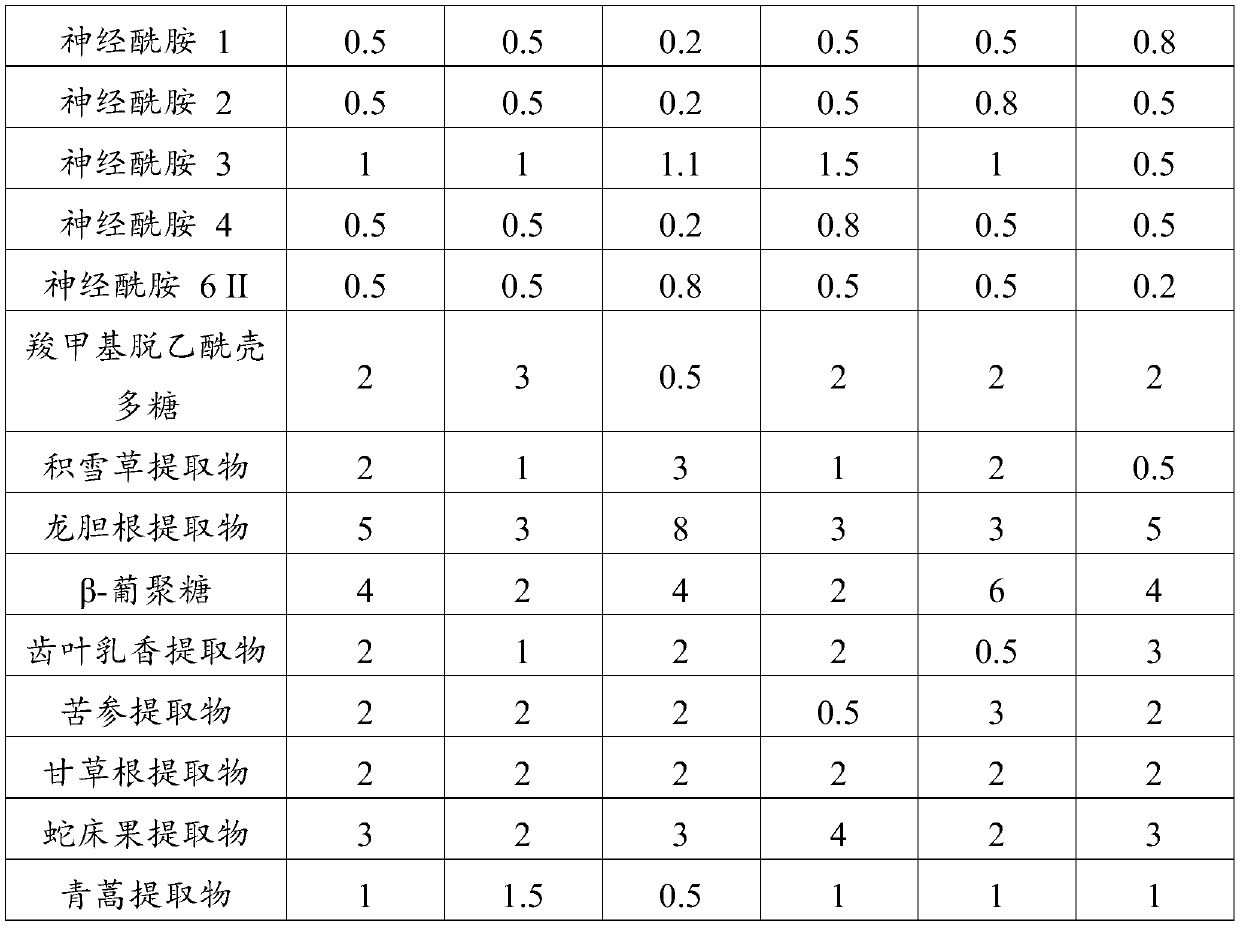

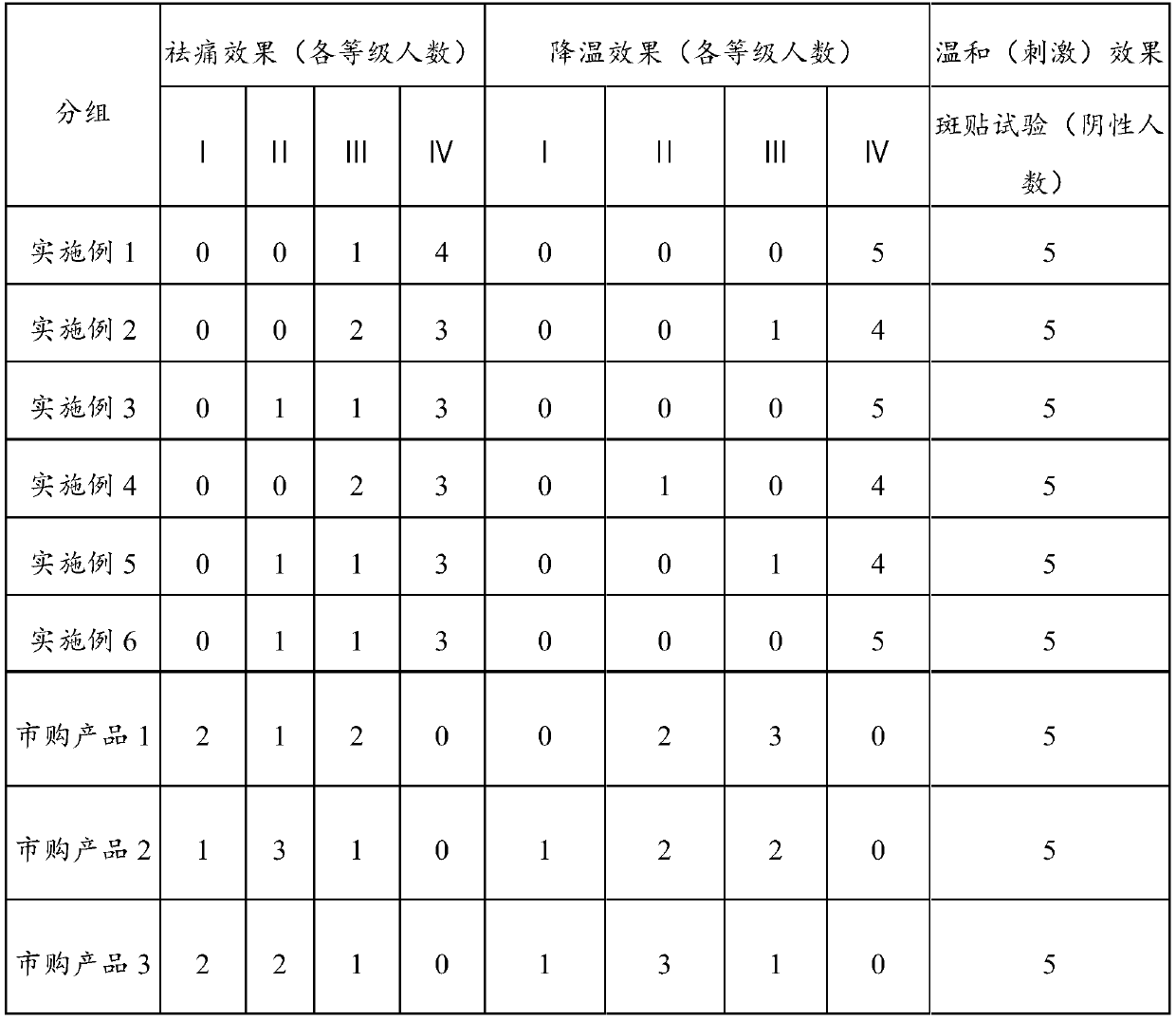

Patents

Literature

61results about How to "Short wetting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for preventing wool loomage from felting by two-bath process using cutinase/protease

InactiveCN101424048AShort wetting timeLower contact angleSolvent-treatmentBiochemical fibre treatmentWoolDyeing

The invention discloses a method for performing an anti-felting process of a wool fabric by a two-bath process by applying cutinase / prolease, which belongs to the technical field of dye and finishing processing of wool fabric. The method aims to overcome the defects that the felt proofing by a wool chlorination method has serious environmental pollution and fabric treated by a single prolease method has poor wettability and high felting shrinkage and achieve the aim of optimizing the treatment effect of the prolease of the wool fabric. All wool grey cloth is extracted and removed with free oil impurities in a carbon tetrachloride / methanol solution first, is presoaked by hot water, then is treated in a cutinase solution, is removed with lipoid layer hydrolysates of scale surface layers through the extraction of carbon tetrachloride / methanol, and then is subjected to decrement processing in a prolease solution to realize the biological processing combined with enzymatic pretreatment and enzyme decrement of wool. Through the invention, a method combined with chemistry and the prolease is substituted by a wool shrinkproofing process by a complete biological method, which not only can effectively improve the decrement rate and the antifelting effect of the wool fabric, promote the improvement of the wettability of the fabric, but also can effectively improve the dyeing depth of the fabric, reduce the fiber damage in the decrement processing, and is also favorable for the protection of ecological environment.

Owner:JIANGNAN UNIV

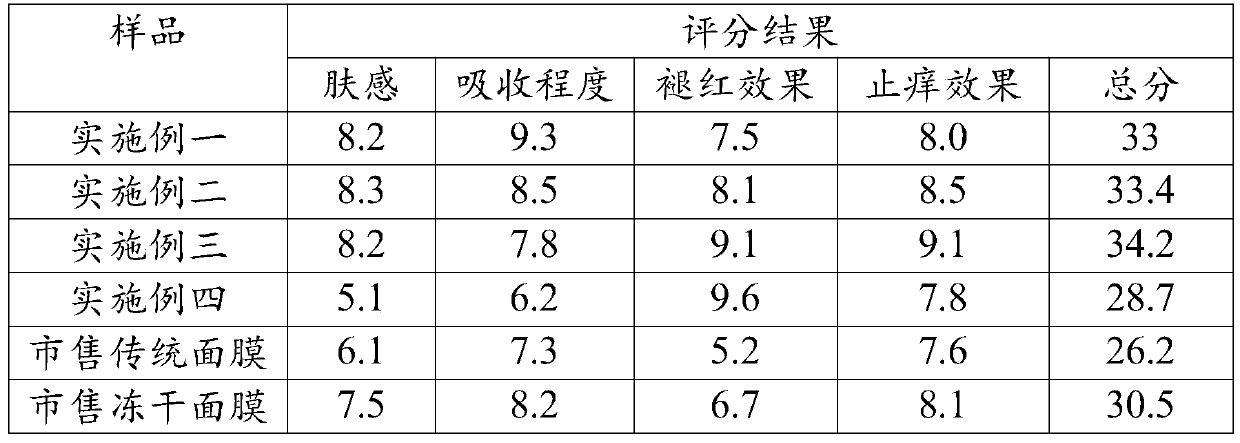

Anti-allergy moisturizing freeze-dried mask and preparation method thereof

InactiveCN110960456AImprove stabilityReduce harmCosmetic preparationsToilet preparationsBiotechnologyMonosodium glutamate

The invention discloses an anti-allergy moisturizing freeze-dried mask. The anti-allergy moisturizing freeze-dried mask is prepared by attaching functional components to mask cloth and then freeze-drying. The functional components comprise, by mass, 1.0 to 2.0 parts paeonia lactiflora root extract, 2.0 to 5.0 parts purslane extract, 4.0 to 8.0 parts of chamomile extract, 0.05 to 3.0 parts of radixscutellariae extract, 0.5 to 3.0 parts of sodium hyaluronate, 0.2 to 1.0 part of tremella polysaccharide, 0.5 to 2.0 parts of allantoin, 0.2 to 2.0 parts of sodium polyglutamate, 2.3 to 5.1 parts offibronectin, 1.5 to 5.6 parts of collagen, 2.0 to 4.0 parts of rhamnose and the balance of deionized water. By utilizing a freeze drying technology, the problem that the activity of the components ofa traditional mask essence is easy to damage is solved, and meanwhile, no preservative is added in the freeze drying process. Irritation caused by the preservative can be reduced. In addition, the mask has the effects of relieving, resisting allergy, diminishing inflammation, resisting bacteria, efficiently moisturizing, repairing skin and resisting aging.

