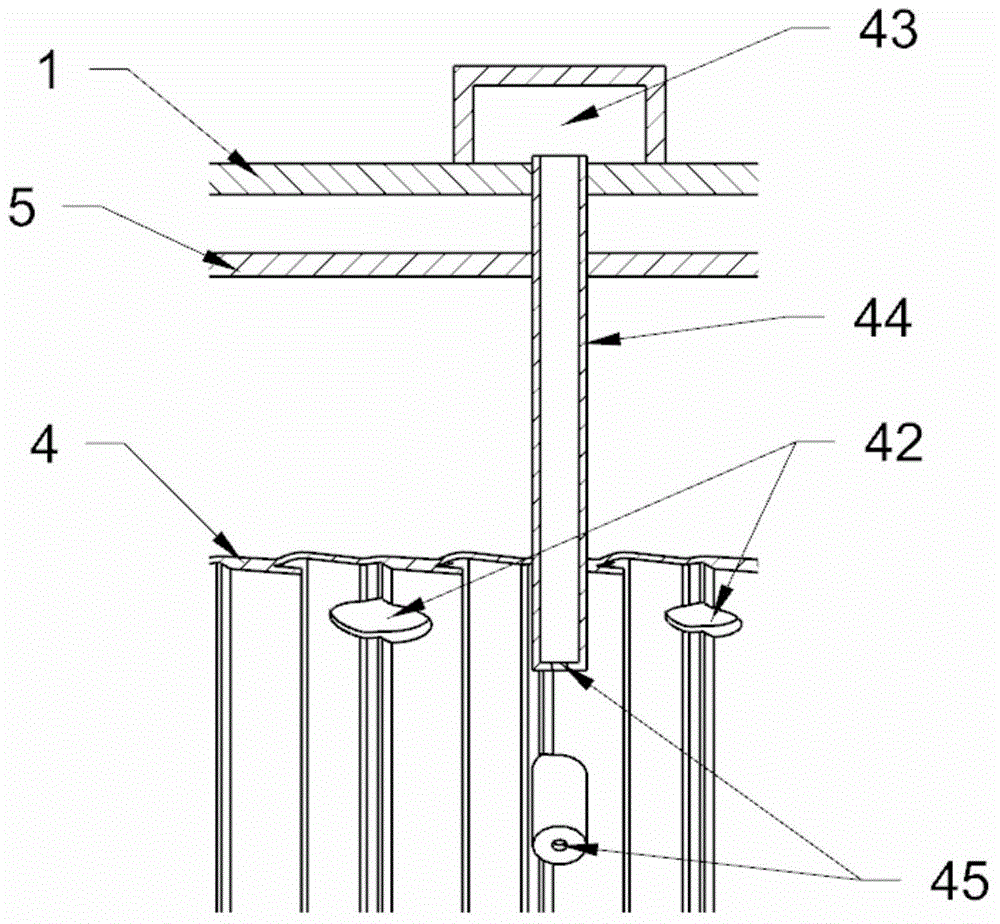

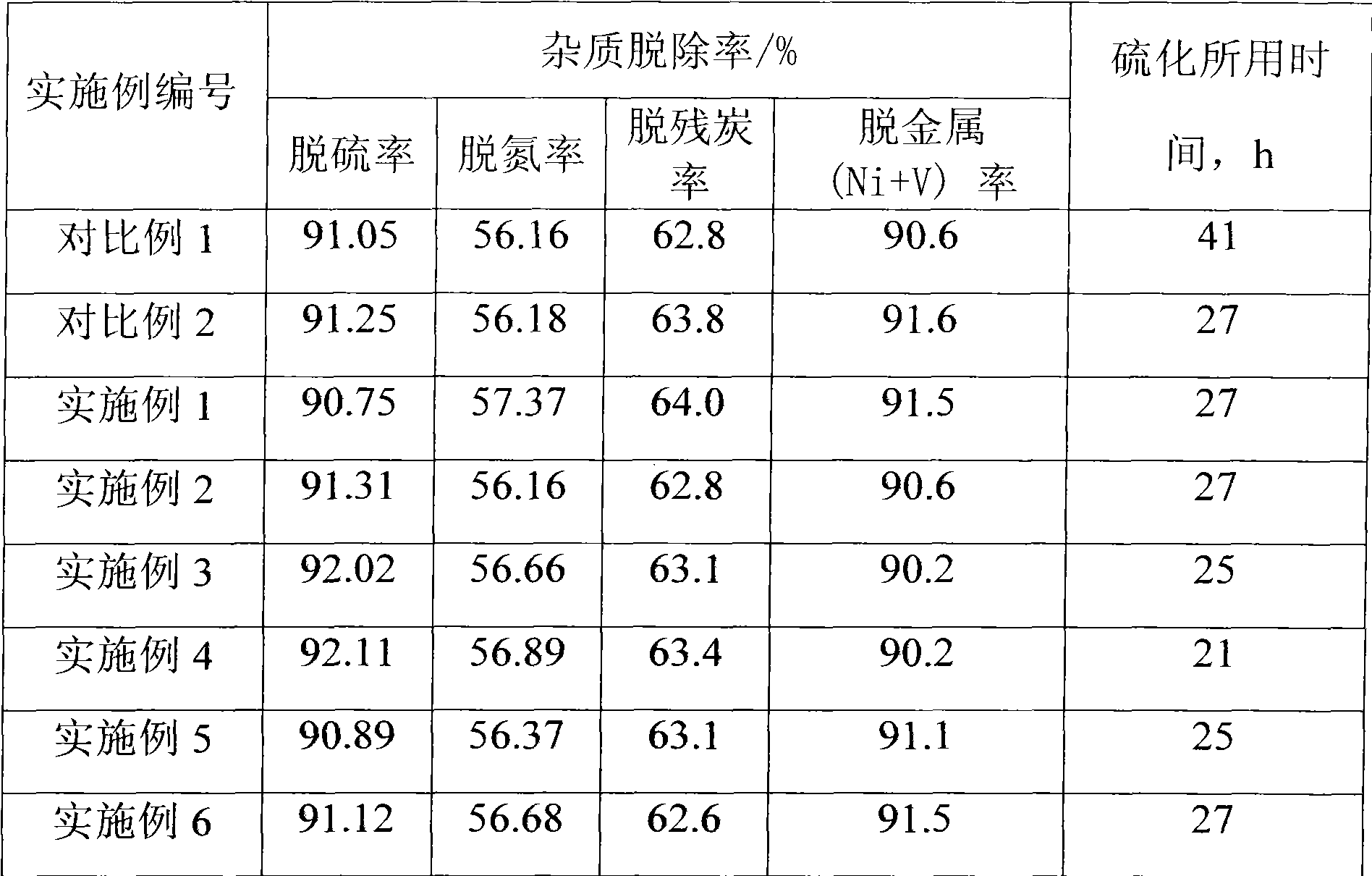

On-stream method of residual oil hydrogenation process

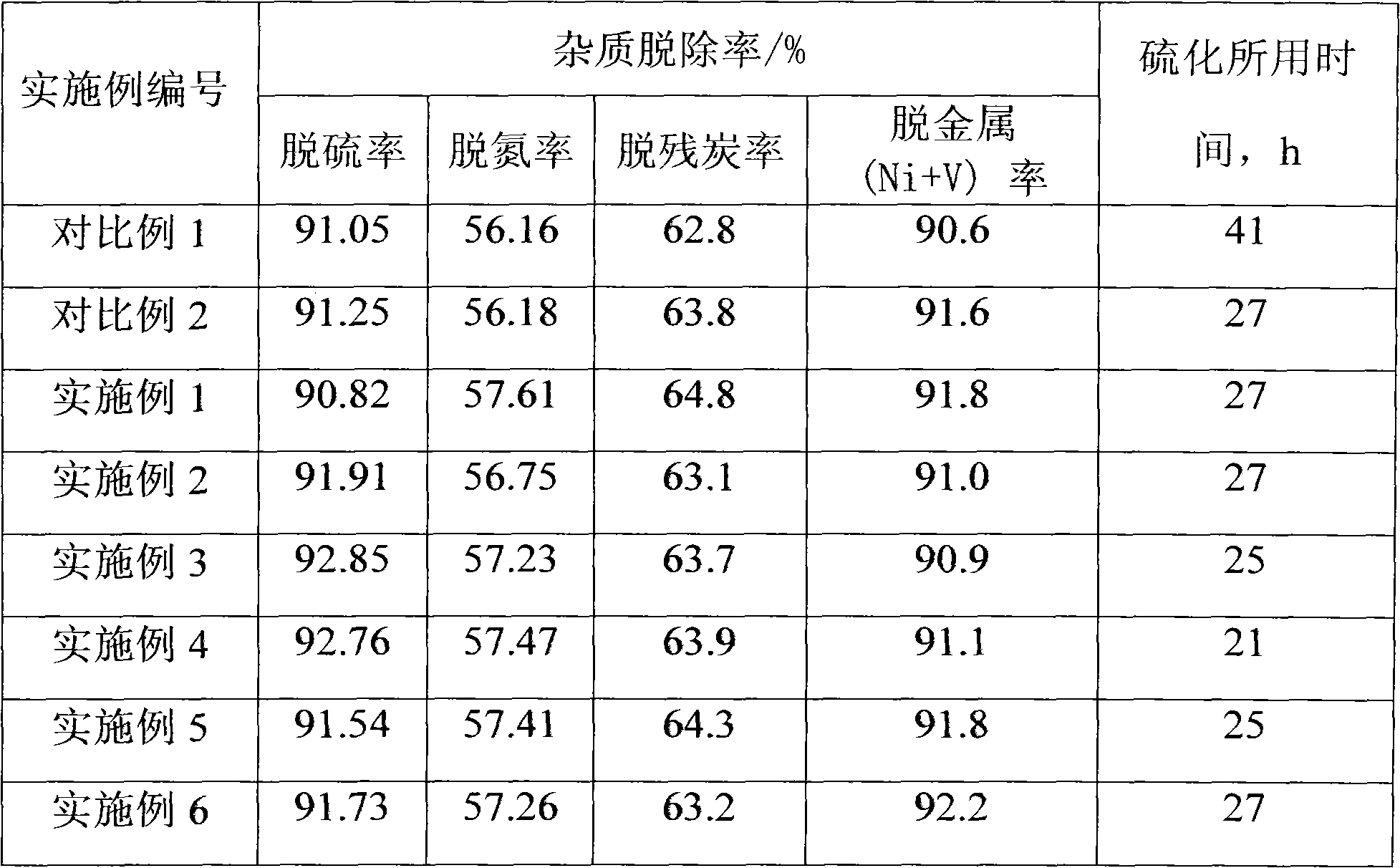

ActiveCN102041044AHigh vulcanization rateHigh sulfur retentionCatalyst activation/preparationRefining to eliminate hetero atomsHydrogenation processOxidation state

The invention discloses an on-stream method of a residual oil hydrogenation process, comprising the steps of: selecting oxidation-state residual oil hydrogenation serial catalysts according to the requirement of the residual oil hydrogenation process, wherein the oxidation-state residual oil hydrogenation serial catalysts comprise a residual-oil-hydrogenation protective agent, a residual-oil-hydrogenation demetalization catalyst, a residual-oil-hydrogenation desulfurization catalyst and a residual-oil-hydrogenation denitrification agent; treating the residual-oil-hydrogenation protective agent, the oxidation-state residual-oil-hydrogenation desulfurization catalyst and the oxidation-state residual-oil-hydrogenation denitrification agent by using an ex-situ pre-sulfurization method; and loading the needed catalysts in a reactor, heating, activating and switching the residual oil raw materials to carry out the hydrogenation. Through the method provided by the invention, ex-situ pre-sulfurization is only carried out on partial catalysts needed by the residual oil hydrogenation process, thereby keeping the advantages of the ex-situ pre-sulfurization process, saving the production cost and preventing the increase of the production cost caused by the high loss, which is easily caused in the ex-situ pre-sulfurization process, as the residual-oil-hydrogenation demetalization catalyst per se has low intensity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid chemical dredging agent for pipeline dredging and preparing method thereof

InactiveCN1488781AAchieve the purpose of dredgingImprove dredging effectCleaning using liquidsSodium dodecylbenzenesulfonateCleansing Agents

The present invention relates to a solid chemical pipe cleaning agent and its preparation method. It is characterized by that it is formed from 52-68% of granular sodium hydroxide, 11-19% of sodium carbonate, 15-21% of high test bleaching powder, 4-10% of sodium dodecyl benzene sulfonate and 0.02% of essence. Said invention has no need of adding metal aluminium, can obtain good cleaning effect, and can be used for killing pathogenic bacteria and insect eggs. Said invention also provides its preparation method and production steps.

Owner:汪立强

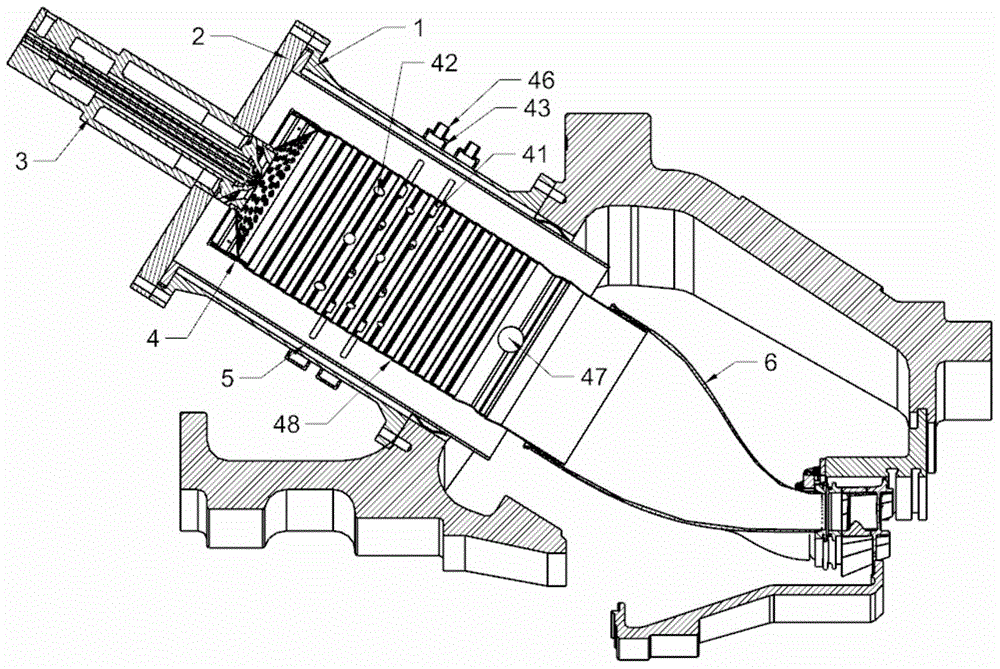

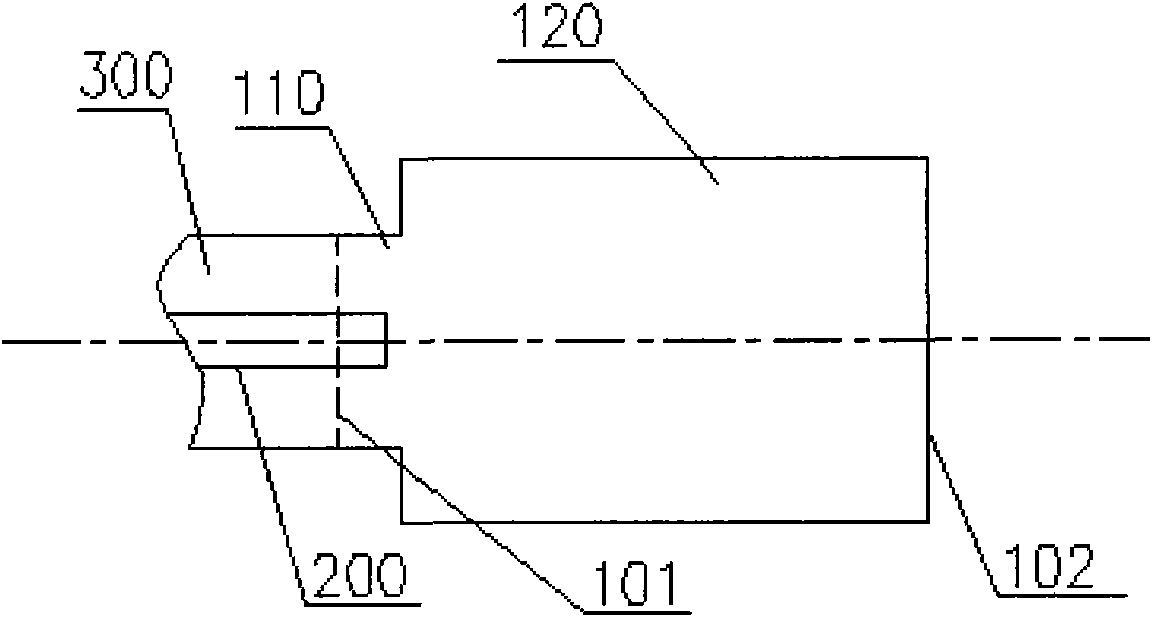

Distributed-flame combustion chamber head structure

ActiveCN104566470AReduce cooling effectReduce consumptionContinuous combustion chamberNitrogen oxidesGeneration rate

The invention relates to the technical field of gas turbine combustion chambers, and discloses a distributed-flame combustion chamber head structure. The distributed-flame combustion chamber head structure comprises a main spray nozzle, a central on-duty spray nozzle, a combustion chamber outer wall and a combustion end plate, wherein the main spray nozzle comprises a plurality of main combustion pipes; the combustion end plate is fixed at the back end of the combustion chamber outer wall; the central on-duty spray nozzle is arranged in the center of the combustion end plate; the main combustion pipes pass through the combustion end plate, extend into the combustion chamber outer wall, and are arranged around the outer side of the central on-duty spray nozzle; at least one radial combustion pipe is arranged on a part, which extends into the combustion chamber outer wall, of each main combustion pipe; the radial combustion pipes are positioned on the upstream of the front end of the central on-duty spray nozzle; each radial combustion pipe is provided with a main fuel spray nozzle; the combustion end plate is provided with a plurality of main air inlets. Distributed flame is established, so that defects caused by non-uniform heat release are overcome, and the generation rate of nitrogen oxides is restrained.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

