Patents

Literature

38 results about "Electronics manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronics manufacturing services (EMS) is a term used for companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs). The concept is also referred to as electronics contract manufacturing (ECM).

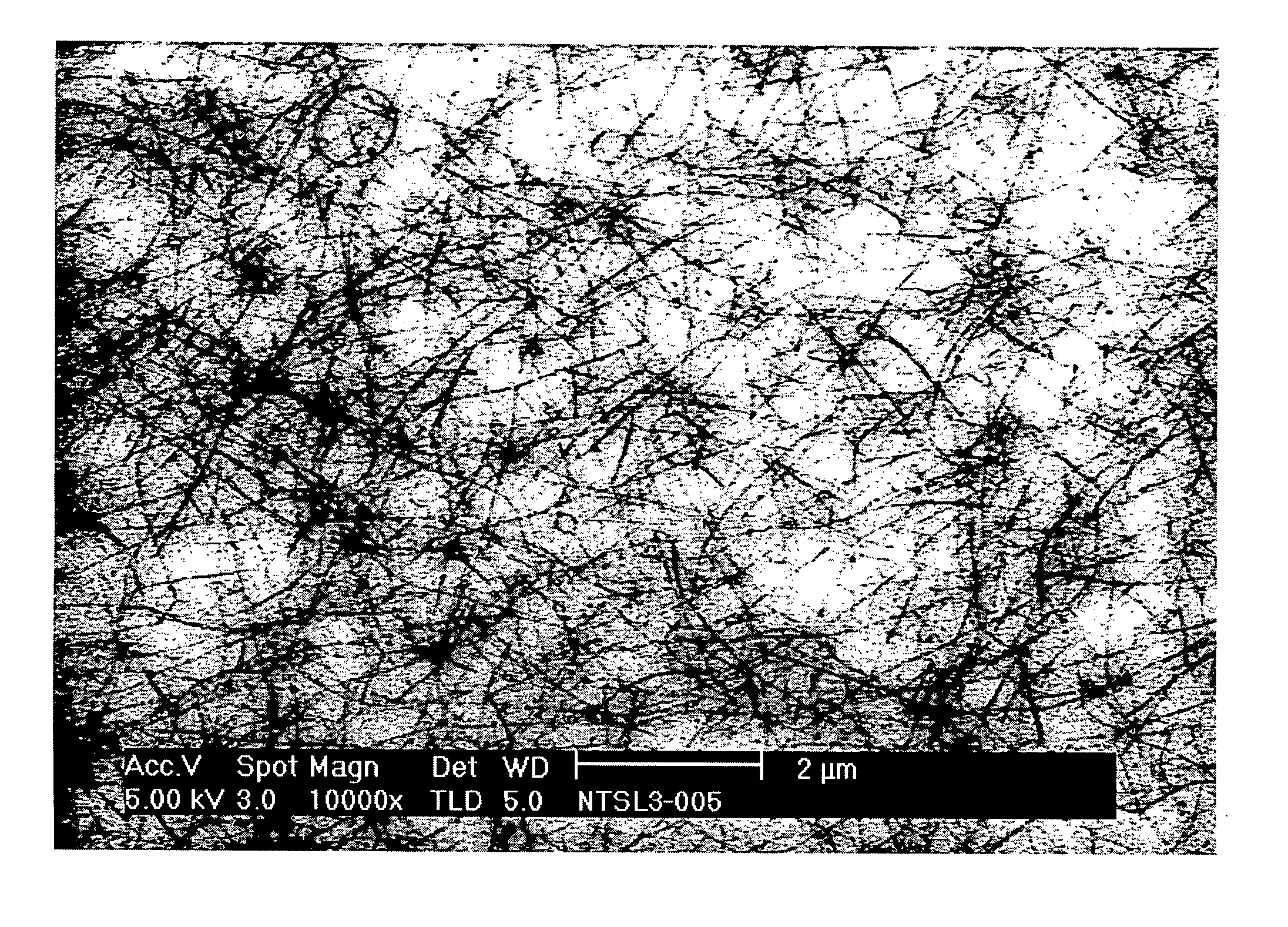

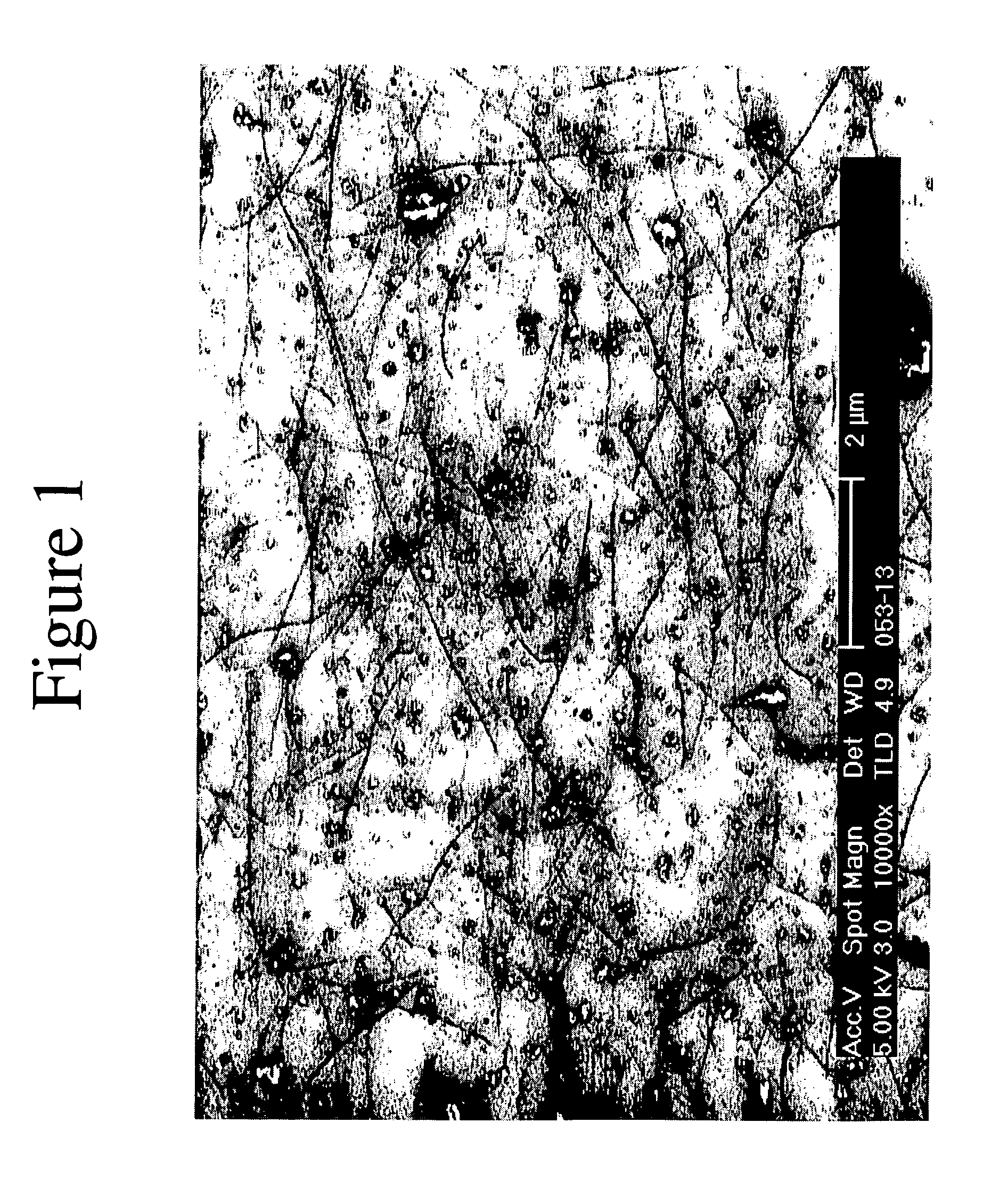

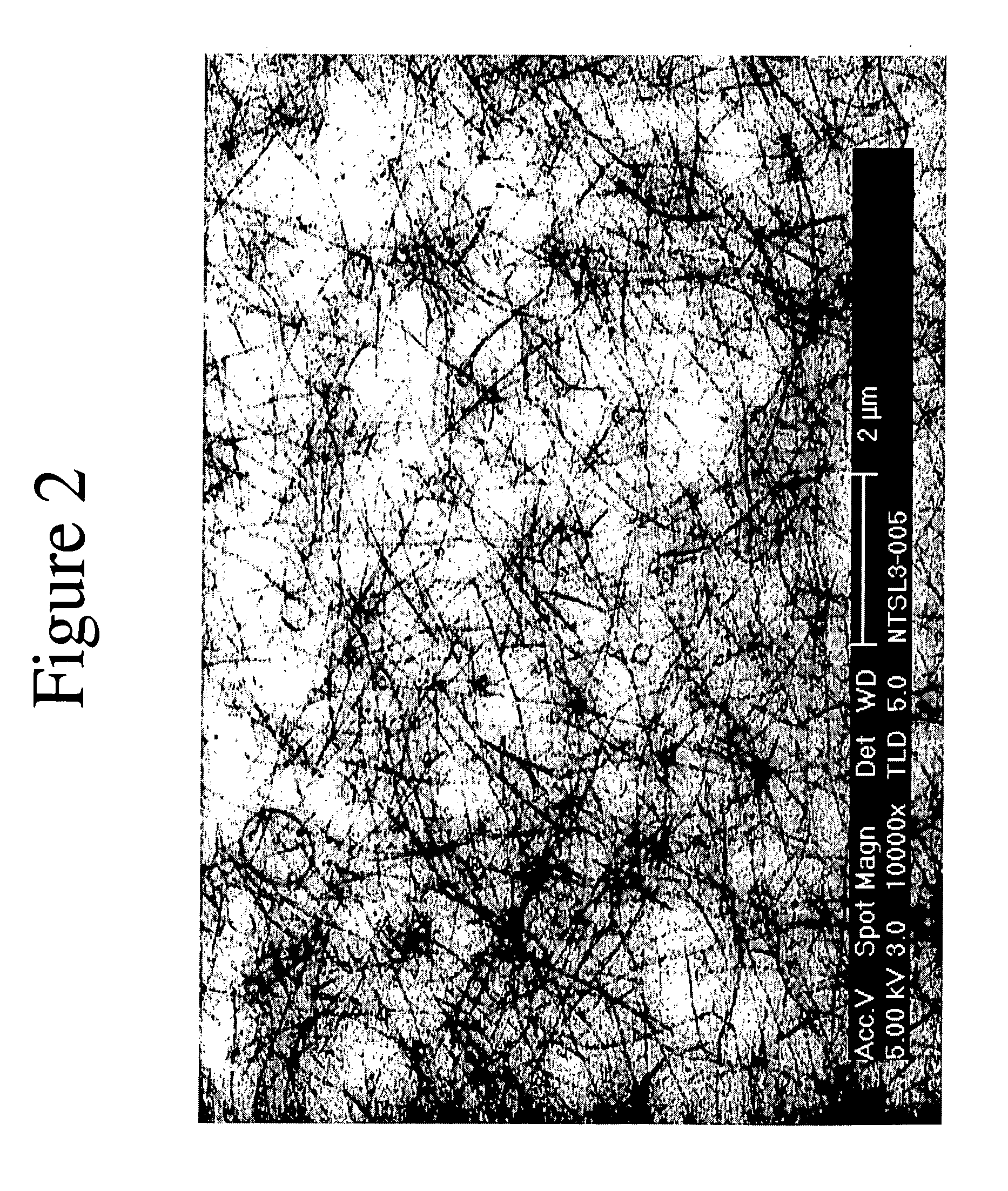

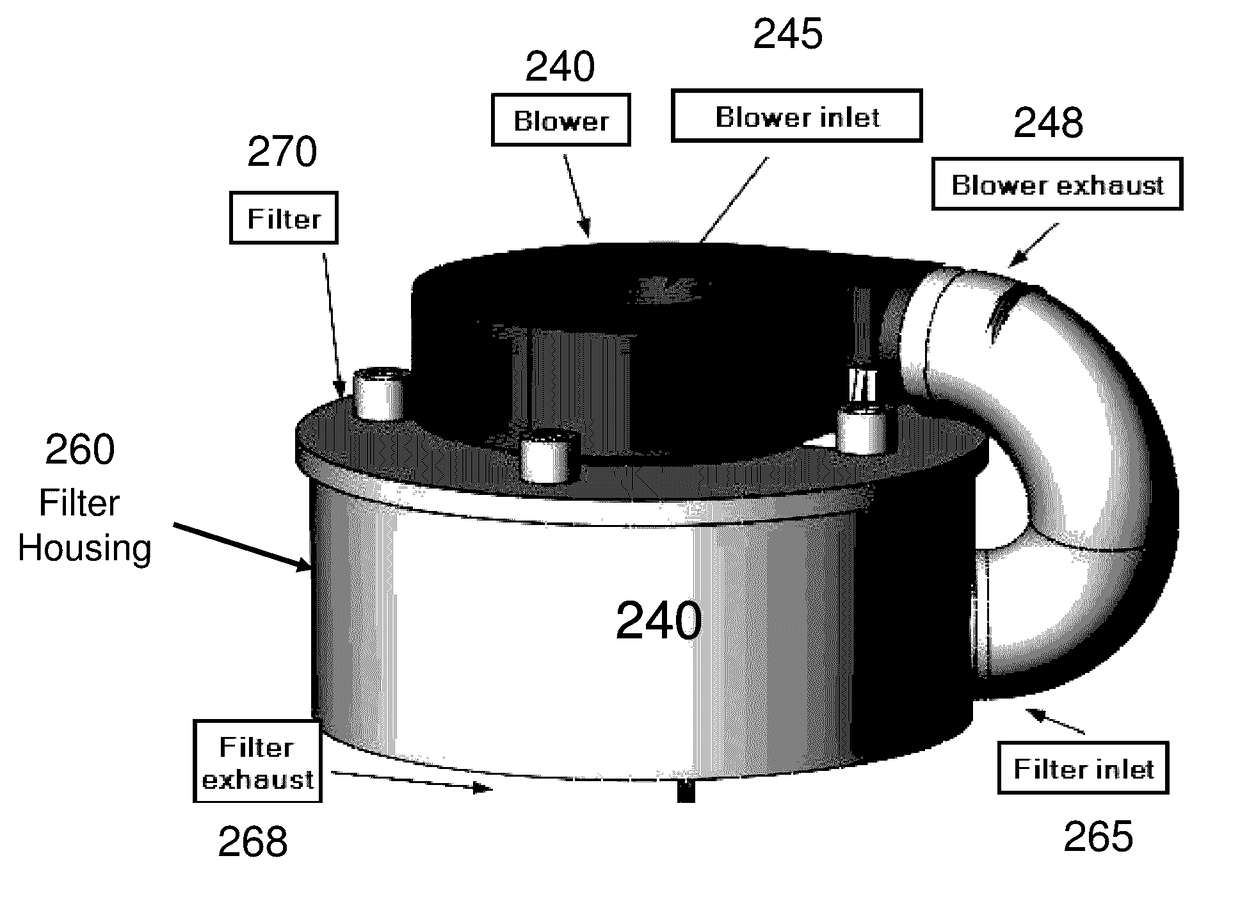

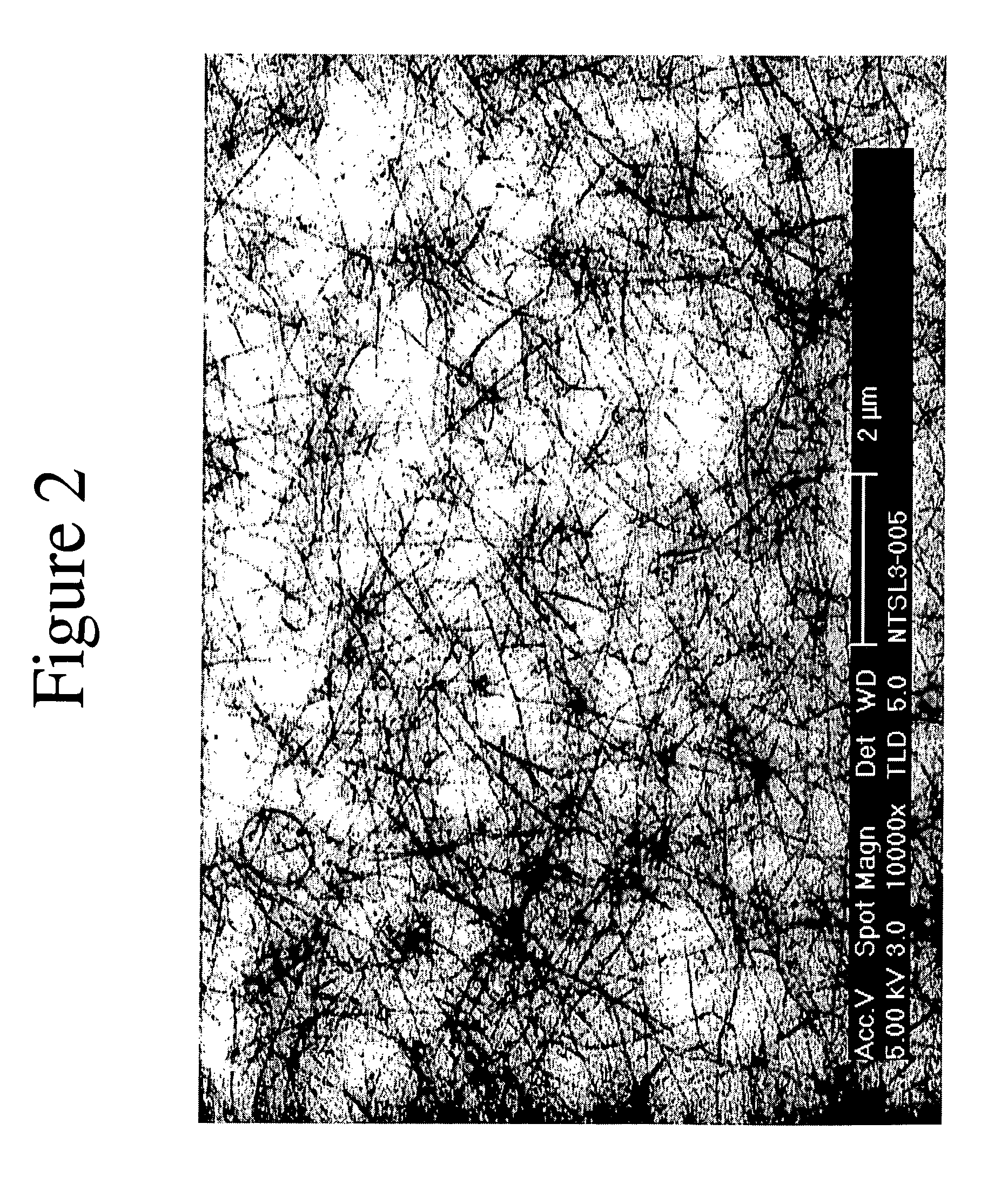

Spin-coatable liquid for use in electronic fabrication processes

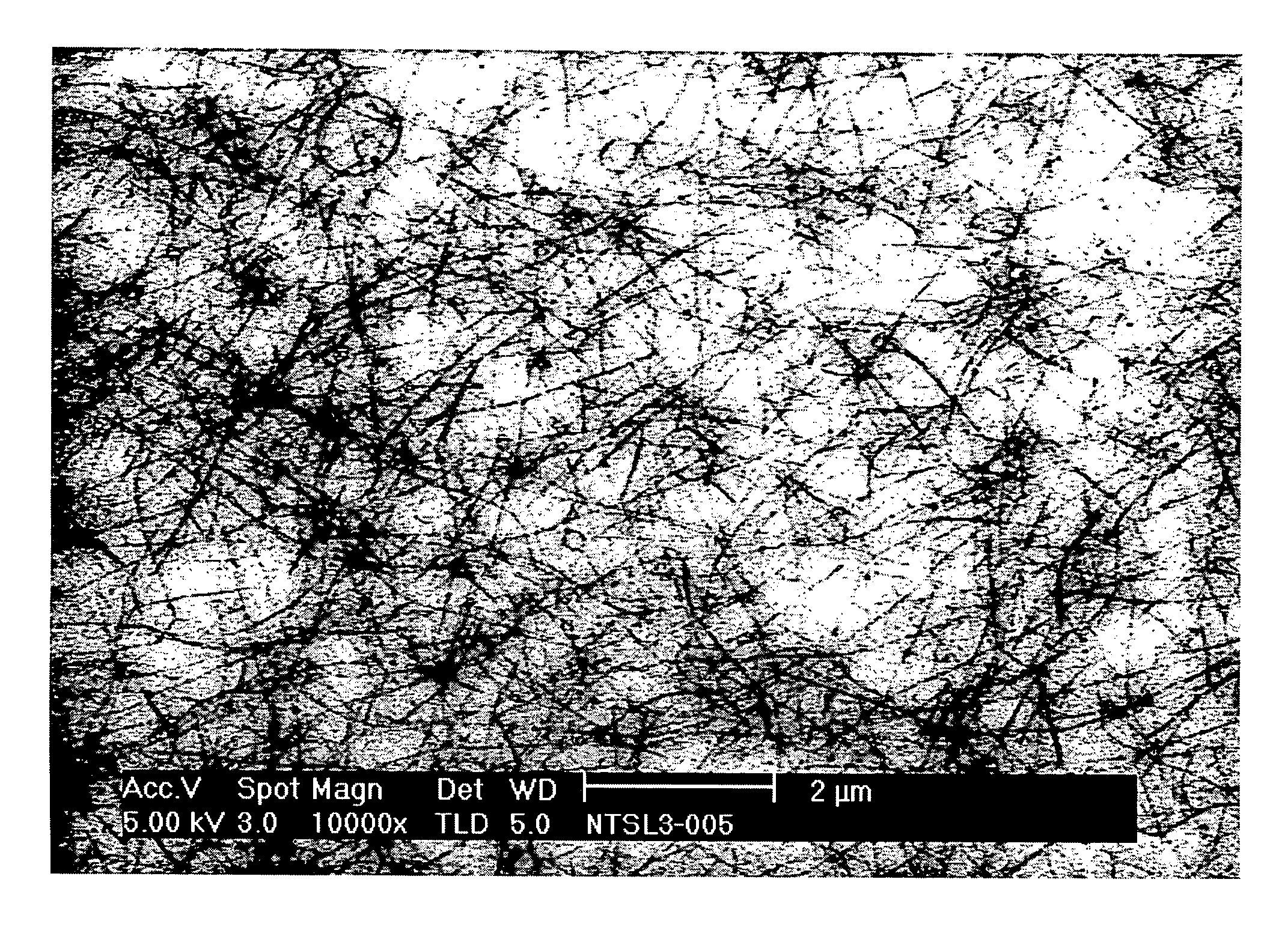

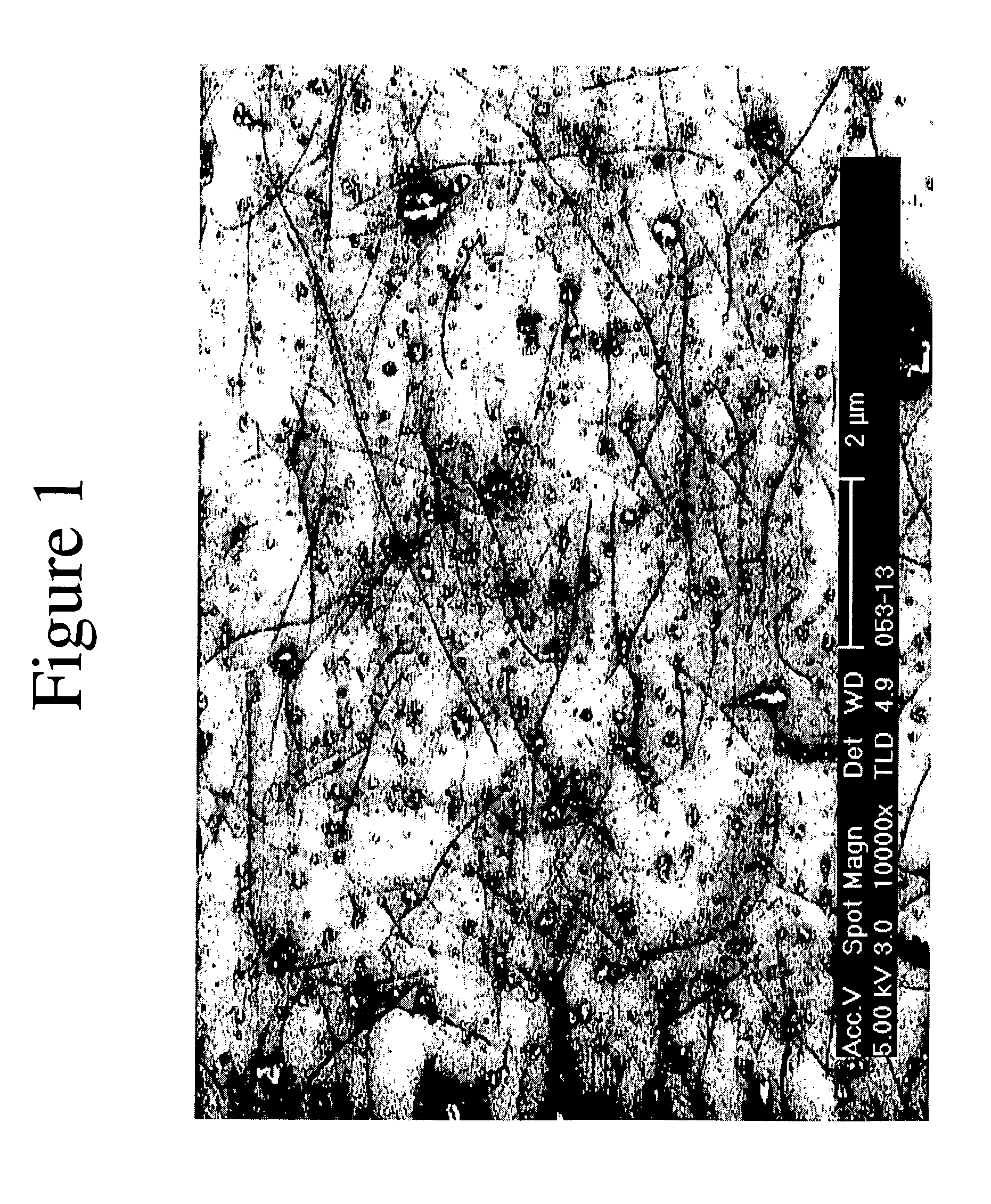

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid containing nanotubes for use in an electronics fabrication process includes a solvent containing a plurality of nanotubes. The nanotubes are at a concentration of greater than 1 mg / L. The nanotubes are pretreated to reduce the level of metallic and particulate impurities to a preselected level, and the preselected metal and particulate impurities levels are selected to be compatible with an electronics manufacturing process. The solvent also is selected for compatibility with an electronics manufacturing process.