Owner:广州市玉鑫化妆品有限公司

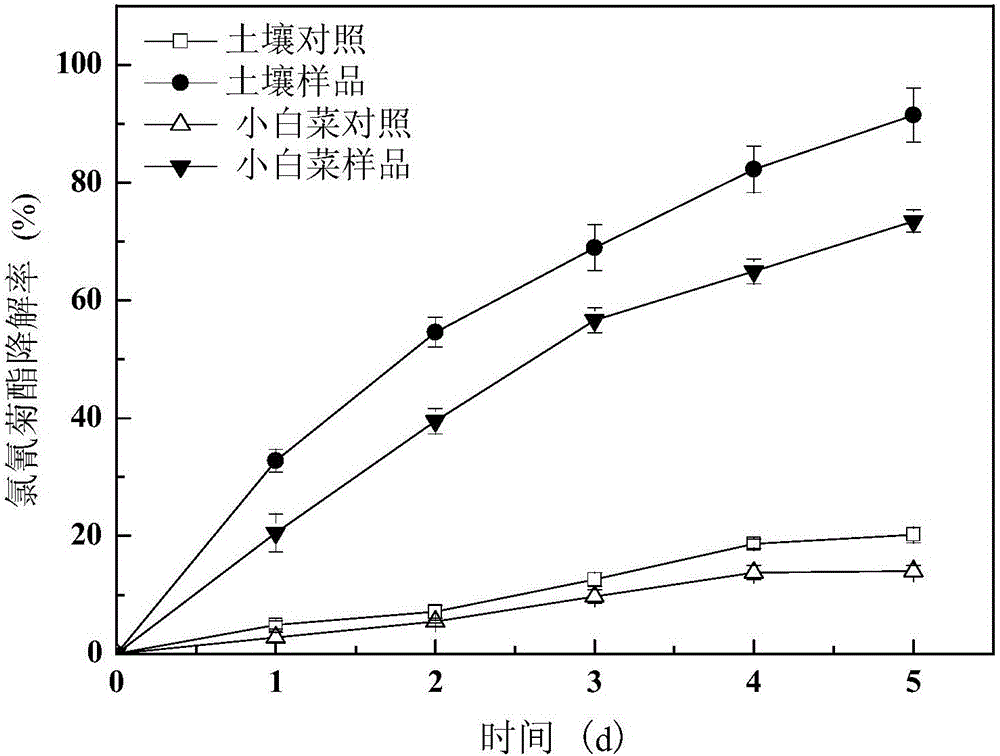

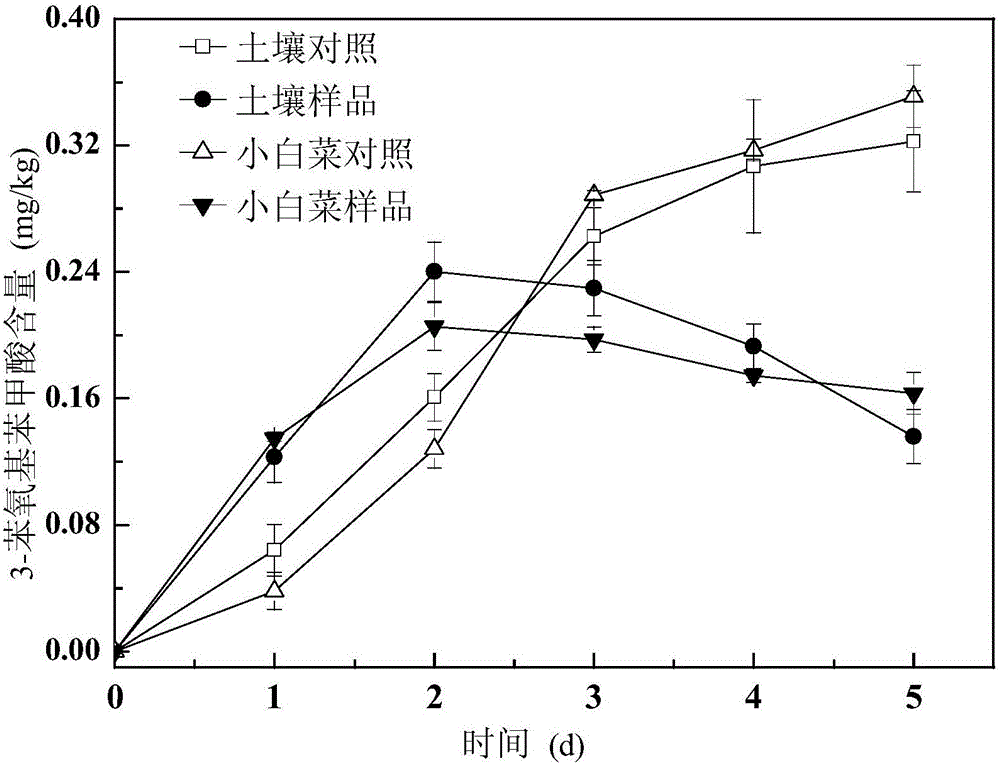

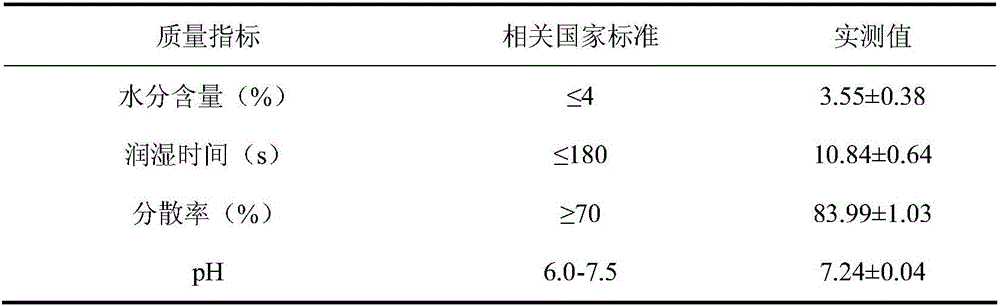

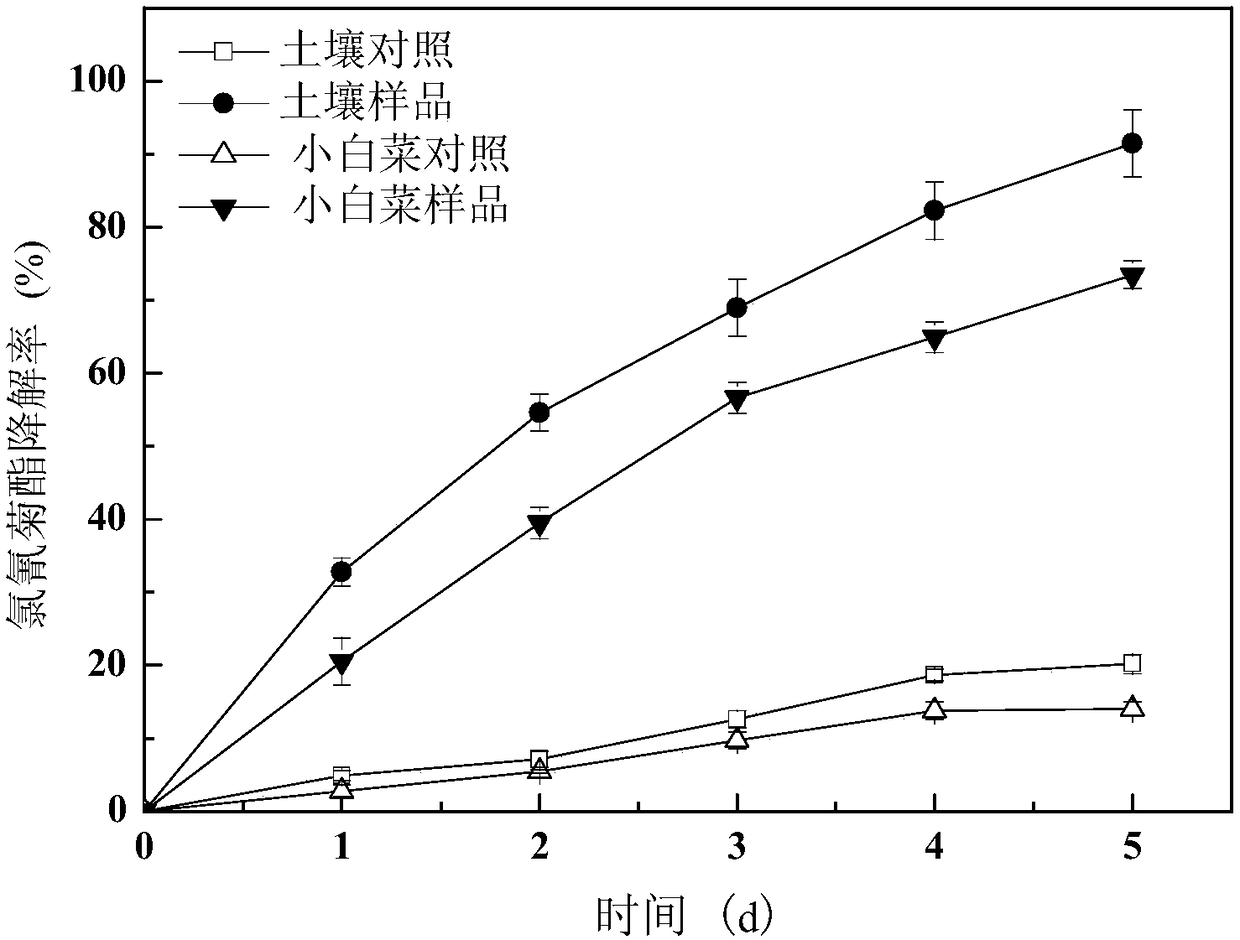

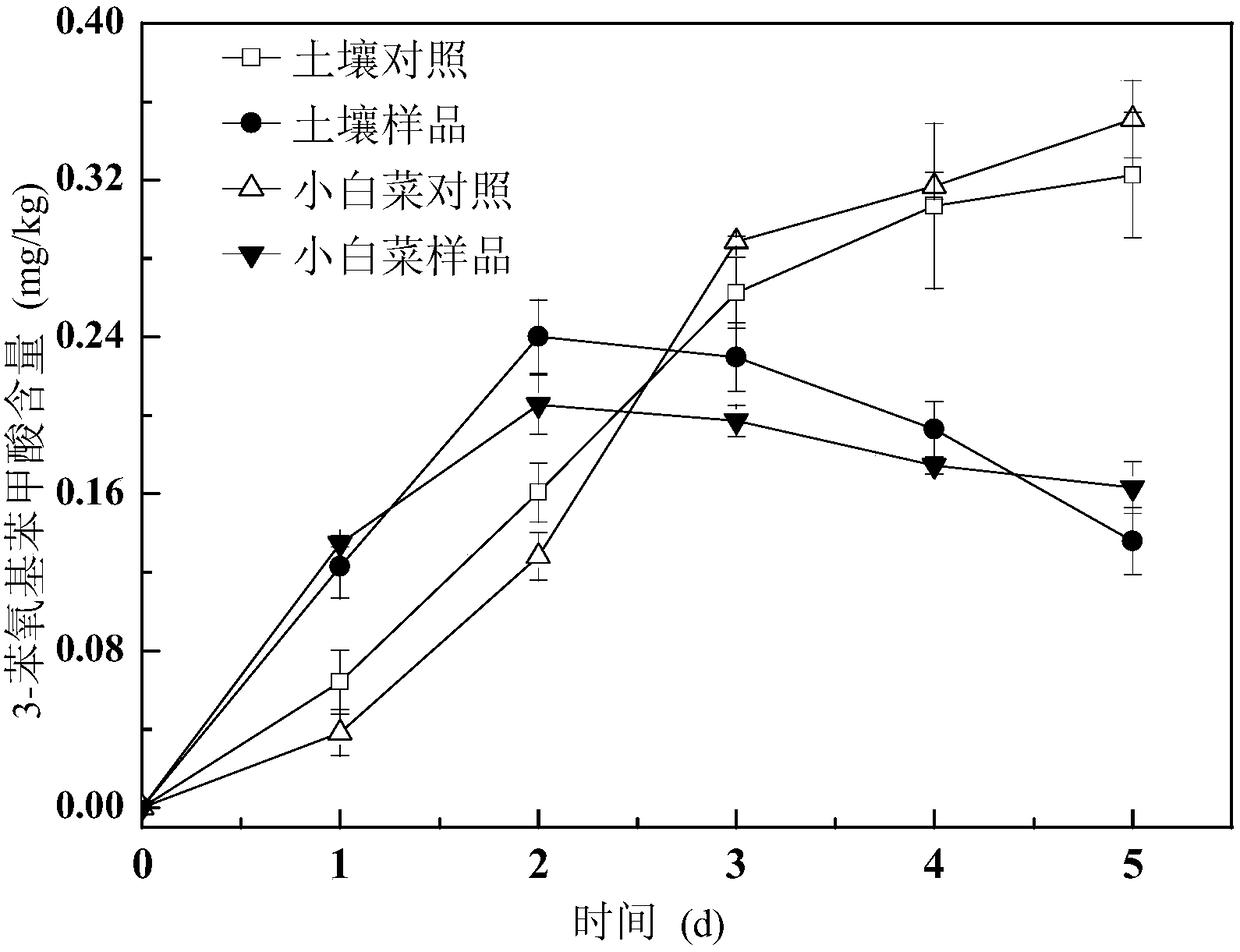

Wettability fungus powder capable of effectively degrading cypermethrin and 3-phenoxy benzoic acid and preparation method

ActiveCN105903148AResidual amount of 3-phenoxybenzoic acid decreasedGood dispersionContaminated soil reclamationBenzoic acidBiotechnology

The invention discloses wettability fungus powder capable of effectively degrading cypermethrin and 3-phenoxy benzoic acid and a preparation method. The wettability fungus powder comprises the raw materials of composite fungus liquid, diatomaceous earth, sodium lignin sulfonate, tween 80, skim milk powder and trehalose; and the composite fungus liquid consists of bacillus licheniformis B-1 fungus liquid and sphingomonas SC-1 fungus liquid. The method comprises the following steps: (1) the diatomaceous earth is added in the composite fungus liquid to obtain a carrier-fungus liquid mixture; the tween 80, the sodium lignin sulfonate, the skim milk powder and the trehalose are added in sterile water having the same volume with the composite fungus liquid to obtain auxiliary solution; and the auxiliary solution and the carrier-fungus liquid mixture are uniformly mixed to obtain fungicide mixed liquid; and (2) the fungicide mixed liquid obtained in the step (1) is dried by the following process parameters in sequence: a temperature from -46 to -48 DEG C is kept by 1.0-3.0 h; a temperature from -36 to -40 DEG C is kept by 1.0-3.0 h; a temperature from -26 to -30 DEG C is kept by 1.0-3.0 h; a temperature from -15 to -20 DEG C is kept by 1.0-3.0 h; a temperature from 0 to 4 DEG C is kept by 10-14 h; a temperature from 8 to 12 DEG C is kept by 1.0-3.0 h; a temperature from 30 to 40 DEG C is kept by 2.0-6.0 h; a temperature from 15 to 25 DEG C is kept by 20-24 h; and the wettability fungus powder is obtained.

Owner:黑龙江棒星食品科技股份有限公司

Cutinase, keratinase and protease one-bath process anti-felting technology

InactiveCN102965955AAvoid damageImprove wettabilityBiochemical fibre treatmentAnimal fibresFiberEcological environment

The invention discloses a wool biological process anti-felting finishing method based on a cutinase, keratinase and protease one-bath process, belonging to the technical field of wool fabric dyeing and finishing, which aims to solve the shortcomings that a wool chlorination anti-felting method causes serious environmental pollution, a single protease method has poor wettability and high felting rate in treating fabric and a cutinase, keratinase and protease three-step method has low treatment efficiency to realize an effect of optimizing wool fabric protease treatment. The method comprises the following steps of: extracting a wool sample to remove free oily impurities; and performing one-bath process treatment in a solution containing cutinase, keratinase and protease of certain concentration, wherein through the synergistic effect of the three enzymes, the hydrophilicity of the fiber scale surface and the acting efficiency of the keratinase and protease in the treatment bath, the removal effect of a scale layer on the wool surface and the anti-felting performance of the wool fabric are improved, and the treatment time is shortened. According to the invention, the biological process anti-felting method can replace the traditional chlorination method, the quality of the wool anti-felting finishing is improved, and protection on ecological environment is facilitated.