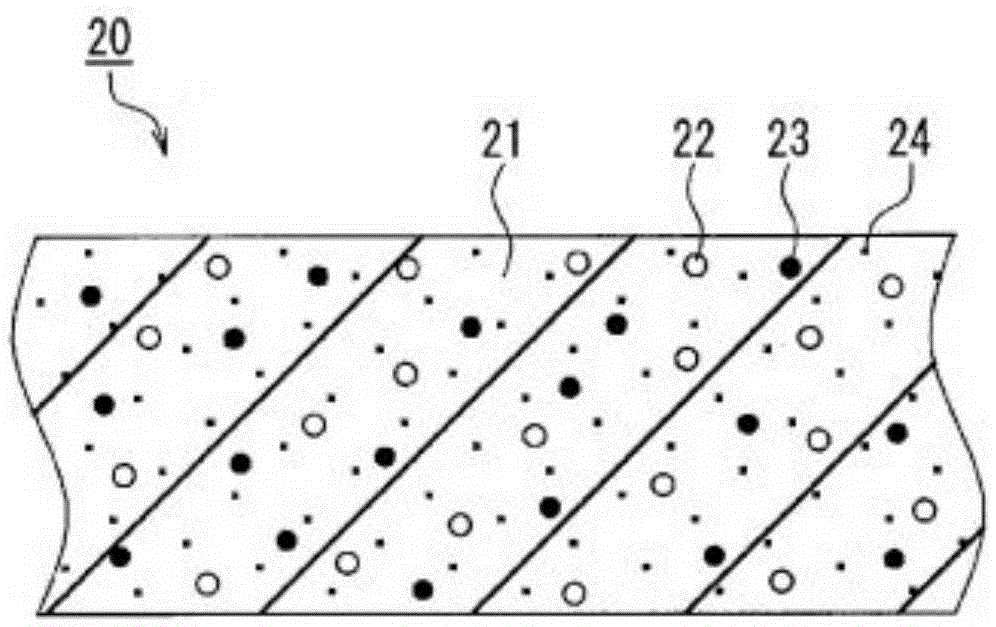

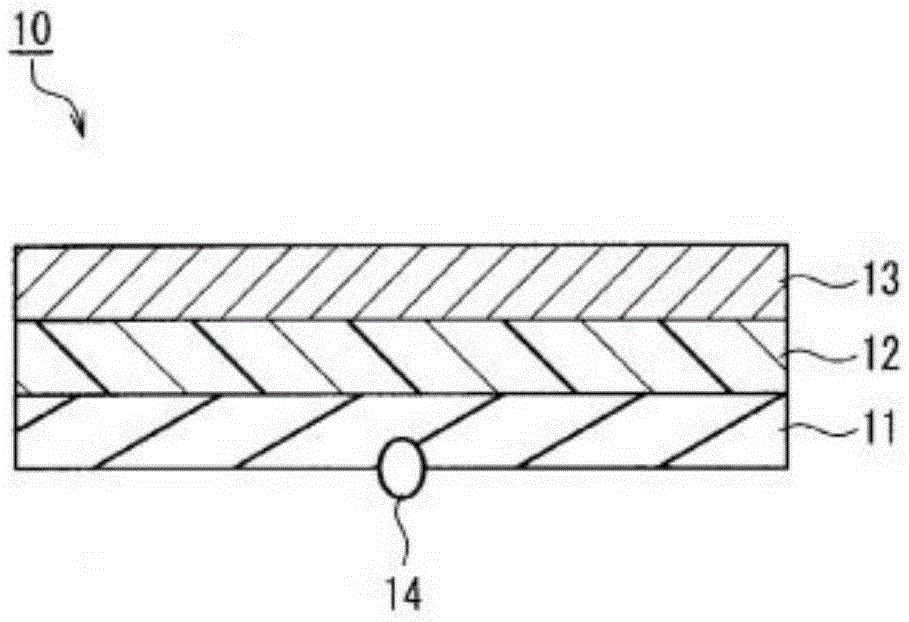

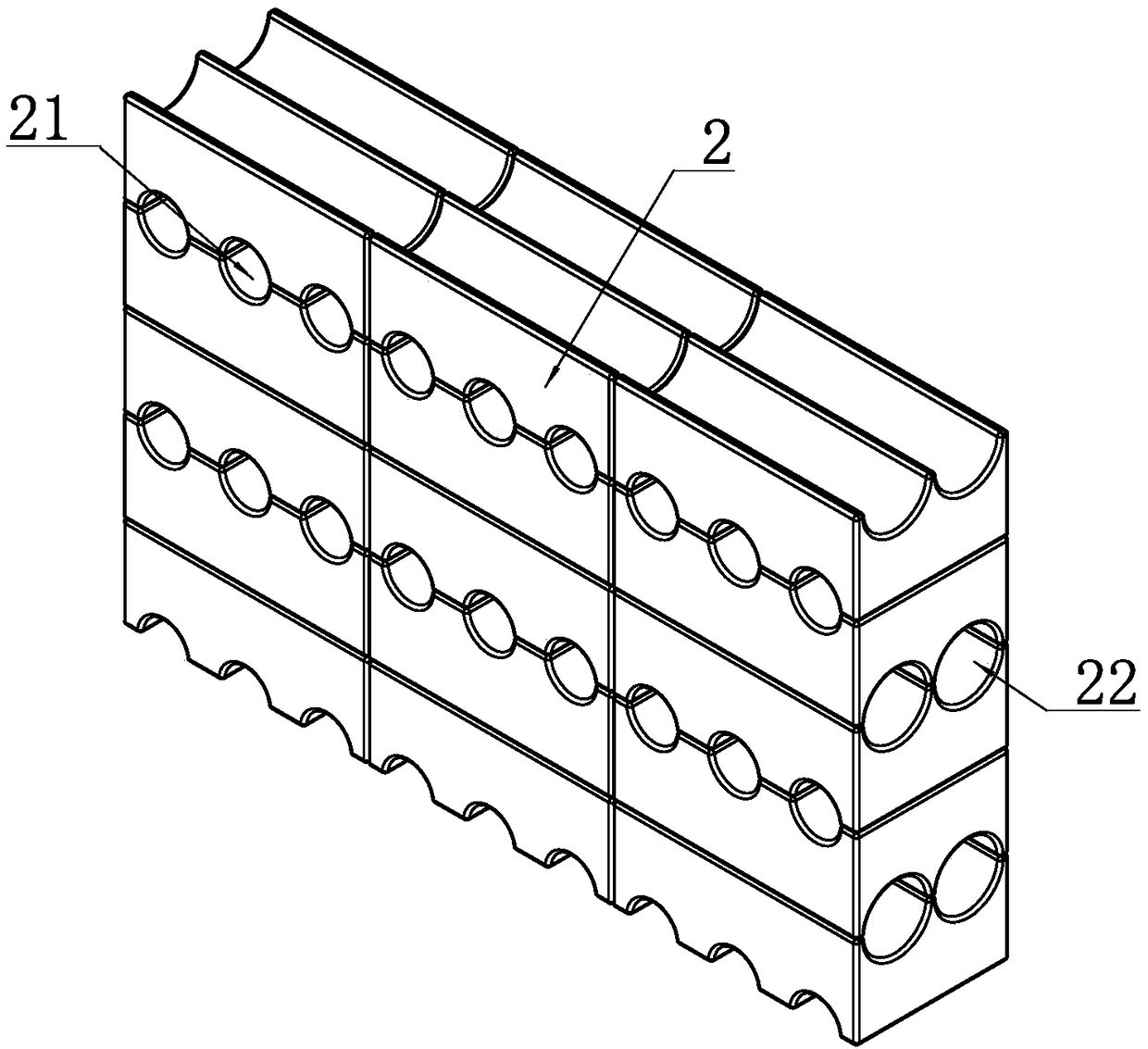

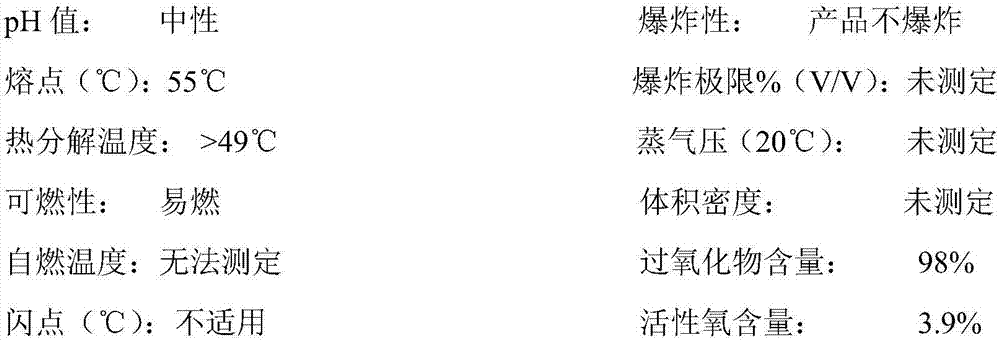

Heat-storage composition

ActiveCN105264039AImprove heat storage capacityImprove thermal conductivitySemiconductor/solid-state device detailsHeat-exchange elementsElectronThermal transmittance

A heat-storage composition (20) according to the present invention comprises a matrix resin (21) and heat-storage inorganic particles (22), wherein each of the heat-storage inorganic particles (22) comprises a substance that can undergo electronic phase transition and can generate latent heat of 1 J / cc or more upon the occurrence of electronic phase transition, and the heat-storage inorganic particles (22) are contained in an amount of 10 to 2000 parts by weight relative to 100 parts by weight of the matrix resin. The heat-storage composition (20) has a heat conductivity of 0.3 W / mK or more. The heat-storage composition may additionally comprise heat-conductive particles (23, 24). The heat-storage inorganic particles are preferably metal oxide particles each containing vanadium as the main metal component. The composition has a high heat storage property and high heat conductivity. The heat-storage silicone material is intercalated between a heat-generating part and a housing for use. Heat coming from the heat-generating part is stored once in the heat-storage composition to delay the conductivity of the heat. During this time, the heat is diffused and therefore partial heating can be avoided. In this manner, uniform heat dissipation can be achieved.

Owner:FUJI POLYMER INDUSTRIES CO LTD +1

Method for regenerating and prevulcanizing hydrogenation catalysts

ActiveCN102039207AImprove active recovery effectEasy to useCatalyst regeneration/reactivationCatalyst activation/preparationVulcanizationActive state

The invention discloses a method for regenerating and prevulcanizing hydrogenation catalysts. After charcoal is inactivated, inactivated hydrogenation catalysts are cooled to a certain temperature and then are directly prevulcanized correctly outside a device. With the method, the regeneration and the prevulcanization of inactivated hydrogenation catalysts are integrated, regenerated catalysts are directly prevulcanized without cooling, active metal components are enabled to be in an active state, and then, the vulcanization effect and the utilization rate of vulcanizing agents can be increased by direct prevulcanization. Experiments show that the process can also increase the activity recovery effect and the usage of regenerated catalysts. In addition, the method also has the advantages of reducing the energy consumption and the production cost and shortening the production period.

