Patents

Literature

74results about How to "Achieve grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

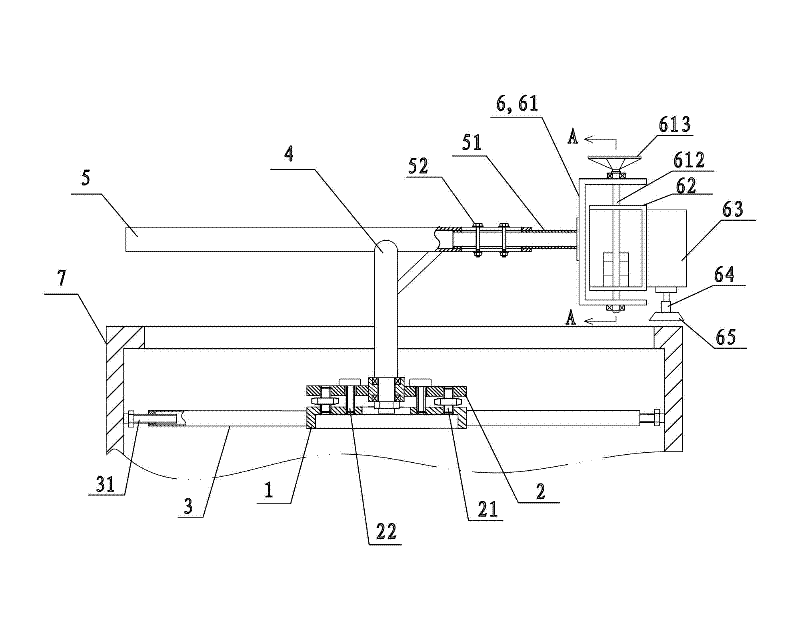

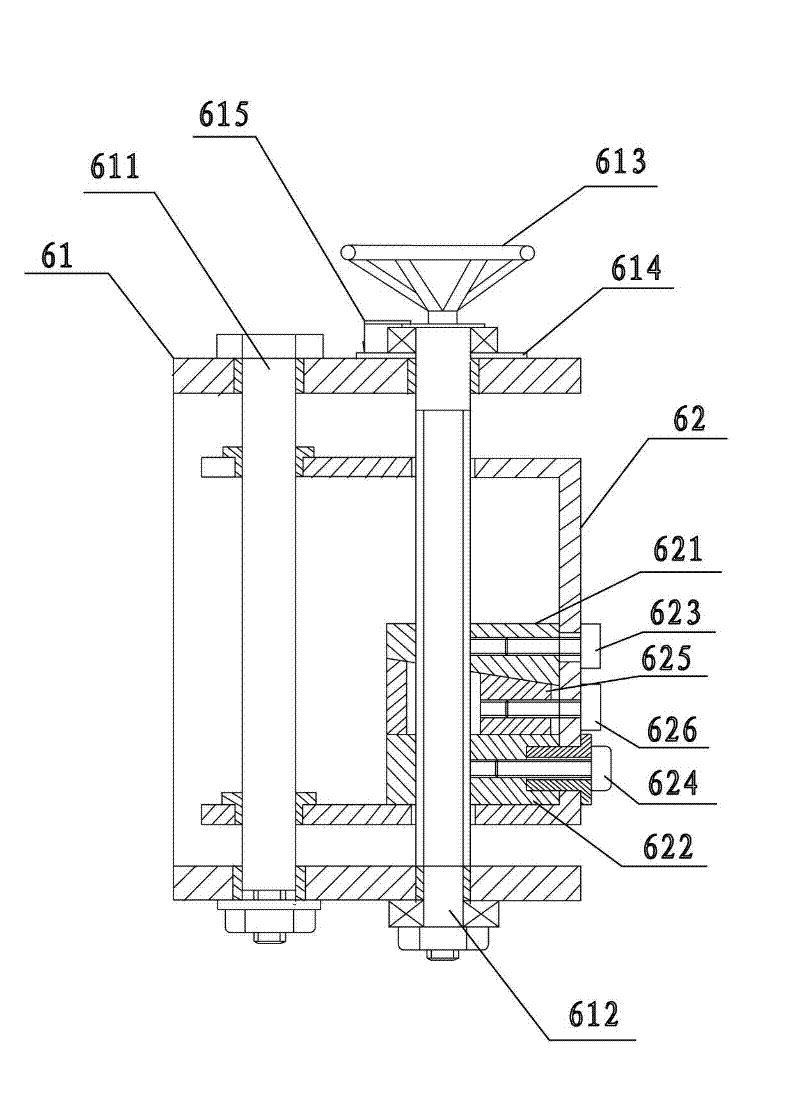

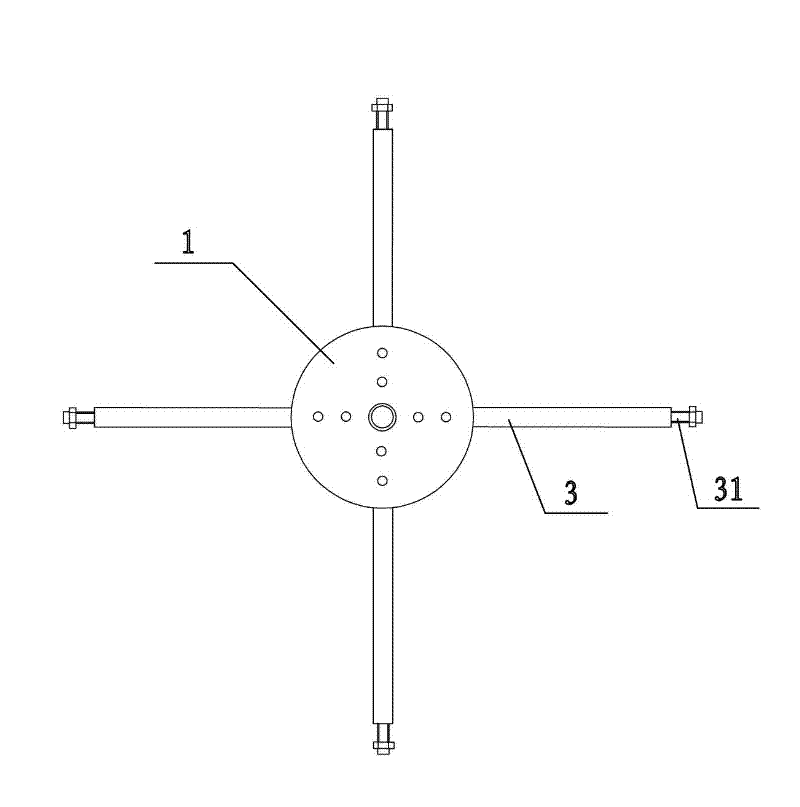

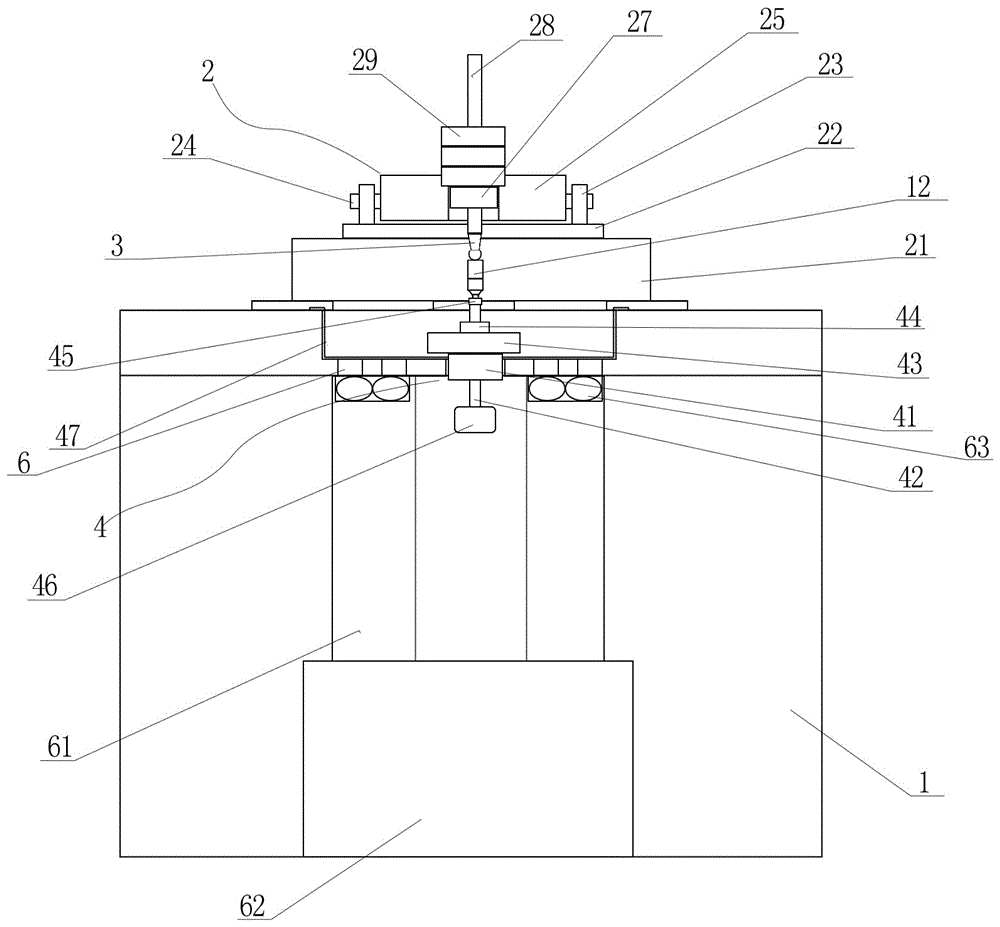

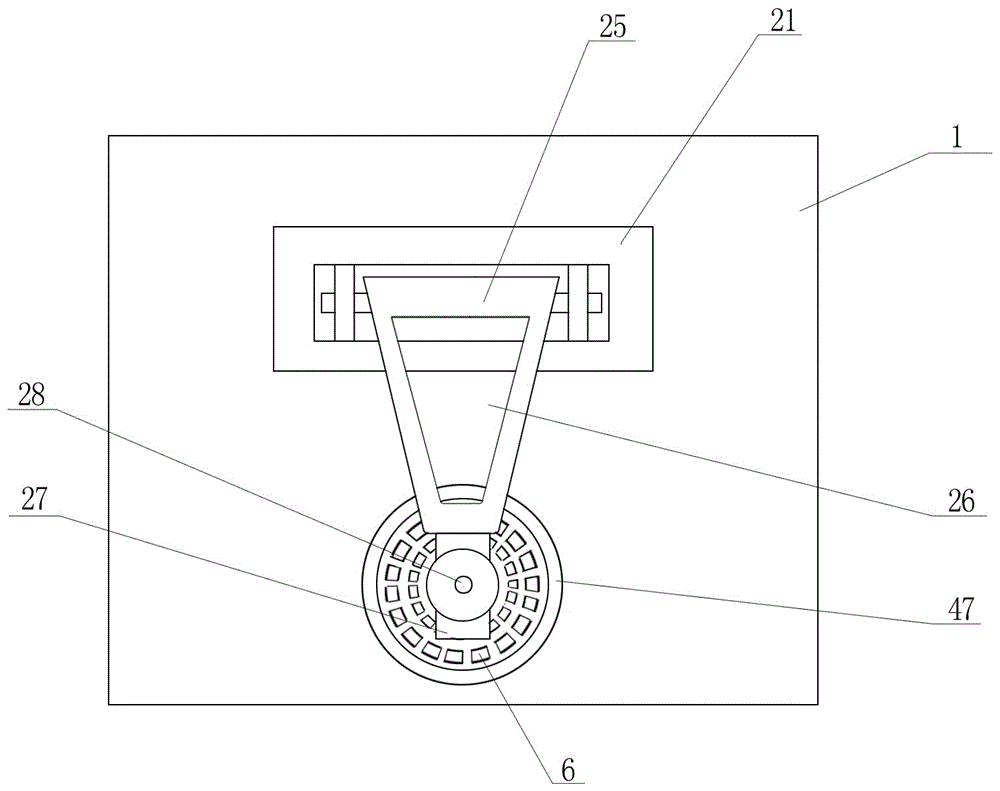

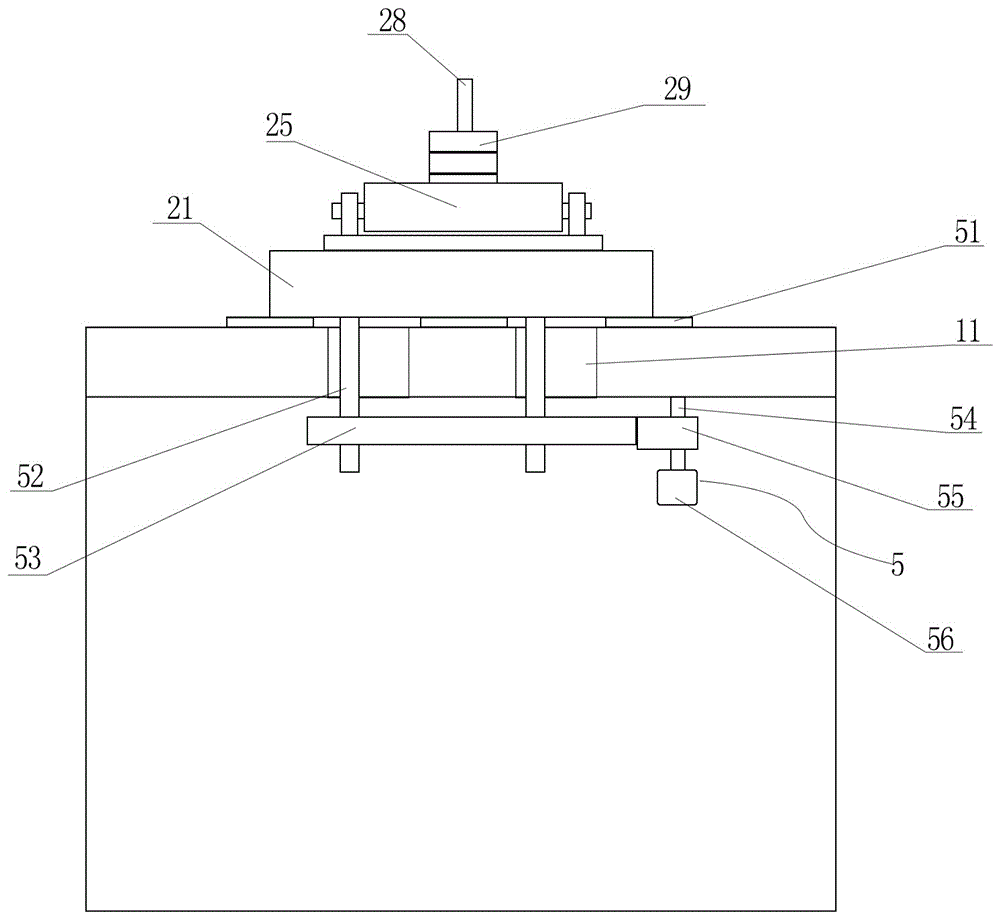

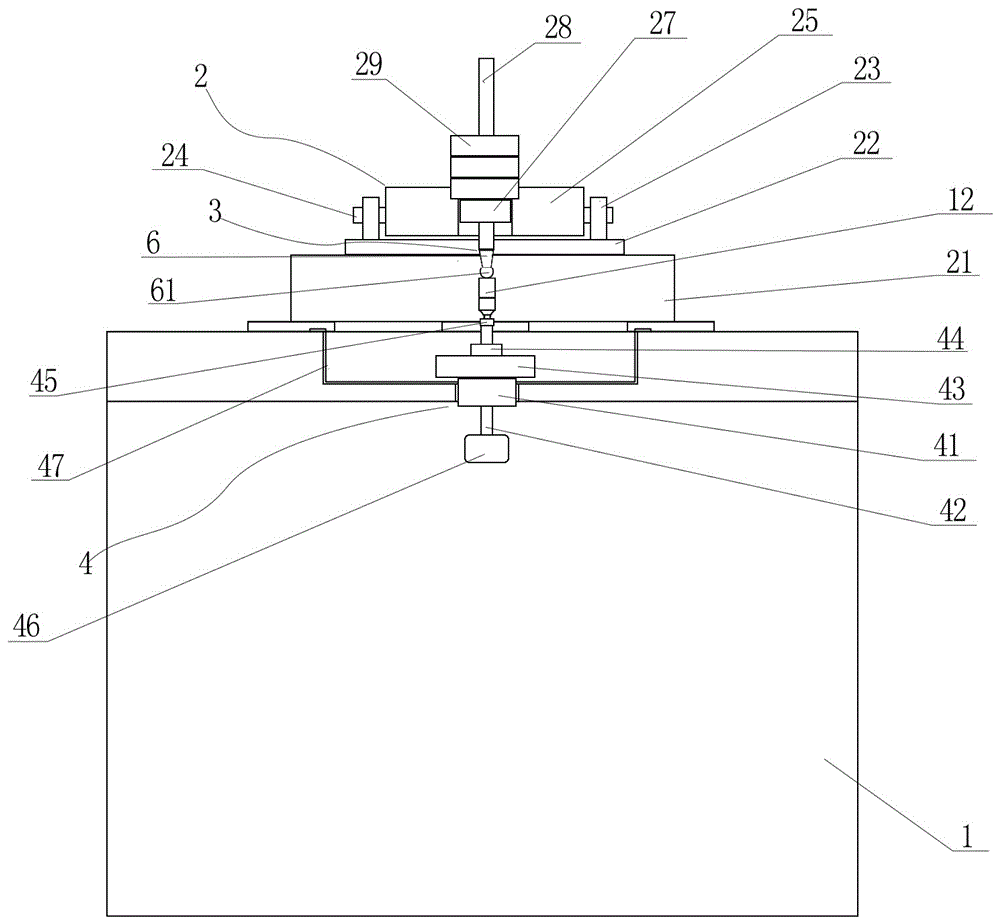

Onsite large-sized flange grinding machine

The invention discloses an onsite large-sized flange grinding machine which comprises a pedestal, wherein a base plane adjusting table is arranged above the pedestal; the side face of the pedestal is horizontally provided with at least two supporting legs for supporting and fixing; the base plane adjusting table is provided with a connecting column which is perpendicular to the upper surface of the base plane adjusting table; the lower end of the connecting column is rotatably connected with the base plane adjusting table, and the upper end of the connecting column is horizontally provided with a rotary arm frame; and one end of the rotary arm frame is connected with a grinding mechanism for processing a flange face. The onsite large-sized flange grinding machine is applied to detecting and grinding a large-sized flange plane at a construction site; the detection accuracy and the grinding accuracy are precise; the grinding effect of a large-sized milling machine is achieved; the working efficiency is effectively increased; the labor intensity of workers is reduced; and the grinding machine is low in production cost and convenient to disassemble and then transport and contributes to market promotion.

Owner:JIANGMEN NANYANG SHIP ENG

High-concentration colored master batch and preparation method thereof

The invention discloses a high-concentration colored master batch. The high-concentration colored master batch is composed of, by mass, 50-70% of colored pigment, 5-15% of a dispersing agent, 20-39% of resin and 0.5-1% of a processing aid. The invention further discloses a preparation method of the high-concentration colored master batch. The preparation method comprises the following steps of 1, weighing the colored pigment, the dispersing agent, the resin and the processing aid according to the mass percentage compounding ratio of the constitute raw materials, and mixing the raw materials in a high-and-low-speed blender mixer till the raw materials are caked; 2, adding the mixed raw materials into a three-roller grinding machine, and conducting grinding till the raw materials are dispersed uniformly; 3, adding the ground raw materials into a single-screw or a double-screw extruder for extrusion and granule cutting. The high-concentration colored master batch and the preparation method thereof have the advantages that the pigment is dispersed uniformly; the surface of the master batch is smooth and free of pores; black spots or toner points do not appear; the preparation method is simple; dispersity is good; consumption of the pigment is saved; no dust is generated in the processing process; a processed product is free of dust or pollution.