Owner:JIANGNAN UNIV

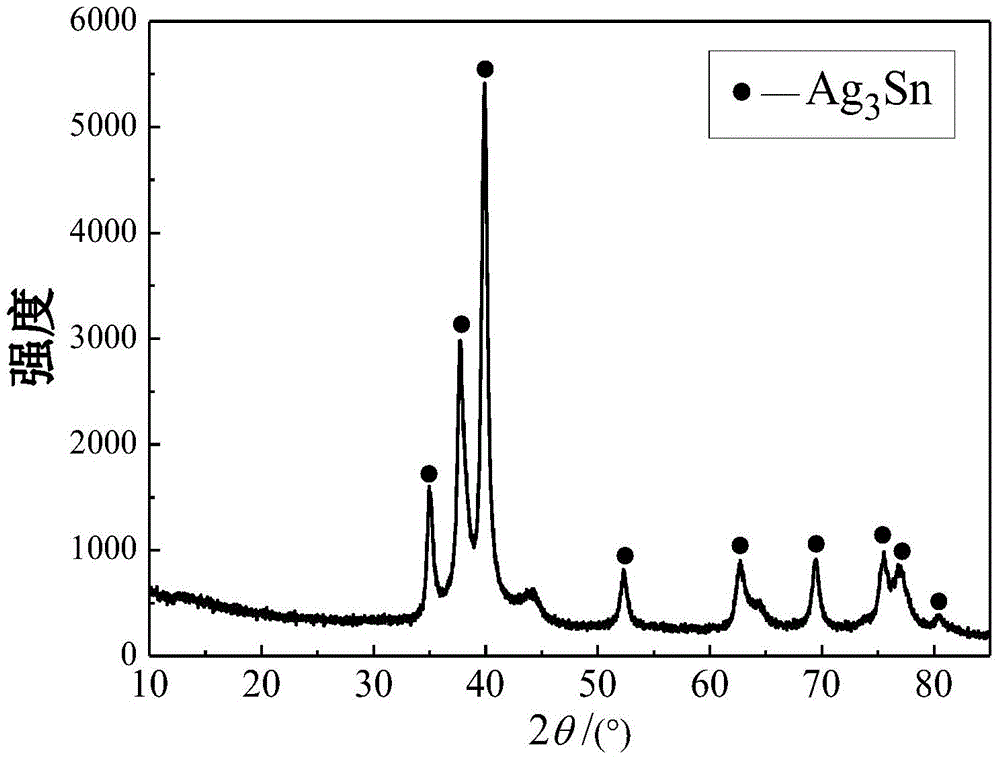

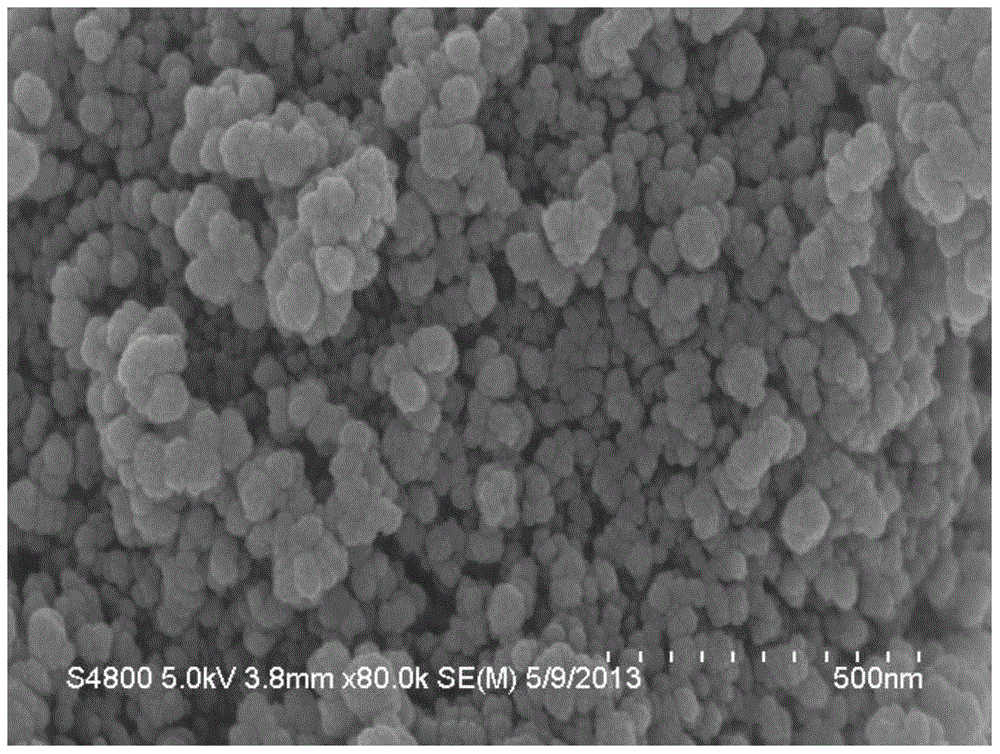

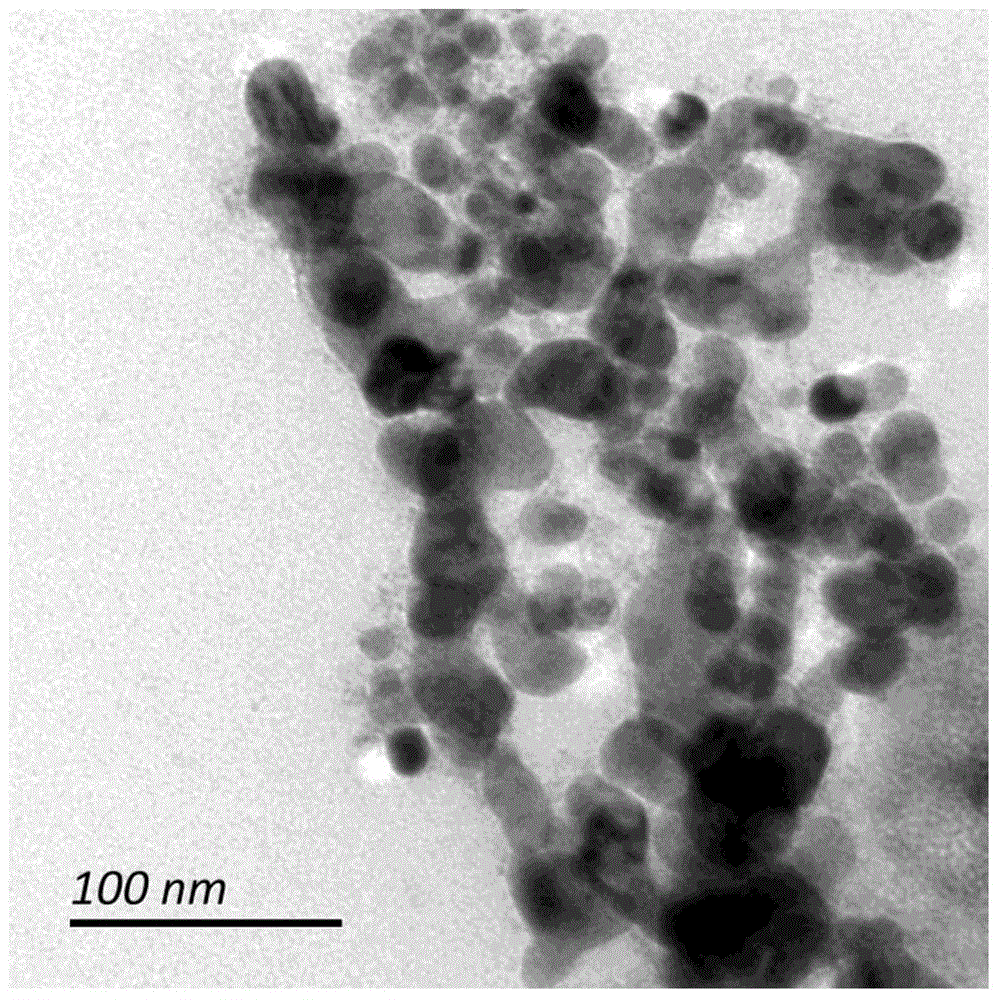

Nanometer Ag3Sn particle reinforced composite lead-free soldering paste and preparation method thereof

InactiveCN104014947AImprove mechanical propertiesLow melting pointWelding/cutting media/materialsSoldering mediaNanoparticleElectronics manufacturing

The invention discloses nanometer Ag3Sn particle reinforced composite lead-free soldering paste and a preparation method thereof, belonging to the technical field of welding materials for assembly of electronic devices. The nanometer Ag3Sn particle reinforced composite lead-free soldering paste is prepared from nanometer Ag3Sn particles and low-Ag lead-free soldering paste through long-time mechanical stirring, and the nanometer Ag3Sn particles are prepared by a chemical reduction method. The preparation method is simple and convenient to operate and has good repeatability. The composite lead-free soldering paste is superior to non-reinforced low-Ag lead-free soldering paste in the processing properties such as melting point, wettability and welding joint mechanical property, and can meet the technological requirements of low cost and high performance on soldering paste in the current electronics manufacturing industry to a great degree.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

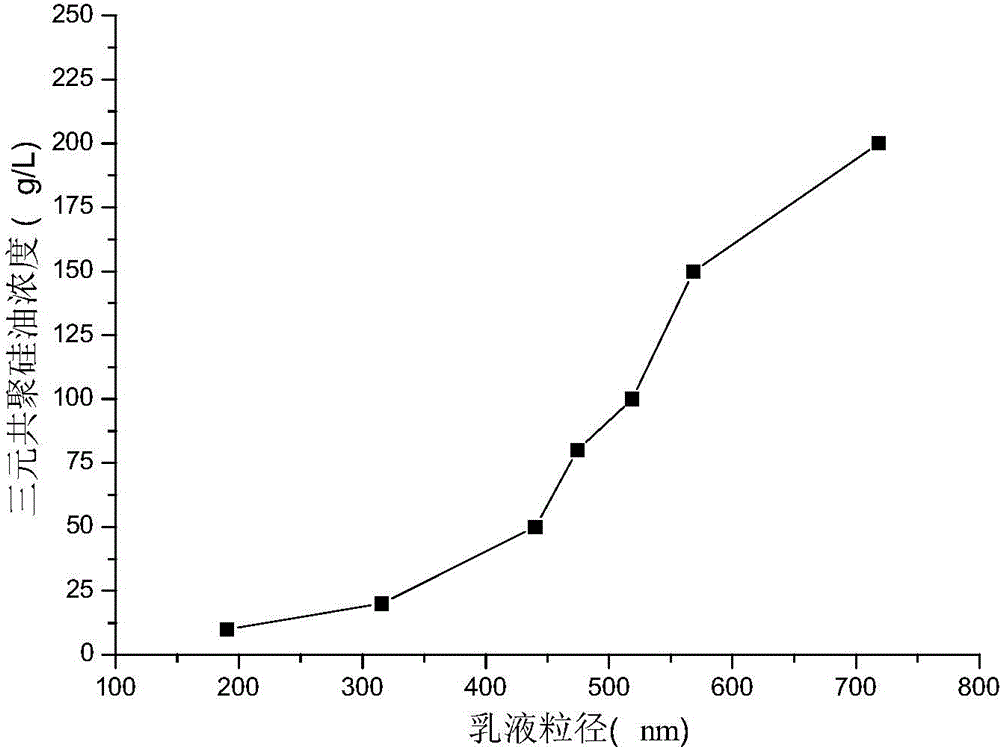

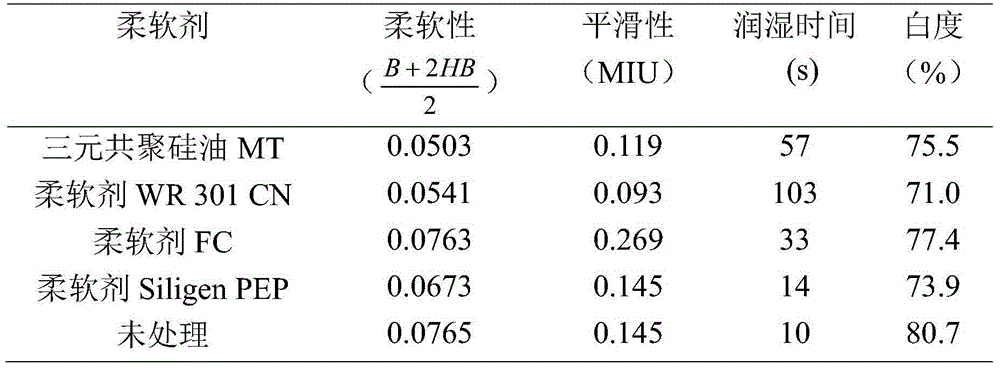

Softener composition as well as preparation method and application of softener composition

The invention discloses a softener composition as well as a preparation method and the application of the softener composition. The softener composition is prepared from the following components in percentage by mass: 1%-99% of ternary-polymerized silicone oil and 1%-99% of amino silicone oil. When the softener composition is applied to softening finishing on cotton fabrics, a good soft and smooth hand feeling is provided for finished products without causing obvious decline of the hydrophilcity of the finished products.

Owner:SHANGHAI ANOKY GRP +1

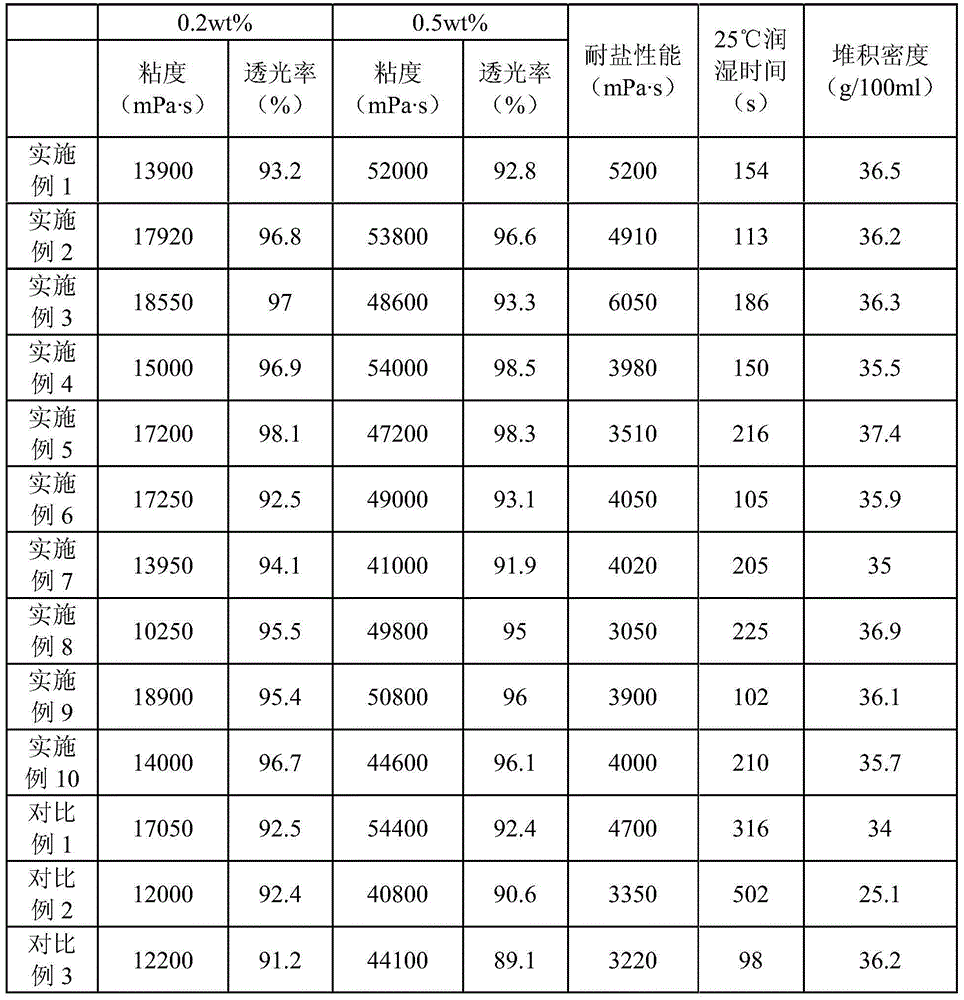

Quick-wetting carboxylic acid copolymer thickening agent and preparation method thereof

ActiveCN104861104AShort wetting timeSmall particle size distribution rangeCross-linkHydrocarbon solvents

The invention provides a preparation method of a quick-wetting carboxylic acid copolymer thickening agent, which comprises the following steps: adding an organic inert solvent containing at least 55wt% of a hydrocarbon solvent, 15wt%-20wt% of a monomer as well as an initiator, a dispersant and a cross-linking agent which are required by reaction into a reaction vessel, and performing reaction at 45-55DEG C for 30-60min; mixing an organic inert solvent containing at least 55wt% of an ester solvent, the rest of the monomer and the initiator, the dispersant and the cross-linking agent which are required by reaction, and adding the mixture into the reaction vessel within 3-6h and reacting under the same reaction temperature; and after all the reactant is dropwise added, raising the temperature to 55-75DEG C, adding the initiator again, performing heat preservation for 1-4h so that the monomer in the reaction system is reacted completely, ending the reaction, and discharging a product. The invention aims to provide the quick-wetting carboxylic acid copolymer thickening agent with quick wetting and dispersing properties and high bulk density, and meanwhile the invention further provides the preparation method of the quick-wetting carboxylic acid copolymer thickening agent.