Owner:CHINA PETROLEUM & CHEM CORP +1

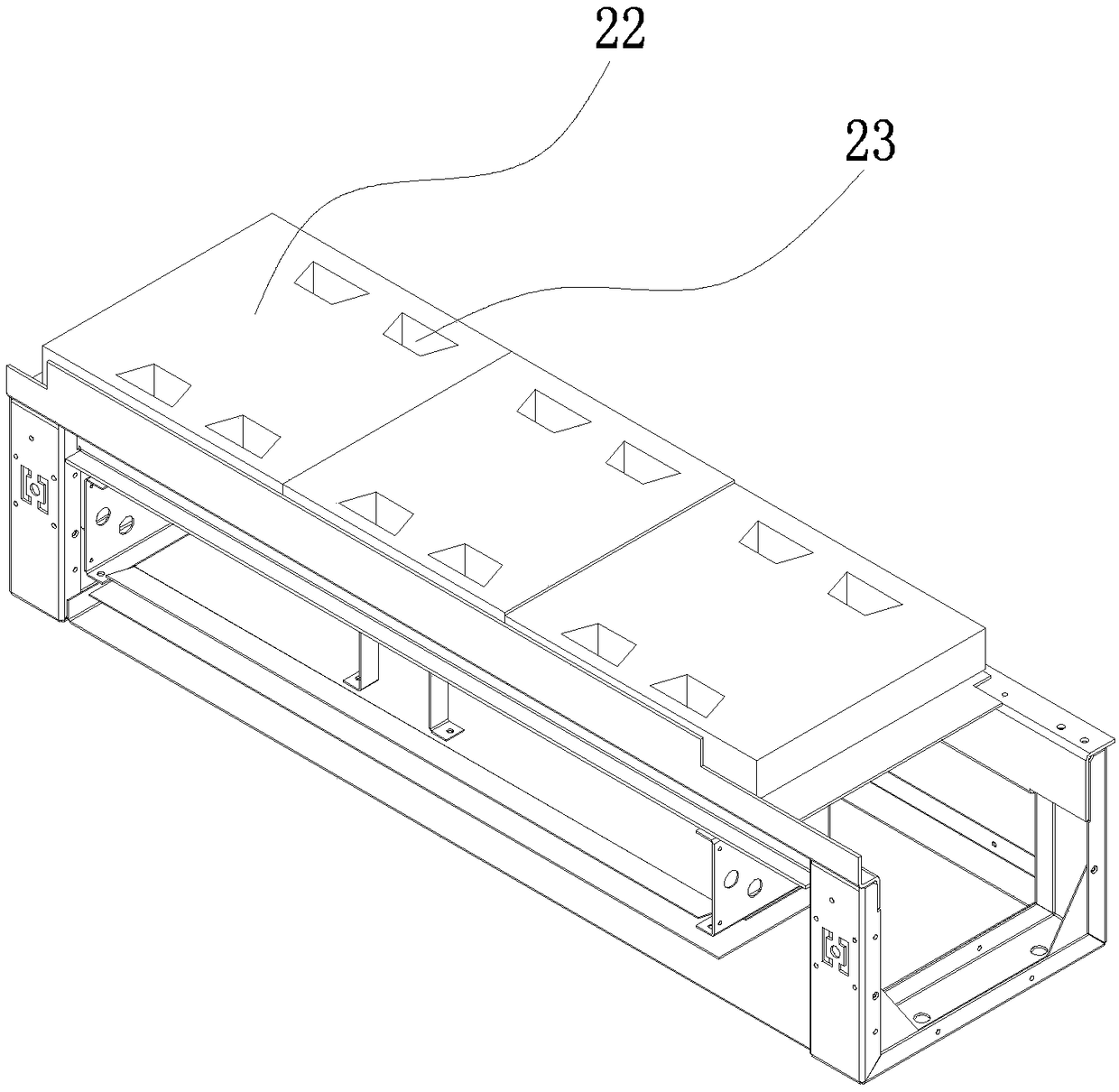

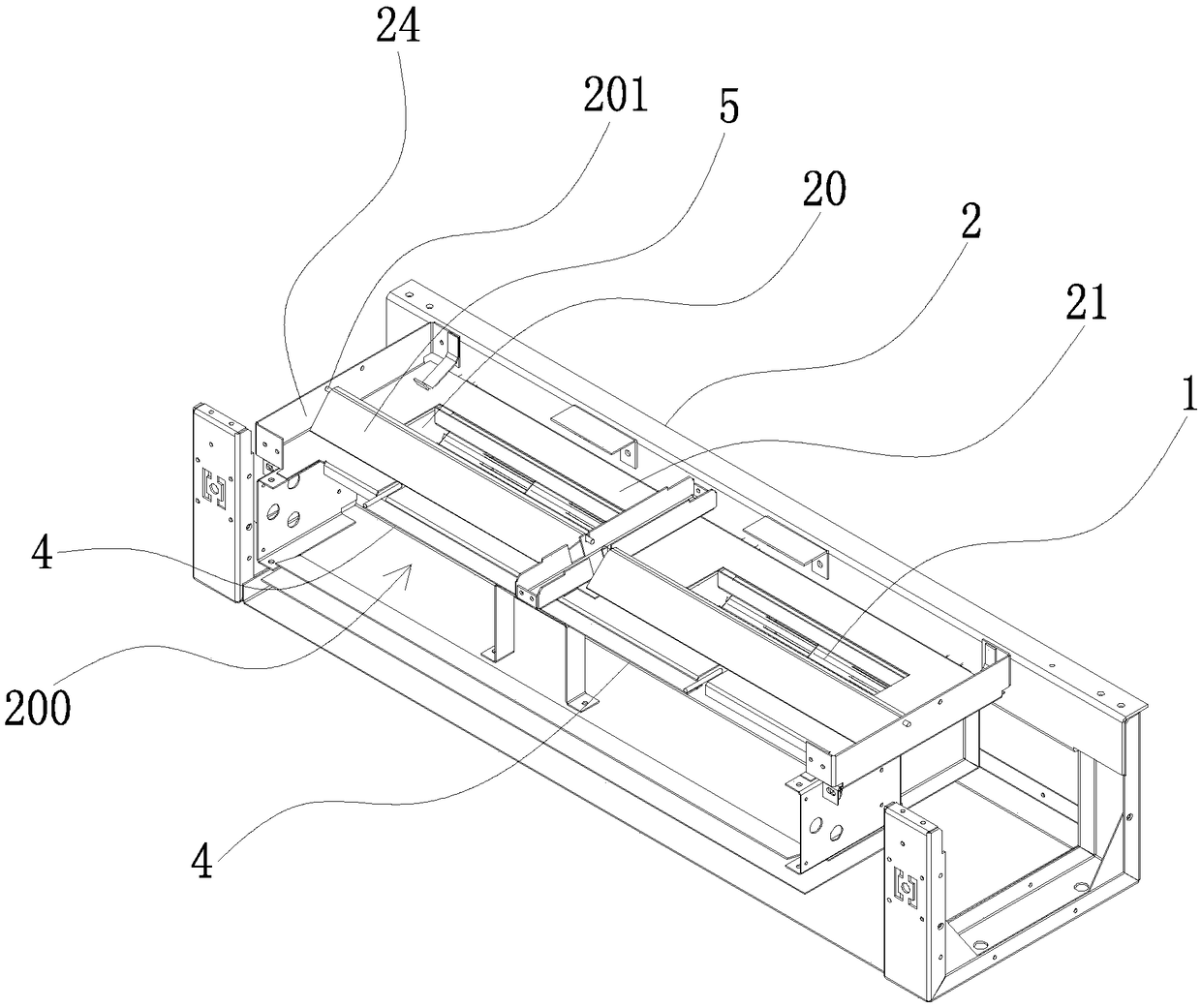

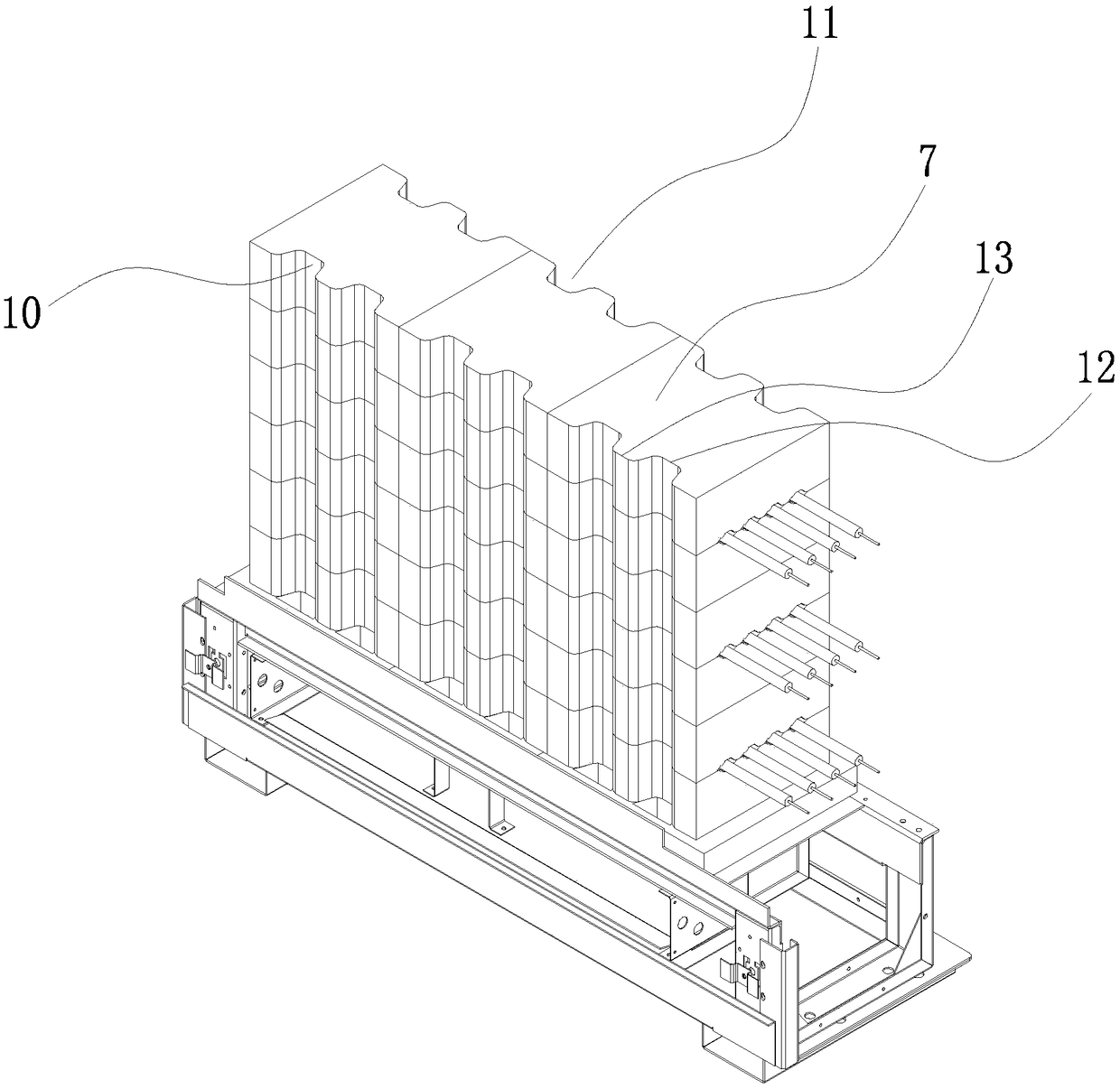

Family type clean energy station

PendingCN108800575ATake advantage ofReduce use costHeat storage plantsStorage heatersInterior spaceElectricity

The invention discloses a family type clean energy station. The energy station comprises a box and a partition plate. The partition plate divides the internal space of the box into a heat storage areaand a heat release drive area. A heat storage body is arranged in the heat storage area and internally provided with heat storage channels and heat release channels. Electric heating assemblies are arranged in the heat storage channels correspondingly. A first heat preservation layer is arranged between the heat storage body and the box. A heat exchanger and a first fan are arranged in the heat release drive area. A shell side outlet of the heat exchanger communicates with an inlet of the first fan. An outlet of the first fan communicates with one ends of the heat release channels through a first pipeline. The other ends of the heat release channels communicate with a shell side inlet of the heat exchanger through a second pipeline. According to the energy station, the national off-peak electricity policy of power peak shaving and valley filling is fully utilized, the energy station is not influenced by the external environment temperature, and the heating requirements of the family type clean energy station for heating, domestic hot water, domestic drying, baking, blanching and the like can be met.

Owner:SHANDONG HUACHUN NEW ENERGY

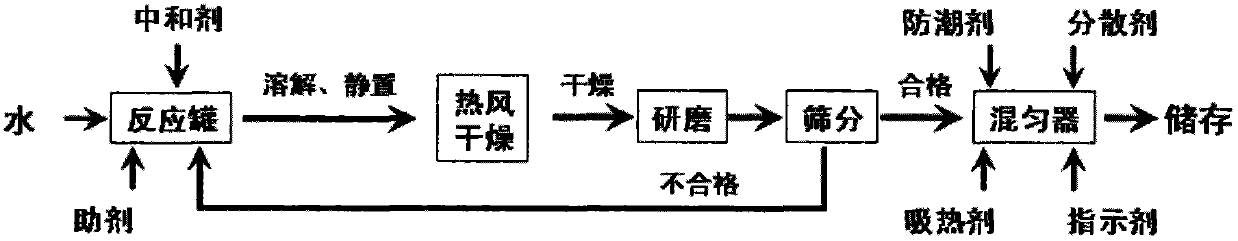

Alkaline powder for treating leaked sulfuric acid and preparation method of alkaline powder

ActiveCN102989114ANo cakingLow hygroscopicityDispersed particle separationMoisture absorptionEnergy consumption

The invention provides alkaline powder for treating leaked sulfuric acid and a preparation method of the alkaline powder. The alkaline powder is prepared from a neutralizer, an aid, a heat absorbent, a moisture-proof agent, a dispersant and an indicator in a certain ratio by a specific method. The raw materials for preparing the alkaline powder are readily available; the preparation method is simple, convenient and low in energy consumption; and the prepared powder does not cake, and is low in moisture absorption and good in settling performance after being sprayed. The alkaline powder can be used for effectively treating the leaked sulfuric acid of which the concentration is 50 to 98 percent or more; and the treatment process has the characteristics of high response speed, low temperature rise, secondary harm prevention, simplicity and convenience in endpoint judgment and the like.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

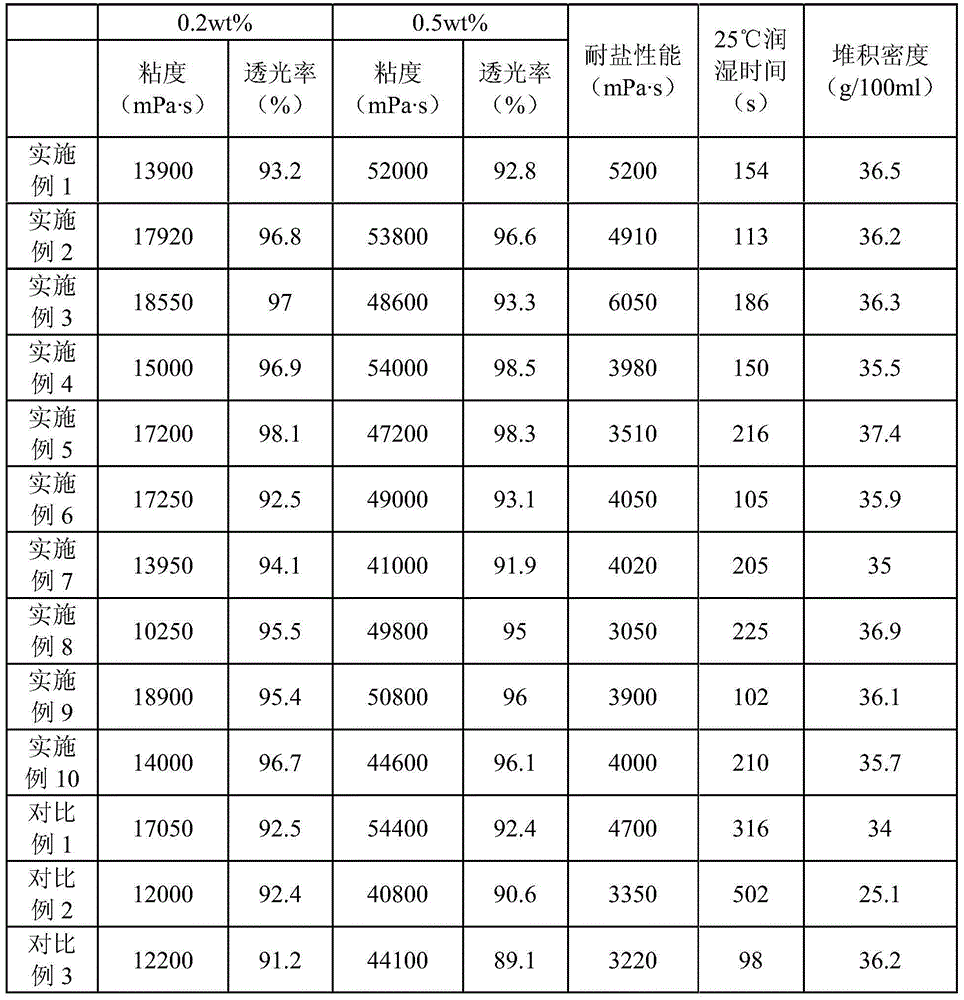

Quick-wetting carboxylic acid copolymer thickening agent and preparation method thereof

ActiveCN104861104AShort wetting timeSmall particle size distribution rangeCross-linkHydrocarbon solvents

The invention provides a preparation method of a quick-wetting carboxylic acid copolymer thickening agent, which comprises the following steps: adding an organic inert solvent containing at least 55wt% of a hydrocarbon solvent, 15wt%-20wt% of a monomer as well as an initiator, a dispersant and a cross-linking agent which are required by reaction into a reaction vessel, and performing reaction at 45-55DEG C for 30-60min; mixing an organic inert solvent containing at least 55wt% of an ester solvent, the rest of the monomer and the initiator, the dispersant and the cross-linking agent which are required by reaction, and adding the mixture into the reaction vessel within 3-6h and reacting under the same reaction temperature; and after all the reactant is dropwise added, raising the temperature to 55-75DEG C, adding the initiator again, performing heat preservation for 1-4h so that the monomer in the reaction system is reacted completely, ending the reaction, and discharging a product. The invention aims to provide the quick-wetting carboxylic acid copolymer thickening agent with quick wetting and dispersing properties and high bulk density, and meanwhile the invention further provides the preparation method of the quick-wetting carboxylic acid copolymer thickening agent.