Owner:ZEON CORP

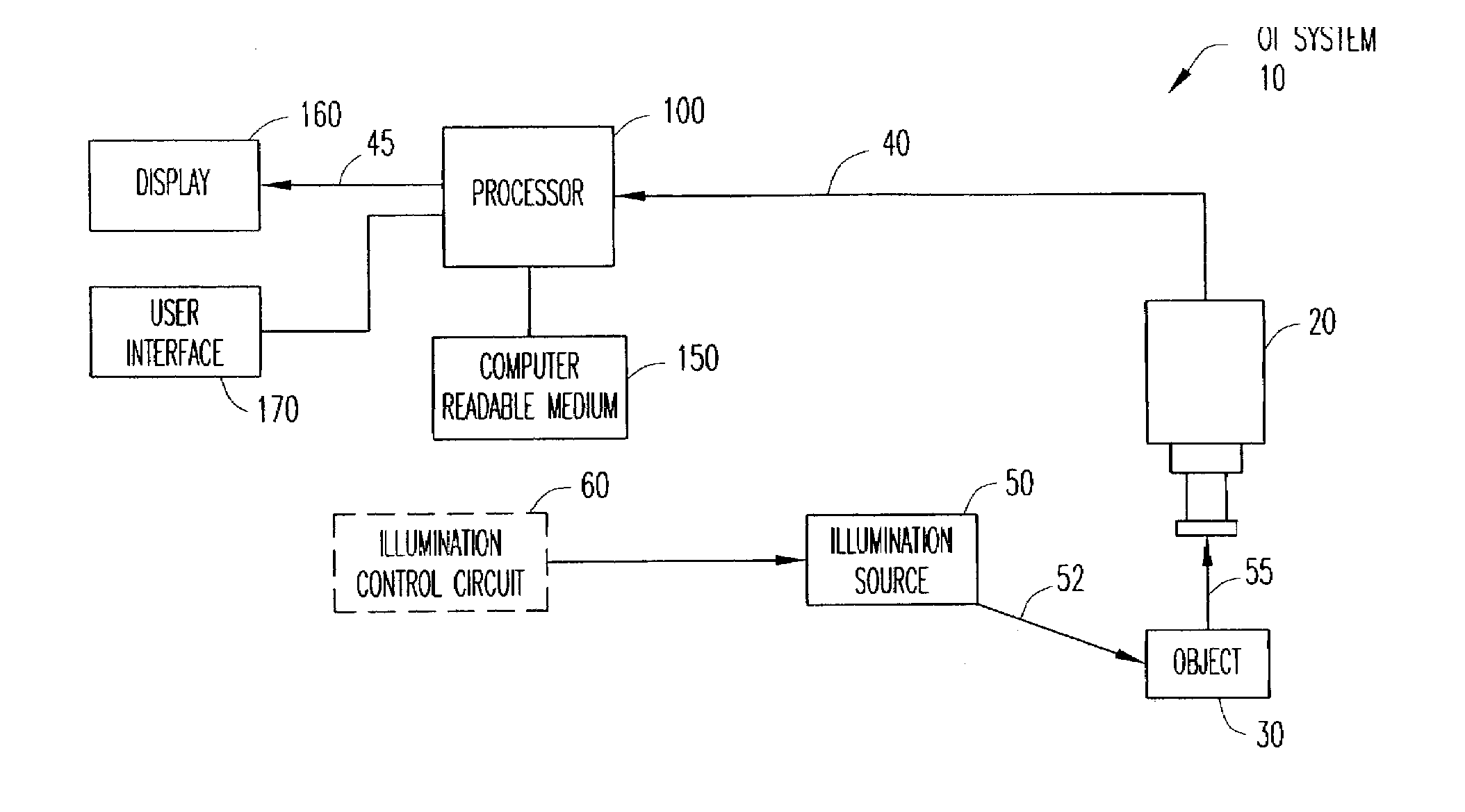

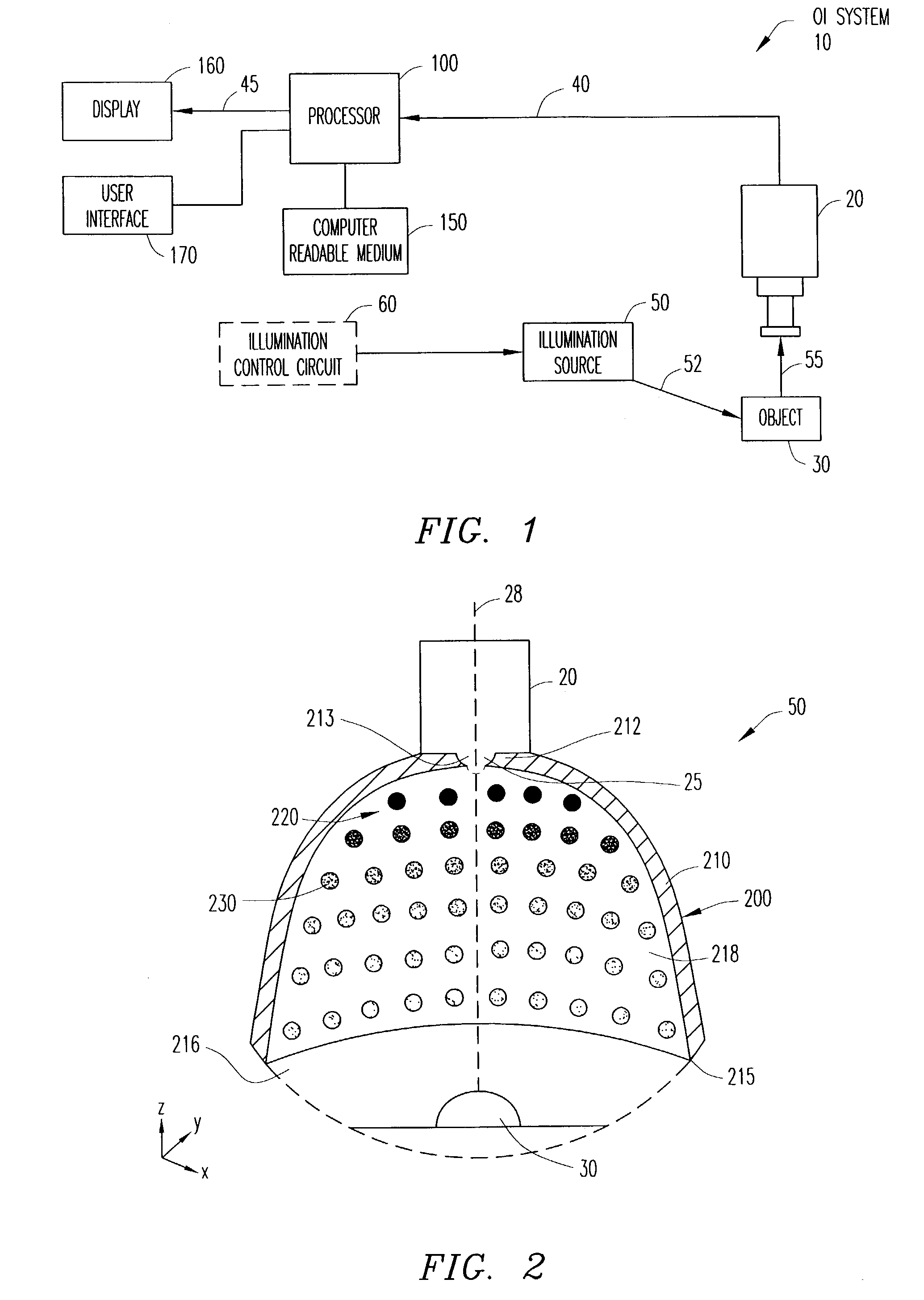

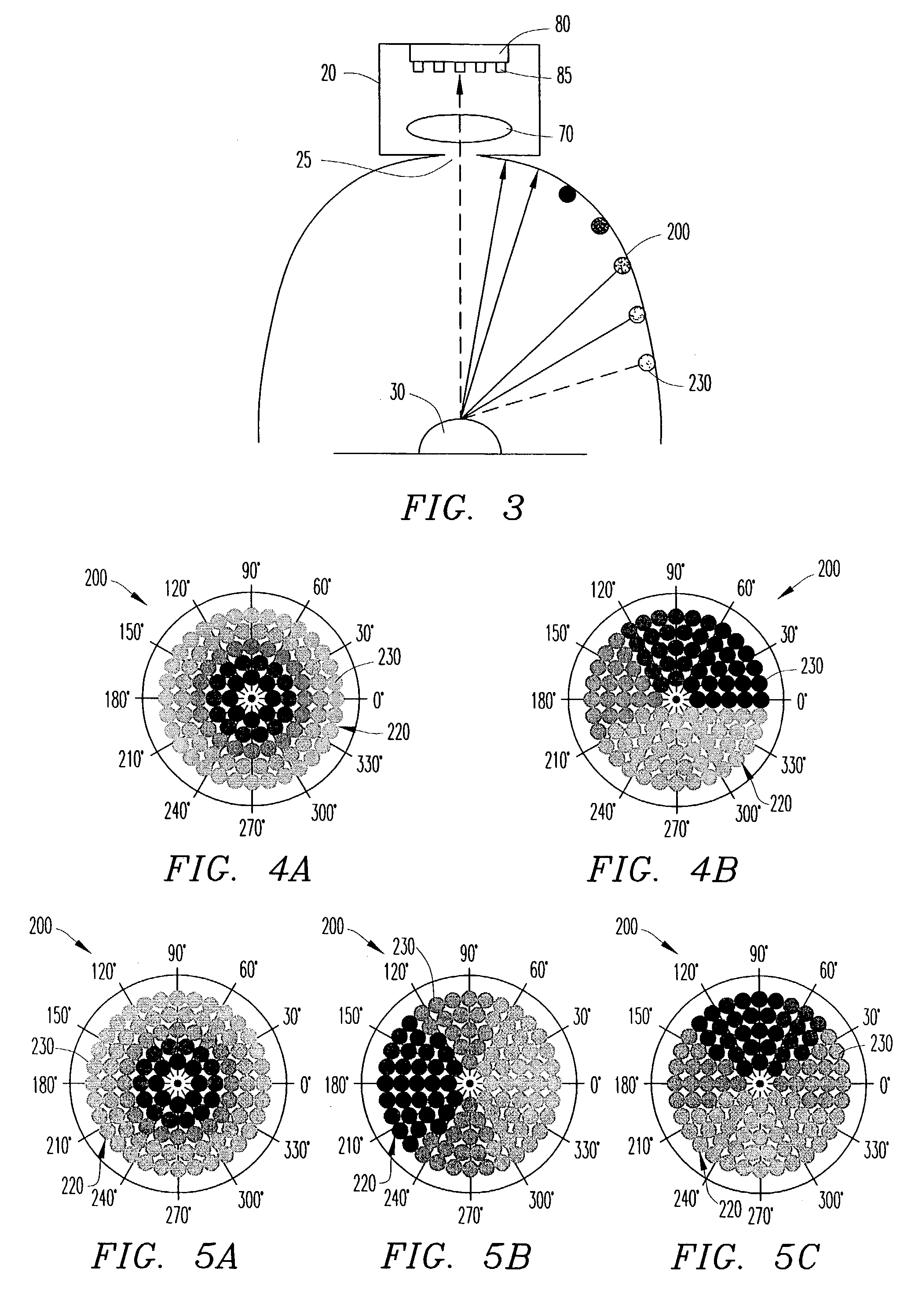

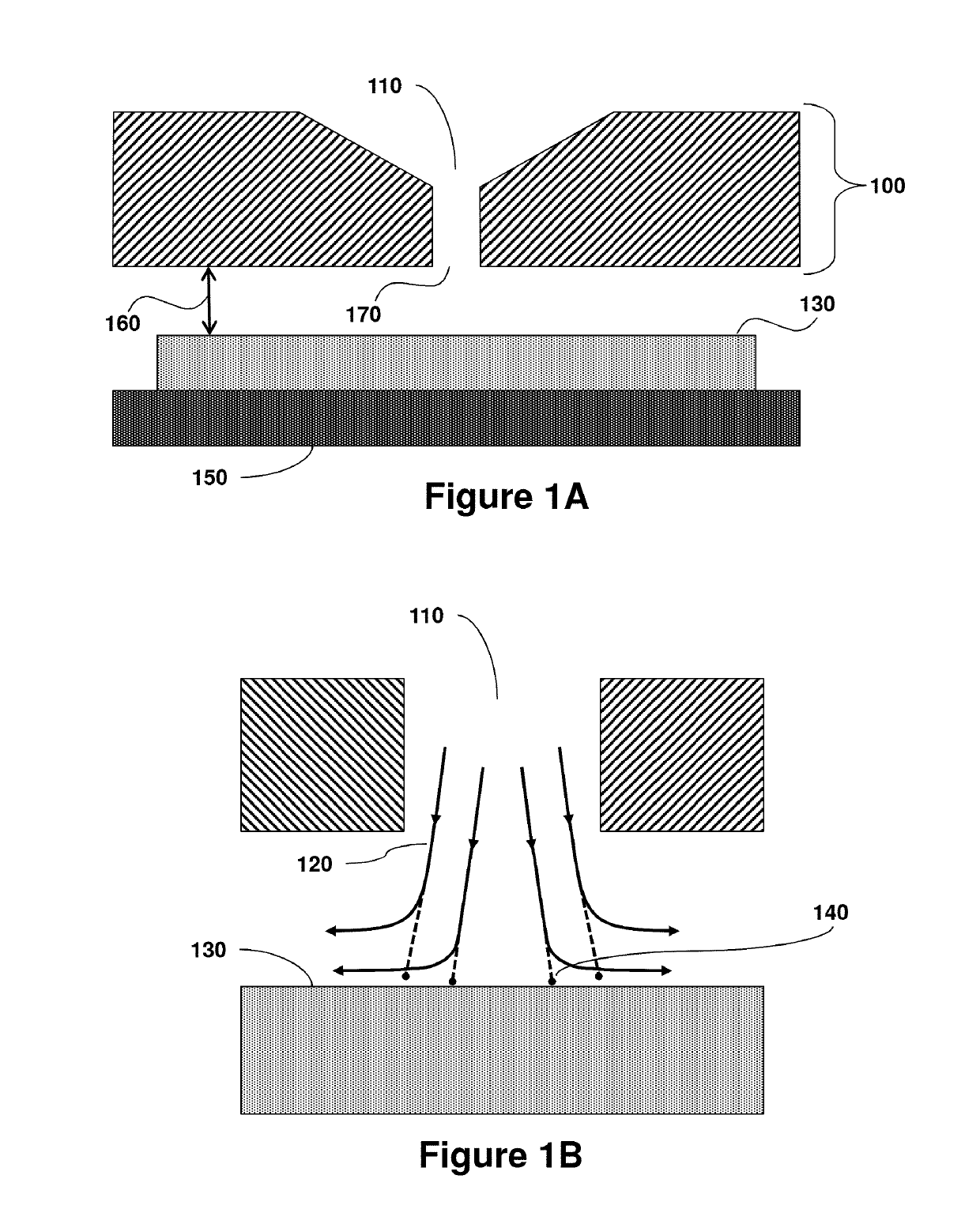

Optical inspection system, apparatus and method for reconstructing three-dimensional images for printed circuit board and electronics manufacturing inspection

Owner:AGILENT TECH INC

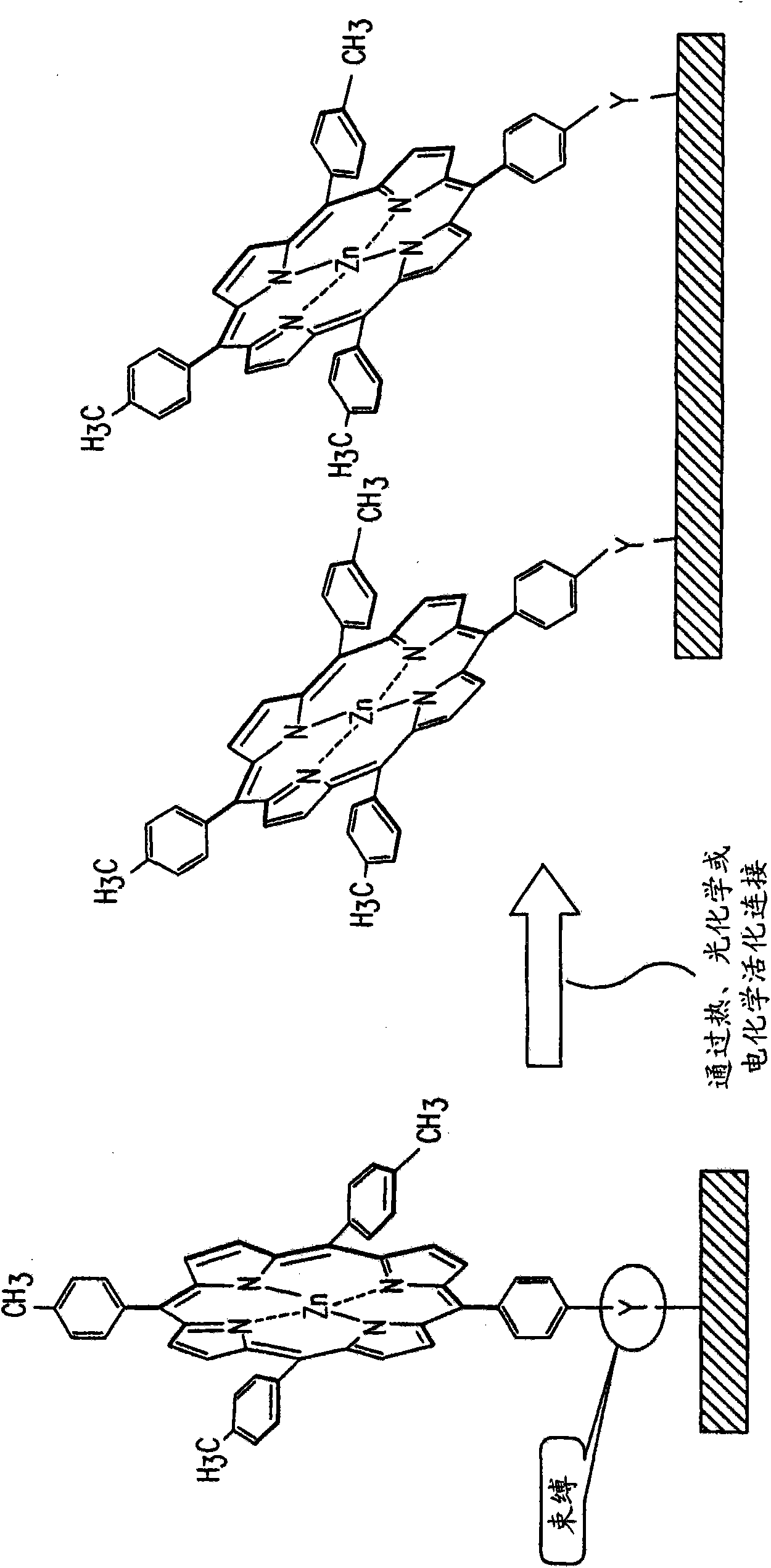

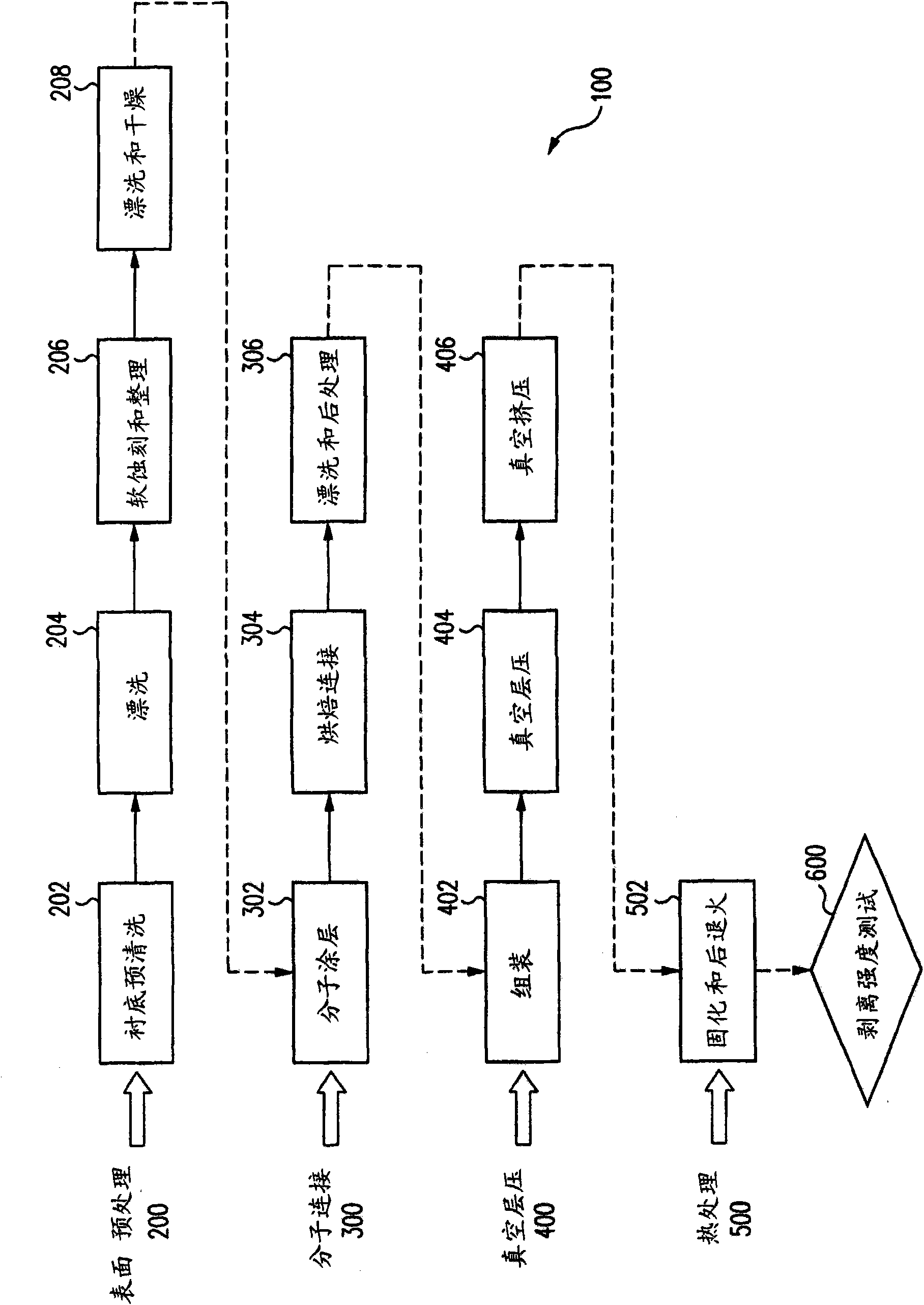

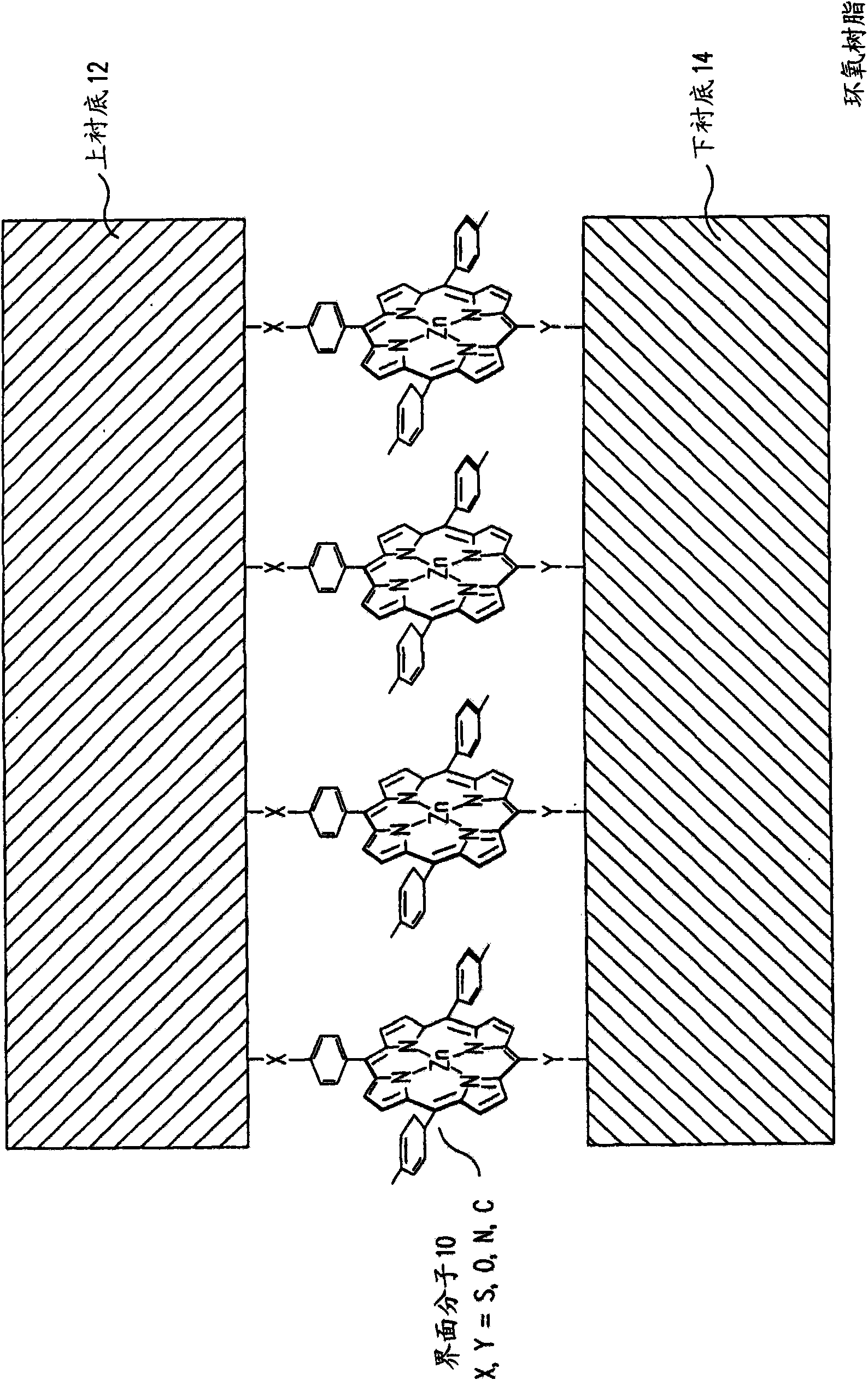

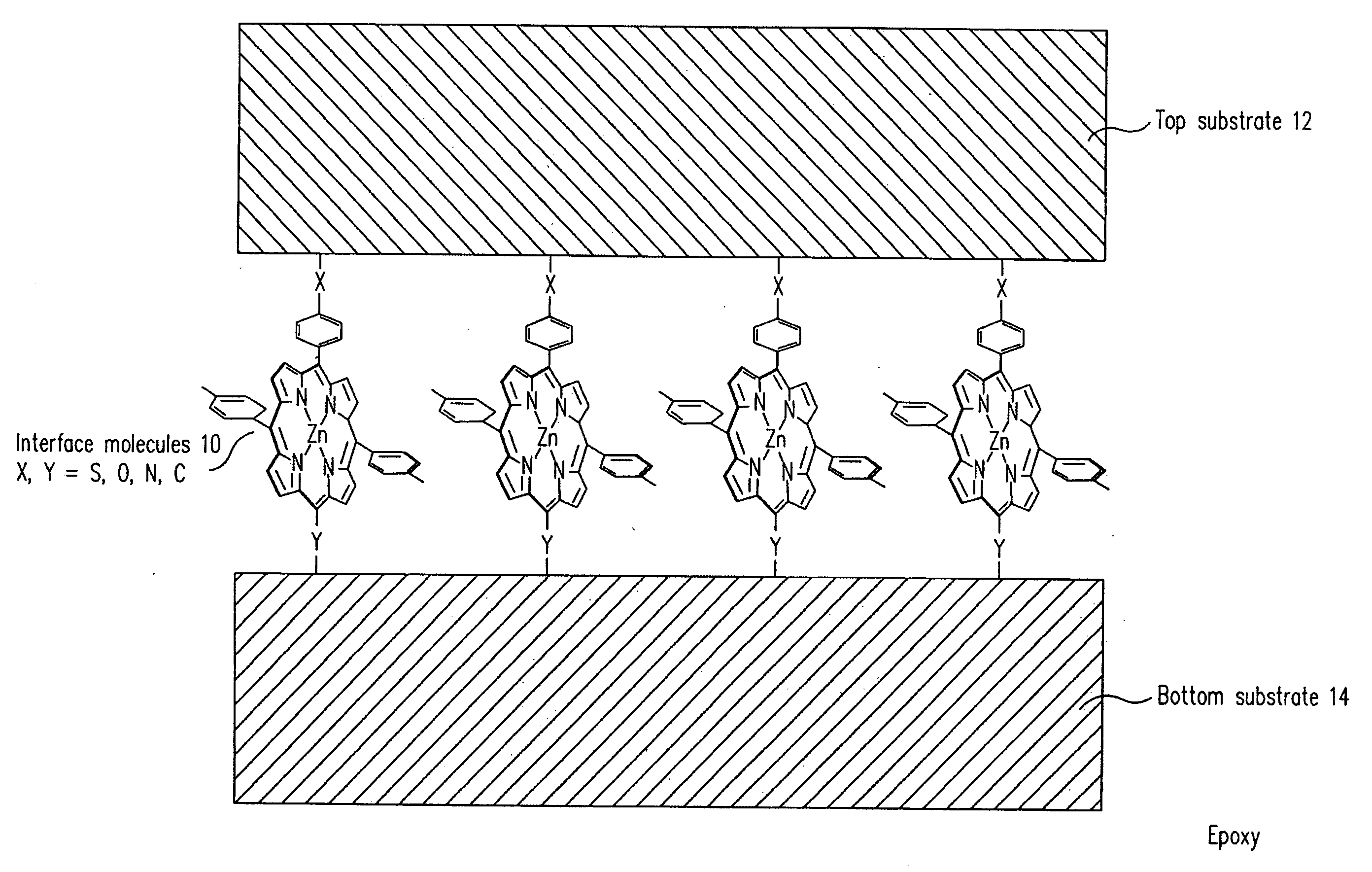

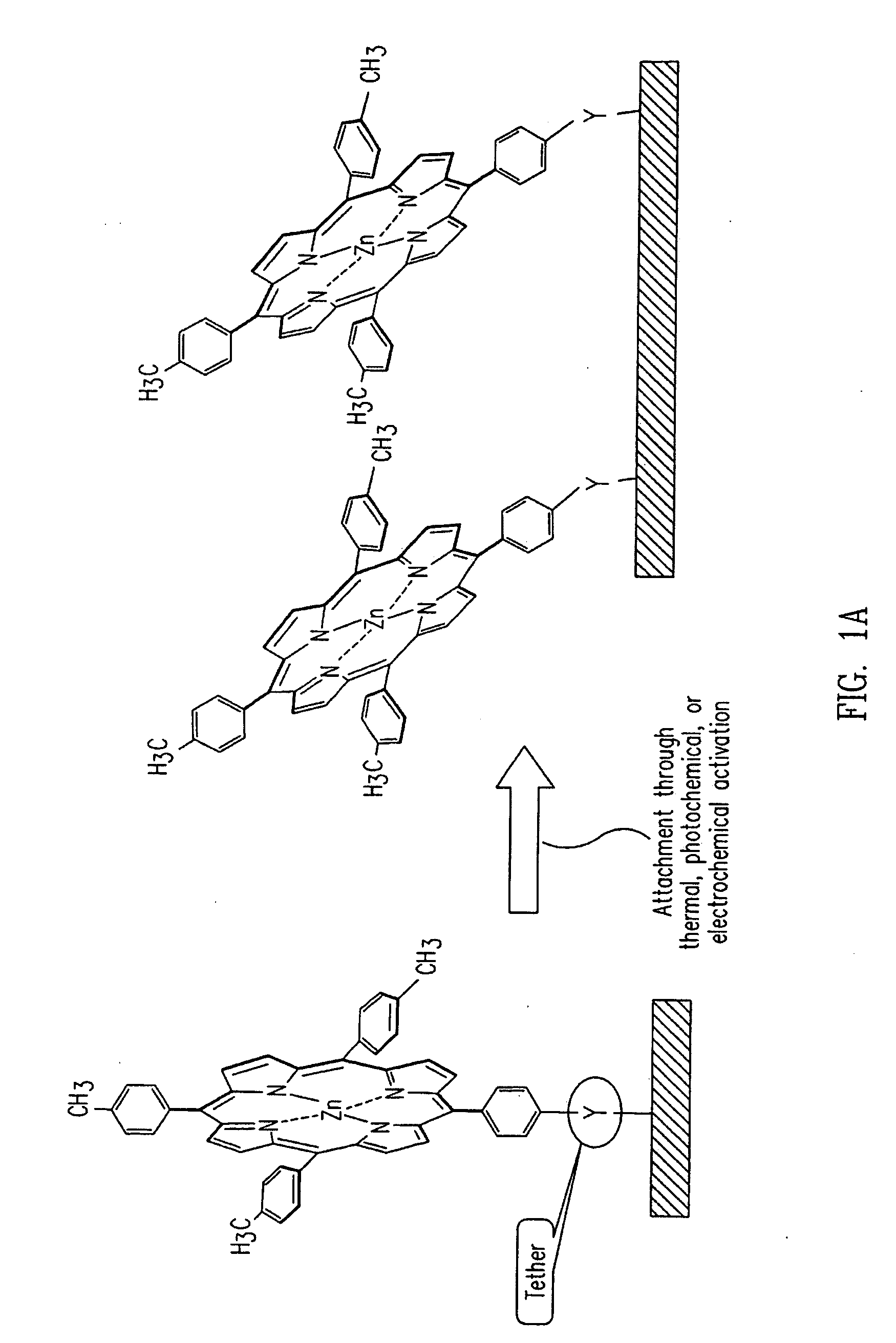

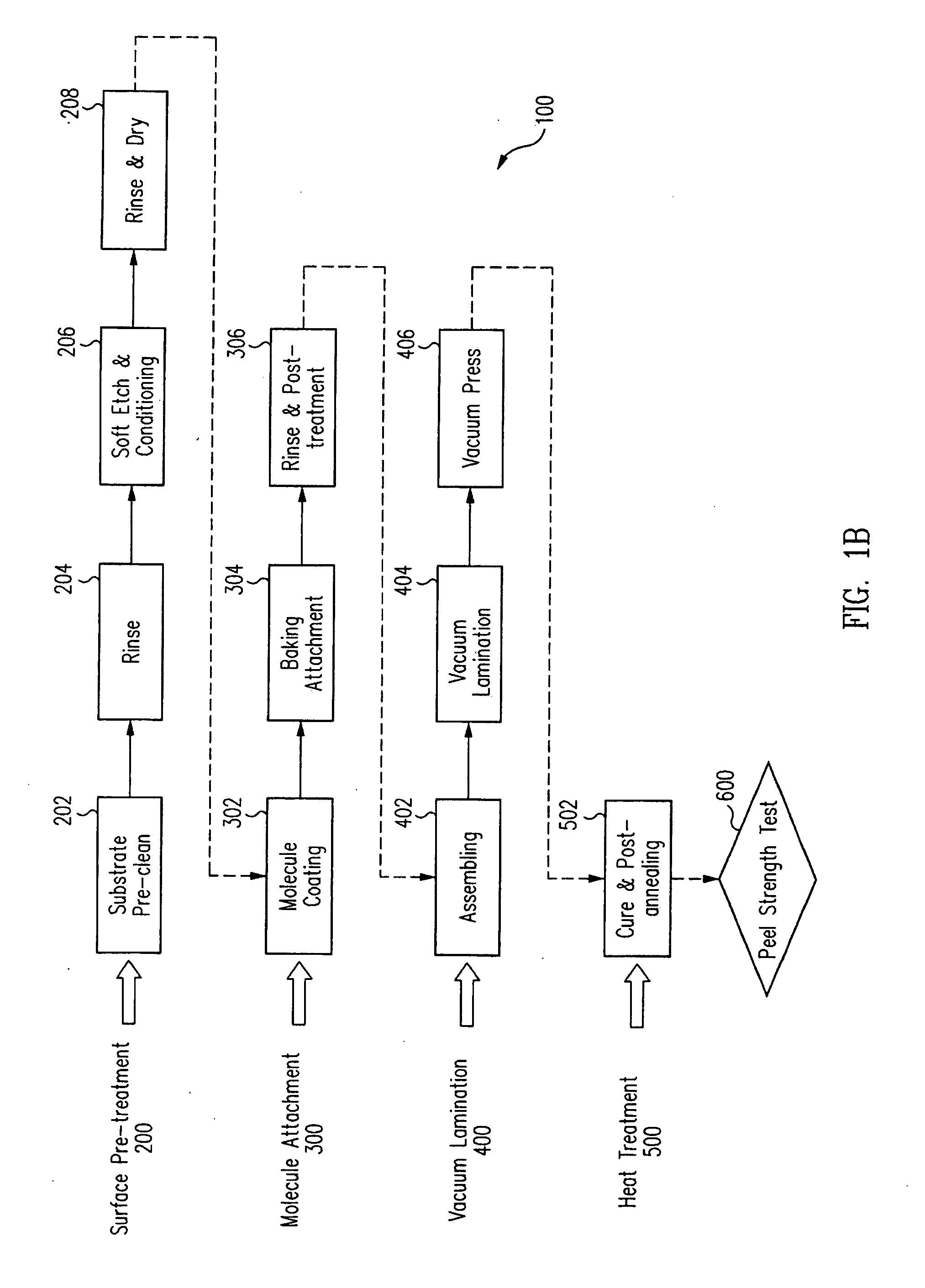

Methods of treating a surface to promote binding of molecule(s) of interest, coatings and devices formed therefrom

InactiveCN101842856AAdhesive processes with surface pretreatmentLiquid/solution decomposition chemical coatingEpoxyDevice form

The present invention generally relates to methods of treating a surface of a substrate, and to the use of the method and resulting films, coatings and devices formed therefrom in various applications including but not limited to electronics manufacturing, printed circuit board manufacturing, metal electroplating, the protection of surfaces against chemical attack, the manufacture of localized conductive coatings, the manufacture of chemical sensors, for example in the fields of chemistry and molecular biology, the manufacture of biomedical equipment, and the like. In another aspect, the present invention provides a printed circuit board, a printed circuit board, comprising: at least one metal layer; a layer of organic molecules attached to the at least one metal layer; and an epoxy layeratop said layer of organic molecules.

