Bottom piece cutting device for dark-red enameled pottery manufacturing

A cutting device and the technology of purple sand pots, which are applied to work accessories, manufacturing tools, stone processing tools, etc., can solve the problems of low work efficiency, cumbersome operation, and many manpower, and achieve the effects of saving manpower, simple operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A negative film cutting device for making purple clay teapots, such as Figure 1-6 As shown, it includes a base 1, a mounting plate 2, a placement plate 3, and a first mounting frame 4. The top of the base 1 is rotatably connected to the mounting plate 2, and the mounting plate 2 is rotationally connected to six placing plates at uniform intervals along the circumferential direction. 3. The first mounting frame 4 is connected to the left side of the top of the base 1, and also includes a lifting component 5 and a moving component 6. The first mounting frame 4 is provided with a lifting component 5 and a moving component 6, and the lifting component 5 and the moving component 6 drive connect.

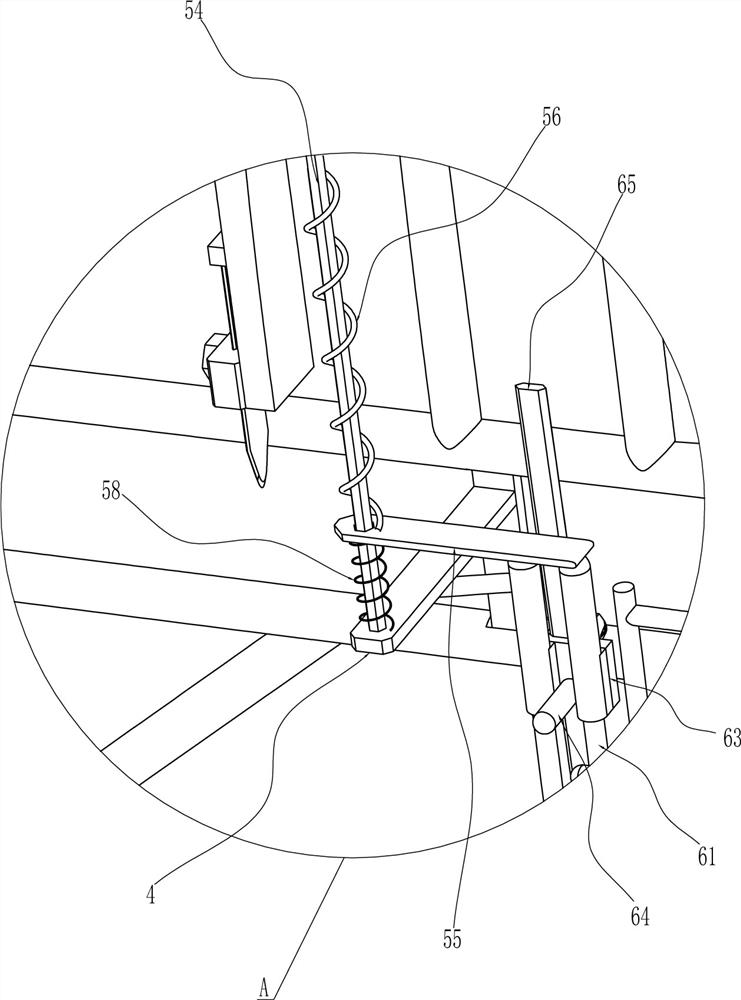

[0031] The lifting assembly 5 includes a second mounting frame 51, a cylinder 52, a connecting plate 53, a rhombus guide rod 54, a slide plate 55, a compression spring 56, an arc cutter 57 and an elastic member 58, and the top of the first mounting frame 4 is connected with a seco...