Owner:GUANGZHOU TINCI MATERIALS TECH

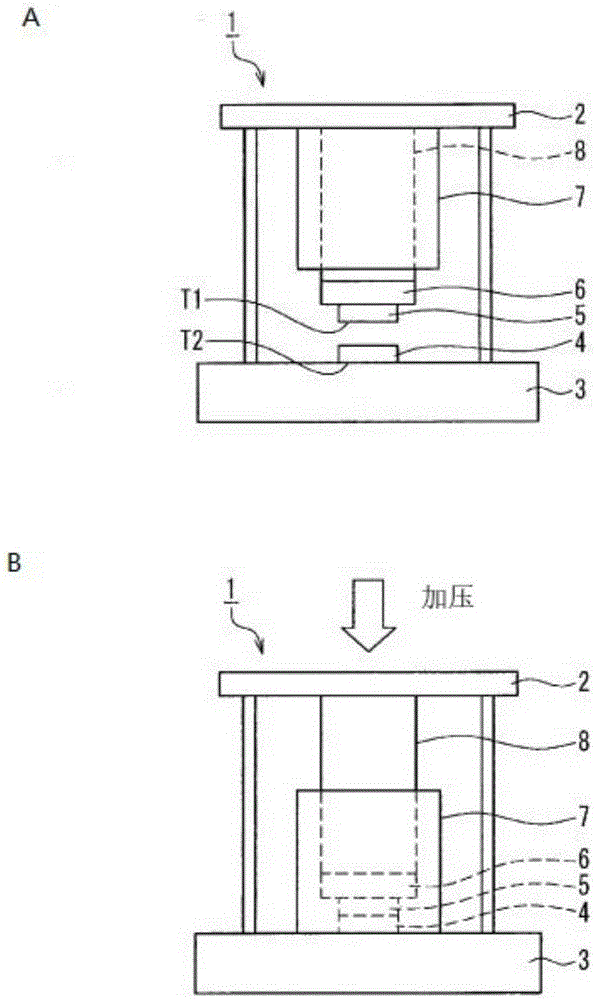

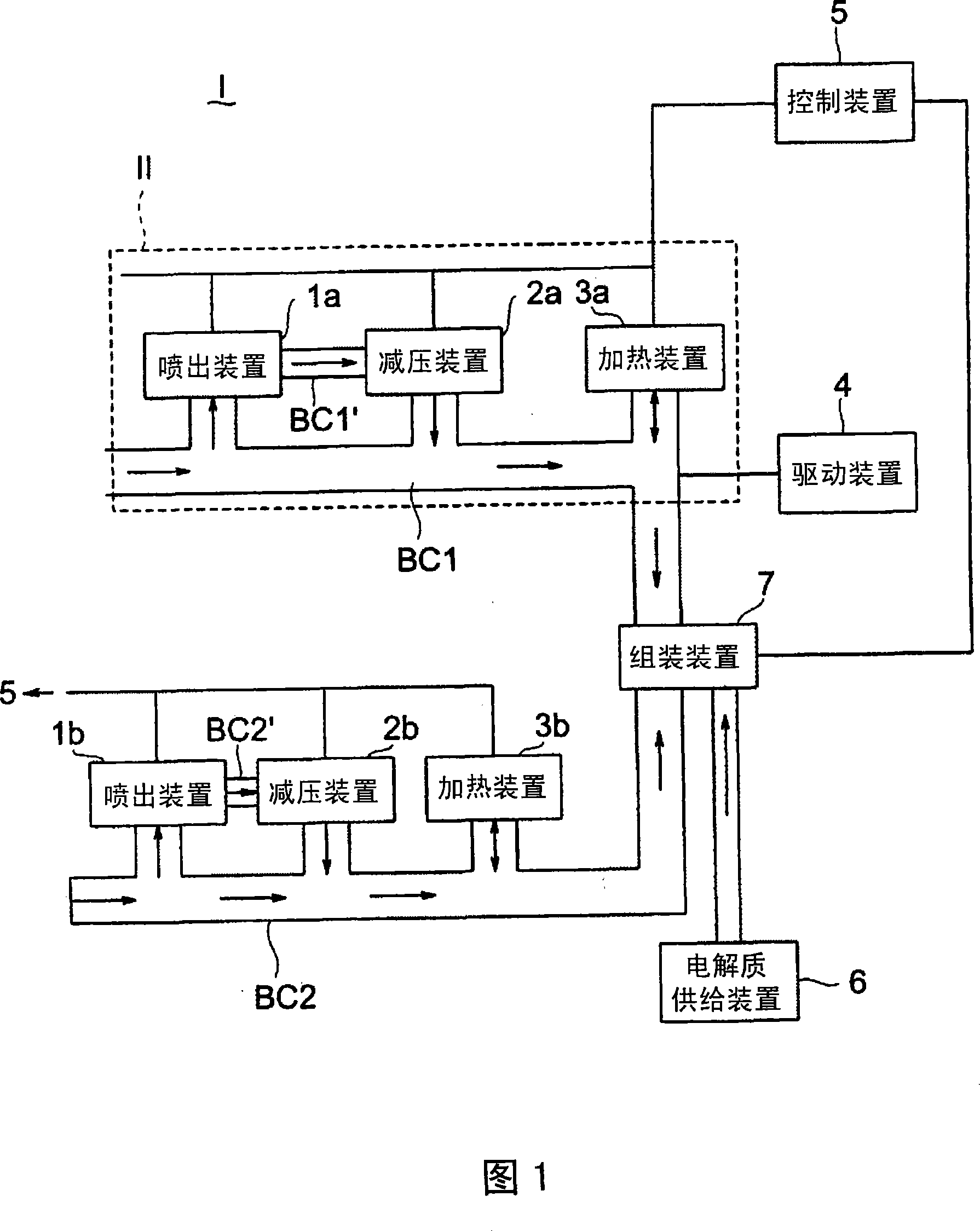

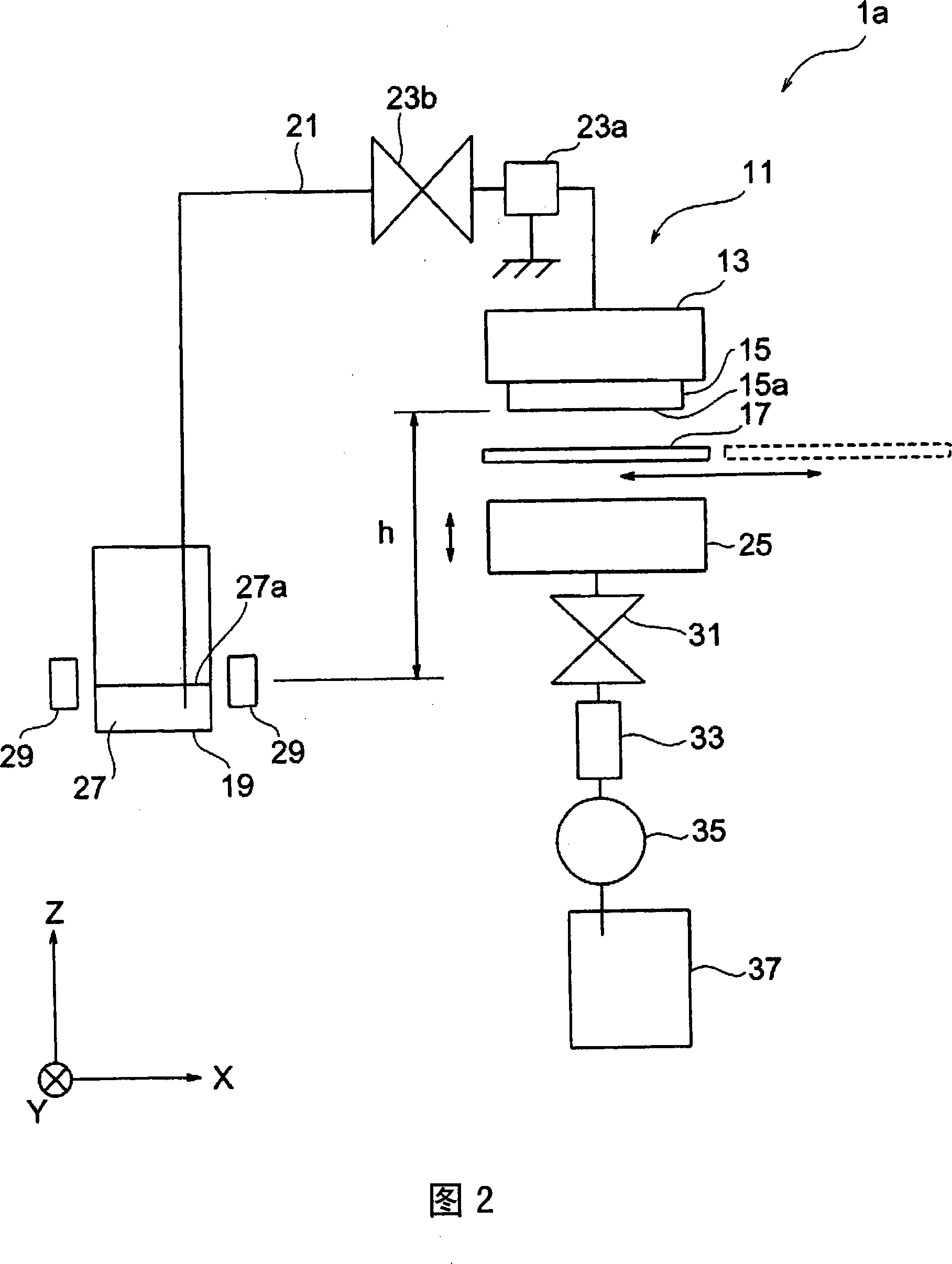

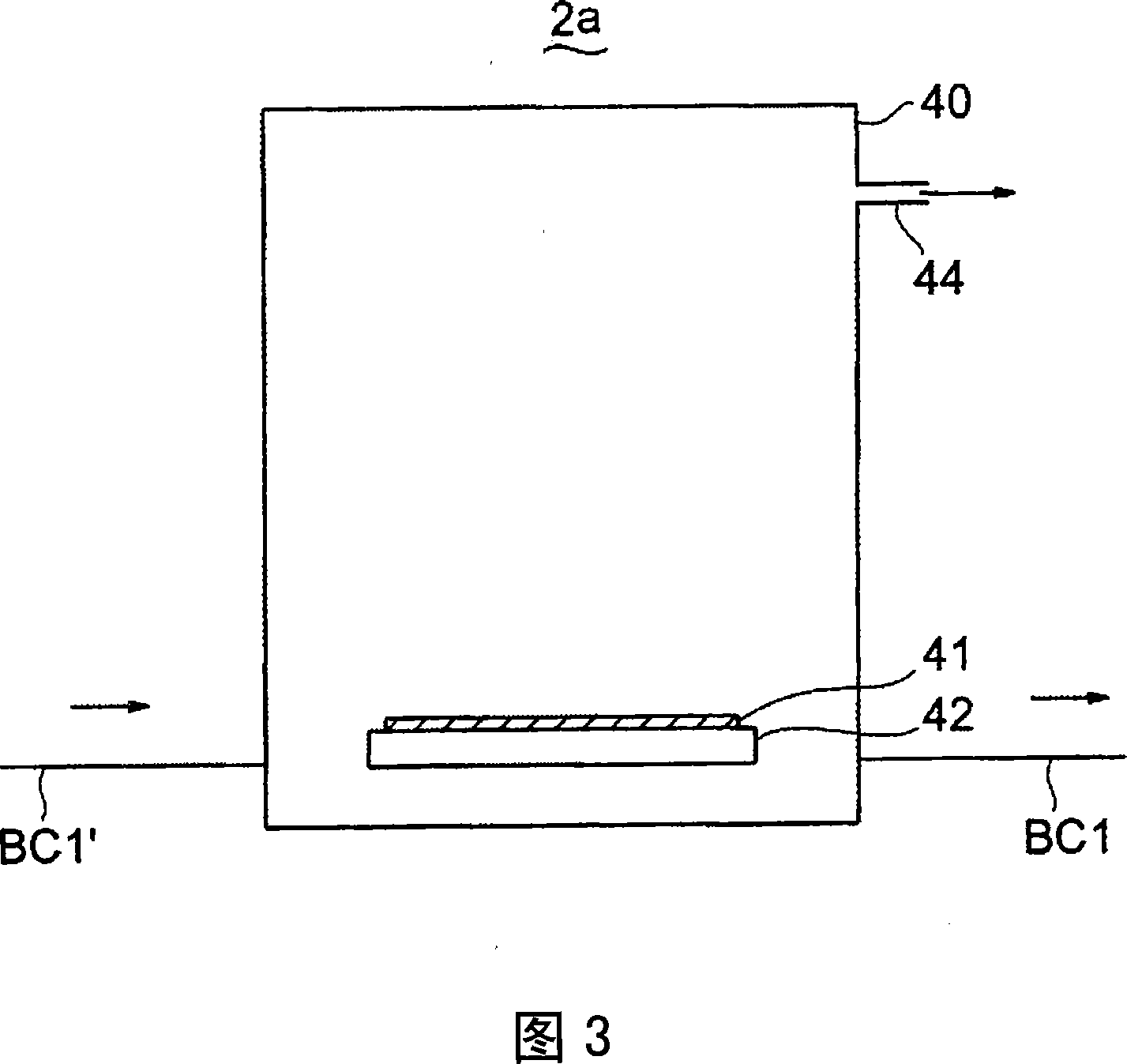

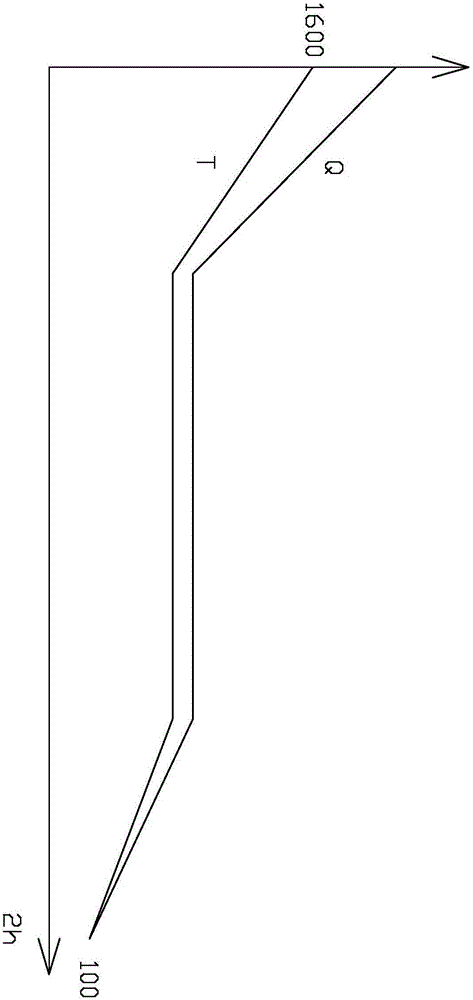

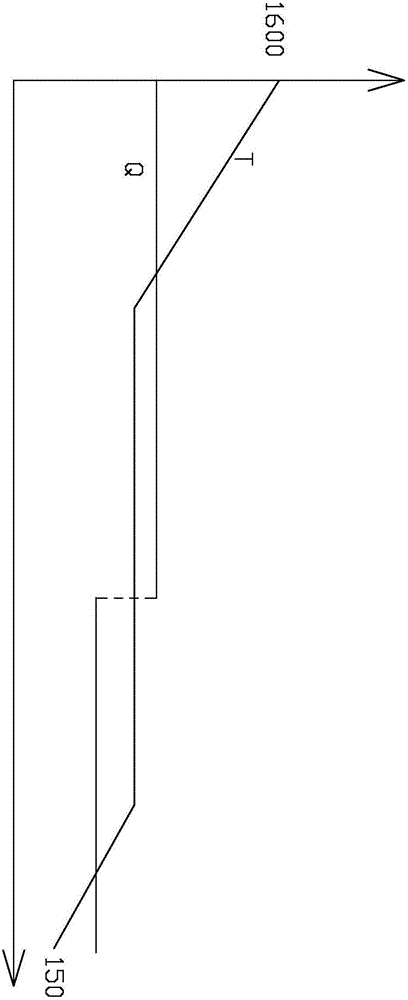

Method for manufacturing electrode, apparatus for manufacturing electrode, and method for manufacturing secondary cell

InactiveCN101055926AUniform heat releaseNo local degradationElectrode manufacturing processesNon-aqueous electrolyte accumulatorsOrganic solventBoiling point

The present invention provides a manufacturing method of an electrode having an electrode layer having a uniform and small thickness without causing drying irregularity, to provide a manufacturing device of an electrode, and to provide a manufacturing method of a secondary battery. This manufacturing method of an electrode is used for manufacturing the electrode having a collector, and the electrode layer formed on the collector and containing an active material. In the manufacturing method of an electrode, a composition for electrode layer formation containing an active material and an organic solvent is discharged on the collector by a droplet discharging device to form a coating film, thereafter an atmosphere including the coating film is depressurized up to pressure for setting the boiling point of the organic solvent at 10-30[deg.]C within a predetermined time and the pressure is kept, whereby the solvent is dried and removed to form the electrode layer. This manufacturing device of an electrode is used for executing the method. This manufacturing method of a secondary battery has a process for forming the electrode by the manufacturing method of an electrode.