Owner:OPTA POLYMER JIANGSU

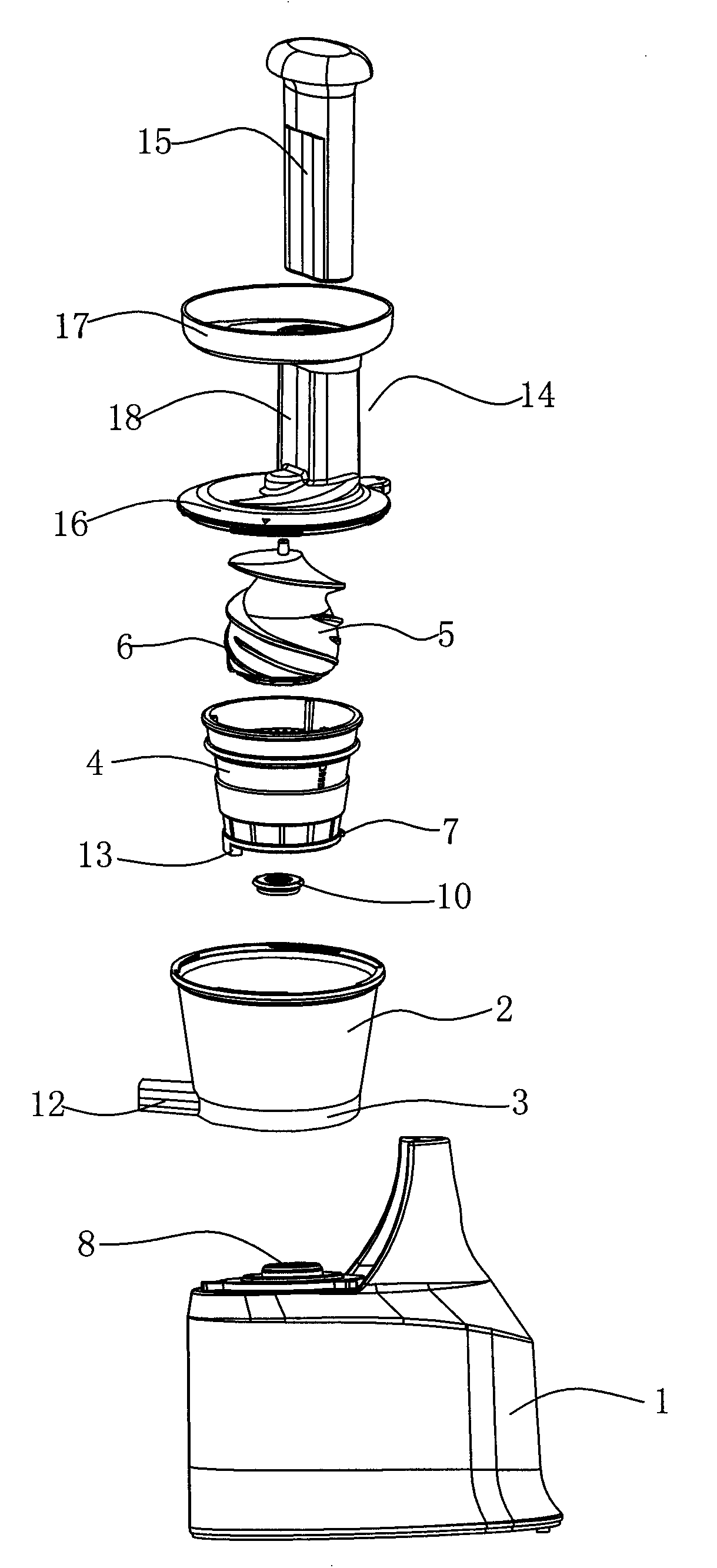

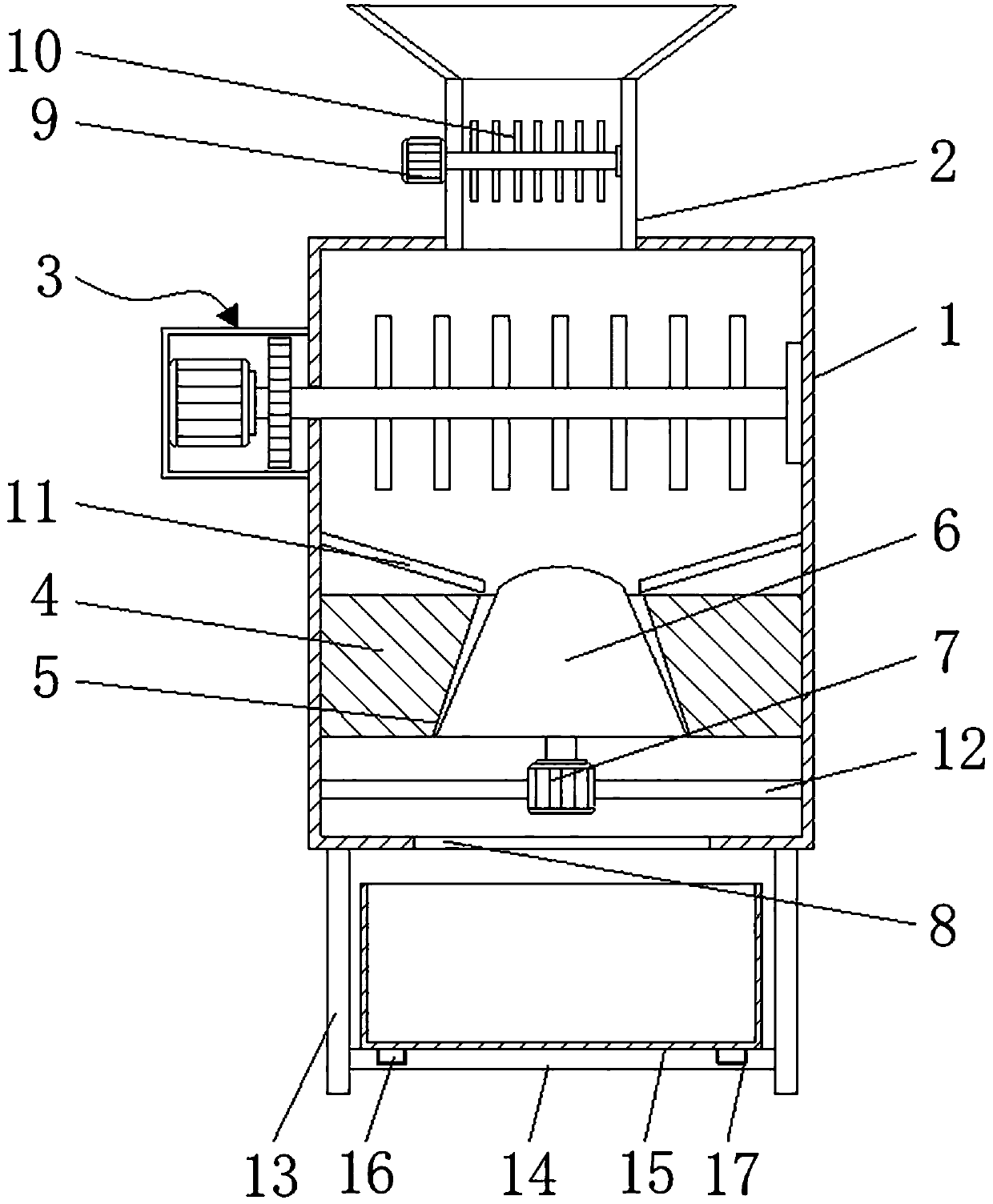

Grinding machine

The invention discloses a grinding machine, which comprises a base and a grinding mechanism arranged on the base, wherein the grinding mechanism comprises a feed cylinder arranged on the base; a grinding cylinder is arranged in the feed cylinder; a grinding rib is arranged on the inner wall of the grinding cylinder; a grinding head is arranged in the grinding cylinder; a grinding clearance is formed between the grinding head and the grinding rib; a drive motor is arranged in the base; the output shaft of the drive motor penetrates through the upper end surface of the base; a connecting shaft is arranged on the bottom surface of the grinding head, penetrates through the bottom surface of the grinding cylinder and the bottom surface of the feed cylinder, and then is connected with the output shaft of the drive motor; a bed opening is formed in the bottom surface of the grinding cylinder; a feed opening corresponding to the bed opening is formed in the bottom surface of the feed cylinder; a discharge pipe communicated with the feed opening is also arranged on the bottom surface of the feed cylinder. Through the adoption of the grinding machine, the real grinding effect can be realized, and the ground food is finer and smoother, and is better in taste.

Owner:NINGBO LONGFAR ELECTRIC APPLIANCES TECH

Oil plant pre-treatment method applicable to aqueous phase process oil extraction

ActiveCN104087411ASolve the shortcomings of uneven pretreatment processSolve the disadvantage of unevennessFatty-oils/fats productionRough surfacePretreatment method

The invention provides an oil plant pre-treatment method applicable to aqueous phase process oil extraction. Oil plants are pretreated by adopting an improved roller type grinding technology, and the improvement ways comprise: mutually extruding the oil plants by utilizing surfaces of multiple rollers; adjusting space between rollers and number of the rollers according to granularity required by different oil plants for extruding in different degrees; adjusting radian and medium height of each roller according to hardness of different materials, bending deformation resistance of each roller, rolling pressure and feeding grain size, wherein the medium height ranges from dozens of microns to several millimeters; guaranteeing uniform grain size in axial discharging; regulating pressure between rollers to be 10-80MPa for controlling the grain size; arranging the rollers in a vertical type (triangle shape), and atomizing the surface of each roller, so that smooth surface of each roller is changed into a rough surface; and promoting feeding, and improving capacity. The oil plant pre-treatment method applicable to the aqueous phase process oil extraction has the advantages that the problems that an oil plant pre-treatment technology is difficult and oil extraction rate is limited in an aqueous phase oil extraction technology are solved, the oil extraction rate is greatly increased and the industrialization development of the oil plant pre-treatment method applicable to the aqueous phase process oil extraction is further promoted.

Owner:JIANGNAN UNIV

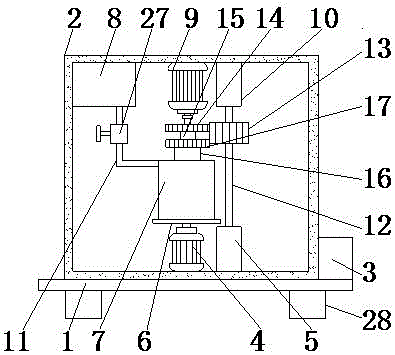

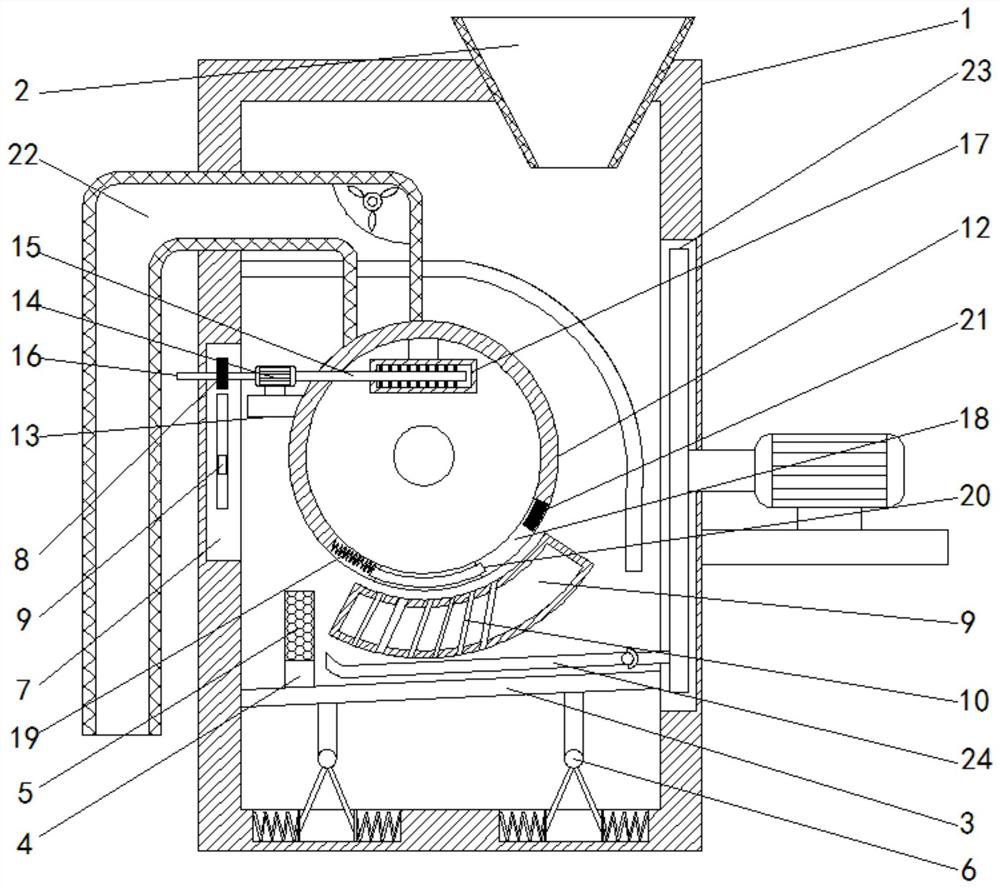

Chemical raw material grinding device high in grinding efficiency

InactiveCN106334600AImprove grinding efficiencyAchieve grinding effectGrain treatmentsEngineeringGrinding wheel

The invention discloses a chemical raw material grinding device high in grinding efficiency. The chemical raw material grinding device high in grinding efficiency comprises a base. A box and a controller are sequentially and fixedly mounted at the top of the base from left to right. A first motor and a first sleeve are sequentially and fixedly mounted at the bottom of an inner cavity of the box from left to right. A turnplate is fixedly mounted on an output shaft of the first motor. A grinding cylinder is fixedly mounted at the top of the turnplate. A water tank, a second motor and a second sleeve are sequentially and fixedly mounted at the top of the inner cavity of the box from left to right. According to the chemical raw material grinding device high in grinding efficiency, by arranging the first motor, the grinding cylinder and the second motor, the effect of grinding chemical raw materials in the grinding cylinder is achieved, and the chemical raw materials needing to be ground are stirred and ground through grinding balls, a grinding wheel and stirring rods while the grinding cylinder rotates, so that the grinding time is greatly shortened, the chemical raw material grinding efficiency is greatly improved, the grinding time is shortened, the grinding device can be used by a user conveniently, and meanwhile the grinding quality is improved.

Owner:WUXI RISHENG CHEM CO LTD

Clean glass column circular head grinding device

ActiveCN105834886APrevent spread of pollutionGuaranteed cleanlinessGrinding carriagesLapping machinesReciprocating motionEngineering

The invention discloses a clean glass column circular head grinding device. The device comprises a frame; the frame is correspondingly provided with a fixing module and a grinding module; a driving module for driving the fixing module to perform a reciprocating motion is arranged in the frame; the grinding module includes a groove formed in the frame; a through groove is formed in the center of the groove; a bearing is arranged in the through groove, and is coaxially provided with a vertical rotating shaft; the rotating shaft is coaxially provided with a rotating disc; the rotating disc is arranged at the upper part of a bearing; a fixed disc is arranged at the upper part of the rotating disc; a grinding wheel is horizontally arranged at the top end of the rotating shaft; a first motor is coaxially arranged at the lower part of the rotating shaft; two circles of arc grooves are downwards formed in the bottom of the groove; the arc grooves are arranged at equal intervals; an annular pipe is arranged at the lower parts of the arc grooves in the frame; a collecting box is arranged at the lower part of the annular pipe; a negative-pressure fan is arranged at the bottoms of the arc grooves; and the negative-pressure fan is arranged in the annular pipe. The clean glass column circular head grinding device has such advantages as simple structure, convenience for use and low cost.

Owner:湛江市百德玻璃制品有限公司

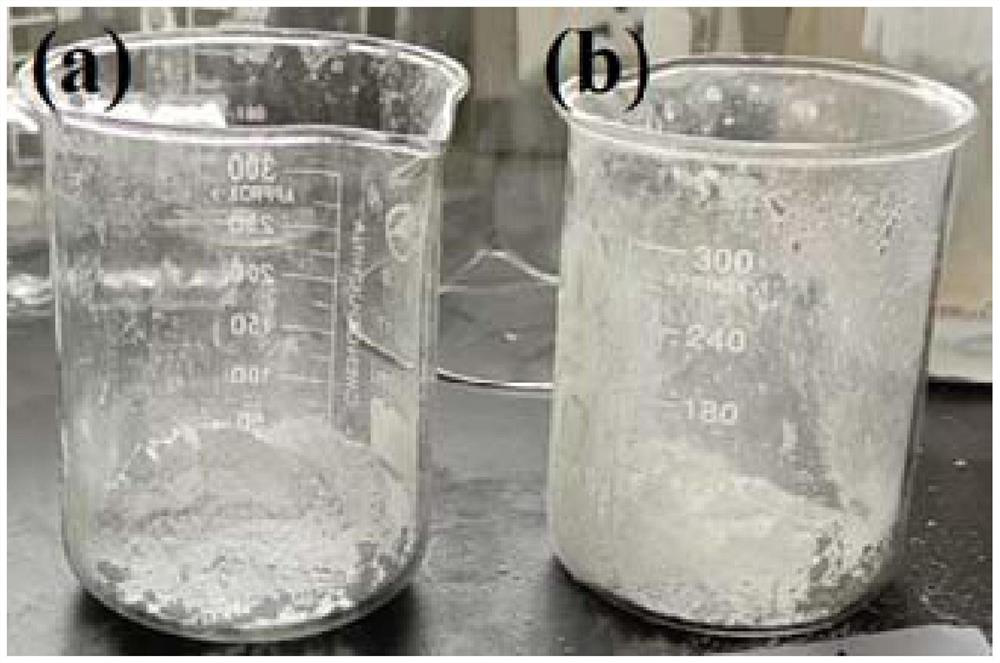

Preparation method of superfine dolomite and application of superfine dolomite

InactiveCN113104877AGood surface morphologyGood dispersionCalcium/strontium/barium carbonatesMagnesium carbonatesCALCIUM HYDROXIDE SOLUTIONSlurry

The invention discloses a preparation method of superfine dolomite and application of the superfine dolomite, and relates to the technical field of dolomite processing. The preparation method comprises the steps: crushing dolomite, and screening to obtain dolomite coarse powder; adding the dolomite coarse powder and a grinding aid into water, and uniformly stirring to obtain dolomite slurry; adding the dolomite slurry into a stripping machine, and carrying out superfine stripping to obtain superfine slurry; dehydrating, drying and crushing the superfine slurry to obtain dolomite fine powder; adding the dolomite fine powder and a calcium hydroxide solution into a four-neck flask provided with a stirrer, then putting the four-neck flask into a constant-temperature water bath, and adding a crystal form control agent while stirring; and then introducing mixed gas of air and carbon dioxide into a three-neck flask for continuous stirring reaction, carrying out spray drying on the reaction liquid, forming powder, and thus obtaining the superfine dolomite. The problems that existing dolomite powder is large in particle size and small in application range, and superfine powder is prone to agglomeration and not prone to uniform dispersion are solved.

Owner:铜陵博锋实业有限公司

Cement grinding aid and preparation method thereof

The invention discloses a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from the following raw materials in parts by weight: 20-30 parts of triethanolamine,10-15 parts of a calcium formate solution, 2-6 parts of a supersaturated urea solution, 1-5 parts of polyethylene glycol, 1-5 parts of sodium citrate, 2-4 parts of molasses and 20-30 parts of water.The preparation method comprises the following steps: mixing triethanolamine, calcium formate solution, sodium citrate, molasses and water, heating to a temperature of 105-130 DEG C, and stirring at aconstant temperature for 30-60 minutes; cooling to 40-50 DEG C, adding the supersaturated urea solution and polyethylene glycol, and continuously stirring at a constant temperature for 15-30 minutes.The supersaturated urea solution and polyethylene glycol are added, an adhesion effect of cement in materials in the grinding process is improved by utilizing an effect achieved by combining the twocomponents, and the distribution and form of material particles can be regulated, so that an effect of grinding the cement materials is achieved.

