Patents

Literature

571results about "Apparatus for cutting/splicing cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

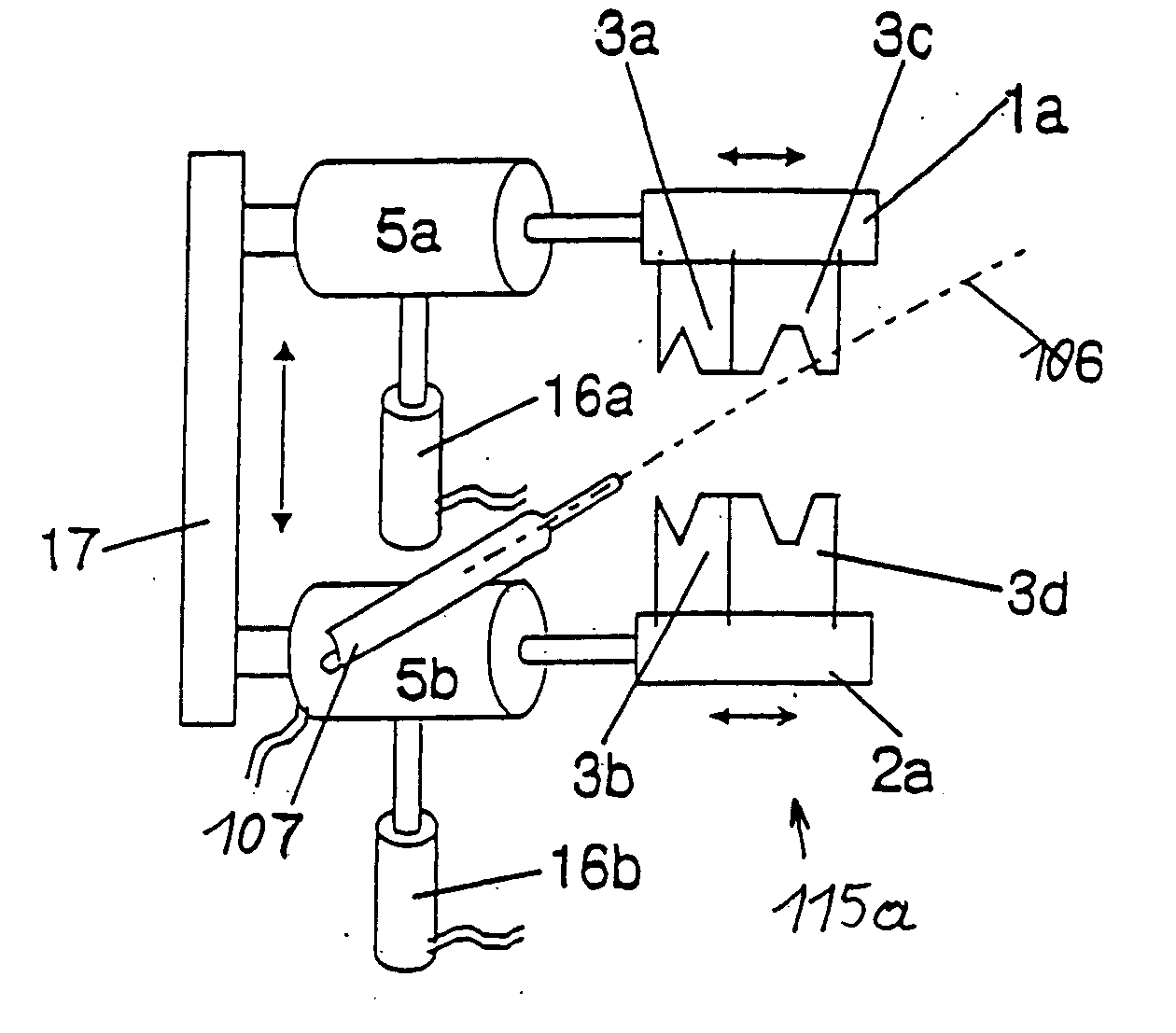

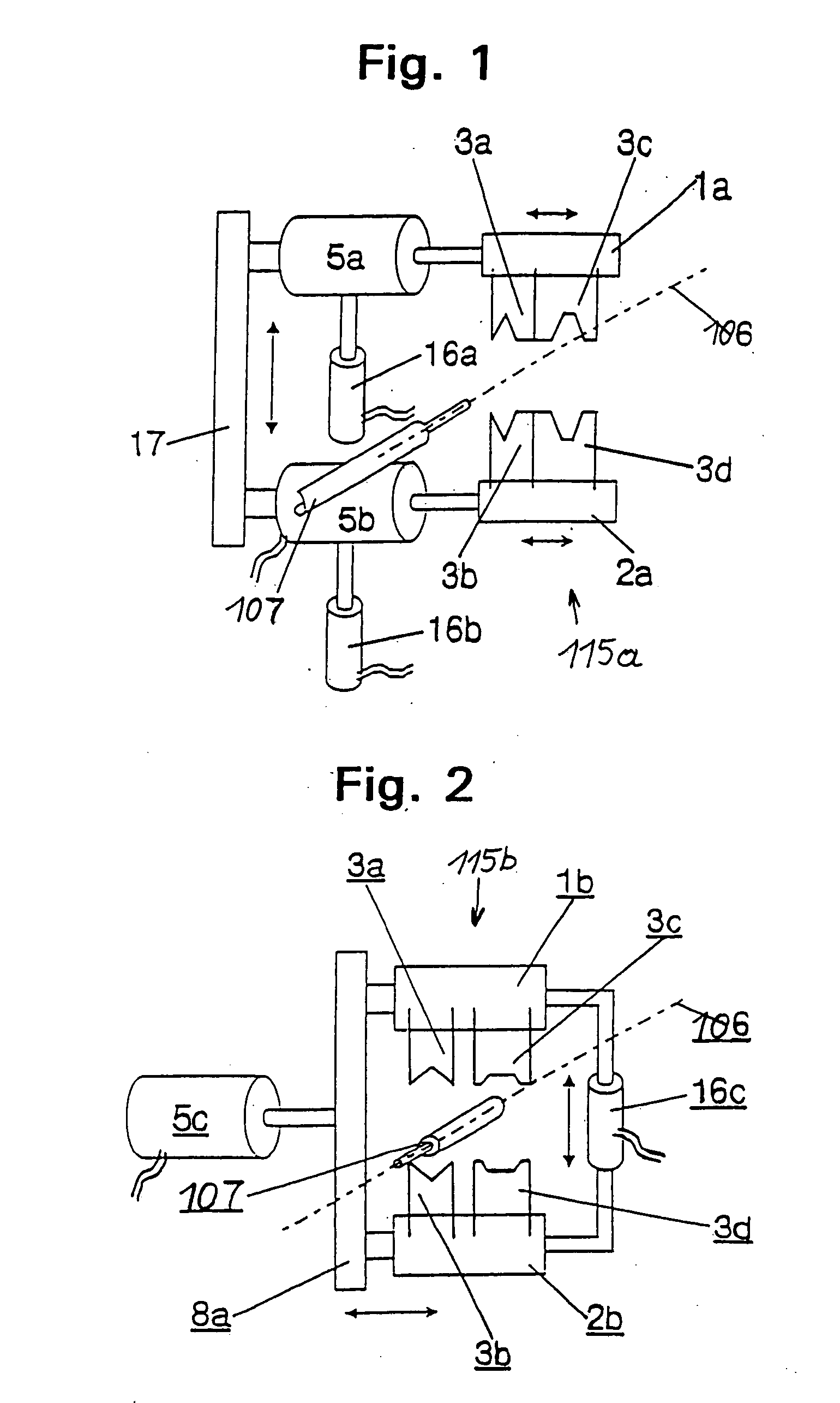

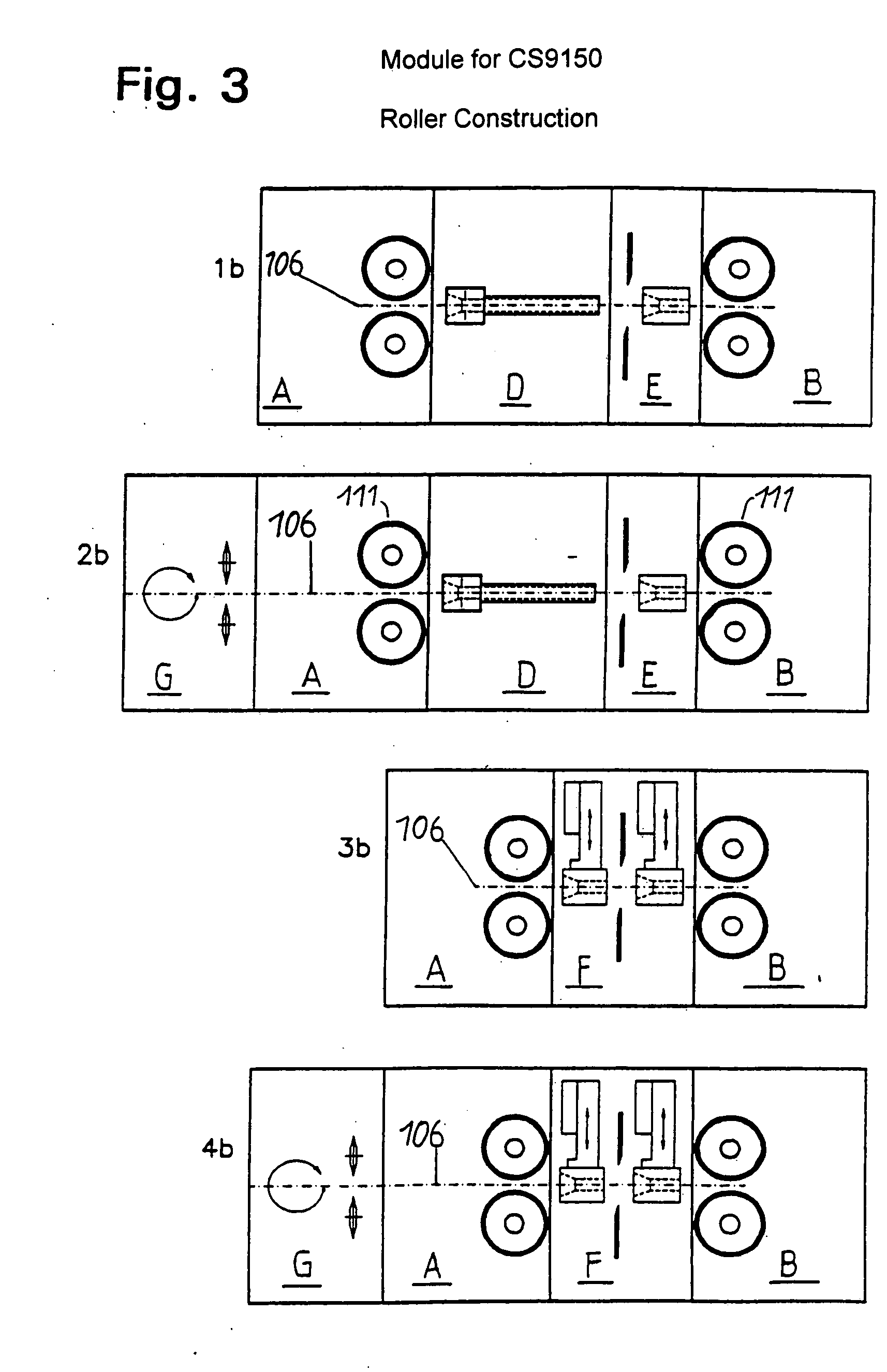

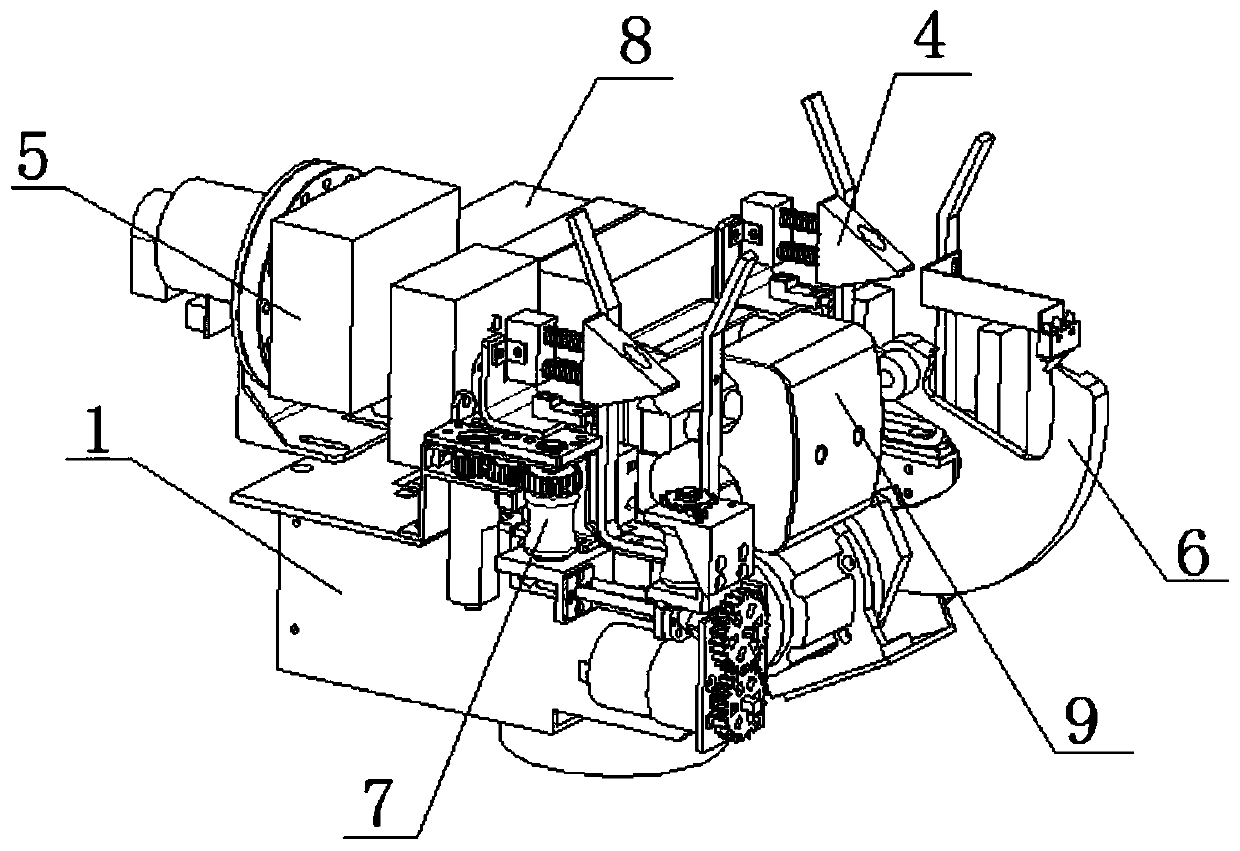

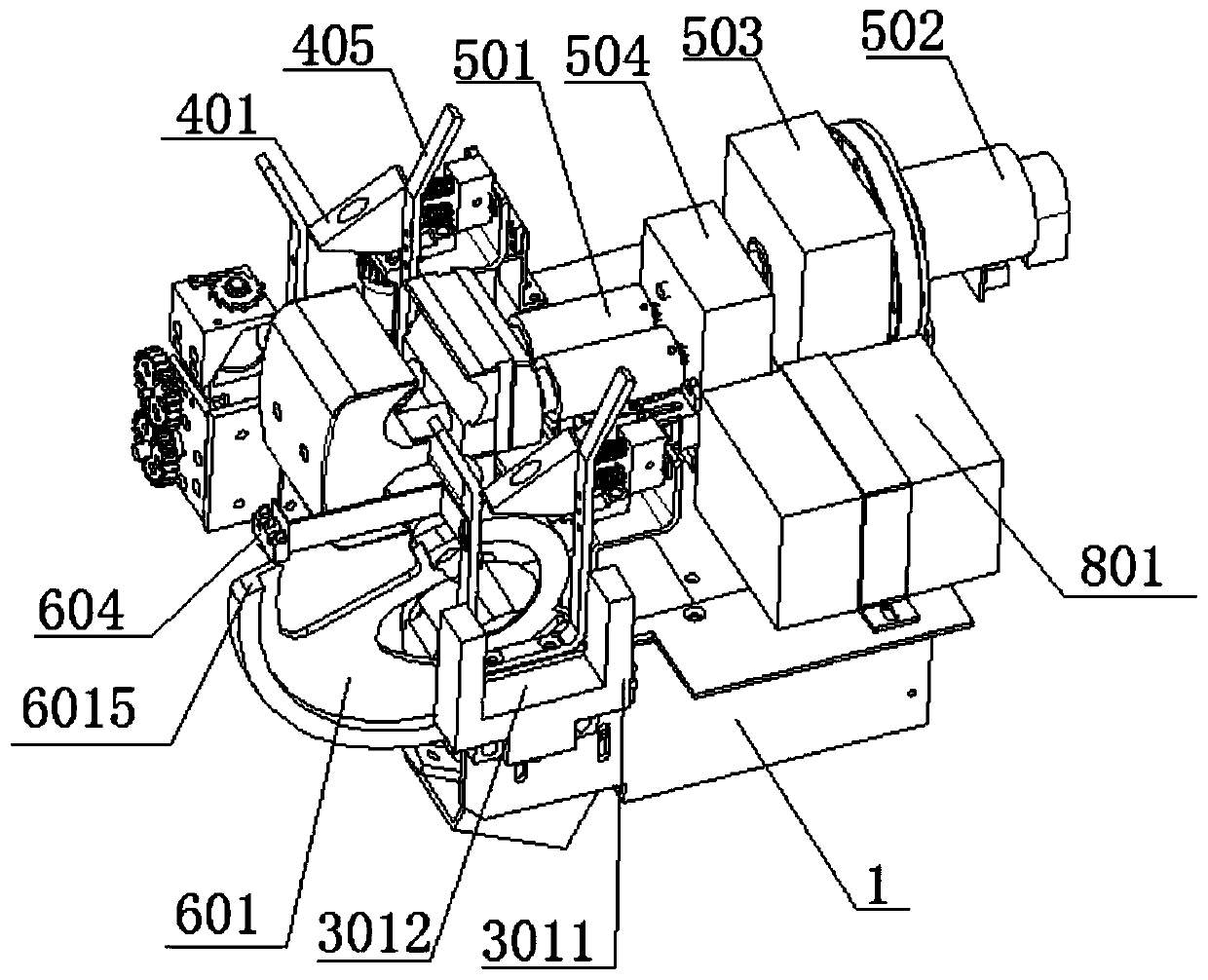

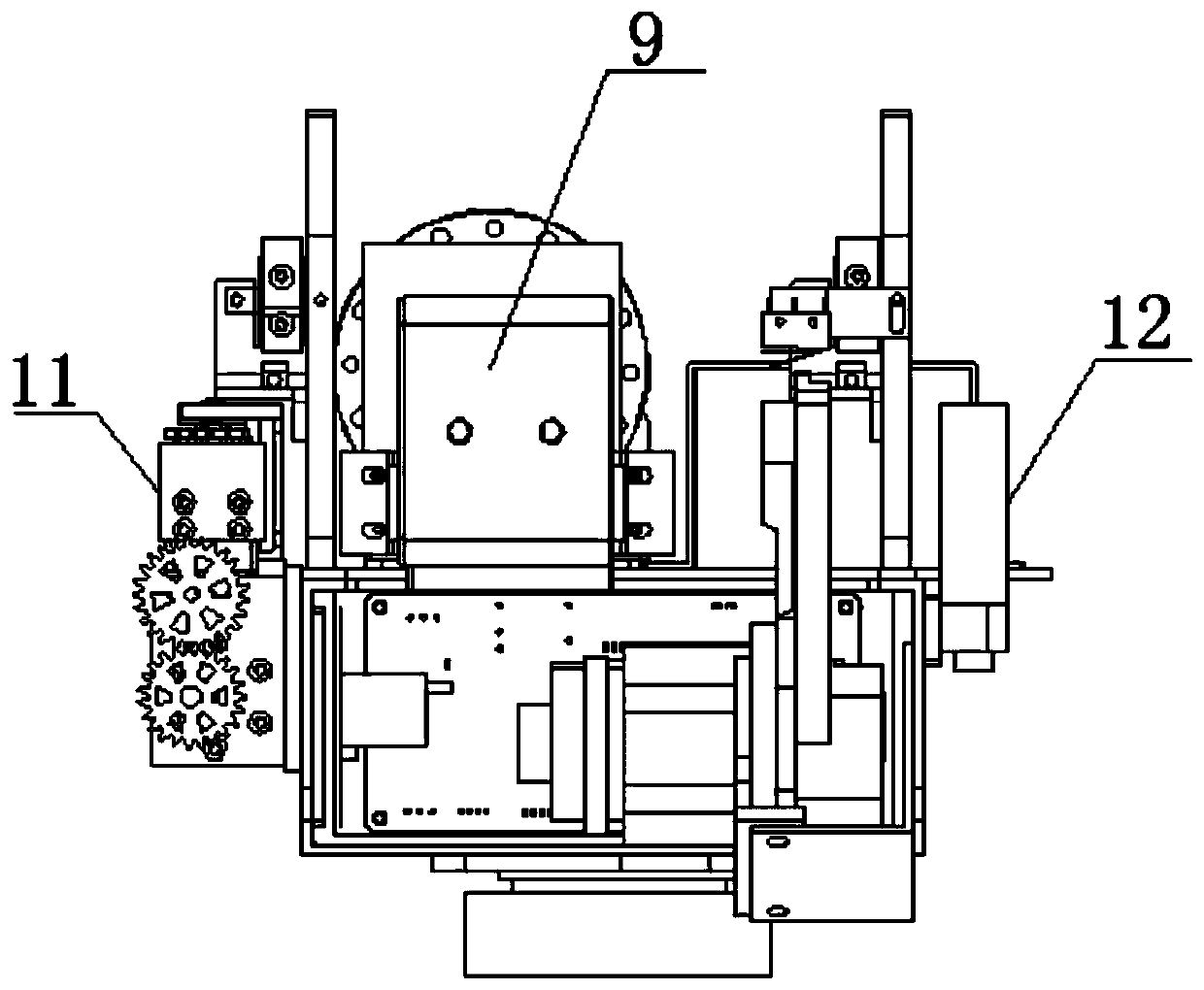

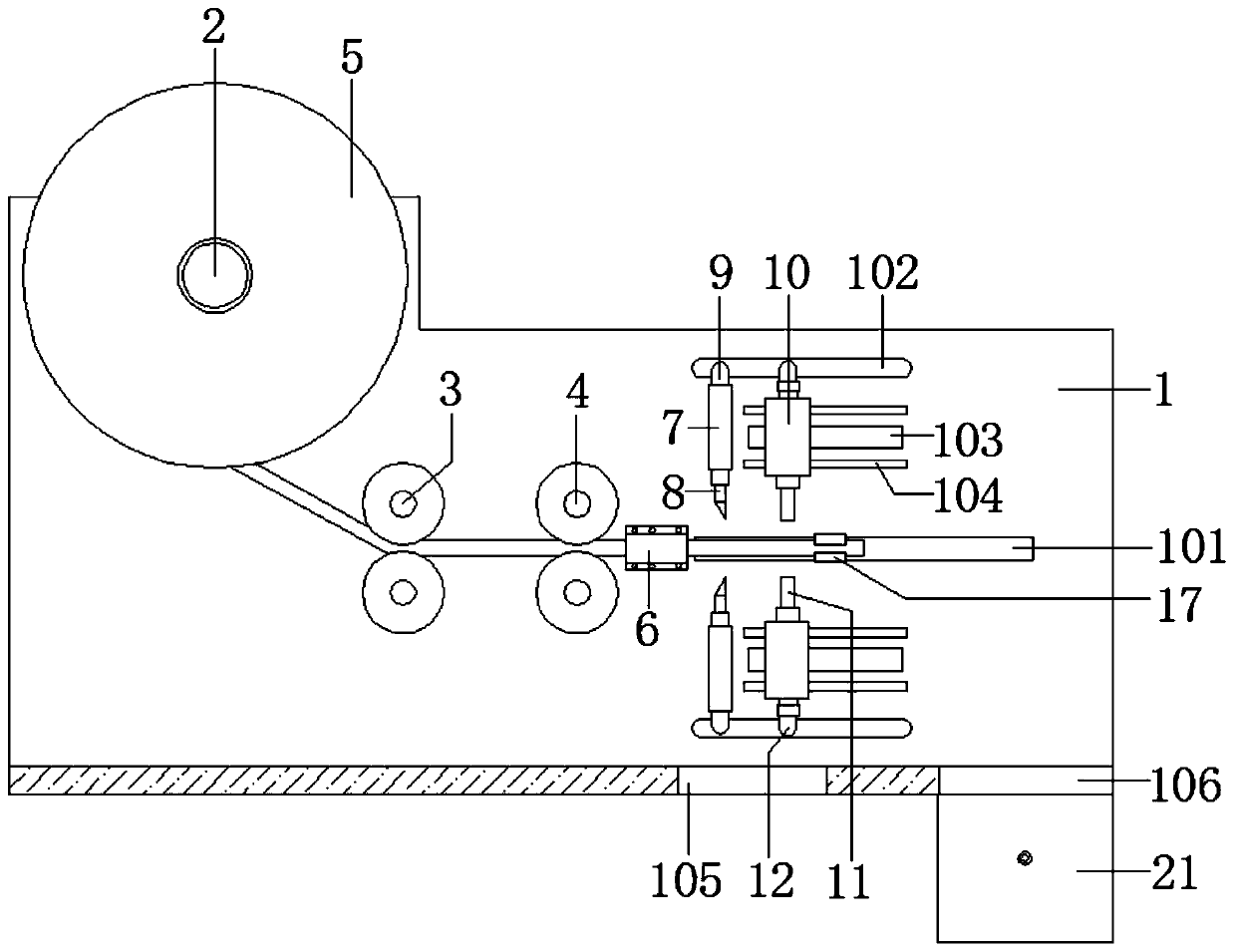

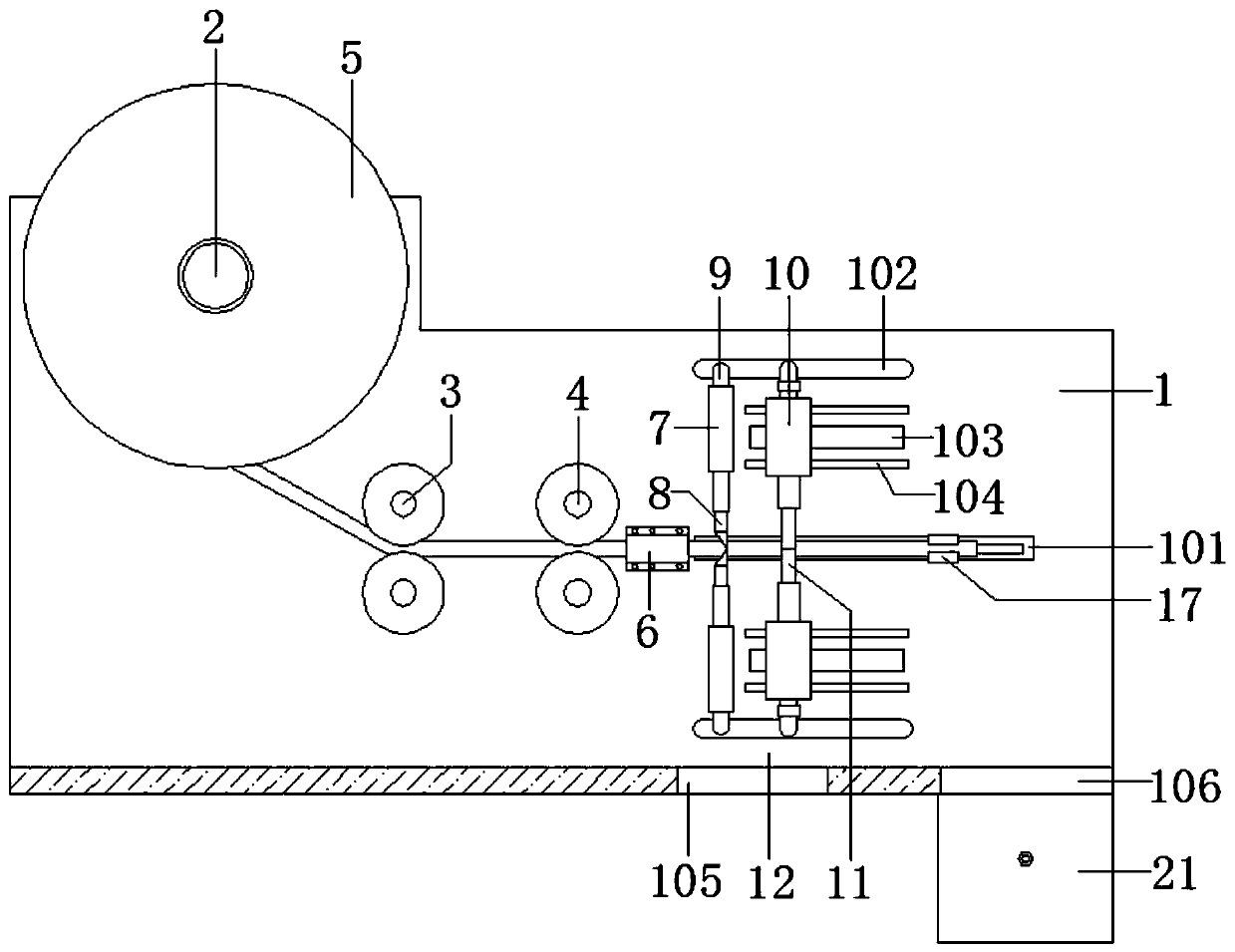

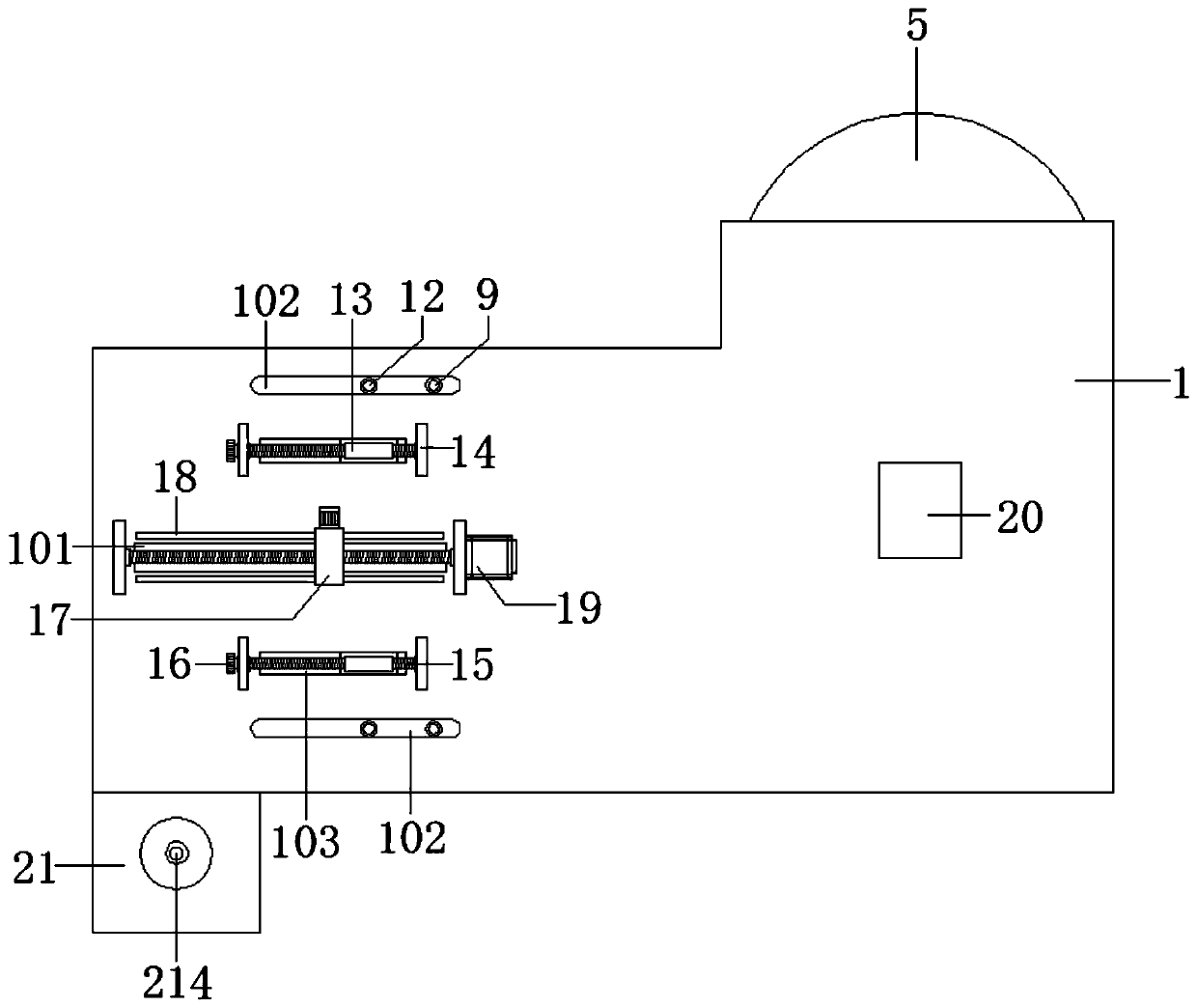

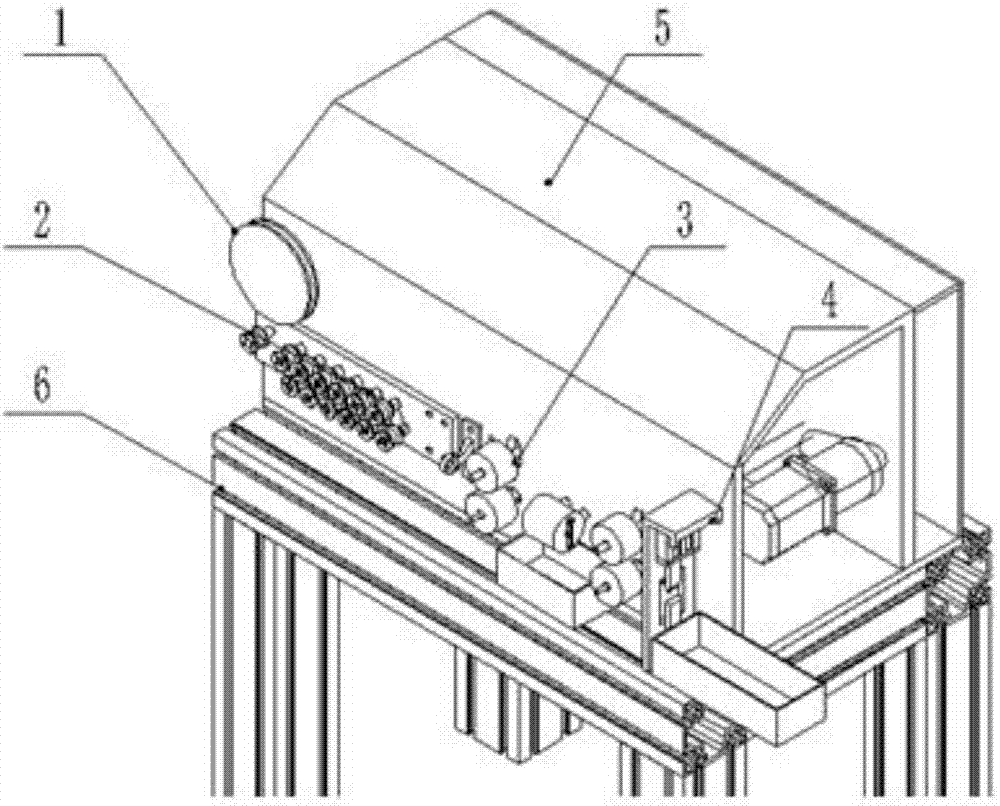

Continuous cable processing apparatus

InactiveUS20050050713A1Practical to useTimely processingApparatus for cutting/splicing cablesOther manufacturing equipments/toolsEngineeringCable transport

A continuous cable processing apparatus for producing cable sections with processed ends comprises a cable transport apparatus having at least one transport means for moving and holding the cable in the axial direction and, transversely thereto, a knife station. According to a special variant, two transport means are arranged in the longitudinal cable direction on both sides of the knife station and, after the cable has been cut through, each hold one of the cable end regions produced on cutting, so that said end regions are movable in the longitudinal cable direction. At least one of these end processing stations is arranged transversely with respect to the longitudinal cable direction, adjacent to the knife station and at least one transport means is movable transversely with respect to the longitudinal cable direction so that a cable end region can be fed to the end processing station.