Embodiment 2

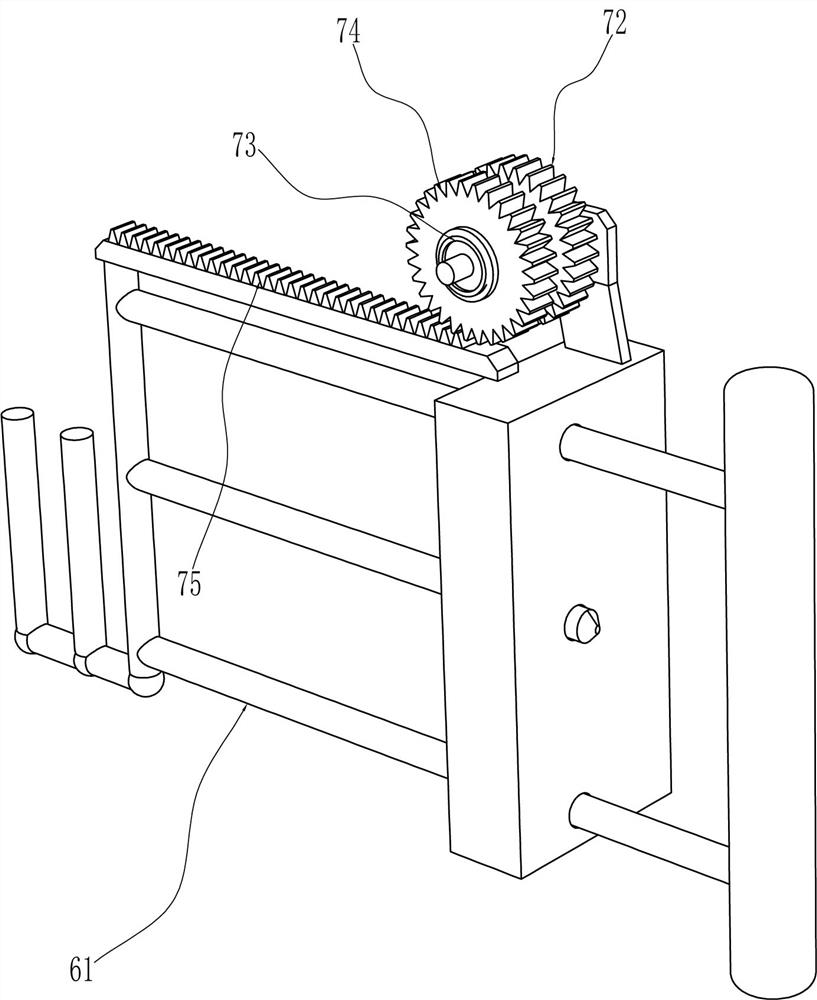

[0035] On the basis of Example 1, such as Figure 7-8As shown, a pulling assembly 7 is also included, and the pulling assembly 7 includes a driving rack 71, a first driving gear 72, a one-way clutch 73, a first transmission gear 74, a spur rack 75 and a second return spring 76, and the connecting plate The right side of 53 is connected with a drive rack 71, and the right side of the first installation frame 4 is connected with a first drive gear 72 in a rotational manner, and the first drive gear 72 will mesh with the drive rack 71. On the transmission shaft of the first drive gear 72 Connected with a one-way clutch 73, the one-way clutch 73 is connected with a first transmission gear 74, the top of the sliding frame 61 is connected with a spur rack 75, and the spur rack 75 will mesh with the first transmission gear 74, and the sliding frame 61 is connected to the first transmission gear 74. A second return spring 76 is connected between the mounting brackets 4 .

[0036] The...

Embodiment 3

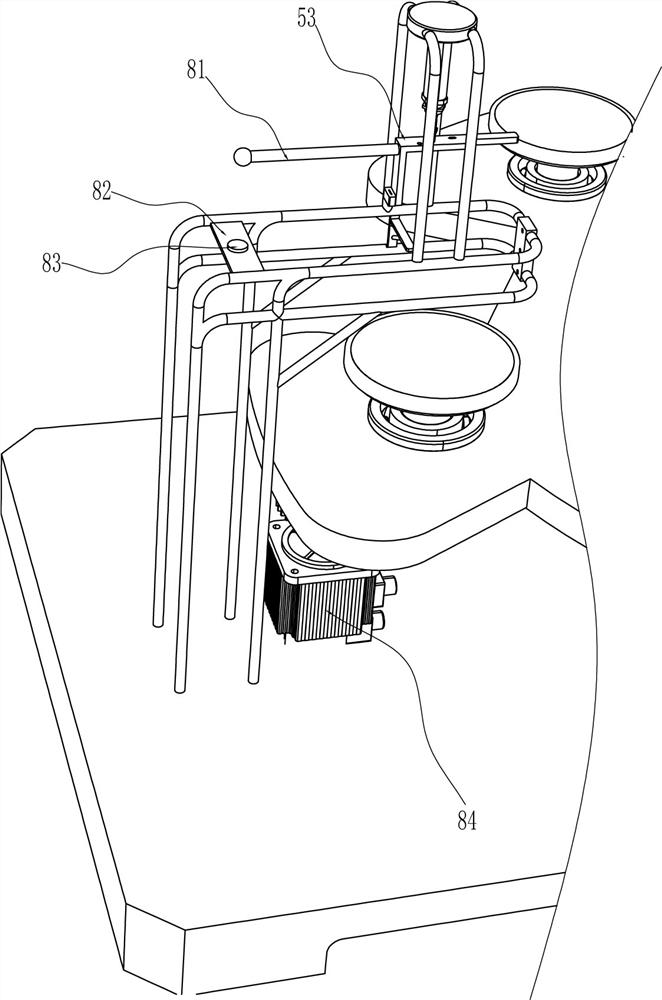

[0038] On the basis of Example 2, such as Figure 9-10 As shown, a driving assembly 8 is also included, and the driving assembly 8 includes a second contact rod 81, a mounting plate 82, a contact switch 83, a motor 84, a second driving gear 85 and a second transmission gear 86, and the left side of the connecting plate 53 is connected to There is a second contact rod 81, a mounting plate 82 is connected to the left side of the top of the first mounting frame 4, a contact switch 83 is connected to the mounting plate 82, the contact switch 83 will contact the second contact rod 81, and a mounting plate 82 is installed on the left side of the base 1 top. Motor 84, motor 84 is electrically connected with contact switch 83, is connected with the second drive gear 85 on the output shaft of motor 84, is connected with the second transmission gear 86 at the bottom of placing dish 3, and the second drive gear 85 can be connected with the second transmission gear 86 meshes.

[0039] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com