Owner:申轲

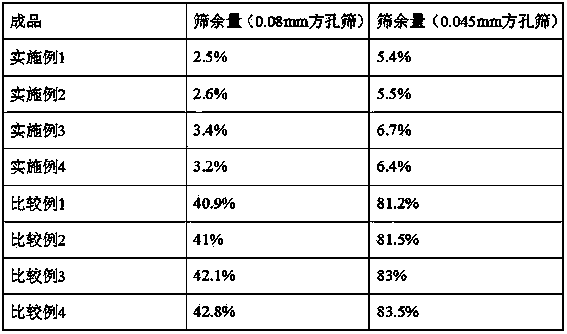

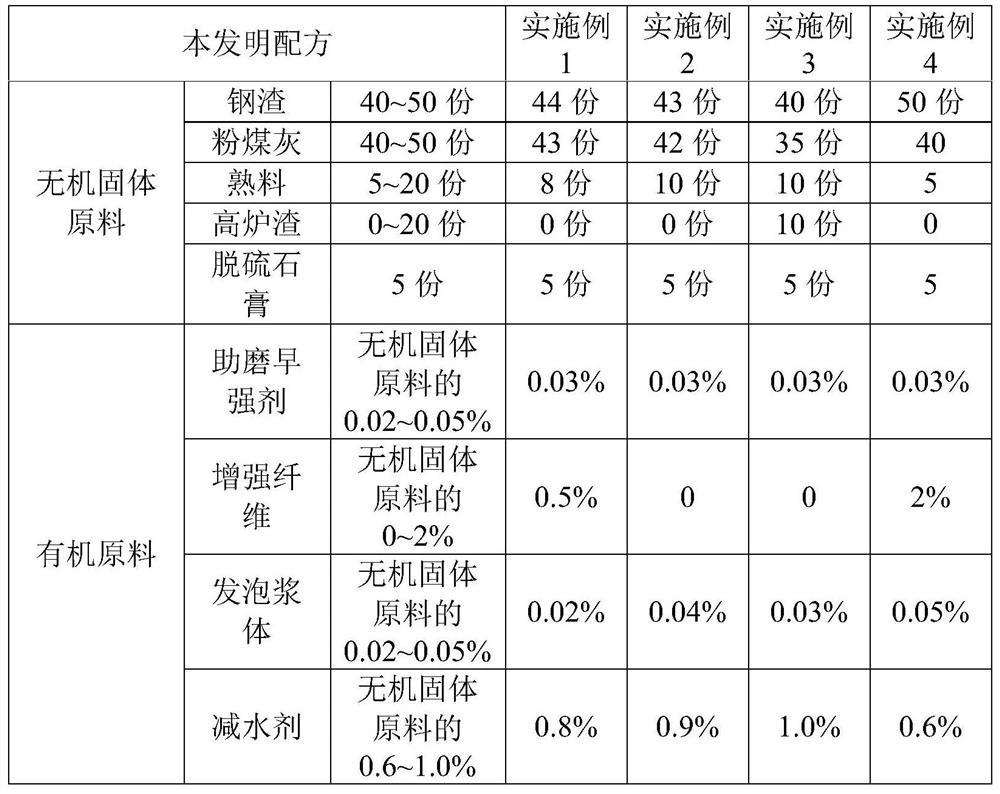

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

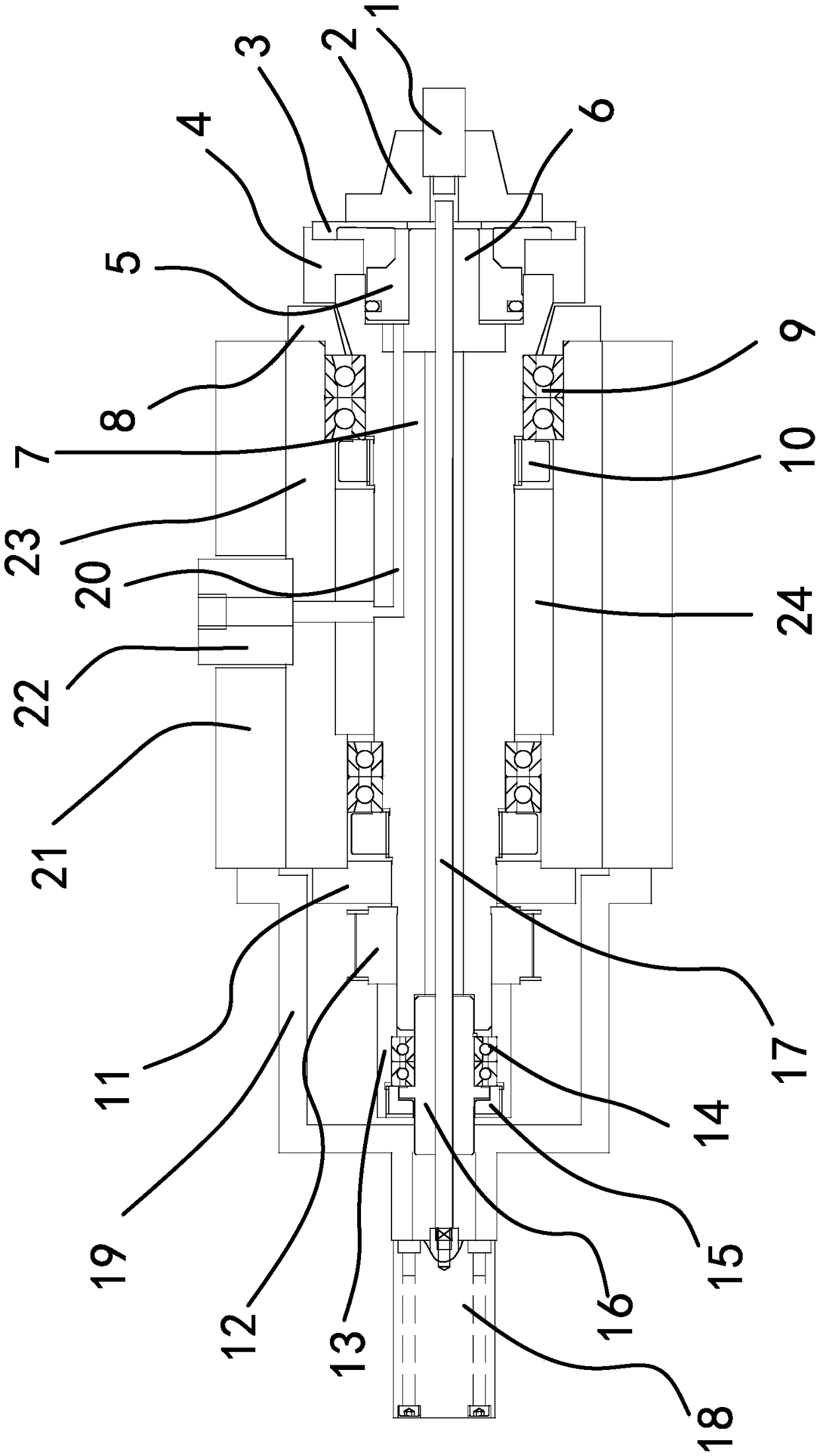

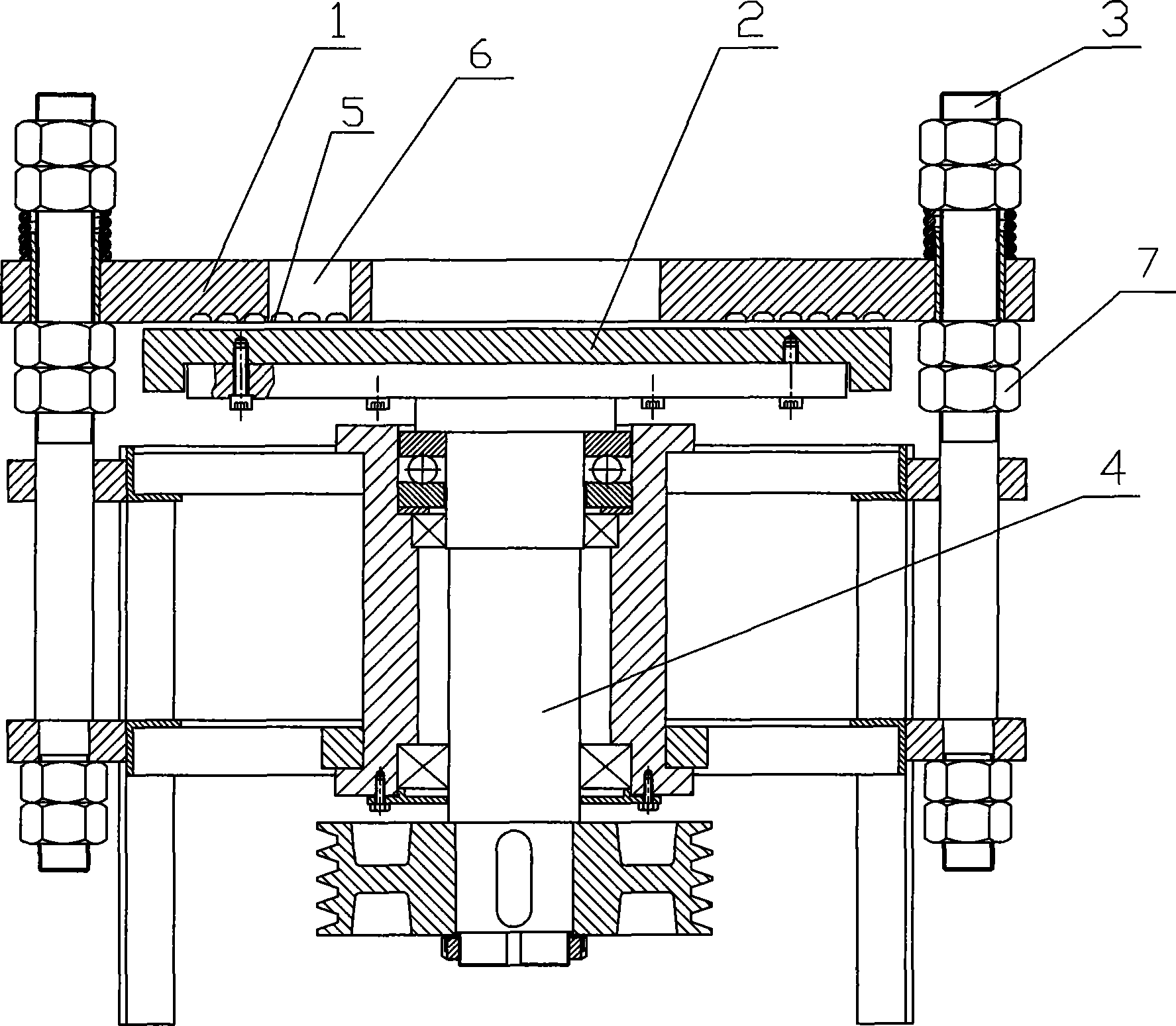

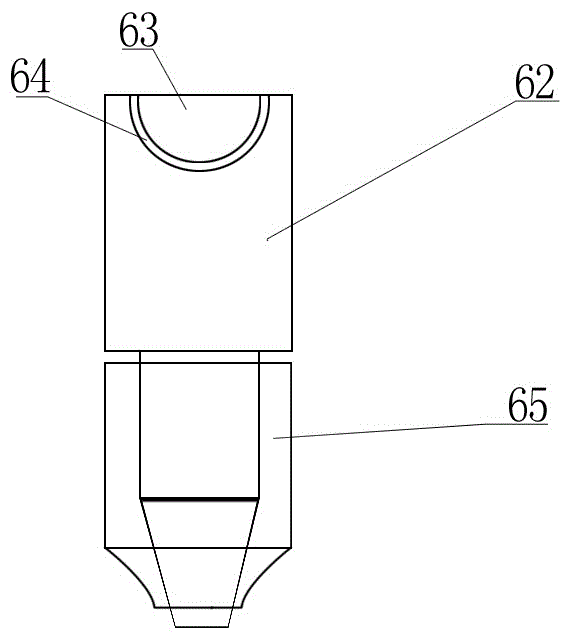

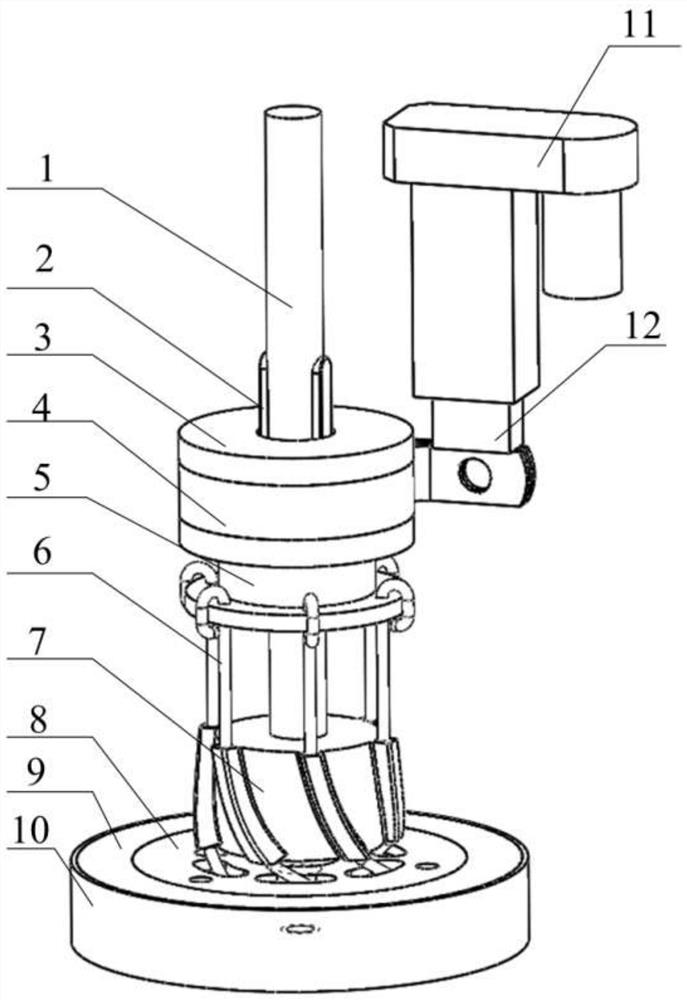

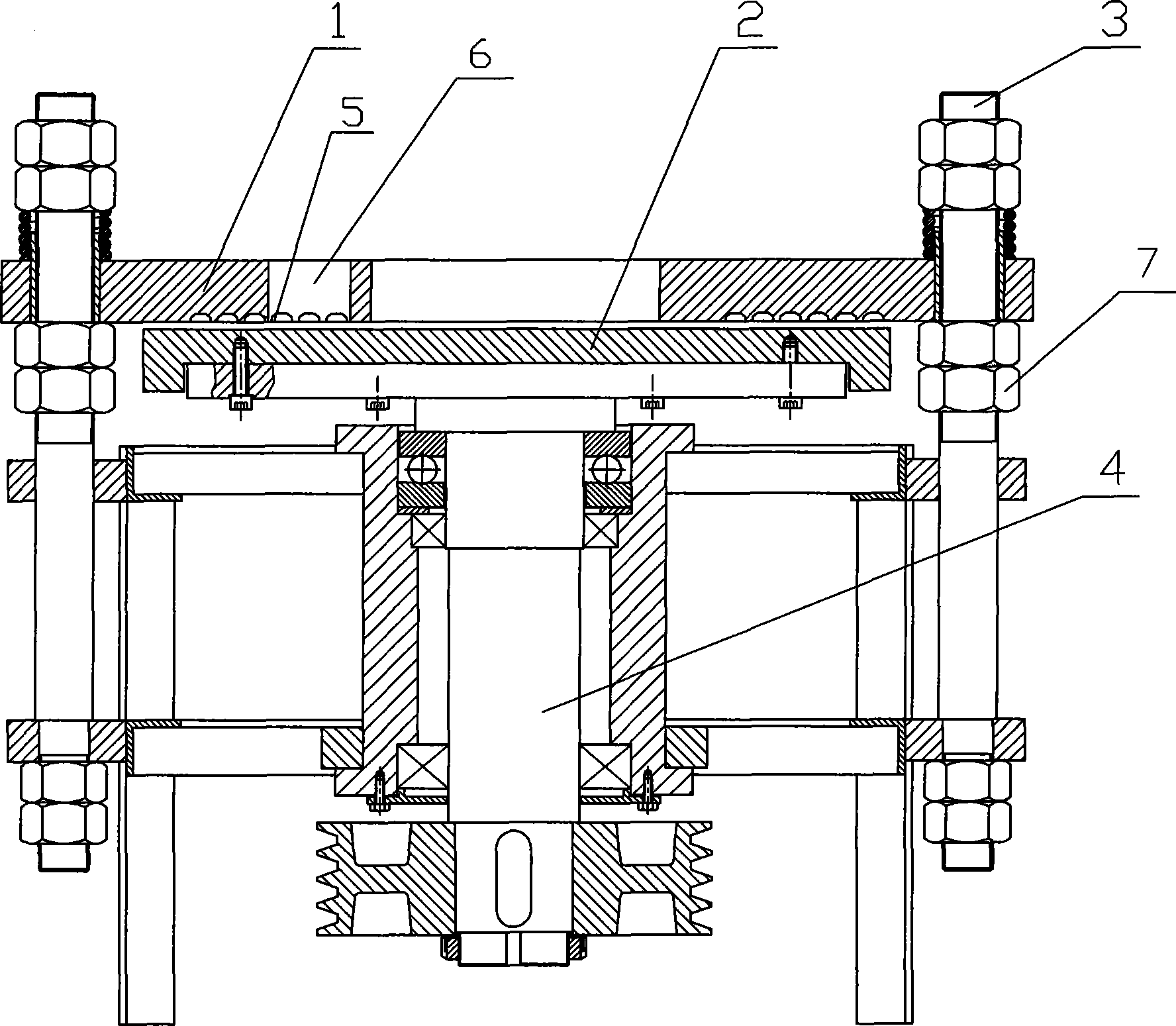

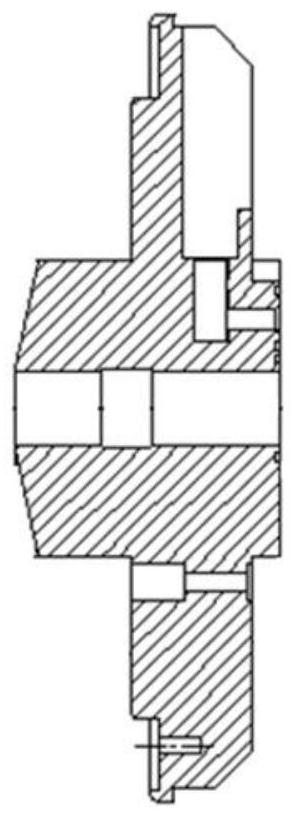

Air pressure diaphragm spring chuck spindle

PendingCN108655437AAchieve grinding effectReduce instabilityChucksGrinding work supportsInlet channelDrive wheel

The invention provides an air pressure diaphragm spring chuck spindle, and belongs to the technical field of machines. The air pressure diaphragm spring chuck spindle comprises a shaft fixing seat, and an air inlet connector seat is mounted on the shaft fixing seat. A bearing pedestal is arranged in the shaft fixing seat. A spindle body penetrates the bearing pedestal, and an air inlet sleeve is arranged between the spindle body and the bearing pedestal. A supporting column is arranged at the head end of the spindle body, and a piston is arranged between the supporting column and the spindle body. The piston communicates with the air inlet connector seat through an air inlet channel, and a diaphragm spring seat is arranged at the head end of the spindle body, a diaphragm spring is arrangedon the diaphragm spring seat, and a chuck for clamping a workpiece is arranged on the outer side of the diaphragm spring. When air enters the air inlet channel, the diaphragm spring can deforms through the piston, and the chuck is in a clamping state. A driving wheel capable of driving the spindle body to rotate is arranged at the rear end of the spindle body. The air pressure diaphragm spring chuck spindle has the beneficial effects of being simple in structure and good in clamping effect.

Owner:宁波锋行自动化科技有限公司

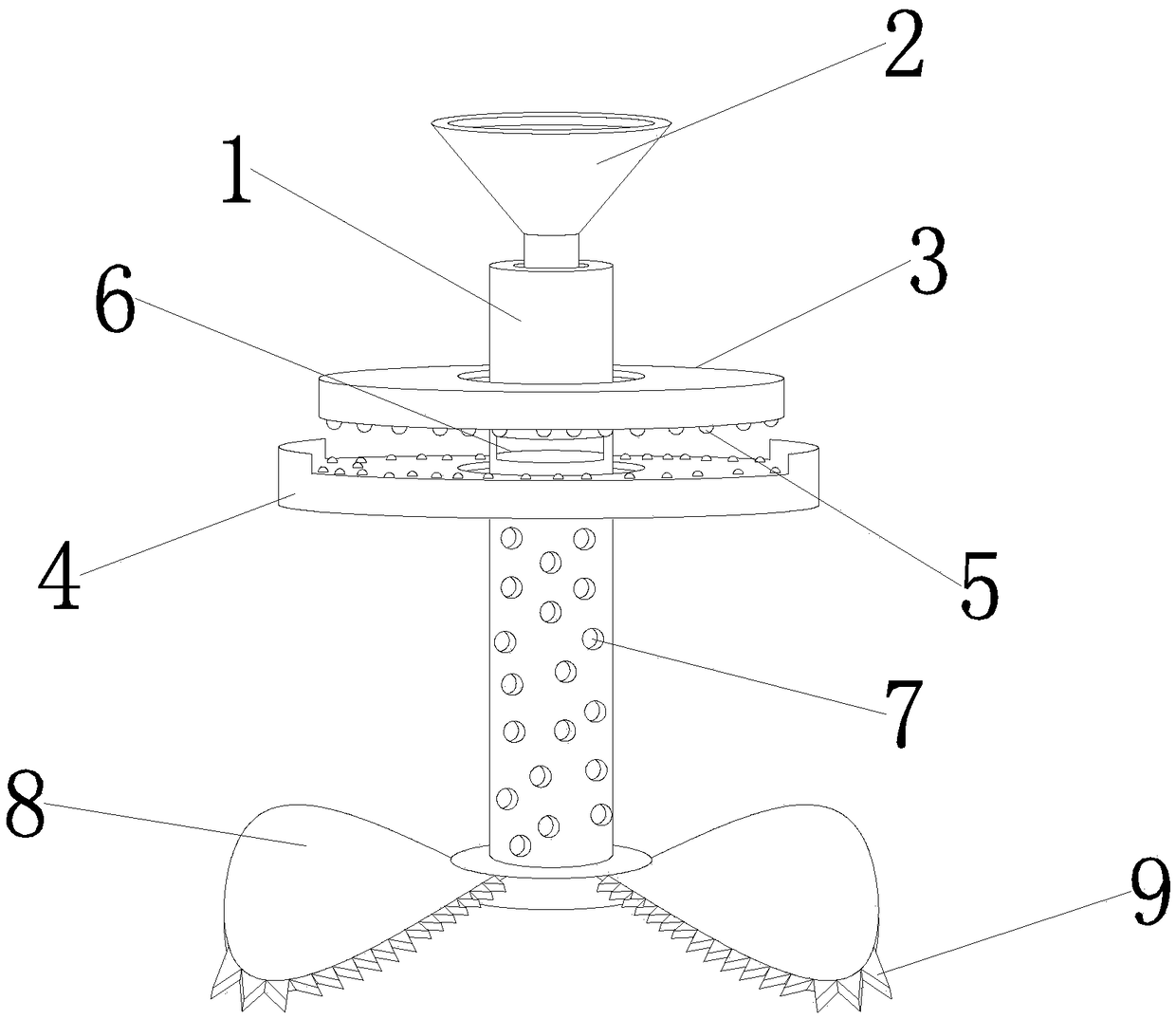

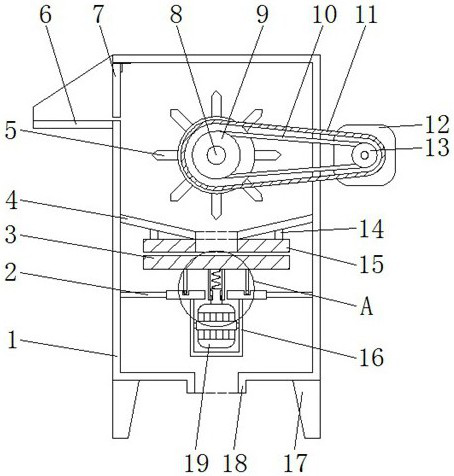

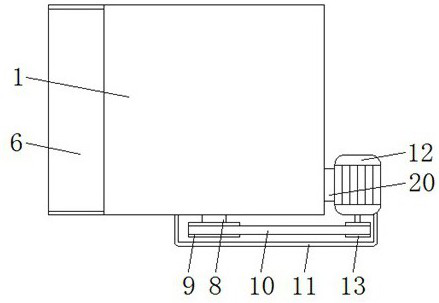

Grinding machine for thin film production ingredients

PendingCN108722627AImprove crushing rateEasy to clean and maintainCocoaGrain treatmentsPistonAdditive ingredient

The invention relates to the technical field of thin films, in particular to a grinding machine for thin film production ingredients. The grinding machine comprises a vertical column, a stirring barrel and a piston. The stirring barrel is arranged at the bottom end of the vertical column and movably connected with the vertical column, and the piston is arranged at the upper end of the stirring barrel and rotatably connected with the stirring barrel; the left side and the right side of the lower end of the vertical column are rotatably connected with two stirring blades, and three or more sharpteeth are closely welded to the front end of each stirring blade; and the front end of the vertical column is movably connected with a movable disc. According to the grinding machine for the thin film production ingredients, a user puts raw materials into the vertical column from the hopper arranged at the upper end of the vertical column, and the raw materials fall onto the upper end of a fixeddisc along with a through groove formed in the front end of the vertical column; then, grinding is conducted through grinding particles arranged on the fixed disc and the movable disc correspondingly,and meanwhile, the movable disc also rotates leftwards and rightwards, so that the grinding effect is achieved; and the ground raw materials flow into the stirring barrel through through holes and then are stirred through the two stirring blades rotatably connected to the bottom end of the vertical column.

Owner:嘉兴市博荣新材料有限公司

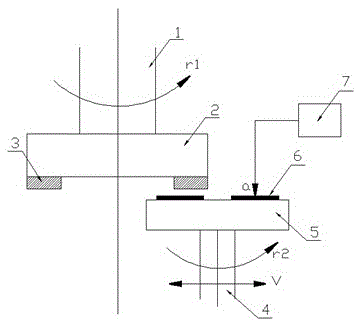

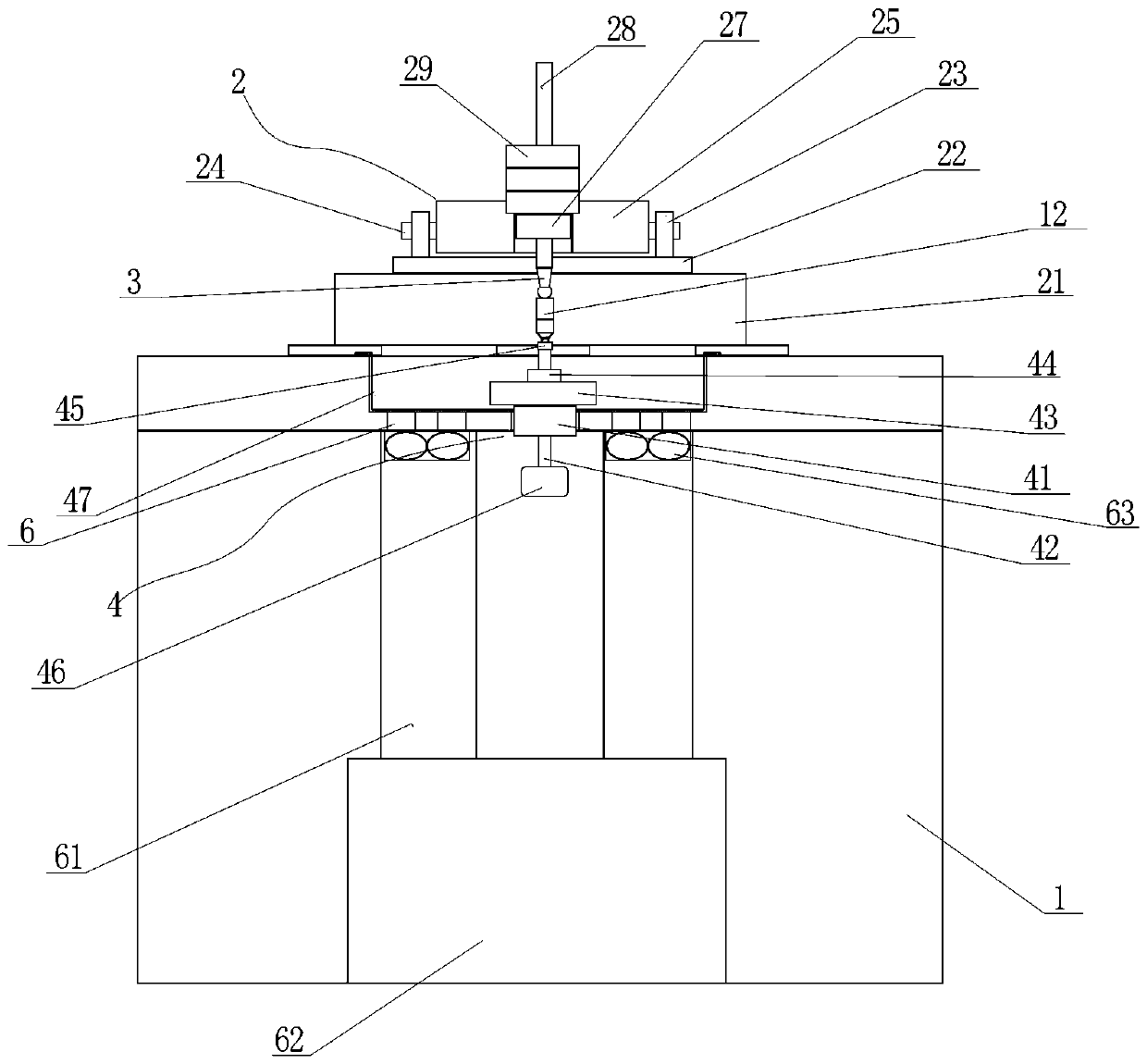

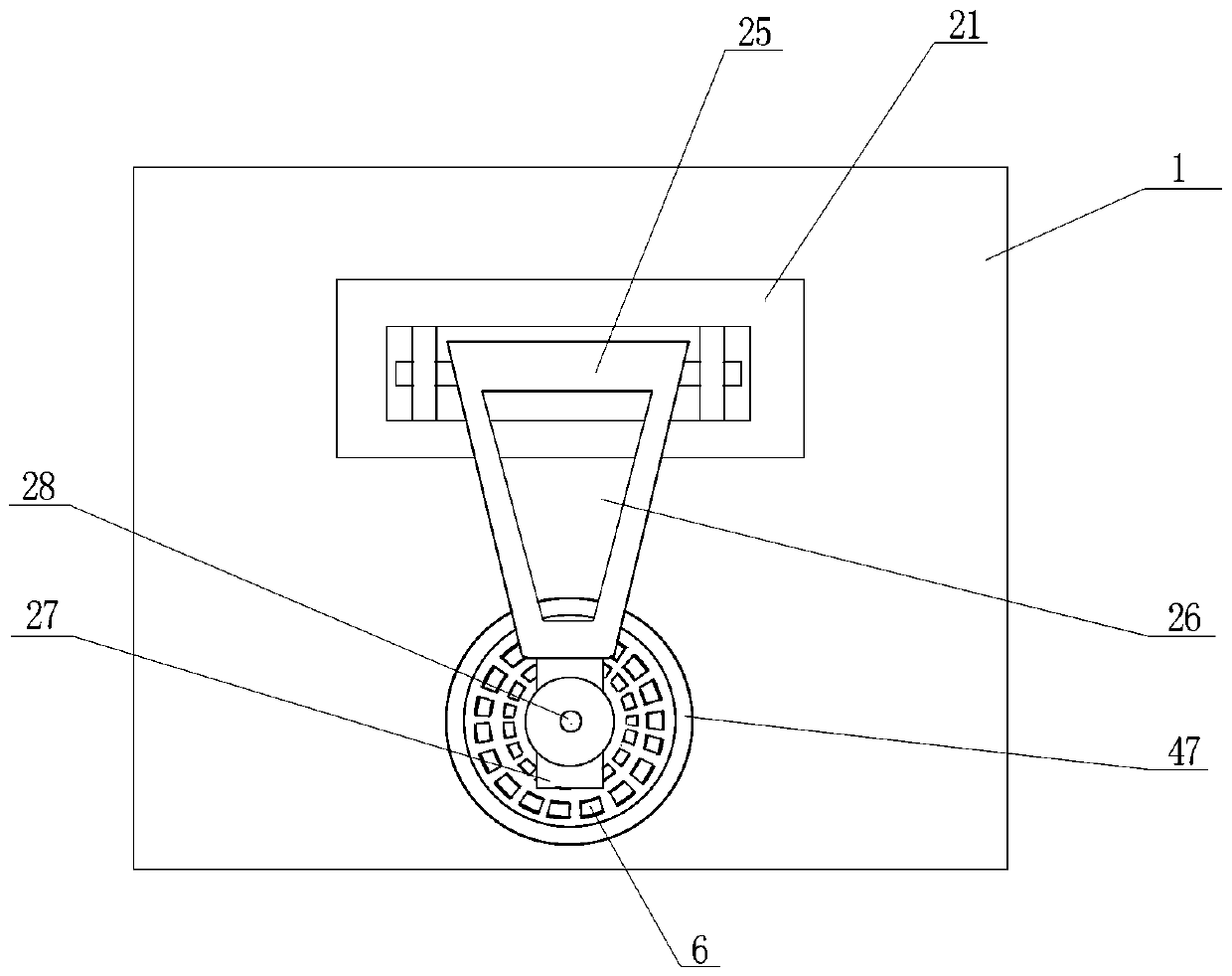

High-speed machining and automatic measuring integrated equipment

InactiveCN105619236AGood chip removal effectNot prone to scratchesLapping machinesGrinding feed controlReciprocating motionUltrasonic vibration

The invention provides high-speed machining and automatic measuring integrated equipment, which comprises a main shaft, a diamond grinding wheel, a workpiece shaft and a porous ceramic plate; the workpiece shaft is connected with an ultrasonic vibration device; vibration of the ultrasonic vibration device is conducted to the diamond grinding wheel; a workpiece is fixed on the porous ceramic plate in a manner of adsorption; the main shaft and the workpiece shaft are not coaxial; the diamond grinding wheel and the porous ceramic plate are separately driven by the main shaft and the workpiece shaft to rotate in a horizontal direction; and the lower side of the workpiece shaft is connected with a guide rail, and can do reciprocating motion in the horizontal direction. The problem that production efficiency is low, and the like due to the fact that removal efficiency of a crisp and hard material is low and thickness needs to be detected during machining is mainly solved by the high-speed machining and automatic measuring integrated equipment provided by the invention.