Owner:ATOTECH DEUT GMBH

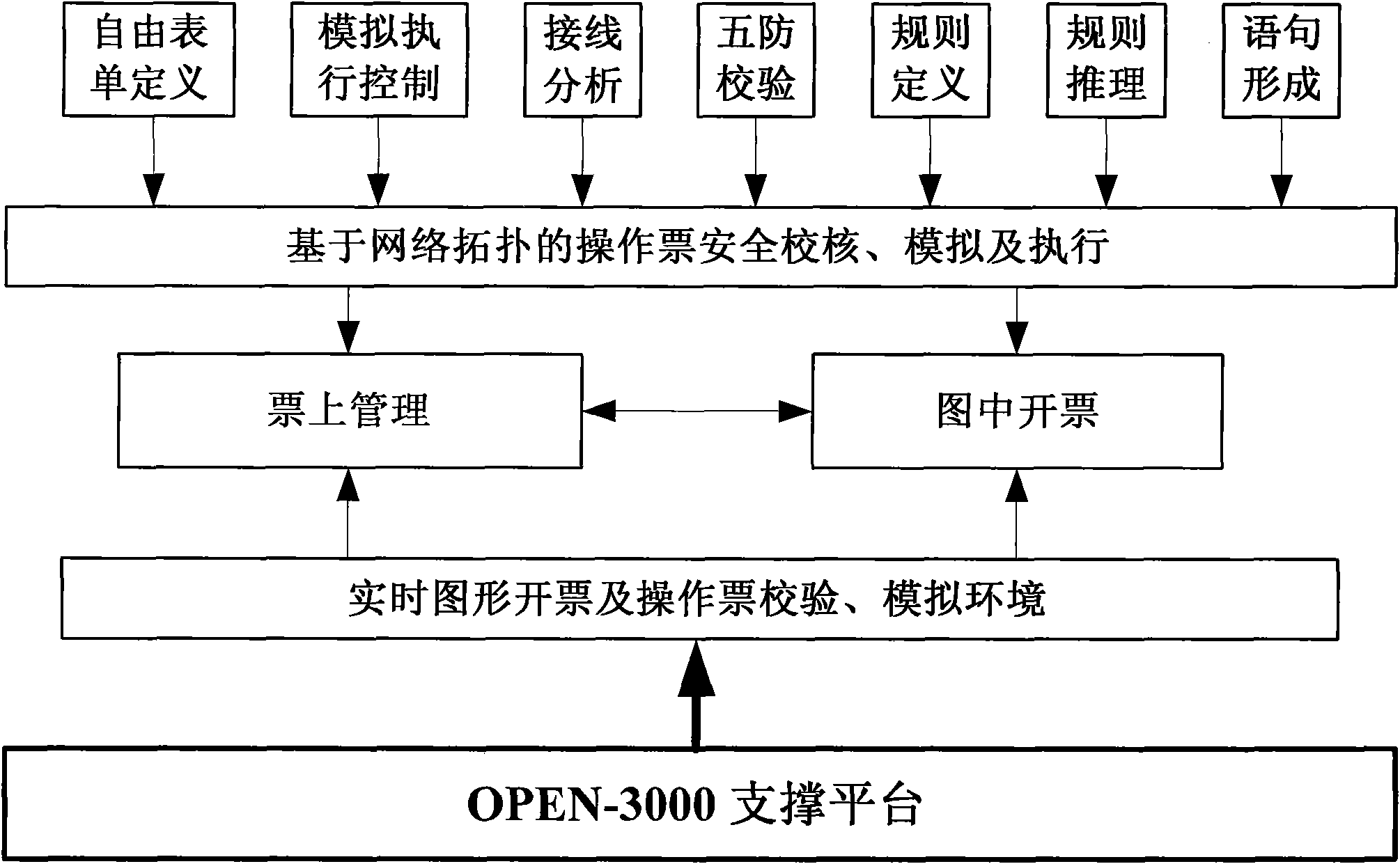

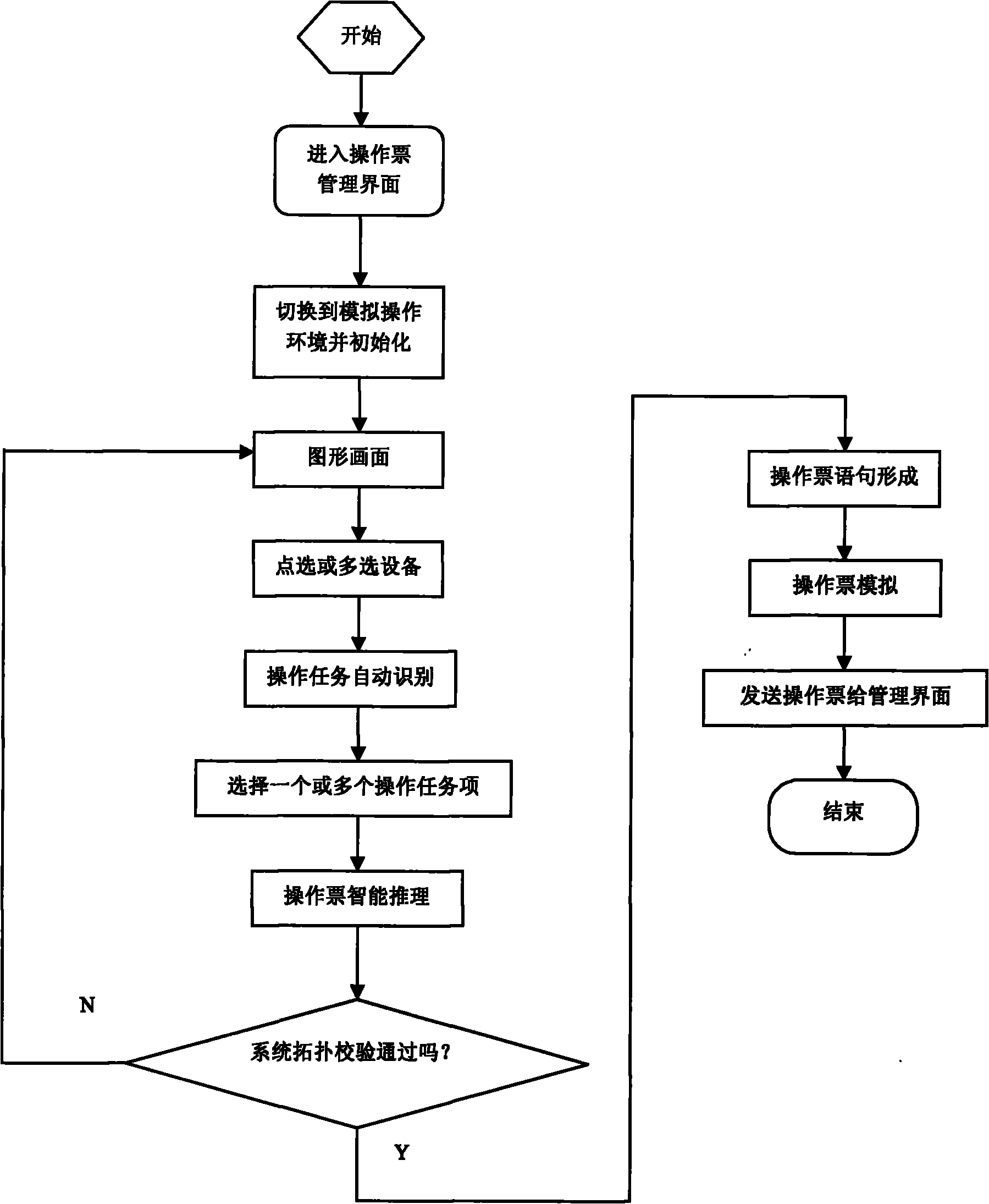

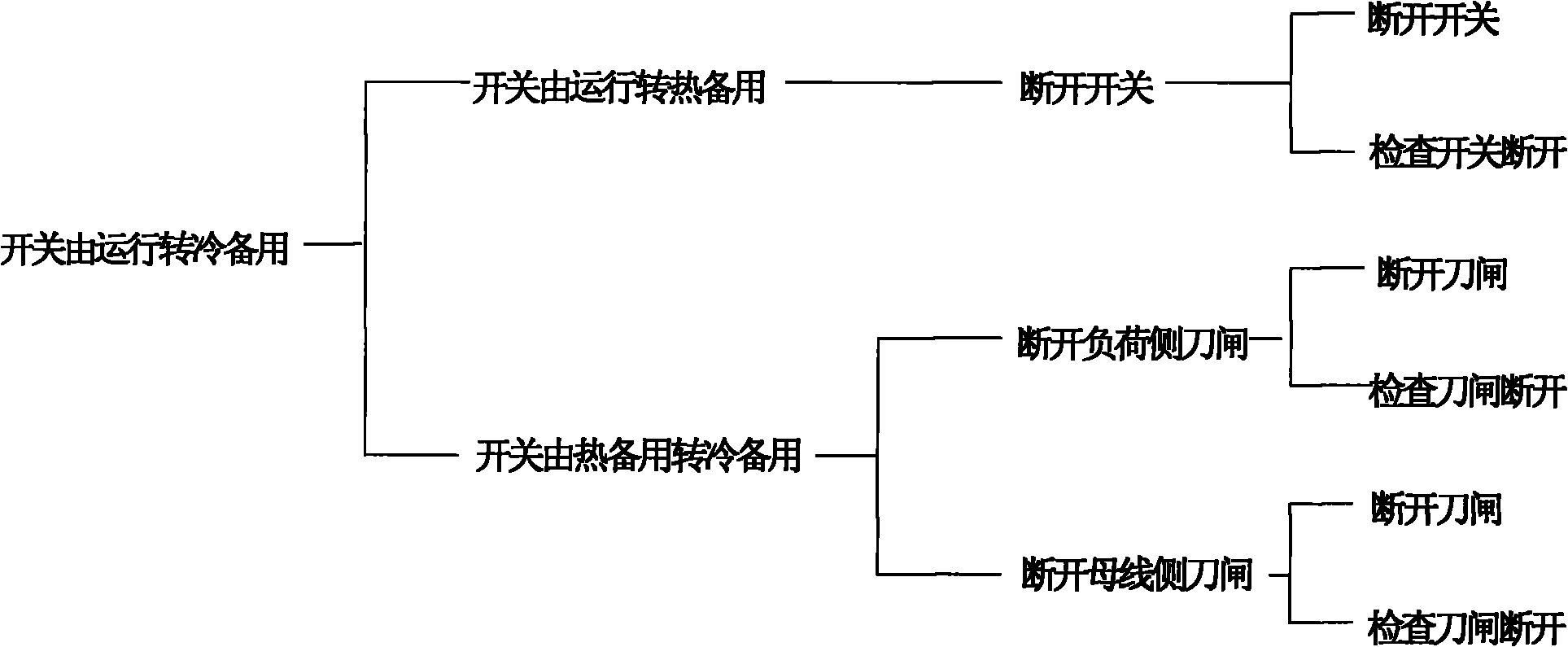

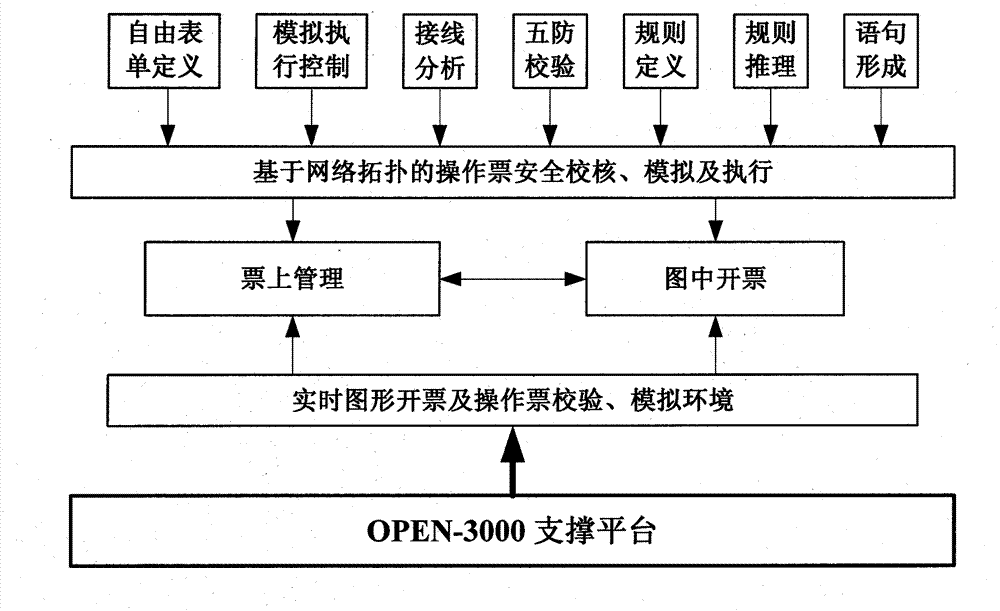

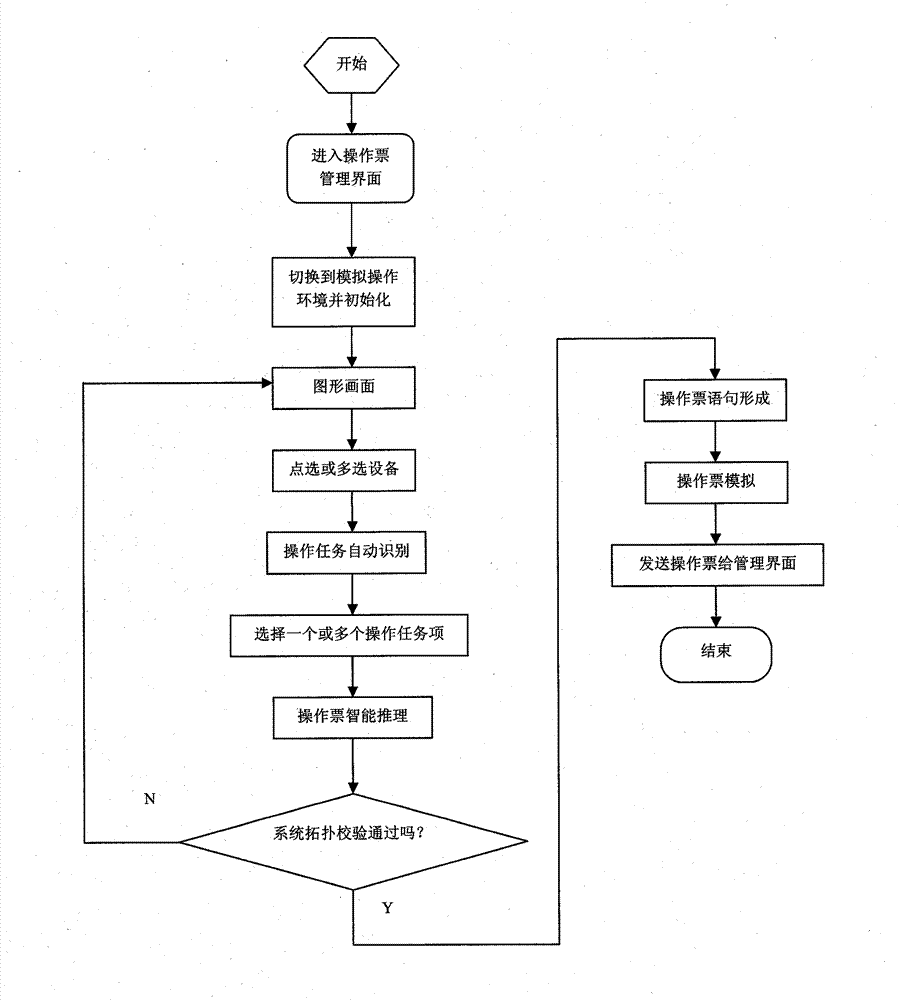

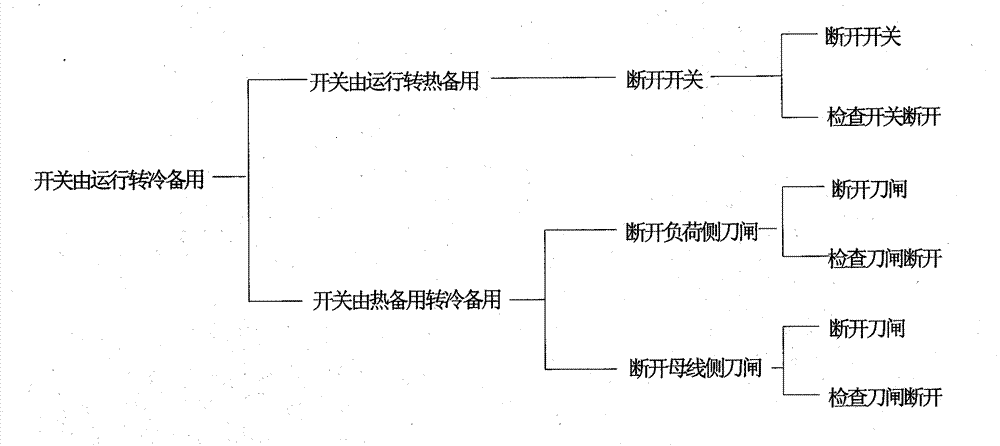

Cross-platform power grid intelligent program-controlled error-preventing system and operation method and interface communication way

InactiveCN102073305AReduce misuseGuaranteed correctnessTotal factory controlProgramme total factory controlCommunication interfaceSCADA

The invention discloses a cross-platform integrated power grid intelligent program-controlled error-preventing system. The system comprises an electronics manufacturing service (EMS) system and a systems applications and products in data processing (SAP) system, wherein the EMS system comprises subsystems, such as a supervisory control and data acquisition (SCADA) subsystem, an intelligent operation order generating subsystem and the like; the SAP system further comprises a 'two orders' management subsystem; the intelligent operation order generating subsystem generates an operation order andtransmits the generated operation order to the SAP system through a communication interface module; after reading the operation order generated by the EMS system to the SAP system, the 'two orders' management subsystem of the SAP system is associated with the corresponding examine and repair form, working order and the like generated by the SAP system, determines the latching relation according to a corresponding operation logic and only sequentially activates the current only correct operation.

Owner:ZHONGSHAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

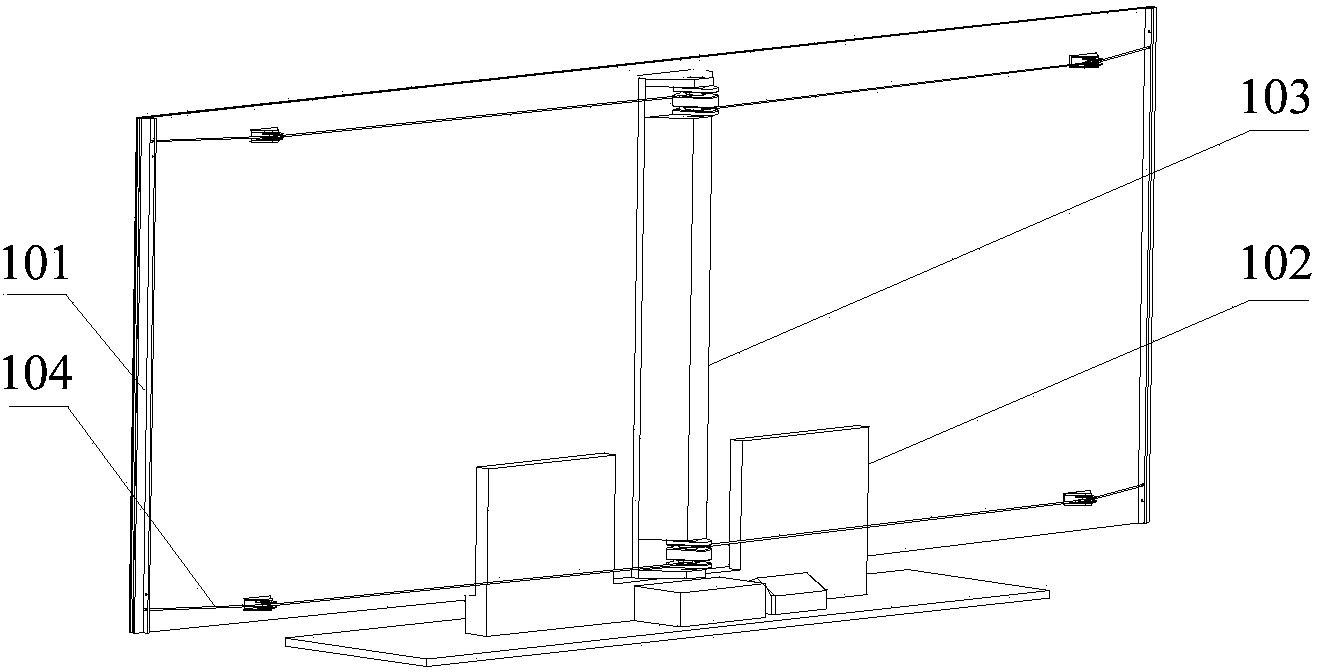

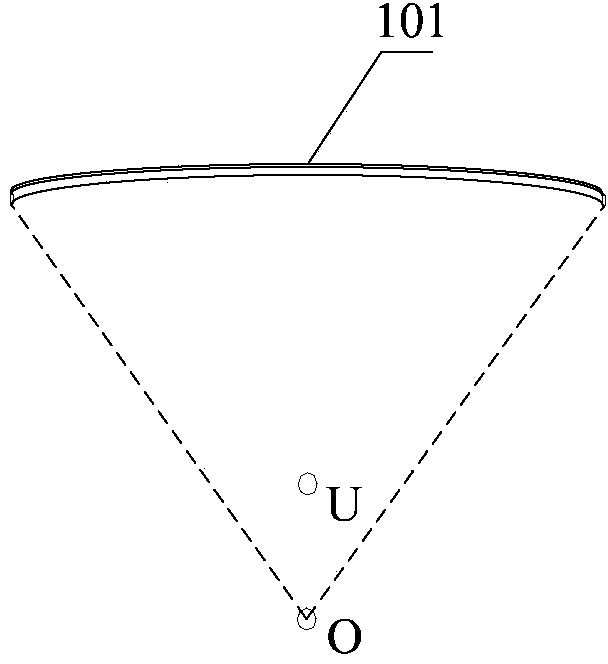

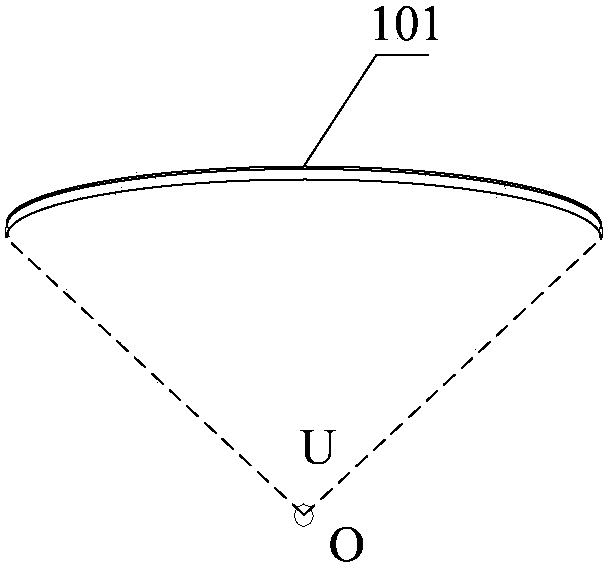

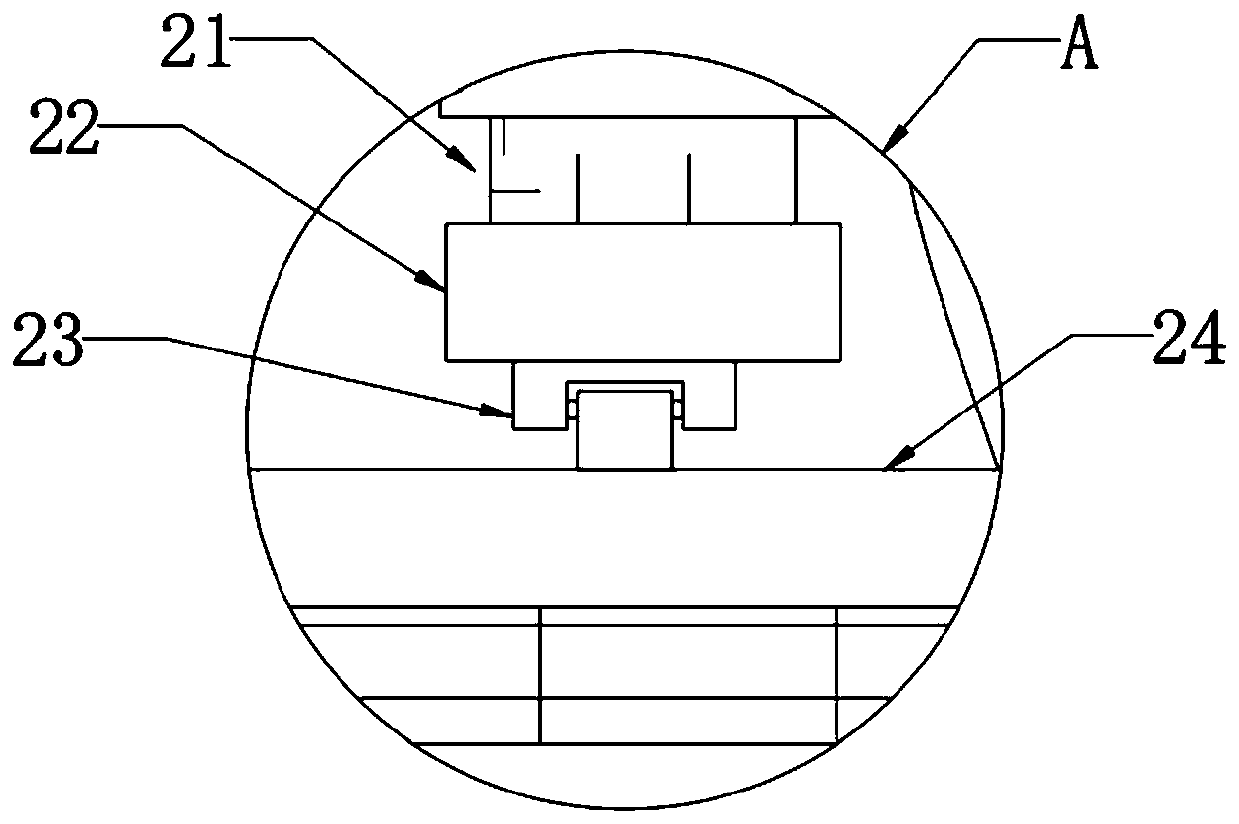

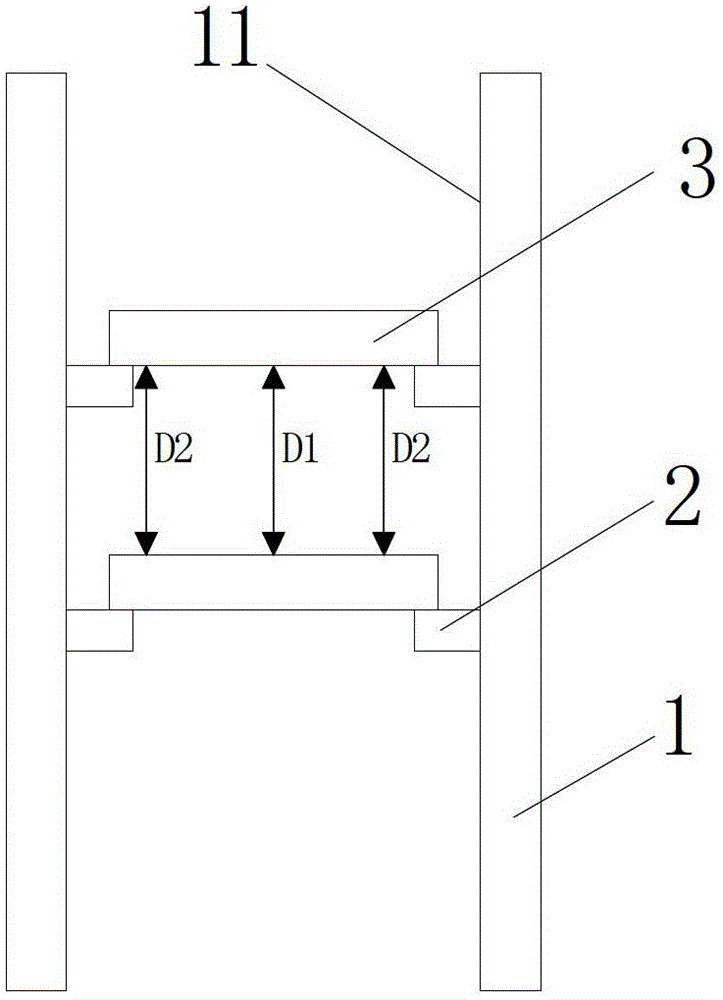

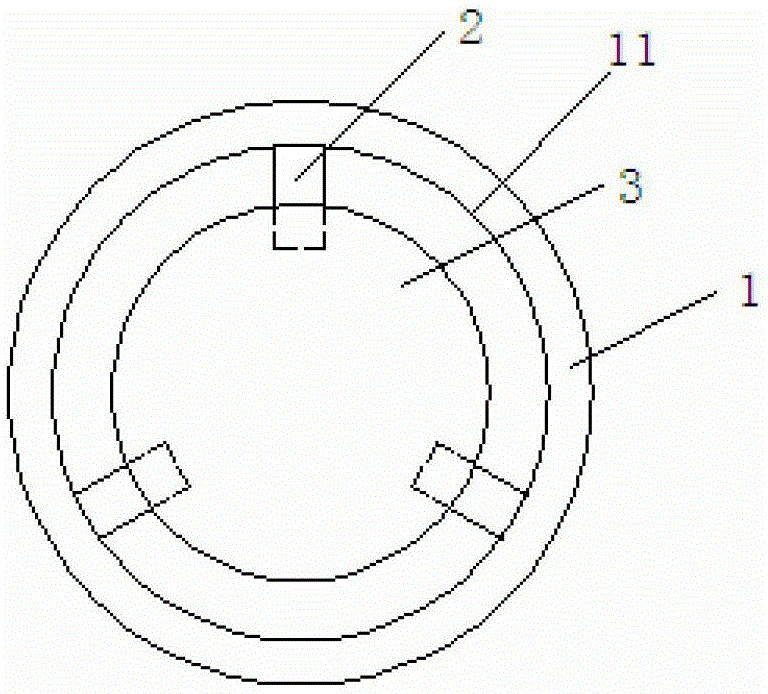

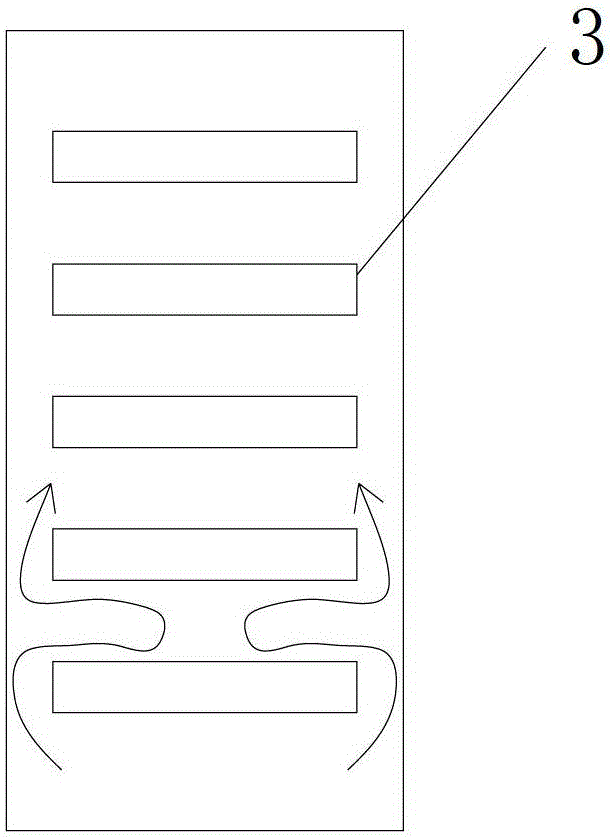

Display device

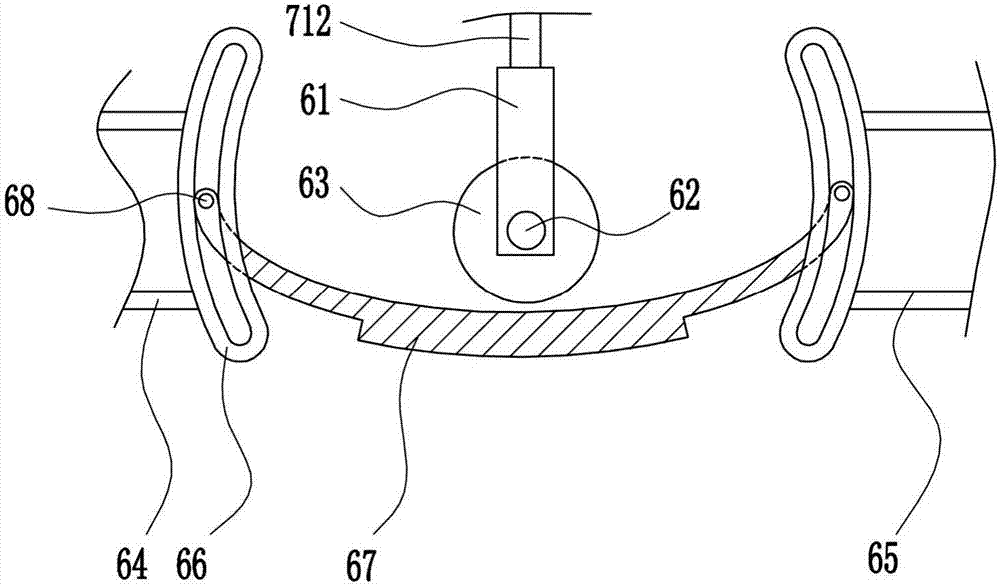

The embodiment of the invention provides a display device, and relates to the technical field of electronics manufacturing. The display device is used for improving user experience to image quality of an electronic product. The display device comprises a display panel and a curvature adjusting mechanism, wherein the display panel is made of elastic materials, the curvature adjusting mechanism is arranged on the back side of the display panel, and comprises a force application part and connecting pieces, one end of each connecting piece is connected with the display panel, the other end of each connecting piece is connected with the force application part, and the force application part can apply force on the connecting pieces so that the connecting pieces can pull or push the display panel to deform elastically. The display device can be applied to electronic devices with high requirements for the display effect.