Owner:GUANGZHOU TINCI MATERIALS TECH

Method for improving instant capacity of soymilk powder

InactiveCN101779704AGood instant solubilityFast dispersionMilk substitutesFood scienceSolubilitySurface modification

The invention discloses a method for improving instant capacity of soymilk powder, belonging to the technical field of food or cosmetics. Common soybeans or peeled soybeans are taken as a raw material, and on the basis of a wet method pulping technology, the instant capacity of the soymilk powder can be improved by using the technologies of regulating ionic strength, surface modification of prion, powder preparation by spray drying, and dry mixing of inorganic salts. The invention has the obvious advantages that hydrophilic structure substances and charge distribution on the surface of soymilk prion are modified by adding salts to be matched with emulsifier under the liquid state and dry powder conditions during the soymilk heat treatment process, thus retaining the good hydrophilic structure of the soymilk protein and improving the dispersibility and solubility of the soymilk powder effectively, wherein the dispersing speed is obviously improved by about 30%, and the wetting time is shortened by about 20min; and the invention improves the instant capacity of the soymilk powder to a certain extent and solves the problem that soymilk powder is difficult to dissolve in uniform emulsion in the current soybean processing industry.

Owner:CHINA AGRI UNIV

Preparation method of Al-Si-Zn rapidly-cooled solder for aluminum alloy/stainless steel brazing

InactiveCN102500957AShort wetting timeImprove wettabilityWelding/cutting media/materialsSoldering mediaElectric arc furnaceSolid joint

The invention relates to a preparation method of an Al-Si-Zn rapidly-cooled solder for aluminum alloy / stainless steel brazing. Zinc powder and solder foil containing aluminum, silicon, iron, copper and magnesium are used as raw materials and are added into a vacuum non-consumable arc furnace, and argon is filled after vacuum pumping; a power supply is turned on, the raw materials are heated to 1400-1500 DEG C at a rate of 28 DEG C per second, the power supply is turned off, and the materials are cooled for 15 minutes; the molten raw materials are taken out, turned and fed into the arc furnace again to be molten once to twice; the cooled alloy block is taken out and ground after melting; and the alloy block is placed into a single-roller melt rapid-quenching device and heated to be molten, the molten alloy is sprayed onto a roller, a solder foil band with the width of 15mm and the thickness of 120Mum can be formed via band spinning, and thus the Al-Si-Zn rapidly-cooled solder is prepared. The prepared solder has good wetting performance, the wetting time for stainless steel can be reduced, and the stainless steel and aluminum can be wetted simultaneously, so that solid joints can be formed between the stainless steel and the aluminum.

Owner:HENAN UNIV OF SCI & TECH

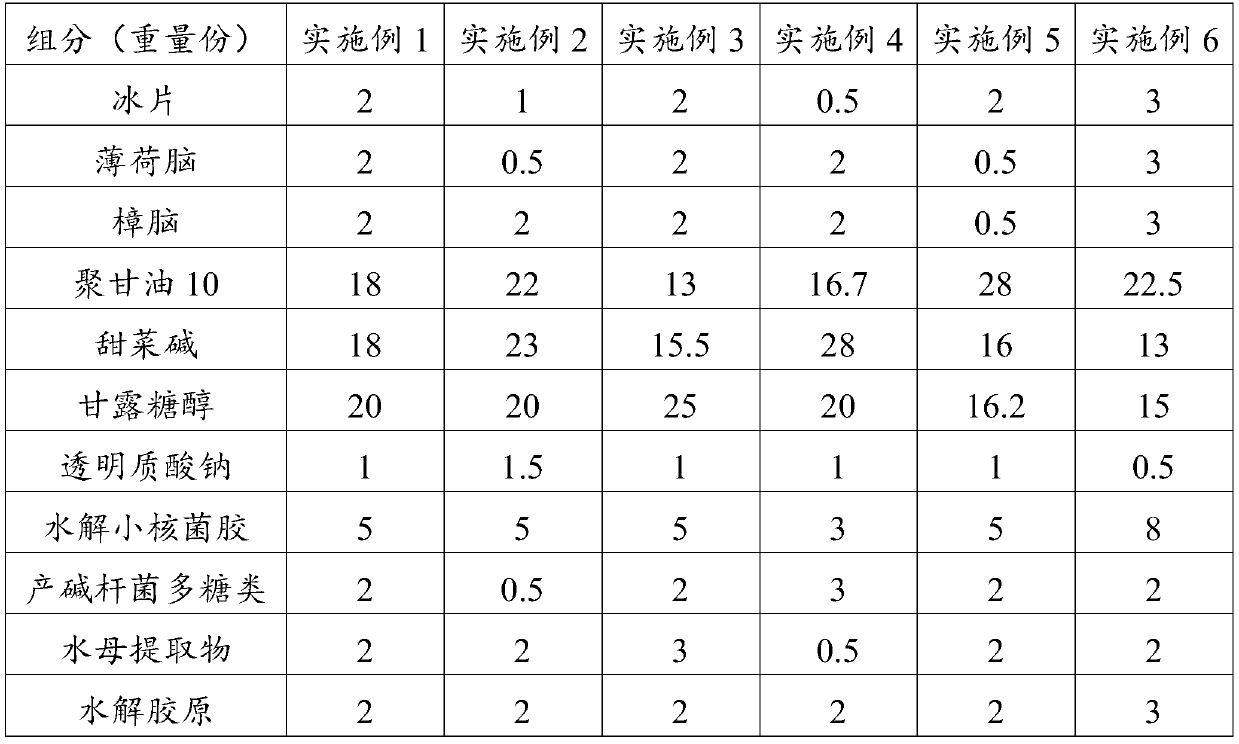

Medical cold compress patch

The invention discloses a medical cold compress patch. The medical cold compress patch is prepared by attaching an effective component to a non-woven fabric or a silk cloth and then carrying out freeze drying; the effective component comprises a cooling composition and a moisturizing composition; the cooling composition contains borneol, menthol and camphor. The medical cold compress patch does not contain moisture, it is not needed to add a preservative, and the skin damage or allergic phenomenon caused by the preservative can be reduced; the medical cold compress patch is more flexible to use, the wetting time is short, and the medical cold compress patch can be used after being wetted in combination with clean water or other nutrient water. The cold compress patch obtained after freezedrying treatment can reduce the loss of heat sensitive substances, some oxidizable substances in the cold compress patch are protected, and the stability of the cold compress patch is improved. The cold compress patch is applicable to physical defervescence and cold compress physiotherapy of closed soft tissue. Heat is removed by vaporization of moisture and natural cooling components contained bythe cold compress patch, and the effects of pain reliving through cold compress, percutaneous absorption and slow-release drug delivery can be achieved.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

Anti-oxidation flux and preparation method thereof

InactiveCN105855750AReduce tensionPrevent oxidationWelding/cutting media/materialsSoldering mediaVegetable oilDichlorodifluoromethane

The invention discloses an anti-oxidation flux and a preparation method thereof. The anti-oxidation flux is prepared from, by weight, 100-200 parts of vegetable oil modified rosin, 120-150 parts of ethyl alcohol, 60-80 parts of carbitol, 40-120 parts of polyethylene glycol, 20-60 parts of sebacic acid, 50-80 parts of maleic acid, 90-100 parts of malic acid, 40-60 parts of citric acid, 20-30 parts of butyl acetate, 7-15 parts of malonic acid amide, 20-60 parts of nicotinamide, 10-20 parts of zinc nitrate, 20-60 parts of olein, 40-80 parts of isocyanate and 40-90 parts of dichlorodifluoromethane. The preparation method includes: adding the raw materials, performing heating reaction, adding the nicotinamide, and well stirring. The anti-oxidation flux is excellent in wettability, surface tension of welded materials is reduced, and accordingly surface oxidation of the welded materials is prevented.

Owner:傅兴琴

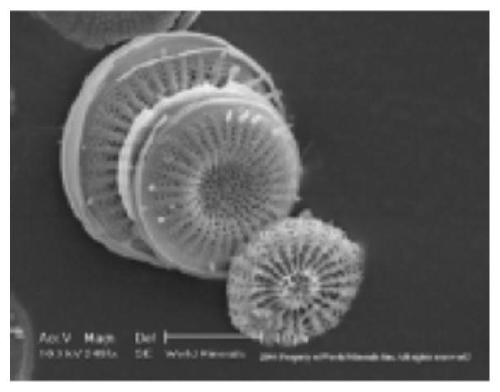

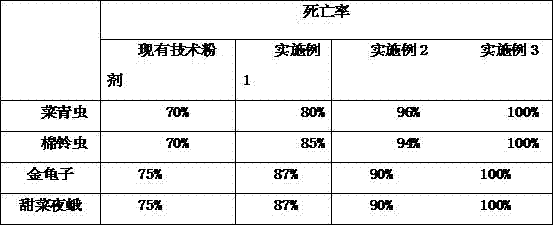

Diatomite-Metarhizium anisopliae pesticide composition and application thereof

InactiveCN111165482AGood effectWide range of insecticidalBiocideAnimal repellantsFrankliniella intonsaCitrus volkameriana

The invention relates to the technical field of pesticides, in particular to a diatomite-Metarhizium anisopliae pesticide composition and application thereof. According to the invention, the diatomite-Metarhizium anisopliae pesticide composition is prepared by compounding diatomite with a specific zigzag structure and Metarhizium anisopliae; the prepared pesticide composition is relatively good inpesticide effect and relatively wide in insecticidal range, and has relatively good pesticide effects on various pests such as citrus red spiders, citrus scale insects, frankliniella occidentalis, whiteflies, liriomyza sativae, prodenia litura, tea lesser leafhoppers, tea yellow thrips, tea geometrids, apolygus lucorum and grape aphids. Besides, the diatomite-Metarhizium anisopliae wettable powder is further prepared from a specific wetting agent and a dispersing agent, and the prepared diatomite-Metarhizium anisopliae wettable powder is good in wettability and spreadability, high in suspension rate and short in wetting time.

Owner:本生(惠州)生物技术有限公司

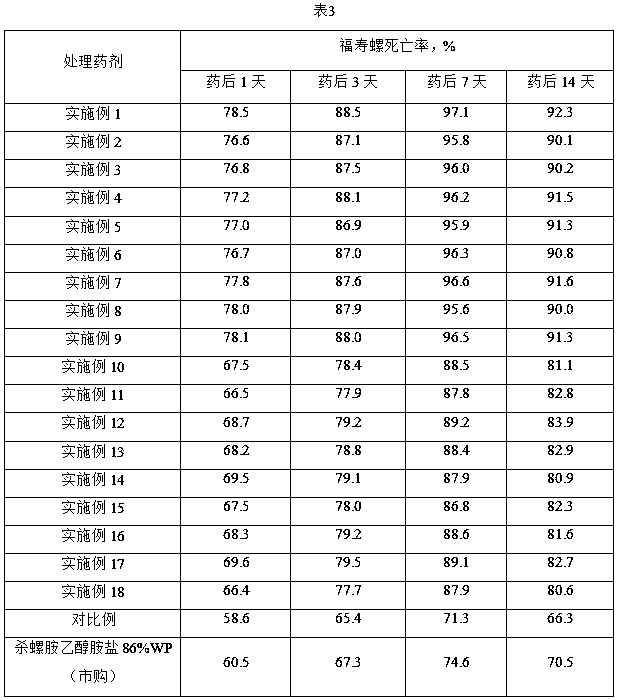

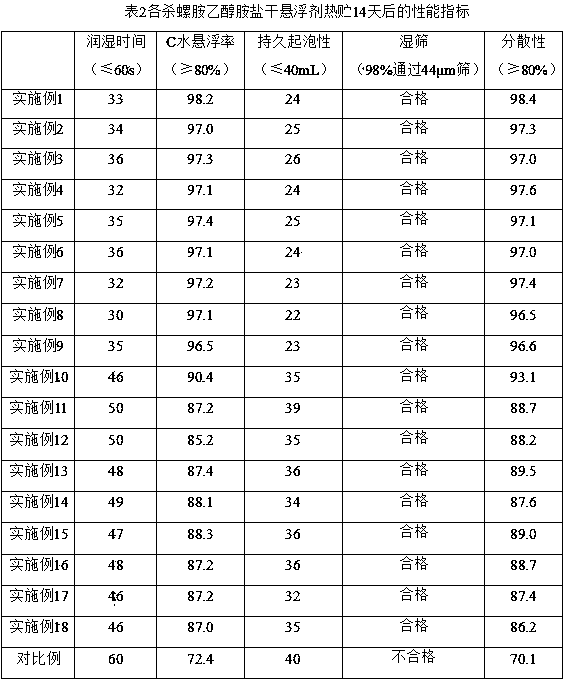

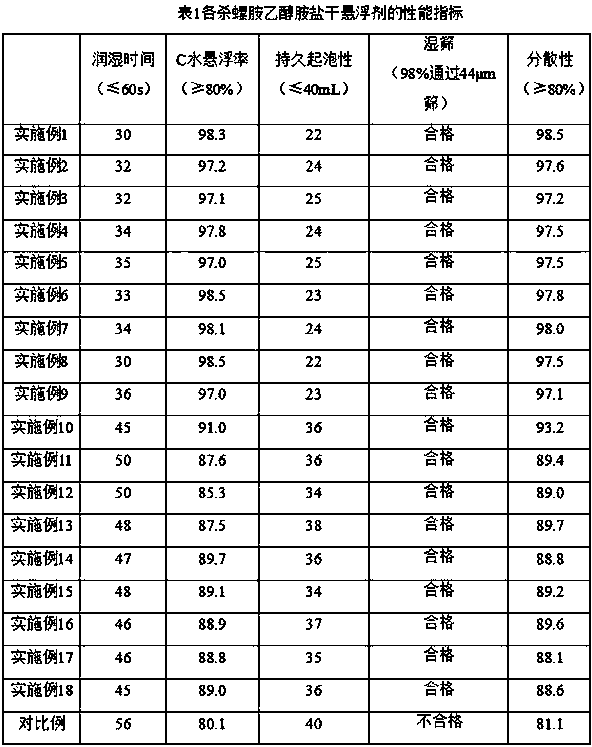

Niclosamide ethanolamine dry flowable and preparation method thereof

The invention discloses a niclosamide ethanolamine dry flowable and a preparation method thereof. The dry flowable comprises an effective component and additives, wherein the effective component is niclosamide ethanolamine; the additives include a dispersing agent, a wetting agent, a disintegrating agent, a defoaming agent and a filler. According to the dry flowable, the effective component content is high and up to 90%; the dry flowable is small in particle size, outstanding in performance, high in storing stability and low in storing and carrying cost, has high activity to mollusc pests suchas ampullaria gigas, oncomelania and snail, and is fast to disinfect insects, long-lasting in effect, and convenient to use.