Owner:SCHLEUNIGER HLDG

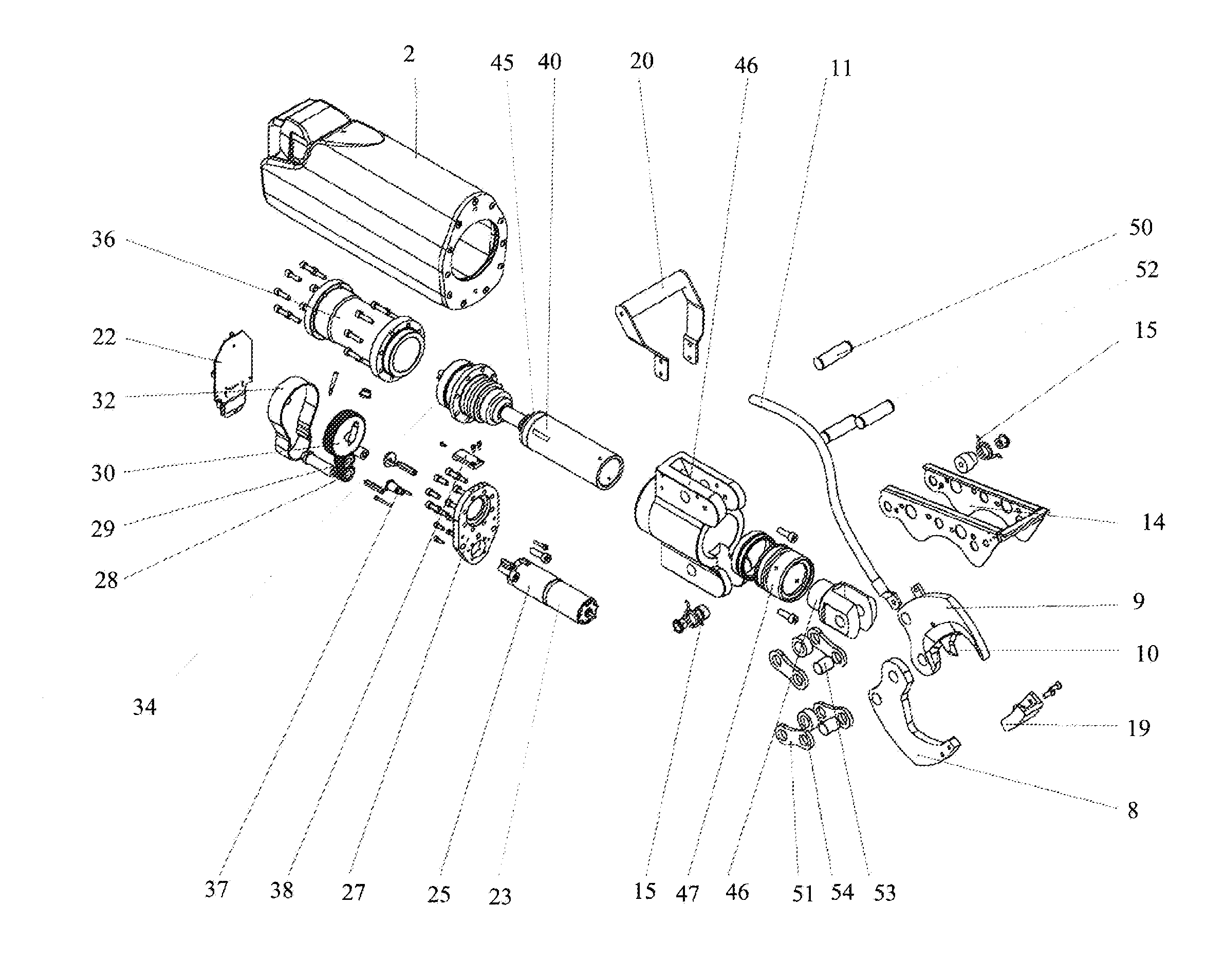

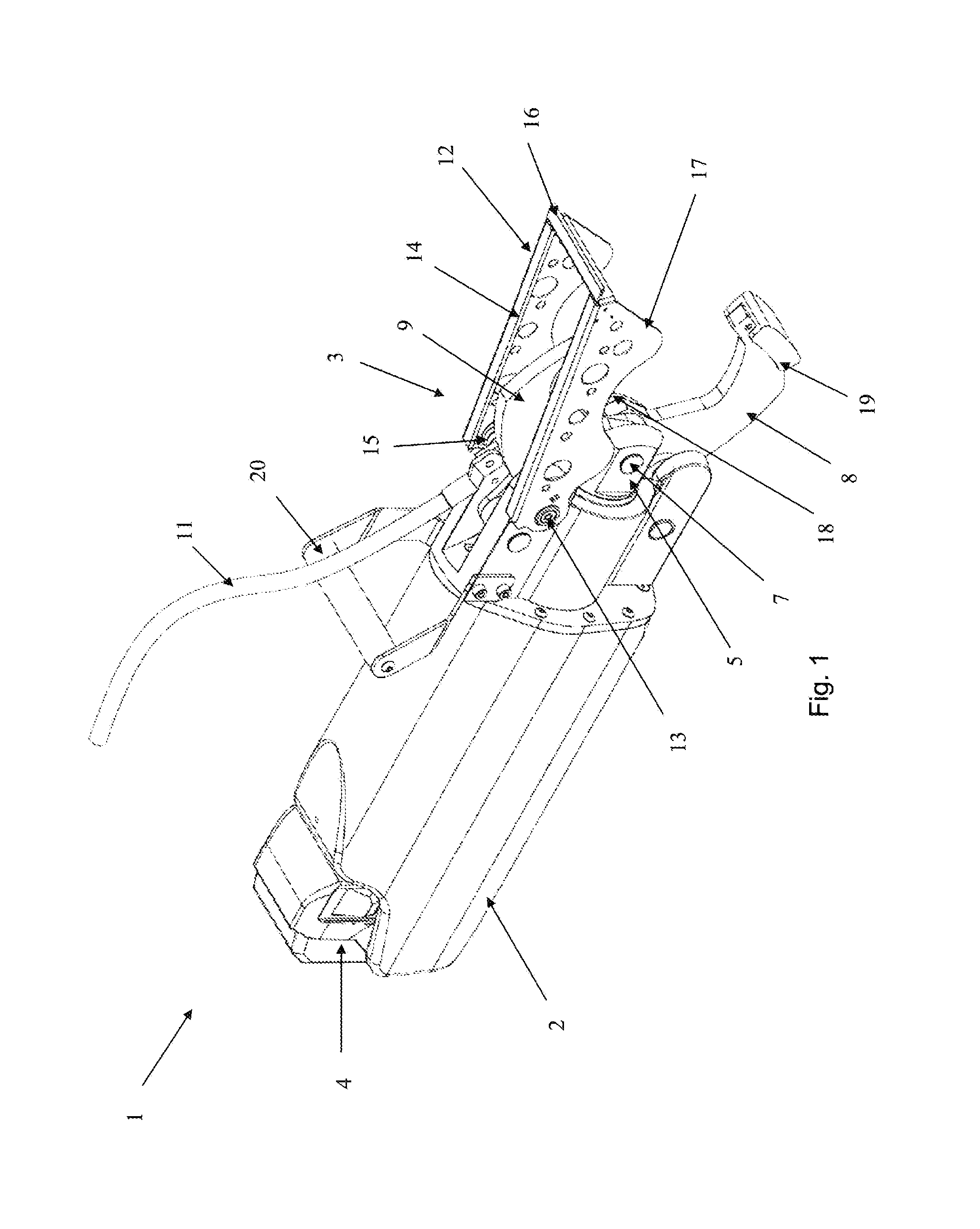

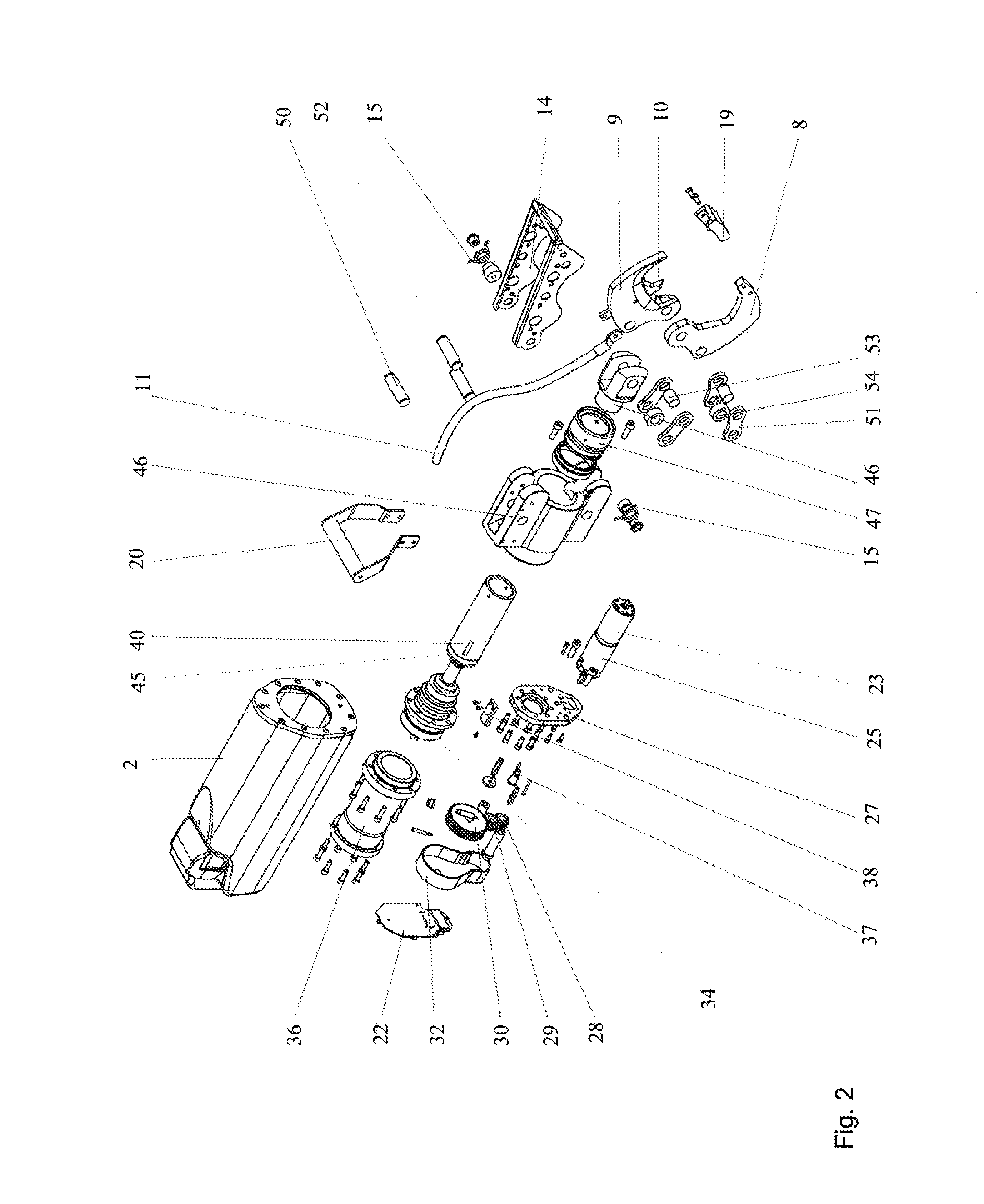

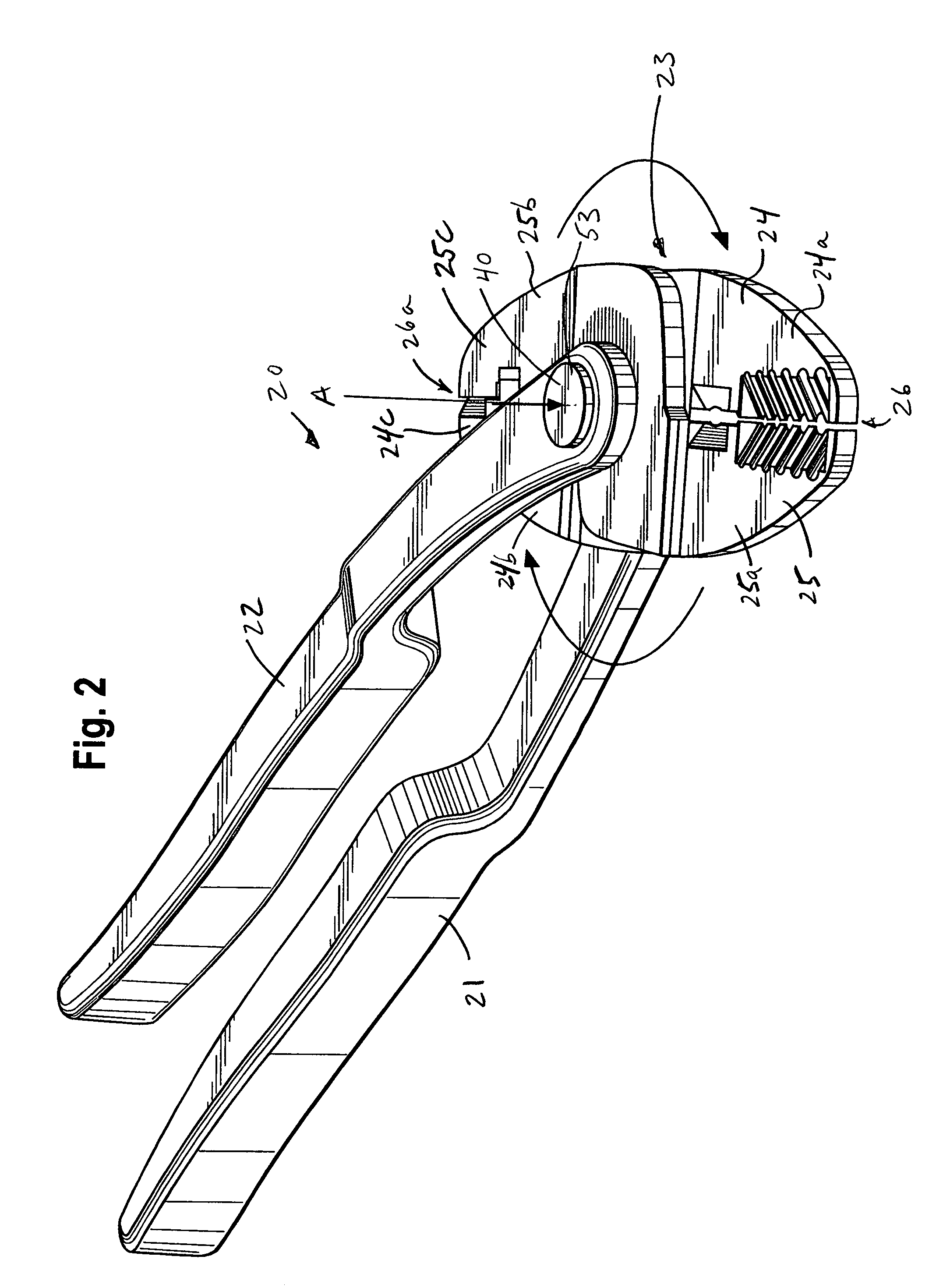

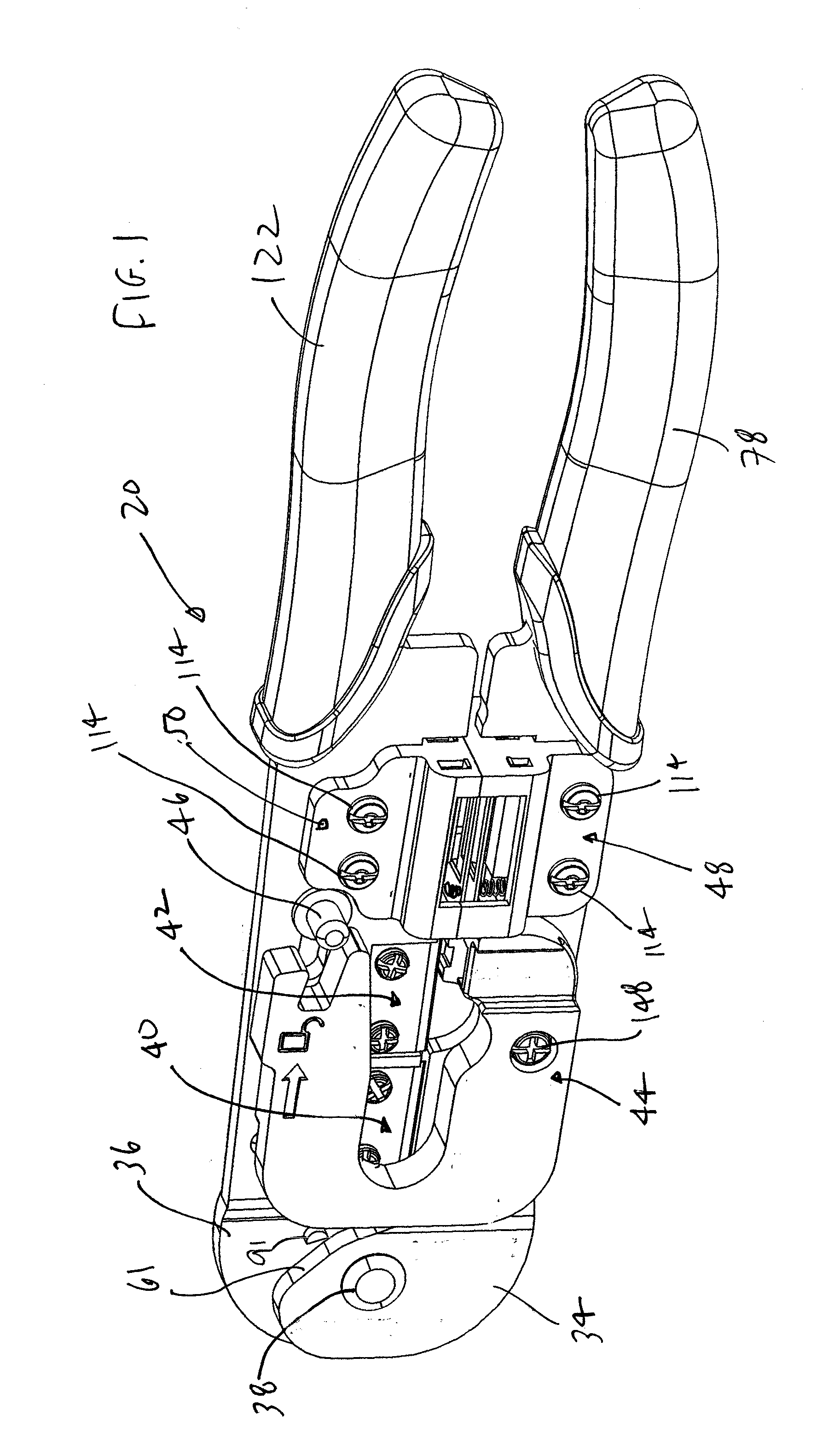

Portable electromechanical tool

InactiveUS20140157522A1Small sizeImprove tool lifeApparatus for cutting/splicing cablesDrilling rodsRoller screwEngineering

Portable electromechanical tool comprising a unit (2) enclosing a continuous current electric motor (23) powered by a storage battery (4), a mechanical reduction gear (25) driven by the output shaft of said motor, which activates a working head (3) by means of a device (40) for converting the rotary motion of the motor (23) into a longitudinal translation movement, which is transmitted to said working head (3). According to the invention, said converting device (40) comprises a planetary roller screw, said screw comprising a threaded part (41), which is driven in rotation by said reduction gear to transmit motion via planetary rollers (43) to a threaded nut (42) that drives a mobile part (5) of said working head (3) in translation.