Owner:HISENSE VISUAL TECH CO LTD

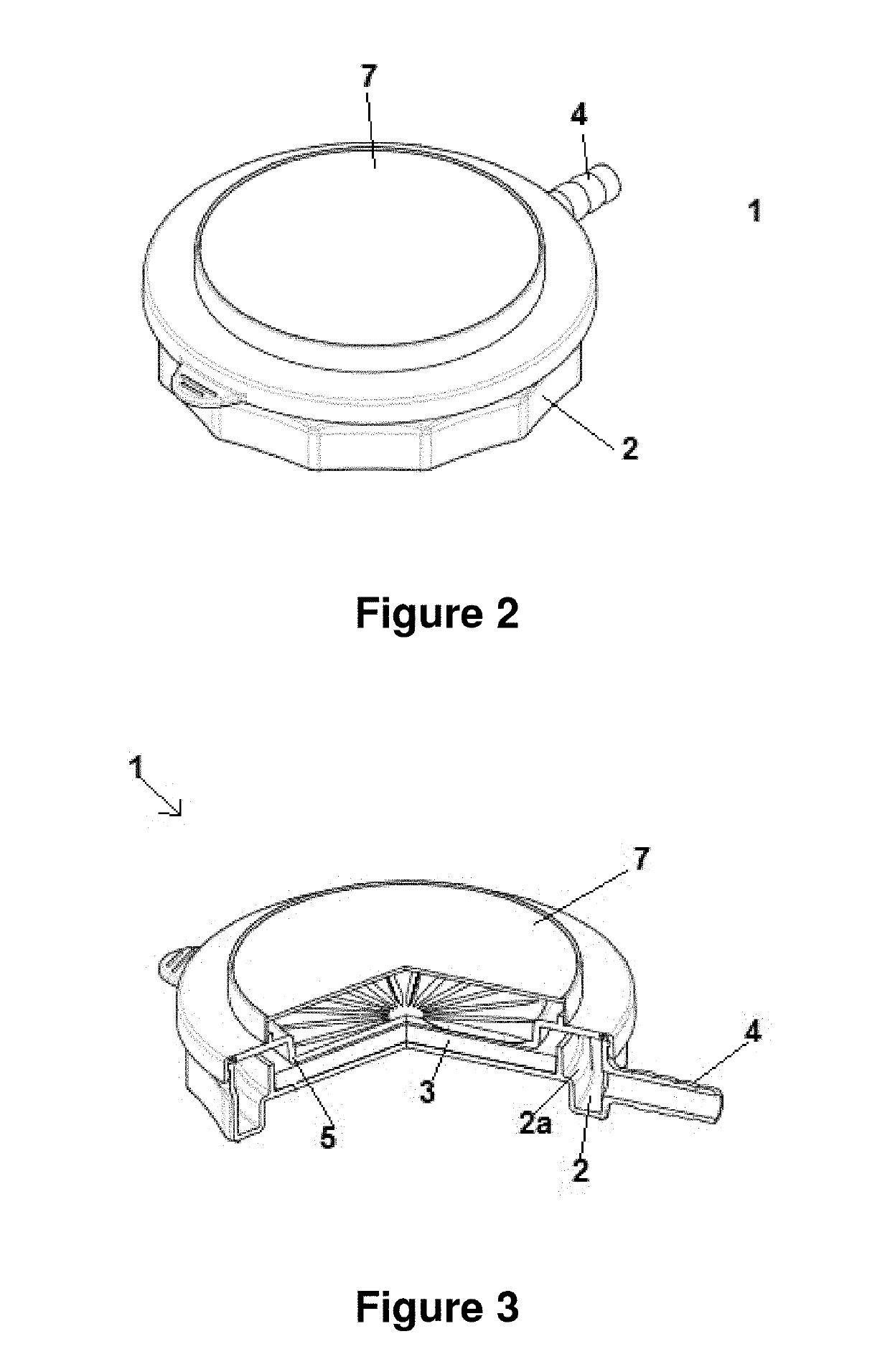

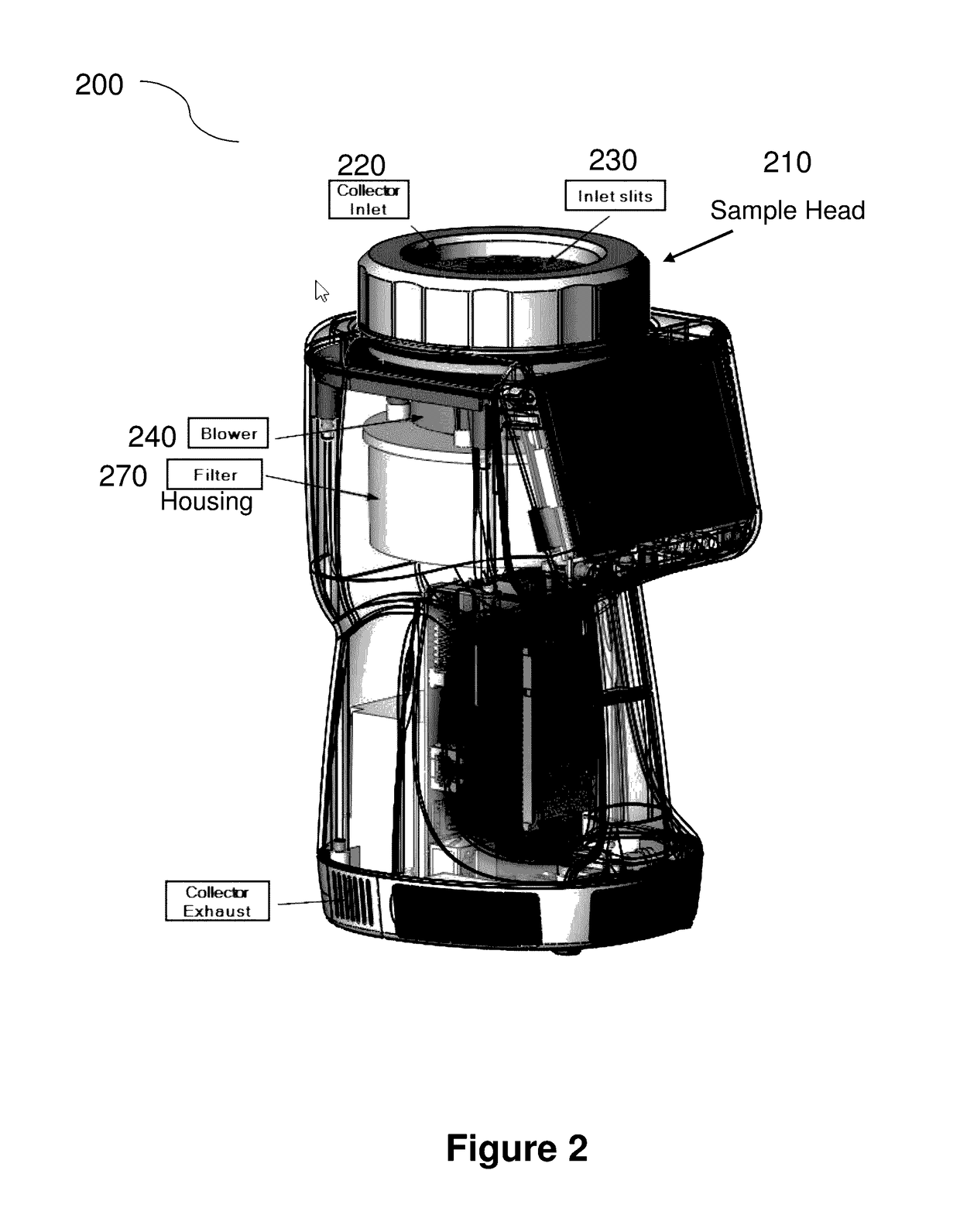

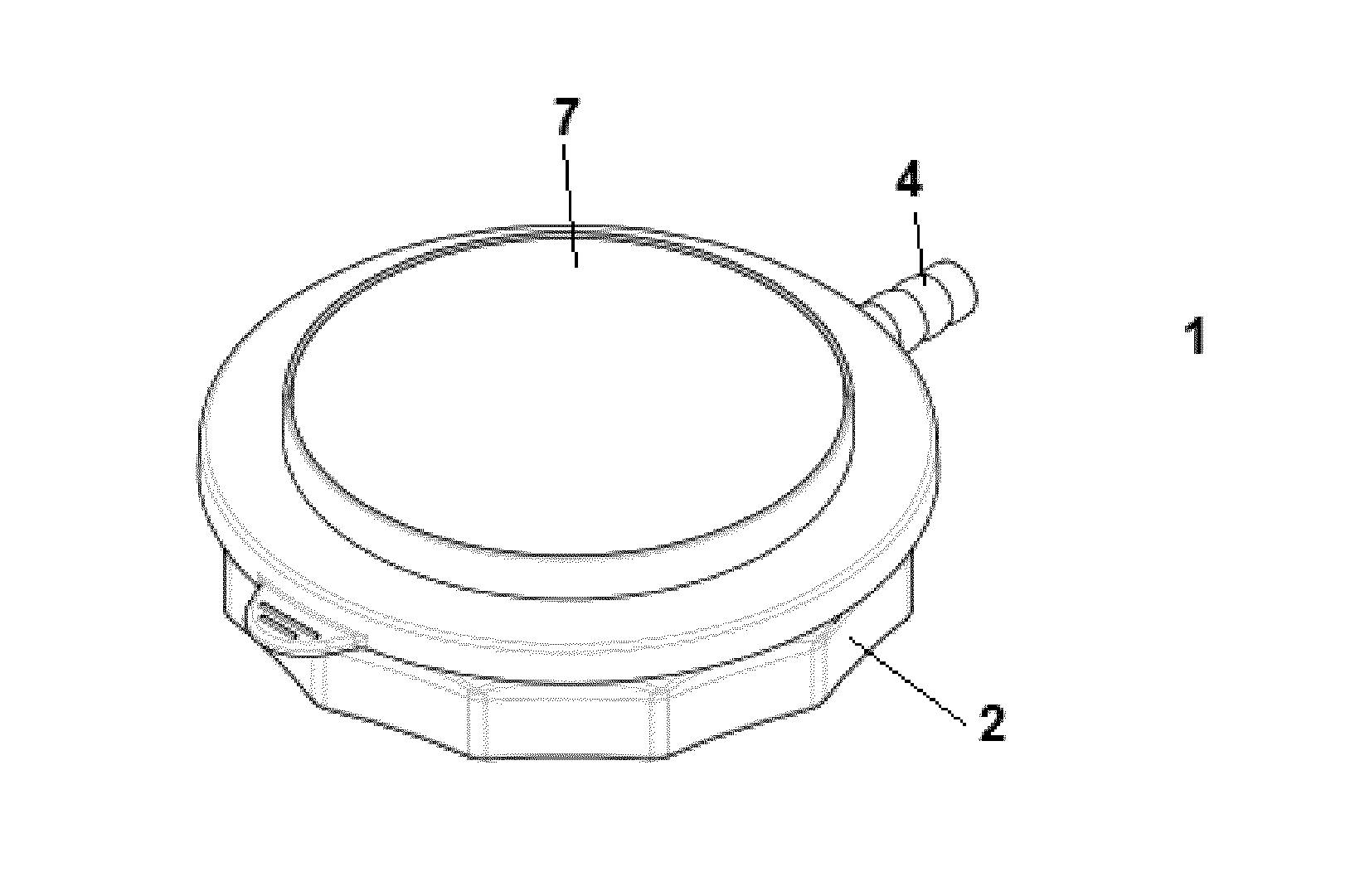

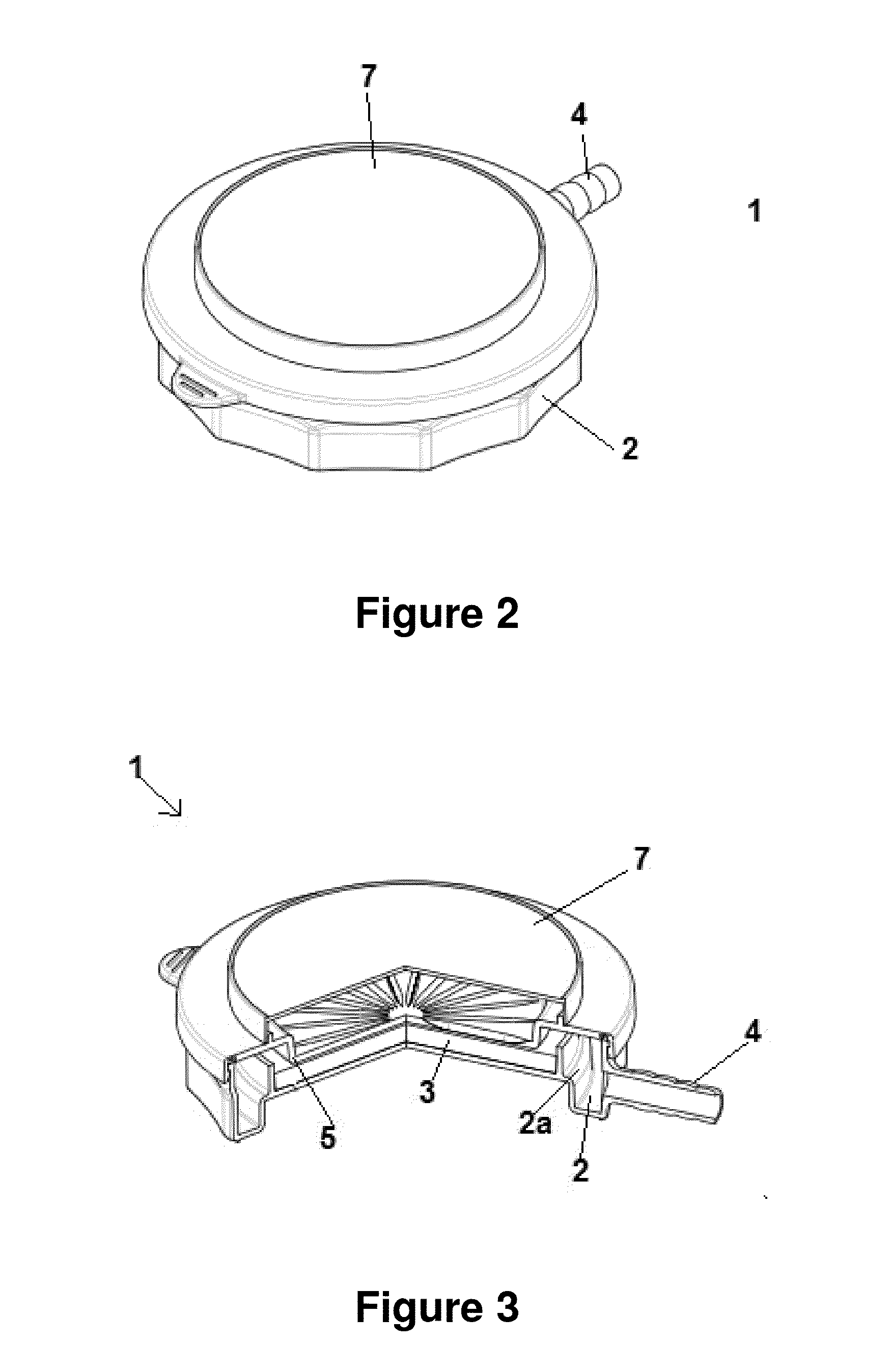

Microbial air sampler integrating media plate and sample collection device

ActiveUS10345200B2Minimize, or entirely eliminate, risks associated with user handlingEffective sampling and growthBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismPharmacy medicine

The invention generally provides devices and methods for sampling, detecting and / or characterizing particles, for example, via collection, growth and analysis of viable biological particles such as microorganisms. Devices and methods of the invention include particle samplers and impactors for collecting and / or analyzing biological particles in manufacturing environments requiring low levels of particles, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. Devices and methods of the invention incorporate an integrated sampler and impact surface, such as the receiving surface of a growth media, in a manner to minimize, or entirely eliminate, risks associated with user handling, such as the occurrence of false positive determinations due to contamination of the impact surface during particle sampling, growth or analysis processes.

Owner:PARTICLE MEASURING SYST

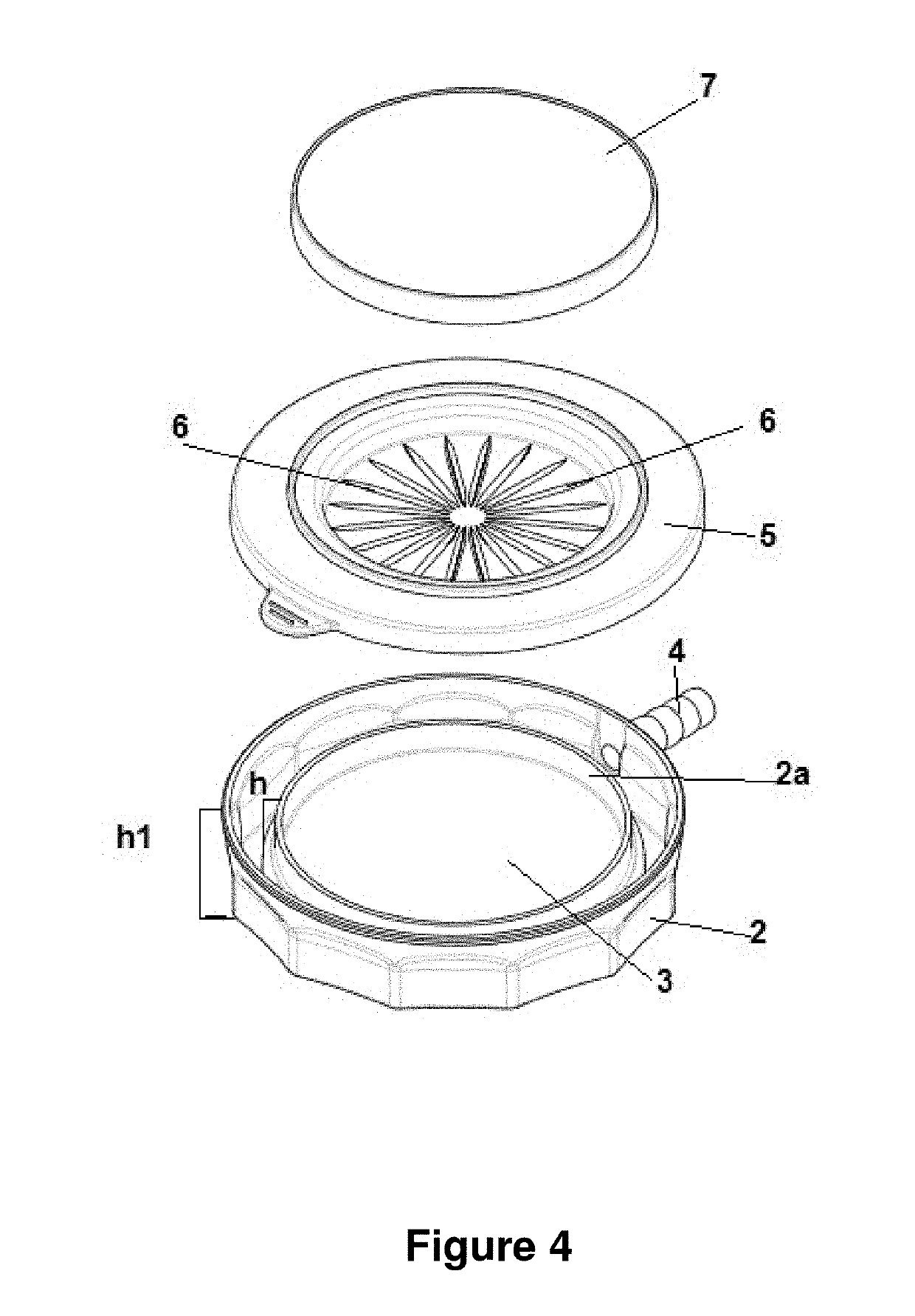

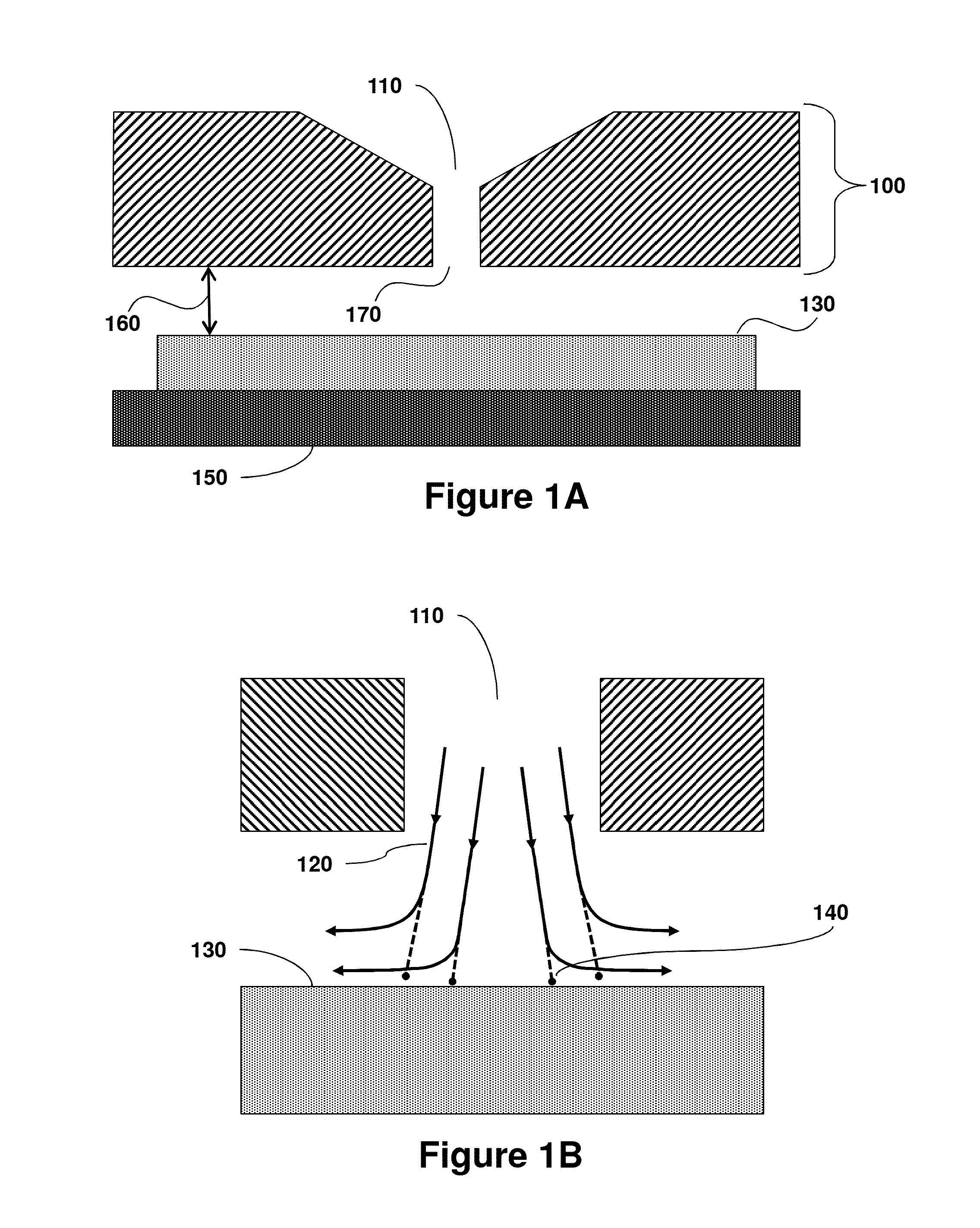

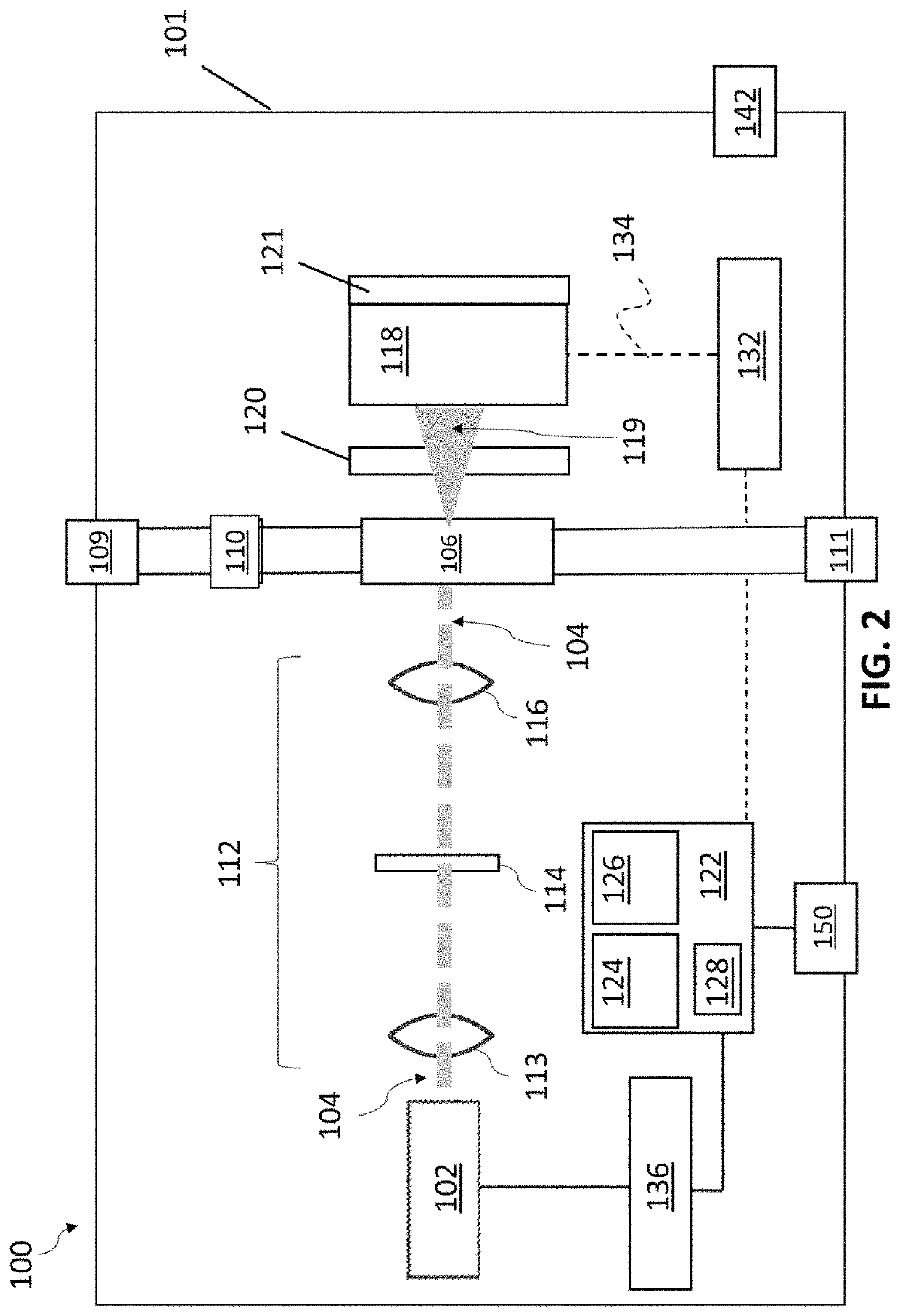

Filter and blower geometry for particle sampler

ActiveUS9631222B2Eliminate and minimize potentialMinimizing potential impactMicrobiological testing/measurementWithdrawing sample devicesEngineeringElectronics manufacturing

The invention provides devices and methods for sampling, detecting and / or characterizing particles. Devices and methods of the invention, including particle samplers, impactors and counters, include a filter component for removing particles in the exhaust flow of the device, for example, to eliminate or minimize the potential for the device itself to provide source of particles in an environment undergoing particle monitoring. This aspect of the present devices and methods is particularly useful for monitoring particles in manufacturing environments requiring low levels of particles, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products.

Owner:PARTICLE MEASURING SYST

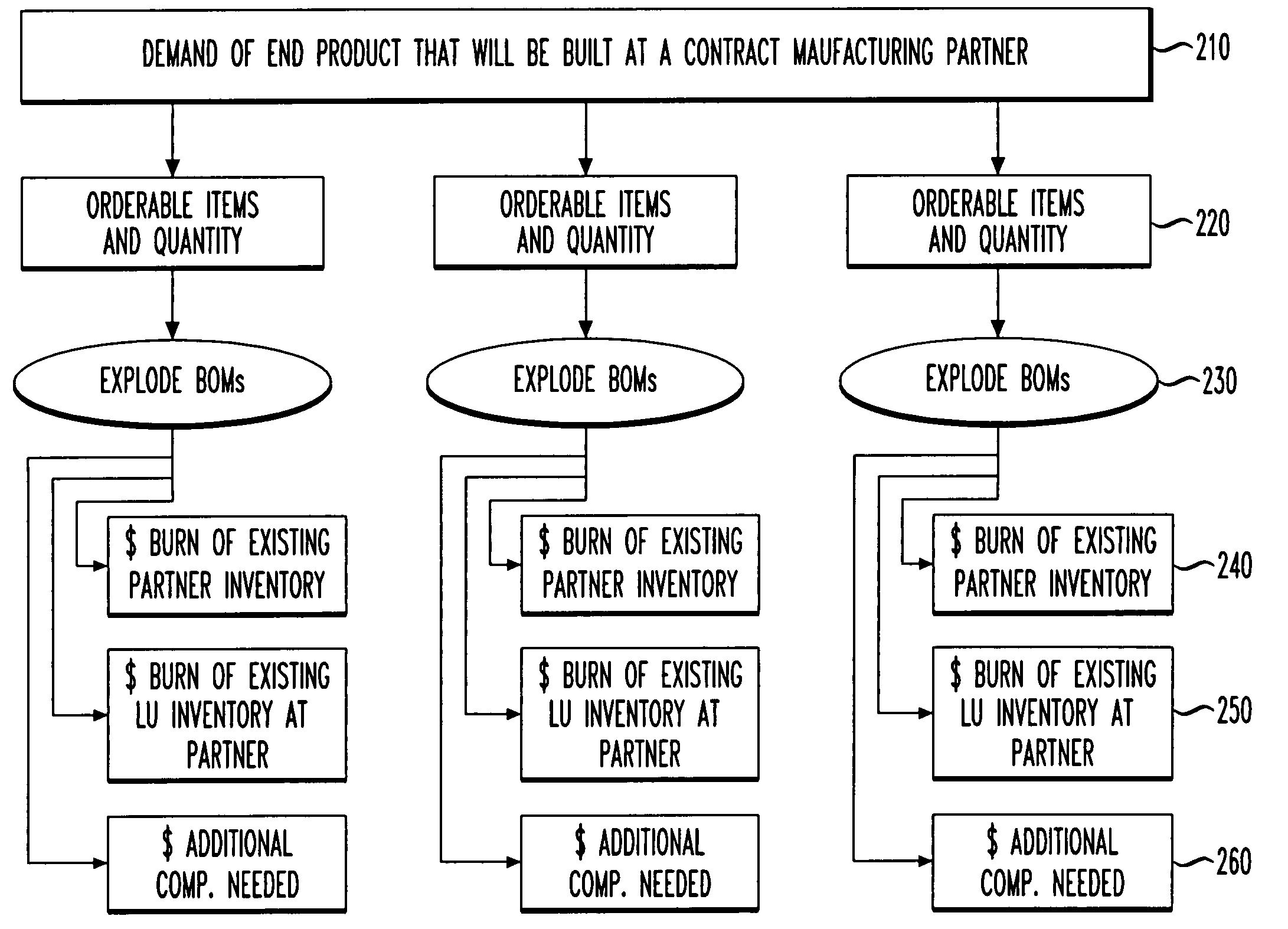

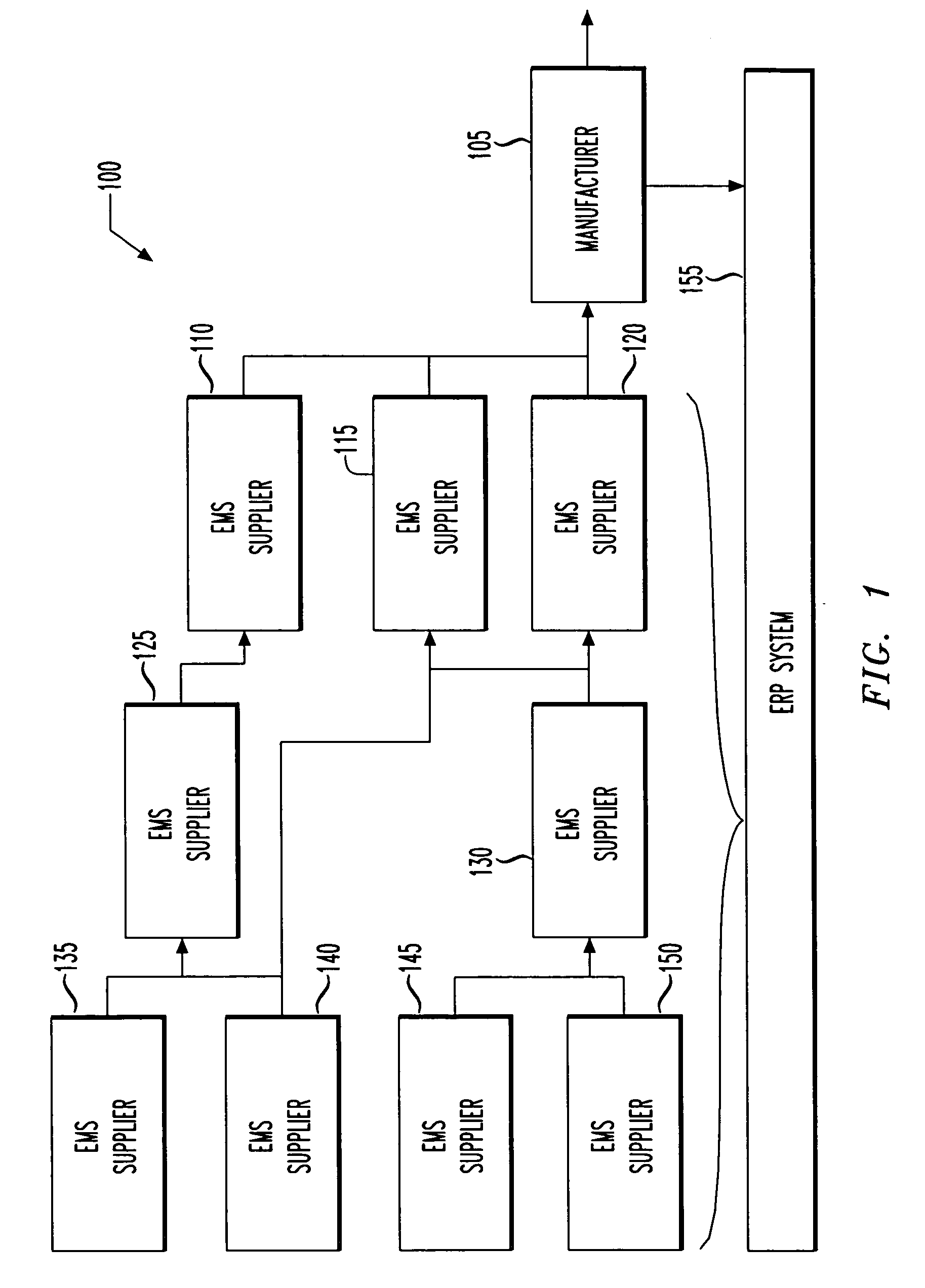

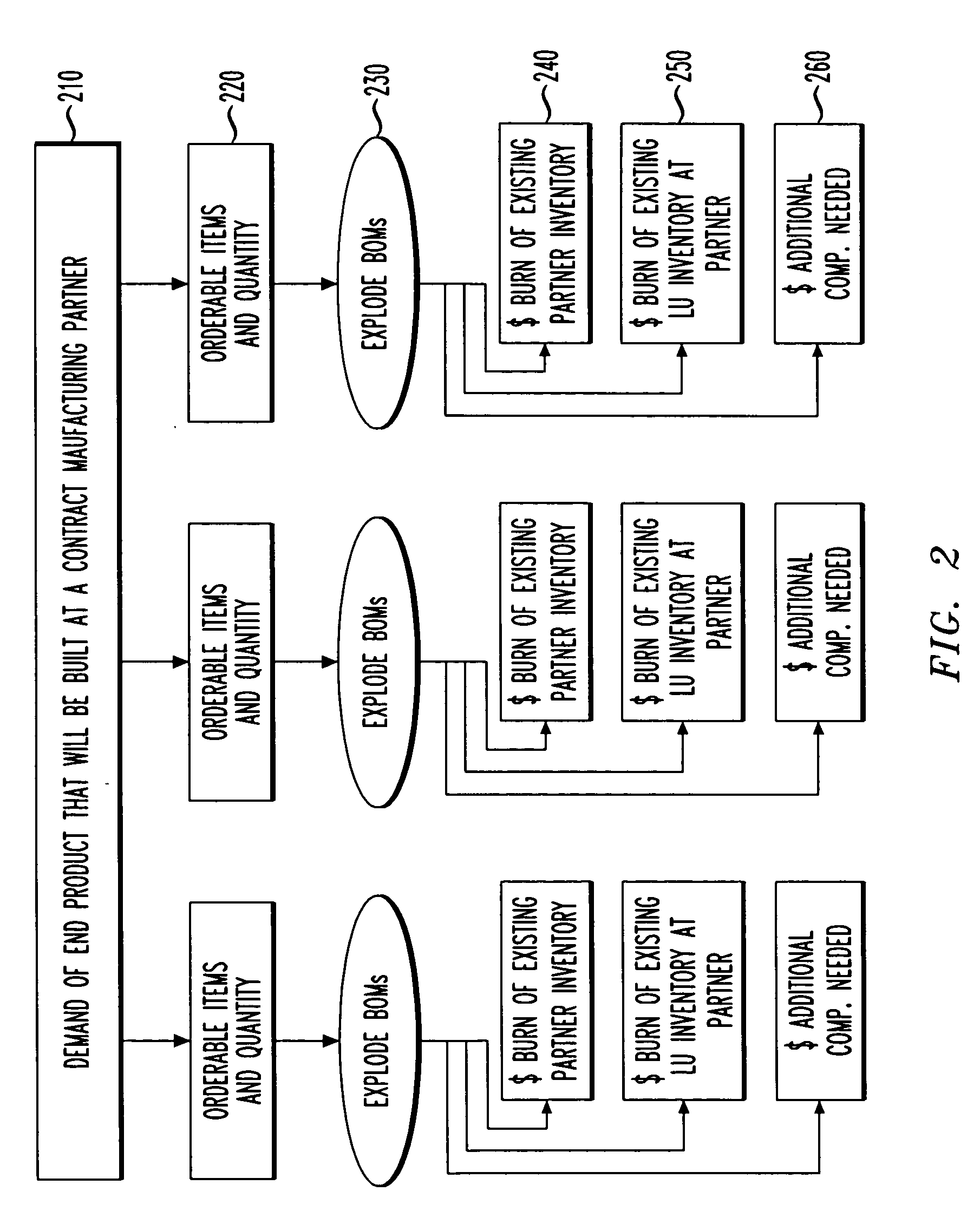

System and method for mitigating inventory risk in an electronic manufacturing services-based supply chain management and manufacturing execution system

InactiveUS20050288979A1Reduce riskReduce inventory riskSpecial data processing applicationsManufacture execution systemEnterprise resource planning

A system and method for mitigating inventory risk and an enterprise resource planning (ERP) system incorporating such system or method. In one embodiment, the system includes: (1) a uniqueness factor calculator configured to assign, to parts in an associated production database, uniqueness factors that are a function of a number of different products into which said parts go and (2) a risk report generator associated with said uniqueness factor calculator and configured to generate a report of risks associated with said products and based on said uniqueness factors.