Owner:哈尔滨秋冠光电科技有限公司

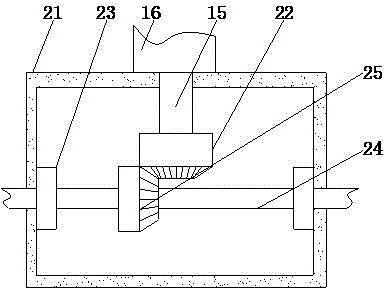

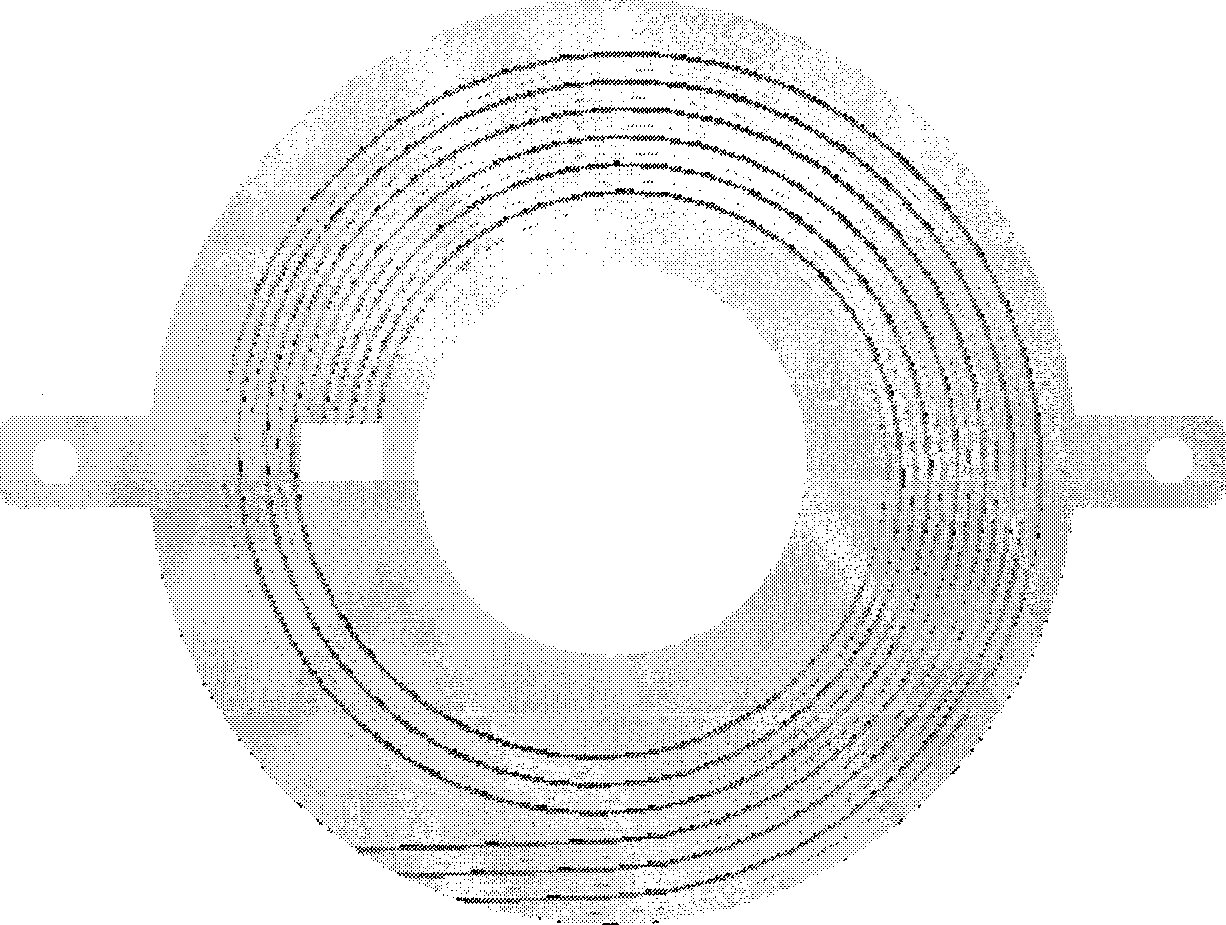

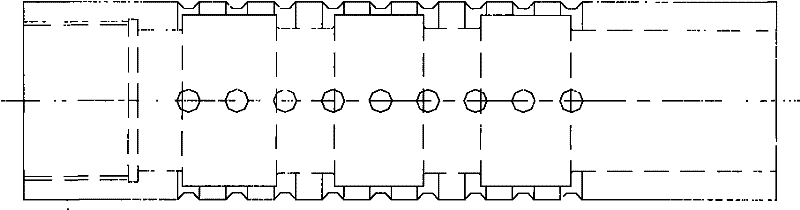

Machine tool for grinding glass drill

The invention relates to a glass drilling and grinding machine tool, comprising a frame, and a mainshaft which is rotatablely arranged in the frame; the upper end of the mainshaft is fixedly connected with a grinding disc; a material guide disc which is provided with a material inlet is arranged in parallel above the grinding disc; the material guide disc is arranged on the frame, with the height being adjustable. The clearance between the material guide disc and the grinding disc forms a grinding working area; one surface of the material guide disc facing the grinding disc is provided with a spiral track that matches the section and the glass drill; the spiral track is communicated with the material inlet; the outlet of the spiral track extends to the outer edge of the material guide disc. The invention provides the glass drilling and grinding machine tool which has high efficiency, generates no pollution, and saves material.

Owner:ZHEJIANG UNIV OF TECH

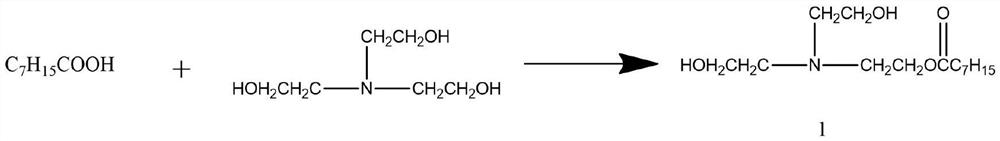

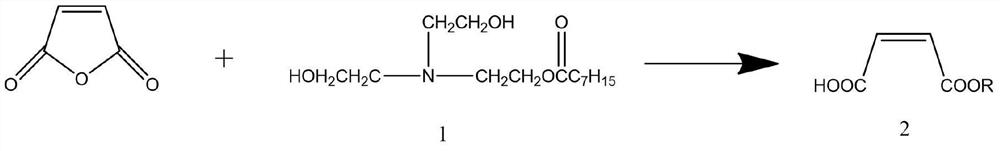

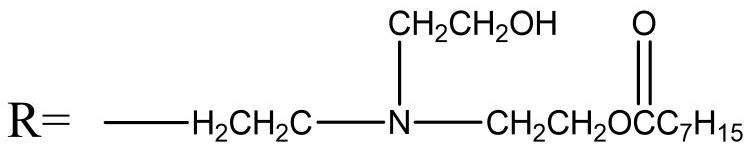

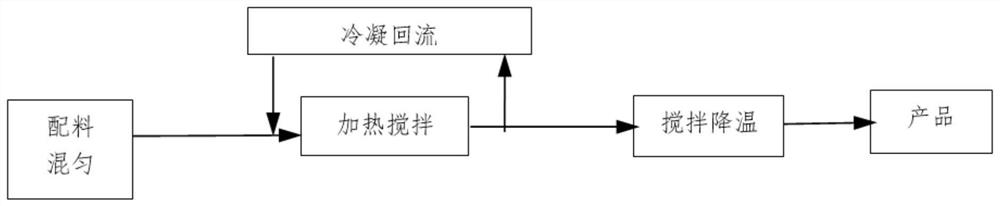

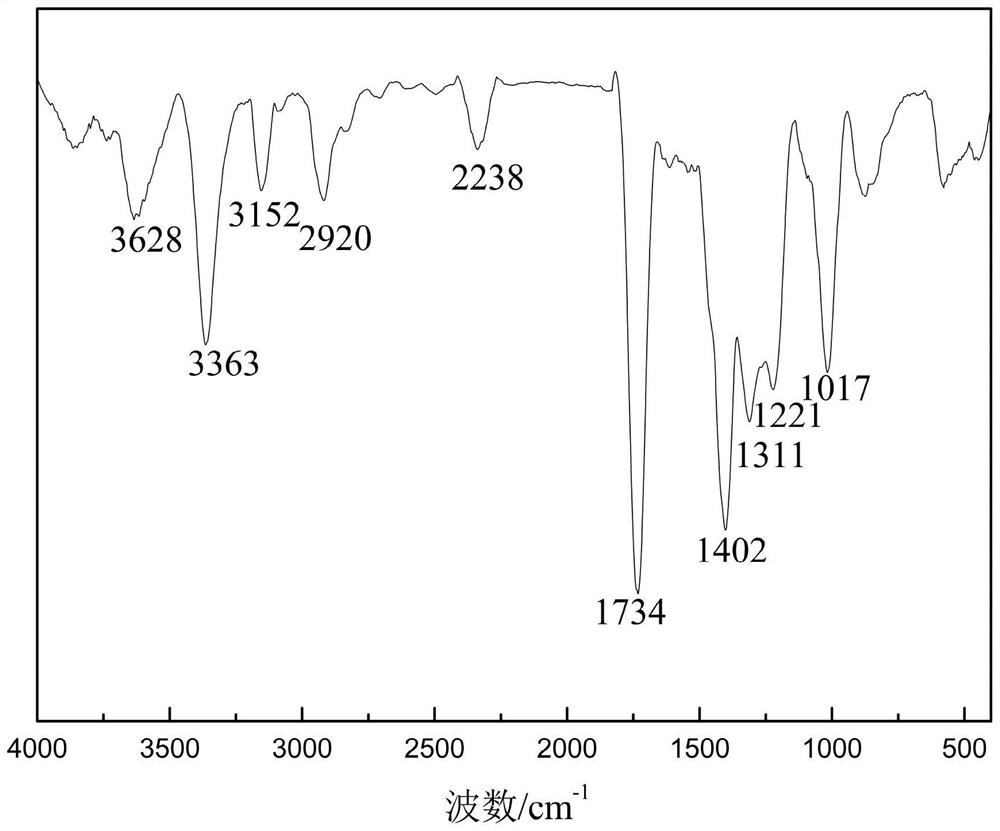

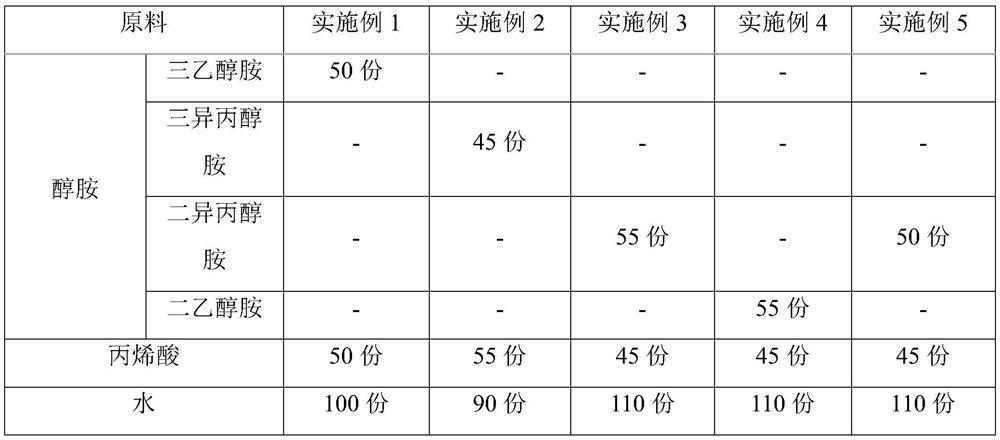

Modified grinding-aiding early strength agent for steel slag as well as preparation method and application method of modified grinding-aiding early strength agent

The invention discloses a modified grinding-aiding early strength agent for steel slag as well as a preparation method and an application method of the modified grinding-aiding early strength agent, and relates to the field of steel slag grinding aiding. The modified grinding-aid early strength agent comprises (a) 60%-75% of ester compounds based on the total weight of the modified grinding-aid early strength agent; (b) 5%-15% of polyacrylic acid based on the total weight of the modified grinding-aid early strength agent; (c) 10%-35% of alcohol amine and acrylic acid monomers based on the total weight of the modified grinding-aid early strength agent, the preparation method comprises the following steps: adding water into alcohol amine and acrylic acid, uniformly mixing, heating while stirring, reacting at 60-80 DEG C for 3-4 hours, and cooling the solution to room temperature to obtain the modified grinding-aiding early strength agent which is applied to grinding of a gel material with high doping amount of steel slag, so the problems of low grinding efficiency of an existing grinding aid, low activity of the steel slag in the early stage, complex synthesis process, high cost and the like are solved. The preparation process is simple, the raw material cost is low, the finished product quality and performance are stable, the use effect is good, and the 7d strength increase is greater than or equal to 30%.

Owner:安徽马钢嘉华新型建材有限公司 +1

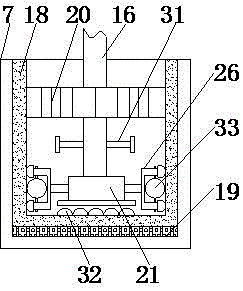

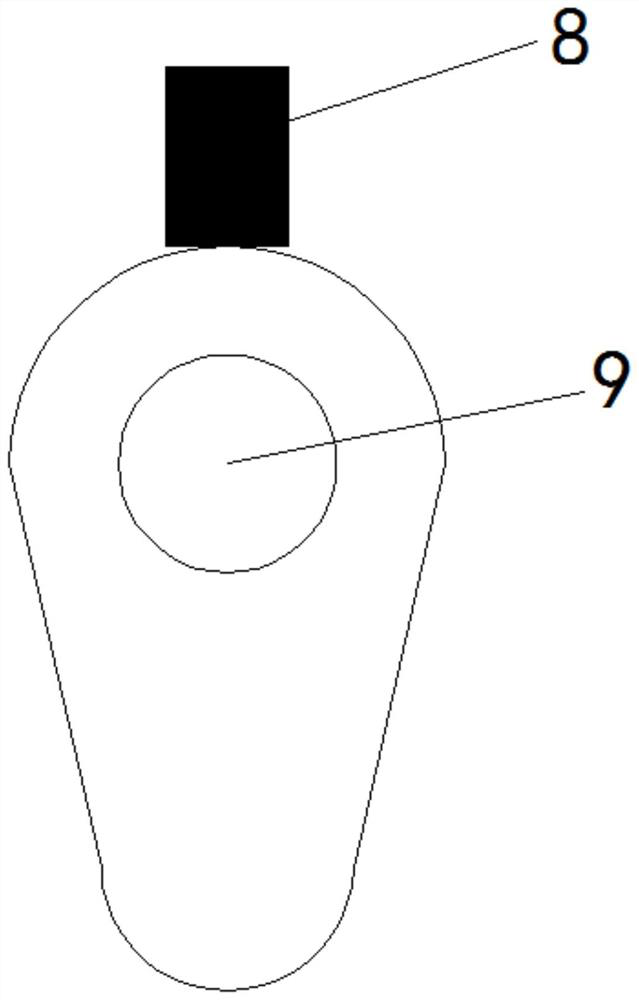

Absorption type glass column circular head grinding device

ActiveCN105834856AAvoid breakingAchieve grinding effectGrinding drivesSpherical surface grinding machinesReciprocating motionEngineering

The invention discloses an absorption type glass column circular head grinding device. The device comprises a frame, and is characterized in that the frame is correspondingly provided with a fixing module and a grinding module; a driving module for driving the fixing module to perform a reciprocating motion is arranged in the frame; the fixing module includes a bracket; a fixed plate is arranged on the bracket; vertical plates are vertically arranged at the two ends of the fixed plate, and are correspondingly provided with through holes; a roller shaft is connected between the two through holes, and is coated with a tripod capable of rotating along with the roller shaft; the front end of the tripod is connected with a fixed block; a vertical rod is vertically arranged on the fixed block; the vertical rod is coated with multiple bearing blocks at the upper part of the fixed block; the lower part of the vertical rod includes a butting column; the butting column includes a conical rod; a fixed ball is arranged at the lower part of the conical rod; and the fixed ball is manufactured by a magnet material. The absorption type glass column circular head grinding device has such advantages as simple structure, convenience for use and low cost.

Owner:欧璧医药包装科技(中国)有限公司

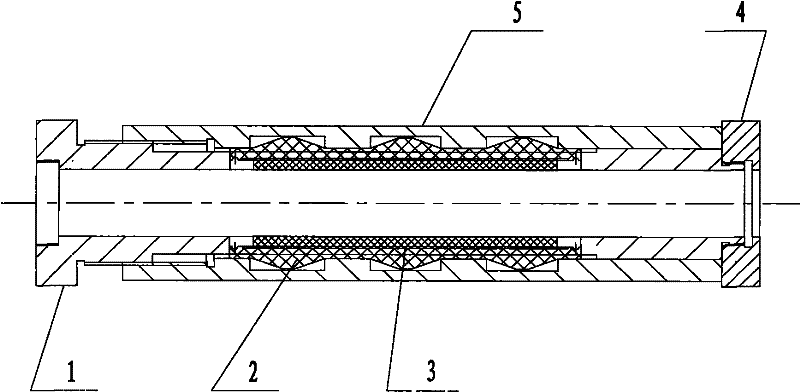

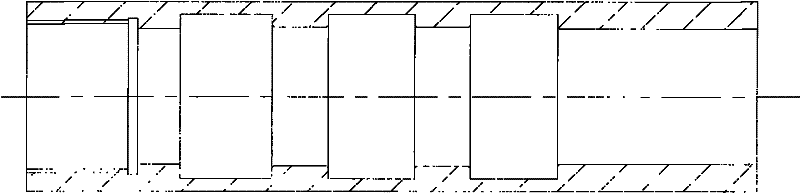

Cylindrical grinding device

InactiveCN102049709AAchieve grinding effectGood transition connectionRevolution surface grinding machinesArchitectural engineeringOuter Cannula

The invention relates to a cylindrical grinding device for bars or pipes with different lengths and external diameters, and belongs to the field of machinofacture grinding and polishing. In the cylindrical grinding device, an inner casing pipe is arranged in an outer casing pipe and is in threaded connection with one end of the outer casing pipe, and the other end of the inner casing pipe is connected with a baffle ring; the baffle ring compacts the outer casing pipe; a step through groove is formed on the side wall of the inner casing pipe; and a sand strip is fixed in the step through groove. The cylindrical grinding device has certain grinding allowance, has the polishing effect which is close to the requirement of a finishing polish process, produces the better transitional connection effect between a coarse grinding process and the finishing polish process, reduces labor strength and improves production efficiency.

