Method capable of quantitatively evaluating workloads of departments and individuals carrying out one-piece flow production in labor intensive industries

A labor-intensive, quantitative evaluation technology, applied in the field of industrial assembly line production, can solve the problems of low education and lack of vocational training, management problems, slow implementation, etc., to solve the loss of skilled workers, the method is simple, and the targeted Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

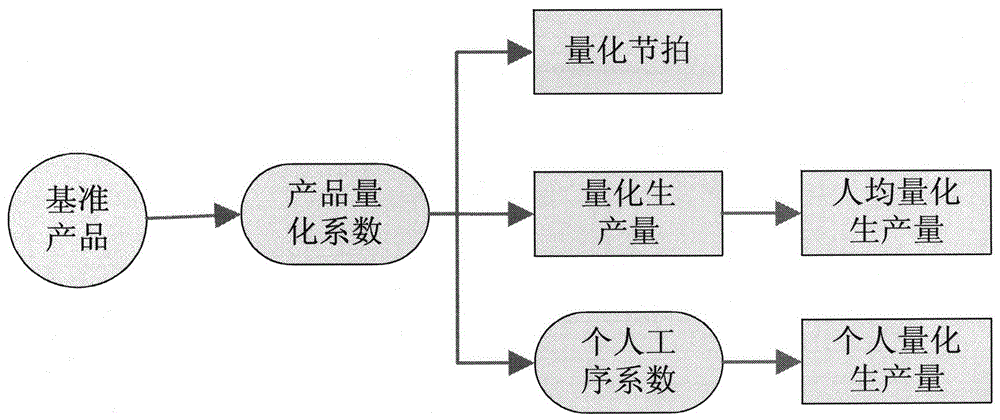

Method used

Image

Examples

Embodiment Construction

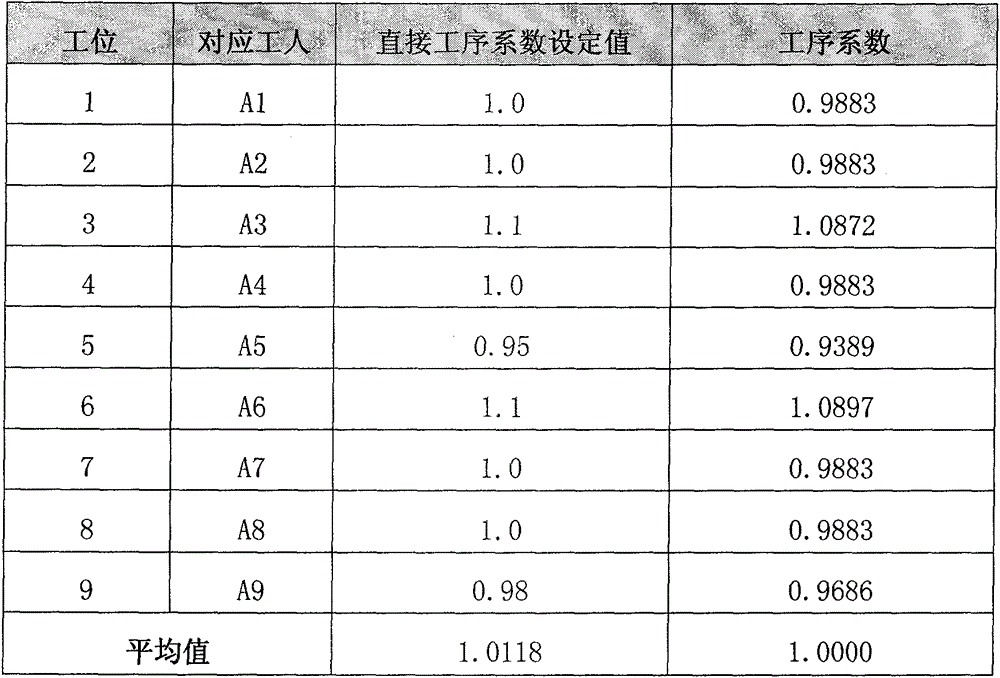

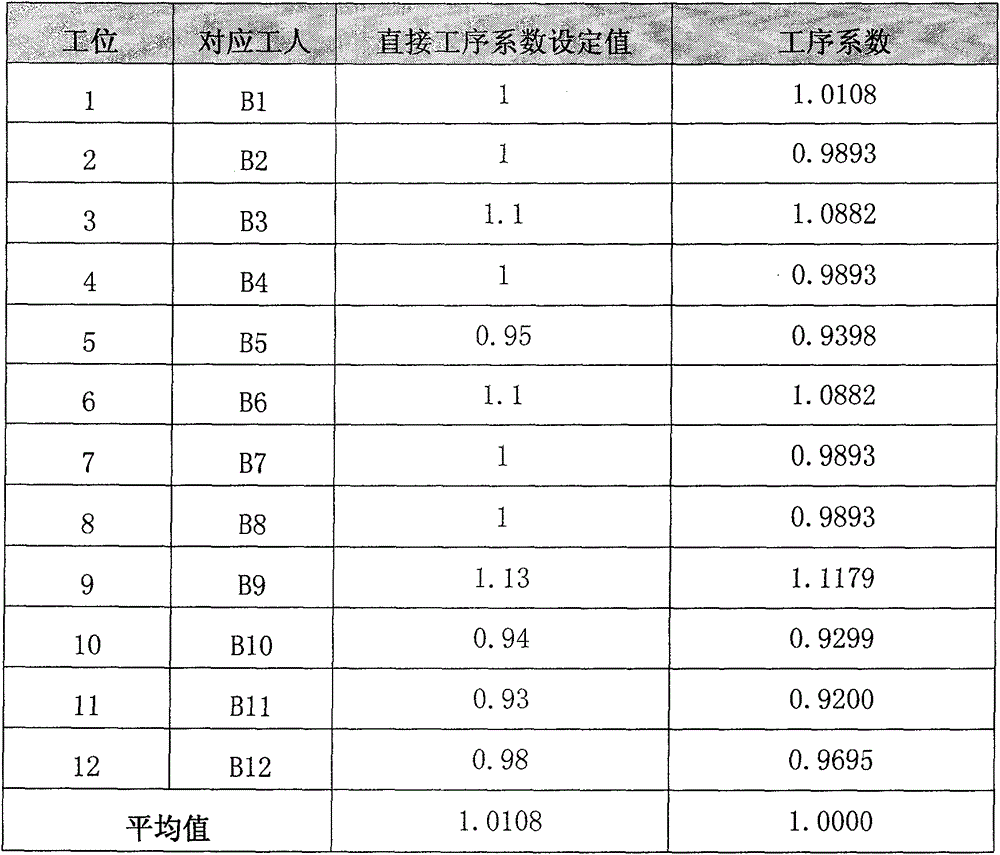

[0013] Take a small garment factory as an example to illustrate the implementation below.

[0014] In order to promote "single-piece flow production", the clothing factory transformed the No. 10 workshop of the factory into a "single-piece flow" production line. Quantitative evaluation of the workload of production departments and individuals in the production of "piece flow". The garment factory mainly produces a certain brand of men's clothing, and the products are mainly men's shirts, men's suits (tops), and men's trousers (bottoms); the garment factory has 10 workshops and 3 production lines using "single piece flow" The assembly lines are: production line 101, production line 102, and production line 103. The following is its specific description.

[0015] 1. The enterprise defines a typical product of the enterprise as a "benchmark product", and agrees that the workload of workers with general proficiency in processing the benchmark product is the "benchmark product wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com