Owner:LUCENT TECH INC

Microbial air sampler integrating media plate and sample collection device

ActiveUS20150075301A1Minimize, or entirely eliminate, risks associated with user handlingEffective sampling and growthApparatus sterilizationWithdrawing sample devicesPharmacy medicineEngineering

The invention generally provides devices and methods for sampling, detecting and / or characterizing particles, for example, via collection, growth and analysis of viable biological particles such as microorganisms. Devices and methods of the invention include particle samplers and impactors for collecting and / or analyzing biological particles in manufacturing environments requiring low levels of particles, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. Devices and methods of the invention incorporate an integrated sampler and impact surface, such as the receiving surface of a growth media, in a manner to minimize, or entirely eliminate, risks associated with user handling, such as the occurrence of false positive determinations due to contamination of the impact surface during particle sampling, growth or analysis processes.

Owner:PARTICLE MEASURING SYST

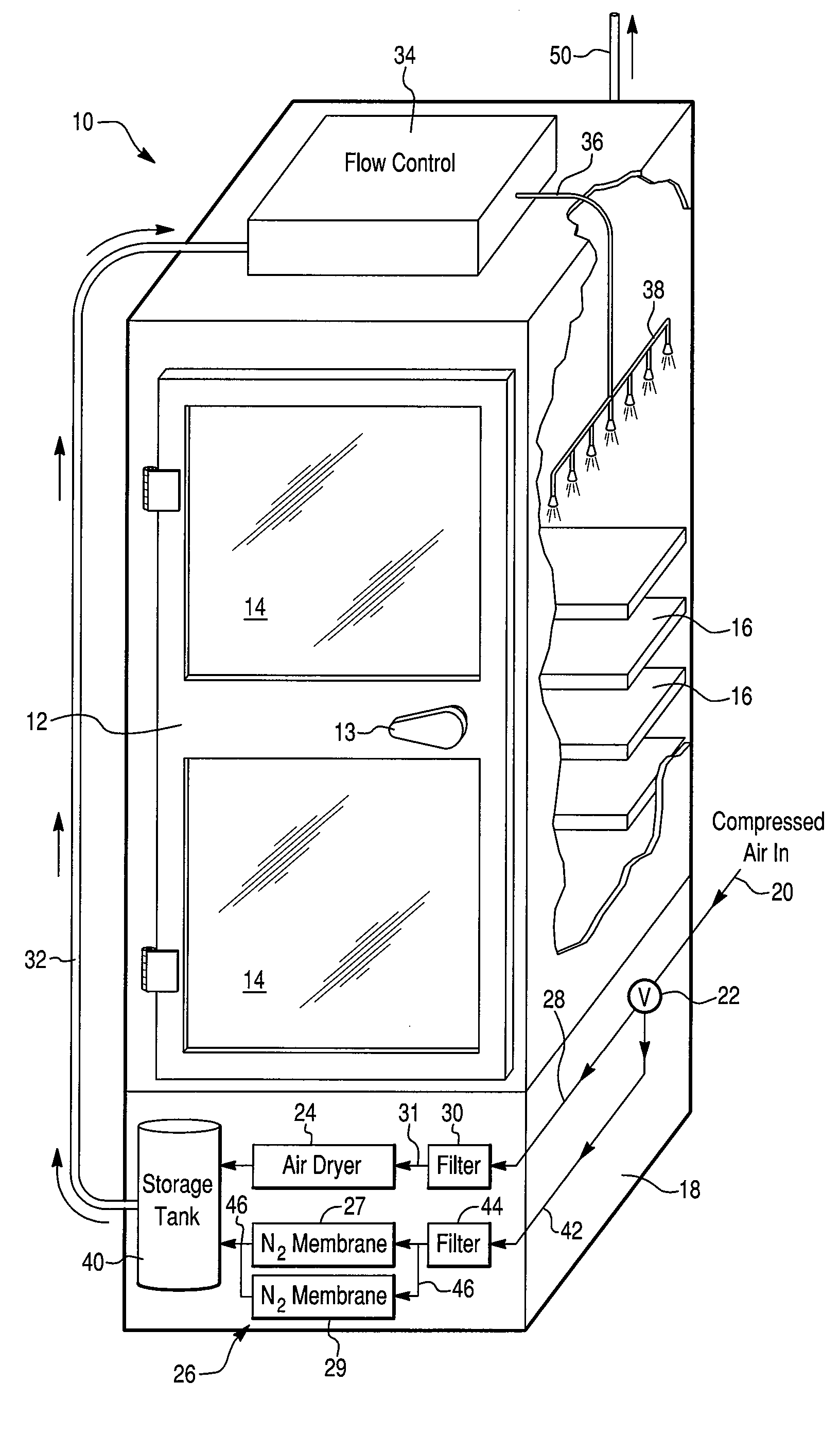

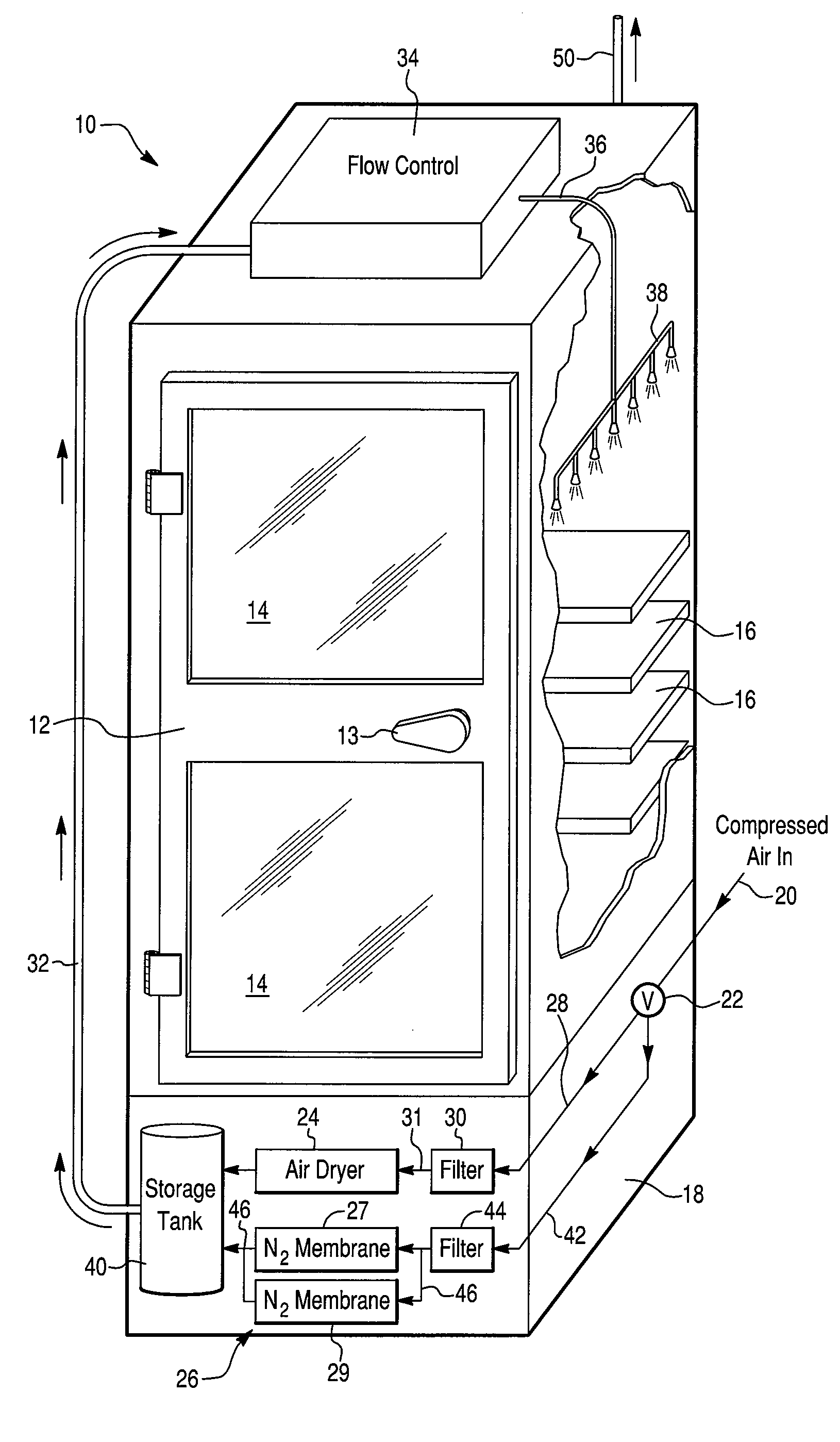

Dry Cabinets for Use in Moisture Sensitive Device Management in Electronics Manufacturing

InactiveUS20070068035A1Prevent moisture-induced failureLow costDrying gas arrangementsDrying machines with progressive movementsNitrogen generatorEngineering

A dry cabinet for storing surface mount devices in a low humidity environment containing an integrated dry gas forming means in the form of a desiccator or a nitrogen generator which can receive a source of compressed air and form a dry air stream or a concentrated dry nitrogen stream which can be directed into the interior space of the cabinet to maintain the environment within the cabinet a low relative humidity. The cabinet with it self contained dry gas forming source is more economical than prior art dry cabinets which require a centralized nitrogen source.

Owner:THERIAULT MARTIN

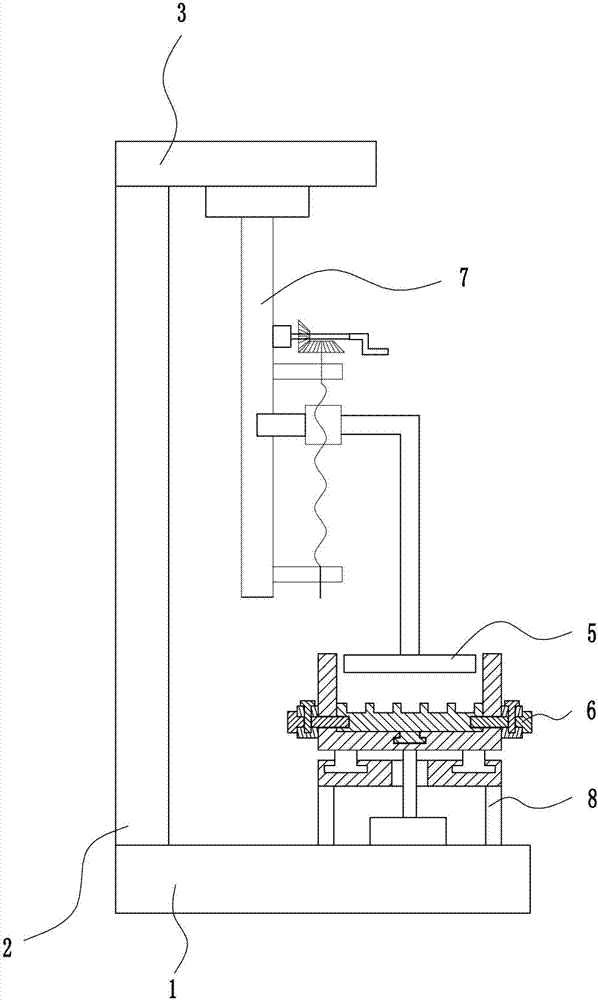

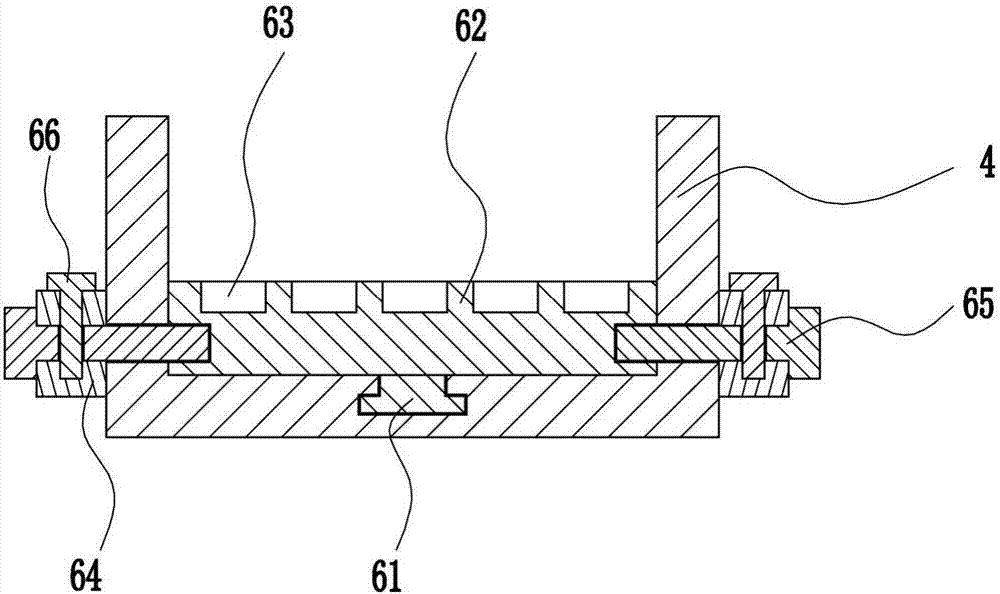

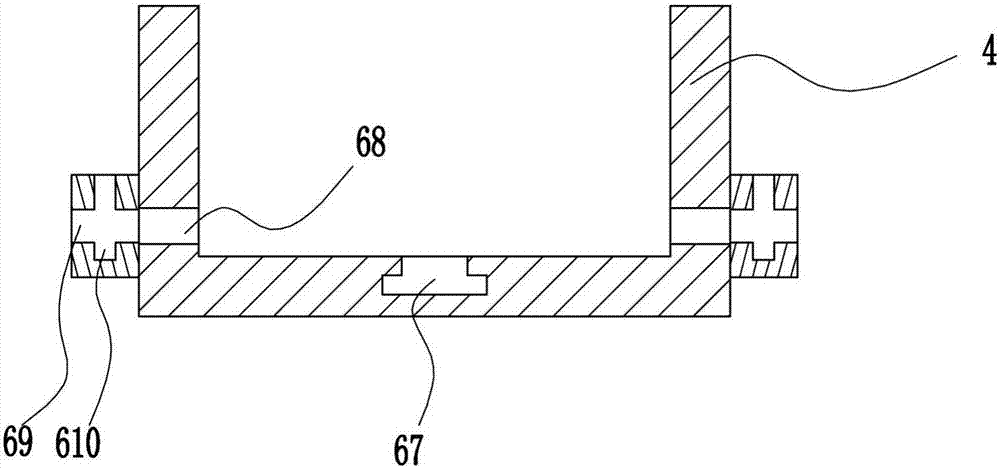

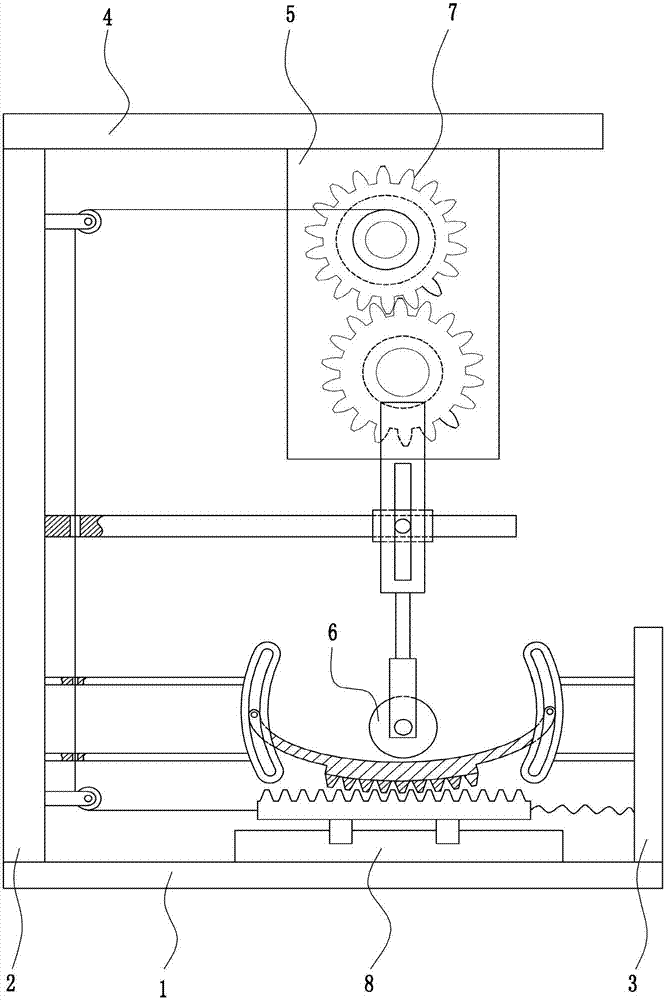

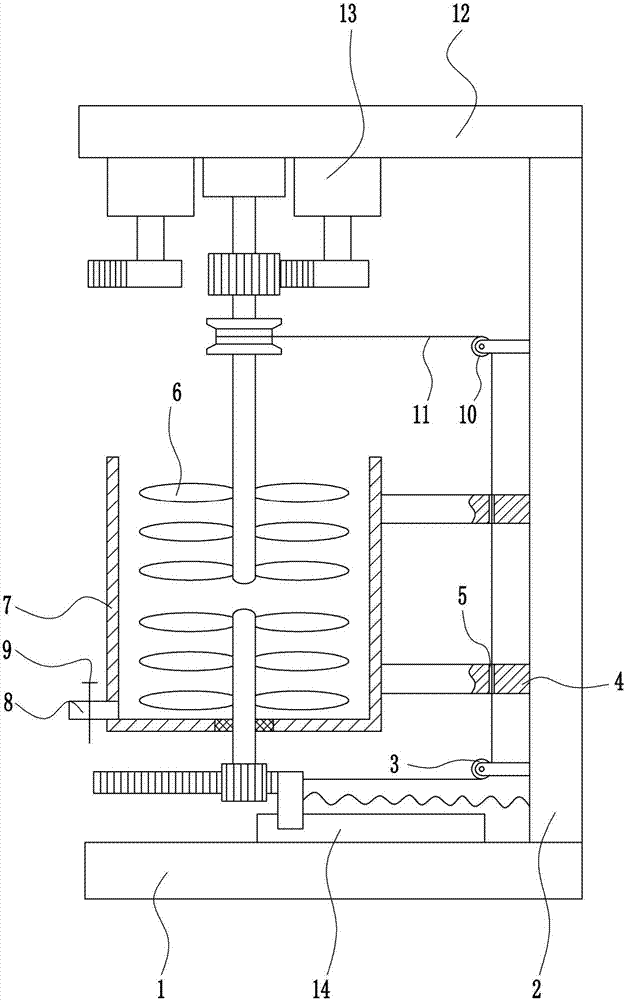

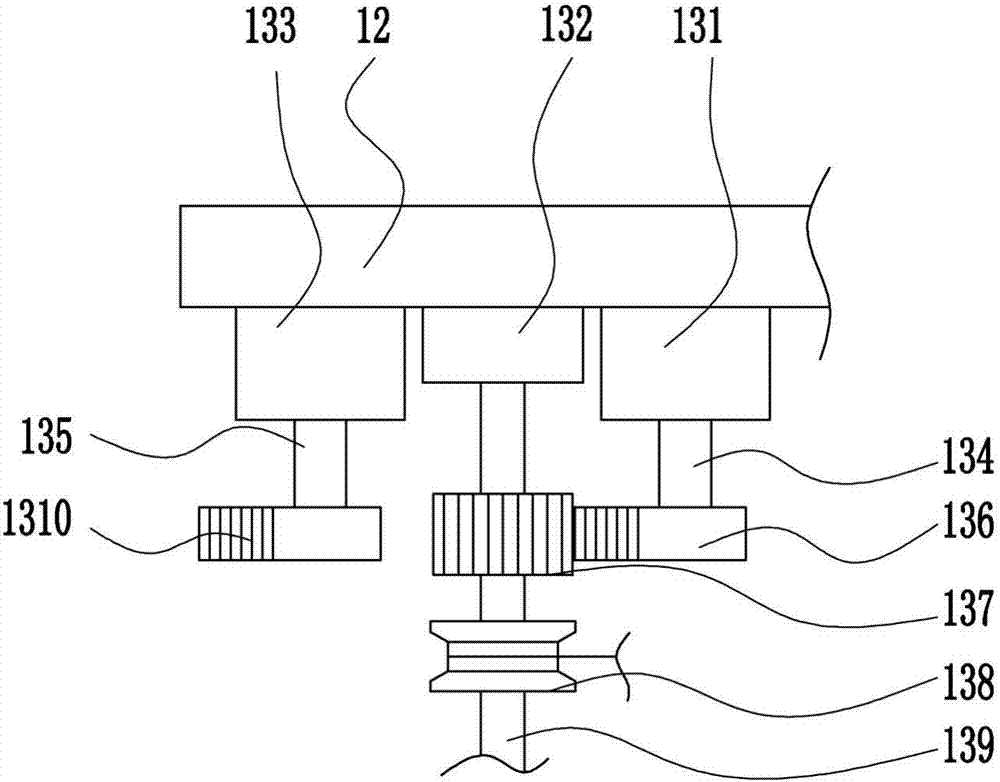

Wafer grinding equipment for electronic product manufacturing

InactiveCN106938436AEasy to operateImprove grinding efficiencyGrinding drivesLapping machinesEngineeringElectronics manufacturing

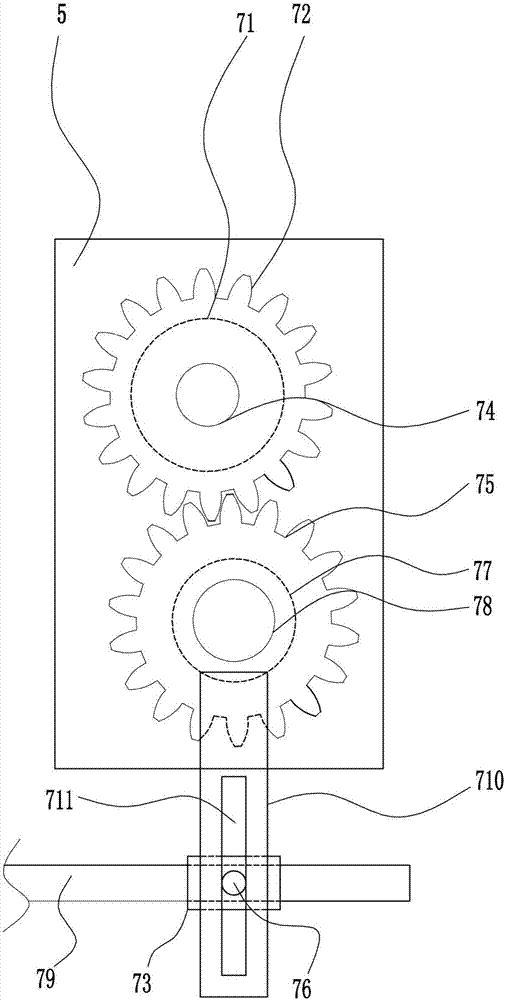

The invention relates to a grinding device, in particular to a wafer grinding device used in the manufacture of electronic products. The technical problem to be solved by the present invention is to provide a wafer grinding device for the manufacture of electronic products which is simple in operation, capable of simultaneously grinding wafers of different sizes, and high in grinding efficiency. In order to solve the above-mentioned technical problems, the present invention provides such a wafer grinding equipment used in the manufacture of electronic products, which includes a bottom plate, a left frame, a top plate, a grinding frame, a grinding sheet, an adjustment mechanism, etc.; The top of the left frame is connected with a top plate, the right side of the top of the bottom plate is equipped with a rotating mechanism, the rotating mechanism is connected with a grinding frame, the bottom of the grinding frame is connected with an adjustment mechanism, the middle of the bottom of the top plate is installed with a lifting mechanism, and the bottom of the lifting mechanism is connected with a grinding sheet. In the invention, different wafers can be placed in different adjustment mechanisms and then ground, thereby achieving the effects of simple operation and high grinding efficiency.

Owner:苍南博雅科技有限公司

Methods of Treating a Surface to Promote Binding of Molecule(s) of Interest, Coatings and Devices Formed Therefrom

InactiveUS20090056991A1Facilitate depositionEasy to attachVacuum evaporation coatingSputtering coatingEpoxyDevice form

The present invention generally relates to methods of treating a surface of a substrate, and to the use of the method and resulting films, coatings and devices formed therefrom in various applications including but not limited to electronics manufacturing, printed circuit board manufacturing, metal electroplating, the protection of surfaces against chemical attack, the manufacture of localized conductive coatings, the manufacture of chemical sensors, for example in the fields of chemistry and molecular biology, the manufacture of biomedical equipment, and the like. In another aspect, the present invention provides a printed circuit board, a printed circuit board, comprising: at least one metal layer; a layer of organic molecules attached to the at least one metal layer; and an epoxy layer atop said layer of organic molecules.

Owner:ATOTECH DEUT GMBH

Grinding machine for preparing conductive silver adhesive for electronic product manufacturing

InactiveCN106964422AAchieve grinding effectImprove grinding efficiencyGrain treatmentsAdhesiveEngineering

Owner:苍南博雅科技有限公司

Applicator liquid for use in electronic manufacturing processes

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid containing nanotubes for use in an electronics fabrication process includes a solvent containing a plurality of nanotubes. The nanotubes are at a concentration of greater than 1 mg / L. The nanotubes are pretreated to reduce the level of metallic and particulate impurities to a preselected level, and the preselected metal and particulate impurities levels are selected to be compatible with an electronics manufacturing process. The solvent also is selected for compatibility with an electronics manufacturing process.

Owner:ZEON CORP

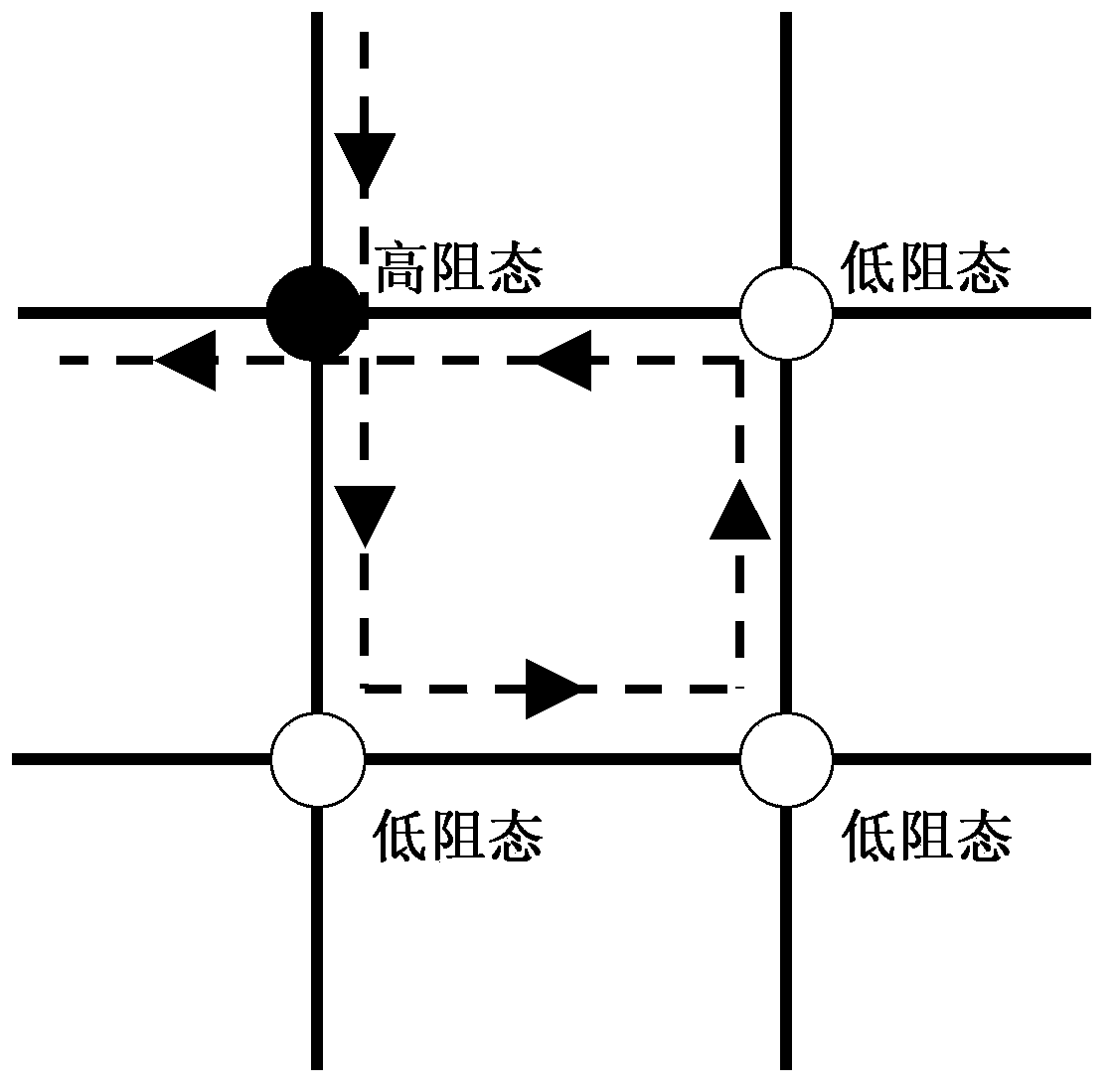

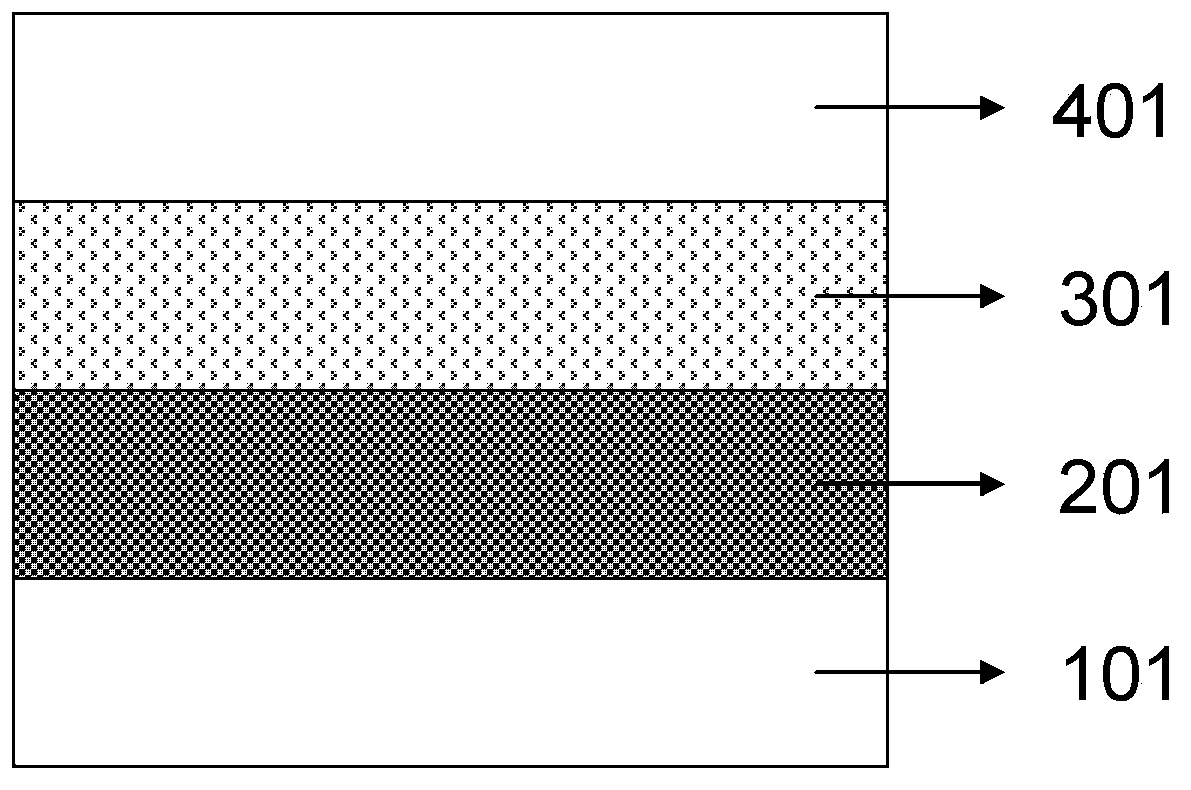

Resistive random access memory(RRAM) with self-rectification characteristic and preparation method thereof