Owner:QINGDAO RAINBOW CHEM CO LTD

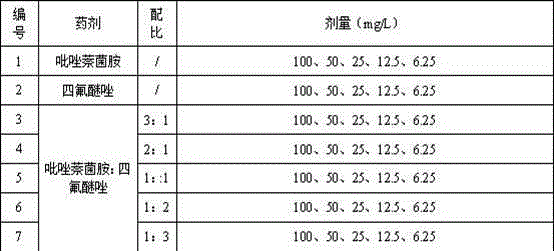

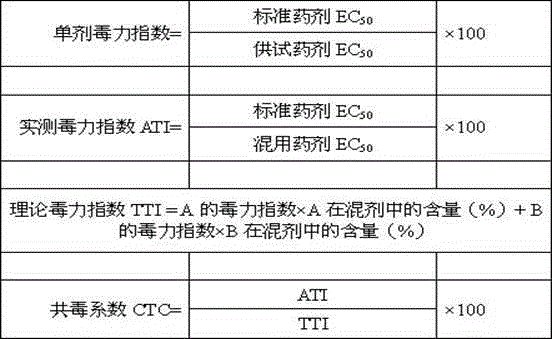

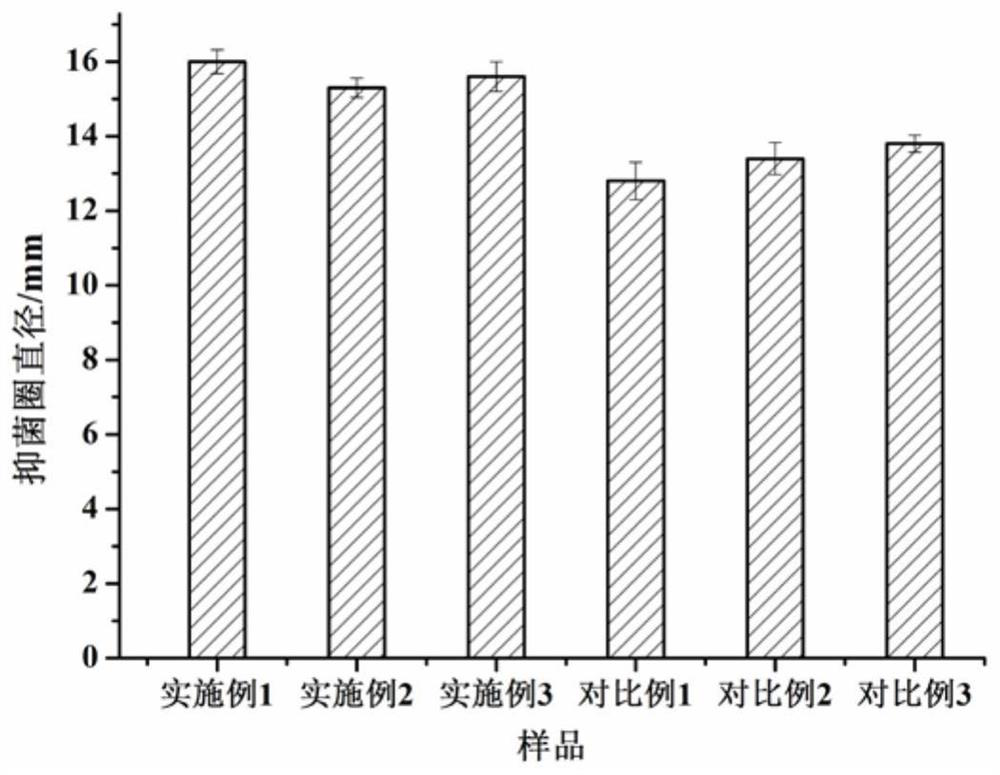

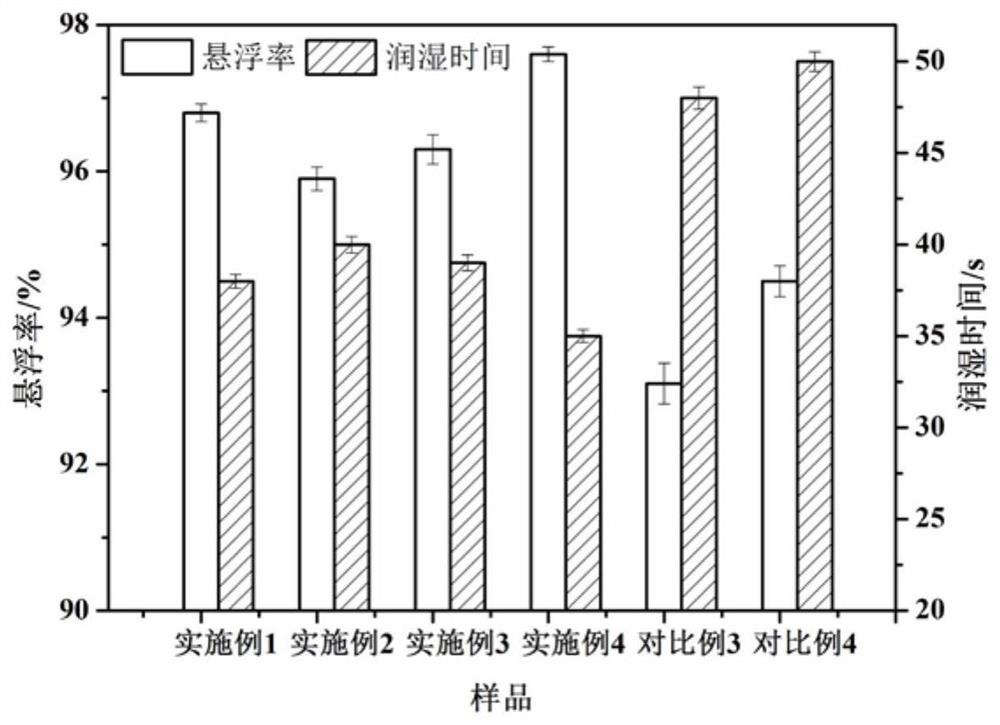

Isopyrazam and tetraconazole bactericidal composition and application thereof

InactiveCN104430379AGood synergyImprove the bactericidal effectBiocideFungicidesMedicineActive component

The invention provides an isopyrazam and tetraconazole bactericidal composition and an application thereof. Two effective component of the composition have an excellent synergistic effect. Specifically, the weight ratio of isopyrazam to tetraconazole in the composition is 10:1 to 1:10 based on active components, and preferably 5:1 to 1:5. The bactericidal composition disclosed by the invention has a quite good prevention and treatment effect in preventing and treating strawberry powdery mildew and can be used for reducing the dosage of a used pesticide, lowering the cost of the pesticide and also relieving the pressure to environment.

Owner:浙江威尔达化工有限公司

Sn-Zn-Cr alloy lead-free solder preparation method

Disclosed is a Sn-Zn-Cr alloy lead-free solder preparation method which comprises, (1) preparation of Sn-Cr intermediate alloy, which consists of mixing Cr 0.005-1.5%, Zn 3-12%, and balancing Sn, elevating temperature to above the fusion point of the metal Cr, melting and thermally insulating, fully stirring, charging the residue Sn raw material into the furnace, waiting for dissolution, cooling down, thermally insulating, continuing stirring simultaneously, (2) smelting of Sn-Zn-Cr alloy, which consists of charging the Zn raw material into melting Sn-Cr intermediate alloy, waiting for complete dissolution, fully stirring, thermally insulating, cooling down, thermally insulating while agitating continuously, finally cooling down to room temperature or casting as requirement.

Owner:SHANGHAI JIAO TONG UNIV

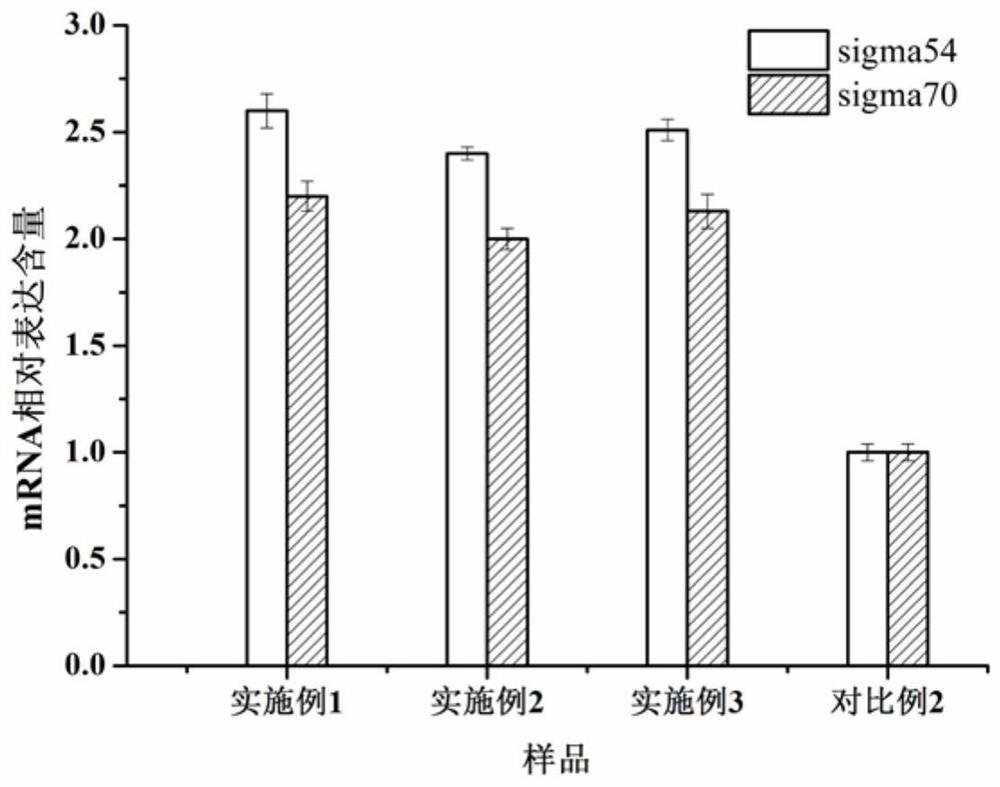

Microbial source bactericide for preventing and treating plant diseases and preparation method thereof

ActiveCN112006035AStrong dipping abilityPromote secretionPlant growth regulatorsBiocideBiotechnologyMicroorganism

The invention provides a microbial source bactericide for preventing and treating plant diseases and a preparation method thereof, and belongs to the technical field of microbial pesticides. The preparation method of the microbial source bactericide comprises the following steps: performing slant culture on a biocontrol strain to obtain an activated strain; inoculating into a liquid culture mediumand culturing to obtain liquid seeds of each strain; transferring the liquid seeds of each strain into a solid-state fermentation culture medium containing red alga amino acid, carrying out fermentation culture, soaking in sterile water, and filtering to obtain fermentation liquor of each strain; and mixing the fermentation liquor, compounding with a carrier and an auxiliary agent, carrying out spray drying, and carrying out jet milling to obtain the microbial source bactericide. The microbial source bactericide prepared by the method has the advantages of good suspension rate, short wettingtime, strong bacteriostasis and obvious control effect on plant diseases.

Owner:JIANGXI NEW DRAGON BIOTECH

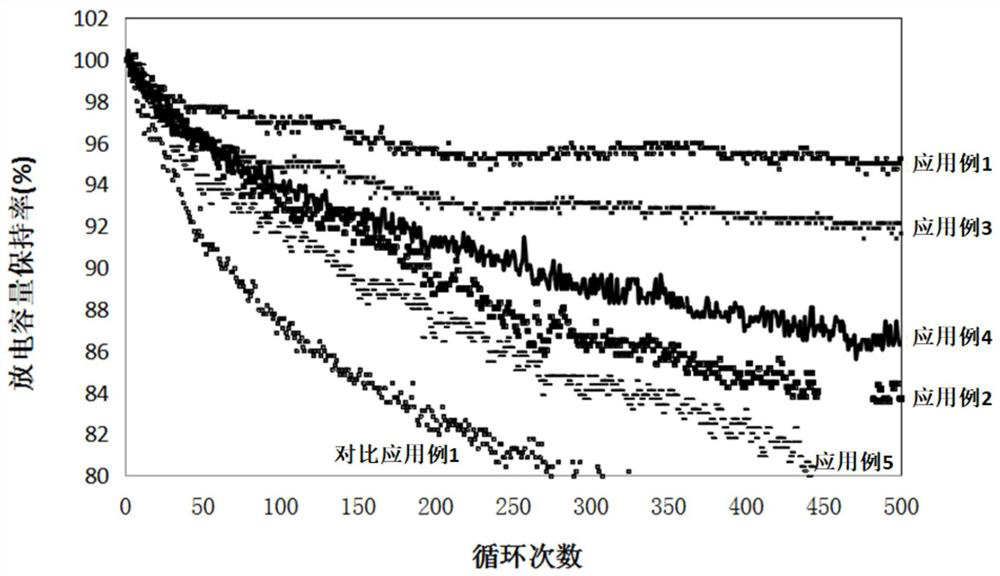

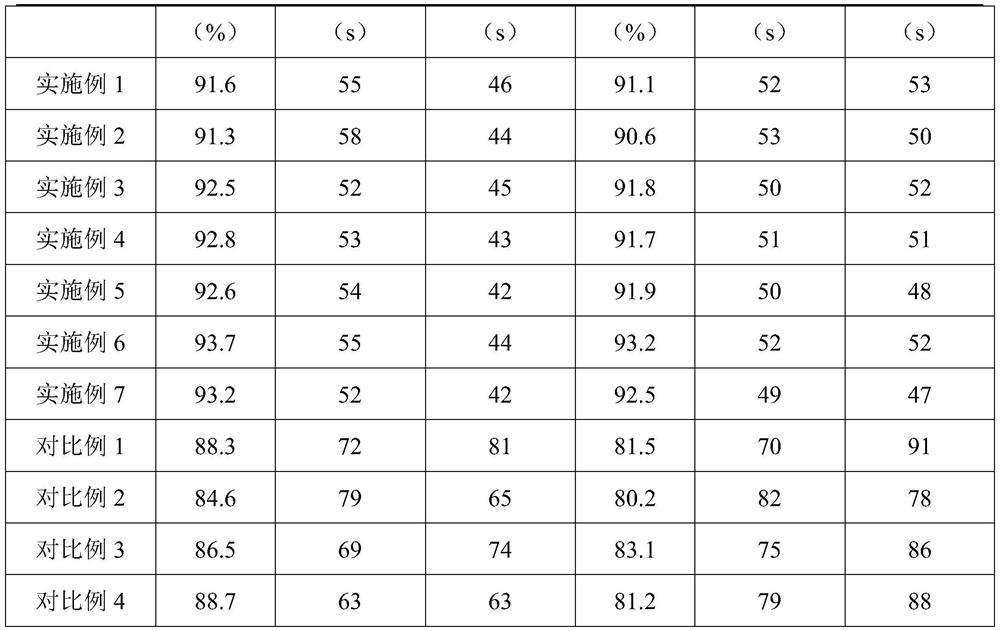

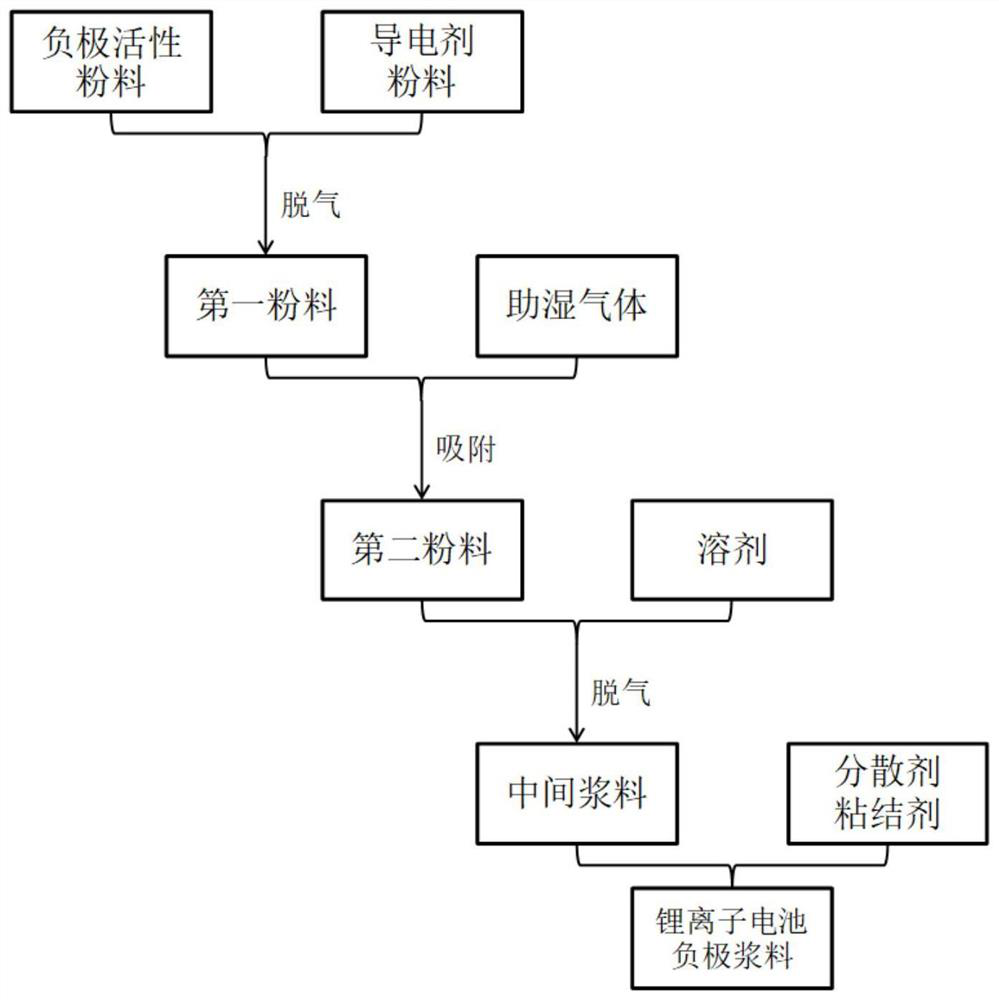

Lithium ion battery cathode slurry, preparation method thereof, and lithium ion battery

ActiveCN112366310AImprove dispersion uniformityIncrease wetting rateSecondary cellsPositive electrodesElectrical batteryLithium-ion battery

The invention provides lithium ion battery cathode slurry, a preparation method thereof, and a lithium ion battery. The preparation method comprises the following steps: (1) mixing positive electrodeactive powder with conductive agent powder, and degassing to obtain first powder; (2) mixing the first powder with a wetting aid gas to obtain second powder; (3) mixing the second powder with a solvent, and degassing to obtain intermediate slurry; and (4) mixing the intermediate slurry with a binder to obtain the lithium ion battery positive electrode slurry. According to the preparation method provided by the invention, the wettability of the powder in the preparation process of the positive electrode slurry is improved, the wetting time is shortened, the production capacity is improved, andthe time cost is saved; and the lithium ion battery is high in energy density and excellent in electrochemical performance.