Owner:PUYANG ZHONGSHI GROUP

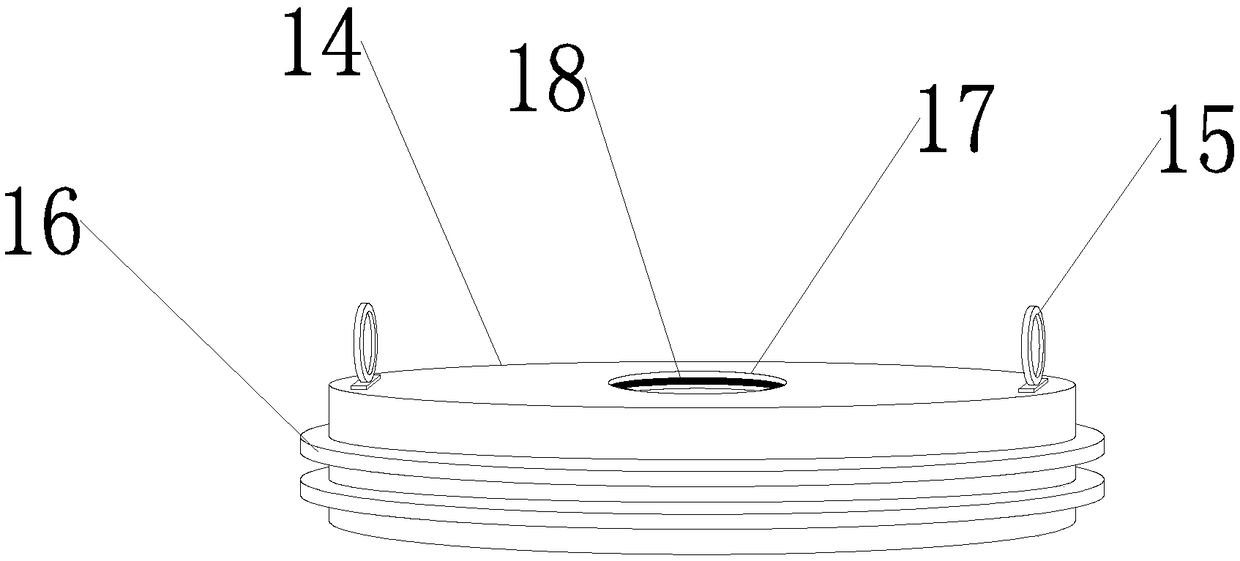

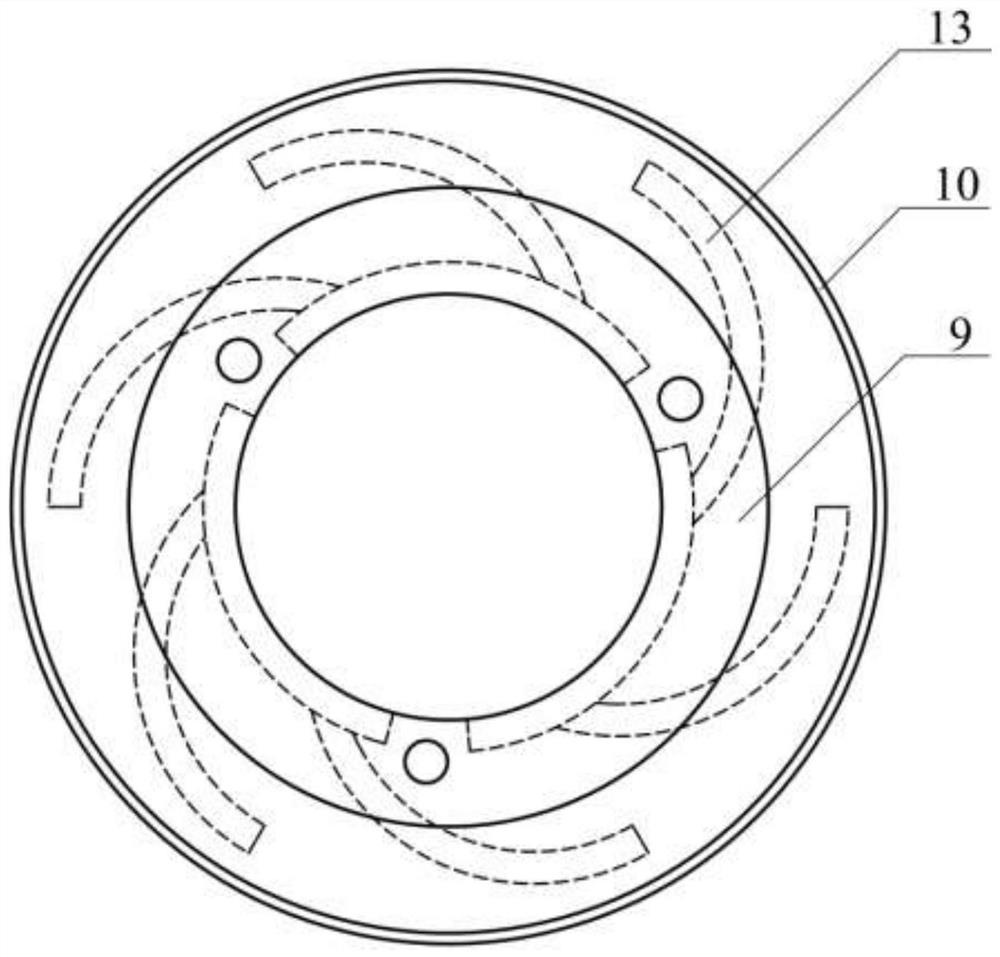

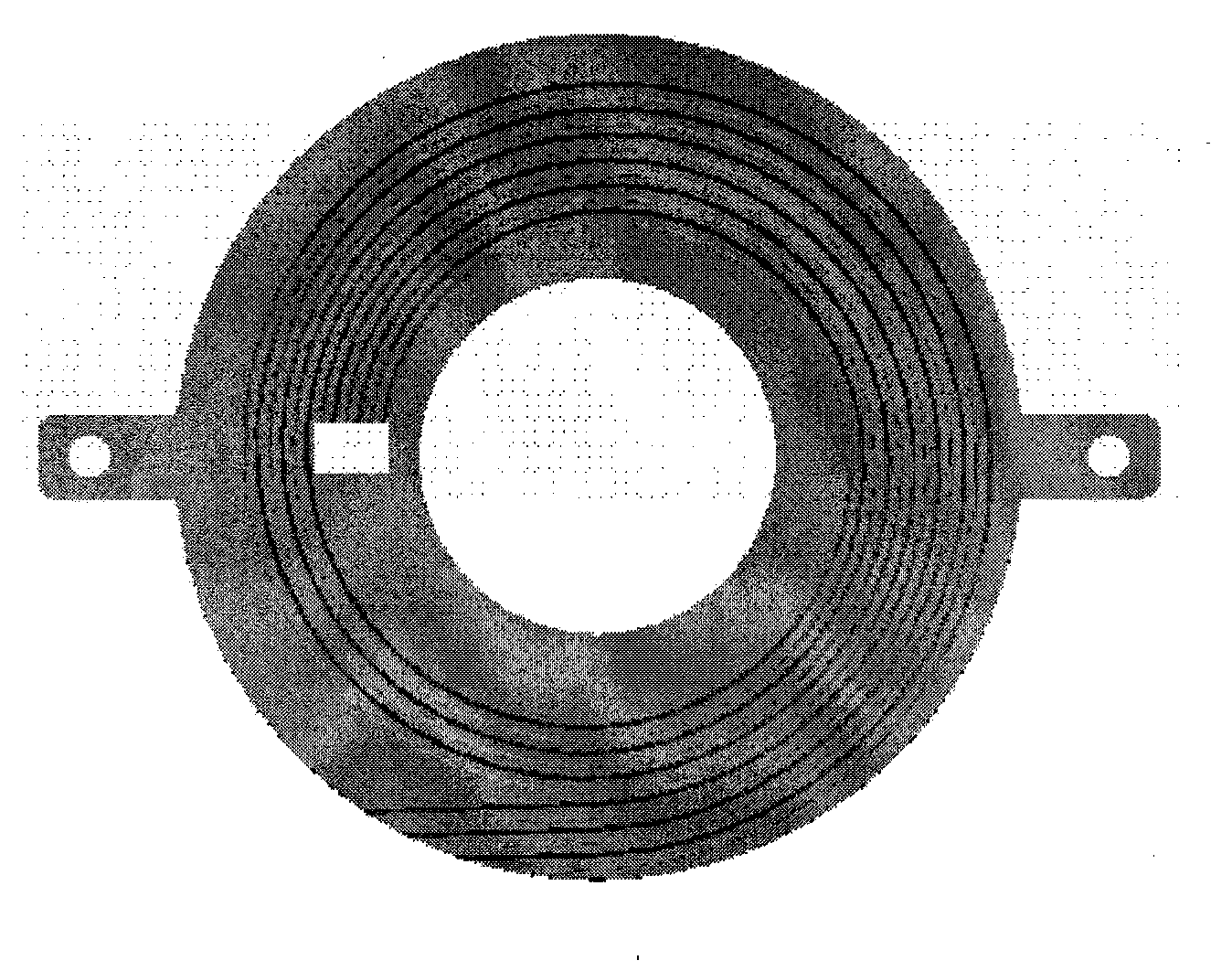

Active compliance wheel-shaped abrasive belt mechanism

ActiveCN112720176AAchieve online regulationAchieve grinding effectGrinding drivesGrinding machinesInterference fitCircular disc

The invention discloses an active compliance wheel-shaped abrasive belt mechanism. The active compliance wheel-shaped abrasive belt mechanism comprises a grinding contact wheel, an abrasive belt sleeves the outer circle of the grinding contact wheel, an on-wheel disc is arranged in the grinding contact wheel, a rib commutator is arranged in the center of the on-wheel disc, a rotating main shaft is arranged in the center of the rib commutator in a penetrating mode, the rotating main shaft and the rib commutator are in interference fit, a bearing structure is further arranged on the upper portion of the rotating main shaft, the bottom of the bearing structure is fixedly connected with a flange plate, a plurality of reinforcing ribs are evenly arranged between the flange plate and the rib commutator, and the bearing structure is further connected with an electric push rod structure. The problem that in the prior art, in abrasive belt grinding, on-line control over the machining process of a thin-walled workpiece with non-uniform thickness is difficult to conduct is solved.

