50% clothianidin wettable powder

A wettable powder, clothianidin technology, applied in insecticides, biocides, animal repellents, etc., can solve the problem of low utilization rate of active ingredients, improve the effect of rain erosion resistance, low environmental impact, Excellent disintegrability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

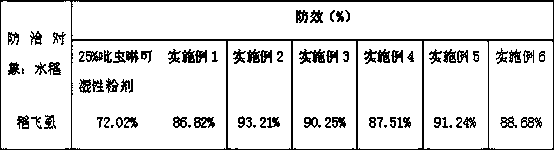

Examples

Embodiment 1

[0042] The present embodiment provides a kind of 50% clothianidin wettable powder, and this water dispersible granule comprises the following components by mass percentage:

[0043] Clothianidin technical: 47.5%, dispersant: 25%, disintegrant: 10%, the rest is filler, the sum of the above components is 100%.

[0044] The dispersant is a mixture of sodium lignosulfonate and sodium dimethyl naphthalene sulfonate, wherein sodium lignosulfonate: sodium dimethyl naphthalene sulfonate = 2:3 by mass ratio; disintegrant is ammonium sulfate; filler For kaolin.

[0045] The preparation technology of above-mentioned water dispersible granule specifically comprises the following steps:

[0046] (1) Coarsely pulverize clothianidin technical material, wetting agent, dispersant, disintegrating agent and filler, and use jet mill to pulverize;

[0047] (2) Stirring and mixing the coarsely pulverized components in step (1), and performing ultrafine airflow pulverization to obtain an ultrafine...

Embodiment 2

[0051] The present embodiment provides a kind of 50% clothianidin wettable powder, and this water dispersible granule comprises the following components by mass percentage:

[0052] Clothianidin technical: 52.5%, wetting agent: 5%, dispersant: 10%, disintegrant: 30%, the rest is filler, the sum of the above components is 100%.

[0053] The wetting agent is alkyl naphthalene sulfonate; the dispersant is a mixture of sodium lignosulfonate and sodium dimethyl naphthalene sulfonate, wherein sodium lignosulfonate: sodium dimethyl naphthalene sulfonate = 2 by mass ratio : 3; disintegrant is ammonium sulfate; filler is kaolin.

[0054] The preparation technology of above-mentioned water dispersible granule specifically comprises the following steps:

[0055] (1) Coarsely pulverize clothianidin technical material, wetting agent, dispersant, disintegrating agent and filler, and use jet mill to pulverize;

[0056] (2) Stirring and mixing the coarsely pulverized components in step (1),...

Embodiment 3

[0060] The present embodiment provides a kind of 50% clothianidin wettable powder, and this water dispersible granule comprises the following components by mass percentage:

[0061] Clothianidin technical: 50%, wetting agent: 10%, dispersant: 5%, disintegrant: 20%, the rest is filler, the sum of the above components is 100%.

[0062] The wetting agent is alkyl naphthalene sulfonate; the dispersant is a mixture of sodium lignosulfonate and sodium dimethyl naphthalene sulfonate, wherein sodium lignosulfonate: sodium dimethyl naphthalene sulfonate = 2 by mass ratio : 3; disintegrant is ammonium sulfate; filler is kaolin.

[0063] The preparation technology of above-mentioned water dispersible granule specifically comprises the following steps:

[0064] (1) Coarsely pulverize clothianidin technical material, wetting agent, dispersant, disintegrating agent and filler, and use jet mill to pulverize;

[0065] (2) Stirring and mixing the coarsely pulverized components in step (1), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com