Owner:SEIKO EPSON CORP

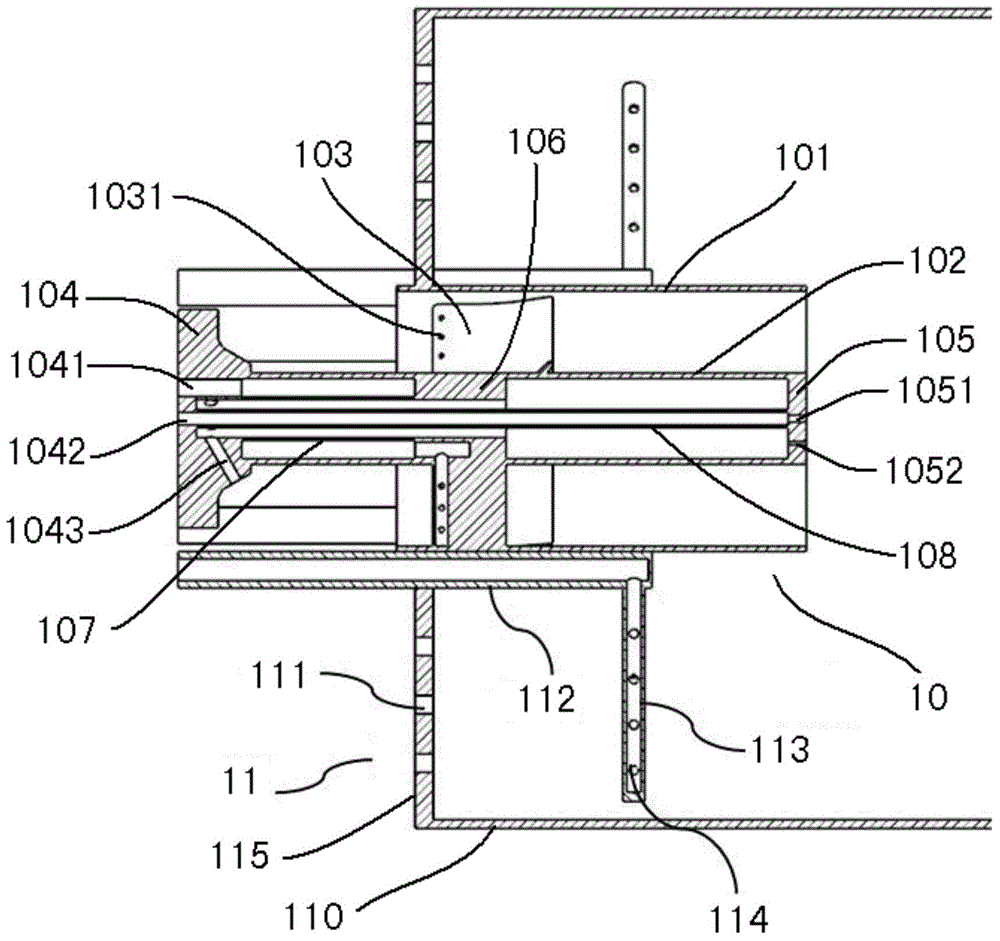

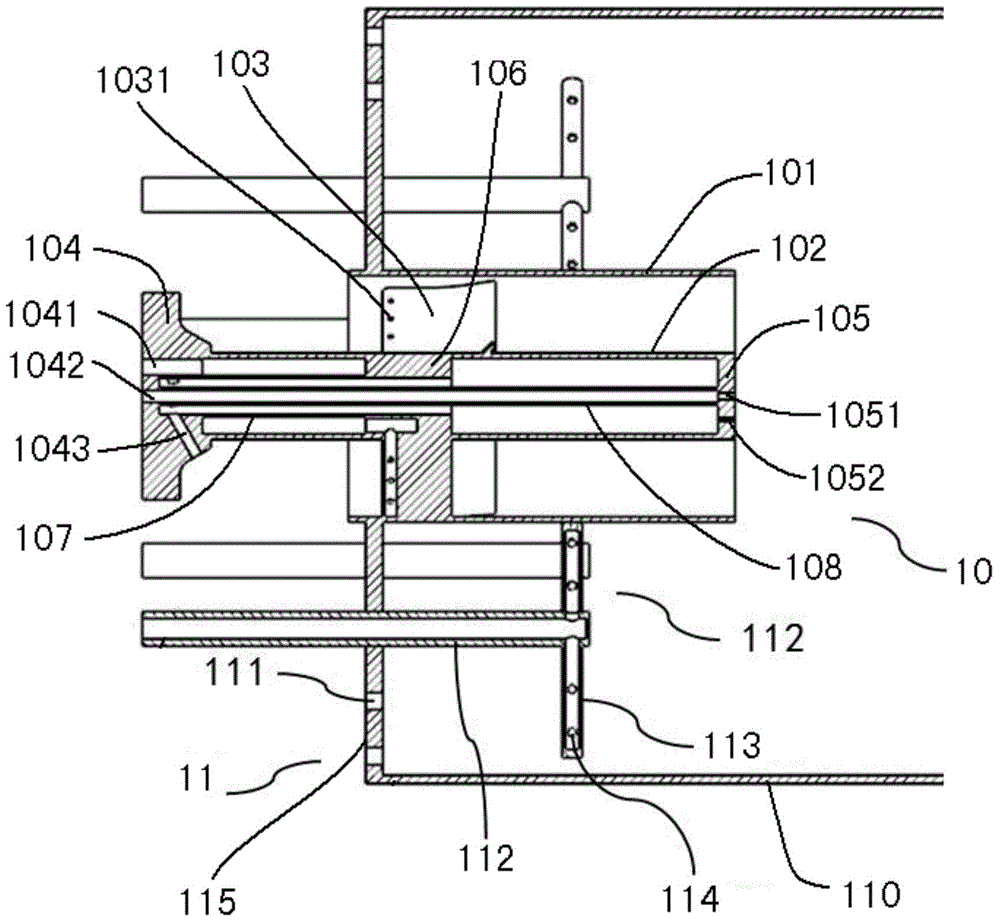

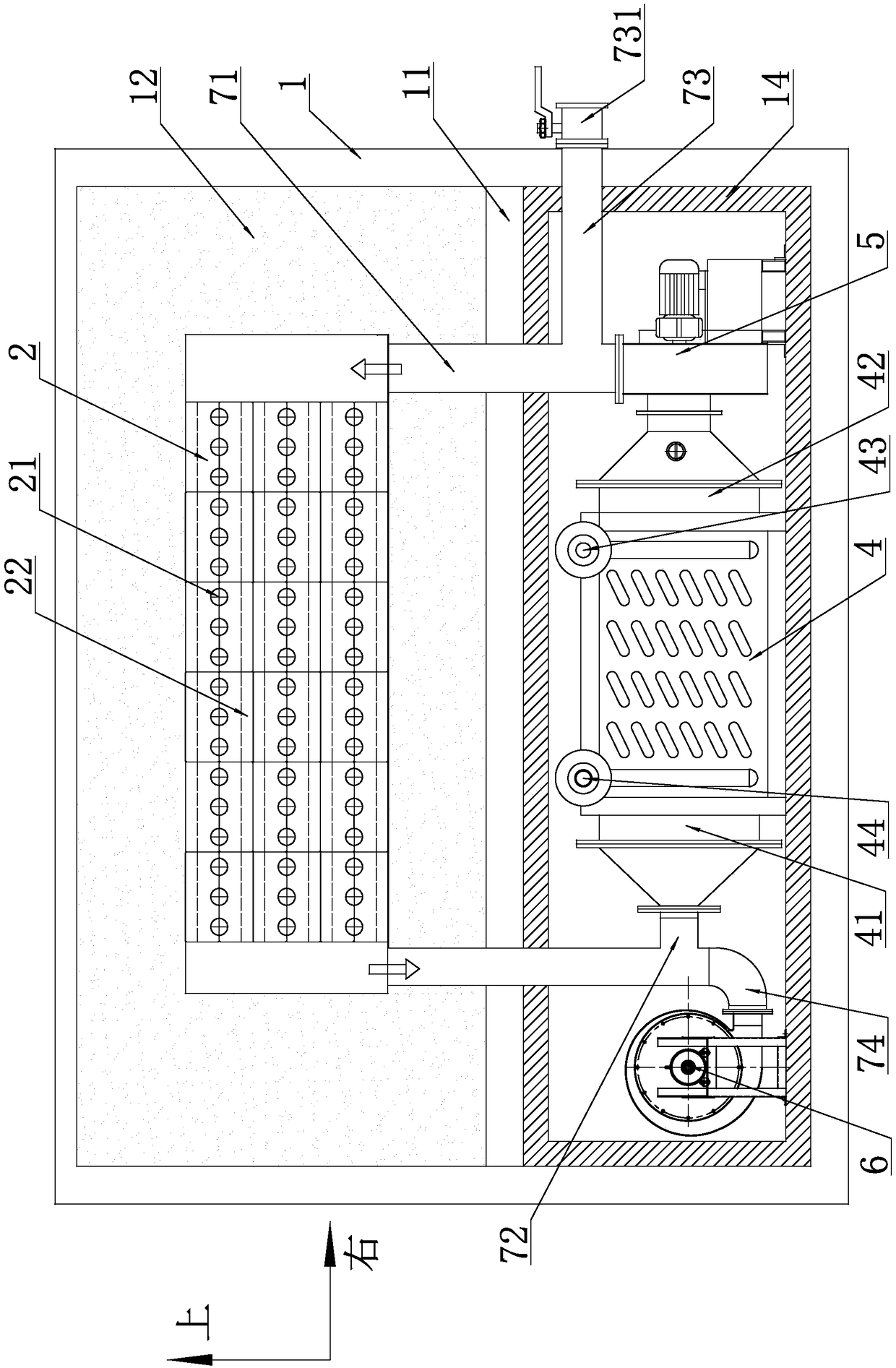

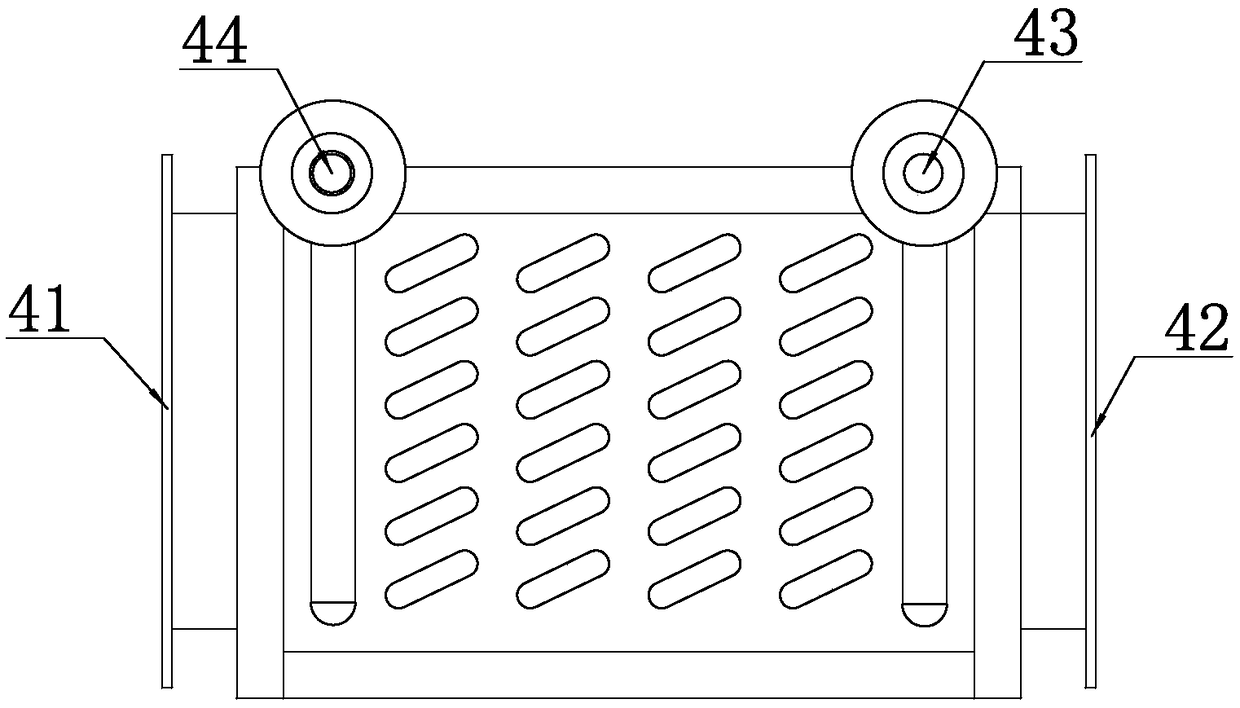

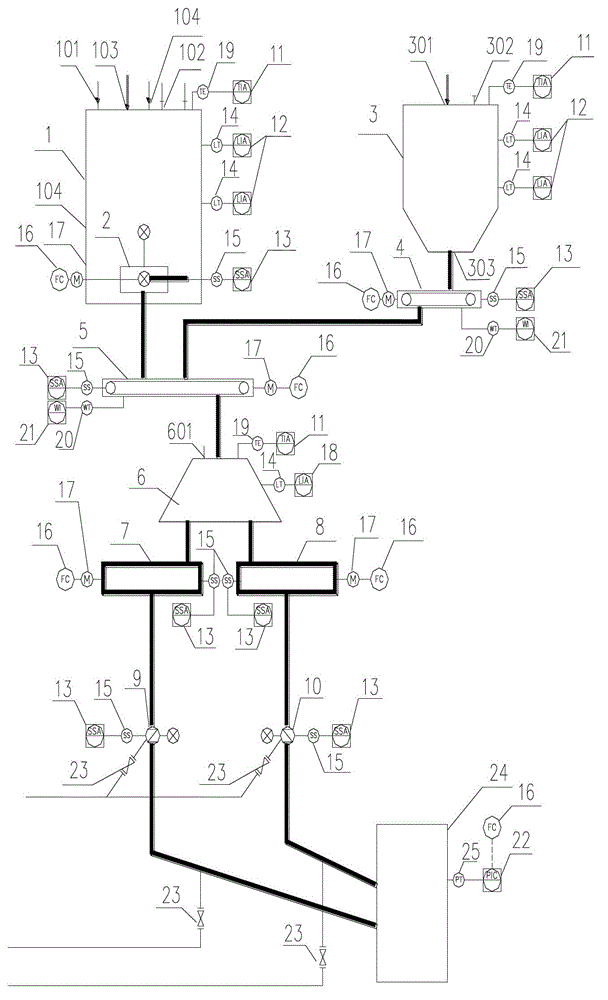

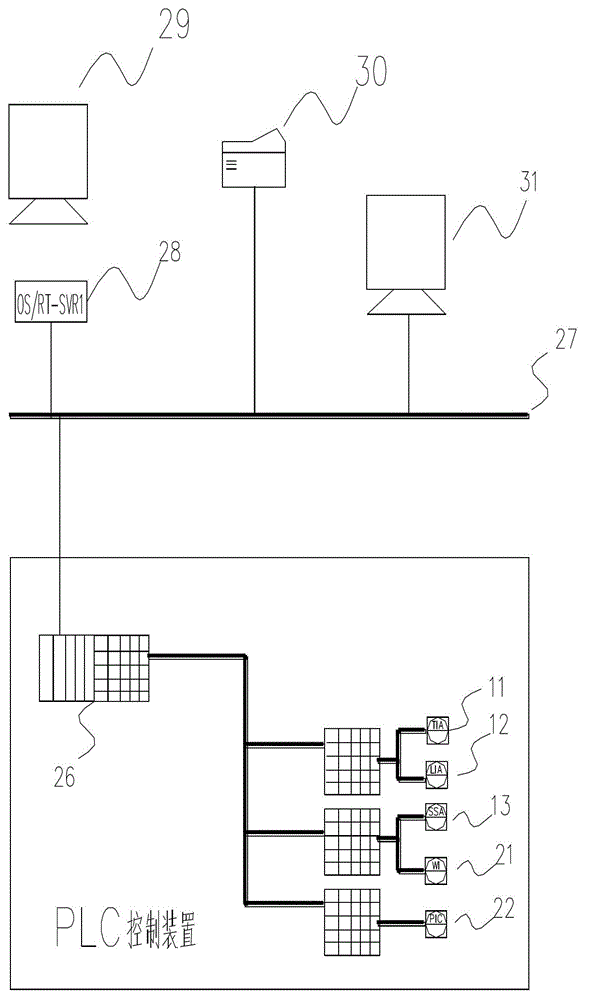

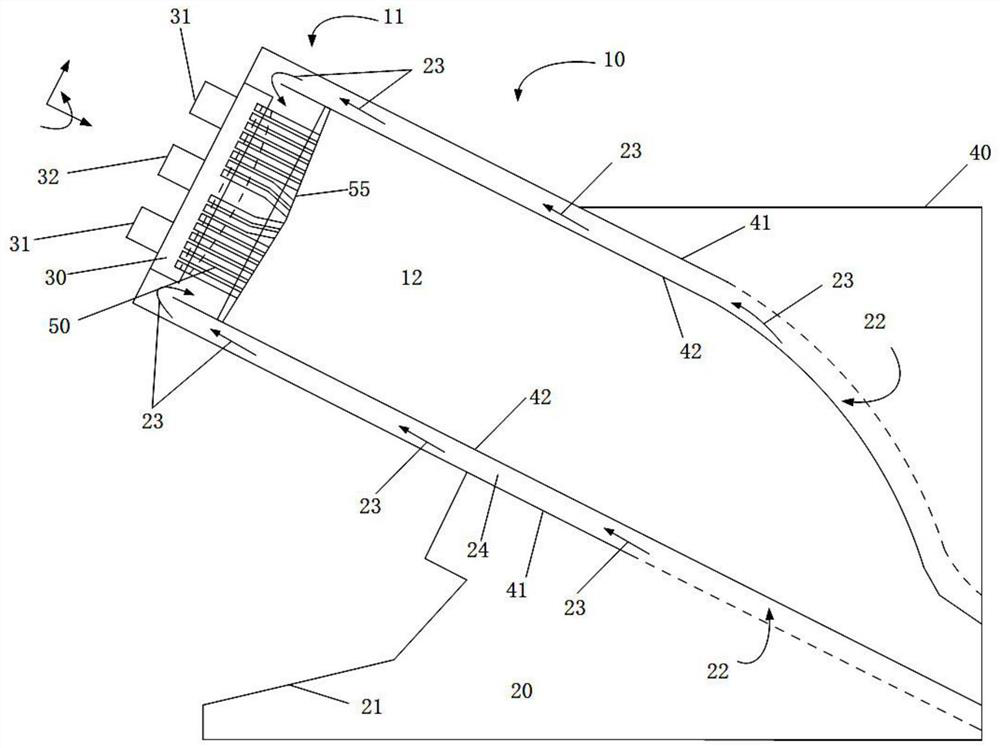

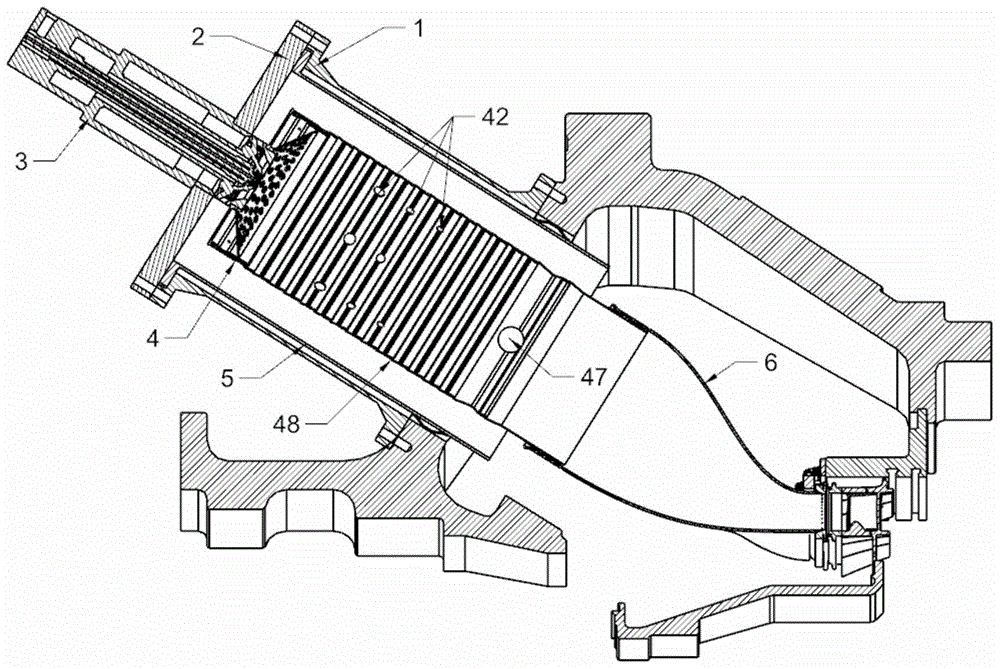

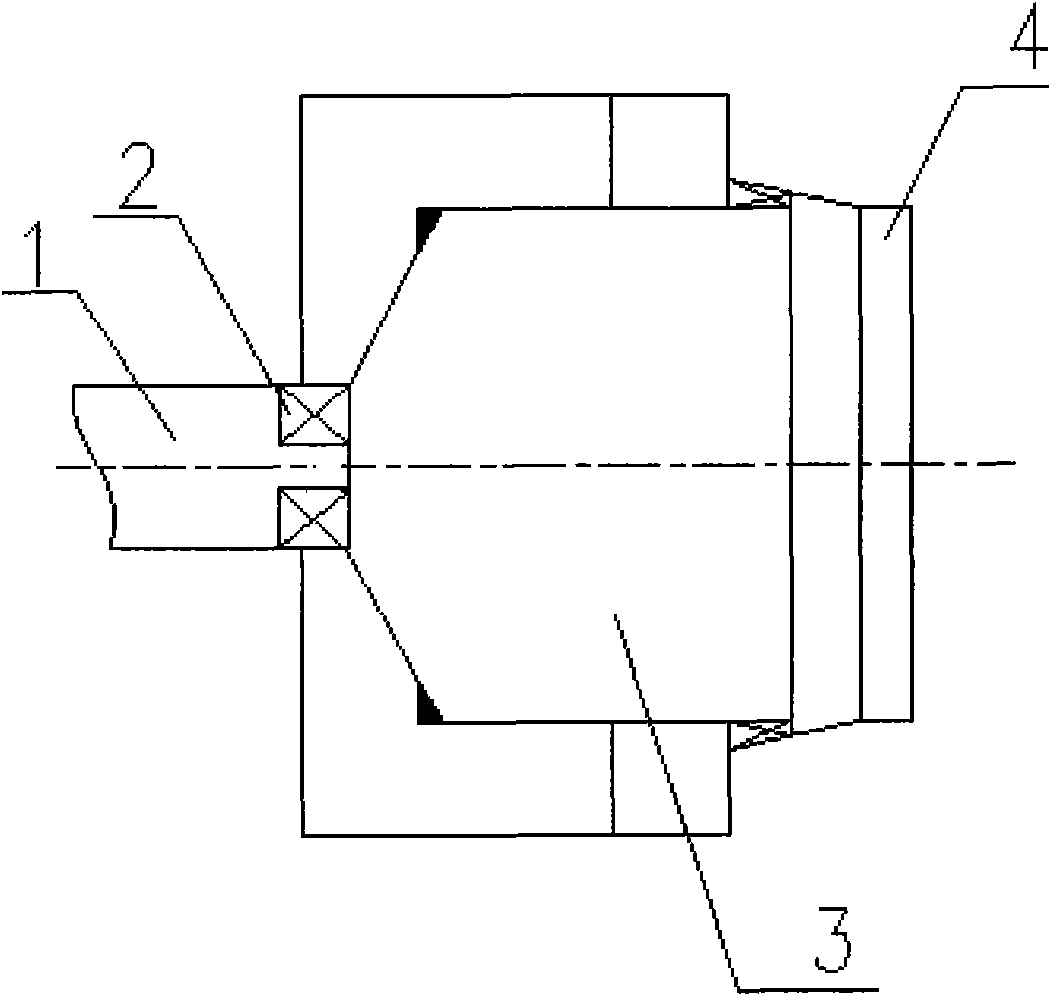

Mixed fit device for biomass fuel, paper sludge and coals

ActiveCN102980201ALow calorific valueUniform heat releaseIncinerator apparatusLump/pulverulent fuel feeder/distributionBoiler furnaceControl system

The invention relates to a mixed fit device for biomass fuels, paper sludge and coals. Biomasses in a biomass bunker are conveyed to a variable frequency scraper conveyor through a biomass bunker screw conveyor; coals in a coal bunker are conveyed to the variable frequency scraper conveyor through a variable frequency coal screw conveyor; an output end of the variable frequency scraper conveyor is connected with an input end of a boiler-front mixing device through a coal drop pipe; and an output end of the boiler-front mixing device is connected with a boiler through a spiral distributor and a spiral feeder. In order to prevent the boiler-front blockage and tube pulling, the system is provided with a primary hot-air system. The fuel mixing technology adopts paper sludge (absolute dried), wood chips (absolute dried), and fuel coals distributed in normal operation (at most not exceed 20%); and the optimal operation effect is achieved through a PLC control system with high automation degree of the mixed fit of the biomass fuels, the paper sludge and the coals in front of a boiler. The sludge incineration technology has is superior, is combined with a sludge incineration power generation technology, and is a sludge treatment technology popular with paper making enterprises.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG CO LTD

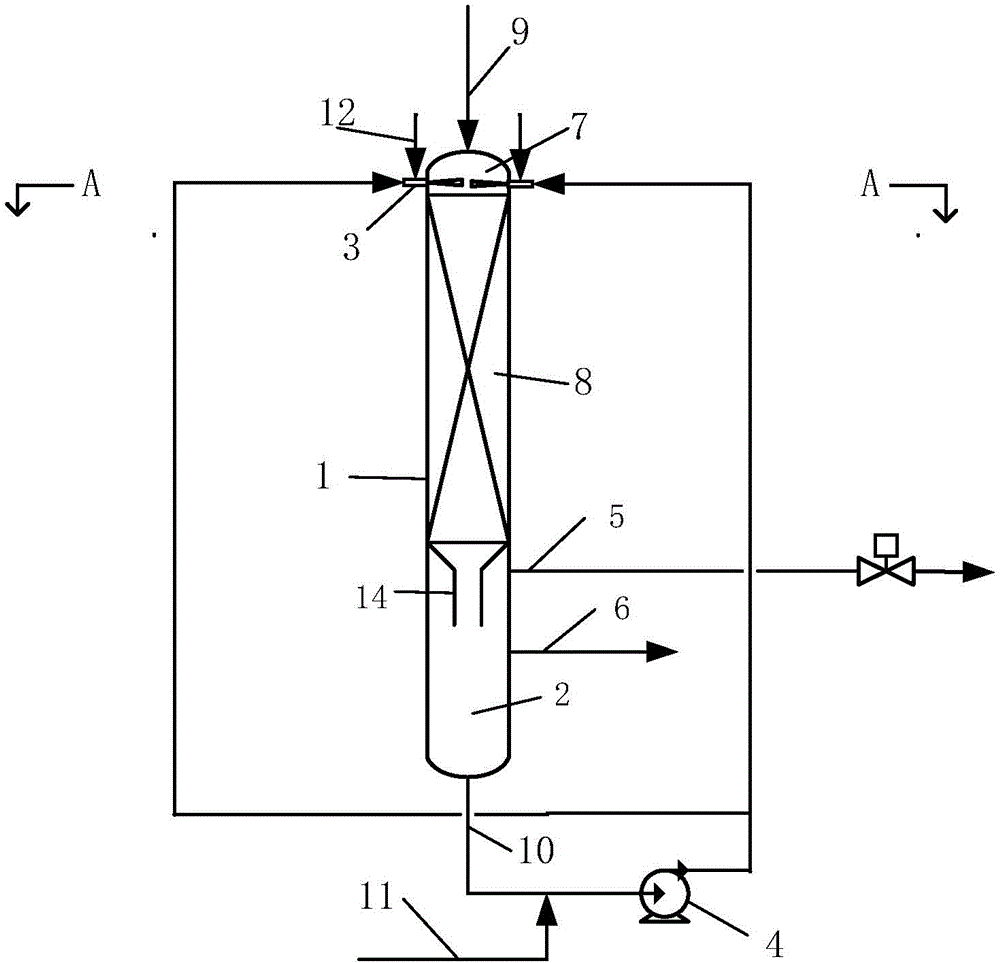

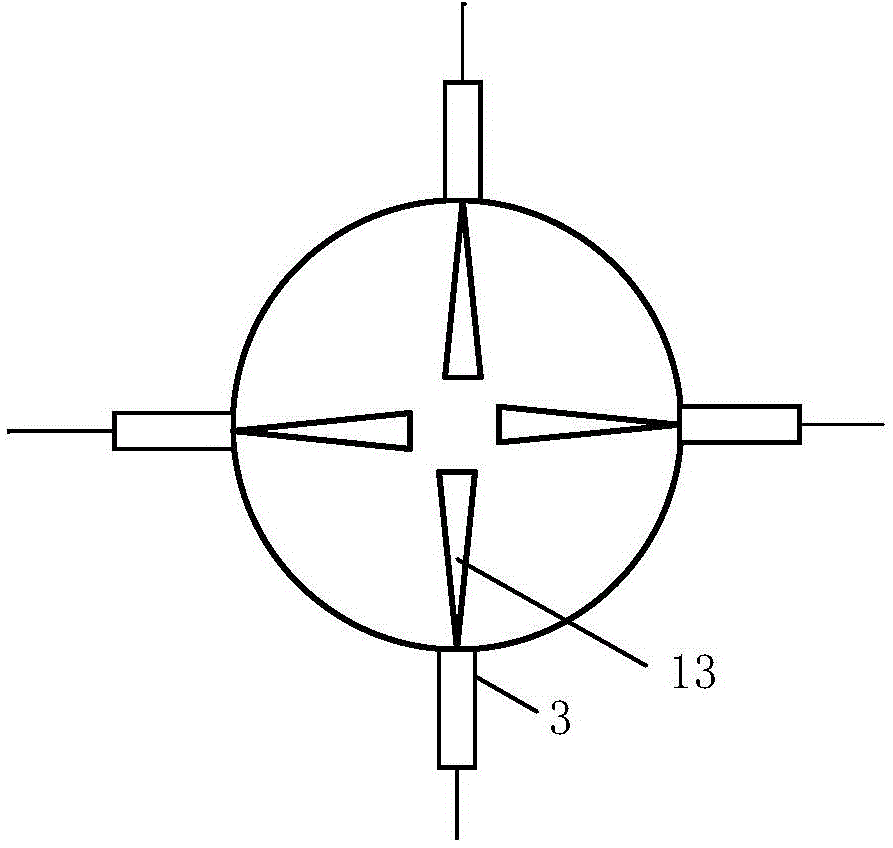

Liquid acid alkylation reactor and application method thereof

ActiveCN105268394AImprove conversion rateSimple mechanical structureLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferJet flow