Owner:XIAN UNIV OF TECH

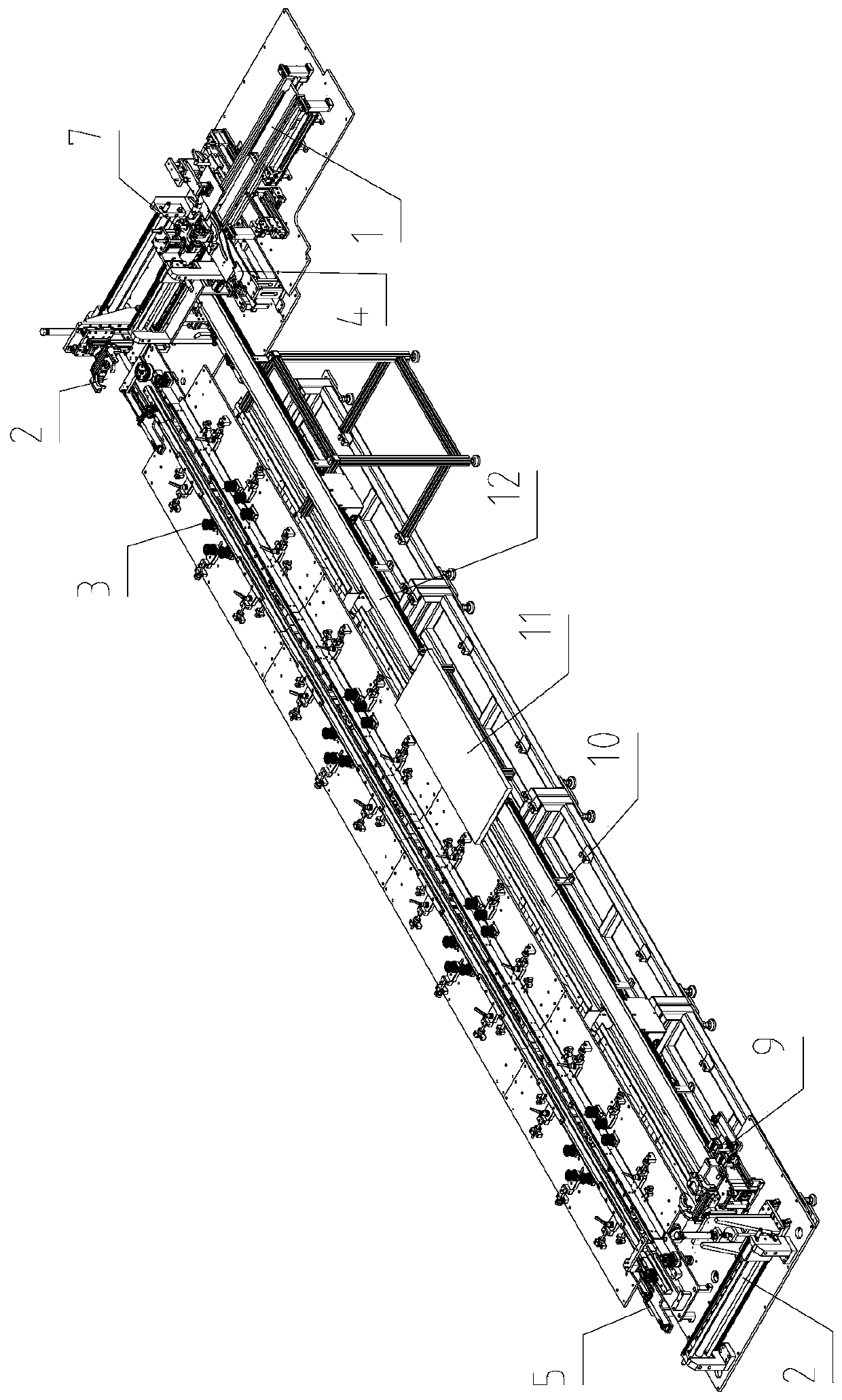

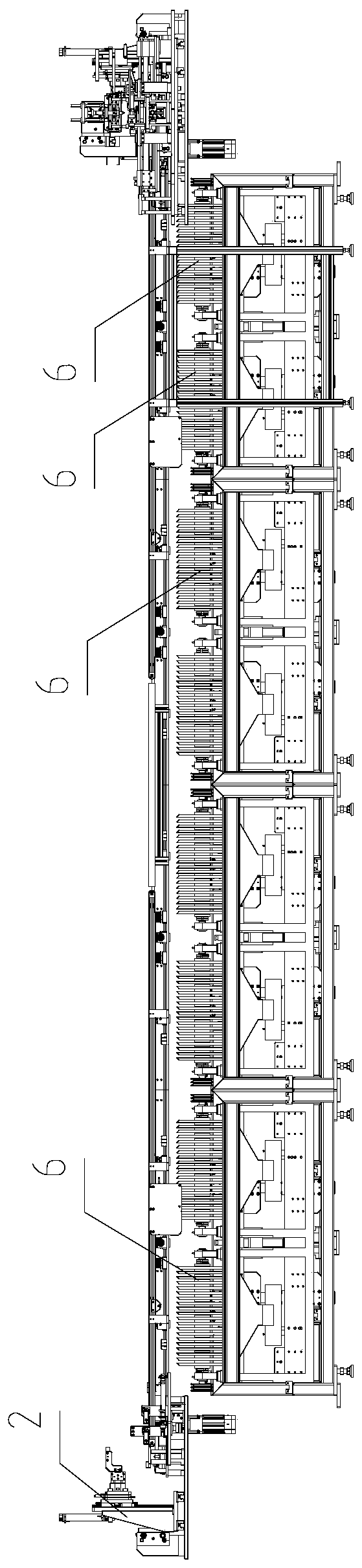

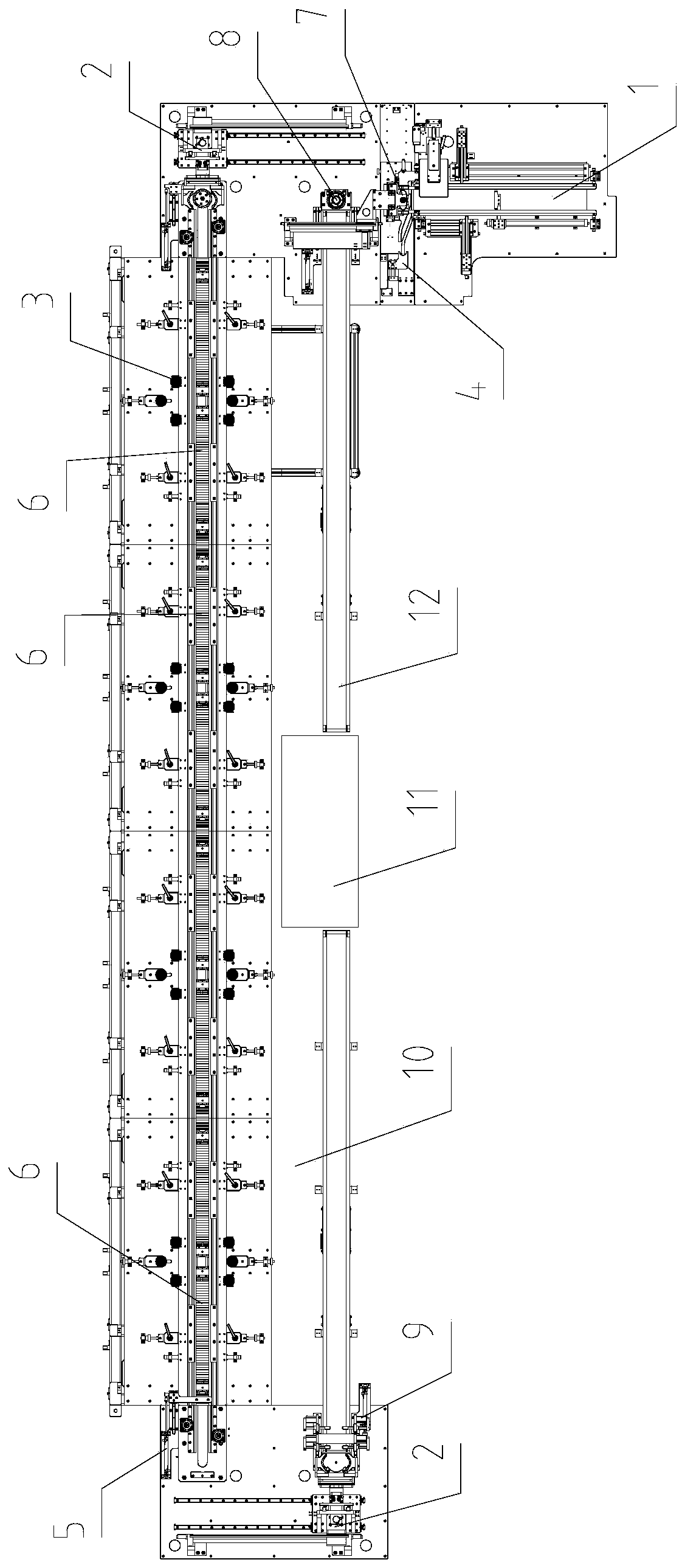

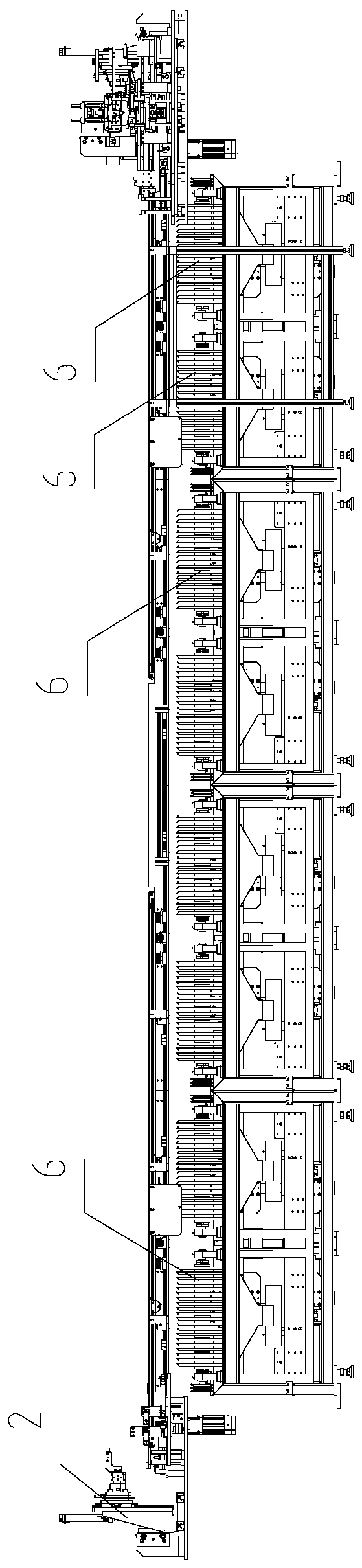

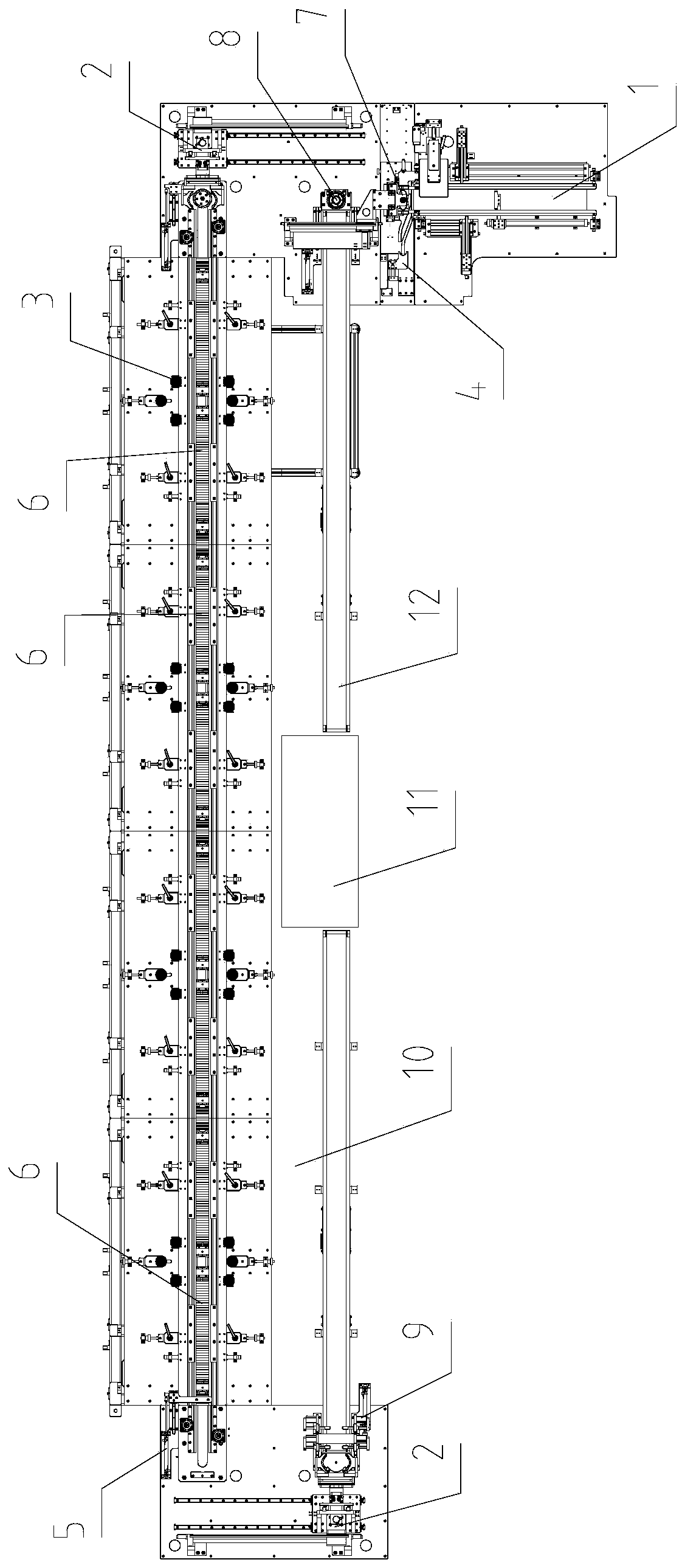

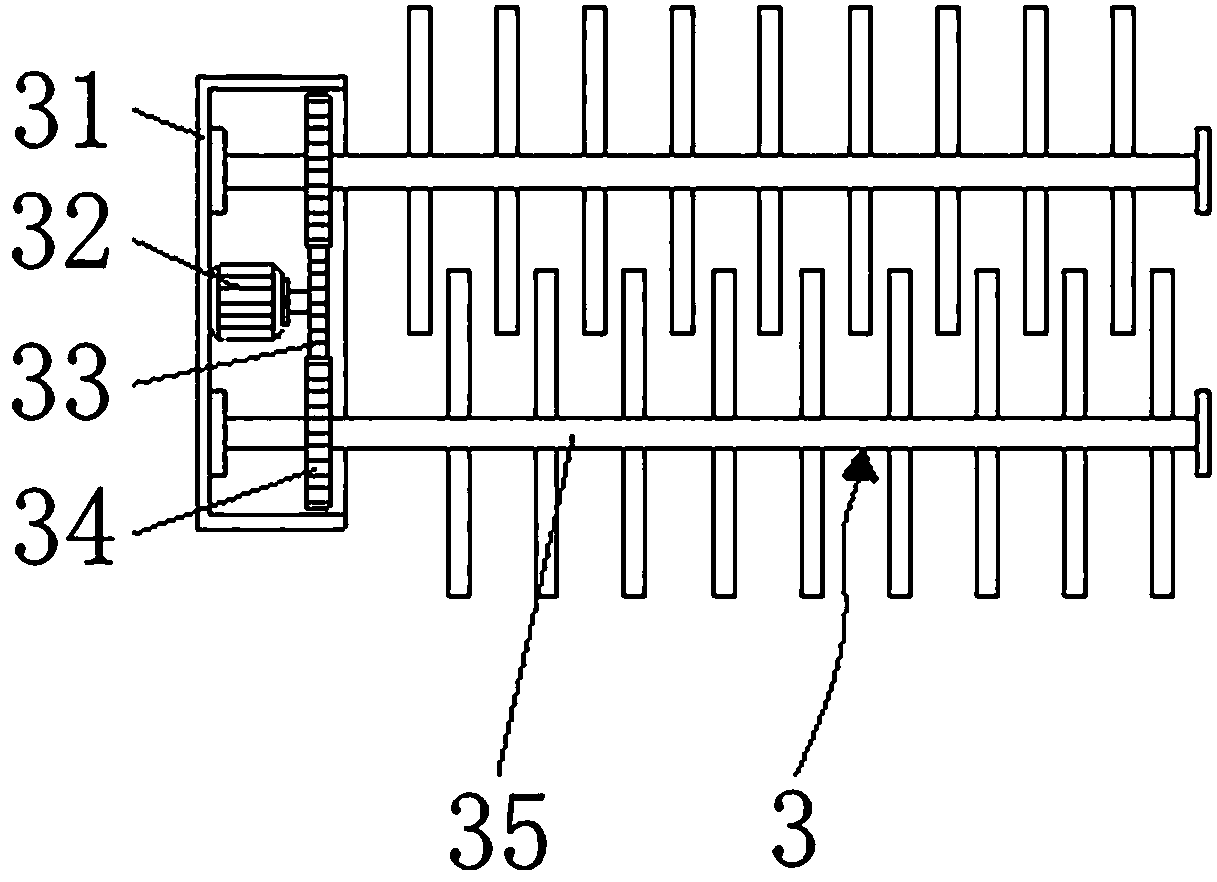

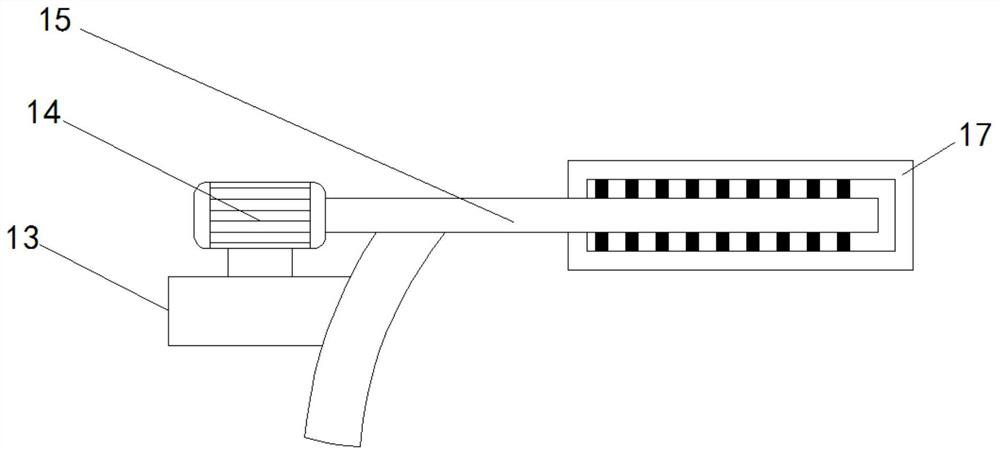

Fiber differential feeding composite grinding device

PendingCN111109834AEnhanced adsorption and adhesionImprove processing efficiencyGrinding drivesBristleGrindingWheel drive

The invention provides a fiber differential feeding composite grinding device, which improves the working efficiency of industrial fiber grinding, improves the grinding quality and grinding consistency, reduces the labor intensity and reduces the manufacturing cost. The device comprises a clamp walking mechanism, and a wire grinding assembly is arranged at the bottom of the clamp walking mechanism. The clamp walking mechanism comprises a walking mechanism supporting plate. A pair of walking sliding rails is arranged on the walking mechanism supporting plate. A positioning walking sliding groove is formed between the pair of walking sliding rails. A left driving belt wheel and a right driving belt wheel are arranged on the walking mechanism supporting plate respectively, the left driving belt wheel and the right driving belt wheel drive synchronous toothed belts to move respectively, and the synchronous toothed belts driven by the left driving belt wheel and the right driving belt wheelrespectively move in the positioning walking sliding groove in a differential mode. The fiber differential feeding composite grinding device can be widely applied to a fiber surface polishing process.

Owner:威海联创工业自动化科技股份有限公司

Machine tool for grinding glass drill

Owner:ZHEJIANG UNIV OF TECH

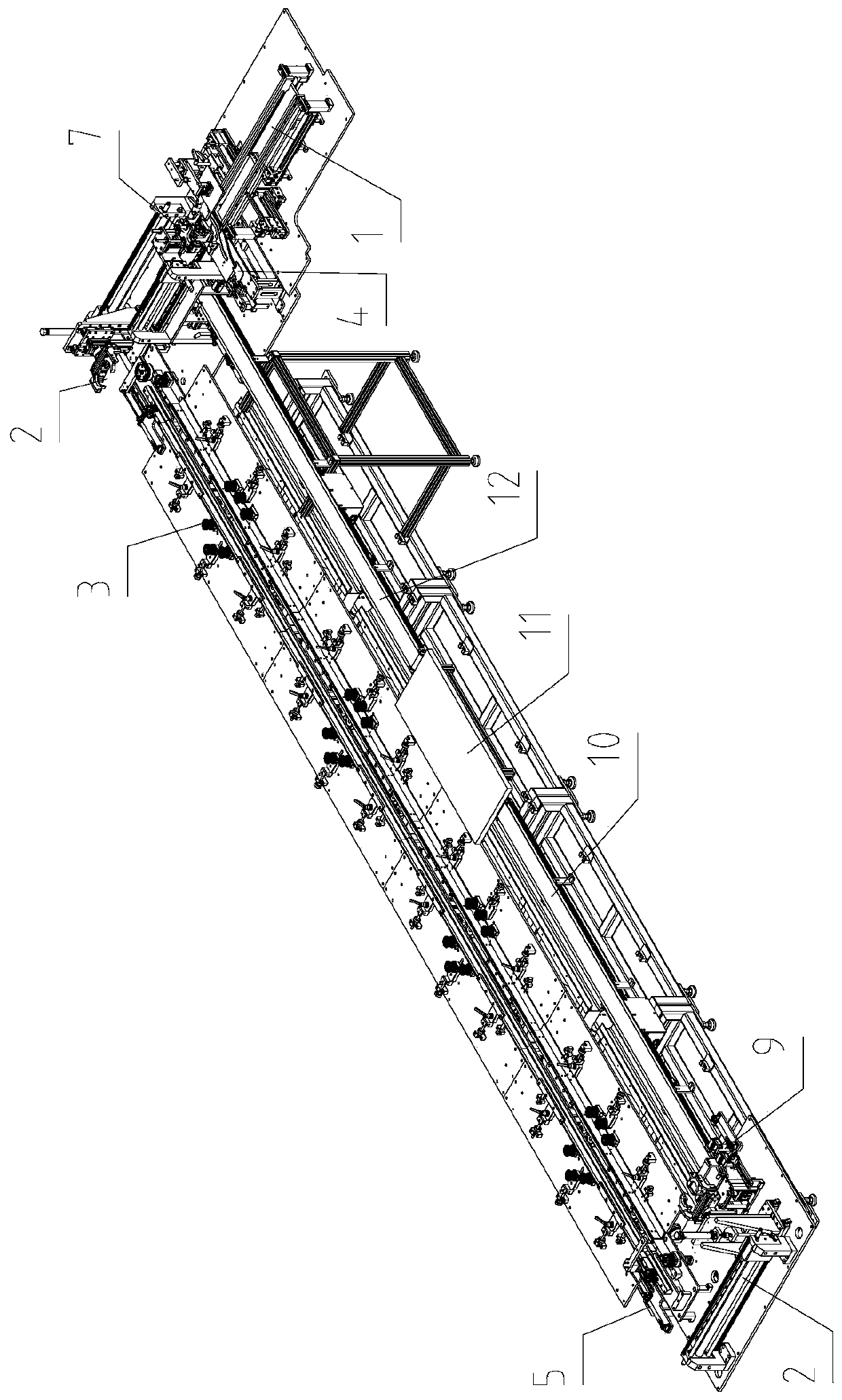

Automatic fiber polishing device

PendingCN111168544ARealize fully automatic operationAchieve grinding effectGrinding carriagesGrinding machinesFiber bundleEngineering

The invention provides an automatic fiber polishing device which comprises a fiber feeding mechanism, wherein a fiber separating mechanism is arranged on one side of the fiber feeding mechanism; a fiber bundle collecting and inserting mechanism is arranged on one side of the fiber separating mechanism; a clamp carrying mechanism is arranged on one side of the fiber bundle collecting and insertingmechanism; a clamp travelling mechanism is arranged on one side of the clamp carrying mechanism; and a fiber polishing component is arranged at the bottom of the clamp travelling mechanism. The automatic fiber polishing device solves the problems that the existing manual fiber polishing industry is low in efficiency, and poor in polishing quality and consistency to cause that fibers cannot be usedon batches. The automatic fiber polishing device can be widely applied to the fiber surface polishing technology.

Owner:威海联创工业自动化科技股份有限公司

Novel light burning kiln fine grinding device

The invention discloses a novel light burning kiln fine grinding device which comprises a box body. The top of the box body communicates with a filling pipe, the left side of the box body is providedwith a crushing mechanism, the crushing mechanism comprises a placing box, a first motor, a first gear, a second gear and a first crushing rod, the bottom of the surface of an inner cavity of the boxbody is fixedly connected with a fixing plate, the surface of the fixing plate is provided with a first through hole, a grinding plate is arranged in the first through hole, and a second motor is fixedly connected to the bottom of the grinding plate. A material filling effect is achieved through the box body and the filling pipe, a material crushing effect is achieved through the crushing mechanism, the effect of placing the grinding plate is achieved through the fixing plate and the first through hole, a material grinding effect is achieved through the grinding plate, the effect of driving the grinding plate to rotate is achieved through the second motor, and the fine grinding device can grind materials uniformly and effectively and is convenient for people to use.

Owner:HAICHENG GUOTIAN MINING CO LTD

Pulping method of positive electrode material with high specific surface area

ActiveCN113054189AImprove crushing effectQuality improvementCell electrodesSecondary cellsActive agentPyrrolidinones

The invention relates to the technical field of lithium ion battery processing, and provides a pulping method of a positive electrode material with high specific surface area. The pulping method comprises the following steps of: S1, adding the dried positive electrode material with high specific surface area, conductive carbon black and polyvinylidene fluoride into a pulping tank, and uniformly stirring and mixing the mixture; S2, adding N-methyl pyrrolidone into the mixture according to the solid content of 70%-90%, stirring or kneading the product at a low speed under the high solid content, then gradually adding N-methyl pyrrolidone the solid content is 40%-50%, stirring continuously, then adding a surfactant, a modifier and a silane coupling agent, stirring the mixture, and gradually adding N-methyl pyrrolidone till the viscosity is 8000-10000 mPa.s; and S3, taking the slurry obtained in the step S2, carrying out high-strength mechanical dispersion, and stirring the slurry. According to the pulping method, the problems that a positive electrode material cannot be dispersed, is jelly-shaped, is low in solid content and agglomerates particles in the prior art are solved.

Owner:河北九丛科技有限公司

Special grinding aid for calcium carbonate powder and use method of special grinding aid

ActiveCN111808438AGood compatibilityModulation of Surface PropertiesPigment treatment with organosilicon compoundsPigment physical treatmentMetallurgyPhysical chemistry

The invention belongs to the field of grinding aids, and particularly relates to a special grinding aid for calcium carbonate powder and a use method of the special grinding aid. The grinding aid comprises a component A and a component B, wherein the component A is an active substance containing amino groups (or imino groups) and sulfonic groups, and the component B is an active substance containing a C-C long chain. According to the application requirement of the grinding aid product, the component A and the component B are added into water according to a certain proportion and stirred. According to the special grinding aid for calcium carbonate provided by the invention, the grinding aid contains a large amount of active substances, so that efficient grinding aiding and modification canbe simultaneously realized on superfine inorganic powder; in addition, the surface performance of the grinding-aid calcium carbonate can be regulated and controlled by controlling the relative contentof the two components.