Owner:MAGE APPL

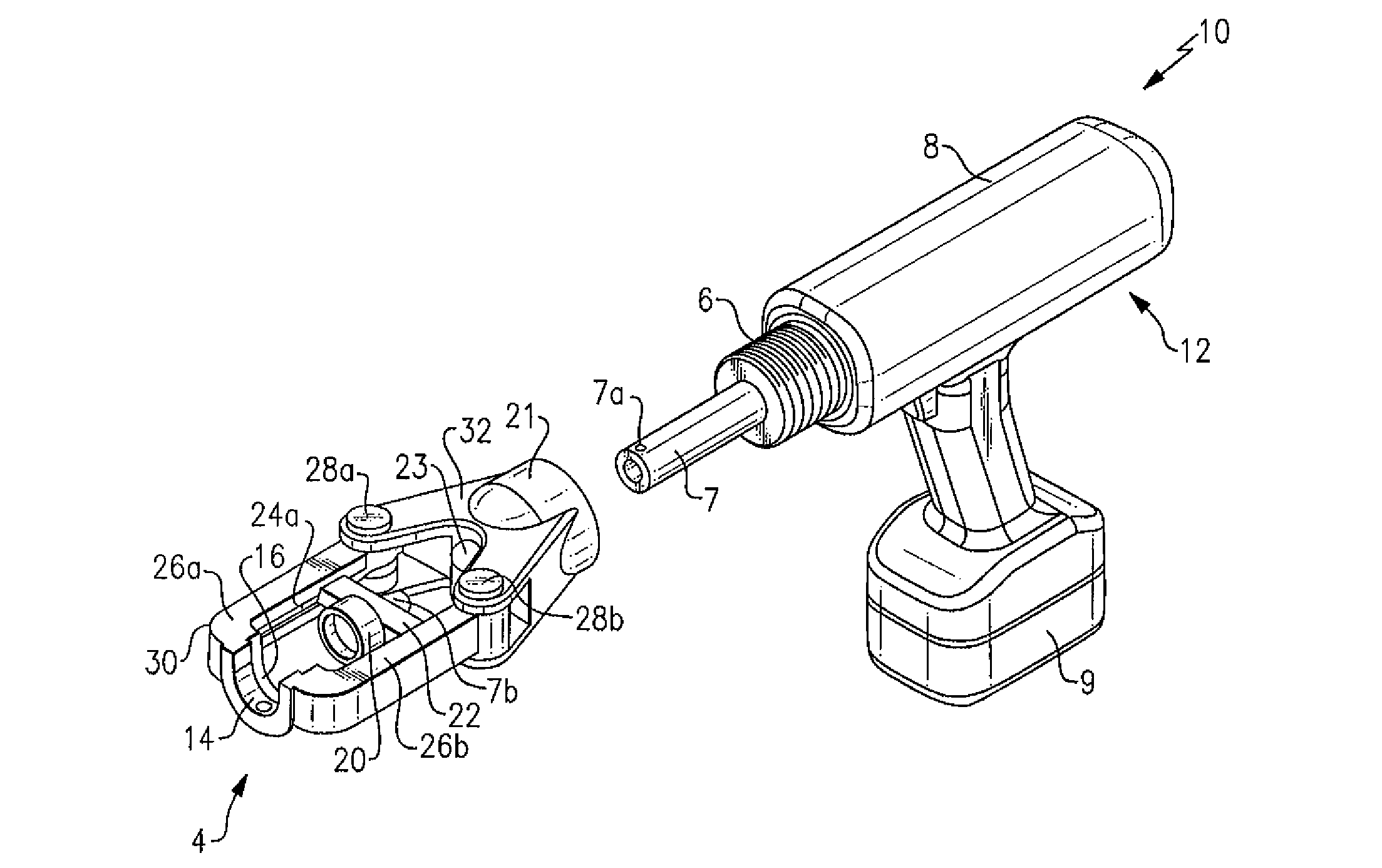

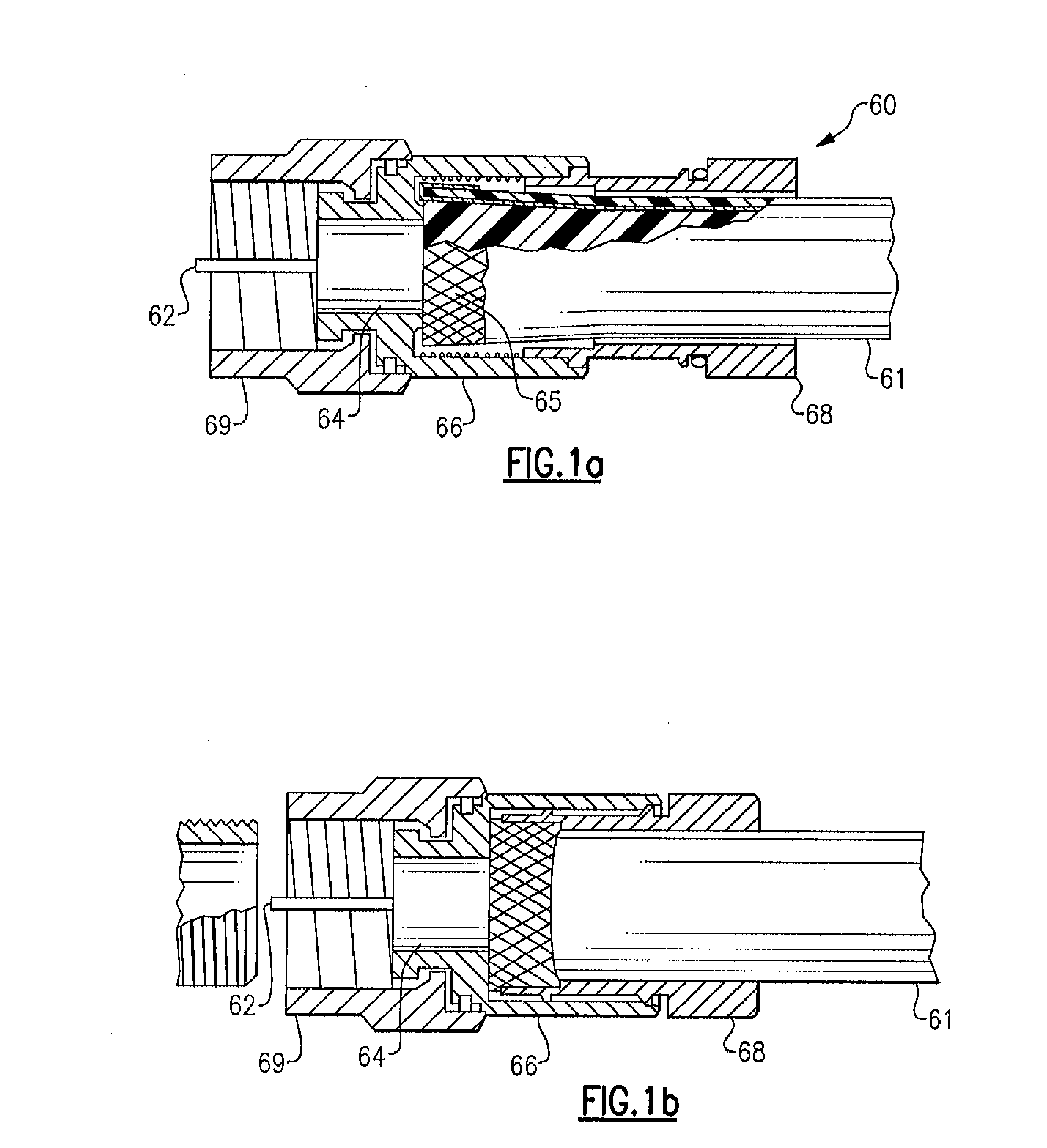

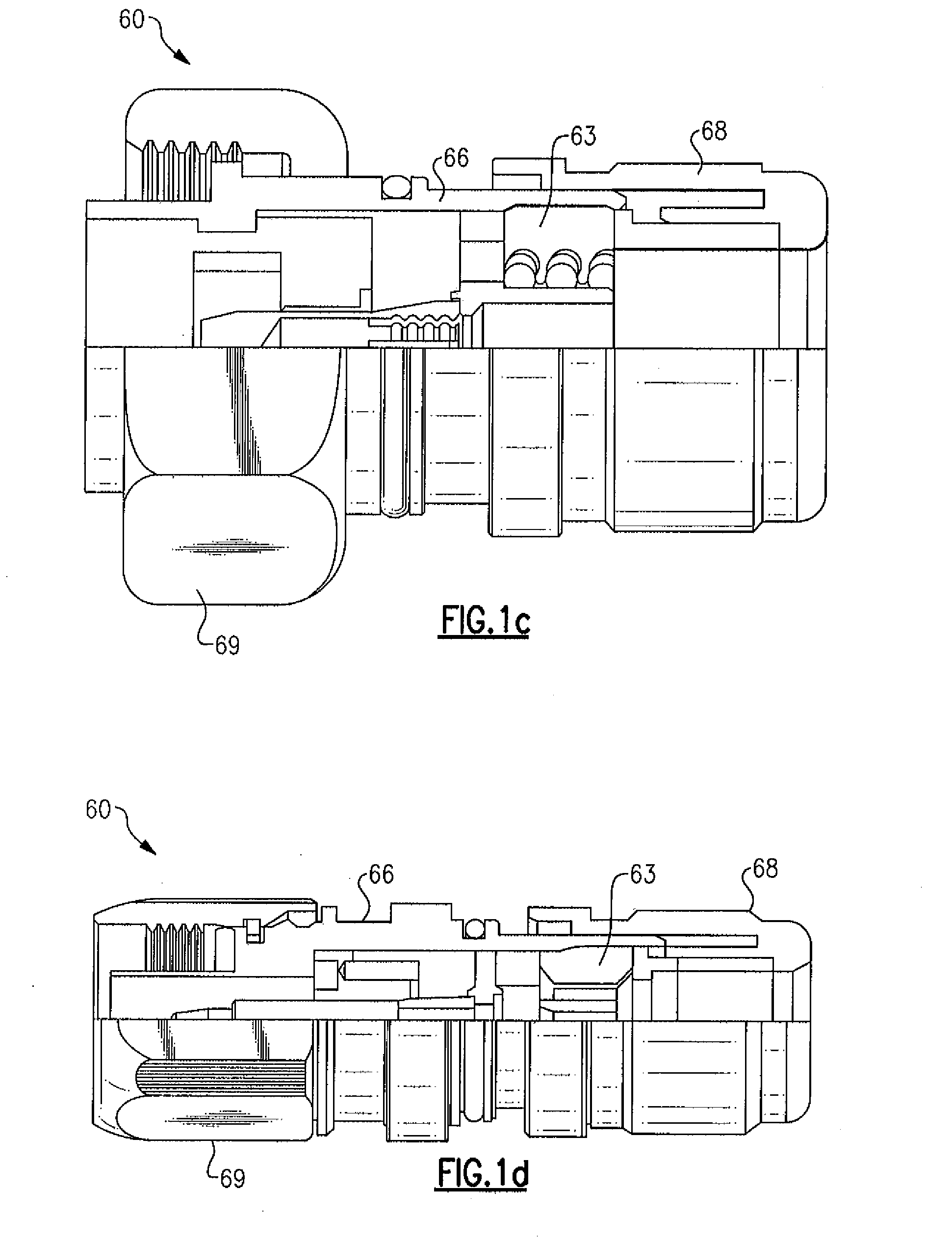

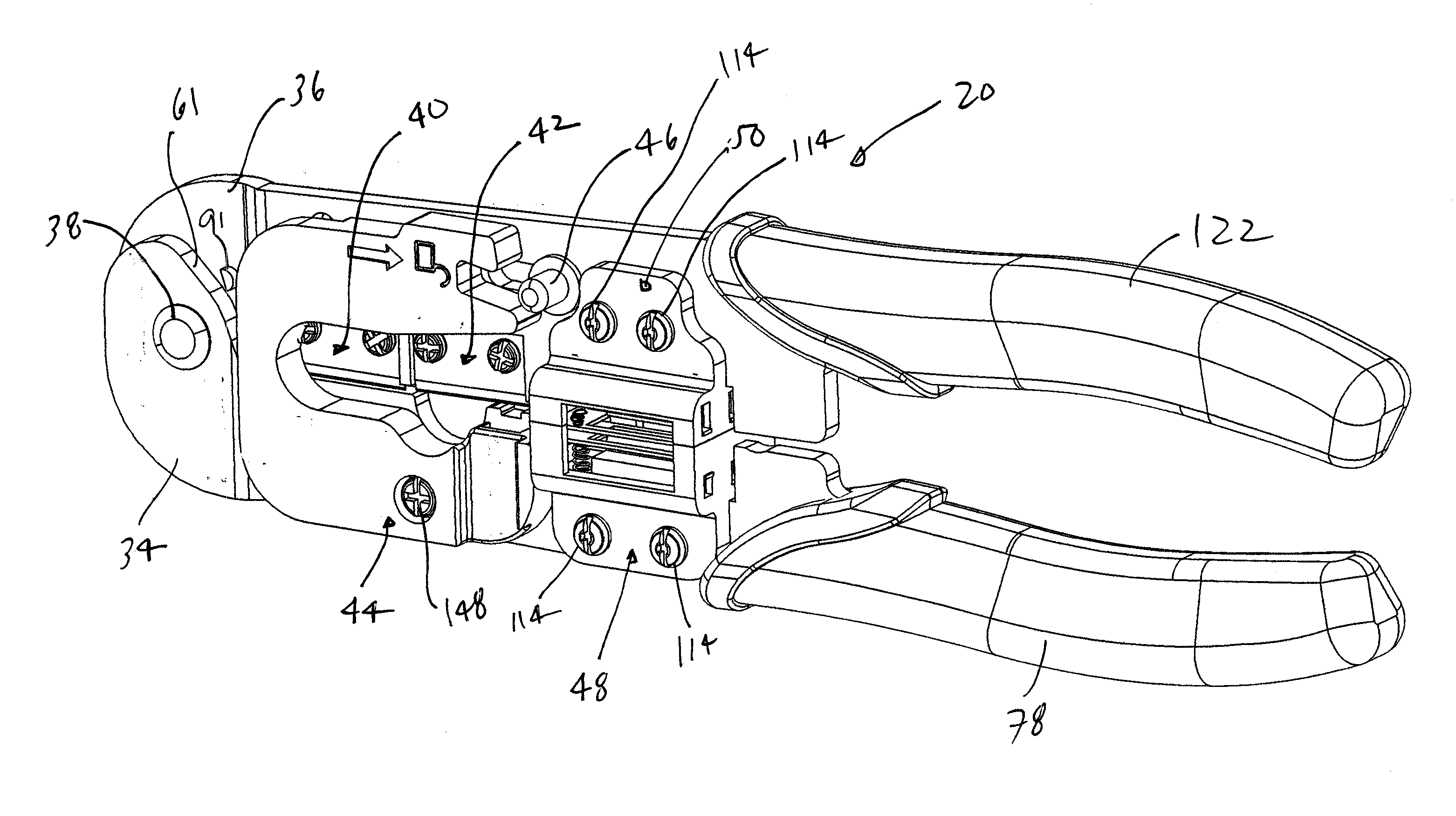

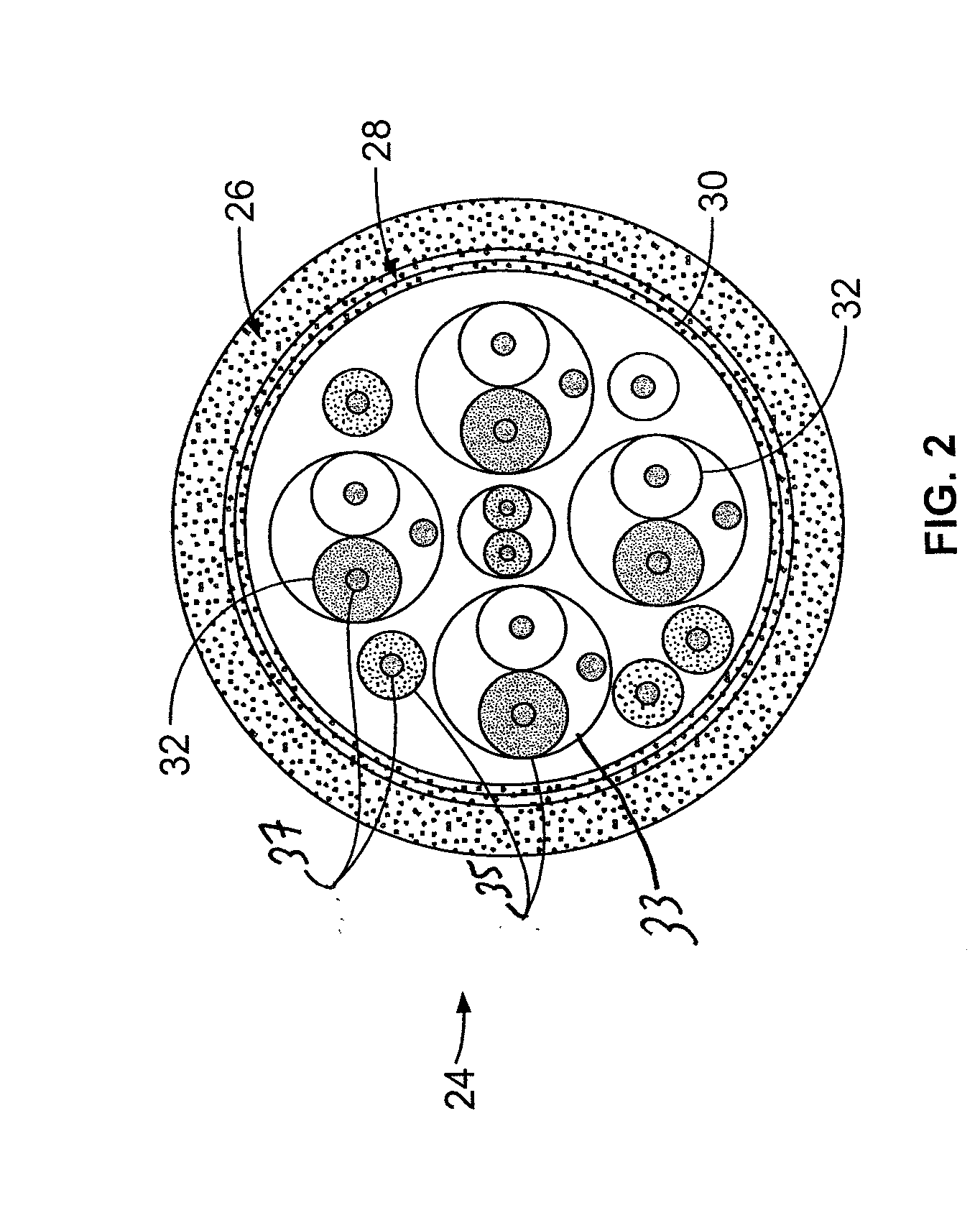

Hydraulic compression tool for installing a coaxial cable connector

InactiveUS7908741B2Suitable for useShaping toolsLine/current collector detailsCoaxial cableEngineering

A hydraulic compression tool for securing a compression type cable connector to a prepared end of a coaxial cable. The tool can include a hydraulic assembly having an axially extendable ram, and a connector frame detachably attached to the hydraulic assembly. The connector frame can include a cable cradle configured to accommodate cables of various sizes and a sleeve for engaging a cable connector. The connector frame can further include a sliding guide structure attached to the cable cradle. The sliding guide structure can include a sliding bar and one or more sliding guides. The sleeve can be attached to the sliding bar. The sleeve can be configured to accommodate connectors of various sizes. Activating the hydraulic assembly can cause the ram to extend, which in turn can cause the sliding bar to move along the longitudinal axis of the cable connector compressing the compression member and connector body into operative engagement with the cable.

