Forming machine for machine-made charcoal production

A technology of forming machine and machine-made charcoal, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of incapable cutting of different lengths of rods, so as to improve production and processing efficiency, reduce labor, and cut Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

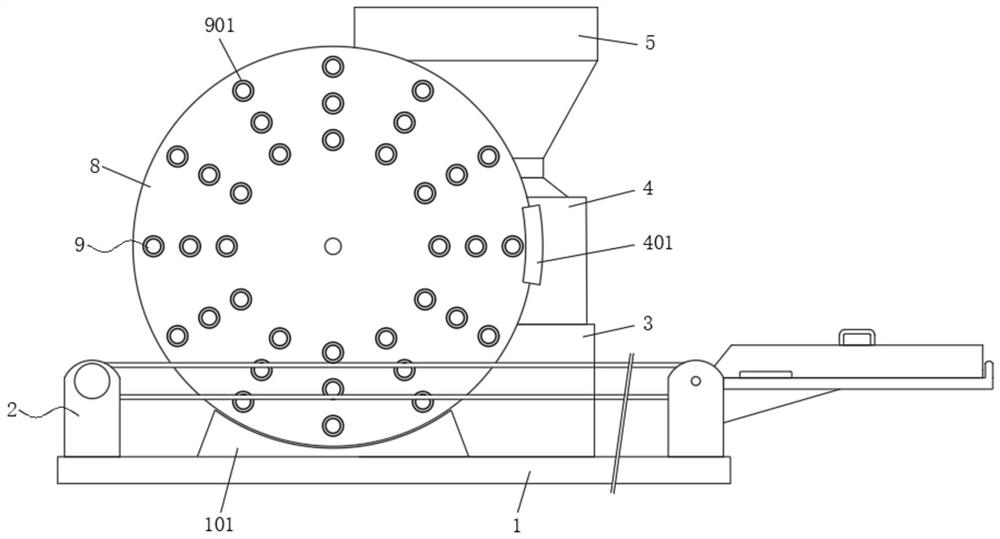

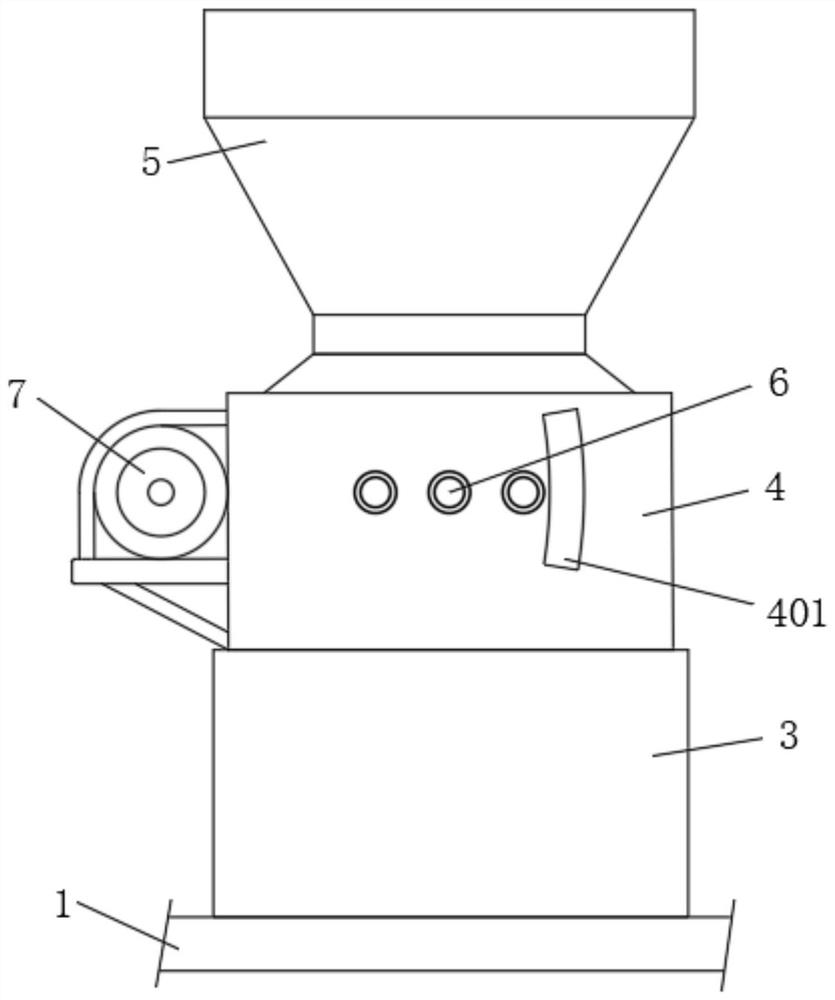

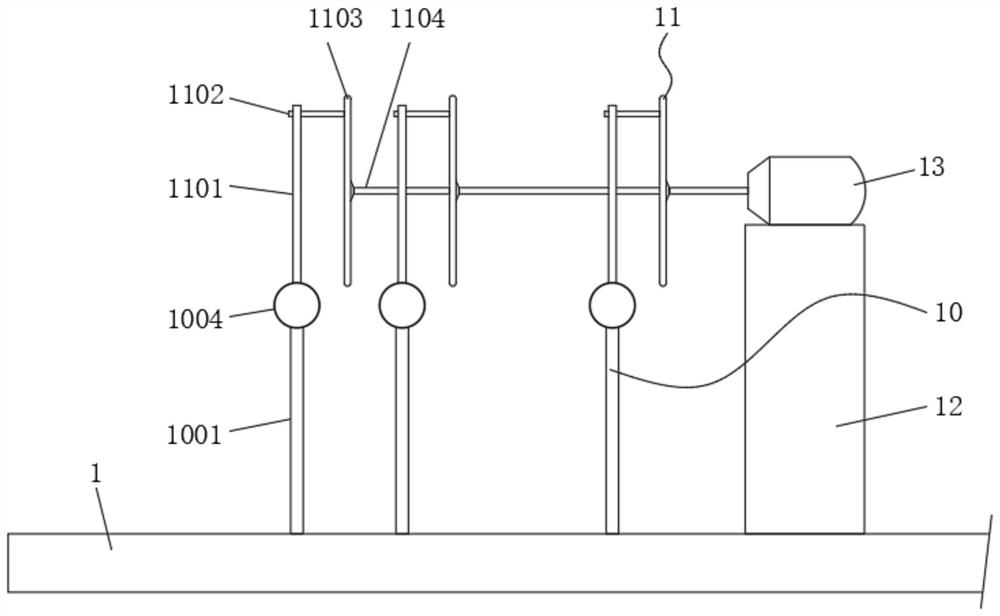

[0028] Embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Given, the present invention includes a base 1, a transmission mechanism 2 is installed on one side of the top of the base 1, a first base 3 is installed on one side of the top middle of the base 1, and a screw extruder 4 is installed on the top of the first base 3 A feed hopper 5 is installed on the top of the screw extruder 4, and three rod-making tubes 6 are installed on one side of the screw extruder 4. Through the setting of the rod-making tubes 6, the production of salary rods can be effectively carried out. One end of the output machine 4 is equipped with a first speed-regulating motor 7, and the output end of the first speed-regulating motor 7 is equipped with a disc 8. Through the setting of the first speed-regulating motor 7, the disc 8 can be effectively driven to rotate. The surface of the disc 8 is equidistantly provided with cutting pipe groups 9, through which the cutting pip...

Embodiment 2

[0029] Embodiment two, on the basis of embodiment one, by Figure 4 and Figure 5 Given, the transmission mechanism 2 includes two U-shaped seats 201, and the two U-shaped seats 201 are fixedly installed at both ends of the top side of the base 1, and the tops inside the two U-shaped seats 201 are rotatably installed with a roller 202, and the two The transmission belt 203 is installed between the surfaces of the cylinders 202, and a transmission motor 204 is installed on the top of one end of one of the U-shaped seats 201, and the output end of the transmission motor 204 is fixedly connected with one end of one of the cylinders 202, so that the transmission can be effectively carried out. transmission.

Embodiment 3

[0030] Embodiment three, on the basis of embodiment one, by Figure 5 Given, one side of the other roller 202 is fixedly installed with a fixed frame 14, the top of the fixed frame 14 is provided with a collection box 15, and the middle part of both sides of the top of the collection box 15 is fixedly equipped with a handle 16, so that the transported Machine-made charcoal is collected and processed in a centralized manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com