Owner:HEZHOU UNIV +1

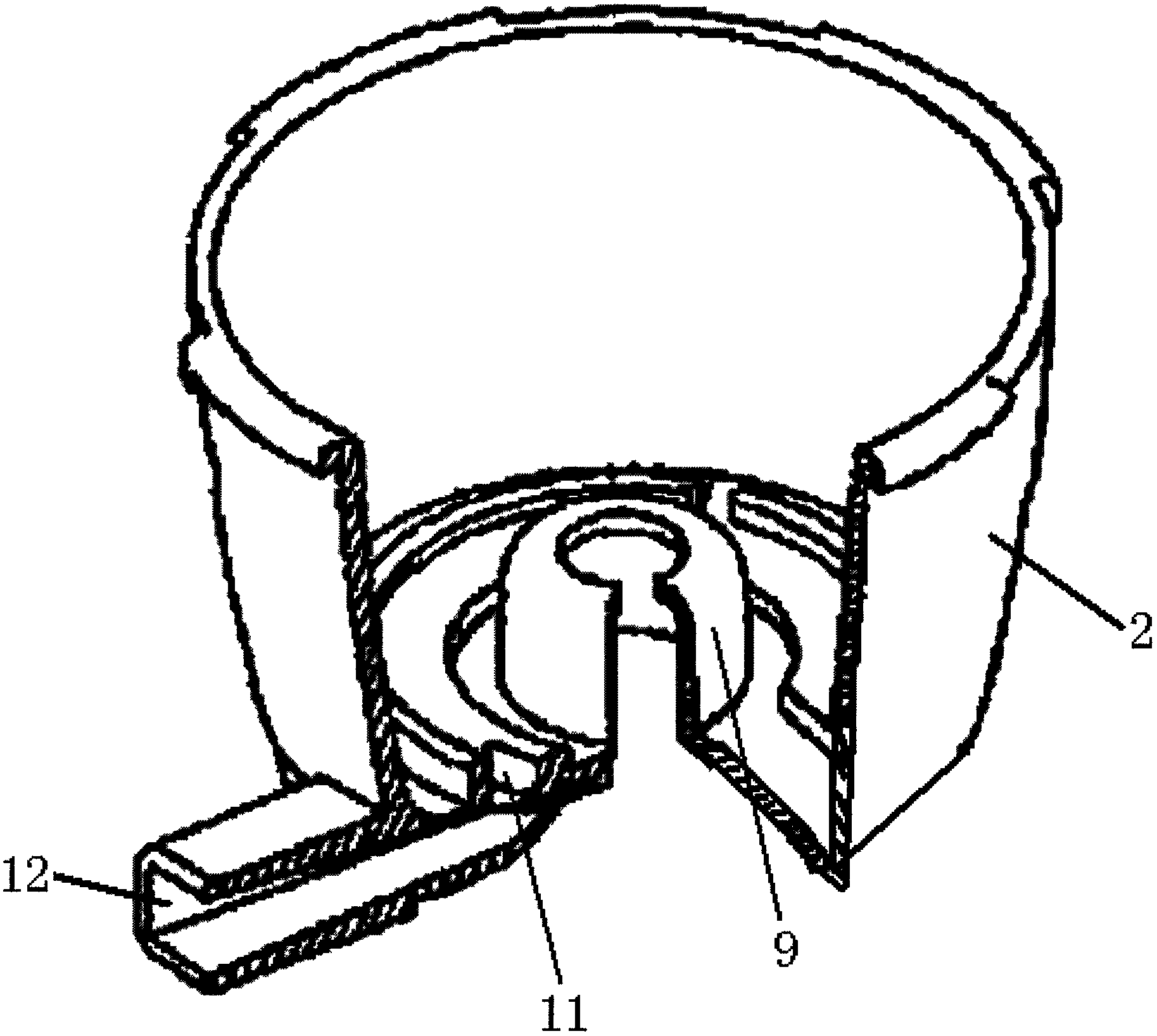

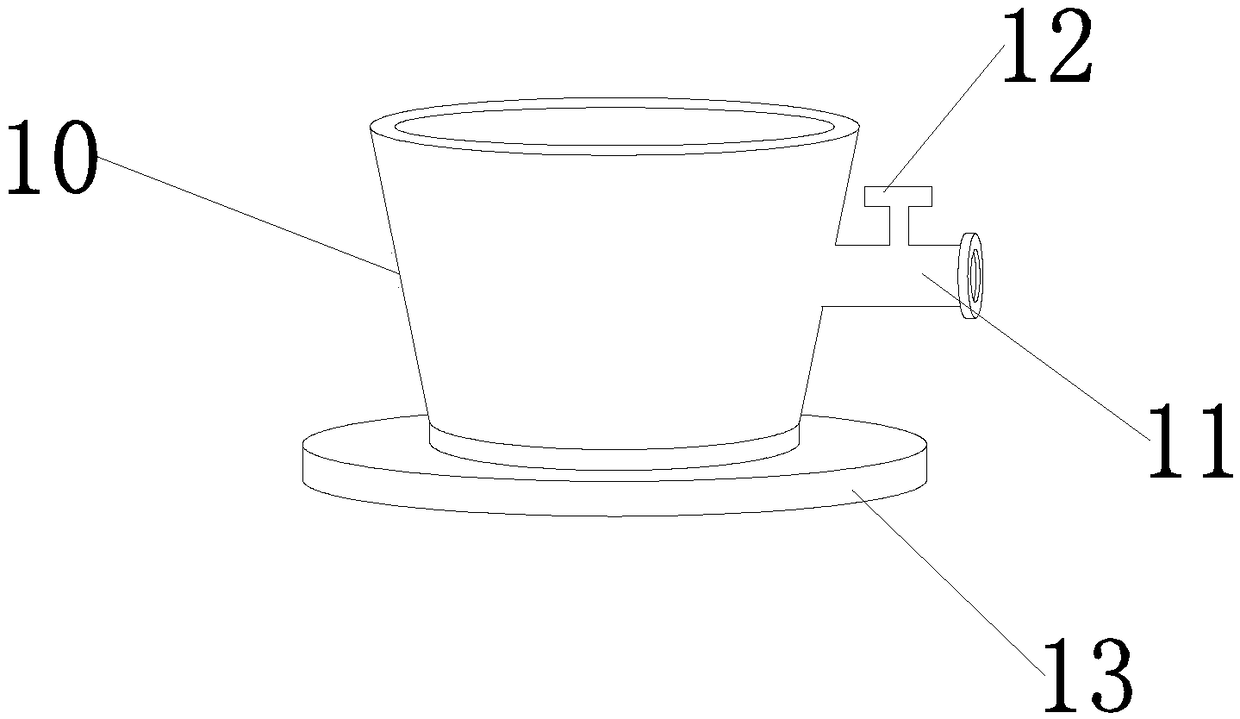

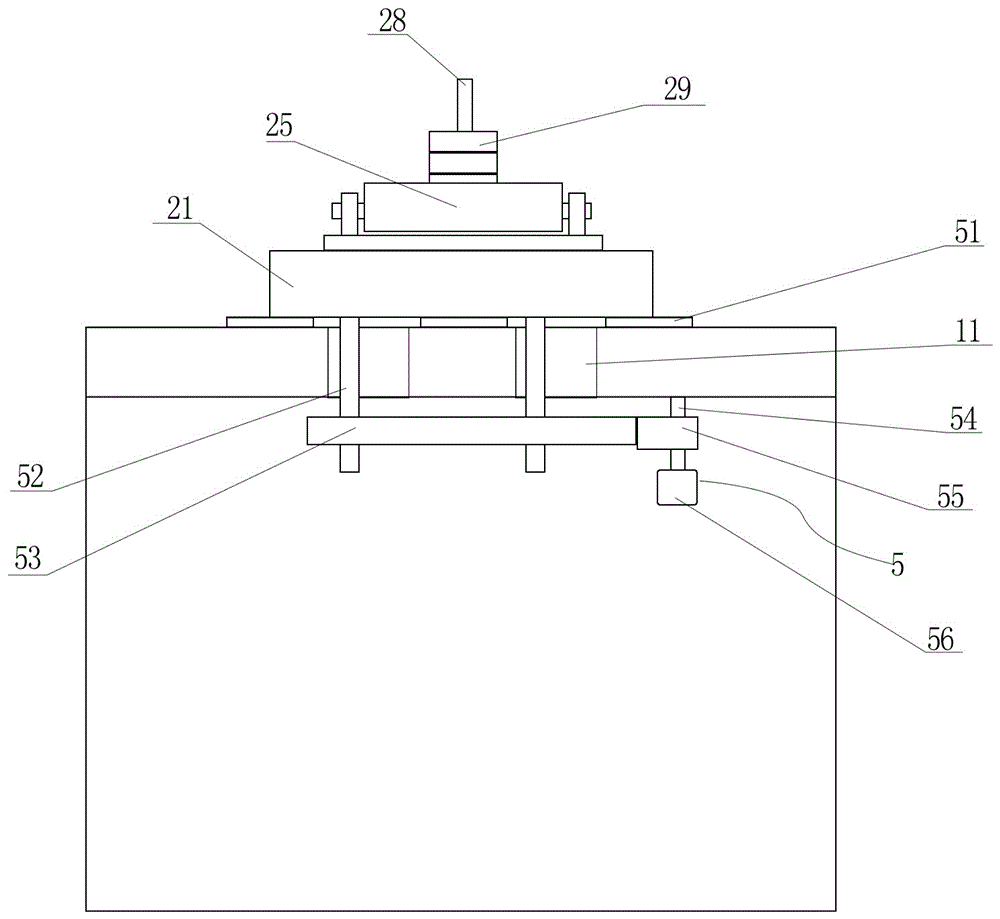

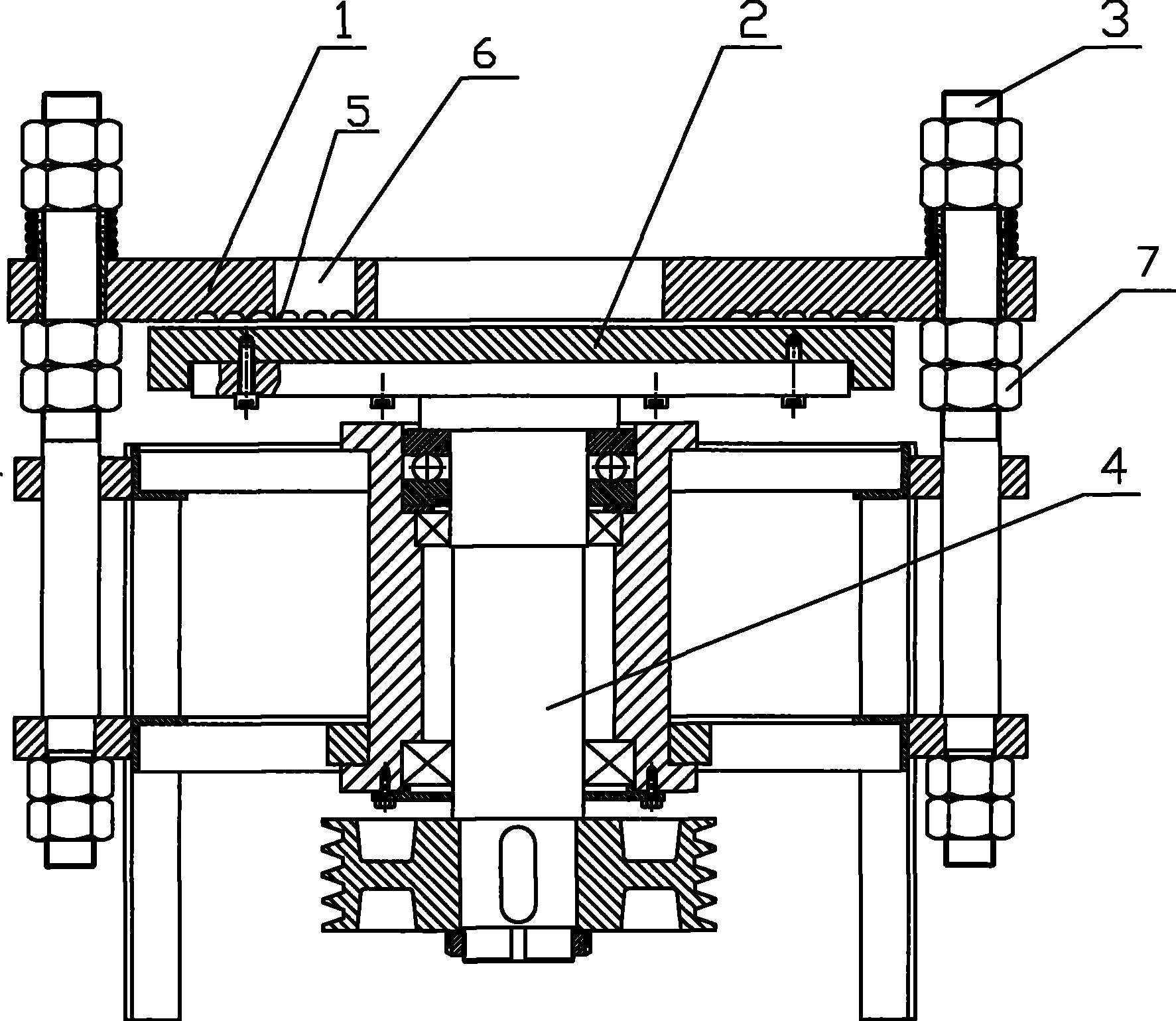

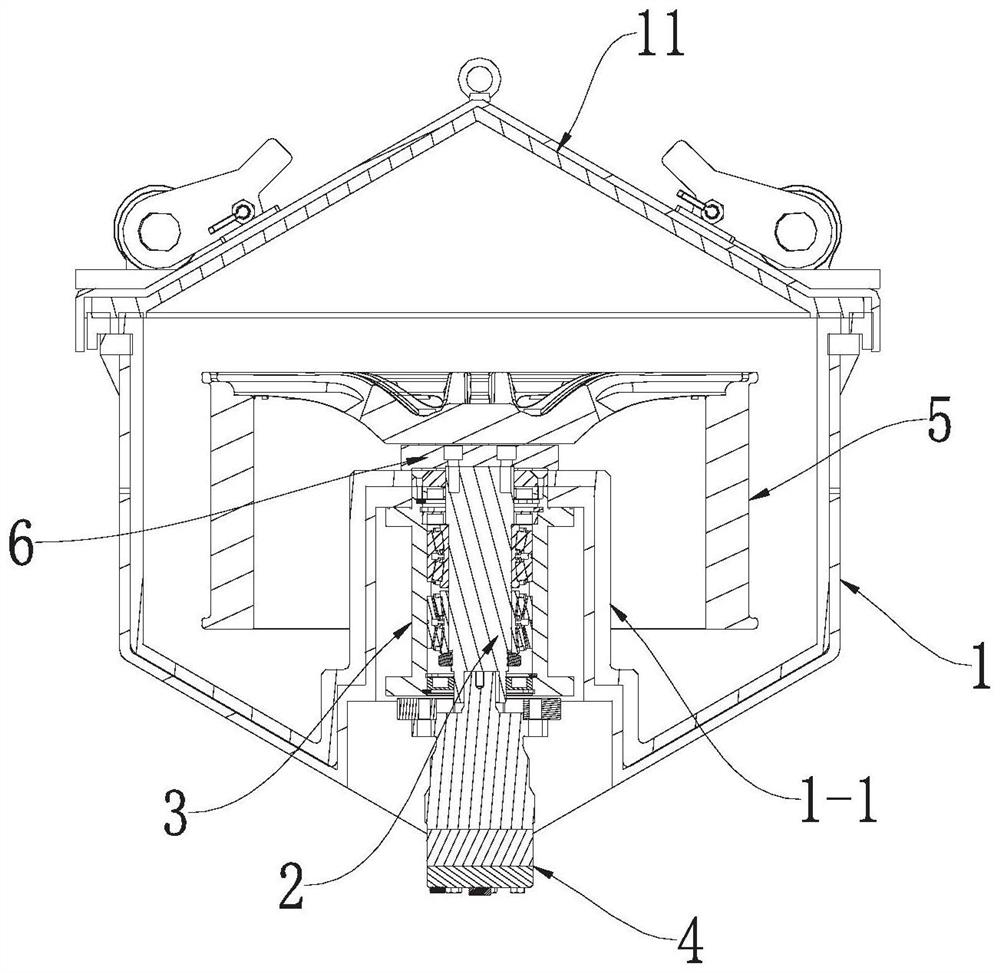

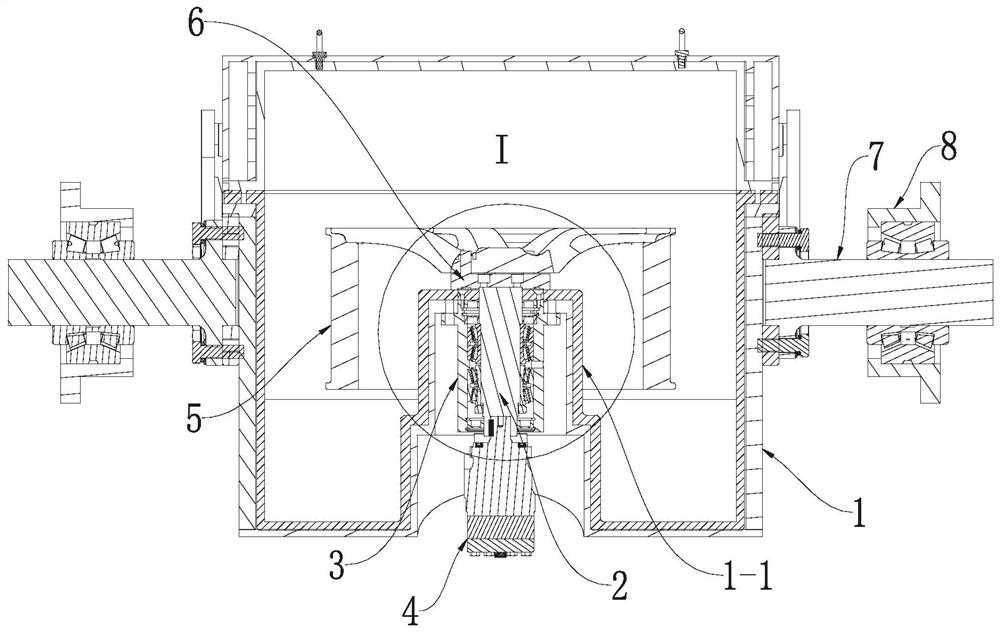

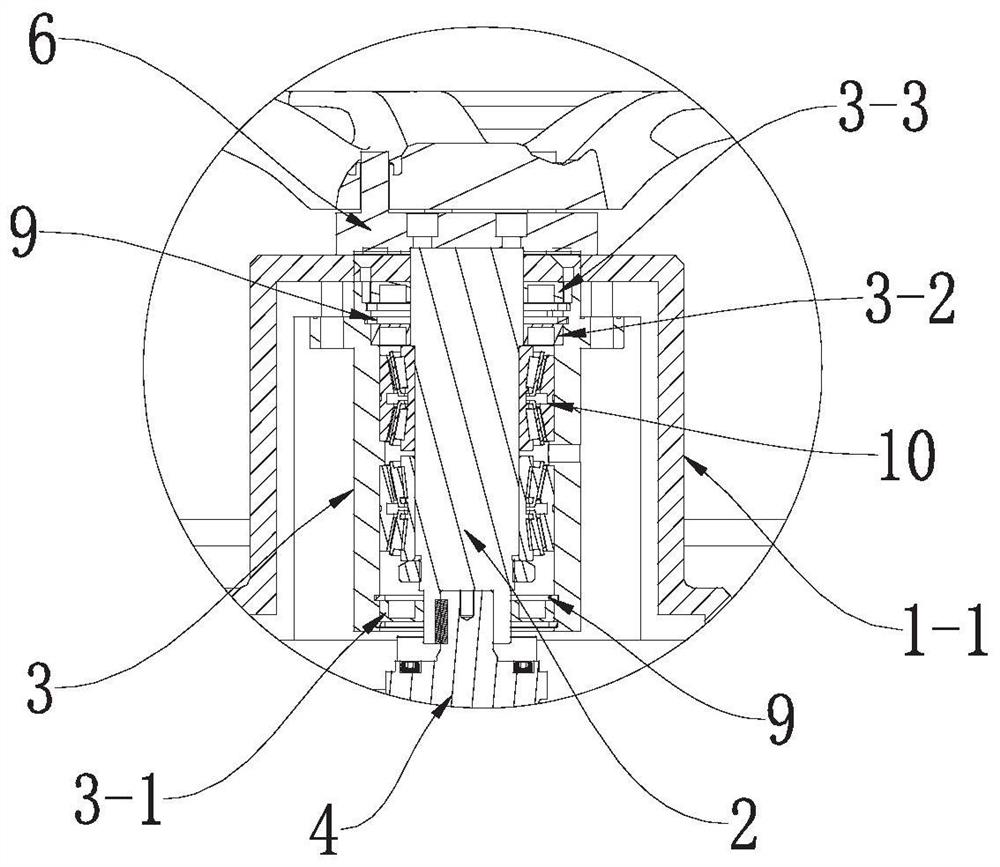

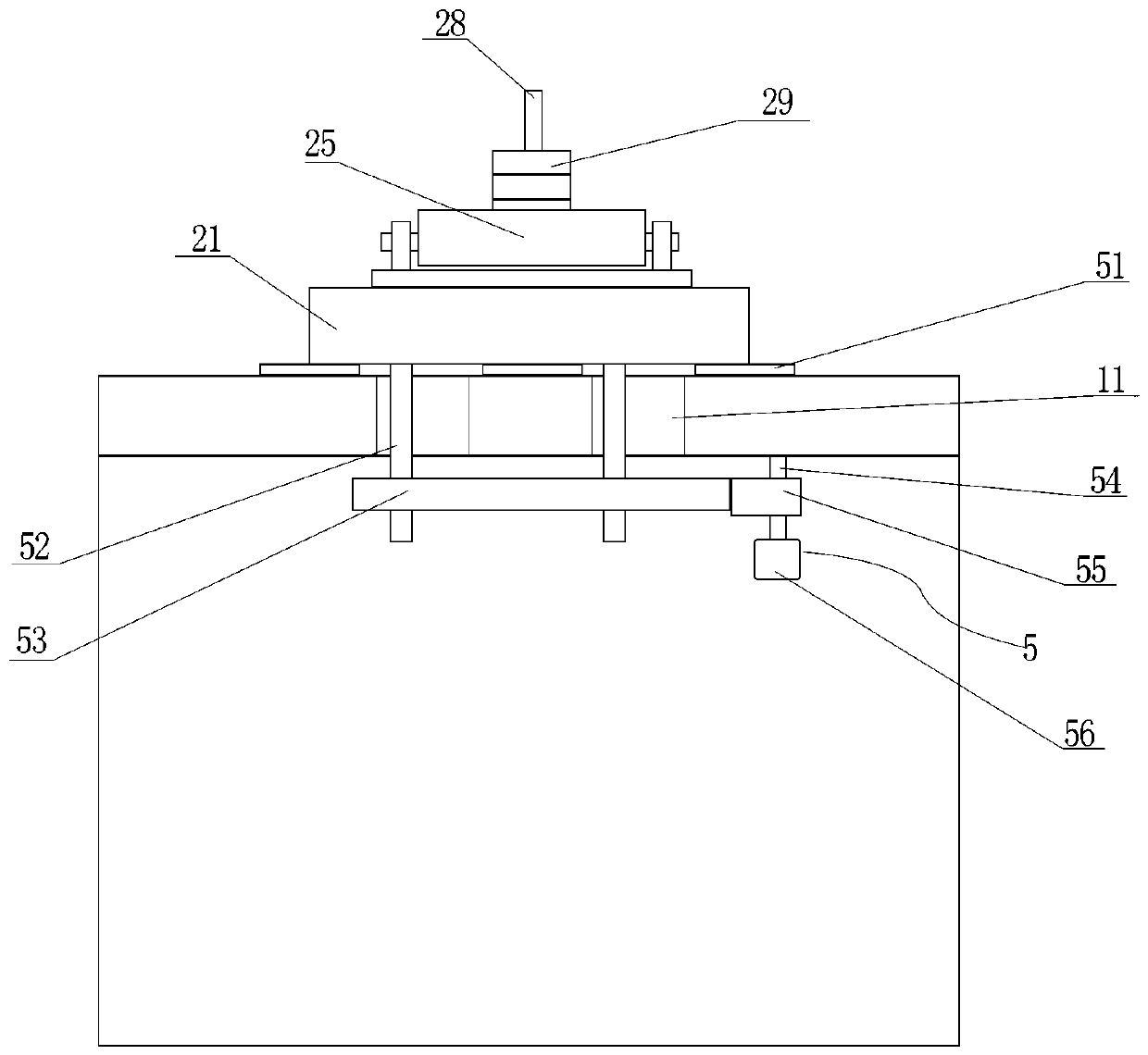

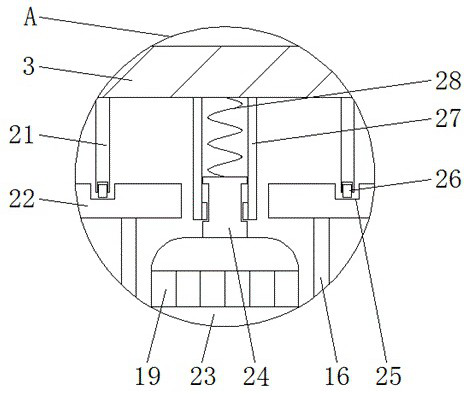

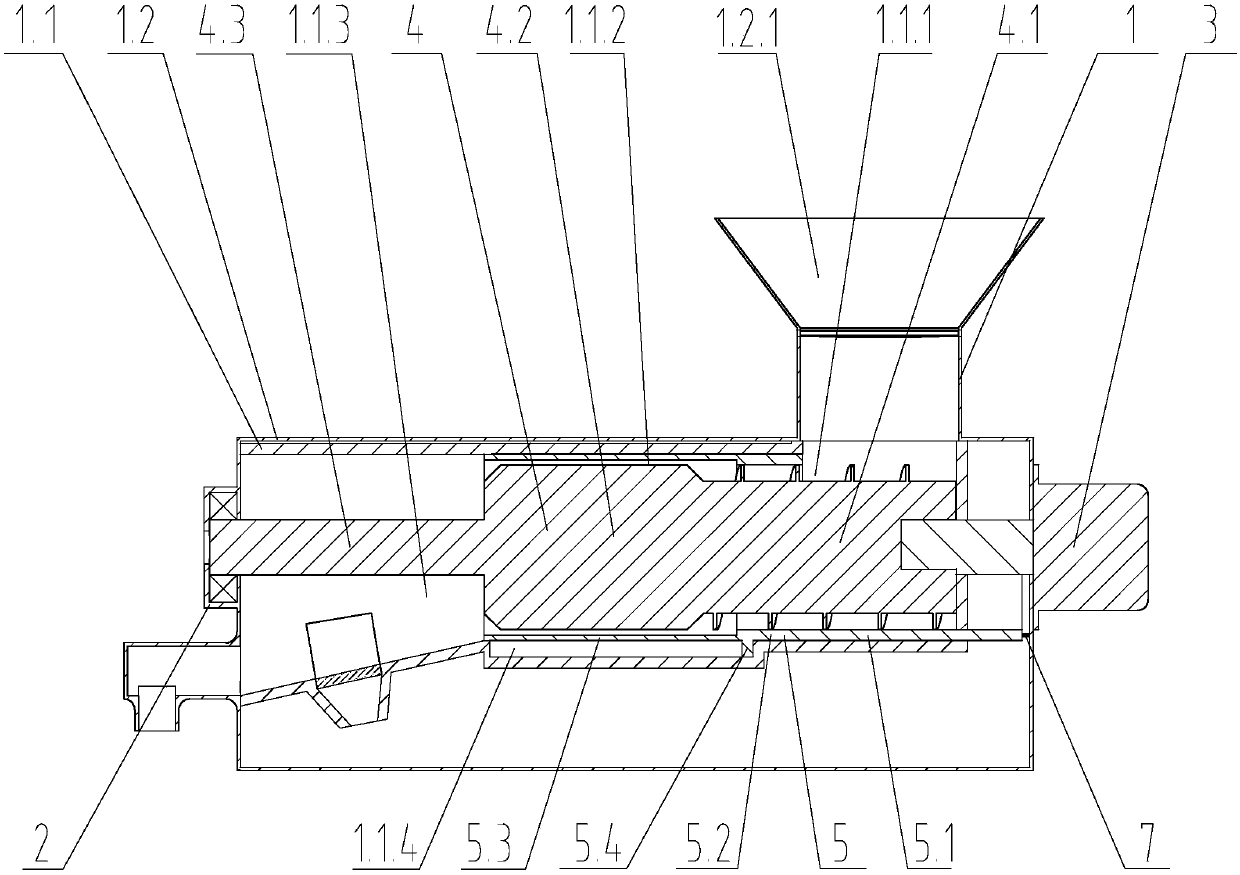

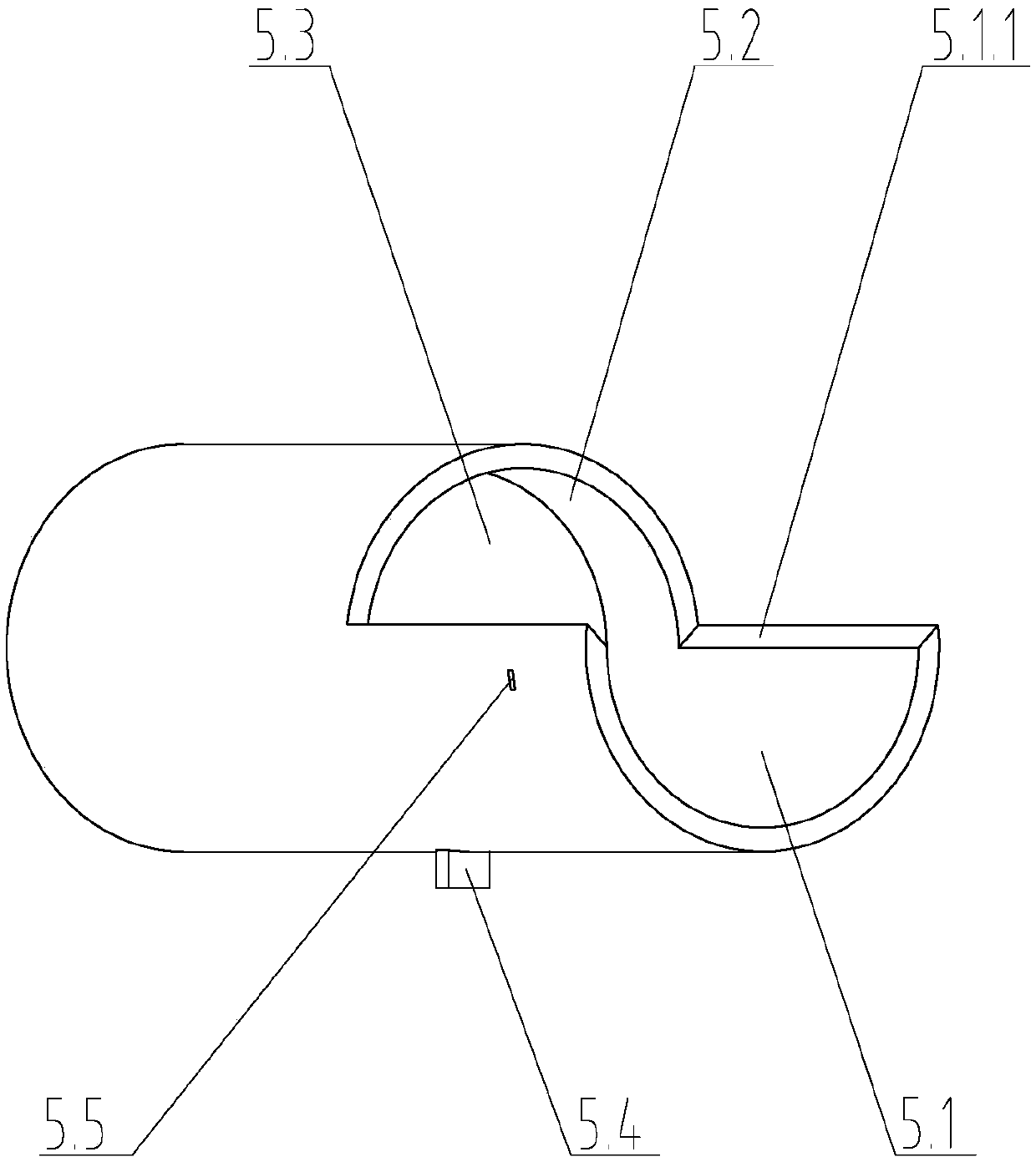

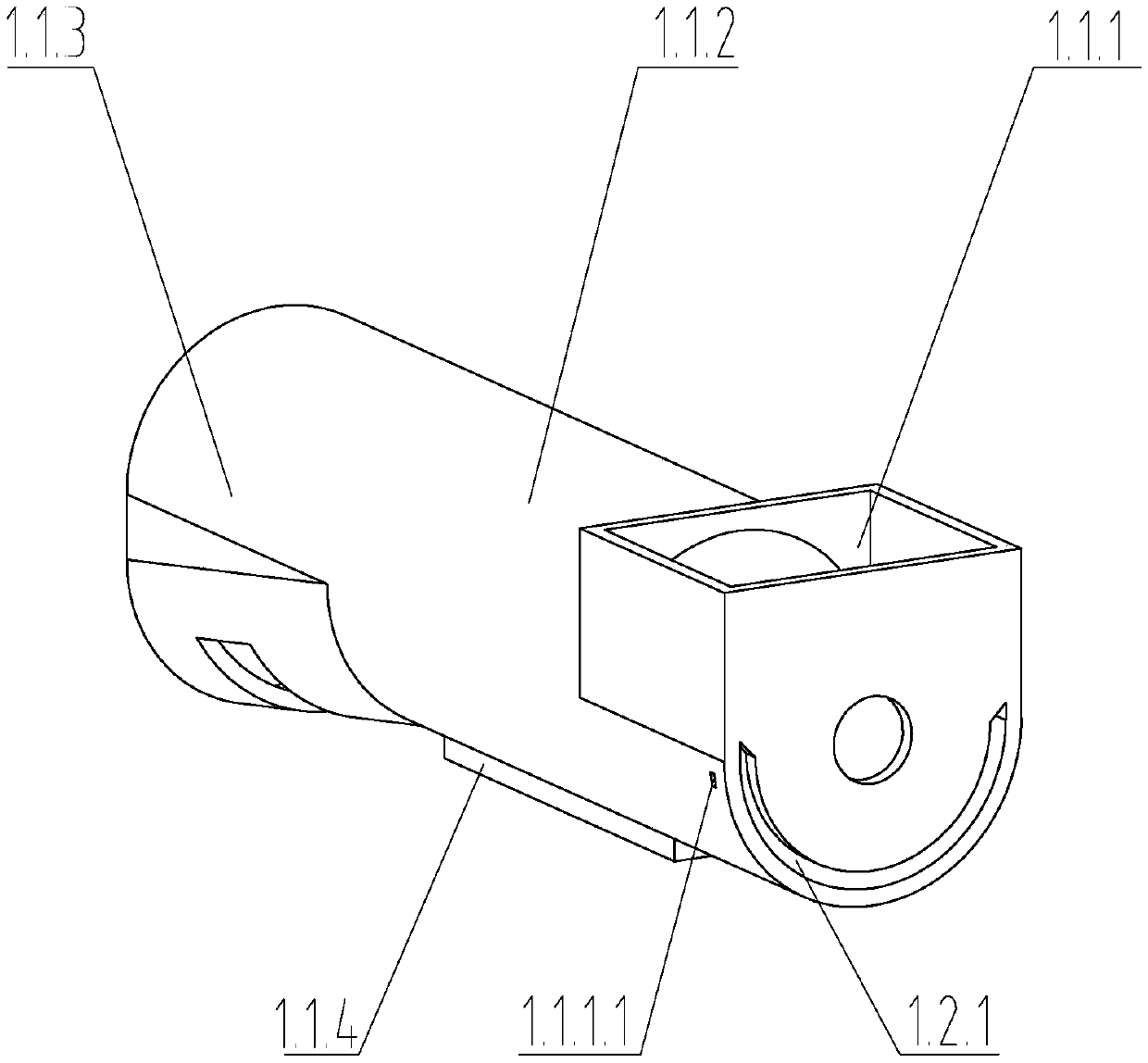

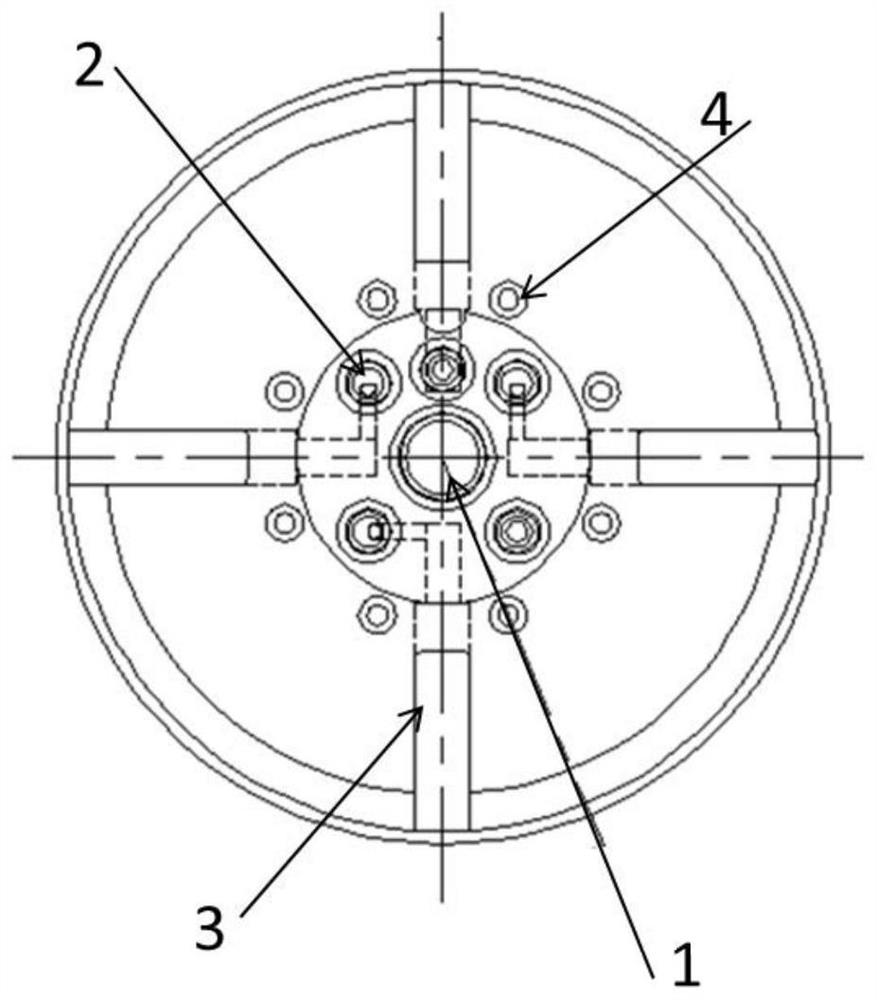

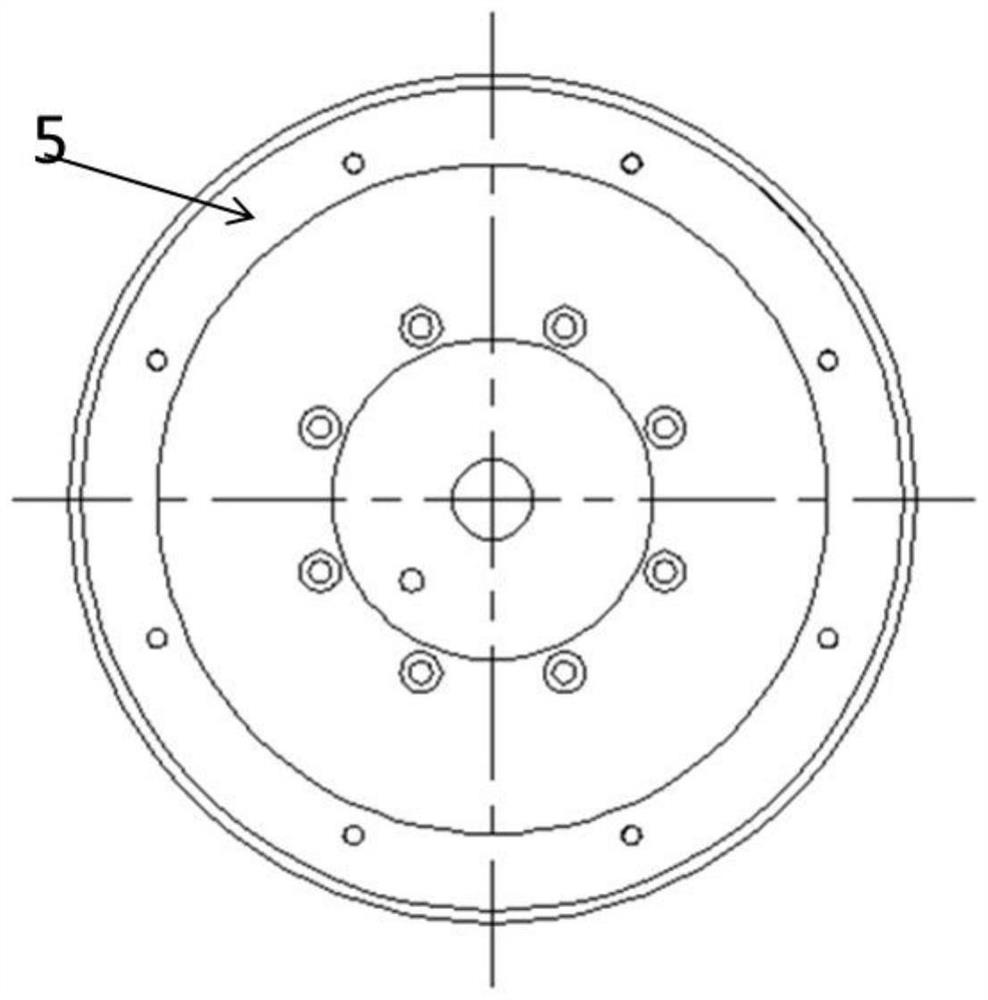

Rolling barrel for hub roll-polishing machine and roll-polishing machine

PendingCN112318356AGrind fullyAchieve grinding effectEdge grinding machinesPolishing machinesPolishingEngineering

The invention discloses a rolling barrel for a hub roll-polishing machine and the roll-polishing machine. The rolling barrel for the hub roll-polishing machine comprises a rolling barrel body (1); a hub rotating shaft (2), a rotating shaft fixing seat (3) and a driving part (4), wherein the hub rotating shaft (2) rotatably supports a hub (5); the rotating shaft fixing seat (3) is fixed at the bottom of the rolling barrel body (1), and the rotating shaft fixing seat (3) is provided with an inner cavity for accommodating the hub rotating shaft (2) so as to support the hub rotating shaft (2); andthe driving part (4) is in transmission connection with the hub rotating shaft (2) so as to drive the hub rotating shaft (2) to rotate. According to the rolling barrel for hub roll-polishing machineand the roll-polishing machine disclosed by the invention, the hub polishing efficiency can be improved.

Owner:昆山金海格智能系统有限公司

Metallurgy ore circulating grinding device

The invention relates to the technical field of metallurgical equipment, and discloses a metallurgical ore circulating grinding device. The device comprises a grinding device body, a powder collecting device is fixedly installed in the grinding device body, a supporting rod is fixedly installed on the left side of the powder collecting device, a motor is fixedly installed on the top of the supporting rod, a brush rod is fixedly installed on the right side of the motor, an electric wire is fixedly connected to the left side of the motor, and a plastic sleeve is fixedly installed on the inner wall of the powder collecting device. After a conductive block is pushed into a circuit through a cam, the brush rod rotates in the plastic sleeve, so that the outside of the plastic sleeve has magnetism to attract ground powder, an electromagnetic relay attracts a sliding block to move rightwards after the circuit is conducted, and therefore the bottom of the powder collecting device is opened; and after the conductive block leaves the circuit, the electromagnetic relay is closed, the powder collecting device is closed, so that the effects that the ground powder is collected and the attracted powder does not fall into the grinding area are achieved.

Owner:王友振

A clean glass column round head grinding device

ActiveCN105834886BPrevent spread of pollutionGuaranteed cleanlinessGrinding carriagesLapping machinesDevice typeReciprocating motion

The invention discloses a clean glass column circular head grinding device. The device comprises a frame; the frame is correspondingly provided with a fixing module and a grinding module; a driving module for driving the fixing module to perform a reciprocating motion is arranged in the frame; the grinding module includes a groove formed in the frame; a through groove is formed in the center of the groove; a bearing is arranged in the through groove, and is coaxially provided with a vertical rotating shaft; the rotating shaft is coaxially provided with a rotating disc; the rotating disc is arranged at the upper part of a bearing; a fixed disc is arranged at the upper part of the rotating disc; a grinding wheel is horizontally arranged at the top end of the rotating shaft; a first motor is coaxially arranged at the lower part of the rotating shaft; two circles of arc grooves are downwards formed in the bottom of the groove; the arc grooves are arranged at equal intervals; an annular pipe is arranged at the lower parts of the arc grooves in the frame; a collecting box is arranged at the lower part of the annular pipe; a negative-pressure fan is arranged at the bottoms of the arc grooves; and the negative-pressure fan is arranged in the annular pipe. The clean glass column circular head grinding device has such advantages as simple structure, convenience for use and low cost.