Owner:JOHN MEZZALINGUA ASSOC INC

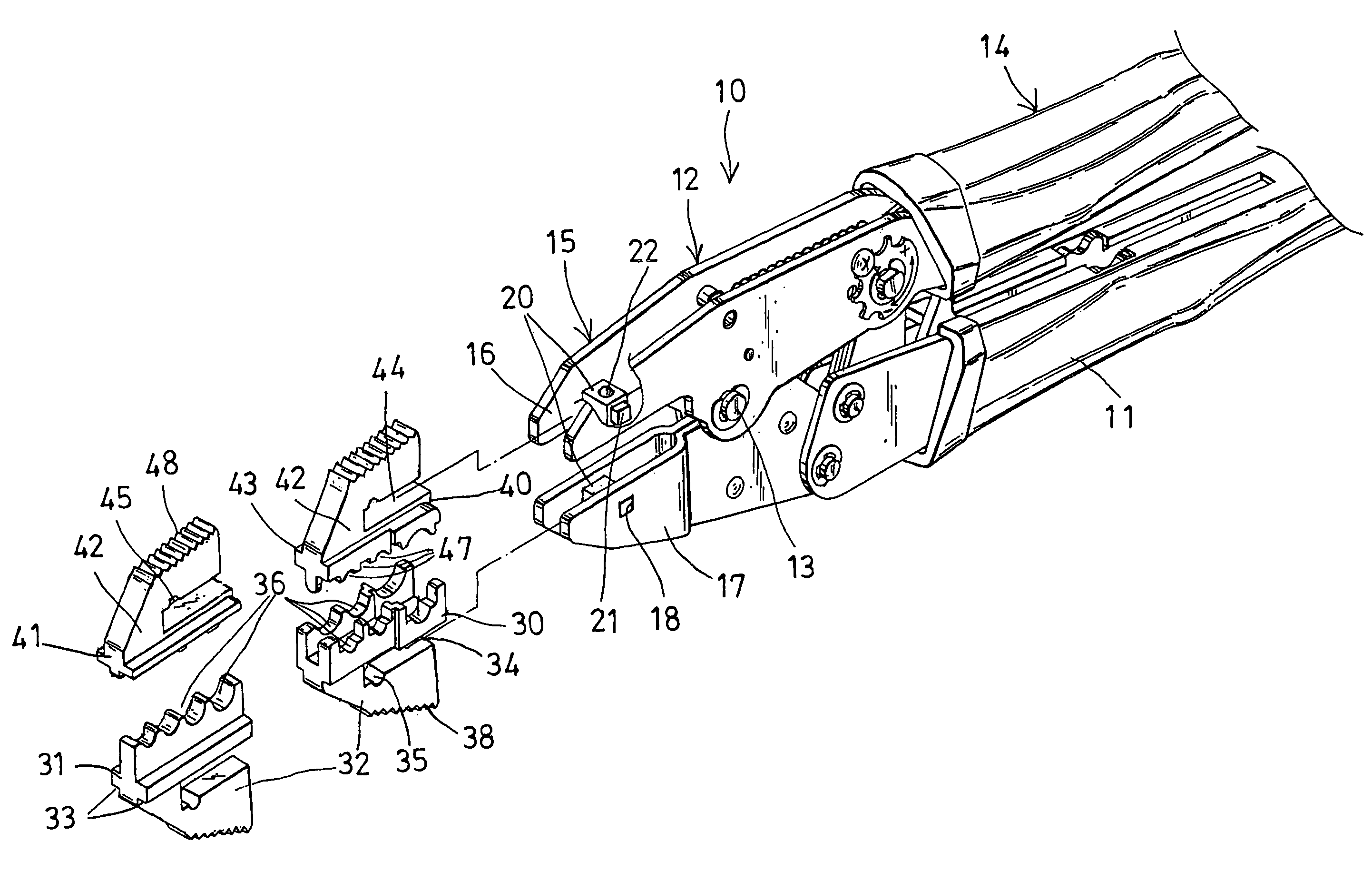

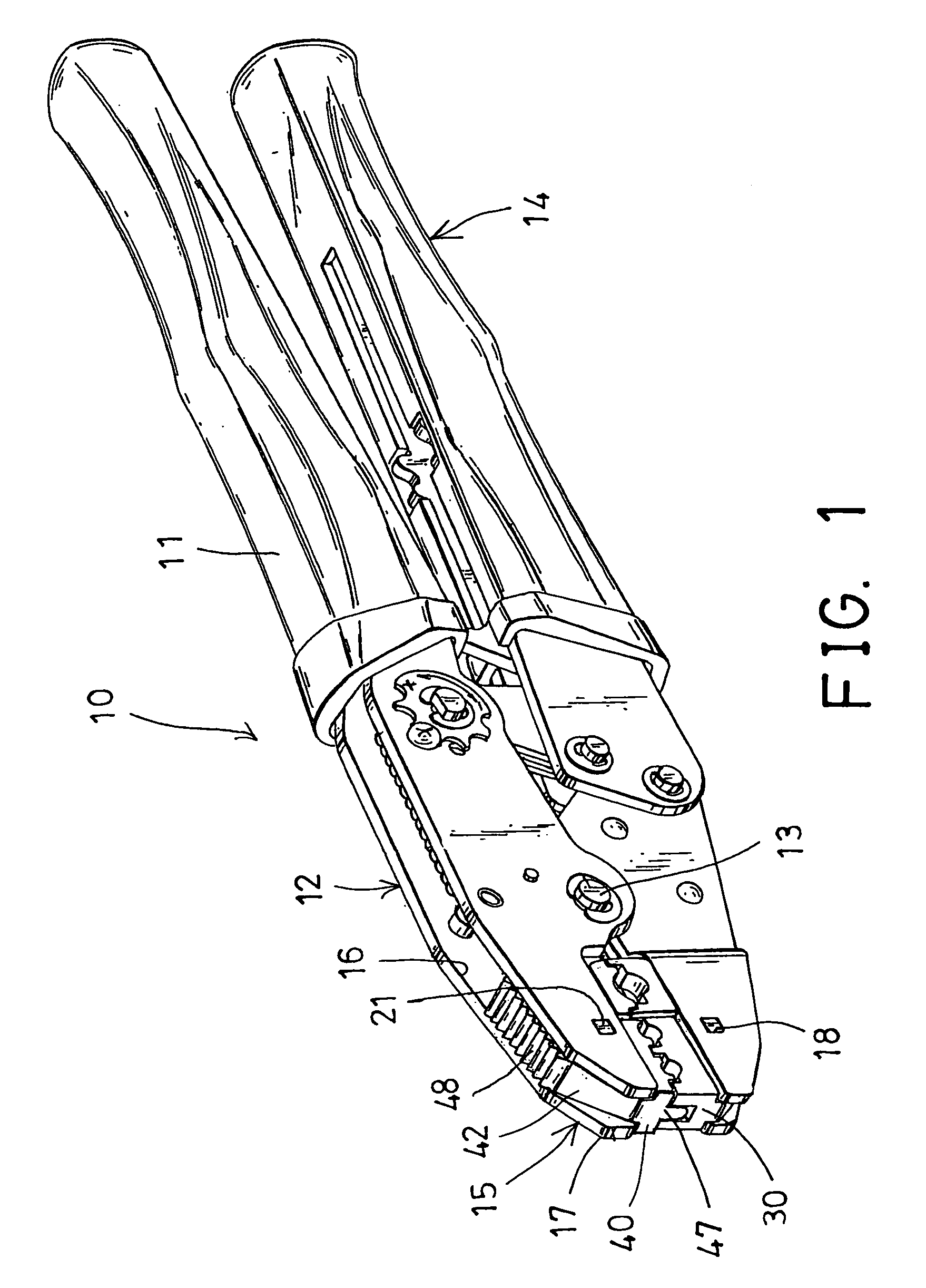

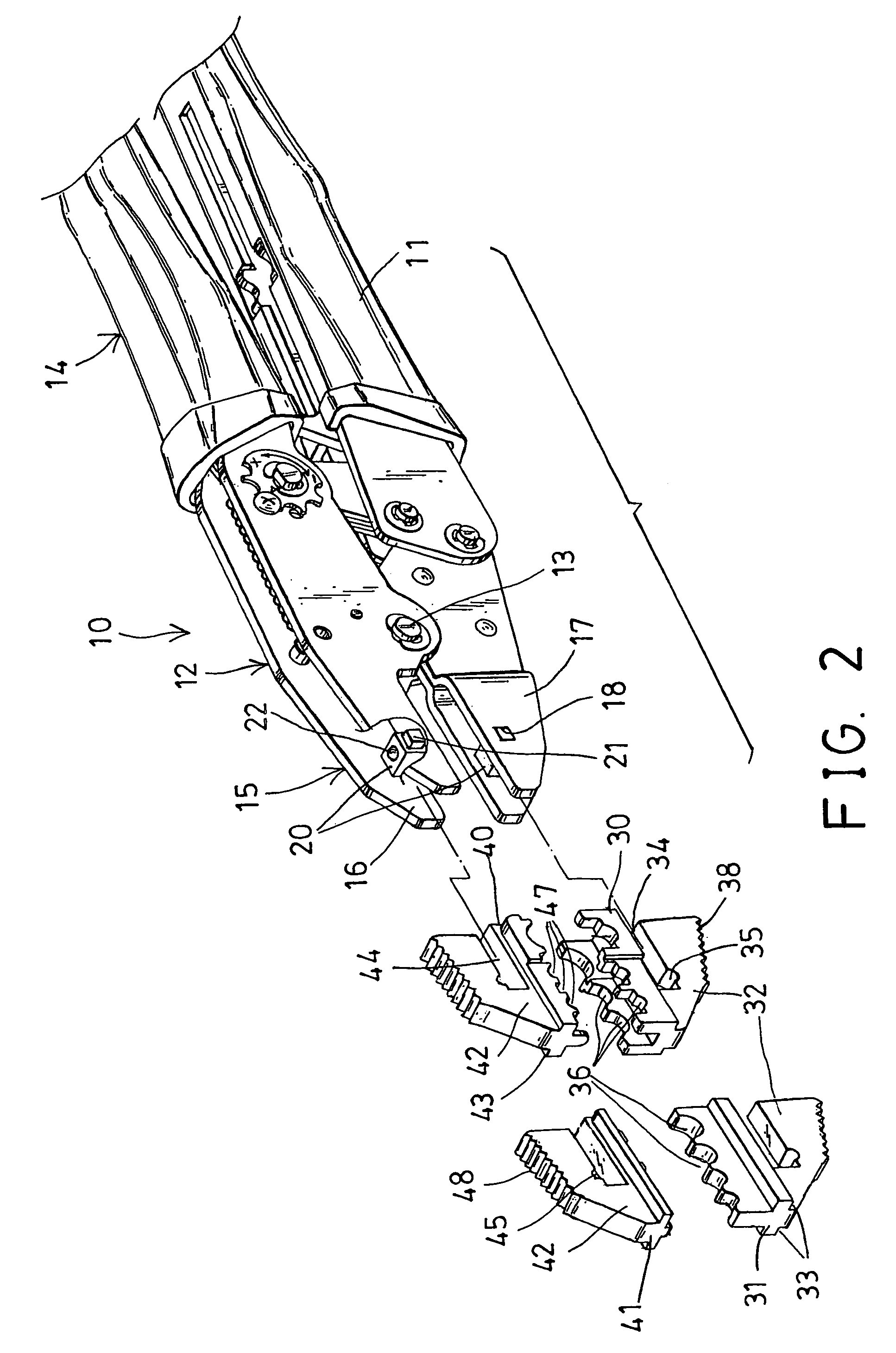

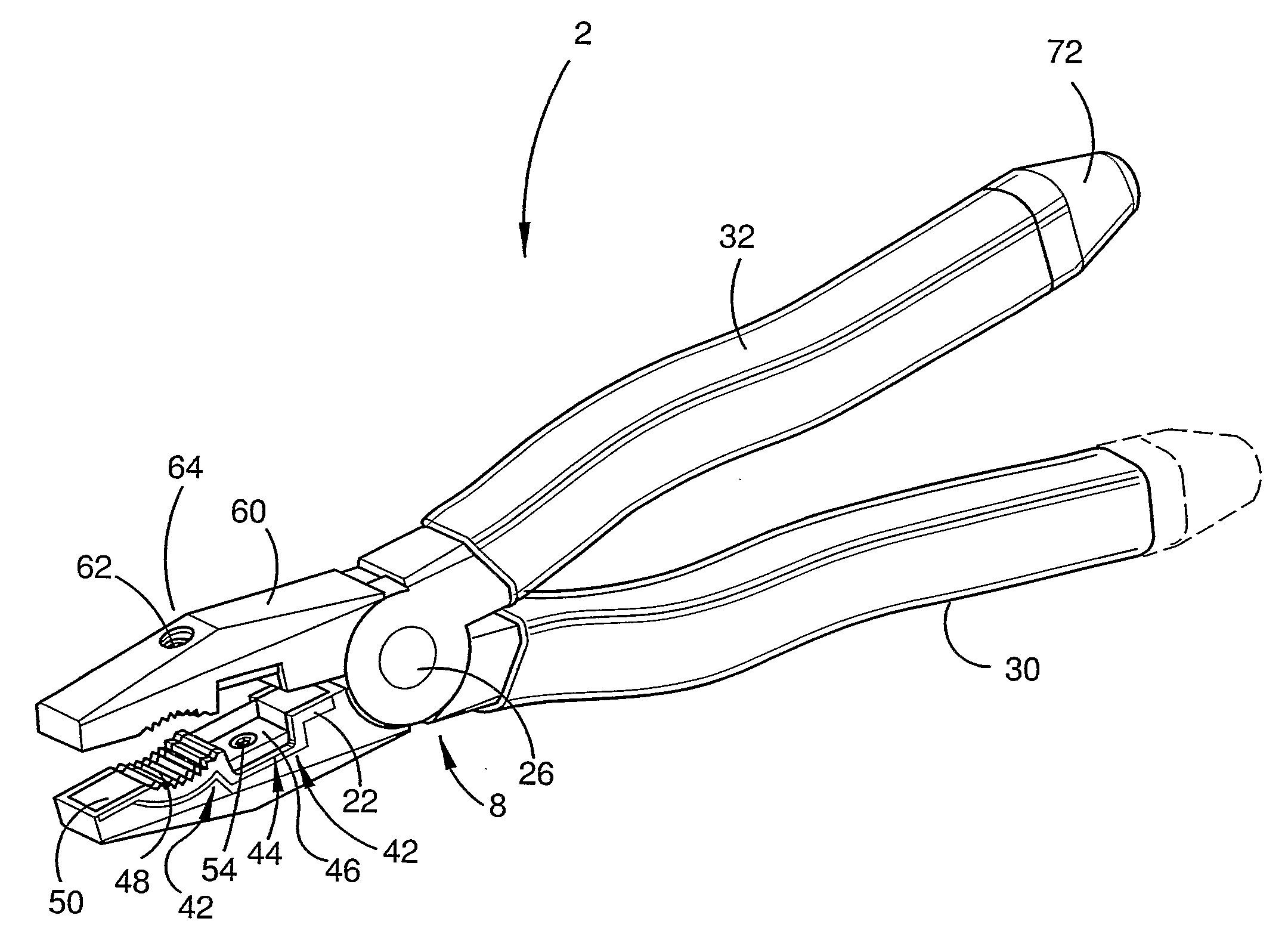

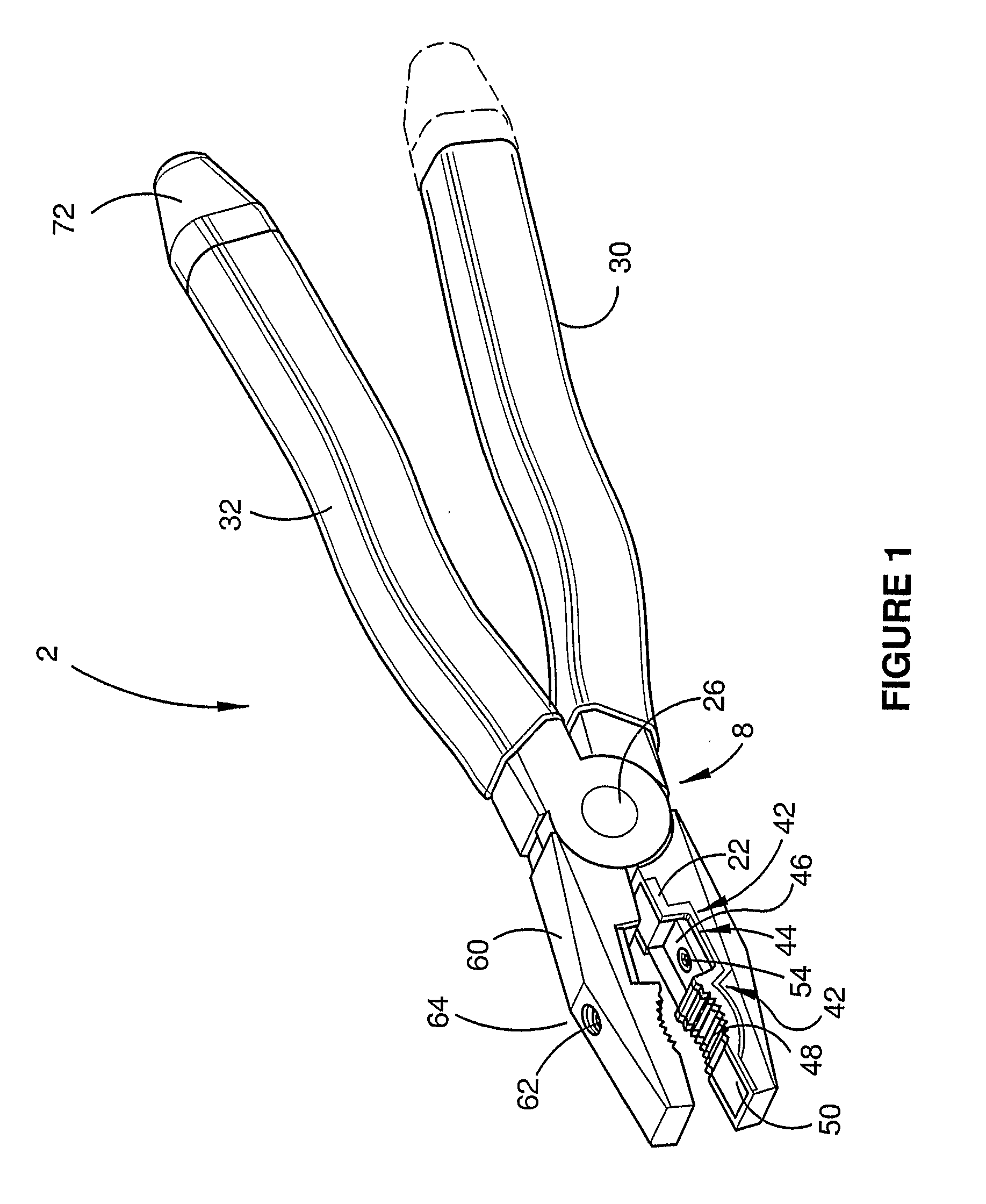

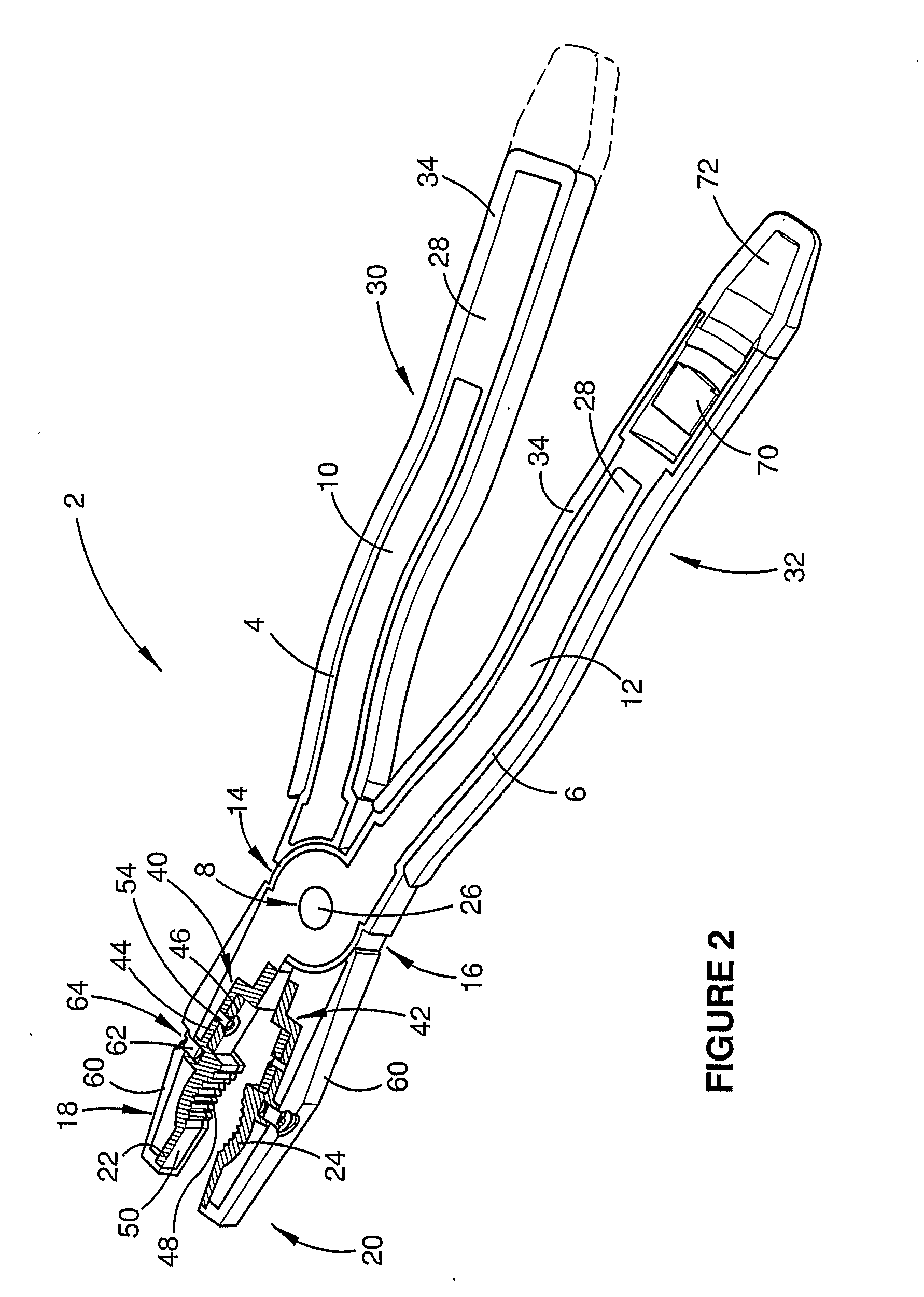

Hand tool for wires

ActiveUS7350393B2Easily and readily and quickly changedQuick changeShaping toolsLine/current collector detailsEngineeringHand tool

Owner:HSUN WANG IND

Insulating Hand Tool

InactiveUS20110030145A1Improve securityApparatus for cutting/splicing cablesPliersMechanical engineeringEngineering

An insulating hand tool having handles of insulating material located at or towards one end of the hand tool capable of being grasped by a person using the hand tool and work elements located at or towards the another end of the hand tool at the nose or head of the tool wherein the work elements include a jaw insert retaining portion for receiving a replaceable cutting insert therein in such a manner to substantially insulate the cutter of the insert from the remainder of the tool to reduce the chance of injuring the person using the tool in the event the cutter contacts a live conductor. The insert is replaceable so that, should the insert be damaged in use, the damaged insert can be replaced by an exchange insert obviating the need to discard the entire tool since only the damaged insert need be replaced.