A liquid acid alkylation reactor and an application method thereof are provided. The reactor comprises a mixing zone, a reaction zone and a liquid collection zone from top to bottom; the mixing zone is internally provided with at least one group of jetting flow mixers, and each group of jetting flow mixers comprises at least two ejectors which are in centrosymmetry at a same horizontal plane; the reaction zone is internally loaded with a packing; the liquid collection zone is connected with inlets of the jetting flow mixers through a circulating pump, the upper part of the liquid collection zone is provided with a gas outlet, and a liquid-phase product outlet is arranged below the gas outlet. The liquid acid alkylation reactor provided by the invention is suitable for an alkylation reaction with sulfuric acid, an ionic liquid or a mixed acid with sulfuric acid as a main component as a catalyst. The reactor is an alkylation reactor which is simple and compact in structure, small in investment, and convenient to operate and maintain, and saves the power.

Owner:CHINA PETROLEUM & CHEM CORP +1

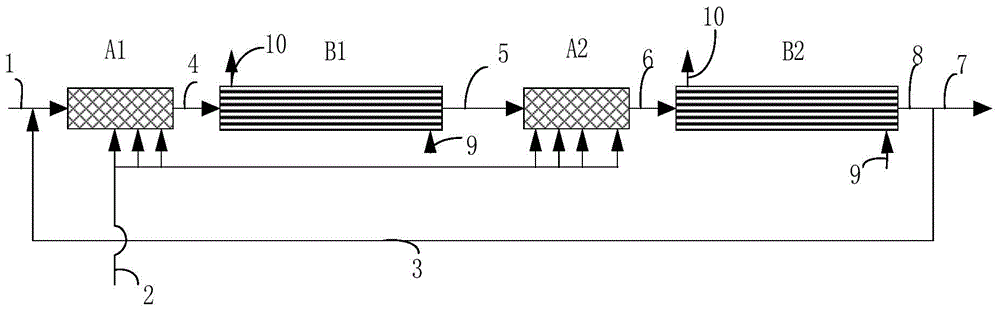

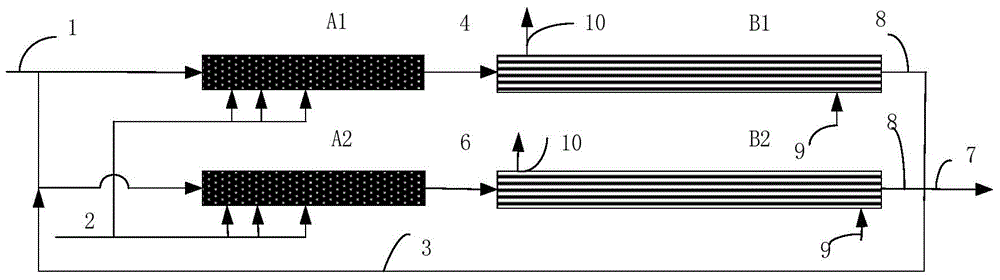

Static tube type alkylation reaction device and alkylation reaction method for liquid acid catalysis

ActiveCN105018134AAvoids disadvantages that impair sealing performanceImprove sealingLiquid hydrocarbon mixtures productionAlkyl transferEmulsion

The invention provides a static tube type alkylation reaction device and an alkylation reaction method for liquid acid catalysis by adopting the same. The reaction device comprises n+1 groups of reactors, wherein n is more than or equal to 1, each group of the reactor comprises a mixed reaction section A and a mixed reaction section B connected in series with the mixed reaction section A, and the mixed reaction section B has a heat exchange function; the mixed reaction section A of the first group of the reactors is marked as A1 which is provided with a fresh liquid acid feed pipeline; the mixed reaction section B of the (n+1)th group of the reactors is marked as Bn+1 which is provided with an alkylation reaction product outlet pipeline for discharging acidolysis hydrocarbon emulsion; part of the acidolysis hydrocarbon emulsion is circulated by a circulating pump; the mixed reaction section A of each group of the reactors is connected with a feed pipeline of an alkylation reaction raw material containing olefin, and the mixed reaction section A is provided with m (m is more than or equal to 1) feed openings for adding the alkylation reaction raw material containing olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

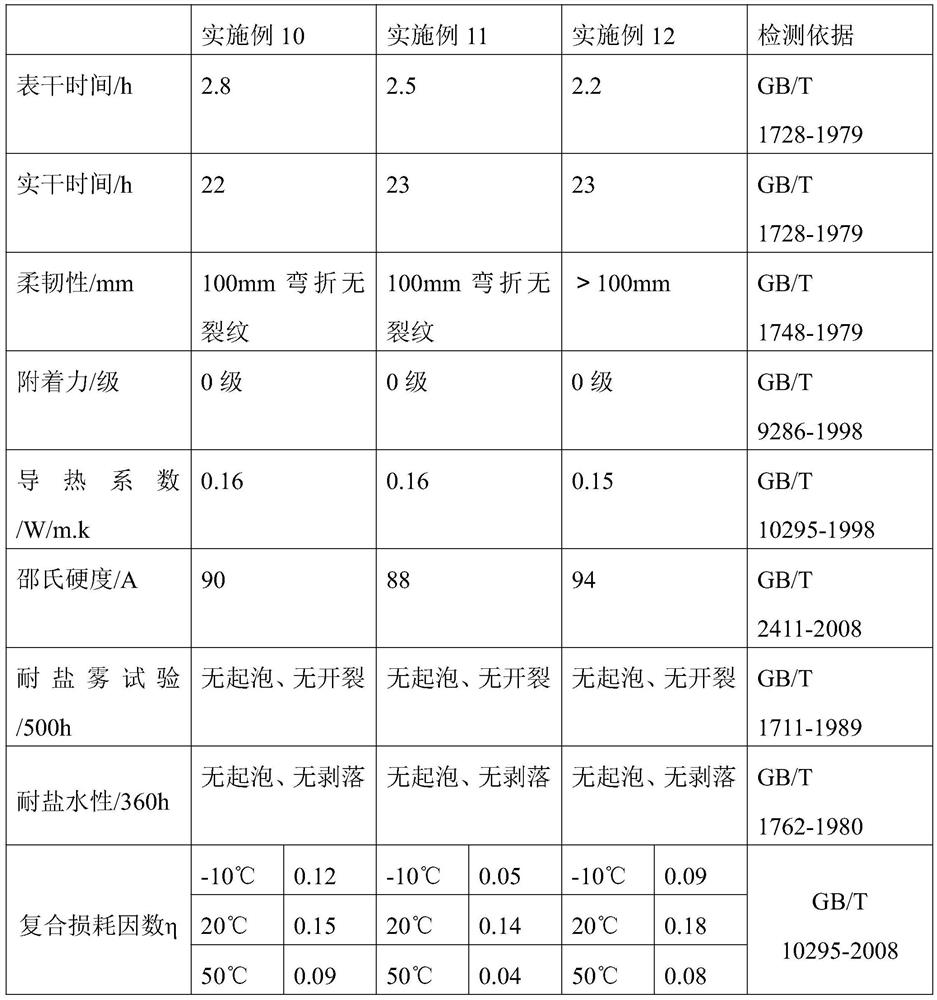

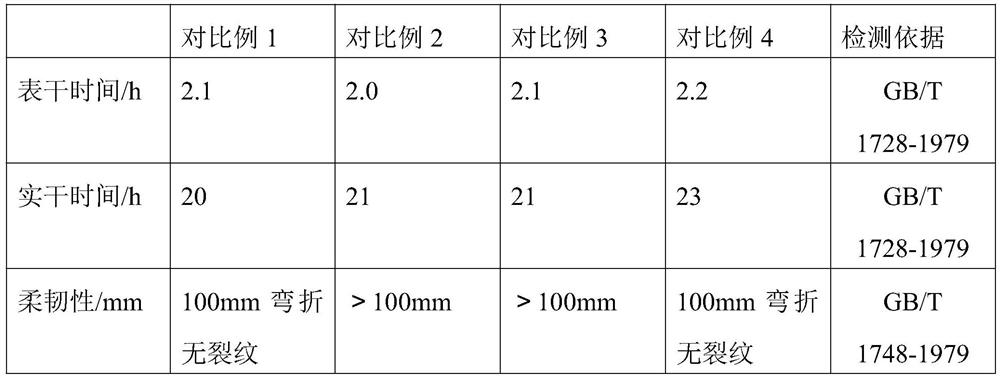

Environment-friendly thermal insulation damping coating and preparation method thereof

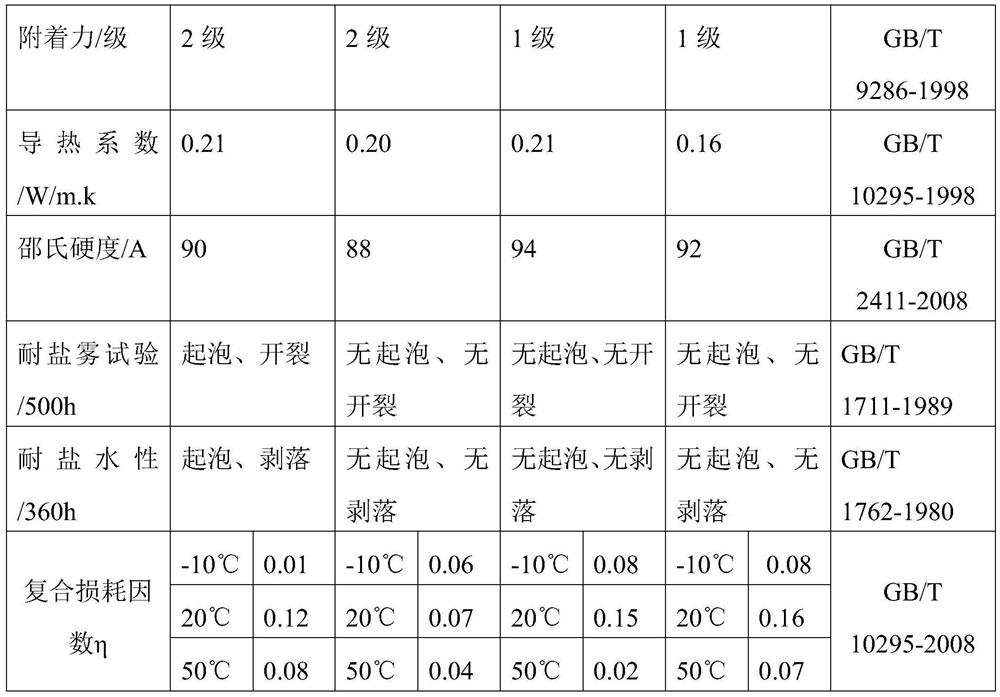

The invention provides an environment-friendly thermal insulation damping coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: flexible acrylic emulsion with the glass-transition temperature of -25 to -15 DEG C, first styrene-acrylic emulsion with the glass-transition temperature of 20-30 DEG C, second styrene-acrylic emulsion with theglass transition temperature of 35 to 45 DEG C, silane-modified hollow glass beads, silane-modified chopped polypropylene fibers and a functional filler. The coating has moderate surface drying timeand hard drying time, has good flexibility, has an adhesive force of 0 grade, has a heat conductivity coefficient reaching the standards of thermal insulation materials, has a composite loss factor eta greater than or equal to 0.05 at -10 DEG C, greater than or equal to 0.14 at 20 DEG C and greater than or equal to 0.04 at 50 DEG C, and has excellent thermal insulation damping performance in a relatively large temperature range.