Owner:湛江市百德玻璃制品有限公司

Straw smashing device for agricultural products

InactiveCN112237098AAchieve grinding effectSmall particle sizeCuttersAgricultural engineeringMotor shaft

The invention discloses a straw smashing device for agricultural products, which comprises a smashing device body, a first grinding plate, a flow guide plate, a fixing plate and a motor shaft. A rotating shaft, the flow guide plate and the fixing plate are installed in the smashing device body, and a driving belt pulley is rotatably installed on one side of a first motor. A baffle is connected tothe inner wall of the upper end of the side, deviating from the first motor, of the smashing device body through a hinge, a second grinding plate is installed on the lower surface of the flow guide plate through a fixing block, a second motor is installed in a motor shell, and the motor shaft is rotatably installed on the upper surface of the second motor. A limiting groove is formed in the outerwall of the upper end of the motor shaft, a limiting block is fixed to the inner wall of the bottom end of a sleeve rod, and the upper surface of the motor shaft is elastically connected with the lower surface of the first grinding plate through a spring. According to the straw smashing device for the agricultural products, the first grinding plate and the second grinding plate can be tightly attached through elastic force of the spring, and the effect of smashing the straw of agricultural products more thoroughly can be achieved.

Owner:新沂市青草地农业发展有限公司

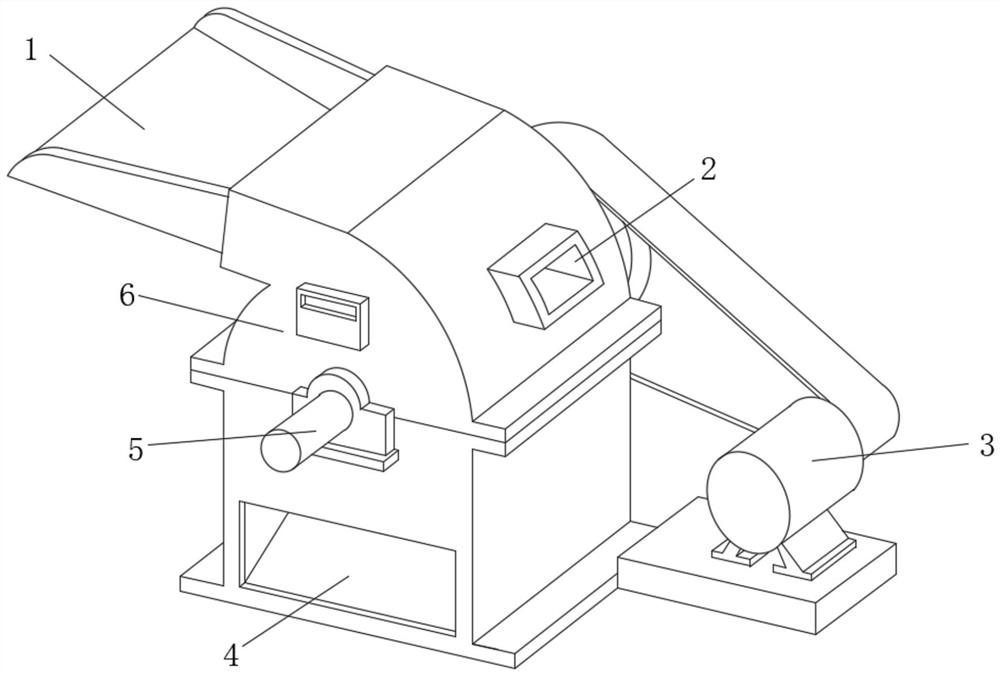

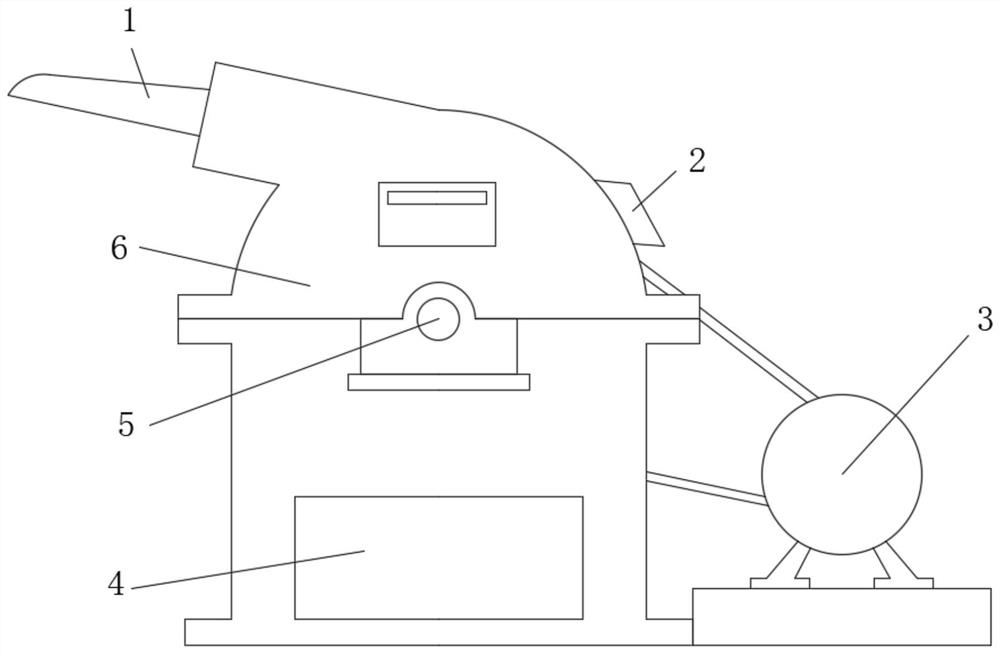

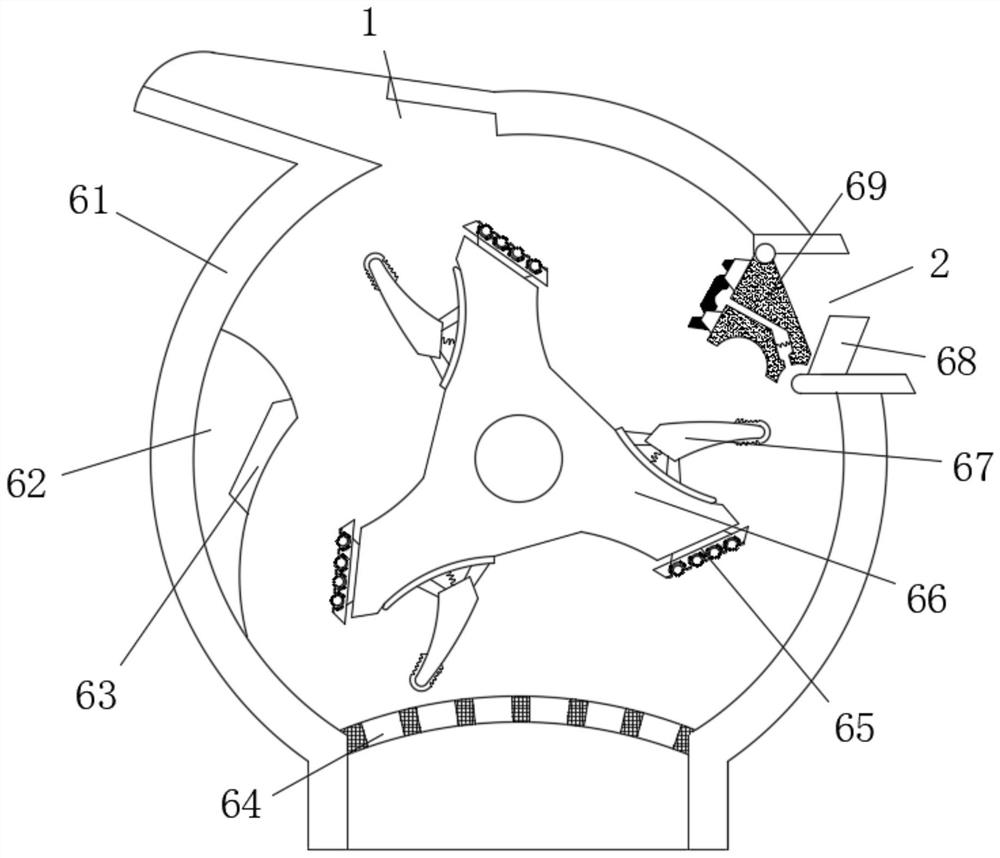

Straw pulverizer

PendingCN112753387AAchieve the cutting effectAchieve grinding effectCuttersElectric machineIndustrial engineering

The invention discloses a straw pulverizer, and relates to the technical field of machines. The straw pulverizer comprises a pulverizing device, a first rotating shaft sleeves the middle of the front face of the pulverizing device, the outer surface of the first rotating shaft is in transmission connection with a rotating motor, a discharge hole is formed in the bottom of the front face of the pulverizing device, and a feeding hole is formed in the left side of the top of the pulverizing device. A scrap outlet is formed in the right side of the top of the pulverizing device, the pulverizing device comprises a machine shell, the top of the machine shell is fixedly connected to the opening end of the feeding hole, the right side of the machine shell is fixedly connected to the left side of the scrap outlet, and a crushing device is rotationally connected to an opening in the left side of the scrap outlet. According to the straw pulverizer, straw enters the straw pulverizing device from the feeding hole, when the rotating motor is started to enable a stirring rotating wheel to rotate clockwise, a pulverizing and cutting device can be matched with a cutting plate to cut and pulverize the straw, and the straw cutting effect is achieved.

Owner:焦超锦

A device for processing grinding balls

ActiveCN107322465BAvoid the phenomenon that is not easy to dischargeAvoid wastingLapping machinesReciprocating motionEngineering

Owner:萍乡市东陶陶瓷有限责任公司

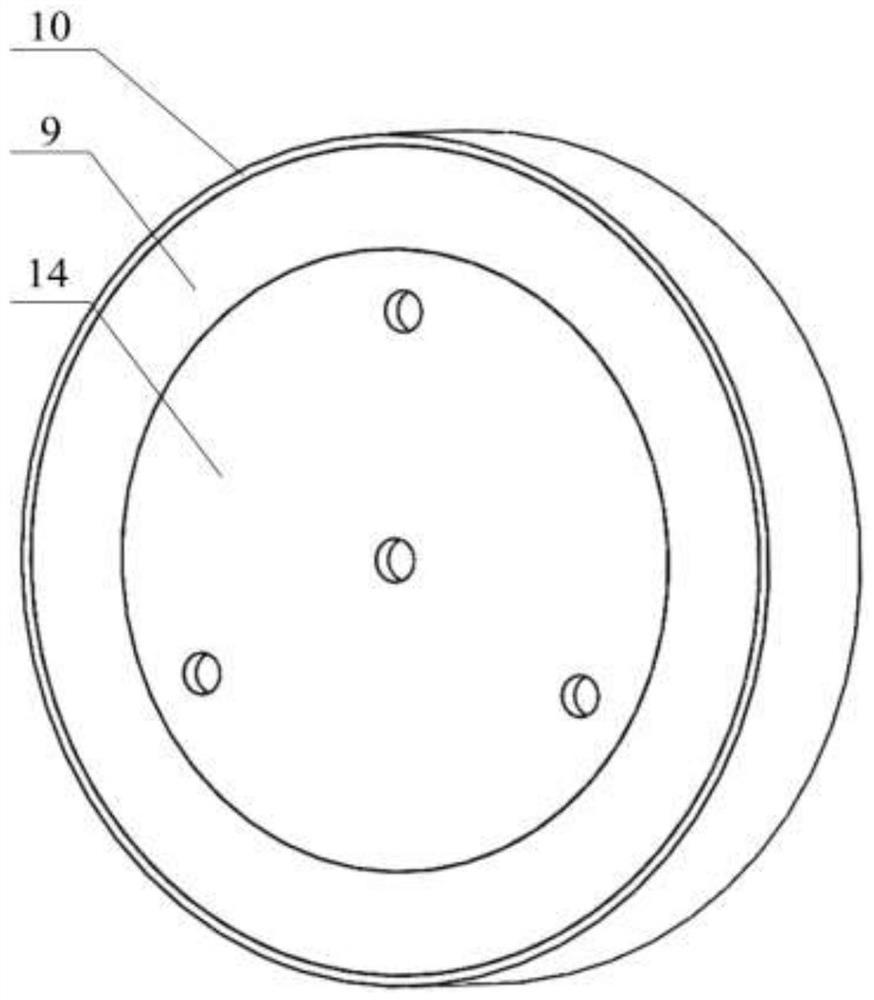

Wafer grinding head and wafer adsorption method

PendingCN114515995ASimple structureEasy to processLapping machinesLapping toolsWaferStructural engineering

The invention provides a wafer grinding head and a wafer adsorption method. The wafer grinding head comprises a grinding head body and a fixing device surrounding the periphery of the grinding head body. The fixing device comprises a first circular ring and a second circular ring which are tightly arranged; the grinding head body, the first circular ring and the second circular ring are kept concentric; a first gas path and a second gas path are arranged on the grinding head body; ventilation grooves are uniformly formed in the first circular ring; and the ventilation groove is communicated with the second gas path. The wafer grinding head provided by the invention is simple in structure, convenient to process and beneficial to industrial production; by means of distribution of internal air paths, the pressure, acting on the surface of the wafer, of an adsorption film at the bottom of the 300 mm Head can be accurately controlled through a machine table, and the effects of loading and unloading the wafer and grinding the wafer are achieved.

Owner:上海江丰平芯电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com