Owner:EVE ENERGY CO LTD

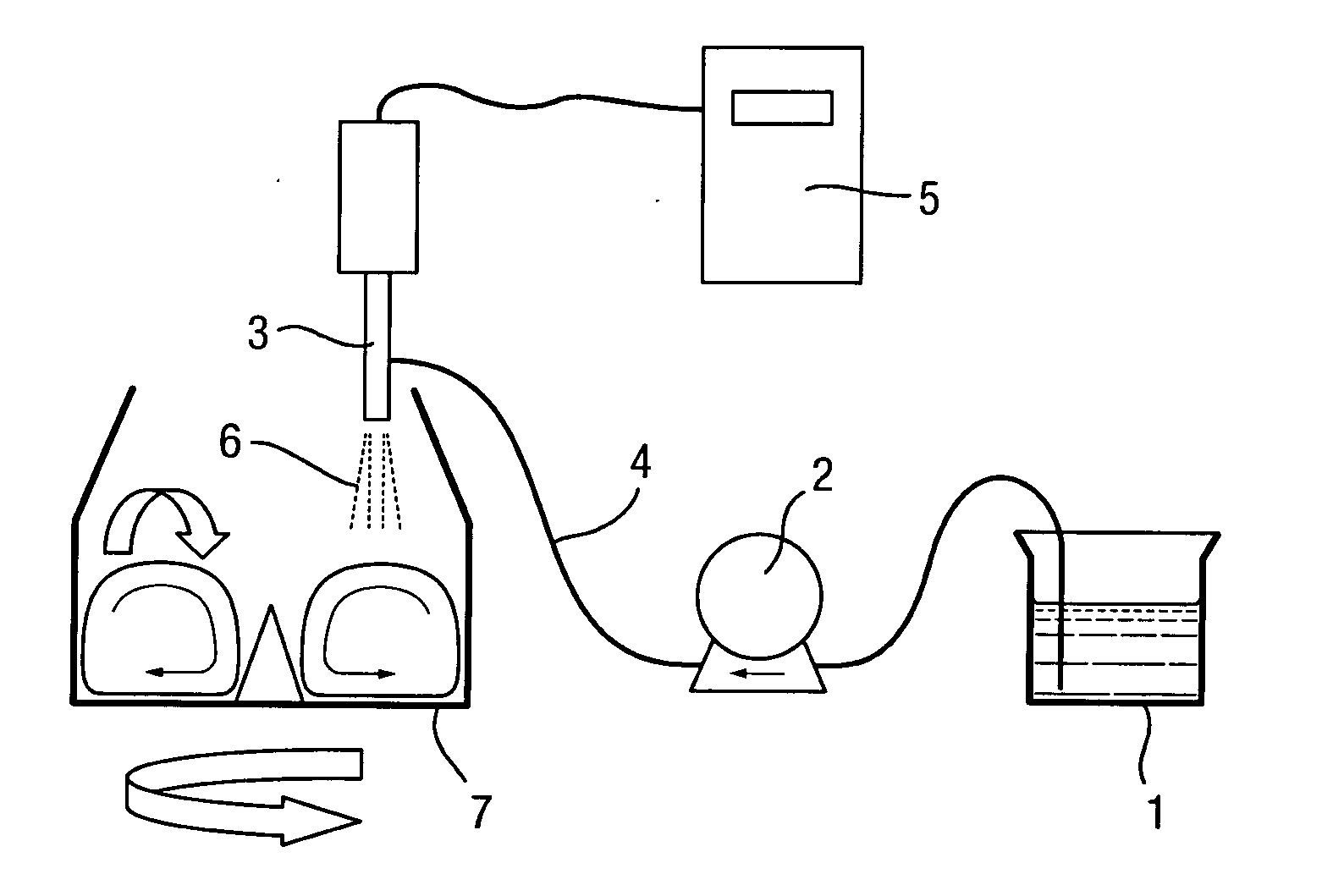

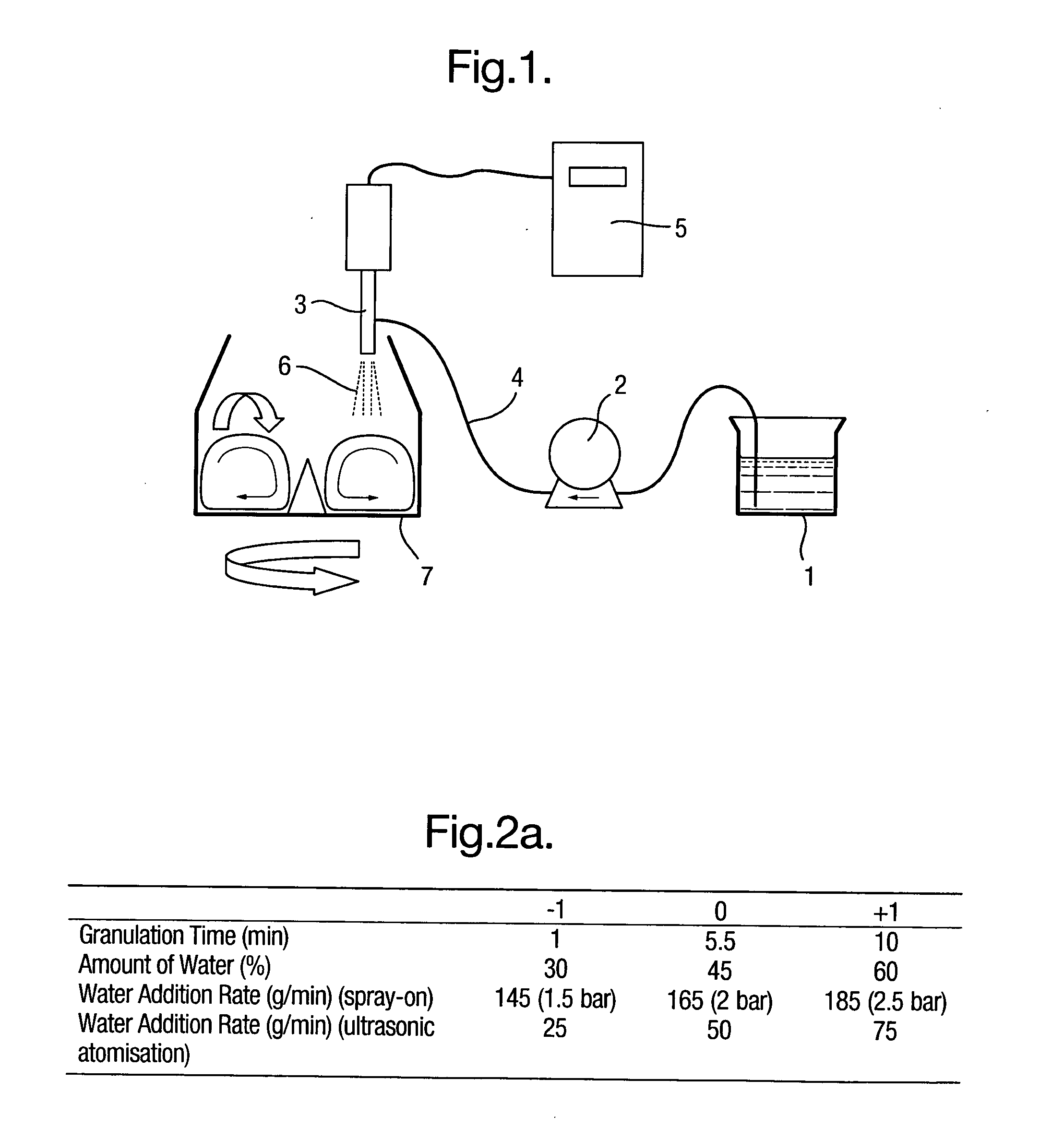

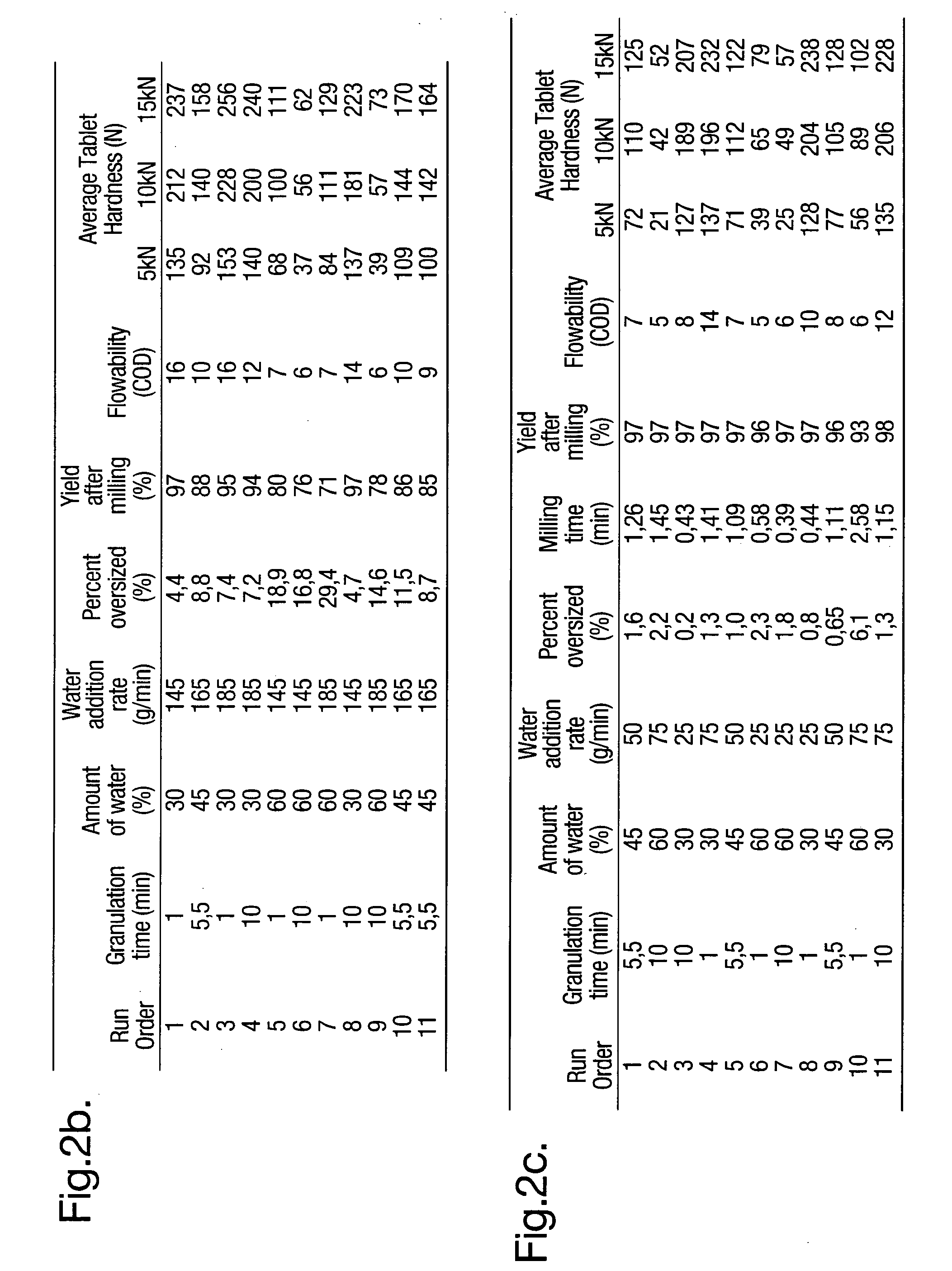

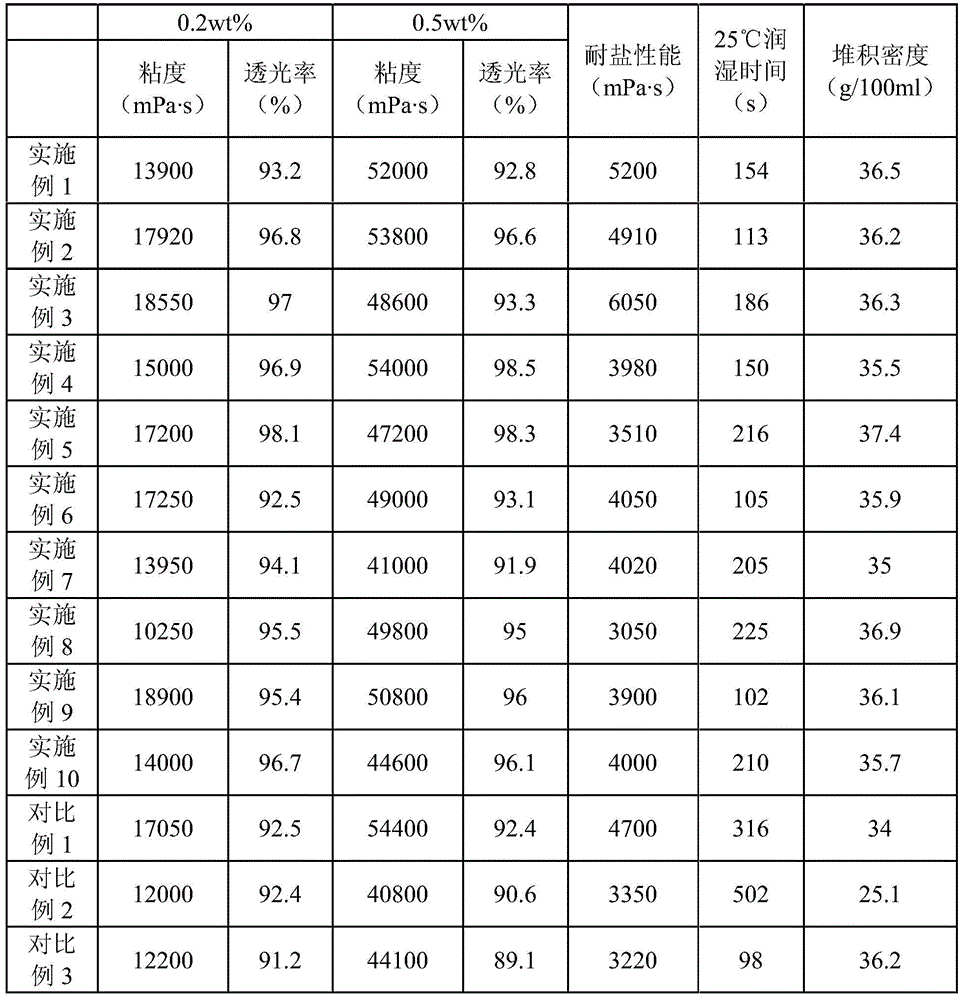

Wet Granulation System Comprising at Least One Ultrasonic Nozzle

InactiveUS20110287168A1Improve liquiditySmall size distributionGranule coatingTransportation and packagingParticulatesUltrasonic nozzle

The present disclosure relates to a system for uniform distribution of a liquid binder onto a surface of particulate solids of at least one pharmaceutical product. The system comprises a substantially circular mixer, provided with rotating means in a lower part, configured to rotate the solids along a periphery of the mixer in a first rotational movement, and at least one ultrasonic nozzle connected to a feeding device providing the said liquid binder, and configured to distribute the liquid binder as droplets onto the surface of the solids during their rotational movement.