Owner:SHANDONG NORTH MODERN CHEM IND

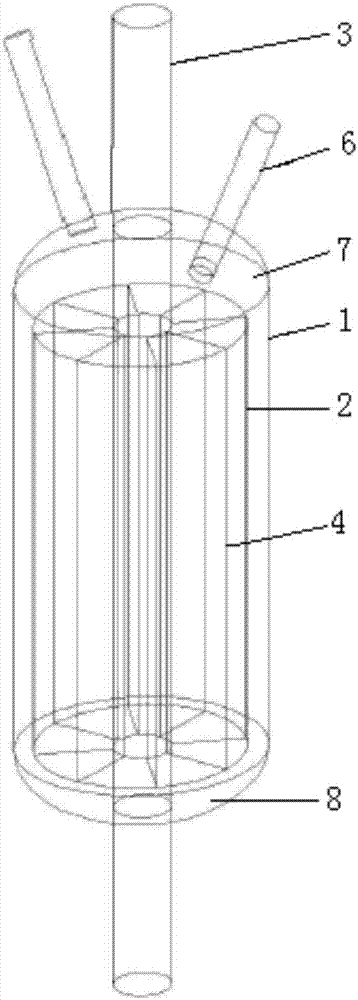

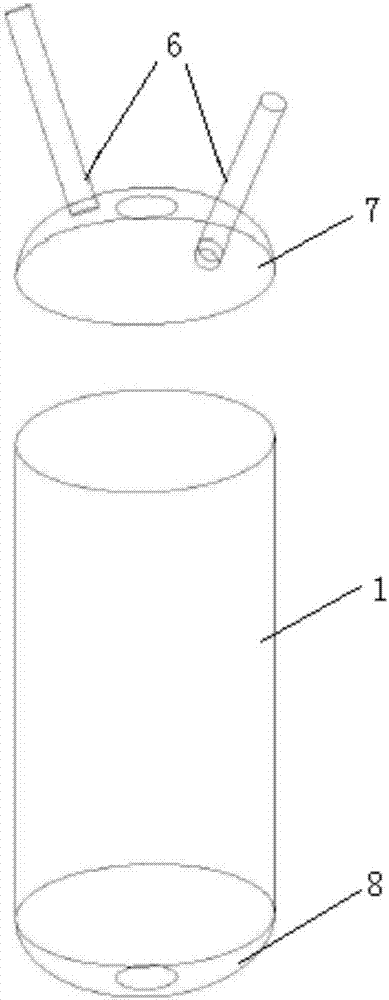

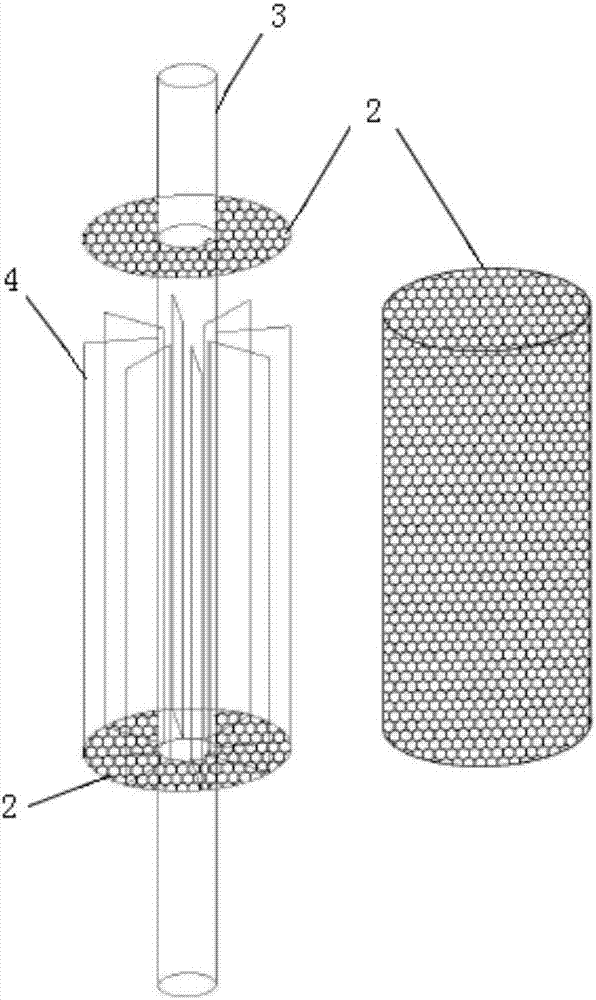

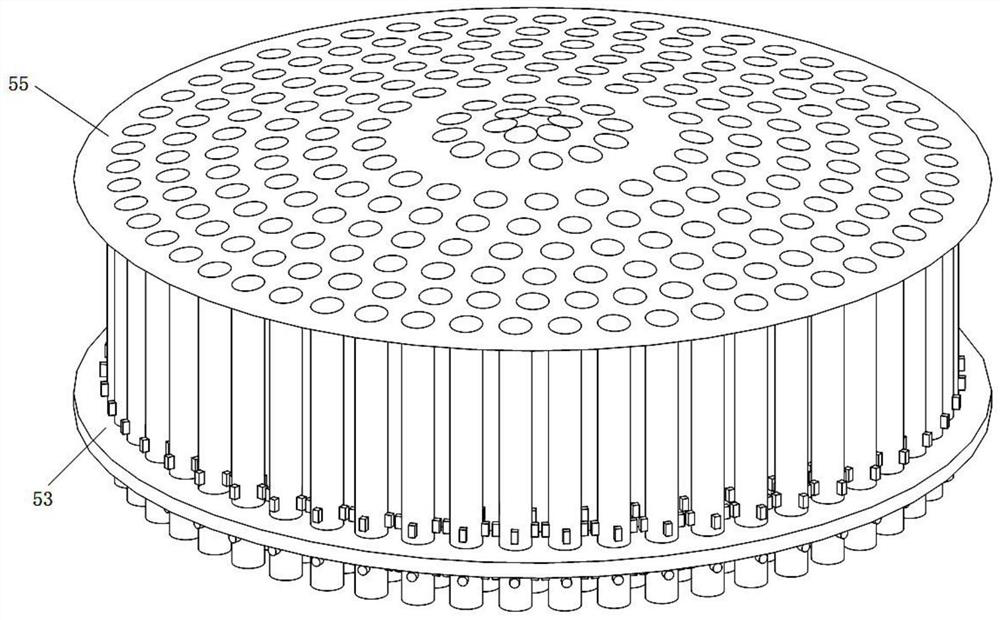

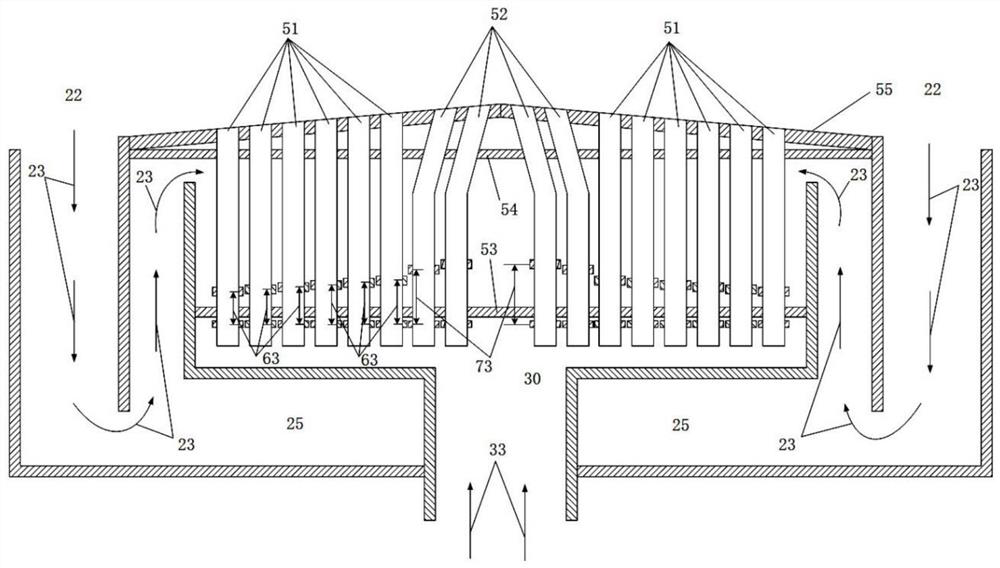

High-efficiency reactor for hydrated salt chemical energy storage

InactiveCN107289803AHigh reaction conversion rateHigh energy storage densityHeat storage plantsHydration reactionEngineering

The invention discloses a high-efficiency reactor for hydrated salt chemical energy storage. The high-efficiency reactor comprises a heat insulation container, a column body for wrapping hydrated salt, a heat exchange pipe, fins, hydrated salt and pipelines, wherein the column body is arranged in the heat insulation container; the heat exchange pipe is arranged at the center of the column body; the multiple fins are uniformly arranged between the heat exchange pipe and the column body; one end of each fin is connected with the outer wall of the heat exchange pipe, and the other end of the fin is connected with the inner wall of the column body; a space between the heat exchange pipe and the column body is filled with the hydrated salt; and the two pipelines are arranged on an upper end cover of the heat insulation container. The high-efficiency reactor for hydrated salt chemical energy storage disclosed by the invention can well enable reaction salt to react with steam; the reaction is faster and more thorough, and the heat transfer and mass transfer effect in a reaction process is obviously enhanced; irreversible loss caused by liquefaction of the hydrated salt due to excessive water absorption can be further effectively avoided, so that the number of times of recycling of an energy storage material is increased, and the service life of the material is prolonged; and meanwhile, the corrosion effect of the liquefied hydrated salt on the reactor is also avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

Micro-premixing combustion chamber used for natural gas turbine and applied to wet air circulation

PendingCN111765491AImprove scalabilityImprove blending uniformityContinuous combustion chamberAir cycleCombustion chamber

The invention discloses a micro-premixing combustion chamber used for a natural gas turbine and applied to wet air circulation. The micro-premixing combustion chamber used for the natural gas turbineand applied to wet air circulation comprises a combustor main body, a flame tube and a combustion chamber cartridge, wherein the combustor main body is arranged on the head part of the combustion chamber; the flame tube is arranged in the combustion chamber cartridge, and is a cylindrical wall surface wrapping the combustion chamber, and the inner side of the wall surface is a combustion area of the combustion chamber; a main fuel inlet and an on-duty fuel inlet are formed in the front end of the combustor main body, and the main fuel inlet is used for inputting a fuel into a main nozzle of acombustor; the on-duty fuel inlet is used for inputting the fuel into an on-duty nozzle of the combustor; and an air chamber is formed in the bottom of the combustion chamber, the air chamber is wrapped with a gas turbine cartridge, communicates to a gap which is formed by a lining of the combustion chamber and the flame tube, and feeds air which comes from an upstream air compressor outlet into an air bin of the combustor through the gap.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

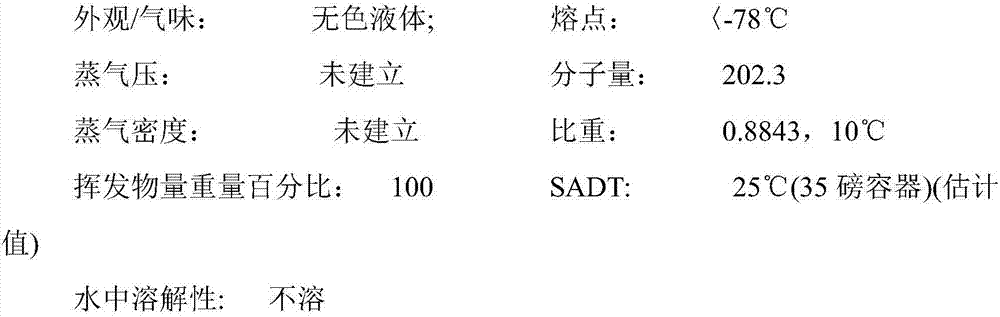

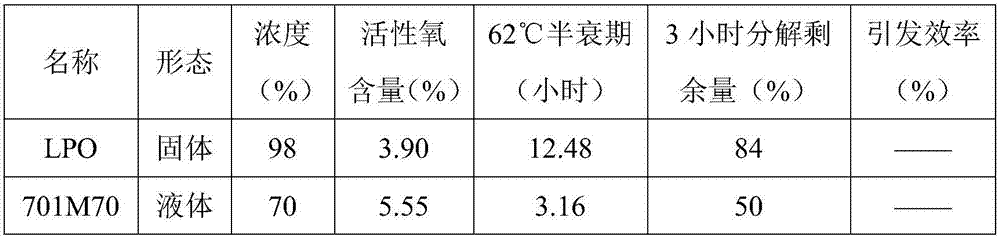

Production technique for mass polyvinyl chloride

InactiveCN107151282AImprove heat transfer performanceUniform heat releaseBulk polymerizationChemistry

The invention discloses a production technique for mass polyvinyl chloride. The production technique for mass polyvinyl chloride comprises a prepolymerization stage and a polymerization stage. A novel initiator Luperox 701M70 replaces an original initiator LPO; a new binary composite initiator formula system is used for polymerization reaction, heat release is balanced in mass polymerization reaction, heat transfer of a system is facilitated, polymerization pressure is controlled stably, heat of the polymerization reaction is easy to control, caking of the product is reduced, the B-grade product rate is reduced, the thermal stability of PVC resin is improved, the inner quality of the product is improved, and the post processing performance of the product is improved.

Owner:YIBIN TIANYUAN GRP CO LTD

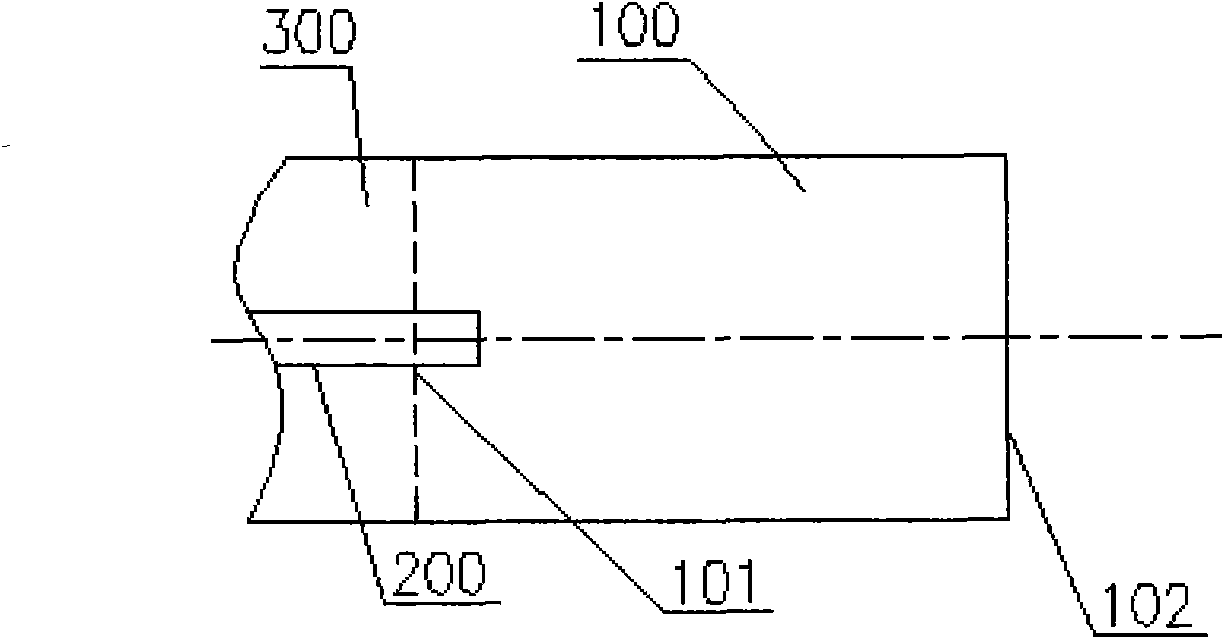

Low-heat value fuel gas combustion chamber of gas turbine

ActiveCN104595927ALean flameout boundary wideningUniform heat releaseContinuous combustion chamberSpray nozzleAutomotive engineering

The invention relates to the technical field of a gas turbine, and specifically discloses a low-heat value fuel gas combustion chamber of the gas turbine. The low-heat value fuel gas combustion chamber comprises a casing, an end cover arranged at the front end of the casing, a head fuel spray nozzle arranged on the end cover, a flow guiding bush arranged in the casing, a flame tube arranged in the flow guiding bush and a transition section connected with the rear end of the flame tube, wherein the front end of the flame tube is connected with the head fuel spray nozzle; a plurality of rows of main combustion holes are distributed in the flame tube along the axial direction; low-heat value fuel spray nozzles are arranged among the main combustion holes in each row of the flame tube. According to the low-heat value fuel gas combustion chamber disclosed by the invention, lower pollutant emission level can be achieved, and the thermo-acoustic oscillation risk is lower.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

On-stream method of residual oil hydrogenation process

ActiveCN102041045BHigh vulcanization rateHigh sulfur retentionCatalyst activation/preparationRefining to eliminate hetero atomsSulfurMetal catalyst

The invention discloses an on-stream method of a residual oil hydrogenation process, comprising the following steps of: selecting oxidation-state residual oil hydrogenation-series catalysts according to the requirement of the residual oil hydrogenation process, wherein the oxidation-state residual oil hydrogenation-series catalysts comprise a residual-oil-hydrogenation protective agent, a residual-oil-hydrogenation metal catalyst, a residual-oil-hydrogenation desulfurization catalyst and a residual-oil-hydrogenation denitrification catalyst, and the oxidation-state residual-oil-hydrogenation desulfurization catalyst and / or the oxidation-state residual-oil-hydrogenation denitrification catalyst are / is processed in an ex-situ presulfurization method; introducing a vulcanizing agent, with the amount accounting for 95-150% of the theoretically-required sulfur amount of all the oxidation-state residual-oil-hydrogenation catalysts, to the catalysts to be subjected to presulfurization; and filling the required catalyst in a reactor, heating, activating, and then switching the residual oil raw materials to carry out hydrogenation. In the method, ex-situ presulfurization is only carried out on partial catalysts required by the residual oil hydrogenation process so that the advantages of saving the production cost and reducing the catalyst loss when the advantage of an ex-situ presulfurization process is kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

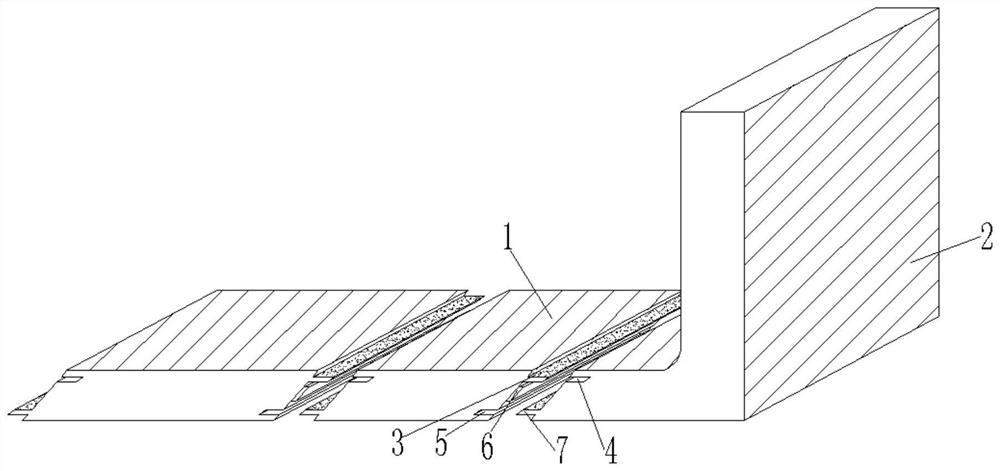

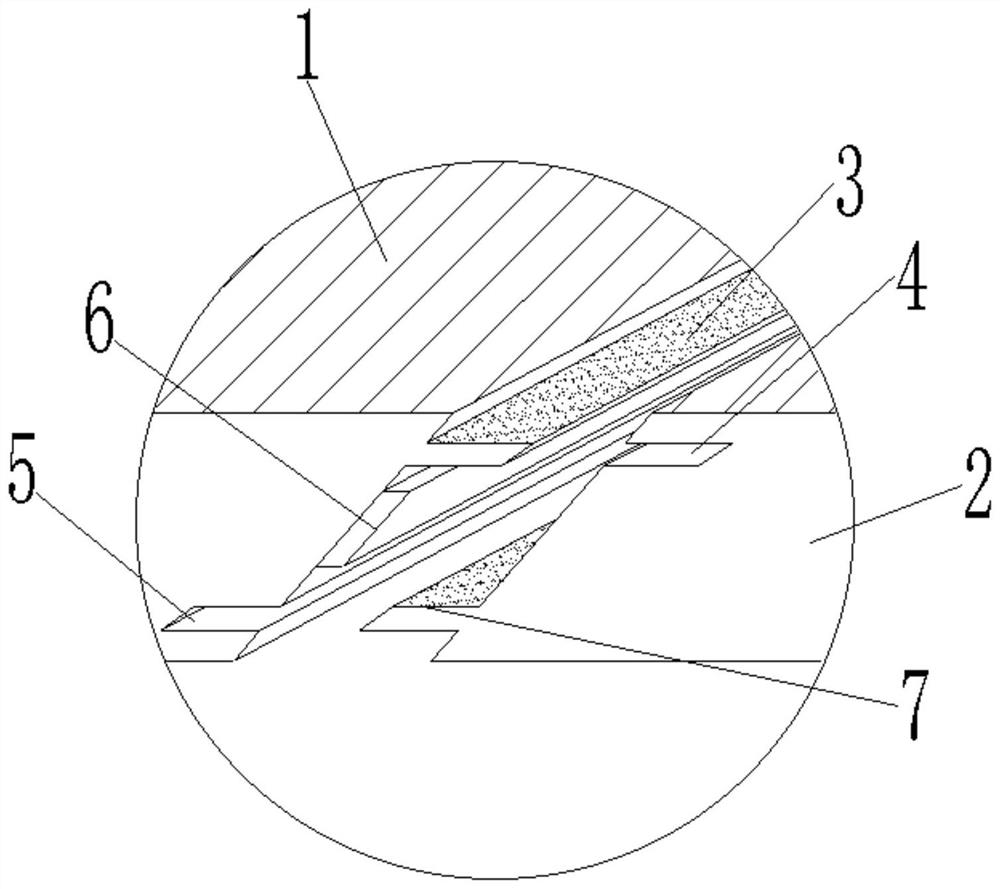

Seamless splicing and paving process of floor cloth for subway vehicle

InactiveCN111635705ASolve warpingClosely connectedAdhesive processesAxle-box lubricationStructural engineeringMechanical engineering

The invention relates to the technical field of floor cloth paving, and in particular, relates to a seamless splicing and paving process of floor cloth for a subway vehicle. The floor cloth comprisesfloor cloth bodies and a skirting cloth body, and a first protruding block is welded to the top of the outer wall of one side of each floor cloth body. A second clamping groove is formed in the bottomof the outer wall of the side, close to each first protruding block, of each floor cloth body, a first clamping groove is formed in the outer wall of the side, close to each first protruding block, of the skirting cloth body, a second protruding block is welded to the bottom of the outer wall of the side, close to each second clamping groove, of the skirting cloth body, and the first protruding blocks are clamped in the first clamping grooves. Beneficial effects of the method are that the floor cloth is bonded after a rubber pipe is pressed; the floor cloth bodies and the skirting cloth bodycan be connected more tightly in a clamping mode, seamless splicing is achieved, the floor cloth is more attractive, meanwhile, the edge warping problem caused by untight connection between the floorcloth bodies and the skirting cloth body can be solved, and the floor cloth is more practical.

