Straw pulverizer

The technology of a straw grinder and crushing device, which is applied in the field of machinery, can solve the problems of poor crushing and cutting effects of the straw grinder, and achieve the effect of improving the crushing effect, improving efficiency, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

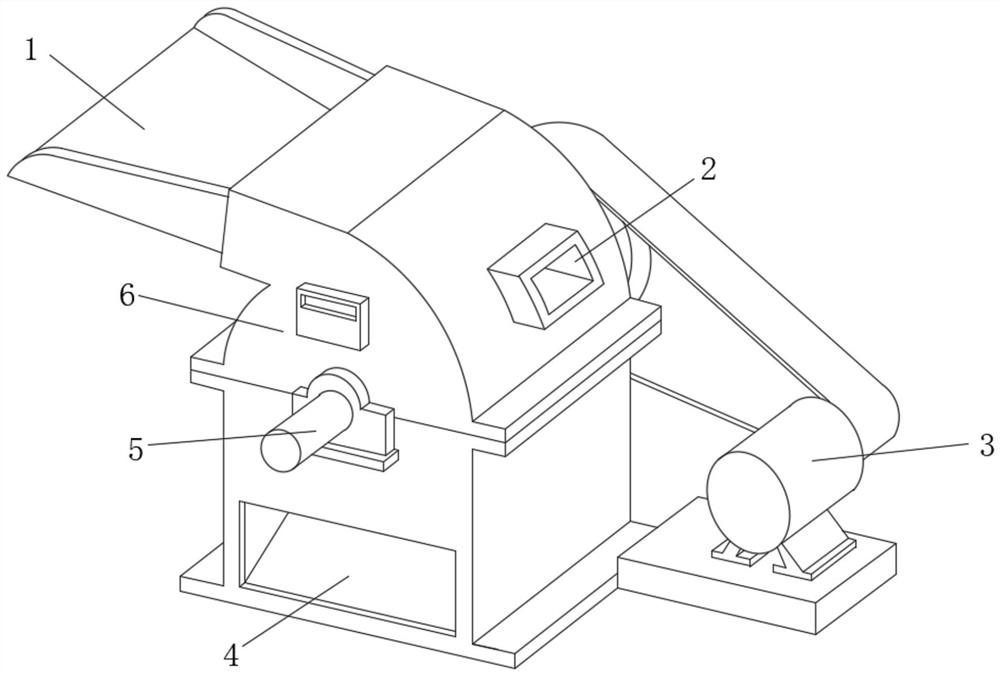

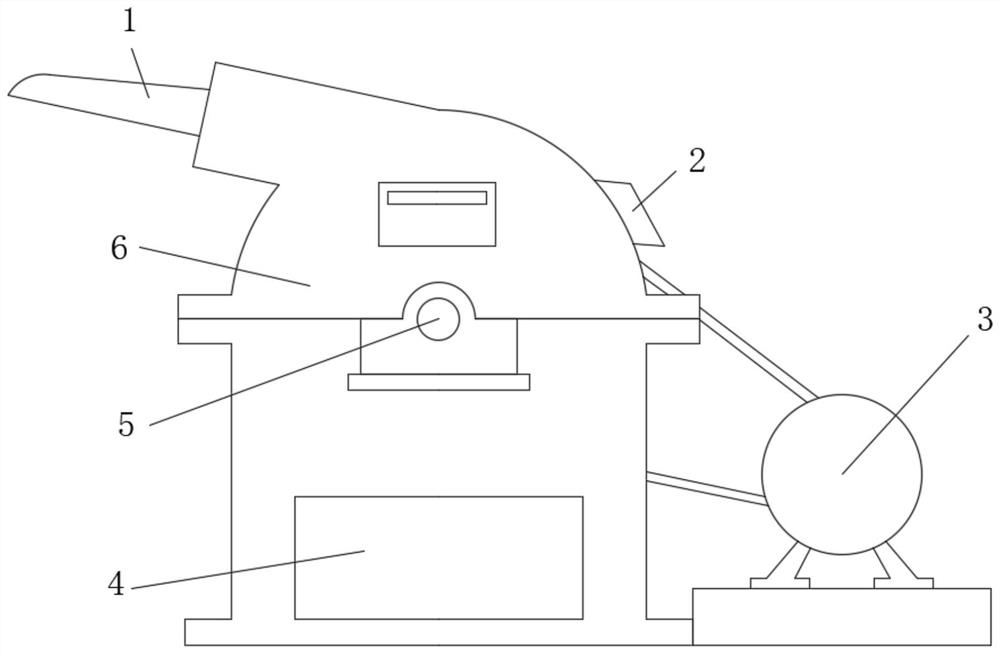

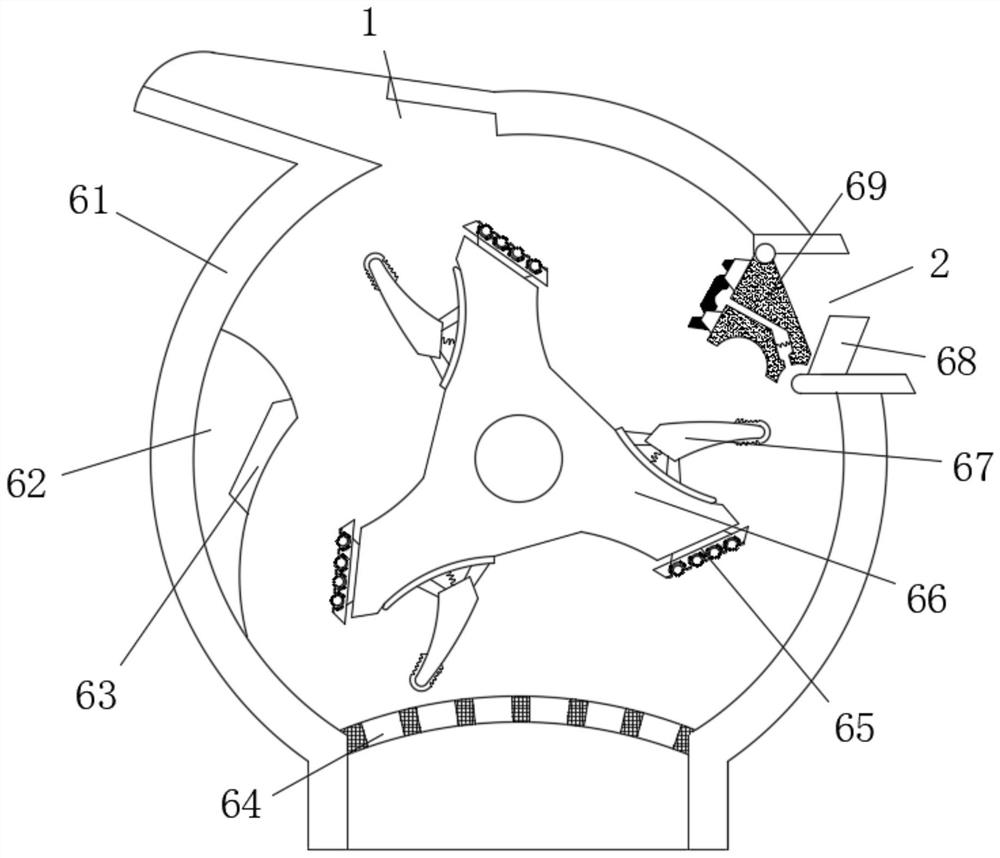

[0032] Such as Figure 1-5As shown, the present invention provides a technical solution: a straw grinder, including a crushing device 6, a first rotating shaft 5 is sleeved in the middle of the front of the crushing device 6, and the outer surface of the first rotating shaft 5 is connected by transmission. There is a rotating motor 3, the bottom of the front of the crushing device 6 is provided with a discharge port 4, the left side of the top of the crushing device 6 is provided with a feed inlet 1, and the right side of the top of the crushing device 6 is provided with a debris outlet 2. The crushing device 6 includes a casing 61, the top of the casing 61 is fixedly connected to the opening end of the feed inlet 1, and the right side of the casing 61 is fixedly connected to the left side of the debris outlet 2, and the debris The opening on the left side of the outlet 2 is rotatably connected with a crushing device 69, and the bottom of the inner cavity of the debris outlet ...

Embodiment 2

[0039] Such as Figure 6-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the crushing device 69 includes a discharge pipe 692 and a rotating block 694, and the outer surface of the discharge pipe 692 is fixedly connected to the casing 61 The bottom of the inner cavity of the discharge pipe 692 is fixedly connected to the bottom end of the limit plate 68, the top of the inner cavity of the discharge pipe 692 is fixedly connected with the second rotating shaft 691, and the discharge pipe 692 passes through the first The two rotating shafts 691 are rotatably connected to the top of the rotating block 694. The inside of the rotating block 694 is provided with a through hole 697. The surfaces on both sides of the inner wall of the through hole 697 are fixedly connected by the second spring 693. The left side of the rotating block 694 A backing plate 695 is fixedly connected to the side, and a grinding device 696 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com