Owner:ASTRAZENECA AB

Coarse cereal flour and preparation method thereof

The invention belongs to the technical field of food processing and particularly relates to coarse cereal flour and a preparation method thereof. The preparation method includes: (1) removing impurities; (2) weighing materials, adding into a mixer, spraying wetting liquid, stirring, mixing, discharging a mixture, spreading, centrifugally dripping, spraying salt water, and spreading to complete wetting; (3) milling the mixture, and separating out cortex, residues, cores and powder to obtain the coarse cereal flour. By mixing of coarse cereals before milling, problems of high energy consumption,low mixing efficiency and incompleteness in mixing after traditional coarse cereal milling are avoided. By adoption of the wetting liquid for wetting, bonding force of a cortex layer, an aleurone layer and endosperm is reduced through water adsorption of endosperm and the cortex layer before milling, and milling energy consumption differences of different materials are reduced; by mixing and mutual extrusion and friction of the different materials, milling efficiency is improved.

Owner:ANHUI FOZILING FLOUR IND

A kind of fast wetting carboxylic acid copolymer thickener and preparation method thereof

ActiveCN104861104BShort wetting timeSmall particle size distribution rangeCross-linkHydrocarbon solvents

The invention provides a preparation method of a quick-wetting carboxylic acid copolymer thickening agent, which comprises the following steps: adding an organic inert solvent containing at least 55wt% of a hydrocarbon solvent, 15wt%-20wt% of a monomer as well as an initiator, a dispersant and a cross-linking agent which are required by reaction into a reaction vessel, and performing reaction at 45-55DEG C for 30-60min; mixing an organic inert solvent containing at least 55wt% of an ester solvent, the rest of the monomer and the initiator, the dispersant and the cross-linking agent which are required by reaction, and adding the mixture into the reaction vessel within 3-6h and reacting under the same reaction temperature; and after all the reactant is dropwise added, raising the temperature to 55-75DEG C, adding the initiator again, performing heat preservation for 1-4h so that the monomer in the reaction system is reacted completely, ending the reaction, and discharging a product. The invention aims to provide the quick-wetting carboxylic acid copolymer thickening agent with quick wetting and dispersing properties and high bulk density, and meanwhile the invention further provides the preparation method of the quick-wetting carboxylic acid copolymer thickening agent.

Owner:GUANGZHOU TINCI MATERIALS TECH

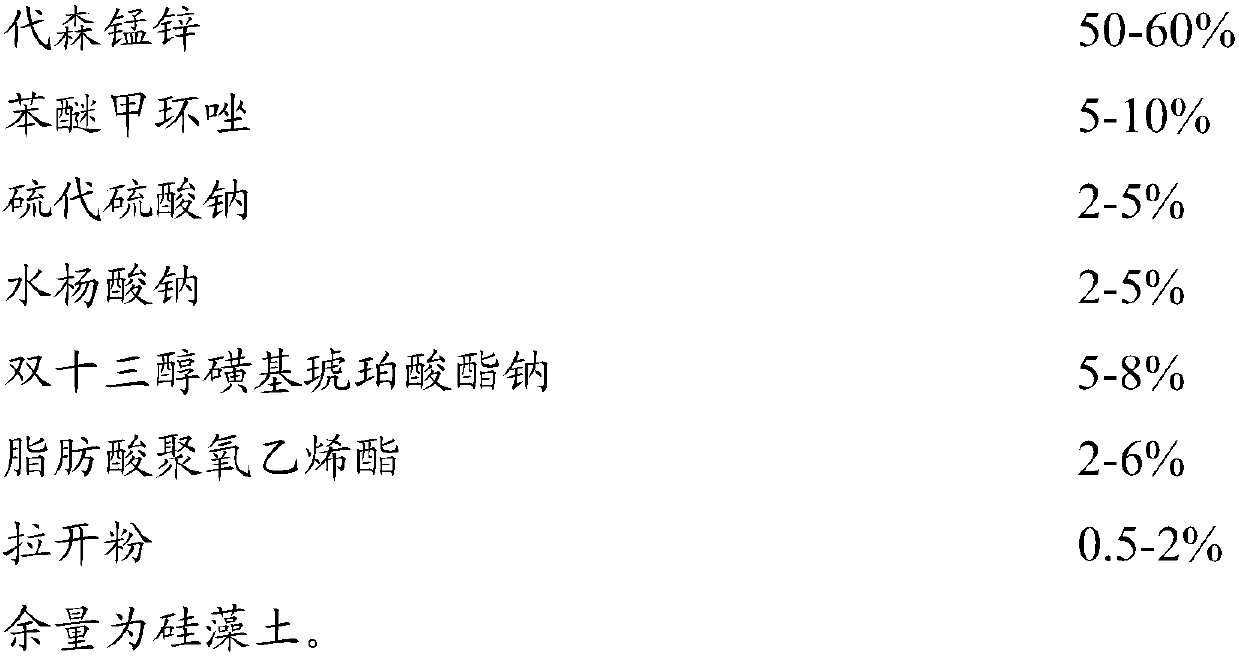

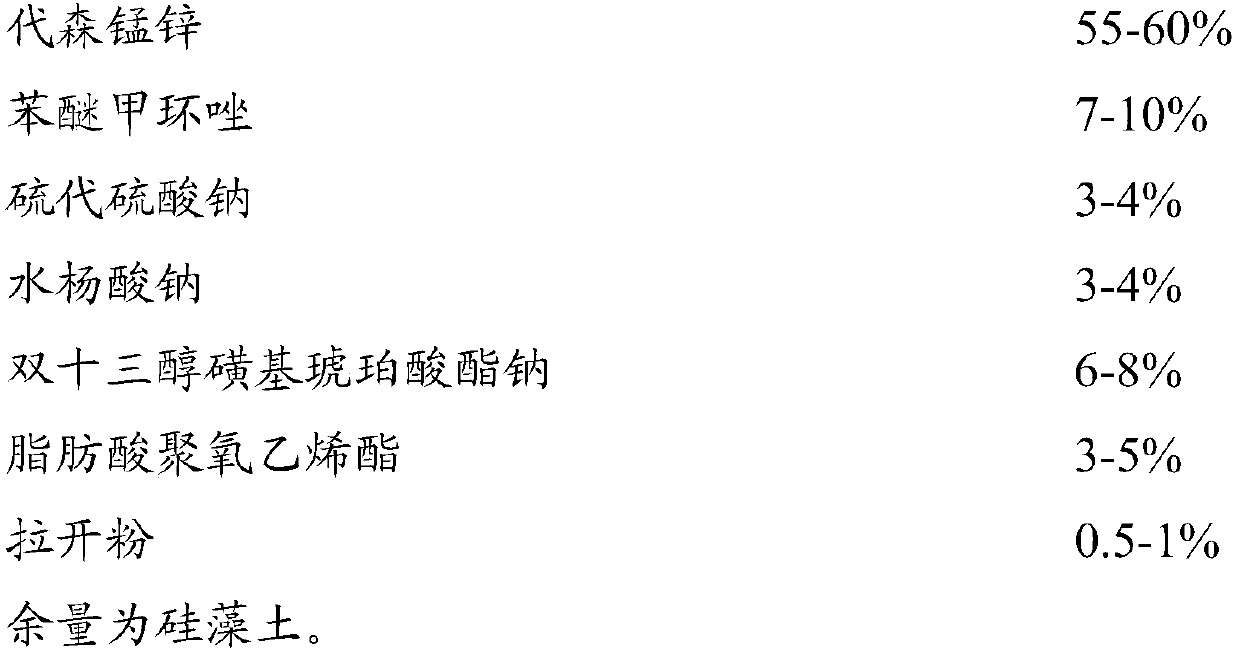

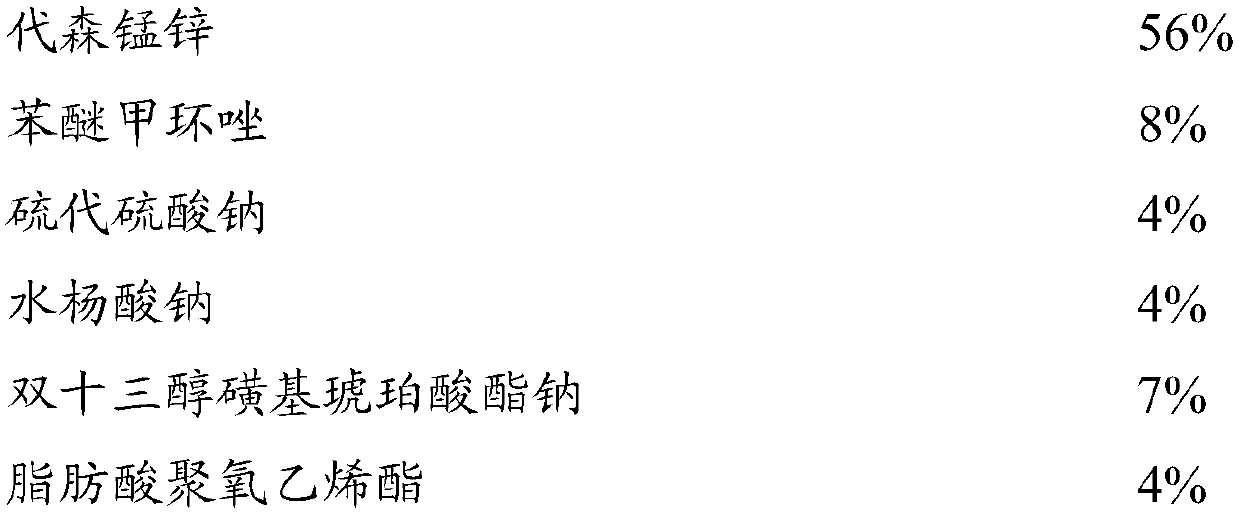

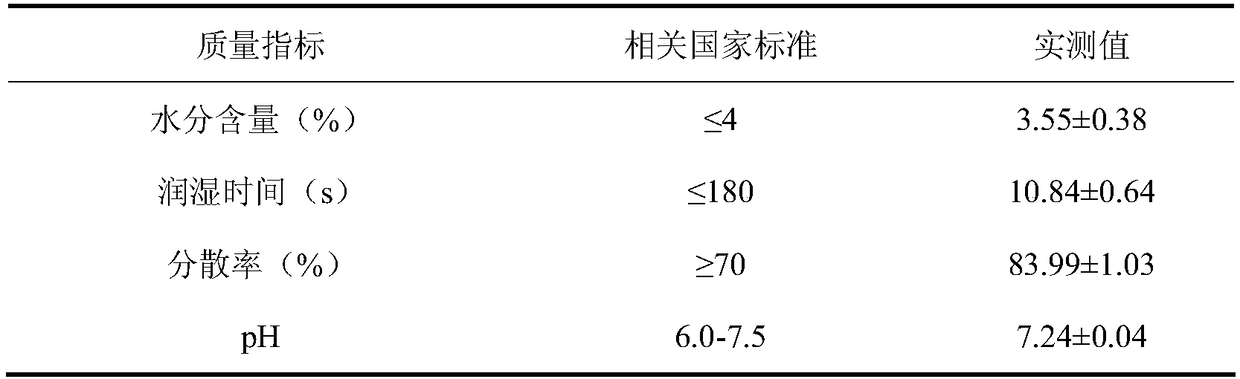

Mancozeb and difenoconazole compounded wettable powder and preparation method thereof

ActiveCN107593740AReduces caking tendencyGood hygroscopicityBiocideFungicidesCarboxylic saltSodium salicylate

The invention discloses mancozeb and difenoconazole compounded wettable powder and a preparation method thereof, which belongs to the field of pesticide preparations. The mancozeb and difenoconazole compounded wettable powder is prepared from the following raw materials by weight percent: 50 to 60 percent of mancozeb, 5 to 10 percent of difenoconazole, 2 to 5 percent of sodium thiosulfate, 2 to 5percent of sodium salicylate, 5 to 8 percent of disodium tridecanol sulfosuccinate, 2 to 6 percent of polyoxyethylene carboxylate, 0.5 to 2 percent of nekal, and the balance of diatomite. The wettablepowder has the advantages of high suspension rate, short wetting time, no agglomeration, good pesticide effect and the like.

Owner:LIER CROPSCIENCE CO LTD

Rare earth tin-base alloy for copper alloy hot dip and preparation method of rare earth tin-base alloy

The invention relates to a rare earth tin-base alloy for copper alloy hot dip. The rare earth tin-base alloy comprises, by mass, 0.1-2.5% of Ni, 0.1-0.5% of Ag, 0.05-0.35% of RE, the balance Sn and unavoidable impurity elements. The rare earth tin-base alloy for copper alloy hot dip has the advantages that alloy ingredients are relative simple, the cost is low, the thickness of a hot dip layer IMC is low, the trend of thickness enlarging is small, cavities and whisker are not easy to generate, and the rare earth tin-base alloy can be used for processing copper and copper alloy strips, especially CuNiSi series of alloy strips. Copper strip products obtained after the alloy is subjected to hot dip are mainly used for manufacturing various types of electronic connectors, electronic connector assemblies and the like in the fields such as integrated circuits, electronic products, intelligent devices and automobile industries.