Owner:安徽省金越亨通交通装备有限公司

Powdered-coal burner and rotary cement kiln using same

InactiveCN102032565AMeet the process needs of calcinationImprove combustion efficiencyRotary drum furnacesPulverulent fuel combustion burnersCoal pipelineEngineering

The invention discloses a powdered-coal burner and a rotary cement kiln provided with the powdered-coal burner. The powdered -coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber is used for maintaining an internal powdered-coal airflow and has a preset excess air coefficient, the heat source is positioned in the internal burning chamber, the internal burning chamber is provided with a feeding opening, a long cylindrical burning segment and a fire outlet, the feeding opening is communicated with a powdered-coal pipeline, and the fire outlet is communicated with the calcining cavity of the rotary cement kiln; and powdered coal passing through the internal burning chamber is burnt by the heat source. The powdered-coal burner provided by the invention can eliminate black powdered-coal fire heads in the calcining cavity, obtain powdered-coal flames with more excellent performance, improve the burning efficiency of the powdered coal and the quality of calcined clinkers, keep the powdered coal in the internal burning chamber to be burnt in the mode of not consuming fuel, simplify the structure of the powdered-coal burner and lower the manufacturing cost and the operating cost of the rotary cement kiln; and meanwhile, the preset excess air coefficient is maintained in the internal burning chamber, so that the reductive burning of the powdered coal is carried out in the internal burning chamber, and the generating quantity and the discharging quantity of fuel-type nitrogen oxides can be reduced.

Owner:YANTAI LONGYUAN POWER TECH

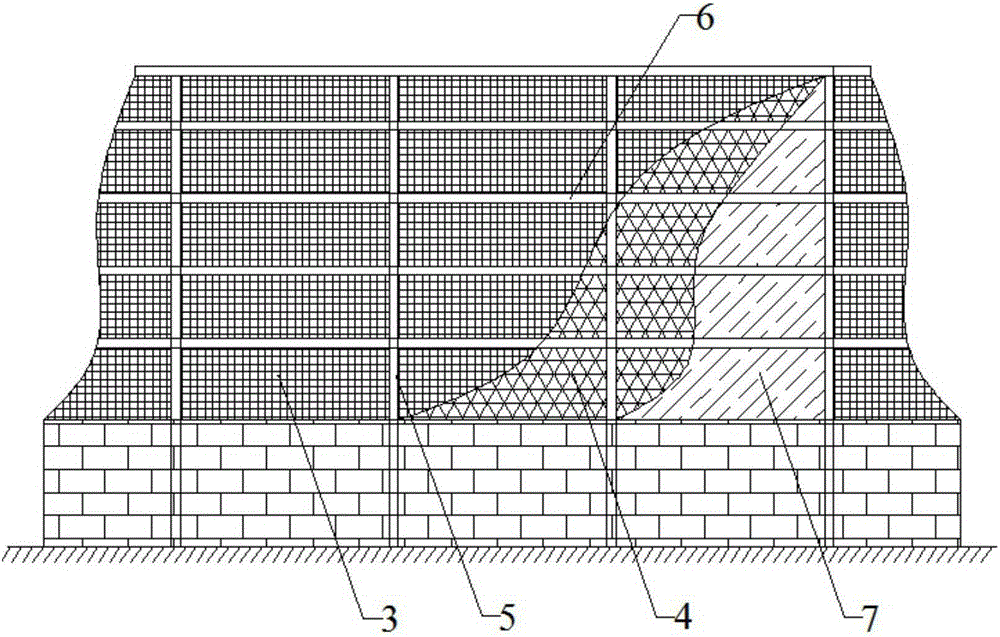

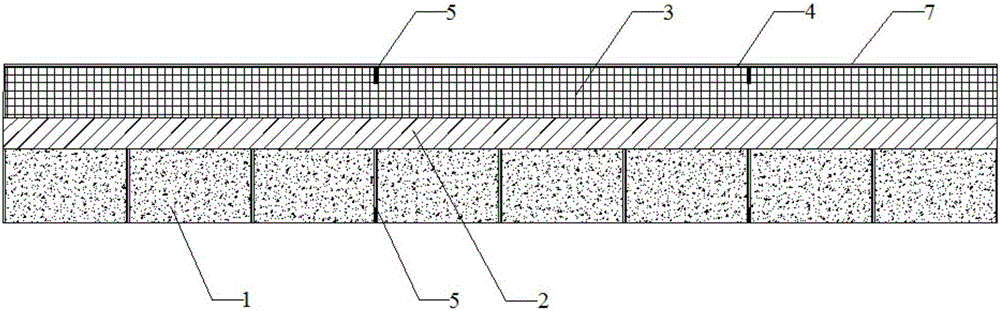

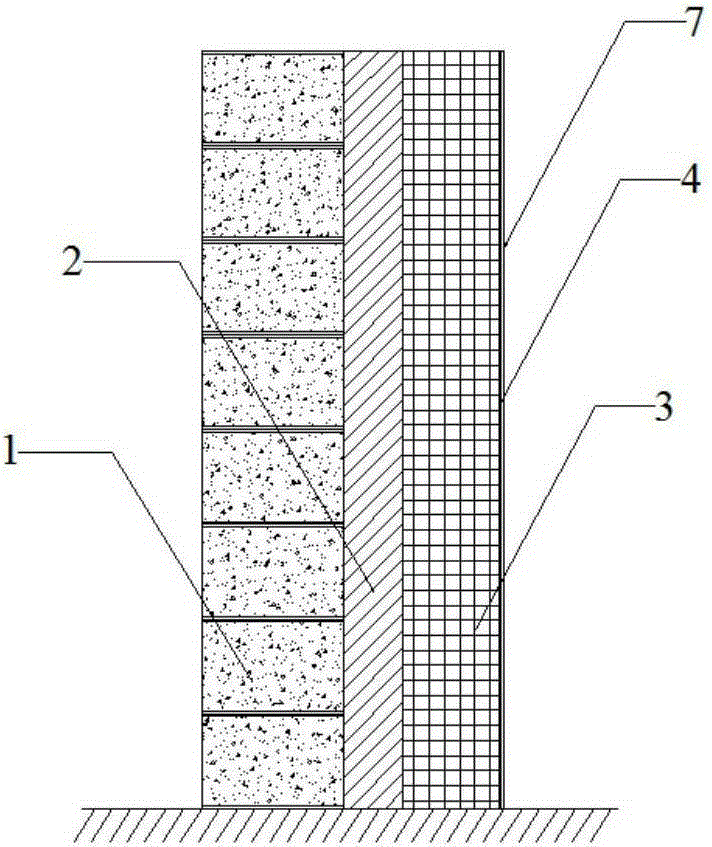

Novel sunlight greenhouse rear wall made of straw blocks

ActiveCN105297947AImprove heat storage capacityLow costSolid waste managementWallsFiberAgricultural engineering

The invention discloses a novel sunlight greenhouse rear wall made of straw blocks. The novel sunlight greenhouse rear wall made of straw blocks comprises a heat-accumulating layer, a heat-insulating layer and a heat preservation layer, and uprights are arranged on the two sides of the rear wall at equal intervals in the length direction of the rear wall; the heat-accumulating layer is isolated from the heat preservation layer through the heat-insulating layer, the heat-accumulating layer is formed by building straw blocks I, the heat preservation layer is formed by building straw blocks II, and the heat-insulating layer is formed by filling polystyrene boards; the outer side of the heat preservation layer is sequentially provided with iron gauze, clamping slots and plastic films; the straw blocks I are prepared from straw fibers, cement and sand according to the mass ratio of 1 to 6-9 to 15-24, and the straw blocks II are prepared from straw fibers and cement according to the mass ratio of 1 to 1.5-2.5. The novel sunlight greenhouse rear wall made of straw blocks composed of the straw blocks I, the polystyrene boards and the straw blocks II has the advantages of being strong in heat storage capacity, low in manufacturing cost, simple in construction technology, environmentally friendly, capable of fully utilizing rural surplus straw materials and the like, and the economic and ecological benefits of agricultural production can be effectively improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

On-stream method of residual oil hydrogenation process

ActiveCN102041044BHigh vulcanization rateHigh sulfur retentionCatalyst activation/preparationRefining to eliminate hetero atomsOxidation stateHydrogenation process

Owner:CHINA PETROLEUM & CHEM CORP +1

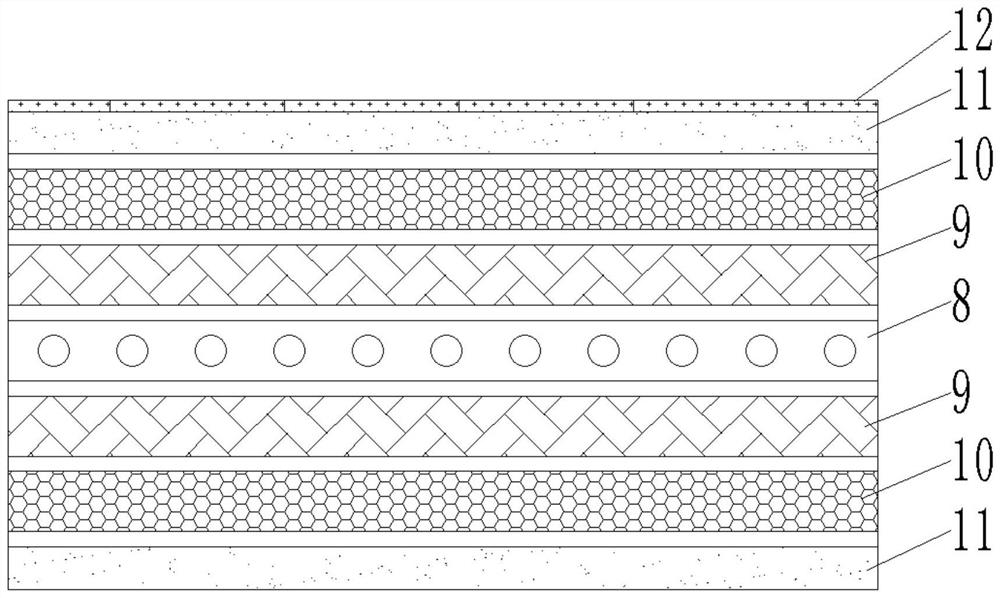

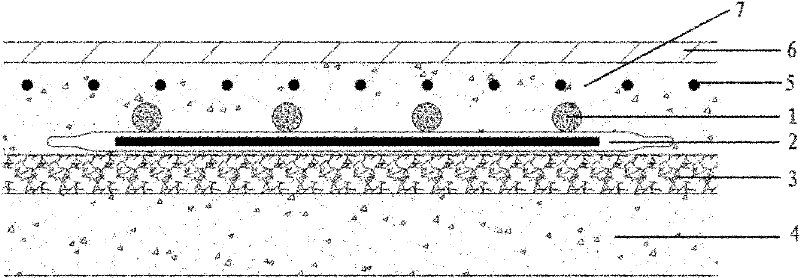

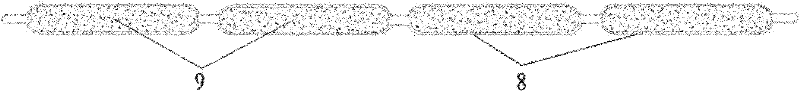

Heat accumulation cushion and heat accumulation type floor heating system

InactiveCN102677859AEvenly distributedImprove absorption rateFlooring insulationsEngineeringAbsorption rate

The invention discloses a heat accumulation cushion and a heat accumulation type floor heating system. The heat accumulation cushion is used for the heat accumulation type floor heating system and comprises an outer packing (8) and heat accumulation materials (9). A closed tabular cavity is formed by the outer packing (8) and the heat accumulation materials (9) are evenly filled into the cavity. The heat accumulation materials in the heat accumulation cushion (10) are distributed evenly. The heat accumulation cushion is paved on a floor heater and is fully contacted with the surface of the floor heater (2). The heat accumulation cushion is even in heat absorption, and higher in heat absorption rate. Due to the tubular shape, the heat accumulation cushion can absorb and release heat evenly, and heat absorption rate is increased.

Owner:MISATO PLAHEAT YIXING

Waste heat recovery method for fused calcium carbide

InactiveCN105910445AUniform heat releaseSolve the problem that waste heat cannot be recycledWaste heat treatmentUranium carbideWaste heat recovery unit

The invention discloses a waste heat recovery method for fused calcium carbide. The waste heat recovery method comprises the following steps that the fused calcium carbide is subjected to forced air cooling, heat is recovered, and by controlling the magnitude of air flow, the purpose that the calcium carbide uniformly releases heat in the forced air cooling process is achieved. According to the waste heat recovery method for the fused calcium carbide, the effect that the calcium carbide uniformly releases the heat is achieved through forced air cooling and controlling over the magnitude of the air flow, and the problems that natural cooling is long in consumption time, the waste heat of the calcium carbide cannot be recycled, heat releasing of calcium carbide subjected to common forced air cooling is discontinuous and uneven, and waste heat recovery is not facilitated are solved.

Owner:ZHONGSHAN MINGYANG ELECTRIC

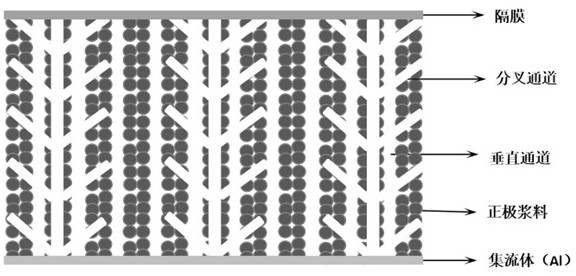

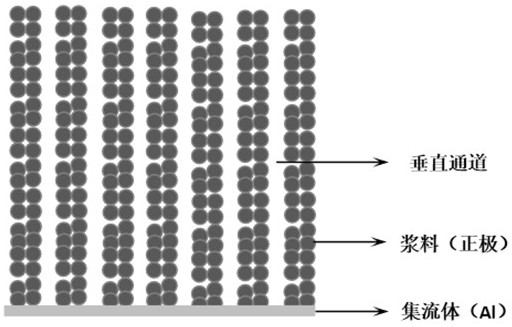

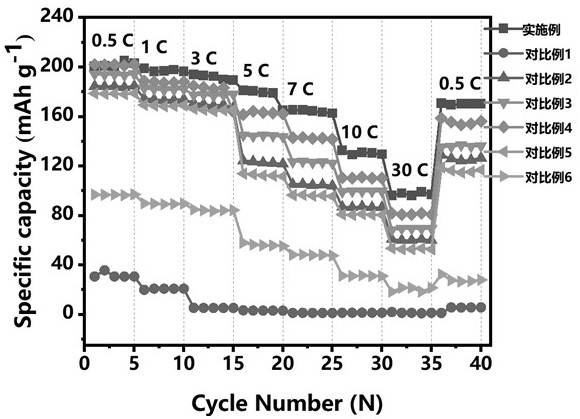

Preparation method of lithium ion battery positive plate

ActiveCN114744160AChange surface propertiesLiquidFinal product manufacturePositive electrodesGadolinium gallium garnetMagnetite Nanoparticles

The invention discloses a preparation method of a positive plate of a lithium ion battery, which comprises the following specific steps: uniformly mixing a high-nickel positive electrode material and a magnetic material through mechanical stirring to obtain high-nickel positive electrode slurry, coating the surface of a current collector with the high-nickel positive electrode slurry, and drying to obtain the positive plate of the lithium ion battery. The magnetic material is directionally arranged in the high-nickel positive electrode slurry by alternately loading and removing a magnetic field, meanwhile, a thick polar plate with a graded multi-dimensional through channel is prepared by utilizing an ice crystal effect, and then the magnetic material in the thick polar plate is recovered by adopting a magnetic recovery device to prepare the positive plate of the lithium ion battery, and the content of Ni in the high-nickel positive electrode material is greater than or equal to 80wt%. The magnetic material is iron-doped gadolinium gallium garnet magnetic nanoparticles. The constructed thick electrode with the hierarchical multi-dimensional through channel is applied to the lithium ion battery, and the rapid charging and discharging capability of the lithium ion battery is realized on the premise of not sacrificing the utilization rate and the capacity of an active material.

Owner:新乡市中天新能源科技股份有限公司

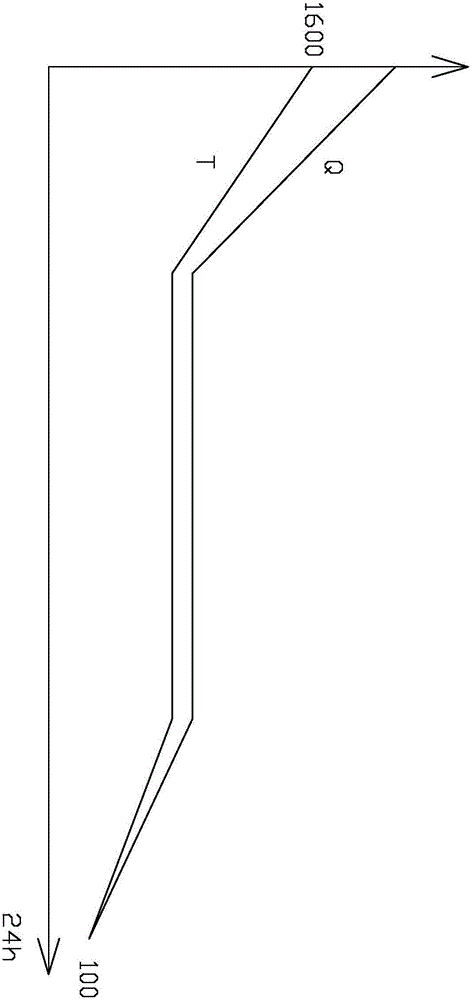

Temperature adjusting damper and heat storage electric heater comprising adjusting damper

PendingCN109506285AUniform heat releaseSimple structureHeating fuelLighting and heating apparatusTemperature controlAutomatic control

The invention relates to a temperature adjusting damper and a heat storage electric heater comprising the adjusting damper. The temperature adjusting damper comprises a shell, at least one ventilationcavity is formed in the shell, a fan is arranged in each ventilation cavity in a distributing mode, a hollow connecting plate is formed on each ventilation cavity, the fans are located at the lower portions of the connecting plates, a positioning plate is arranged on each connecting plate, at least one air outlet is formed in each positioning plate, temperature adjusting partition layers are formed between the connecting plates and the positioning plates, and adjusting mechanisms used for adjusting the size of the air volume of the air outlets are arranged in the temperature adjusting partition layers in a distributing mode. The temperature adjusting damper and the heat storage electric heater comprising the adjusting damper have the advantages that the structure is simple, automatic temperature control is achieved, and the effect is obvious; and bimetallic strips stretch and shrink when feeling the change of the temperature of the air outlets, then the size of the air volume of the air outlets is adjusted, so that the size of the air volume of the air outlets is automatically controlled, the adjusting effect is better, the heat release of the electric heater is more balanced, andthe heat utilization rate of the product is effectively improved.

Owner:ZHEJIANG GIANT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com