ActiveCN103633242AAchieving self-rectification characteristicsImprove integration densityElectrical apparatusHigh densityAmorphous silicon

The invention discloses a resistive random access memory (RRAM) with self-rectification characteristic and a preparation method thereof, and belongs to the micro-electronics manufacturing and memory technical field. The RRAM with the self-rectification characteristic comprises an upper electrode, a lower electrode, a resistance change material layer and an amorphous silicon layer; the RRAM has ambipolar conversion characteristics, and presents positive and negative non-symmetrical rectification characteristics under low resistance state. The RRAM with self-rectification characteristic is used as a storage unit, so no gating transistor and diode are depended; self-rectification characteristic is employed to realize self selection function; the RRAM is simple in structure, easy to be integrated, high in density and low in cost, and can prevent read crosstalk phenomenon in an intersect array composition. The one time programmable memory based on the RRAM is integrated by employing the intersect array composition, preparation temperature is low, thereby realizing three dimensional stack composition with high density.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

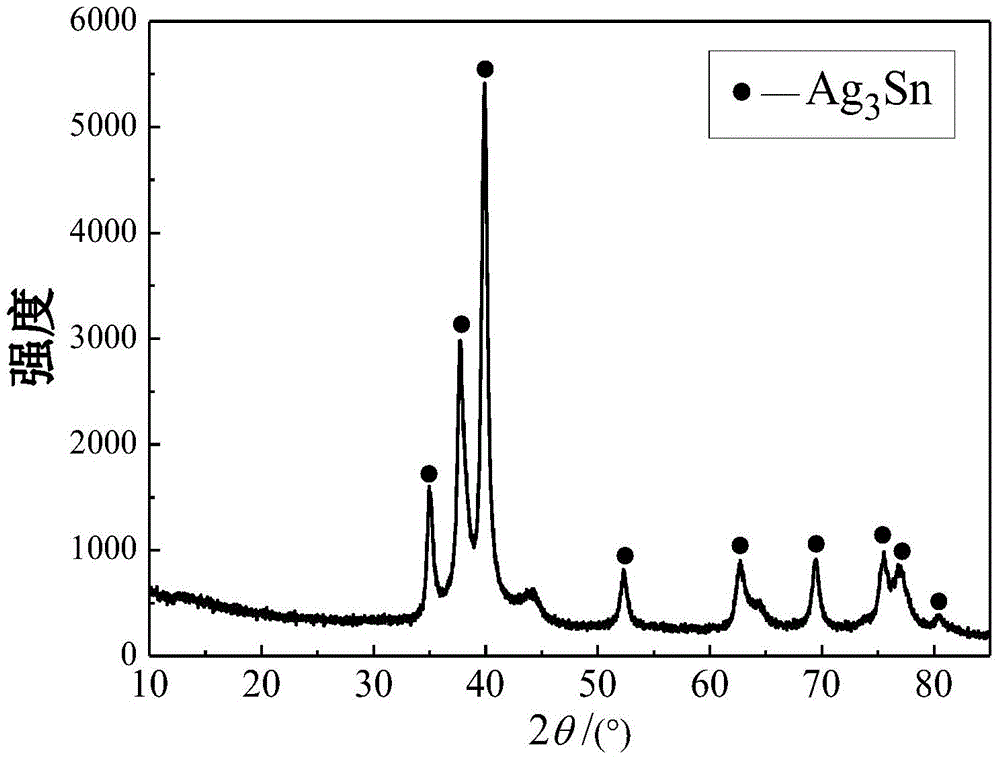

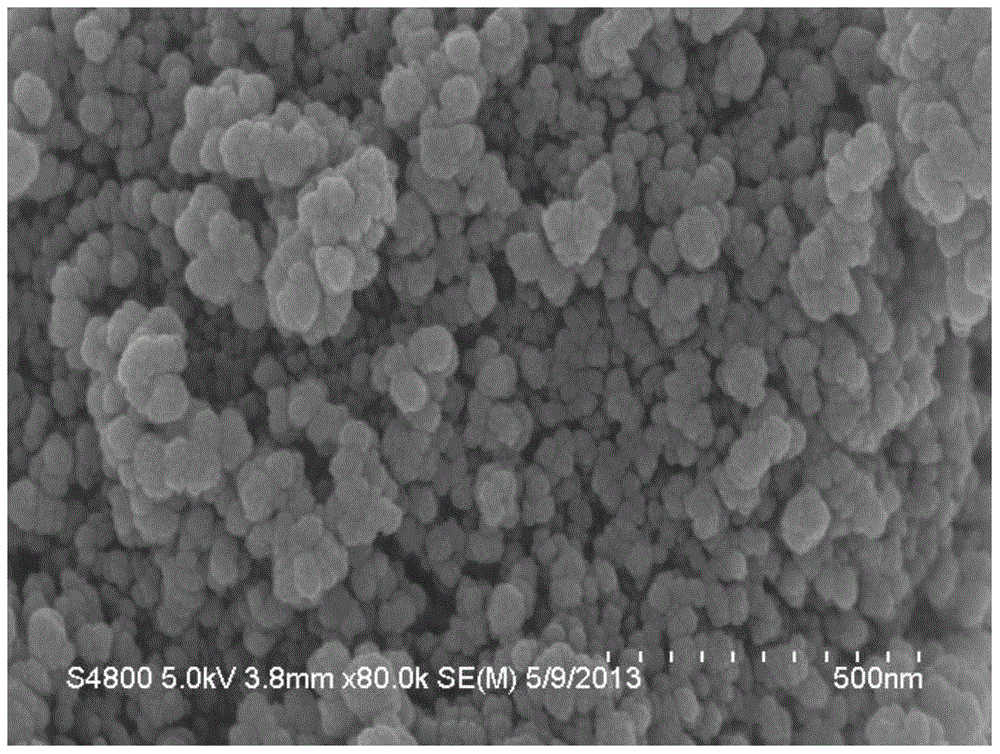

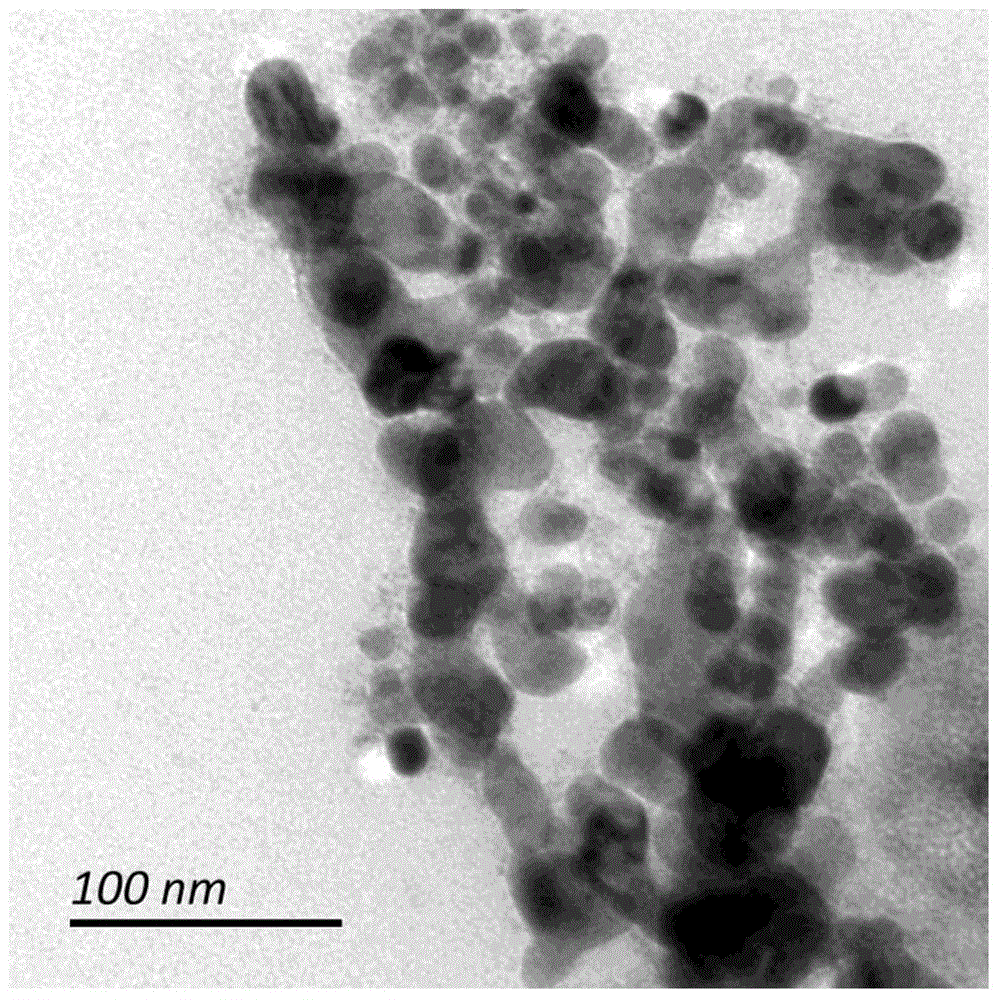

Nanometer Ag3Sn particle reinforced composite lead-free soldering paste and preparation method thereof

InactiveCN104014947AImprove mechanical propertiesLow melting pointWelding/cutting media/materialsSoldering mediaNanoparticleElectronics manufacturing

The invention discloses nanometer Ag3Sn particle reinforced composite lead-free soldering paste and a preparation method thereof, belonging to the technical field of welding materials for assembly of electronic devices. The nanometer Ag3Sn particle reinforced composite lead-free soldering paste is prepared from nanometer Ag3Sn particles and low-Ag lead-free soldering paste through long-time mechanical stirring, and the nanometer Ag3Sn particles are prepared by a chemical reduction method. The preparation method is simple and convenient to operate and has good repeatability. The composite lead-free soldering paste is superior to non-reinforced low-Ag lead-free soldering paste in the processing properties such as melting point, wettability and welding joint mechanical property, and can meet the technological requirements of low cost and high performance on soldering paste in the current electronics manufacturing industry to a great degree.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

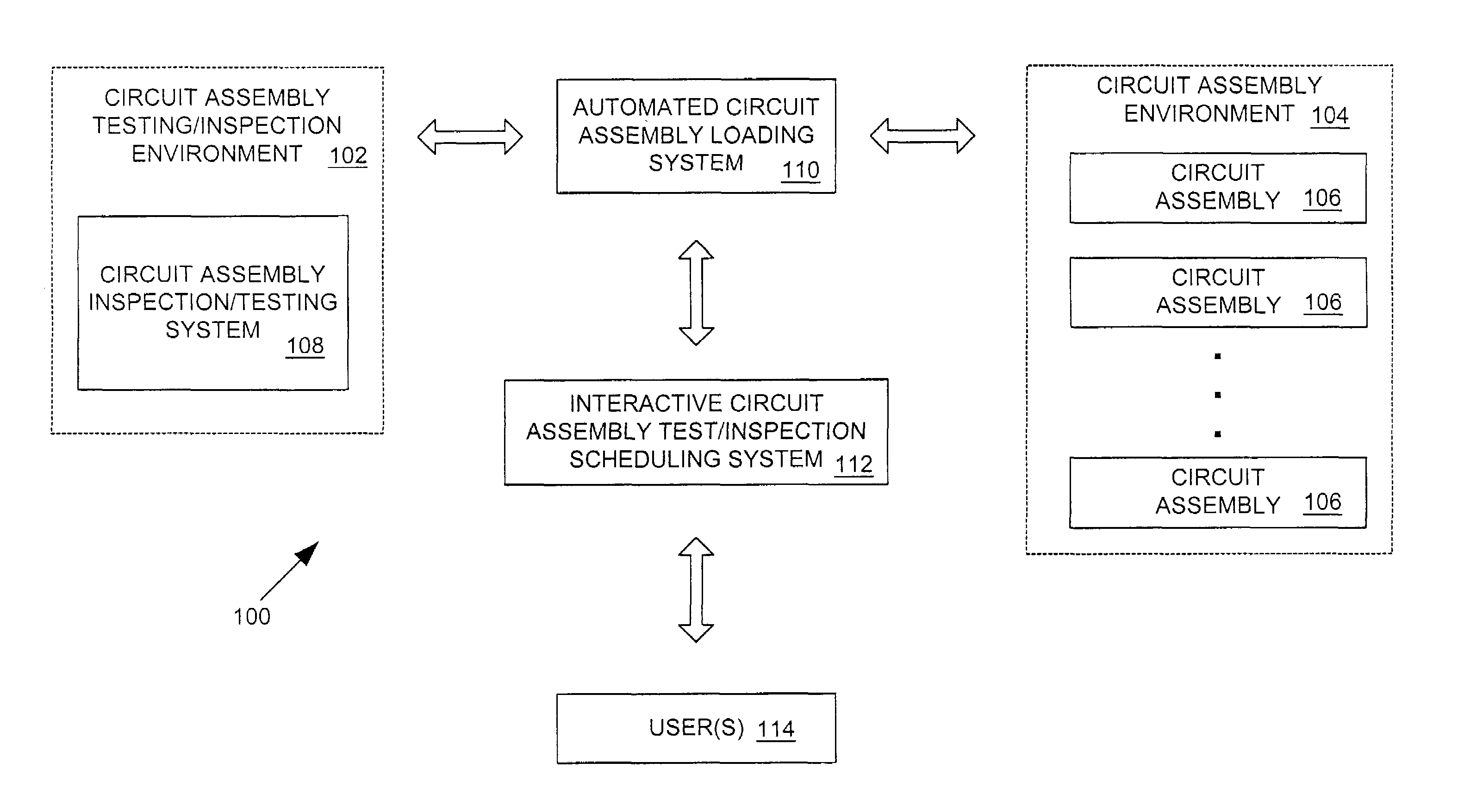

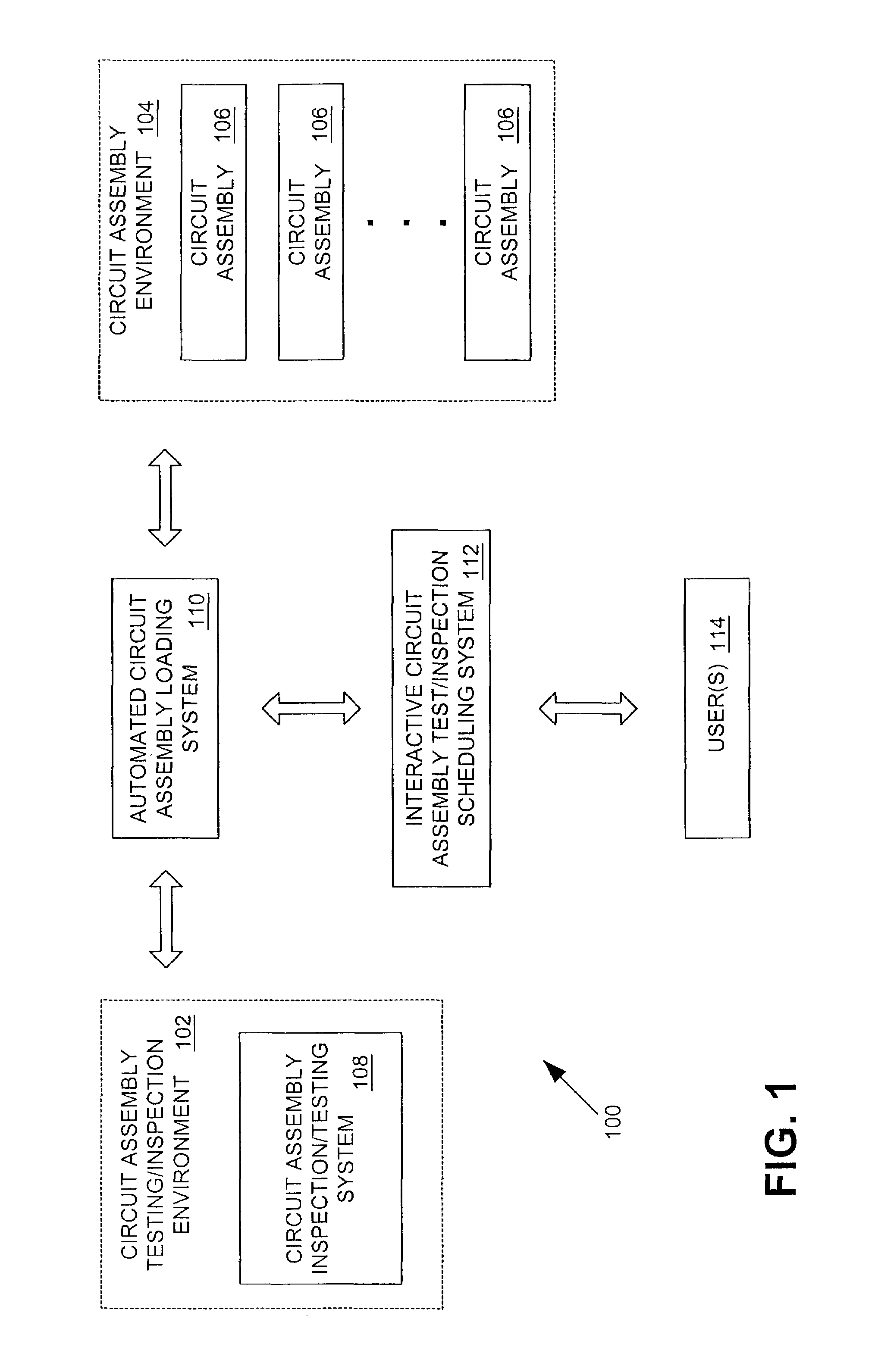

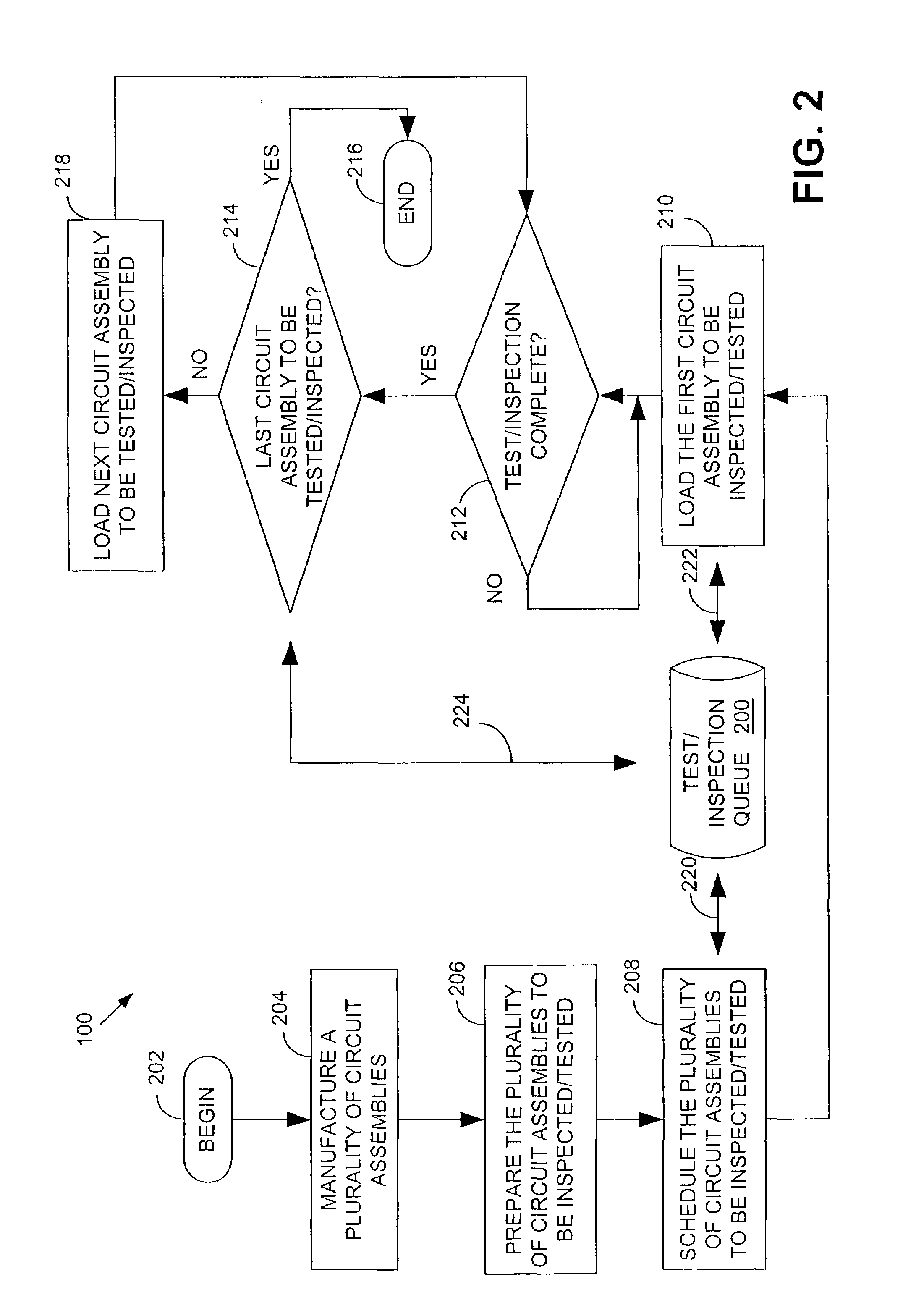

Interactive circuit assembly test/inspection scheduling

InactiveUS7007206B2Hardware monitoringMultiprogramming arrangementsComputer architectureData element

Systems and methods for scheduling circuit assemblies for inspection in an electronics manufacturing environment are provided. One embodiment comprises an interactive system for scheduling circuit assemblies for inspection. Briefly described, one such system comprises: a data structure residing in memory and comprising a plurality of data elements that define the order in which a plurality of circuit assemblies are scheduled to be inspected, each data element comprising a reference to one of the plurality of circuit assemblies; logic configured to control the manner in which the plurality of circuit assemblies are scheduled for inspection based on the data structure; and logic configured to enable a user to modify the data structure.

Owner:AGILENT TECH INC

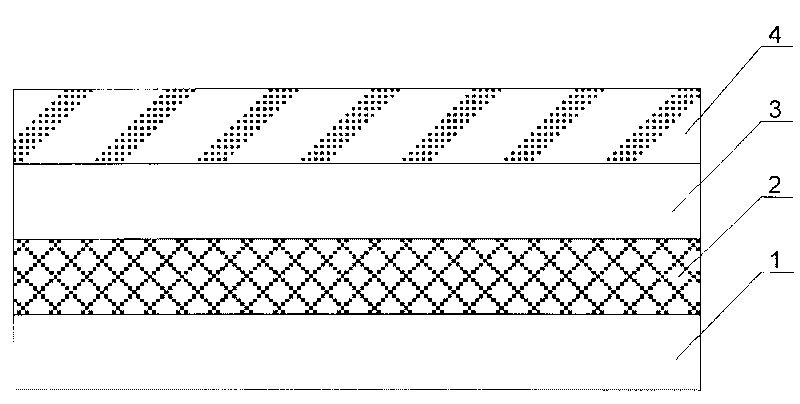

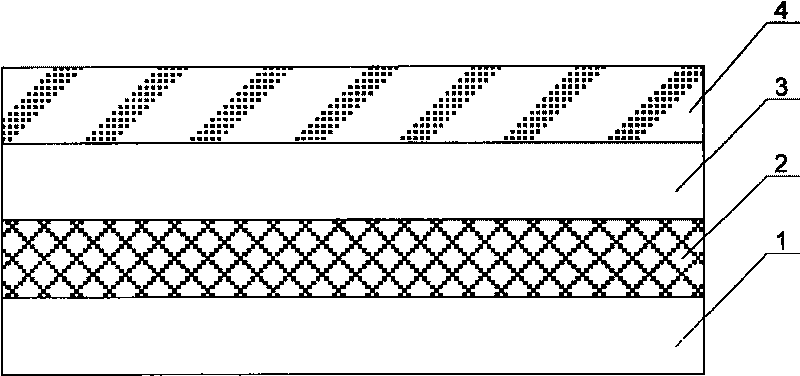

Ultra-high-temperature chemical-resisting label tape

The invention provides an ultra-high-temperature chemical-resisting label tape which has special chemical substances on the coating of a printing surface. The temperature-resisting coating composition of the label tape has very good adherence performance to the substrate, can resist heat and weather, and has good ink-absorbing performance when printed. The ultra-high-temperature chemical-resisting label tape is attached with a heat-resisting acrylic adhesive coating on the upper surface of a release paper layer; and a biaxial tensile polyimide film coating is attached on the upper surface of the heat-resisting acrylic adhesive coating, and a polyurethane and epoxy resin copolymer coating is attached on the upper surface of the biaxial tensile polyimide film coating. The tape has excellent extreme high temperature resistance and chemical resistance and welding resistance, can achieve non-scorching, non-brittle and non-cracking, be applicable to the object processing flow of all the high-temperature projects, can save materials and reduce pollution in the processing of workpieces, and can be widely applied to the electronics manufacturing filed.

