Nanometer Ag3Sn particle reinforced composite lead-free soldering paste and preparation method thereof

A technology of lead-free solder paste and particle reinforcement, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of poor mechanical properties of solder joints, reduced reliability of solder joints, poor wetting performance, etc., and reduce process costs , good matching, strong wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) dissolving stannous octoate and silver nitrate in anhydrous methanol, the concentration of stannous octoate is 0.01mol / L, and the concentration of silver nitrate is 0.03mol / L to obtain solution a, add 1,10-phenanthroline, 1 , the concentration of 10-phenanthroline is 0.05mol / L, mix well to obtain solution b, wherein the reaction temperature is 40°C, and the reaction time is 1h;

[0044] (2) Add 5ml of oleic acid dropwise to 395ml of ammonia water, mix well to obtain solution c, dissolve sodium borohydride solid in solution c, the concentration of sodium borohydride is 0.5mol / L, mix well to obtain solution d;

[0045] (3) Add solution d dropwise to solution b, oscillate and mix evenly to make it fully react. min, get solid 1;

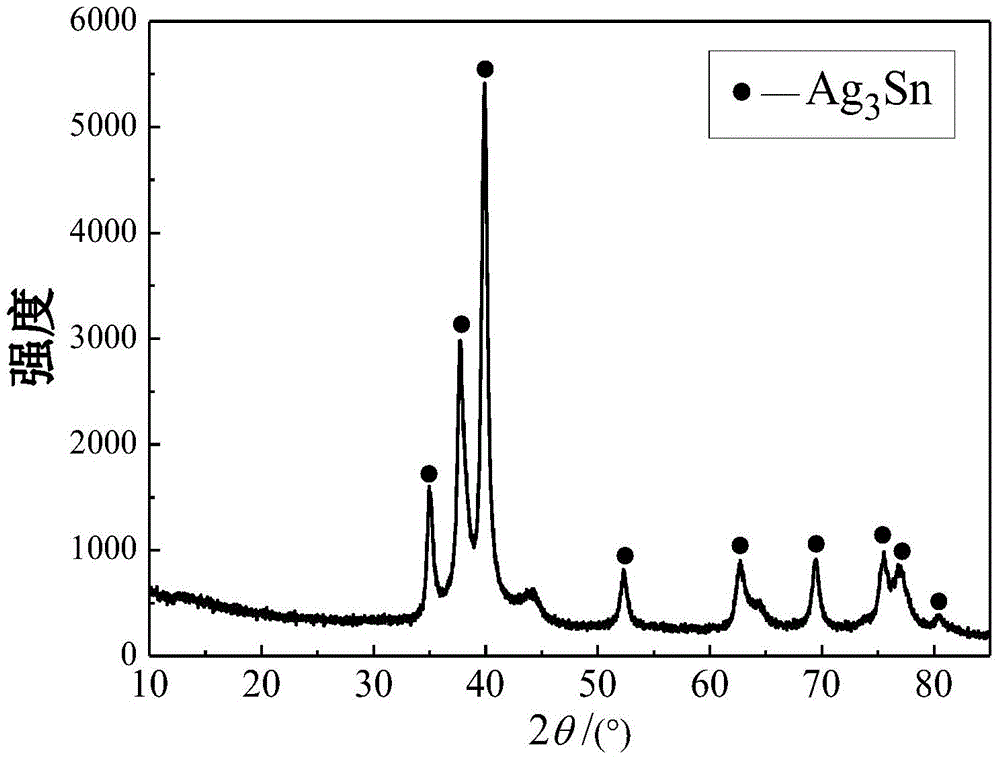