Owner:MANDIC ELJKO

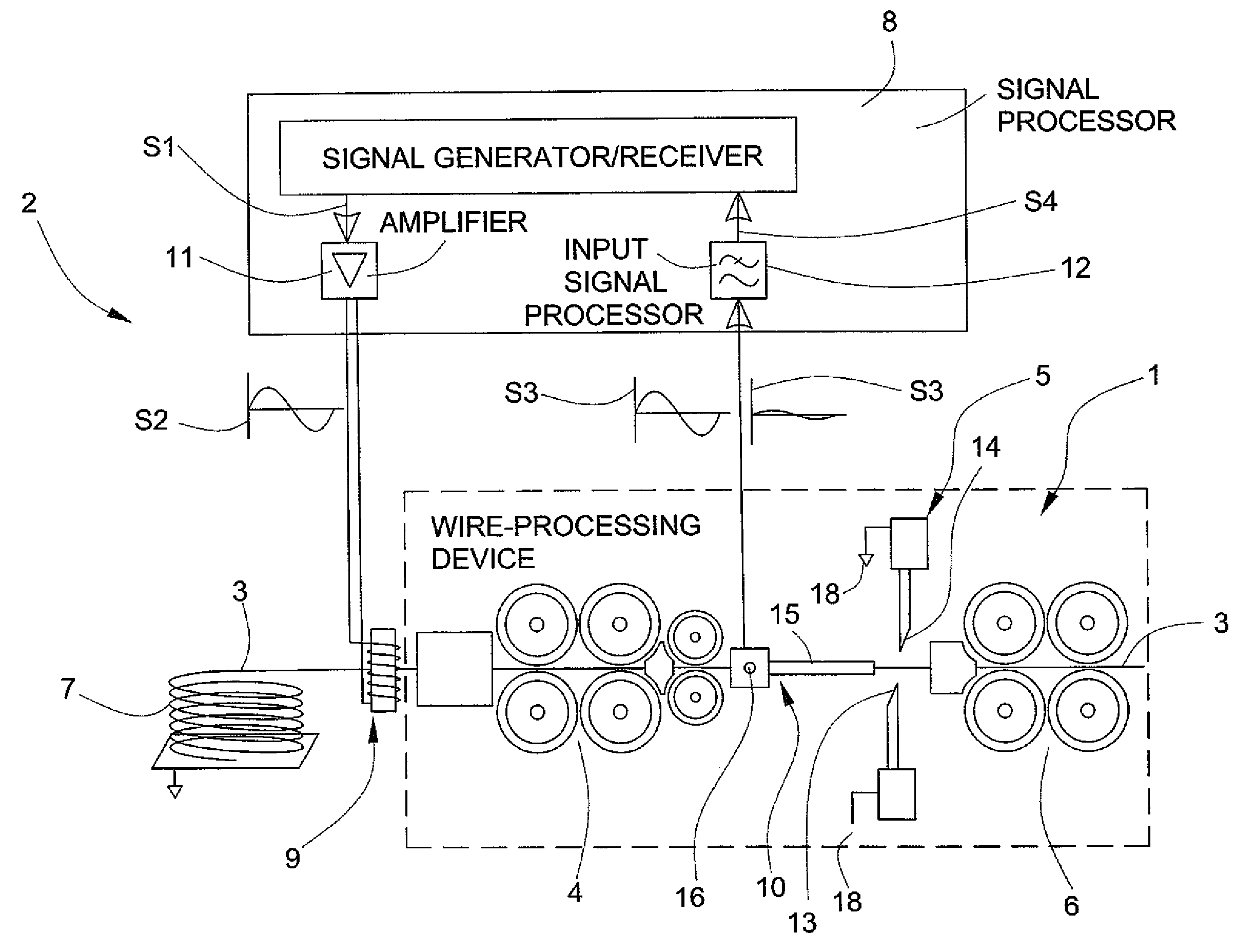

Device to Determine the Diameter of the Conductor of a Wire

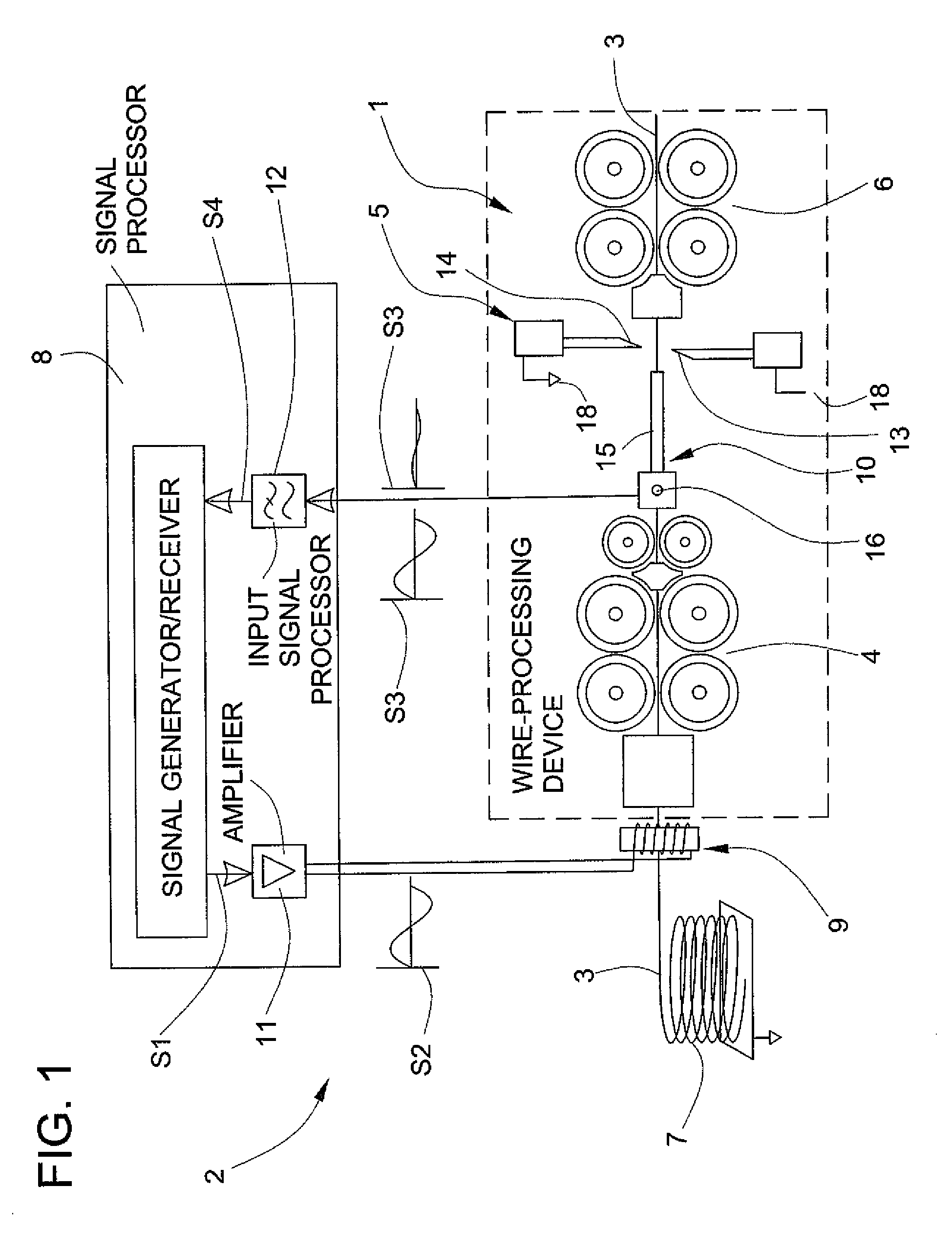

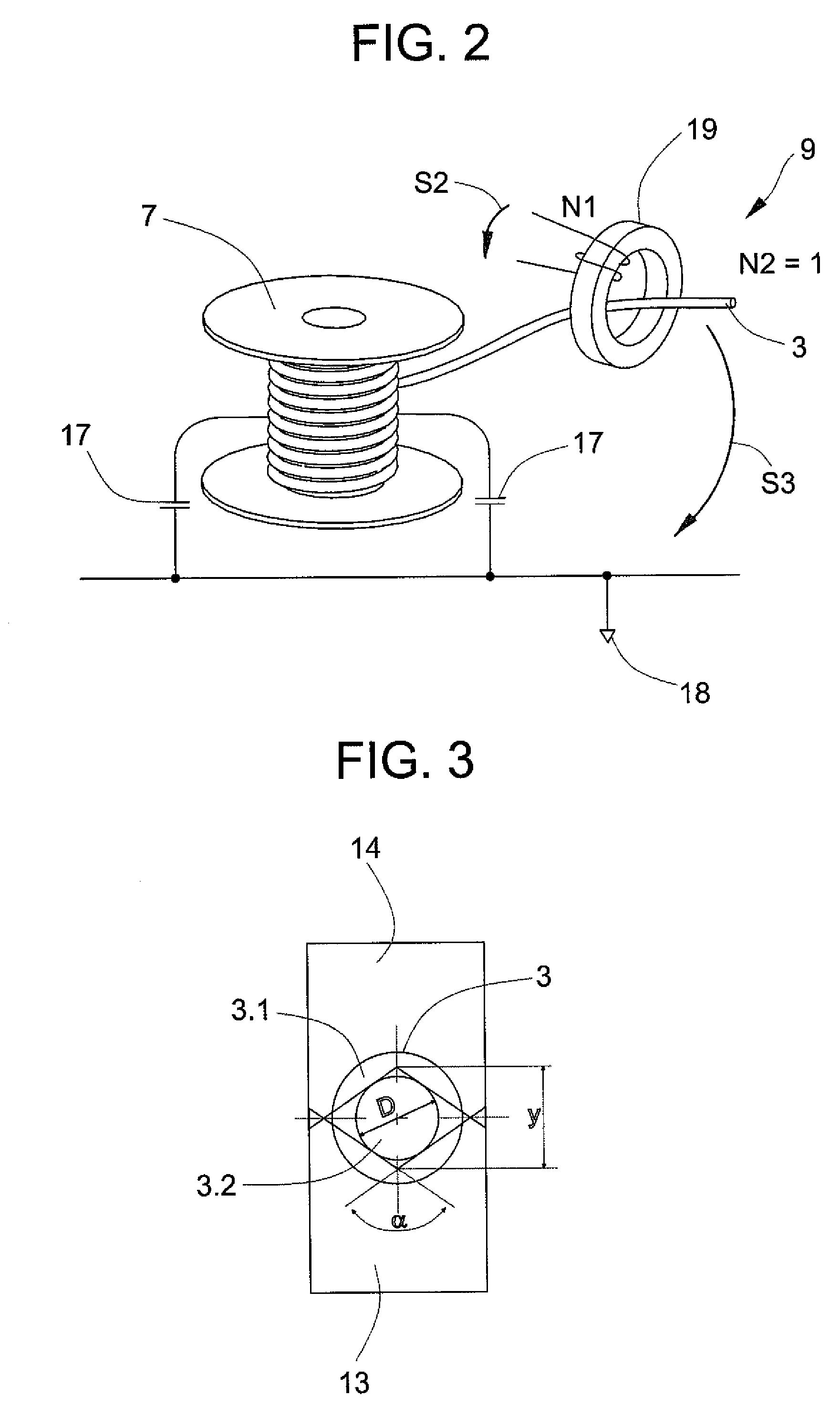

ActiveUS20070121796A1Sure easyShorten the timeApparatus for cutting/splicing cablesSupervisory/monitoring/testing arrangementsElectrical conductorEngineering

A wire-processing device includes a first advancing device, a cutter head, and a second advancing device. The first advancing device pulls the wire out of a wire store and advances according to the desired length of wire to be cut. After the wire is cut through by the cutter head, the wire-ends of the wire-length are processed. The wire-processing device is provided with a device to determine the diameter of the conductor of the wire including an input coupler that applies to the wire an output signal that can be sensed as an input signal and interpreted by a signal processor, wherein the cutters of the cutter head touch the conductor and change the input signal when cutting into the wire.