Owner:东莞市富邦科技应用材料有限公司

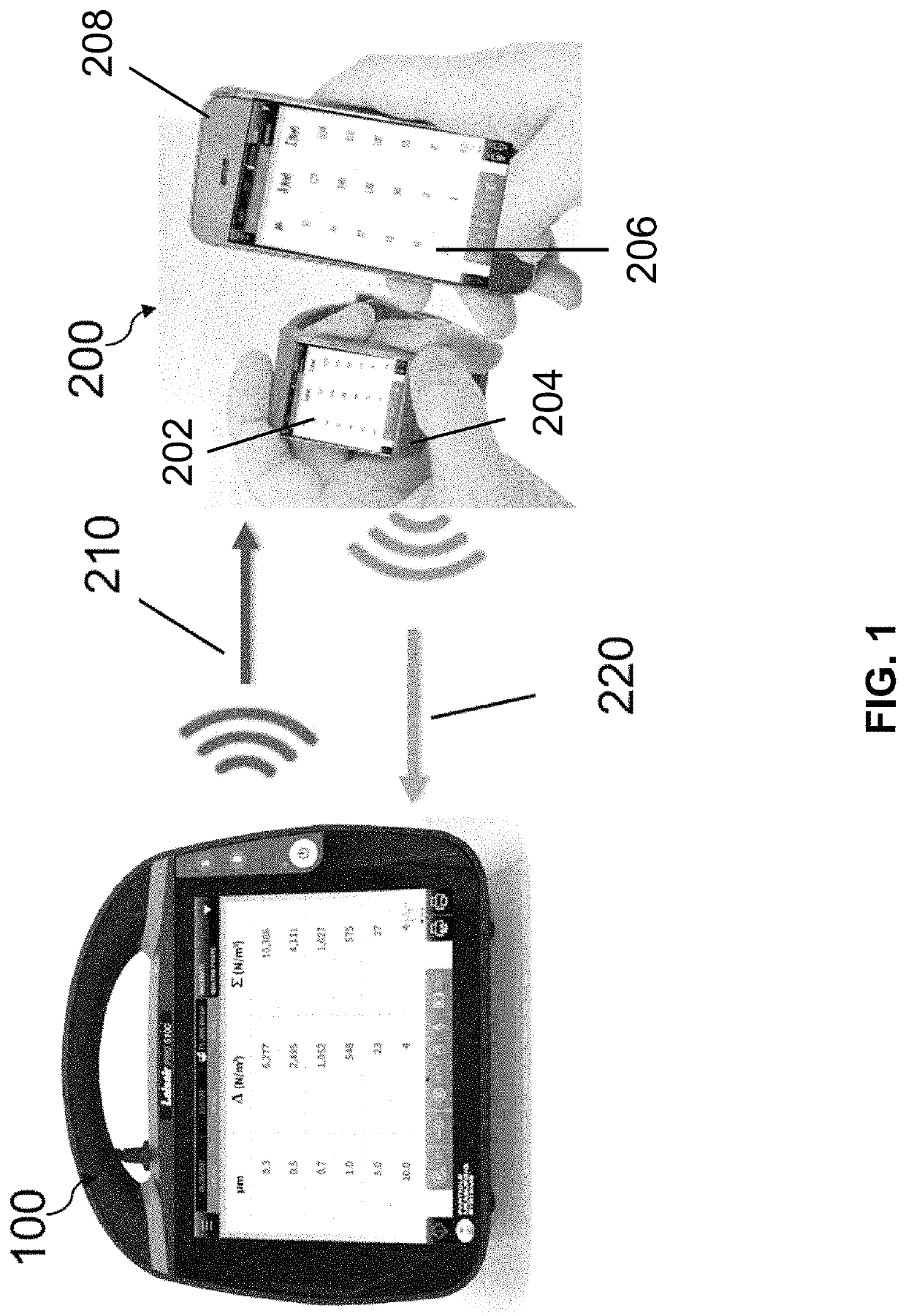

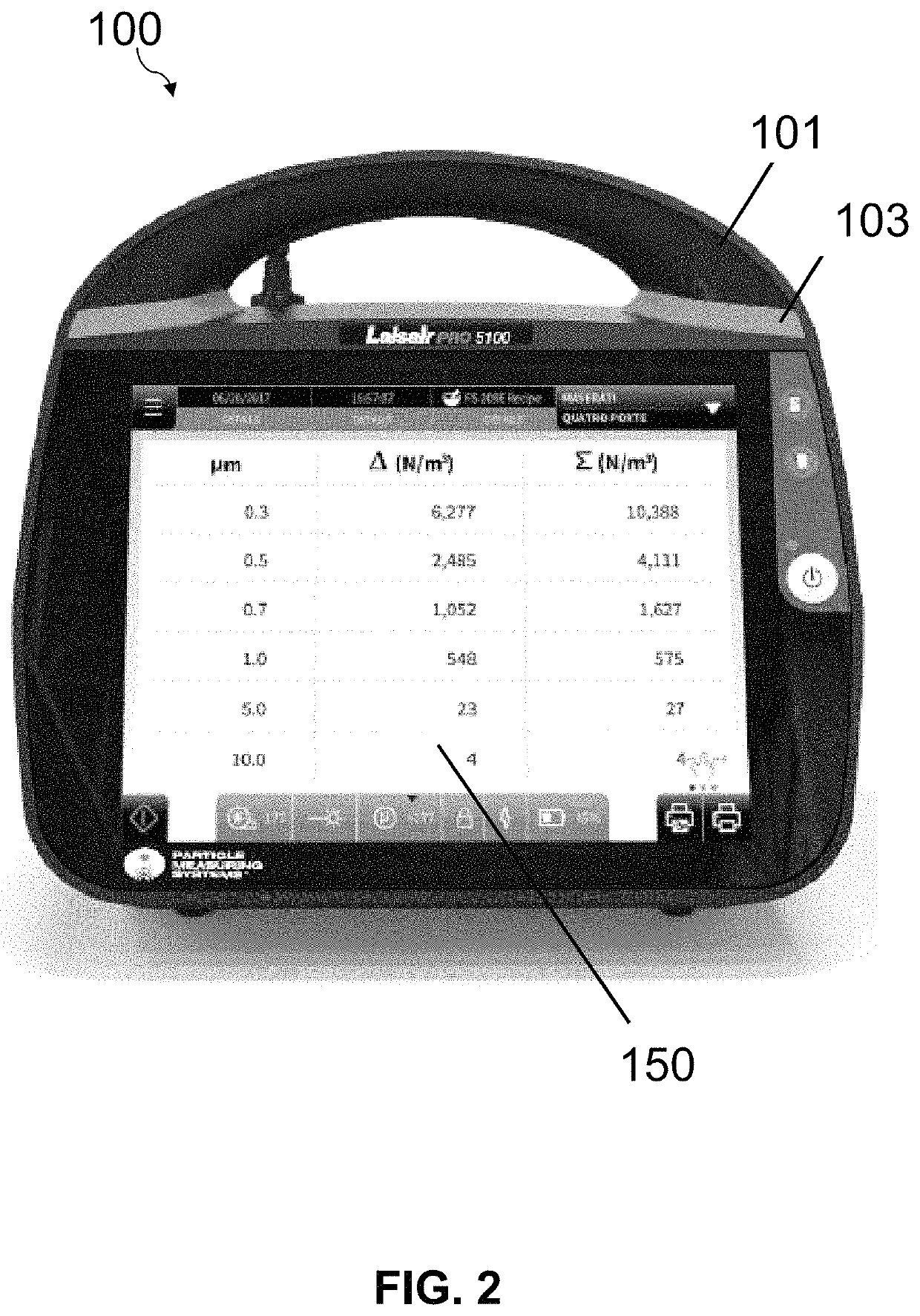

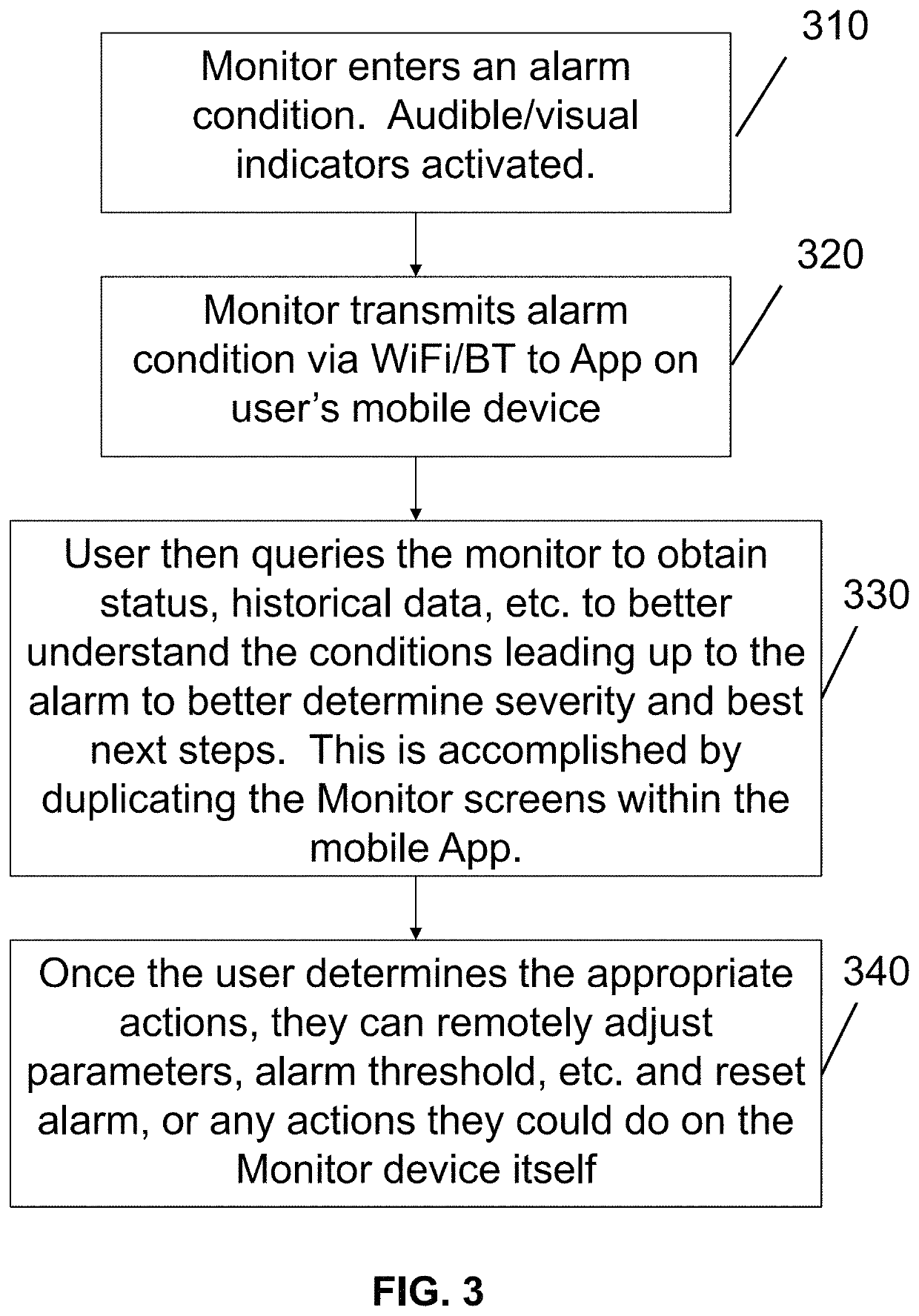

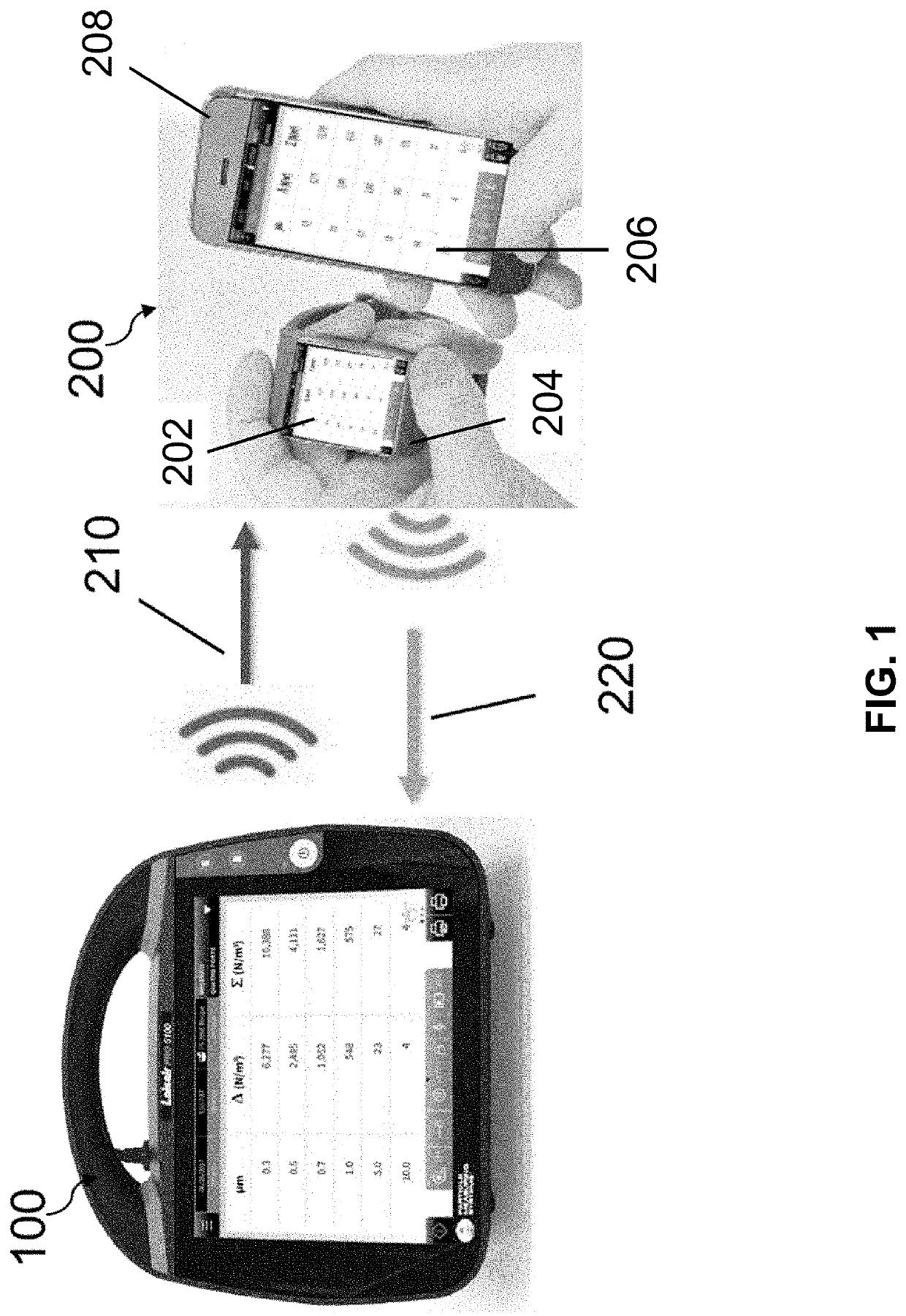

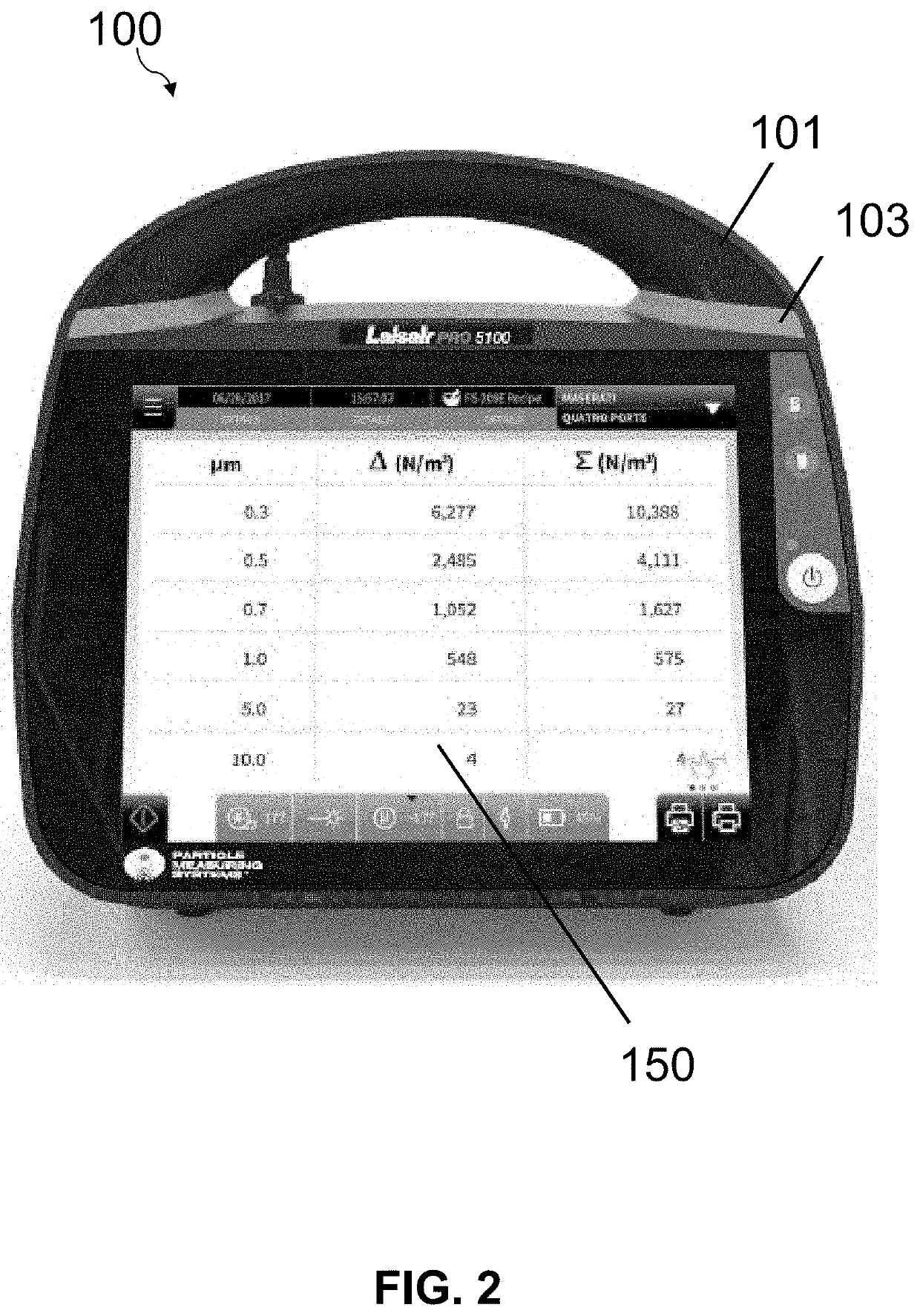

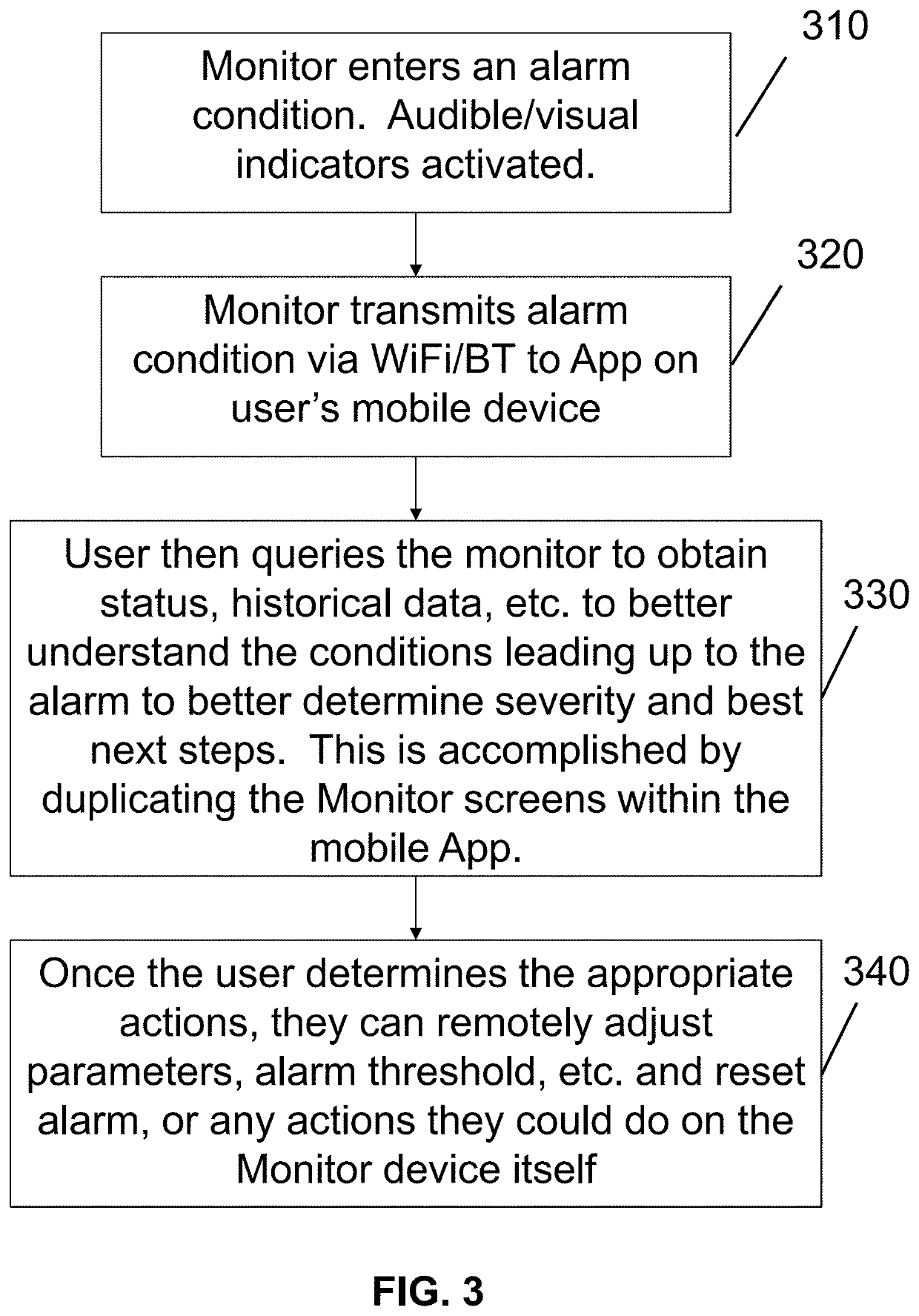

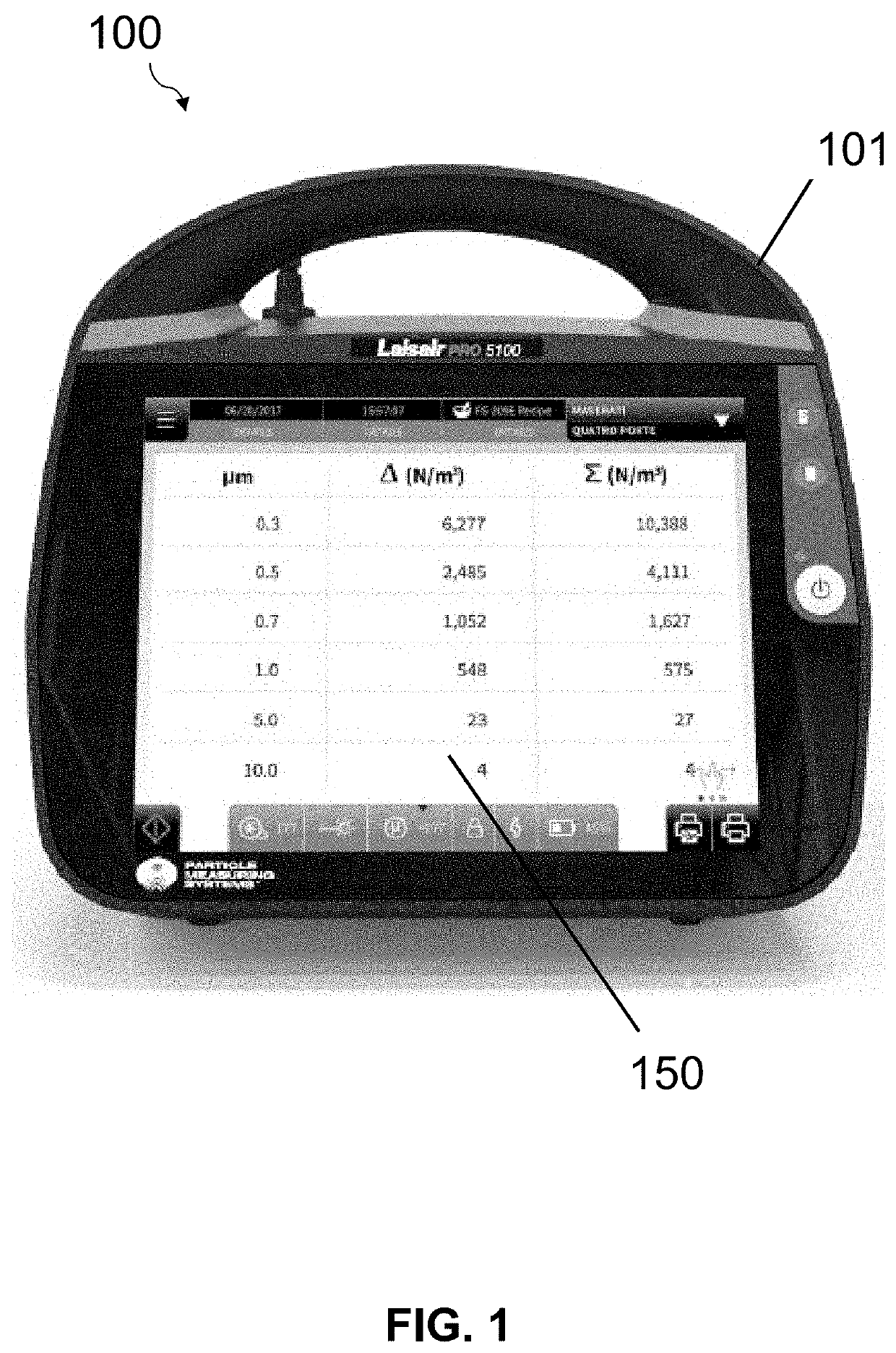

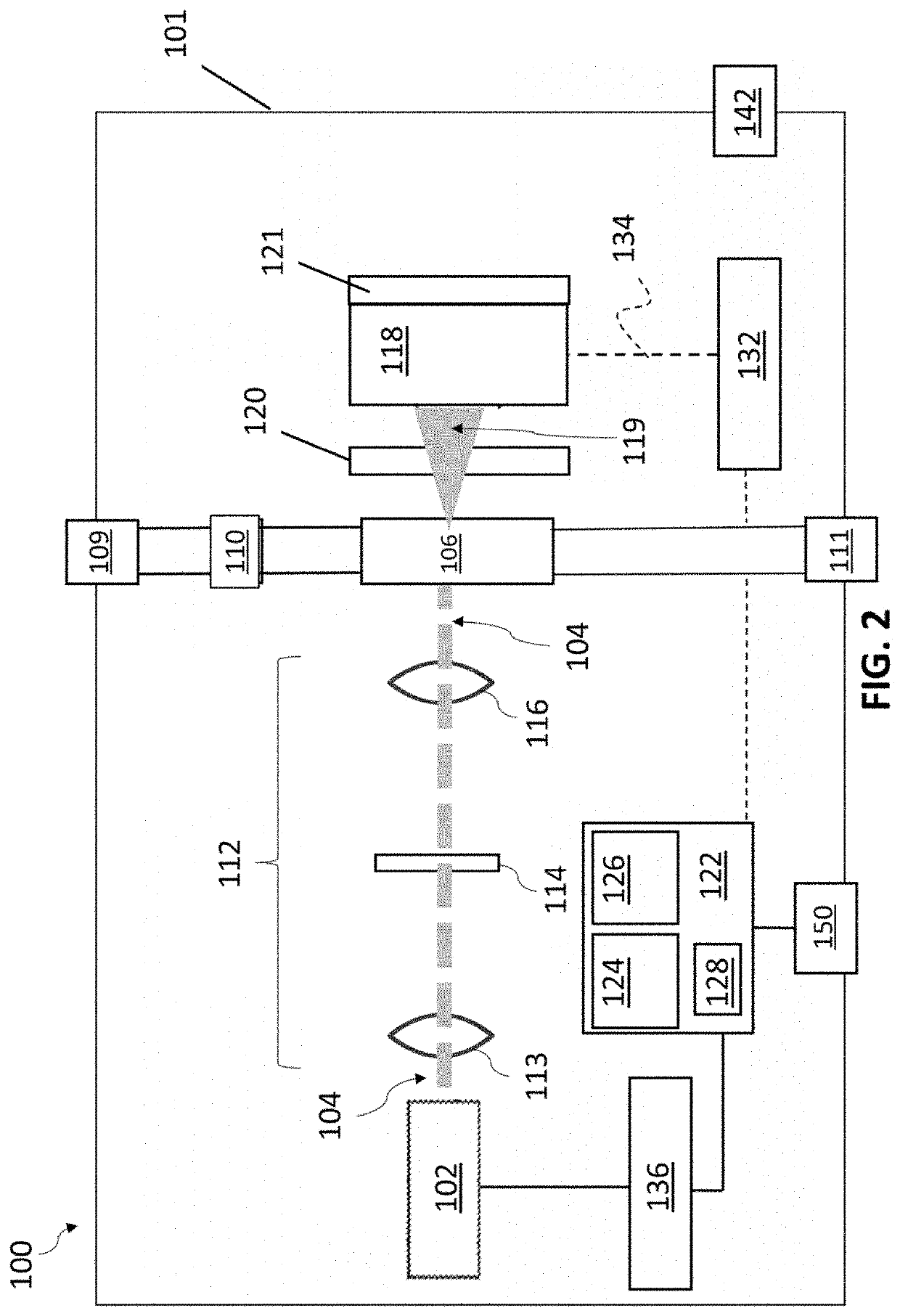

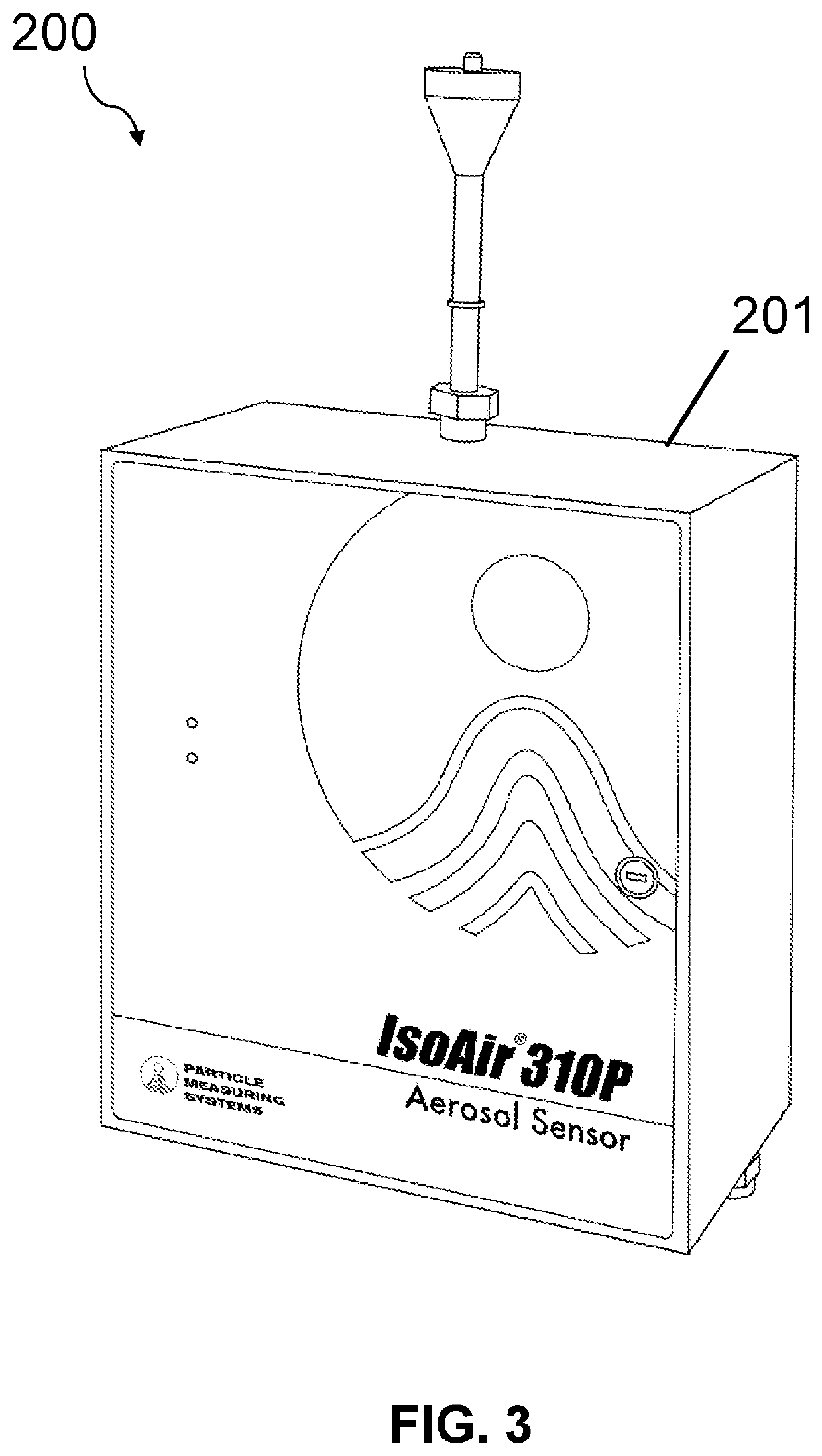

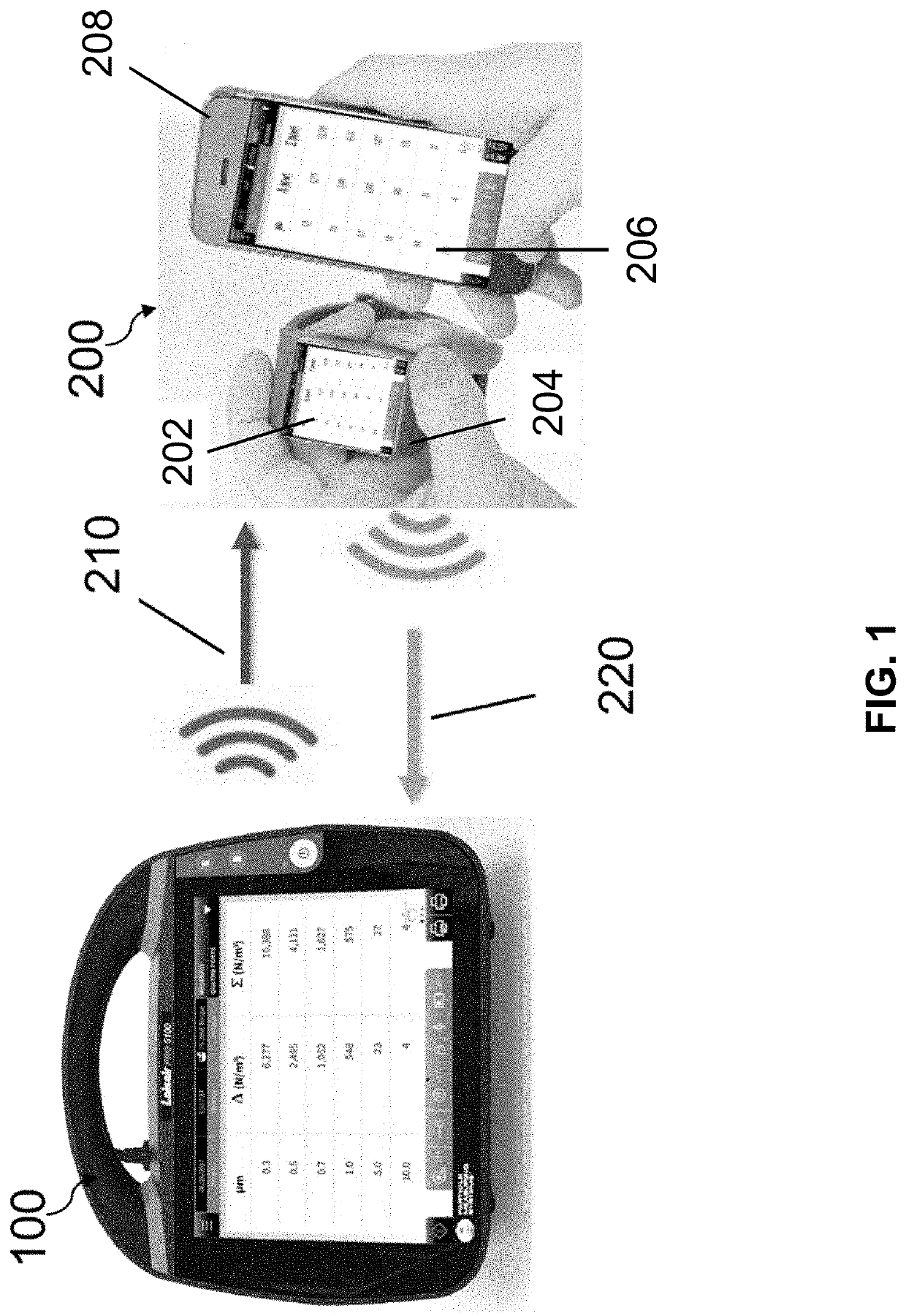

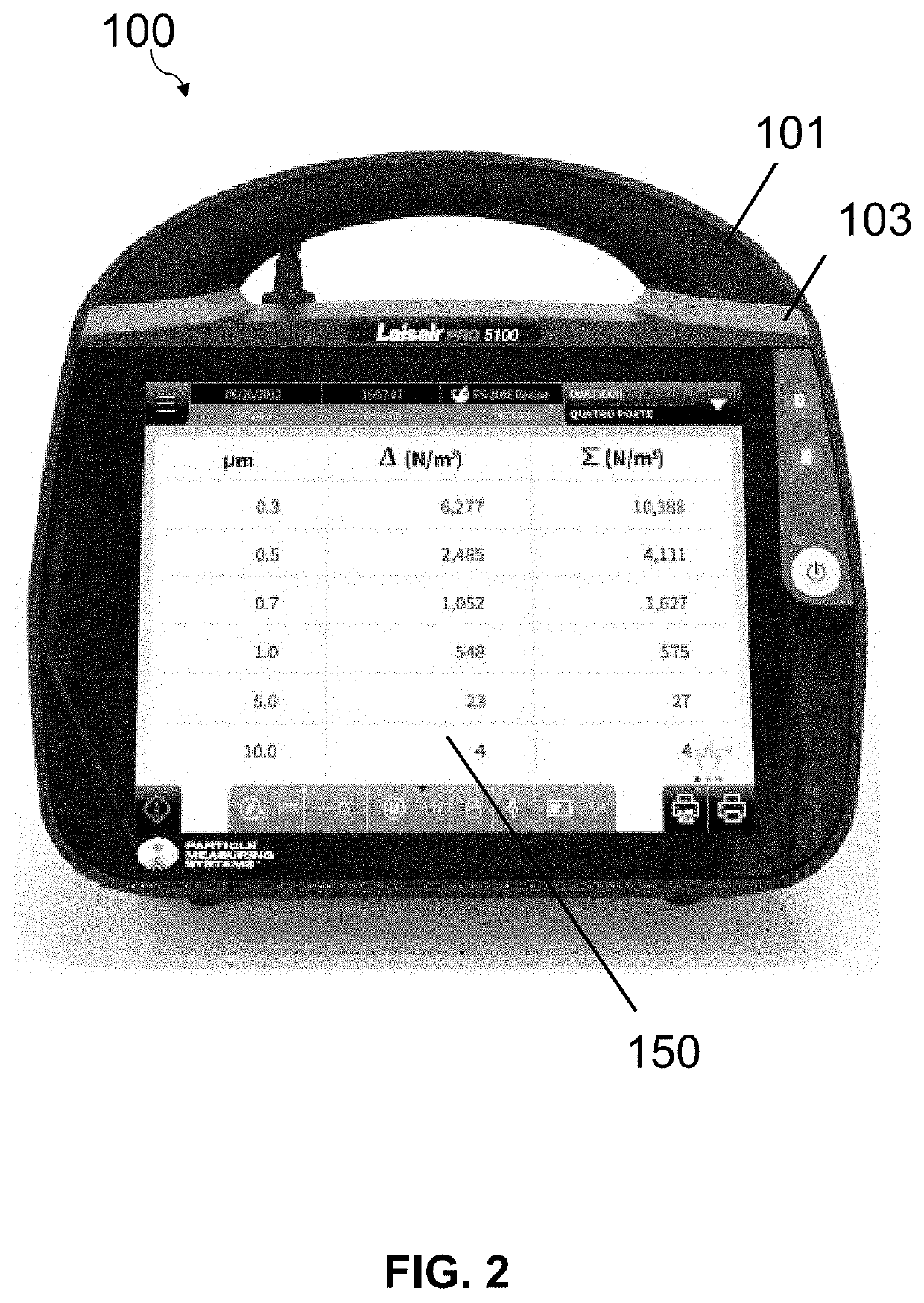

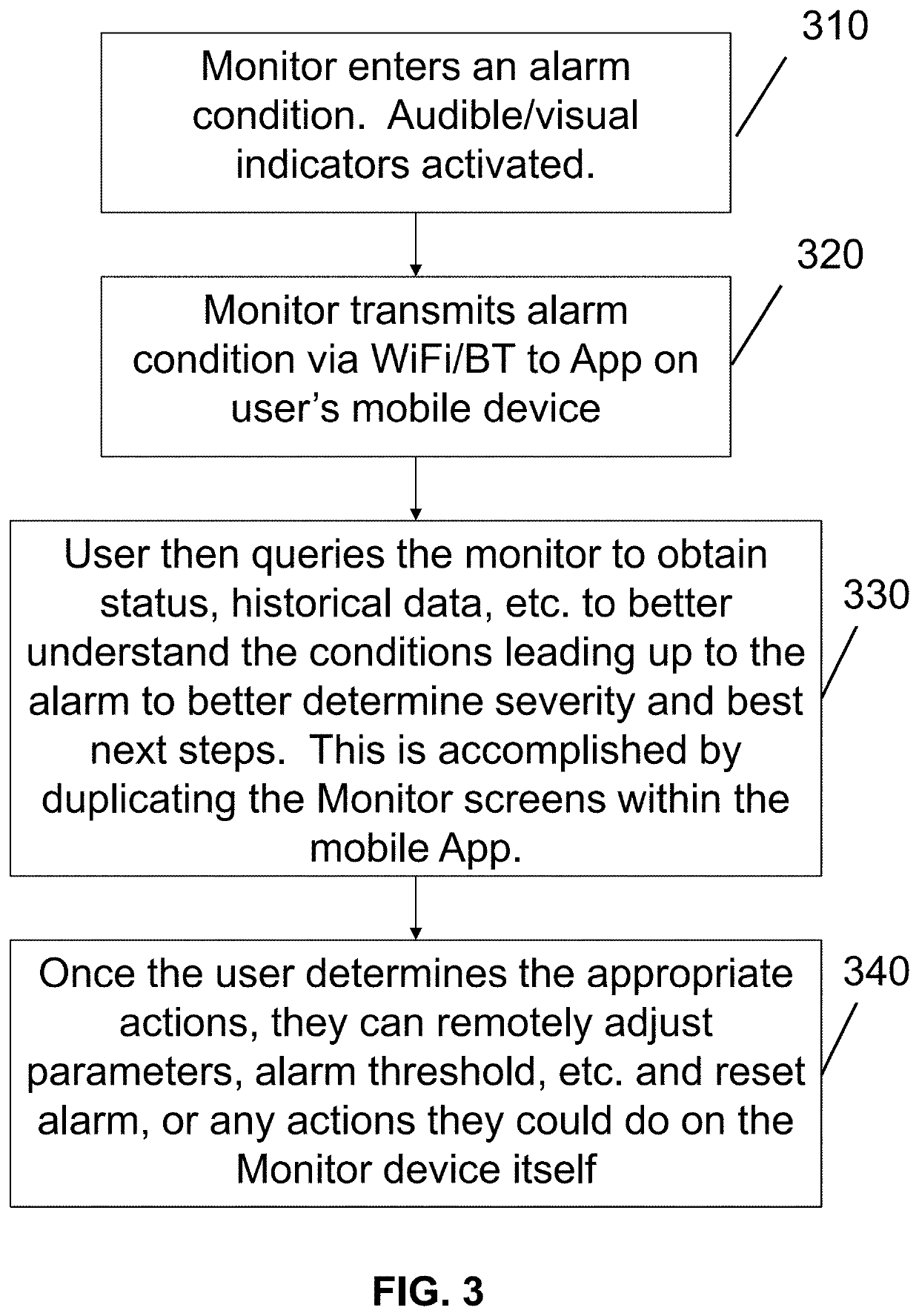

Particle detectors with remote alarm monitoring and control

ActiveUS10997845B2Withdrawing sample devicesSubstation equipmentDisplay deviceElectronics manufacturing