Owner:HENAN UNIV OF SCI & TECH

Wettable bacterial powder capable of efficiently degrading cypermethrin and 3-phenoxybenzoic acid and its preparation method

ActiveCN105903148BResidual amount of 3-phenoxybenzoic acid decreasedGood dispersionContaminated soil reclamationBacillus licheniformisBiotechnology

The invention discloses wettability fungus powder capable of effectively degrading cypermethrin and 3-phenoxy benzoic acid and a preparation method. The wettability fungus powder comprises the raw materials of composite fungus liquid, diatomaceous earth, sodium lignin sulfonate, tween 80, skim milk powder and trehalose; and the composite fungus liquid consists of bacillus licheniformis B-1 fungus liquid and sphingomonas SC-1 fungus liquid. The method comprises the following steps: (1) the diatomaceous earth is added in the composite fungus liquid to obtain a carrier-fungus liquid mixture; the tween 80, the sodium lignin sulfonate, the skim milk powder and the trehalose are added in sterile water having the same volume with the composite fungus liquid to obtain auxiliary solution; and the auxiliary solution and the carrier-fungus liquid mixture are uniformly mixed to obtain fungicide mixed liquid; and (2) the fungicide mixed liquid obtained in the step (1) is dried by the following process parameters in sequence: a temperature from -46 to -48 DEG C is kept by 1.0-3.0 h; a temperature from -36 to -40 DEG C is kept by 1.0-3.0 h; a temperature from -26 to -30 DEG C is kept by 1.0-3.0 h; a temperature from -15 to -20 DEG C is kept by 1.0-3.0 h; a temperature from 0 to 4 DEG C is kept by 10-14 h; a temperature from 8 to 12 DEG C is kept by 1.0-3.0 h; a temperature from 30 to 40 DEG C is kept by 2.0-6.0 h; a temperature from 15 to 25 DEG C is kept by 20-24 h; and the wettability fungus powder is obtained.

Owner:黑龙江棒星食品科技股份有限公司

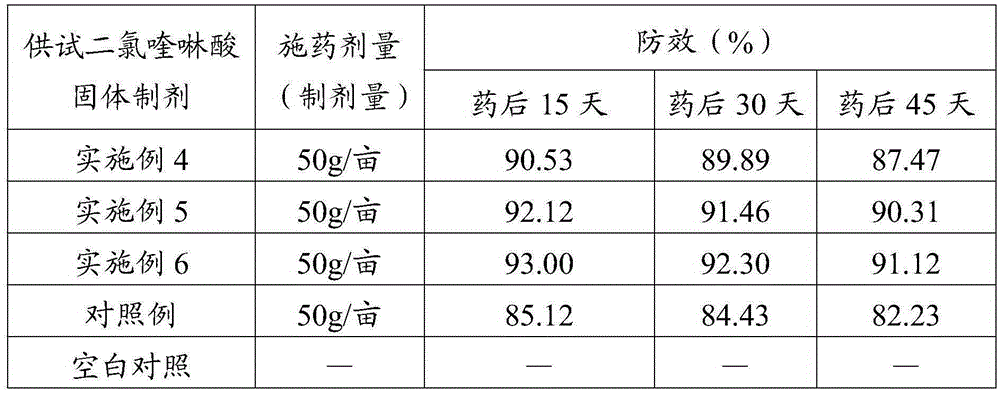

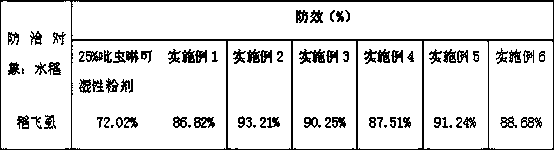

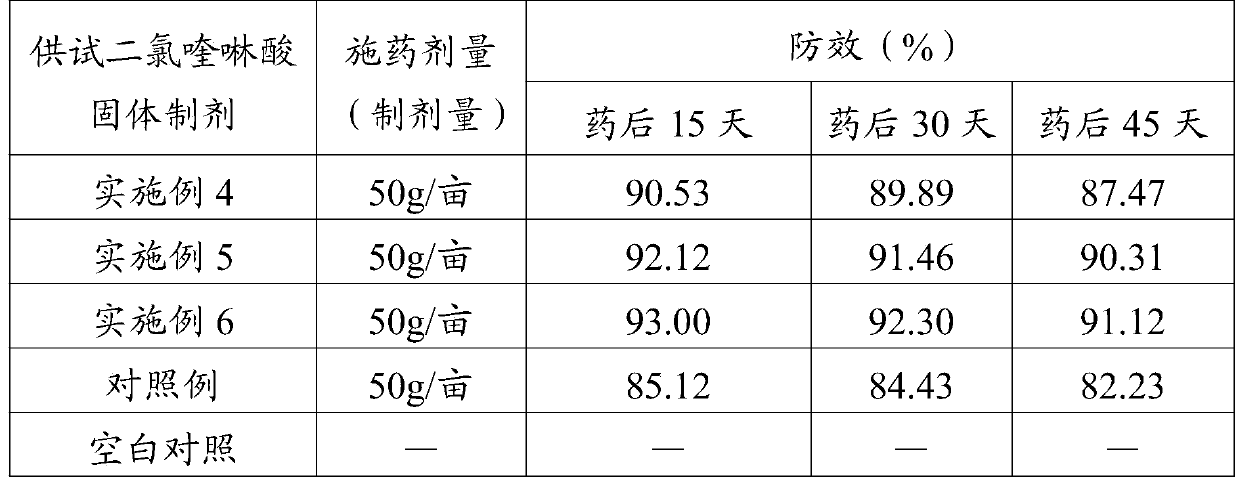

Quinclorac solid preparation and preparation method thereof

ActiveCN105284814AImprove solubilityHigh suspension rateBiocideAnimal repellantsPhytotoxicityInjury control

The invention provides a quinclorac solid preparation. The quinclorac solid preparation comprises 30-70wt% of quinclorac, 2-10wt% of a synergist, 1-3wt% of a thickener, 2-8wt% of a wetting agent, 2-10wt% of a dispersant, and the balance of a filler. The quinclorac solid preparation is obtained through the steps of mixing all above components and crushing. The quinclorac solid preparation prepared in the invention has the advantages of short wetting time, high suspension rate, easy spray, uniform dispersion, difficult generation of local phytotoxicity in practical use; and the quinclorac solid preparation also has the advantages of small dosage, no phytotoxicity to crops, and environmental protection on the basis of meeting of crop weed injury control requirements.

Owner:DALIAN RENBANG CHEM

50% clothianidin wettable powder

InactiveCN107889827AReduce adhesion rateImprove flushing effectBiocideAnimal repellantsSolubilityClothianidin

The invention discloses 50% clothianidin wettable powder. The water dispersible granule is prepared from, by mass, 47.5%-52.5% of clothianidin original medicine, 0-10% of a wetting agent, 0-25% of a dispensing agent, 10%-30% of disintegrant and the balance fillers, and the sum of all components is 100%. The water dispersible granule is high in solubility and high in utilization rate.

Owner:JIANGSU TENGLONG BIOLOGICAL PHARMA

A kind of quinclorac solid preparation and preparation method thereof

ActiveCN105284814BImprove solubilityHigh suspension rateBiocideAnimal repellantsBiochemical engineeringPhytotoxicity

Owner:DALIAN RENBANG CHEM

Wettable powder containing 15% thifensulfuron methyl and preparation method of wettable powder

InactiveCN107950554AReduce adhesion rateImprove permeabilityBiocideAnimal repellantsWettable powderAcrylate

The invention discloses wettable powder containing 15% thifensulfuron methyl. The wettable powder comprises 5-9% of thifensulfuron methyl, 11-14% of acetochlor, 1-8% of auxiliaries, 2-8% of emulsifiers, 1-3% of dispersing agents, 9-13% of adsorbents, 2-9% of alcohol soluble acrylate resin, 2-4% of silicon carbide micro-powder, 0.4-0.7% of graphite fluoride, 0.8-1.2% of composite rare earth and thebalance fillers. The use ratio and the drug property of the powder are increased, production is enlarged, production cost is reduced, process steps are simple, and environmental pollution is avoided.

Owner:JIANGSU TENGLONG BIOLOGICAL PHARMA

A kind of pesticide water dispersible granule and preparation method thereof

ActiveCN110432265BImprove biological activityHigh suspension rateBiocideFungicidesWater dispersibleSpray dried

The invention belongs to the technical field of pesticide preparations, and provides a pesticide water-dispersible granule and a preparation method thereof. A pesticide water-dispersible granule, which is composed of the following components in parts by weight: 15-70 parts of pesticide active ingredients, 5-10 parts of dispersant, 2-5 parts of wetting agent, 5.5-9 parts of disintegrating agent, binder 1-4 parts of agent, 2-10 parts of filler, dispersant is a mixture of poloxamer, chitosan and citric acid with a mass ratio of 4:1:1.5. In the preparation method, the active ingredients of the pesticide, the dispersant, and the disintegrating agent are mixed evenly and then pulverized, then mixed with the wetting agent and binder dissolved in water to obtain a suspension, the suspension is spray-dried, mixed with the filler, squeezed Pressing granulation, drying and other steps. Through the above technical scheme, the problems of single formulation and small application range of the water-dispersible granules in the prior art are solved.

Owner:河北双吉化工有限公司

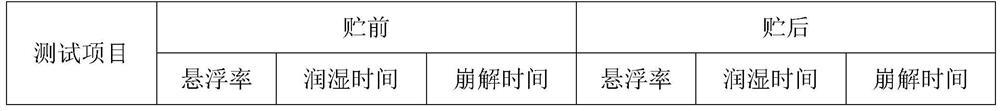

A kind of lithium ion battery negative electrode slurry and its preparation method and lithium ion battery

ActiveCN112366314BImprove dispersion uniformityIncrease wetting rateNegative electrodesSecondary cellsHigh energyBattery cell

The invention provides a lithium ion battery negative electrode slurry and a preparation method thereof and a lithium ion battery. The preparation method comprises the following steps: (1) mixing the negative electrode active powder and the conductive agent powder, and obtaining the first powder after degassing treatment (2) mixing the first powder and the humidity-promoting gas to obtain the second powder; (3) mixing the second powder and the solvent to obtain an intermediate slurry after degassing; (4) mixing the intermediate slurry, dispersing agent and binder to obtain lithium ion battery negative electrode slurry. The preparation method provided by the invention improves the wettability of the powder in the negative electrode slurry preparation process, reduces the wetting time, improves the production capacity, and saves time and cost; the lithium ion battery has high energy density and excellent electrochemical performance .

Owner:EVE ENERGY CO LTD

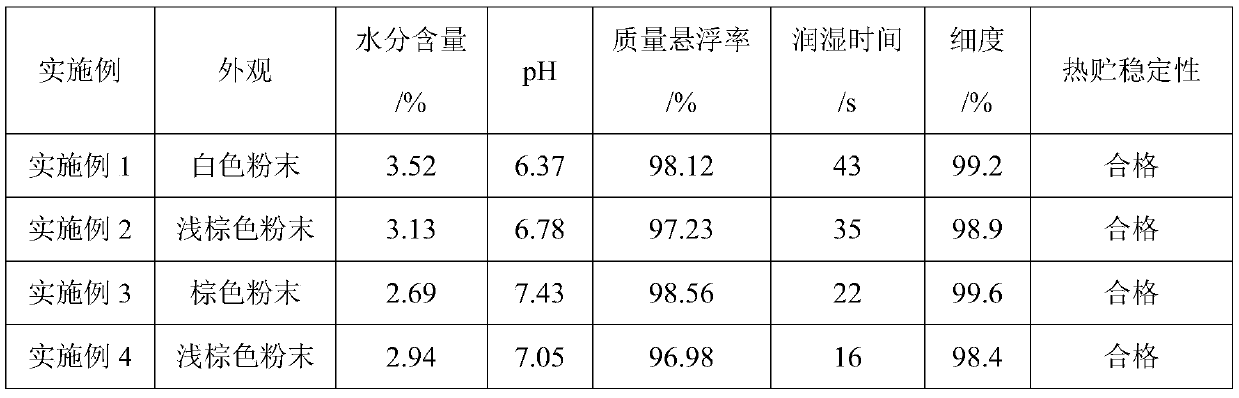

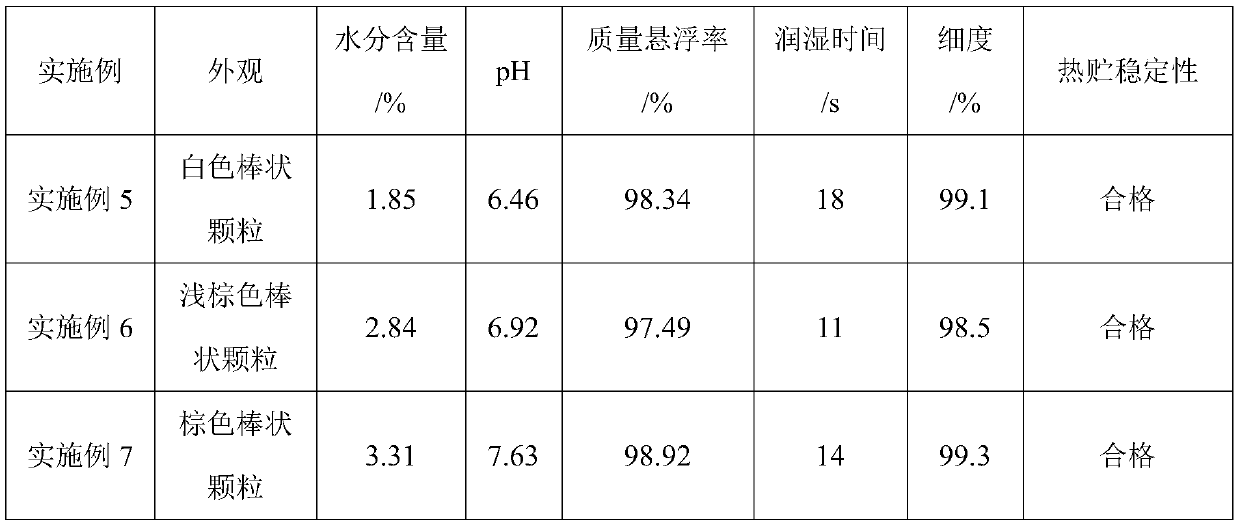

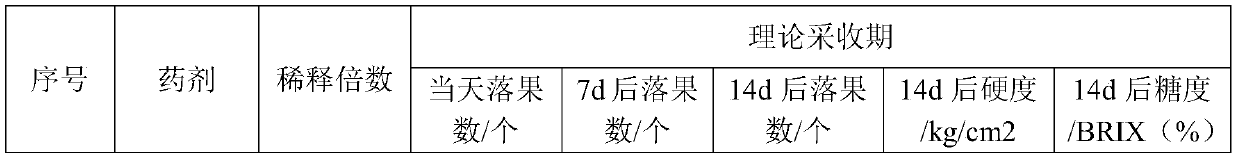

Dispersible solid preparation for preventing fruit drop and its preparation method and use

ActiveCN108770845BWon't clogShort wetting timeBiocidePlant growth regulatorsBiotechnologyHarvest time

The invention discloses a dispersible solid preparation for preventing fruits from falling, and a preparation method and application thereof. The dispersible solid preparation is prepared from the following mass percentages of components: 1%-95% of 1-methylcyclopropene microcapsules, 1%-10% of dispersant, 1%-10% of wetting agent, 0.1%-10% of stabilizer, and the balance of solid carrier, wherein the content of 1-methylcyclopropene in the dispersible solid preparation is 0.01%-4.75%. The dispersible solid preparation obtained by the invention has low moisture content, almost neutral pH value, excellent suspension property, wettability and heat storage stability, and the fineness up to 99.6%, so the preparation will not block nozzles. The sedimentation speed of the preparation is low, so thepreparation can continue to play drug roles for a certain period after application, satisfy the requirement of uniform distribution of medicinal liquid in an open orchard environment system and guarantee the action time, and has a very good effect of preventing fruit falling during harvest, and can prolong harvest time.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com