Owner:KOMAX HOLDING

Power cable cutting device

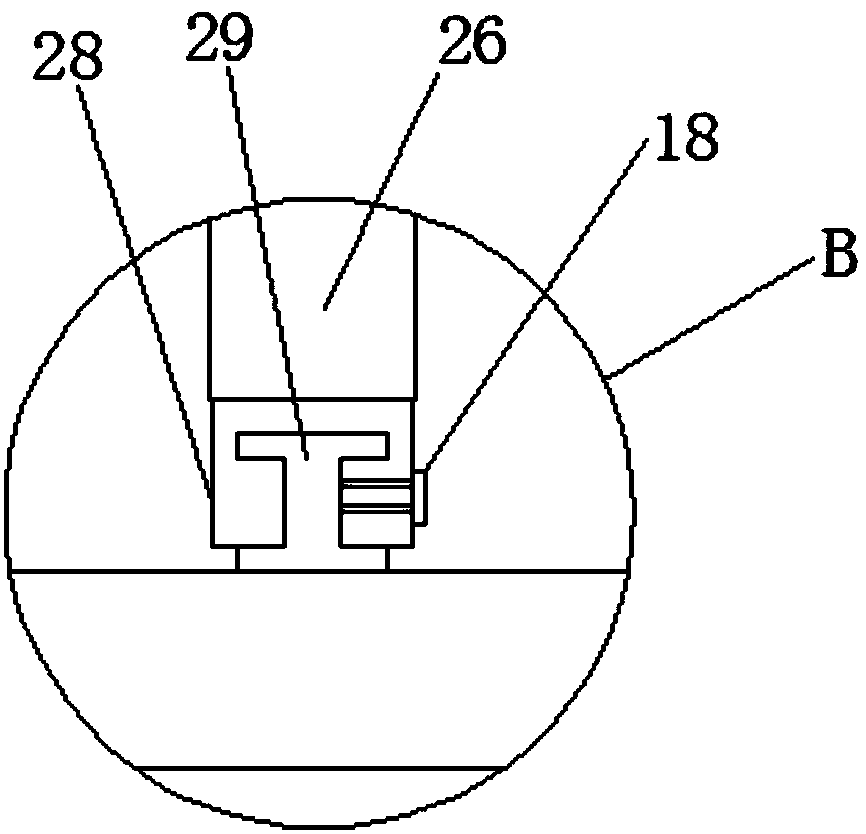

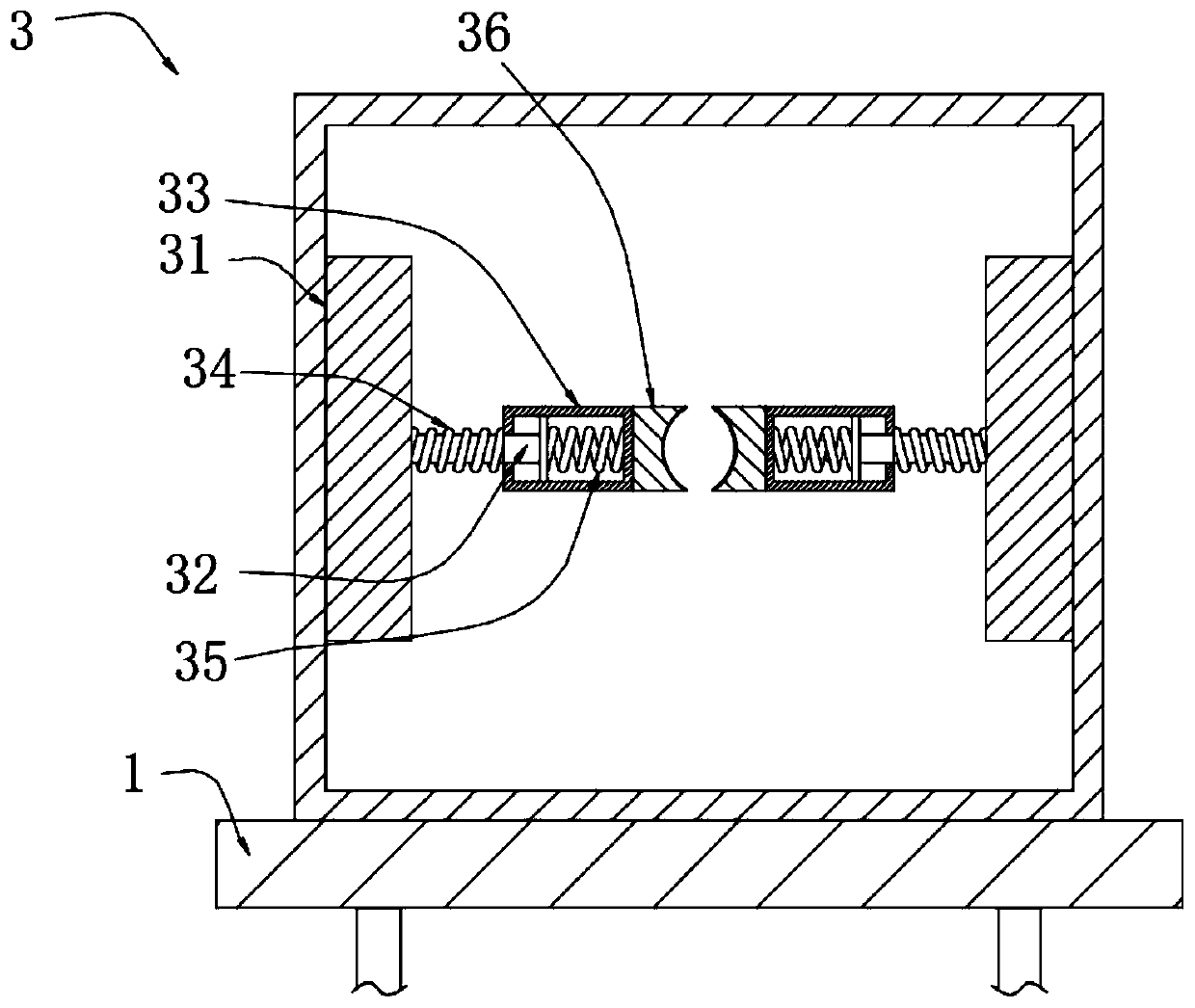

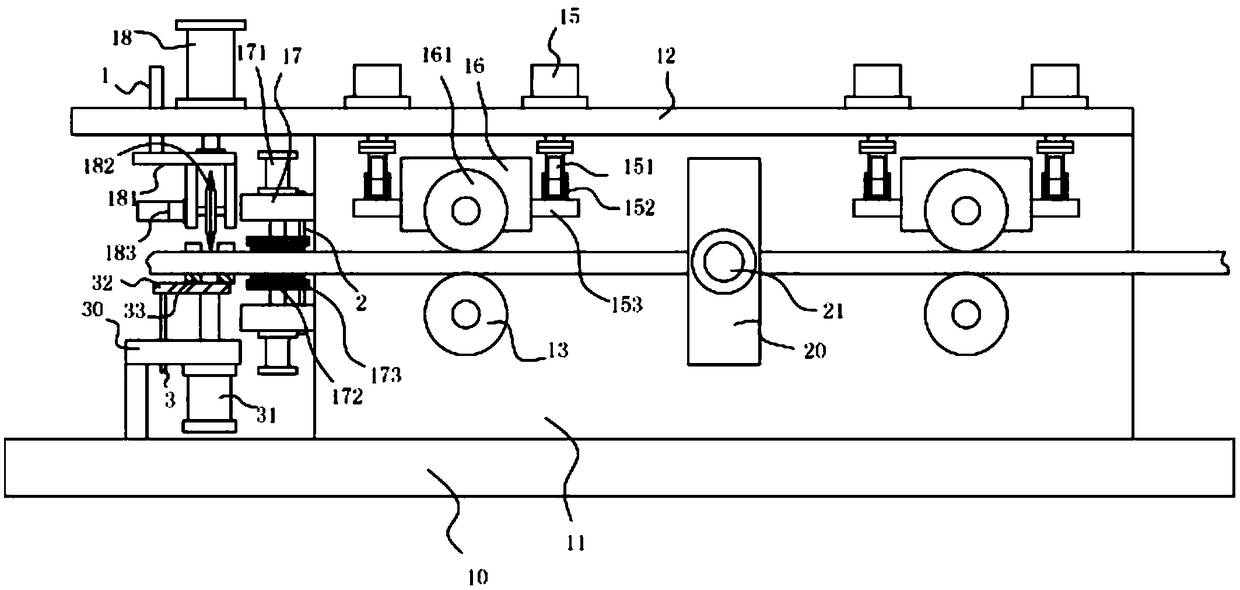

PendingCN107775699AGood truncation effectConvenient truncationApparatus for cutting/splicing cablesMetal working apparatusPower cableSlide plate

The invention discloses a power cable cutting device. The power cable cutting device comprises a support base, wherein vertical plates are arranged on the left side wall and the right side wall of thesupport base; a convex plate is arranged above a second slider; a second cylinder is fixedly mounted on the front side wall of the convex plate and fixedly connected with the outer side wall of a second fixture block through a cushion block; a cutter is located above a first fixture block and the second fixture block. According to the power cable cutting device, a third motor is started to drivea cable feed roller to perform paying off, while a to-be-cut cable penetrates through the through holes in the left vertical plate and the right vertical plate, the second cylinder is started to drivethe second fixture block to move backwards, so that the to-be-cut cable is located between the first fixture block and the second fixture block, then the second cylinder drives the second fixture block to move forwards to clamp the to-be-clamped cable, left-right movement can be realized by a mobile table, accordingly, the cutter is enabled to move to the right sides of the first fixture block and the second fixture block, and a second motor is started to drive the cutter to rotate for cutting the cable.