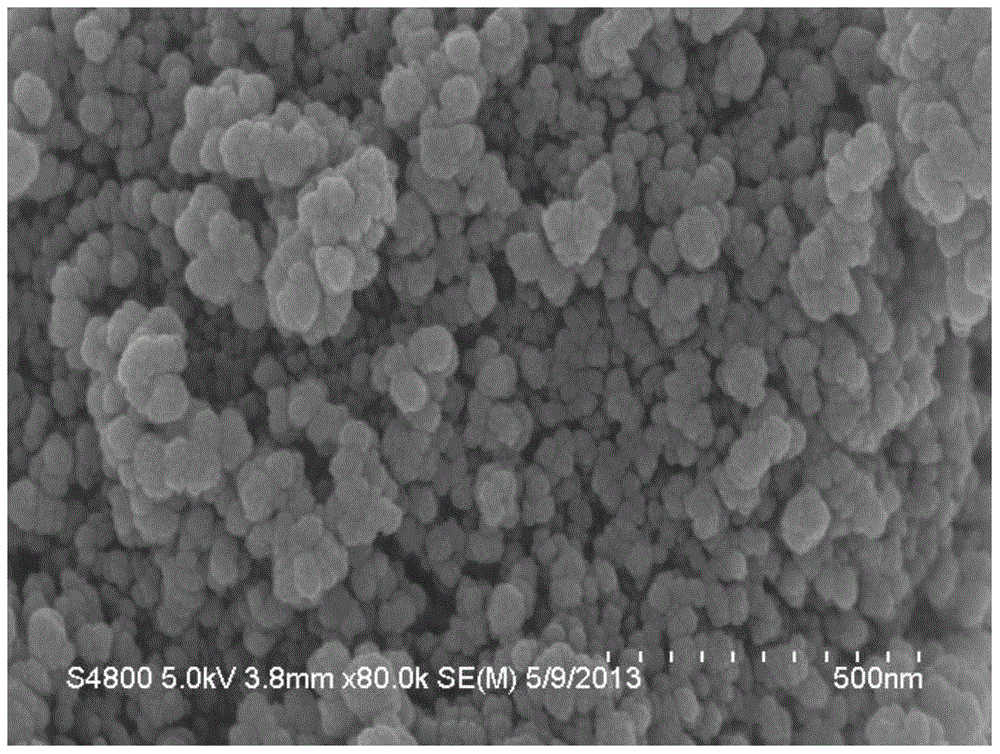

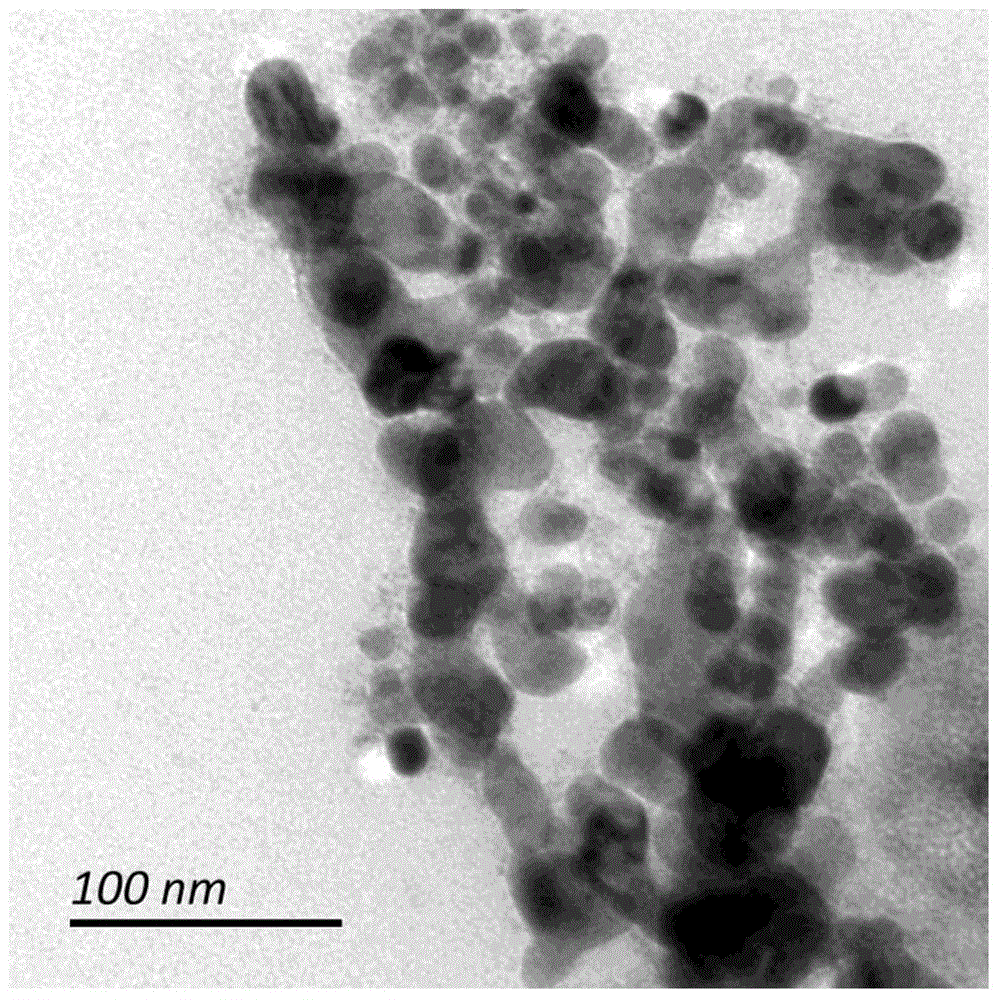

[0046] (4) Solid 1 was vacuum-dried for 8 hours to obtain a black powder, and an X-ray diffraction analyzer was used to carry out phase analysis of the black powder to obtain an X-ray diffraction spectrum, such as figure 1 ,Depend on figure...

Embodiment 2

[0053] (1) Dissolving stannous octoate and silver nitrate in anhydrous methanol, the concentration of stannous octoate is 5×10 -3 mol / L, the concentration of silver nitrate is 1.5×10 -2 mol / L, to obtain solution a, add 1,10-phenanthroline, the concentration of 1,10-phenanthroline is 1×10 -2 mol / L, mixed evenly to obtain solution b, the reaction temperature was 20°C, and the reaction time was 0.5h;

[0054] (2) Add 10ml of oleic acid dropwise into 390ml of ammonia water, mix uniformly to obtain solution c, dissolve sodium borohydride solid in solution c, the concentration of sodium borohydride is 0.1mol / L, mix uniformly to obtain solution d;

[0055] (3) Add solution d dropwise to solution b, oscillate and mix evenly to make it fully react, the reaction temperature is 20°C, the reaction time is 0.25h, then stand for 2h, centrifuge and wash 5 times, each time for 5min, the speed is 3000r / min, get solid 1;

[0056] (4) Solid 1 was vacuum-dried for 6 hours to obtain a black po...

Embodiment 3

[0063] (1) Dissolving stannous octoate and silver nitrate in anhydrous methanol, the concentration of stannous octoate is 5×10 -2 mol / L, the concentration of silver nitrate is 1.5×10 -1 mol / L, to obtain solution a, add 1,10-phenanthroline, the concentration of 1,10-phenanthroline is 1×10 -1 mol / L, mixed evenly to obtain solution b, the reaction temperature was 60°C, and the reaction time was 2h;

[0064] (2) Add 2ml of oleic acid dropwise to 398ml of ammonia water, mix well to obtain solution c, dissolve sodium borohydride solid in solution c, the concentration of sodium borohydride is 1mol / L, mix well to obtain solution d;

[0065] (3) Add solution d dropwise to solution b, oscillate and mix evenly to make it fully react, the reaction temperature is 60°C, the reaction time is 2h, then stand for 8h, centrifuge and wash 20 times, each time for 20min, the speed is 7000r / min , to obtain solid 1;

[0066] (4) Solid 1 was vacuum-dried for 20 hours to obtain a black powder, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com