Owner:PARTICLE MEASURING SYST

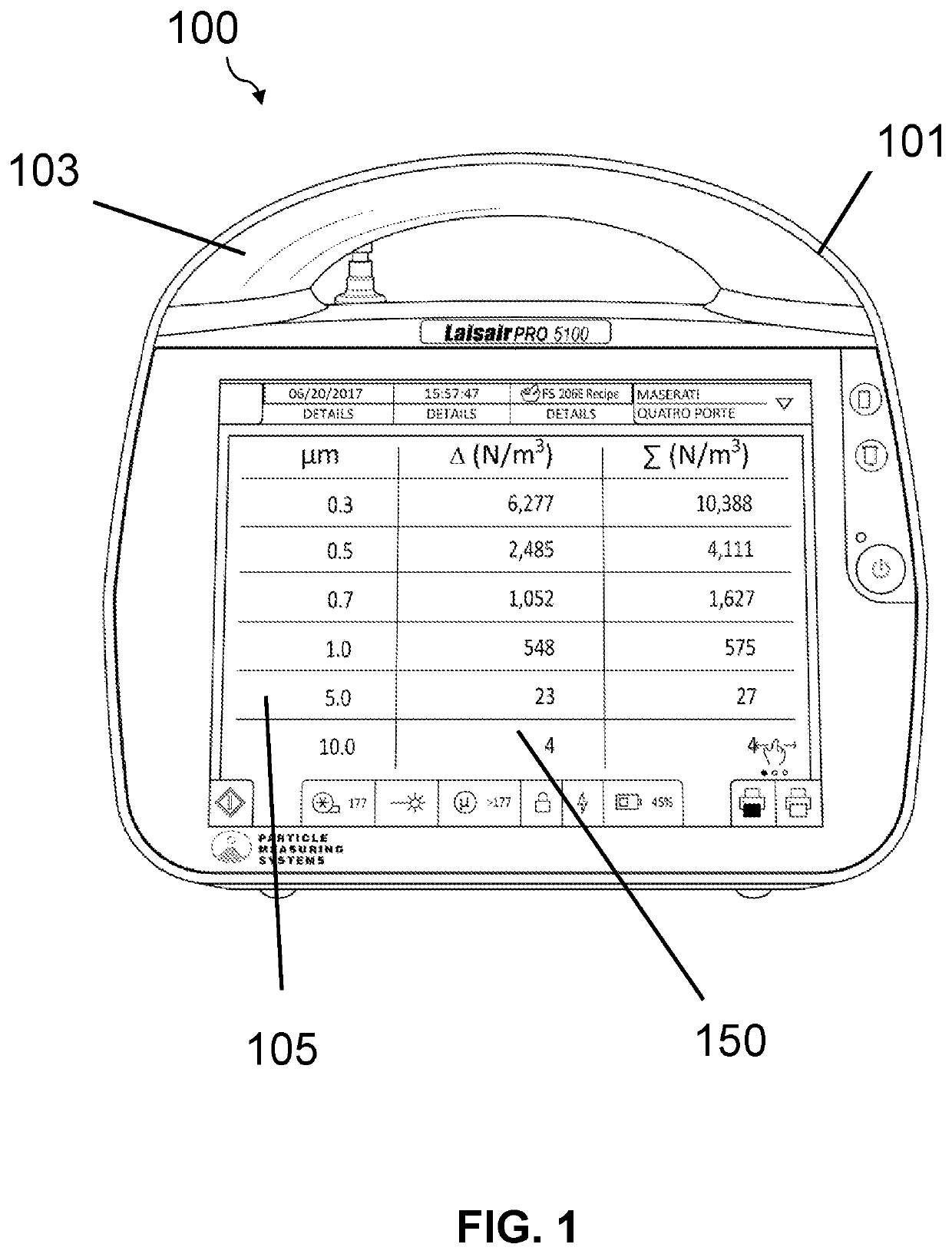

Particle detectors with remote alarm monitoring and control

ActiveUS20210295670A1Withdrawing sample devicesSubstation equipmentDisplay deviceElectronics manufacturing

The invention generally provides devices and methods for particle detection for minimizing human-caused contamination in manufacturing environments requiring low levels of microbes, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. Methods of the invention may incorporate wirelessly transmitting an alarm signal from a particle detector to a remote device, replicating a graphical user interface of the particle detector on an electronic display of the remote device, and passing one or more user instructions from the remote device to the particle detector via the replicate graphical interface of the remote device.

Owner:PARTICLE MEASURING SYST

Antimicrobial particle detectors

ActiveUS20210102884A1Minimize microbial growthGrowth inhibitionSamplingLiquid dispersion analysisBiotechnologyTouchscreen

The invention generally provides systems and methods for particle detection for minimizing microbial growth and cross-contamination in manufacturing environments requiring low levels of microbes, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. In some embodiments, systems of the invention incorporate a housing having an outer surface being a first antimicrobial surface and a touchscreen being a second antimicrobial surface. In some embodiments, substantially all of the outer surfaces of the system are antimicrobial surfaces. In some embodiments, the first antimicrobial surface may comprise an Active Screen Plasma alloyed layer. In some embodiments, the housing may comprise a molded polymer substrate and a metal coating layer bonded to the molded polymer substrate such that at least some exterior surfaces of the housing are metal coated surfaces.

Owner:PARTICLE MEASURING SYST

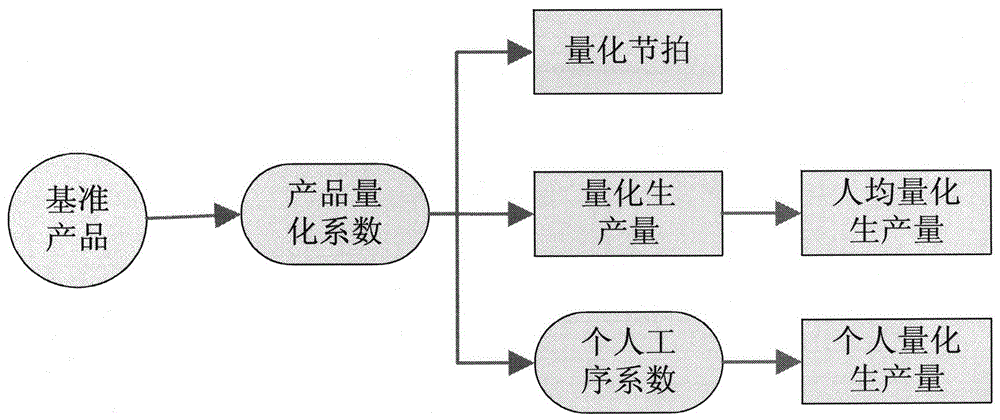

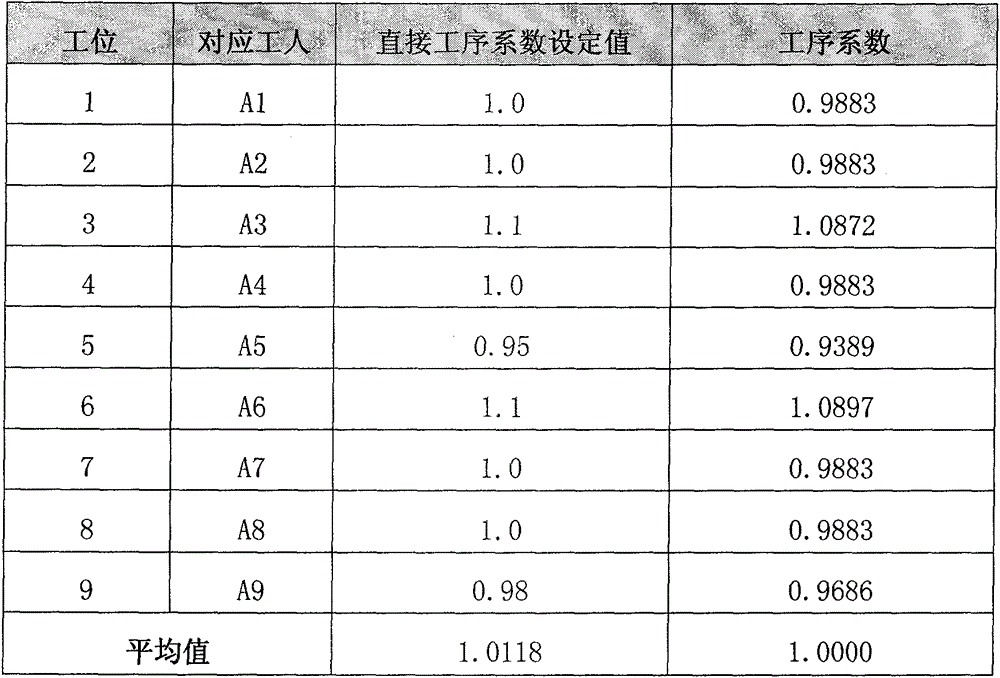

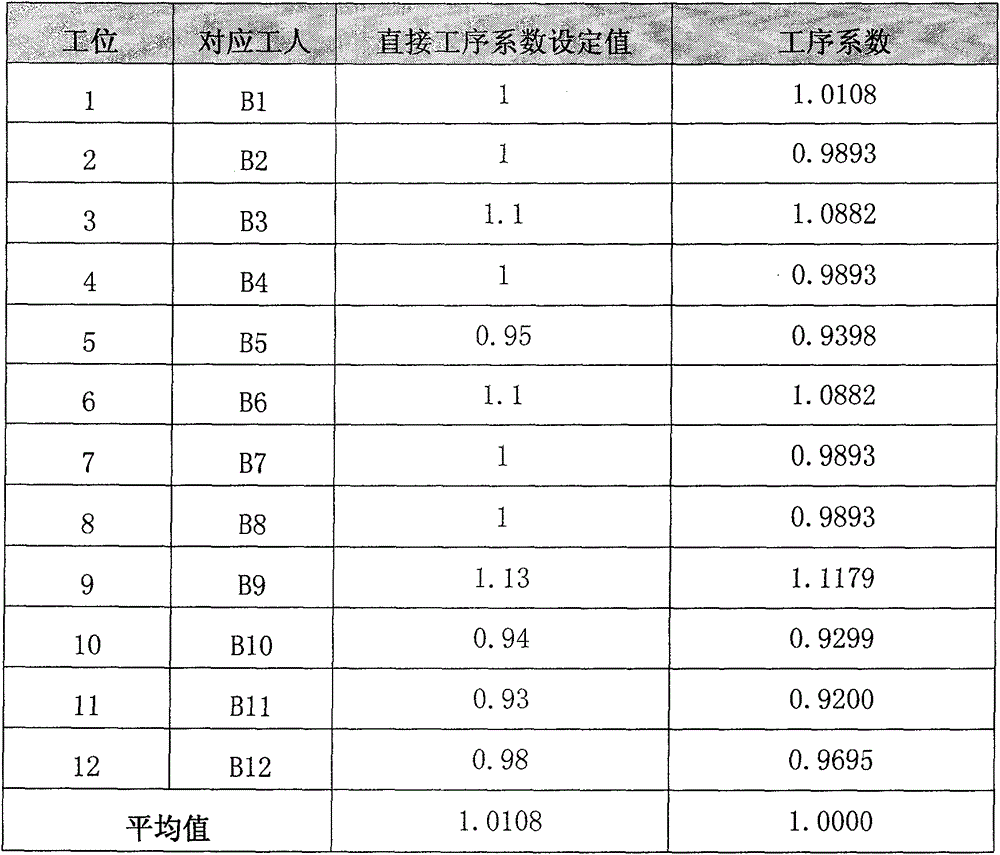

Method capable of quantitatively evaluating workloads of departments and individuals carrying out one-piece flow production in labor intensive industries

The invention discloses a method capable of quantitatively evaluating workloads of departments and individuals carrying out one-piece flow production in labor intensive industries, belonging to the field of industrial flow line production in the labor intensive industries such as clothing, shoemaking and electronics manufacturing. The method is characterized in that the workloads of the departments and the individuals carrying out the 'one-piece flow' production in the labor intensive industries can be quantitatively evaluated, and the working efficiency and the production output of each production line can be counted and compared in real time. The method has the beneficial effects that by virtue of 'individual quantitative throughput' provided in the method, the workload of each worker can be quantitatively evaluated in real time in a source tracing manner, so that the management pertinence of an enterprise is conveniently enhanced, the management level is improved, and the production efficiency is increased.

Owner:HANGZHOU MADE INTELLIGENT TECH

Cross-platform power grid intelligent program-controlled error-preventing system and operation method and interface communication way

InactiveCN102073305BRealize the whole process of paperlessSolve the problem of error prevention in the whole processTotal factory controlProgramme total factory controlCommunication interfaceSCADA

The invention discloses a cross-platform integrated power grid intelligent program-controlled error-preventing system. The system comprises an electronics manufacturing service (EMS) system and a systems applications and products in data processing (SAP) system, wherein the EMS system comprises subsystems, such as a supervisory control and data acquisition (SCADA) subsystem, an intelligent operation order generating subsystem and the like; the SAP system further comprises a 'two orders' management subsystem; the intelligent operation order generating subsystem generates an operation order andtransmits the generated operation order to the SAP system through a communication interface module; after reading the operation order generated by the EMS system to the SAP system, the 'two orders' management subsystem of the SAP system is associated with the corresponding examine and repair form, working order and the like generated by the SAP system, determines the latching relation according to a corresponding operation logic and only sequentially activates the current only correct operation.

Owner:ZHONGSHAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

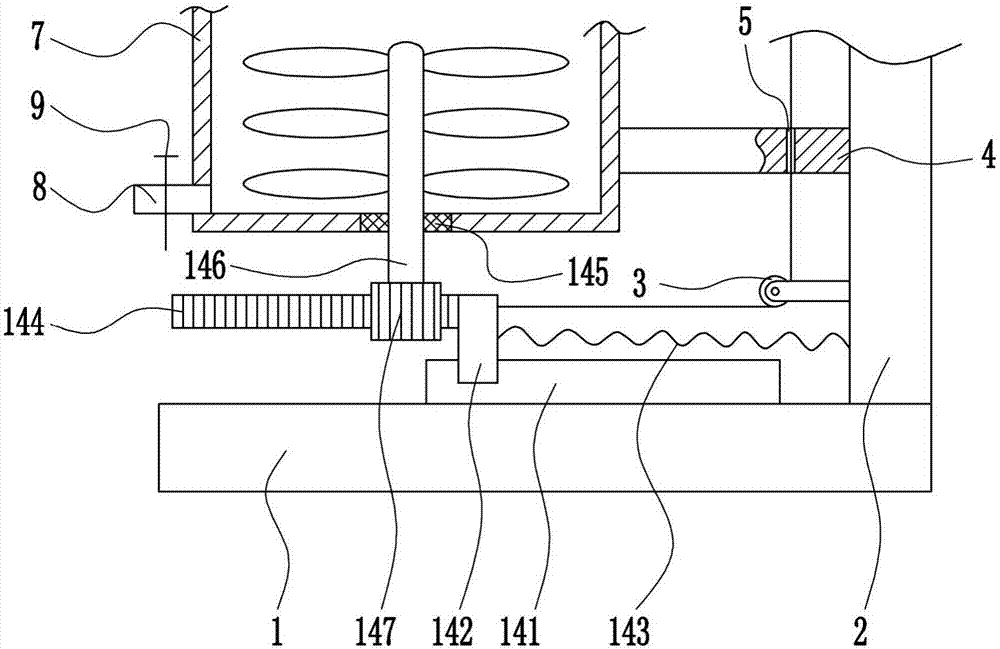

Raw material preparing equipment for manufacturing electronic product plastic housing

InactiveCN106965342AImprove the mixing effectEasy to operateManufacturing technologyPulp and paper industry

The invention belongs to the technical field of electronic product manufacturing, and in particular relates to a raw material preparation equipment used in the manufacture of plastic shells of electronic products. The technical problem to be solved by the present invention is to provide. In order to solve the above technical problems, the present invention provides such a raw material preparation equipment for the manufacture of plastic shells of electronic products, which includes a bottom plate, a right frame, a first fixed pulley, a support rod, a stirring blade, a stirring frame, a discharge pipe, Valves, the second fixed pulley, pull wires, top plate, etc.; the right frame on the top right of the bottom plate, and the support rods are arranged symmetrically up and down in the middle of the left side of the right frame, and there are through holes on the support rods. A discharge pipe is provided at the bottom of the left wall of the frame, a valve is provided on the discharge pipe, and a first fixed pulley is provided at the lower left side of the right frame. The invention drives the stirring blades on the driving mechanism to rotate by controlling the driving mechanism to stir the raw materials, and at the same time drives the stirring blades on the linkage mechanism to rotate.

Owner:湖州雷暴电子科技有限公司

Antimicrobial particle detectors

ActiveUS11215546B2Minimize microbial growthGrowth inhibitionSamplingLiquid dispersion analysisBiotechnologyBio products

The invention generally provides systems and methods for particle detection for minimizing microbial growth and cross-contamination in manufacturing environments requiring low levels of microbes, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. In some embodiments, systems of the invention incorporate a housing having an outer surface being a first antimicrobial surface and a touchscreen being a second antimicrobial surface. In some embodiments, substantially all of the outer surfaces of the system are antimicrobial surfaces. In some embodiments, the first antimicrobial surface may comprise an Active Screen Plasma alloyed layer. In some embodiments, the housing may comprise a molded polymer substrate and a metal coating layer bonded to the molded polymer substrate such that at least some exterior surfaces of the housing are metal coated surfaces.

Owner:PARTICLE MEASURING SYST

Particle detectors with remote alarm monitoring and control

ActiveUS20210104146A1Used in environmentOperation and useWithdrawing sample devicesSubstation equipmentDisplay deviceElectronics manufacturing

The invention generally provides devices and methods for particle detection for minimizing human-caused contamination in manufacturing environments requiring low levels of microbes, such as cleanroom environments for electronics manufacturing and aseptic environments for manufacturing pharmaceutical and biological products, such as sterile medicinal products. Methods of the invention may incorporate wirelessly transmitting an alarm signal from a particle detector to a remote device, replicating a graphical user interface of the particle detector on an electronic display of the remote device, and passing one or more user instructions from the remote device to the particle detector via the replicate graphical interface of the remote device.

Owner:PARTICLE MEASURING SYST

Metal-Safe Solid Form Aqueous-Based Compositions and Methods To Remove Polymeric Materials in Electronics Manufacturing

ActiveUS20150232792A1Excellent bath lifeReduce complexityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSufficient timeFlat panel display

Compositions and methods useful for the removal of organic substances from substrates, for example, electronic device substrates, are provided. A method is presented which uses a minimum amount of solid form concentrate that is diluted into water, introduced into a manufacturing tool and heated, applied to said substrate for a sufficient time to allow penetration and removal of an organic substance, and immediately rinsed with water to achieve complete removal. These compositions and methods are particularly suitable for removing and completely dissolving photoresists of the positive variety most commonly used in the manufacture of a flat panel display (FPD) and other electronic substrates.

Owner:MOORE JOHN

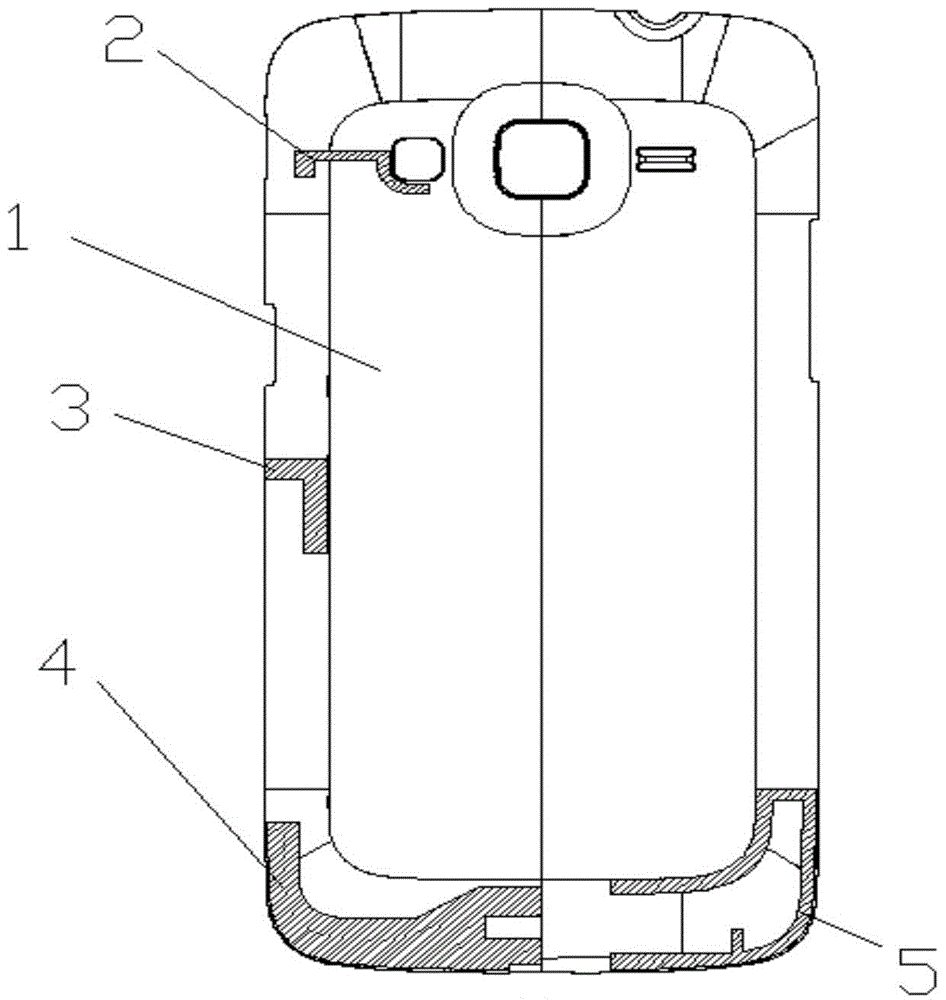

Manufacturing method of electronic product case

ActiveCN103702529BSimilar or consistent flatnessAvoid problems that affect appearanceElectrical apparatus casings/cabinets/drawersManufacturing cost reductionElectronics manufacturing

The invention discloses a method for manufacturing a shell of an electronic product. The method comprises the following steps of A, generating of 3D (Three-Dimensional) drawing file design of an injection mold: reserving an antenna groove by the injection mold when a mold opening 3D drawing file design is generated; B, injection mold processing: carrying out shape processing on the antenna groove when a mold core is processed so as to ensure the integrated forming of an antenna and the shell of the product when the antenna is subsequently processed, and enabling the shell of the product not to be subjected to poor appearance when surface processing is carried out; C, injection molding machine molding: completing the injection molding of the product by utilizing the injection mold, which is already designed and processed in a mold, of the antenna groove; D, mobile phone antenna processing: directly processing a mobile phone antenna in the antenna groove on the surface or the inner wall of a mobile phone plastic piece; E, mobile phone surface processing and coating. According to the method disclosed by the invention, the bottlenecks of a surface decoration technology that the surface of the product is rugged when the mobile phone antenna is assembled or printed on the surface of the product, and the surface of the product needs to be sanded when the mobile phone antenna is produced can be broken through, highly-textured appearance on the surface of the product can be generated, the manufacturing cost can be reduced, and the yield of the product can be increased.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

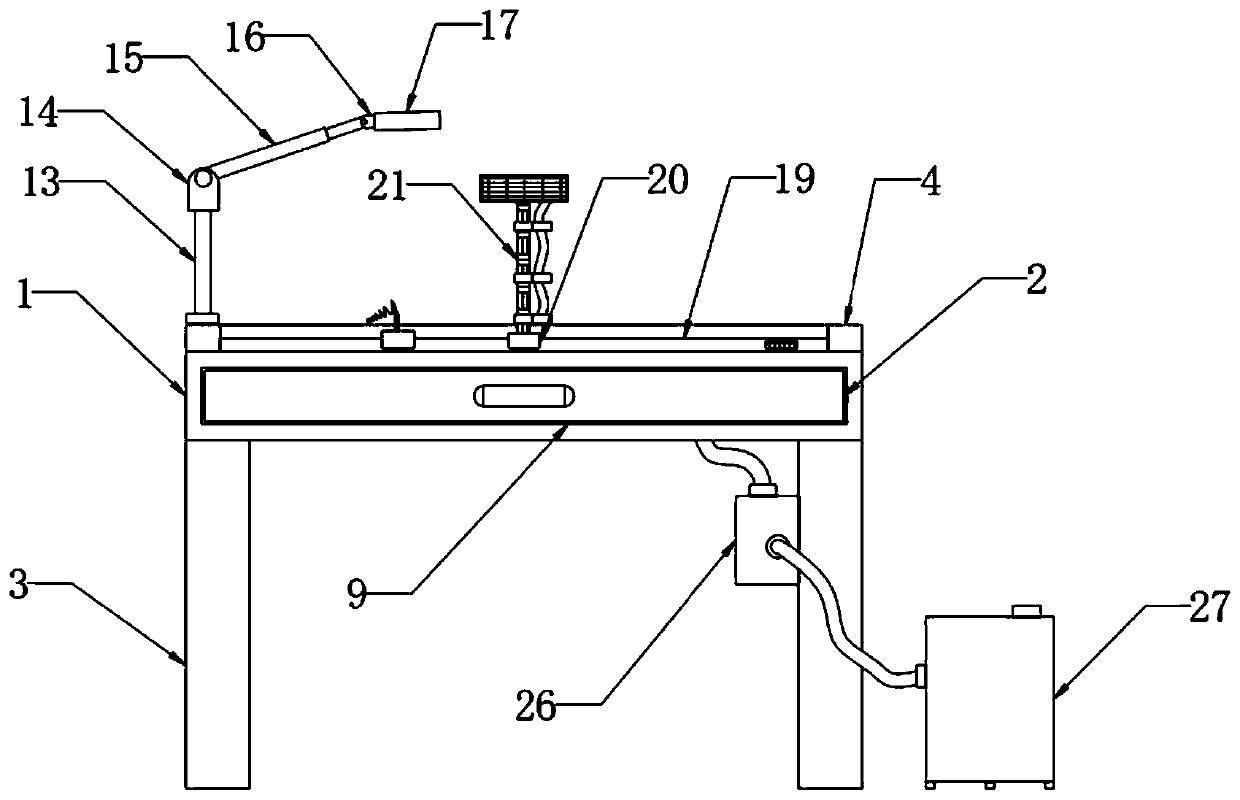

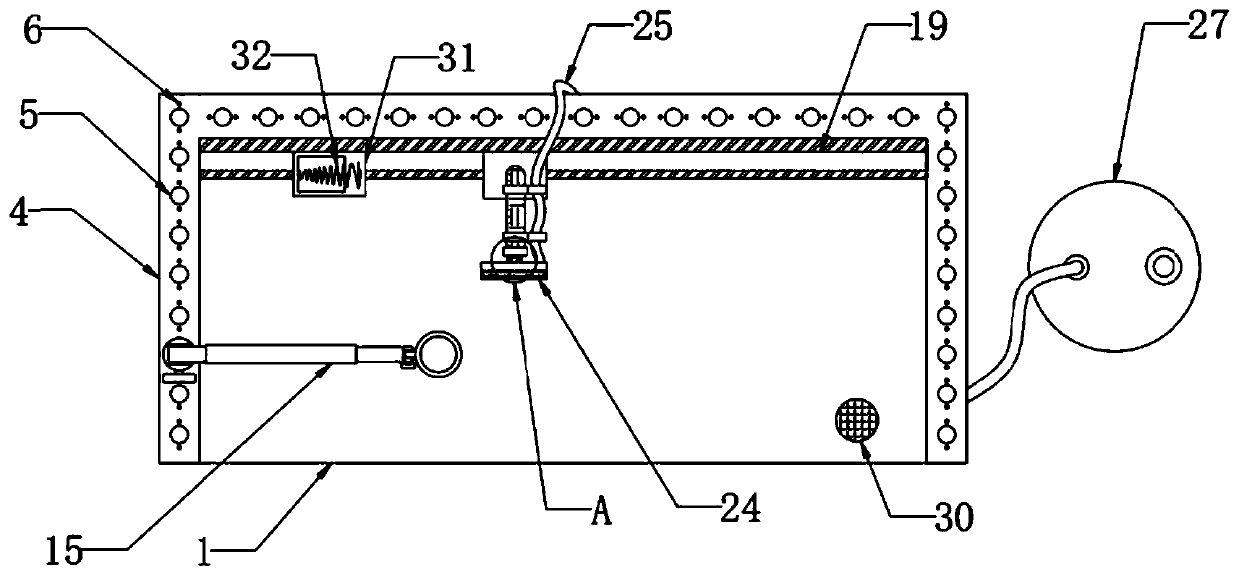

Welding fixture for electronics manufacturing and operating method thereof

PendingCN111390445AEasy to store and placeConvenient Powered LightingLighting elementsDispersed particle separationAir pumpEngineering

The invention discloses a welding fixture for electronics manufacturing and an operating method thereof. Welding work involves an operating floor, a filter box, an air pump and a stabilizing base. Evenly-distributed supporting legs are fixedly installed on the lower surface of the operating floor. A lamp holder table is fixedly installed on the upper surface of the operating floor and further arranged close to the side face of the operating floor. Evenly-distributed lamp holder fixing holes and power supply holes are formed in the surface of the top end of the lamp holder table. According to the welding fixture for electronics manufacturing in the invention, the welding fabrication position can be amplified and illuminated, and the illumination and amplification position can be adjusted within a large range; and meanwhile, power supply illumination can be achieved conveniently by adoption of illuminating lamp beads, welding smokes can be dissolved and filtered conveniently, the good health of users is protected and the welding fixture for electronics manufacturing is suitable for popularization.

Owner:NANJING COLLEGE OF INFORMATION TECH

High temperature oxidation equipment

ActiveCN103280418BGuaranteed uniformityGuaranteed yieldSemiconductor/solid-state device manufacturingBarrel ShapedEngineering

The invention relates to the field of micro-electronics manufacturing, in particular to high-temperature oxidization equipment. The high-temperature oxidization equipment comprises a vertical barrel-shaped wafer boat, wherein a plurality of frustum-shaped supporting rings for placing wafers are arranged in the wafer boat, and the radiuses of the frustum-shaped supporting rings are gradually increased from top to bottom; and the slope of each supporting ring and the inner wall of the wafer boat form an inclination angle alpha. When a high-temperature oxidization technology is performed, reaction gas is fed into the wafer boat; the supporting rings are provided with the slopes, so that the reaction gas can be more easily fed into the center positions of the wafer surfaces, and the gas reaction concentration difference between the edge position and the center position on the upper surface of each wafer is reduced; and therefore, a layer of oxidized film with more uniform thickness grows on the surface of each wafer, and the performance of a device and the production technology are improved simultaneously.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com