Owner:丁家琪

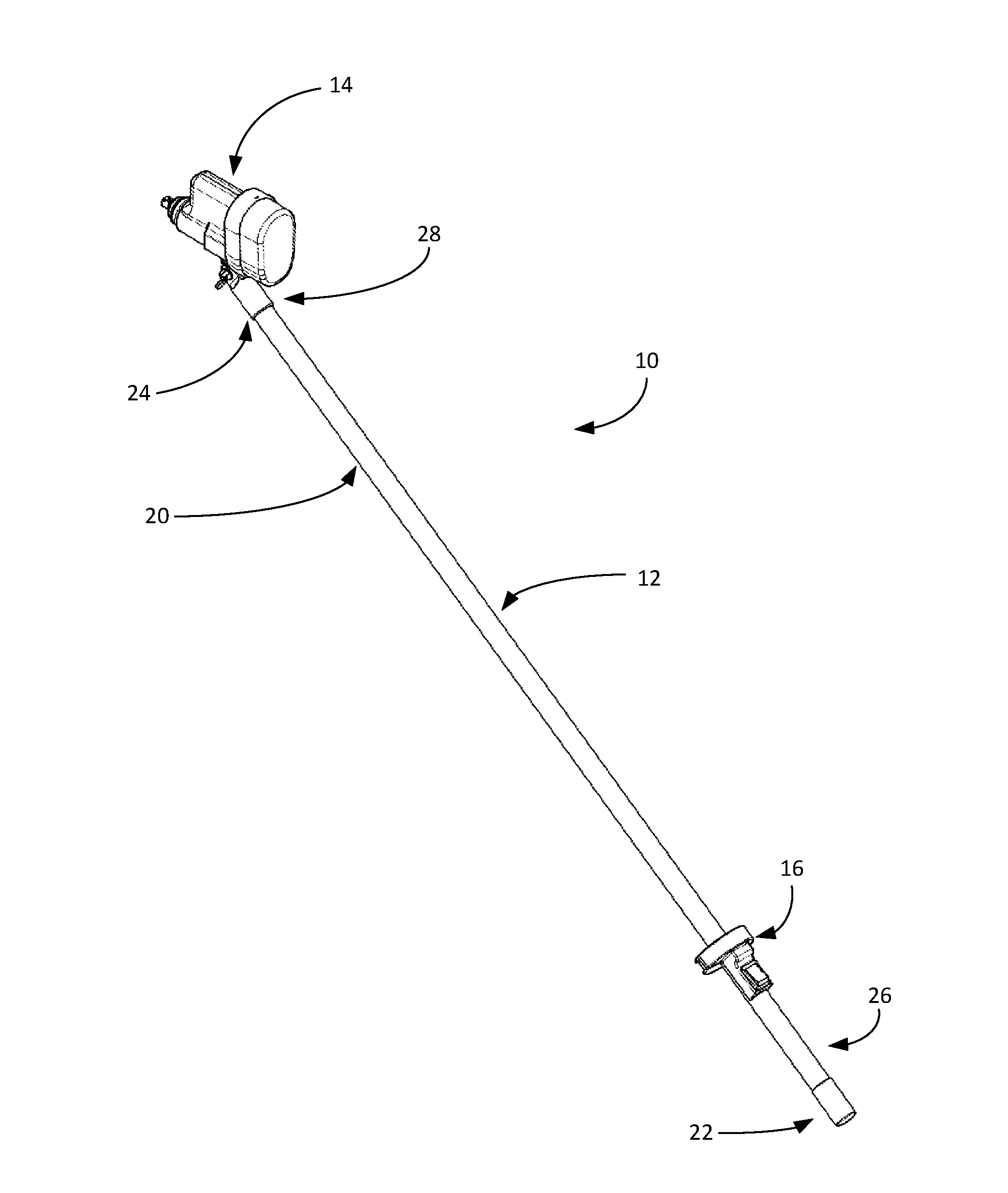

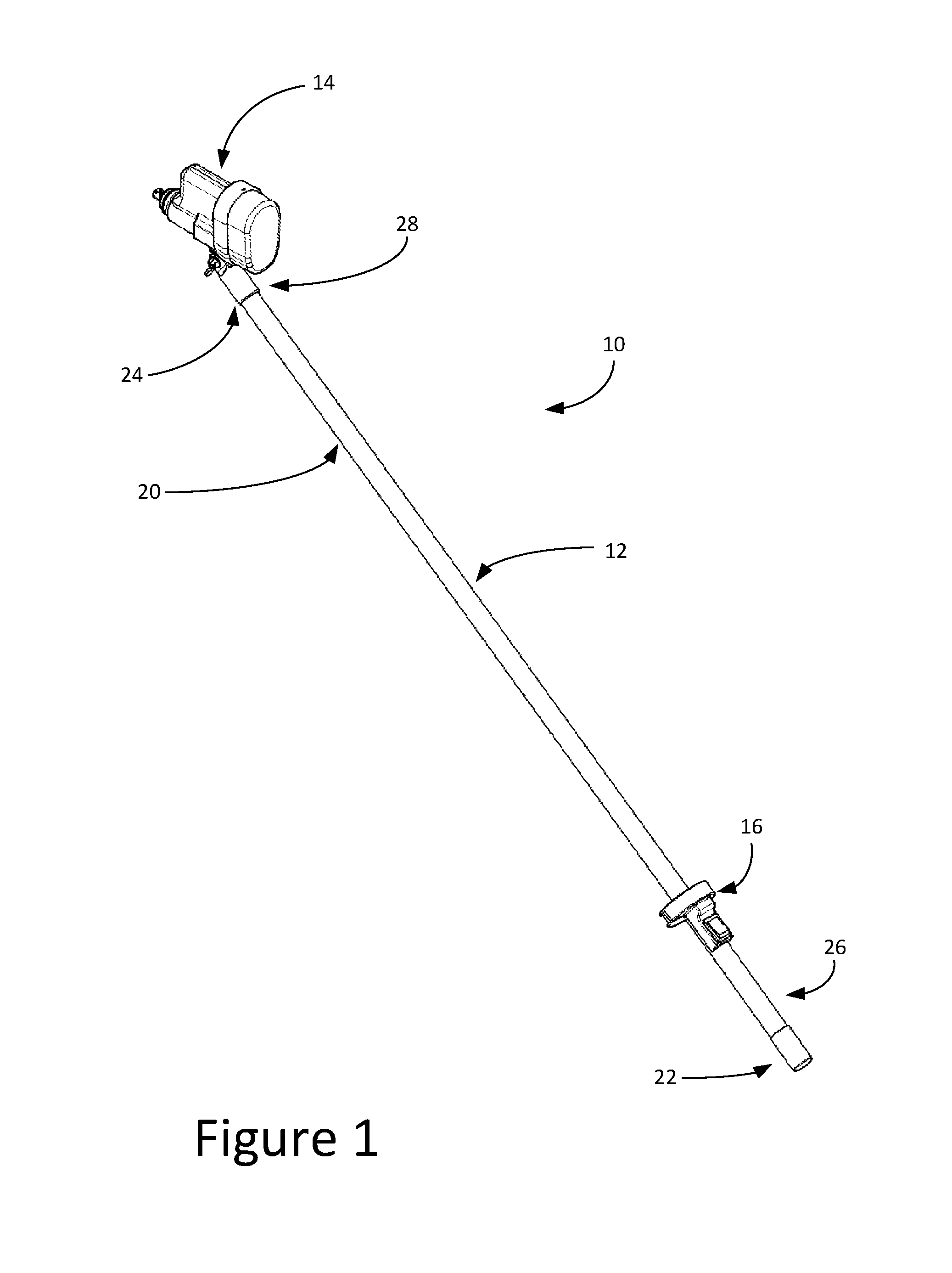

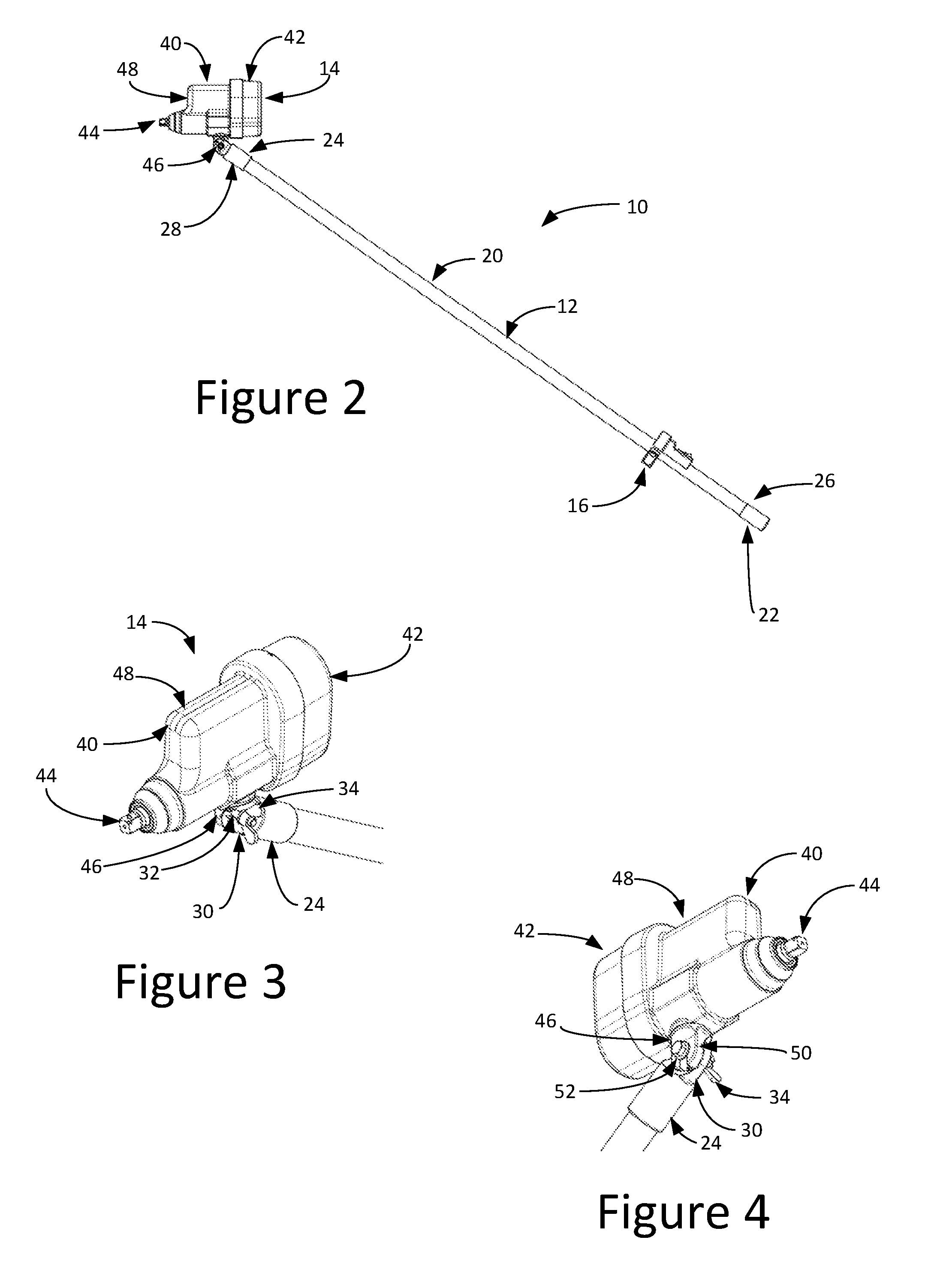

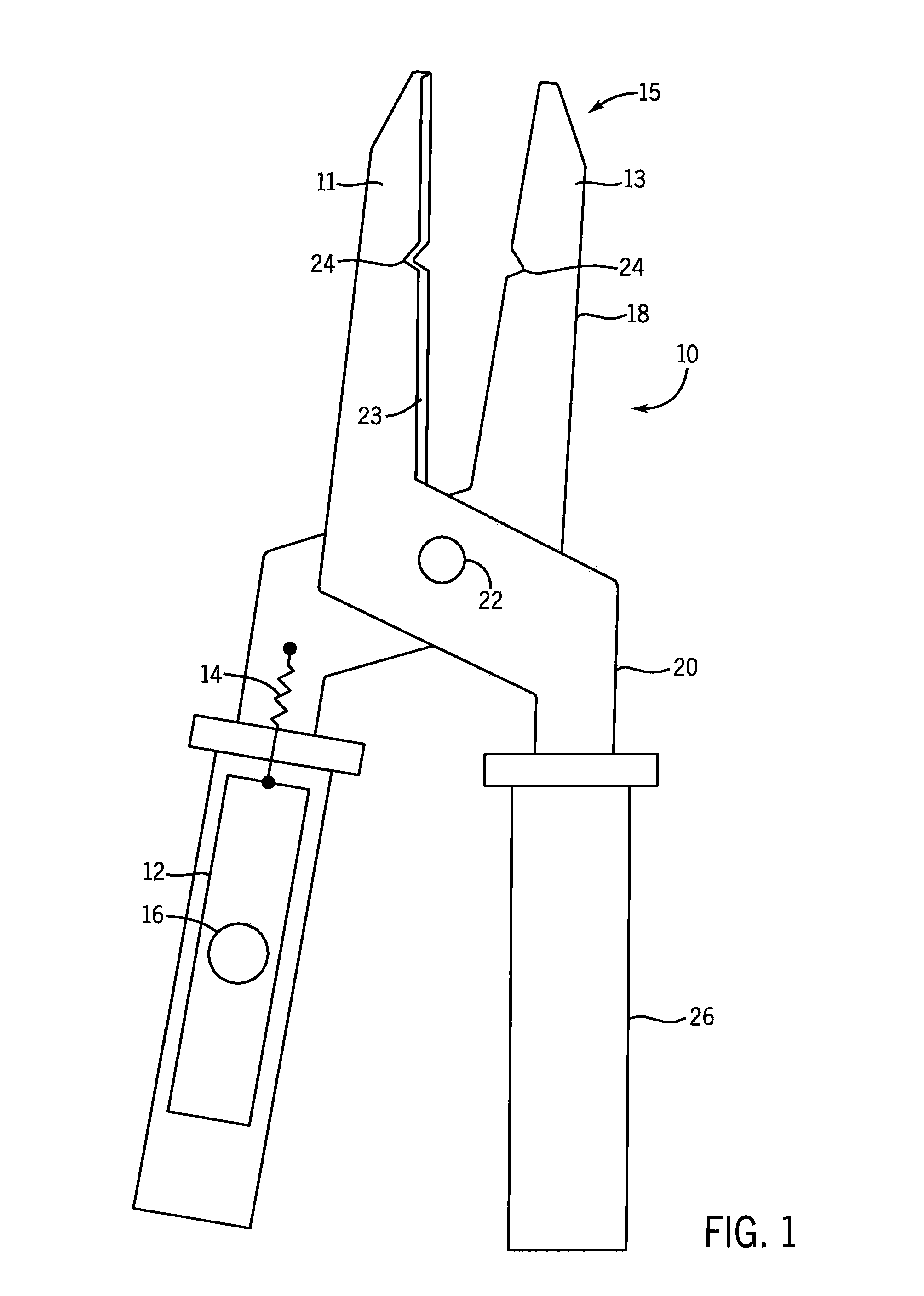

Remote Control Tool Assembly For Use In Live Line Environments

InactiveUS20160344170A1Apparatus for cutting/splicing cablesPortable power-driven toolsRemote controlEngineering

A remote control tool assembly for use in live line environments having an insulated pole (often termed a “hot stick”) with a tool at one end that generally includes a power supply so that the tool is fully isolatable at the end of the insulated pole. At the other end, a tool control transmitter is positioned which is configured to communicate wirelessly with the tool. Thus, the user can operate the tool remotely from the tool controller, which is particularly useful in a live line environment. A tool body assembly and a tool having a tool body assembly is disclosed.

Owner:TAMM CARL RUSSEL

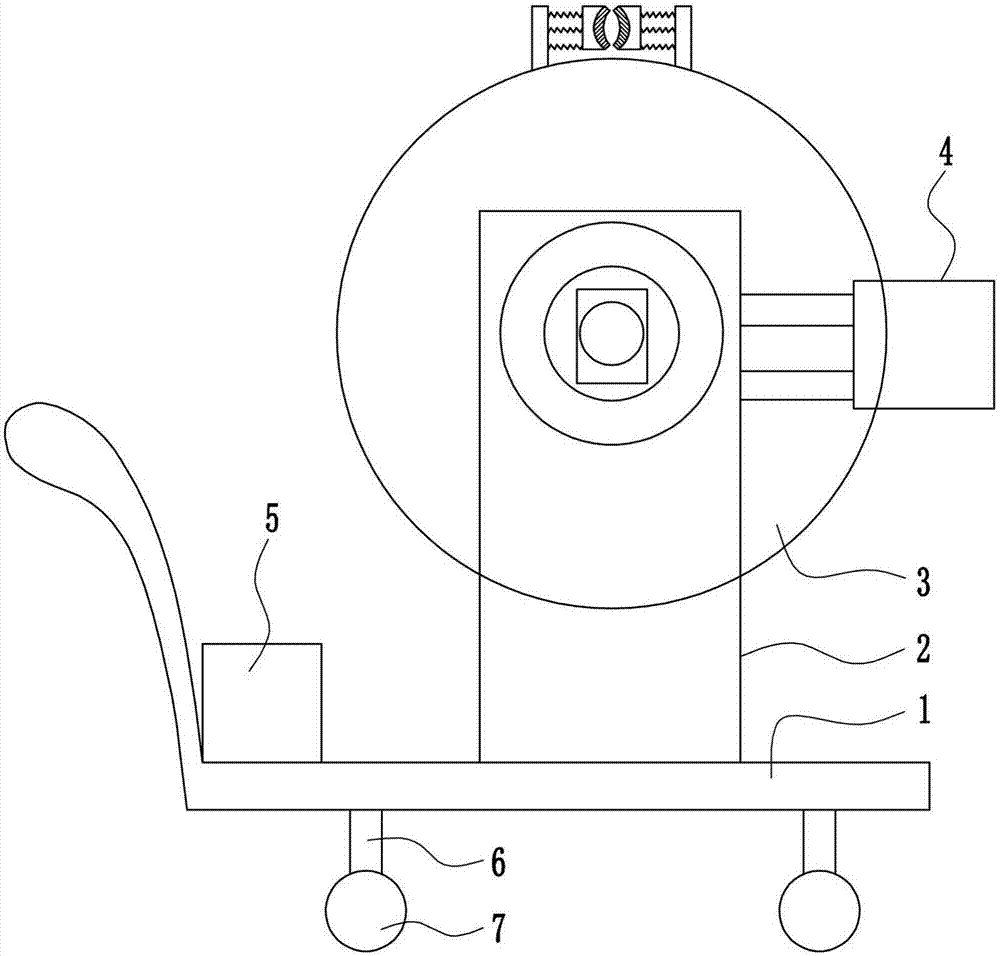

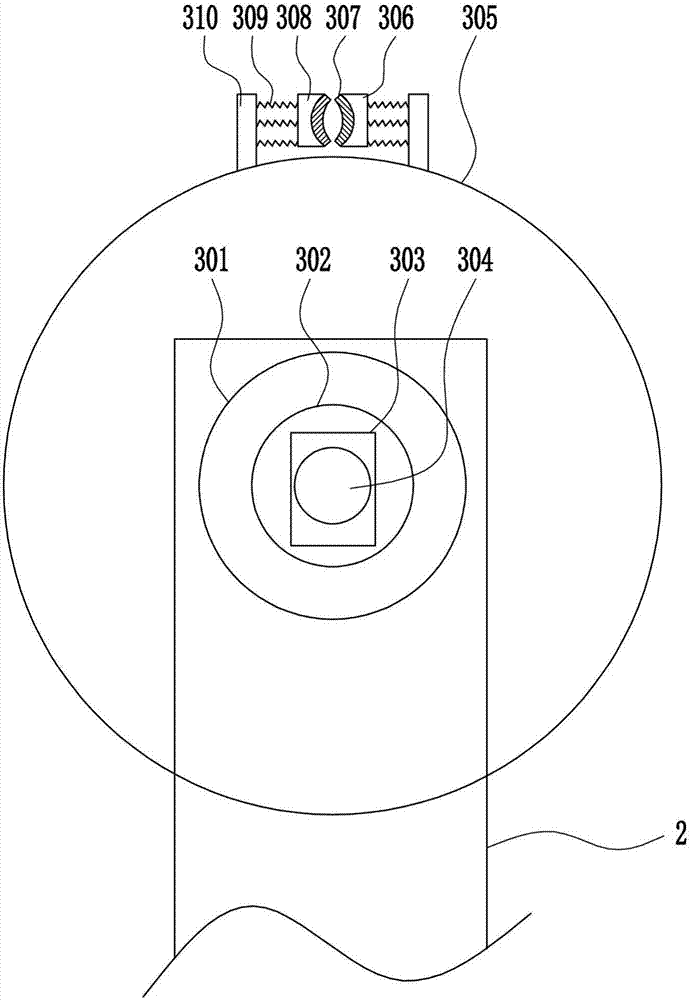

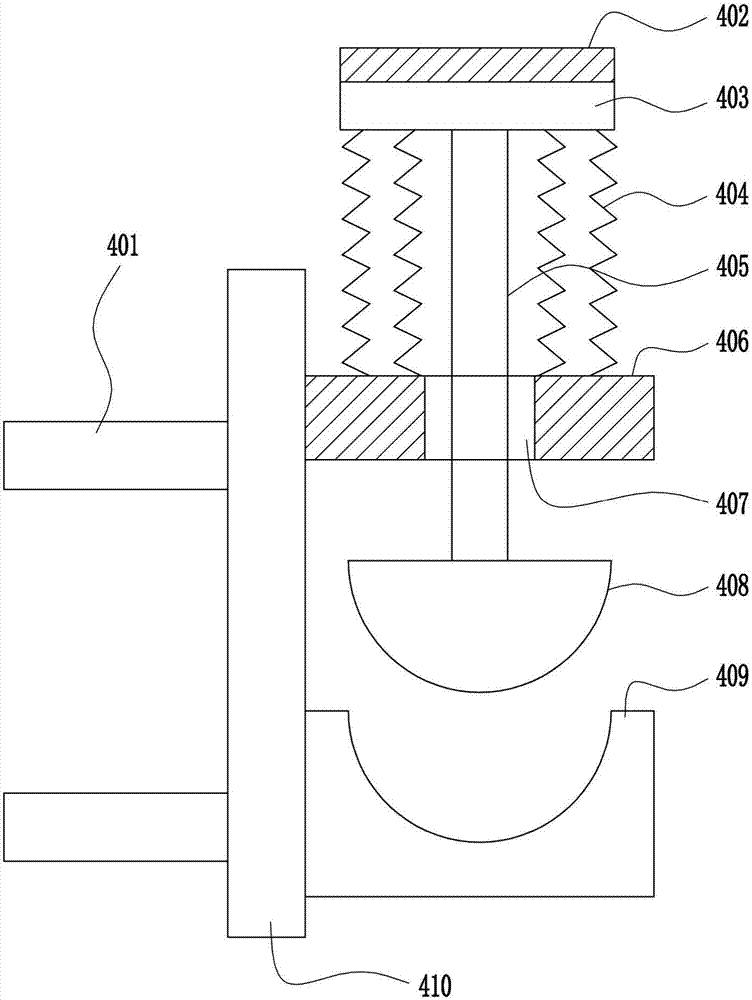

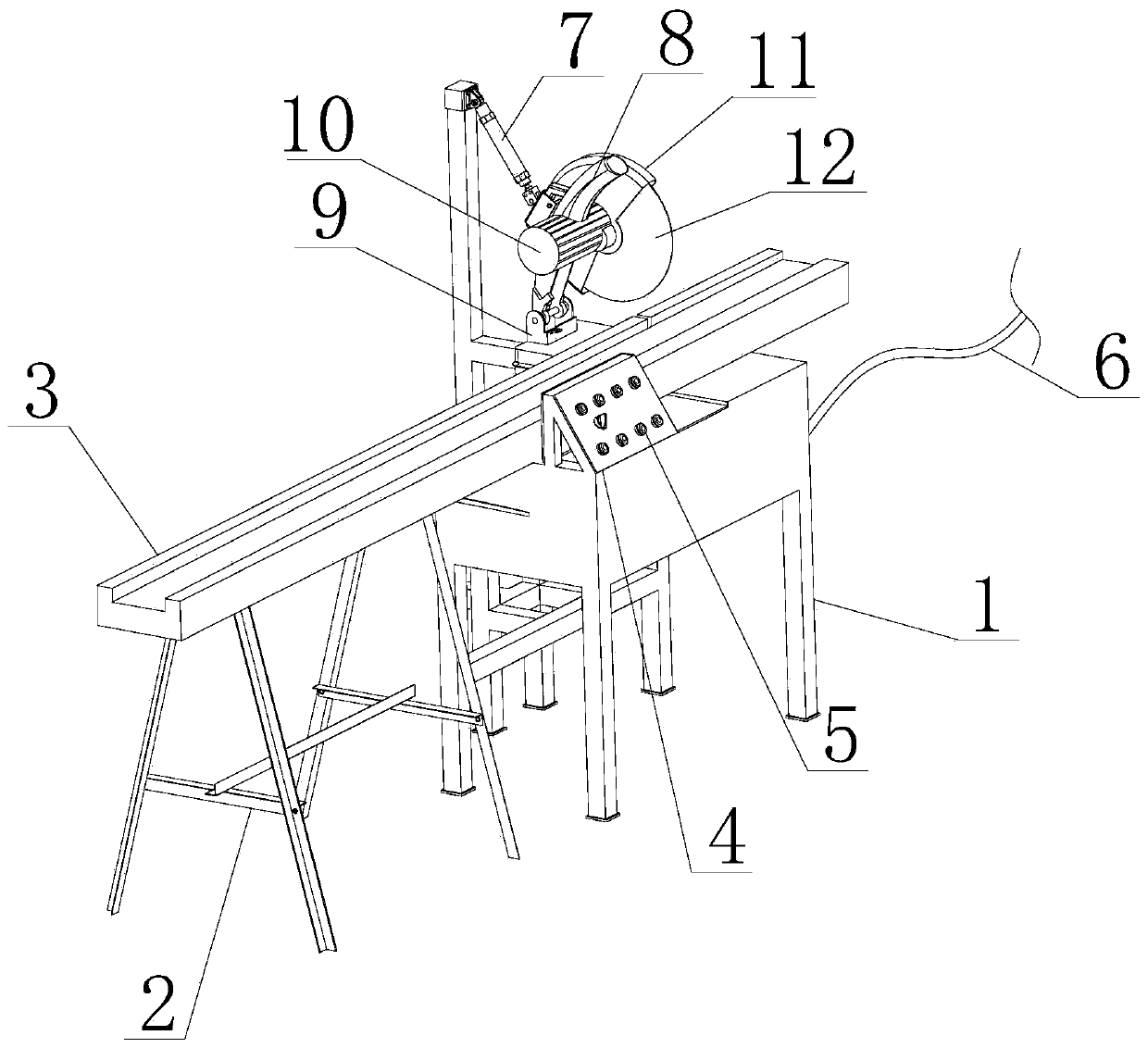

Cable payoff cutting device for power engineering

ActiveCN106921127ASo as not to damageAvoid moving aroundApparatus for cutting/splicing cablesFilament handlingEngineeringPower engineering

The invention relates to a payoff cutting device, in particular to a cable payoff cutting device for power engineering and provides the cable payoff cutting device for the power engineering. In order to solve the technical problem, the cable payoff cutting device for the power engineering, provided by the invention, comprises a cart, wherein struts are arranged at a left side and a right side of the bottom of the cart, a roller is arranged at the bottom of each strut, a storage battery is arranged at a left side of the top of the cart, installation plates are arranged at a front side and a rear side of a middle position of the top of the cart, a payoff device is arranged between the installation plates at the front side and the rear side, the storage battery and the payoff device are connected through a wire, and a cutting device is arranged at a right side of the installation plate at the front side and is arranged at a front side of the payoff device. By the cable payoff cutting device, automatic rotation can be achieved to discharge a cable, the cable payoff cutting device is good in cable fixing effect, and the cable can be cut; and moreover, by arranging a clamping block and an anti-slip cushion, the device is better in stability.

Owner:融创达科技成果转化(江苏)有限公司

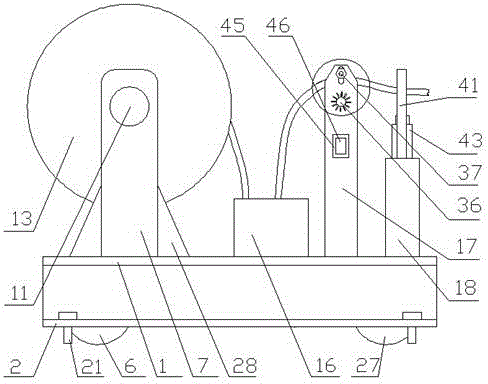

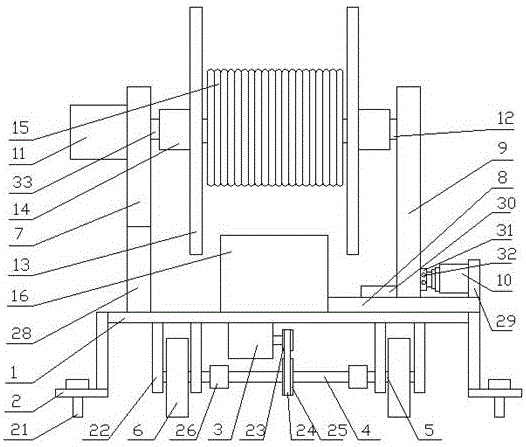

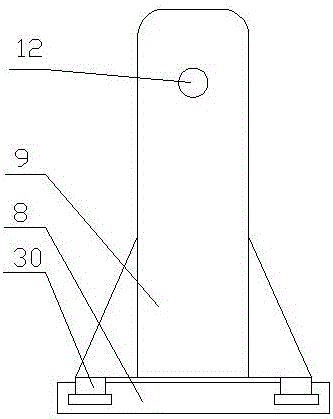

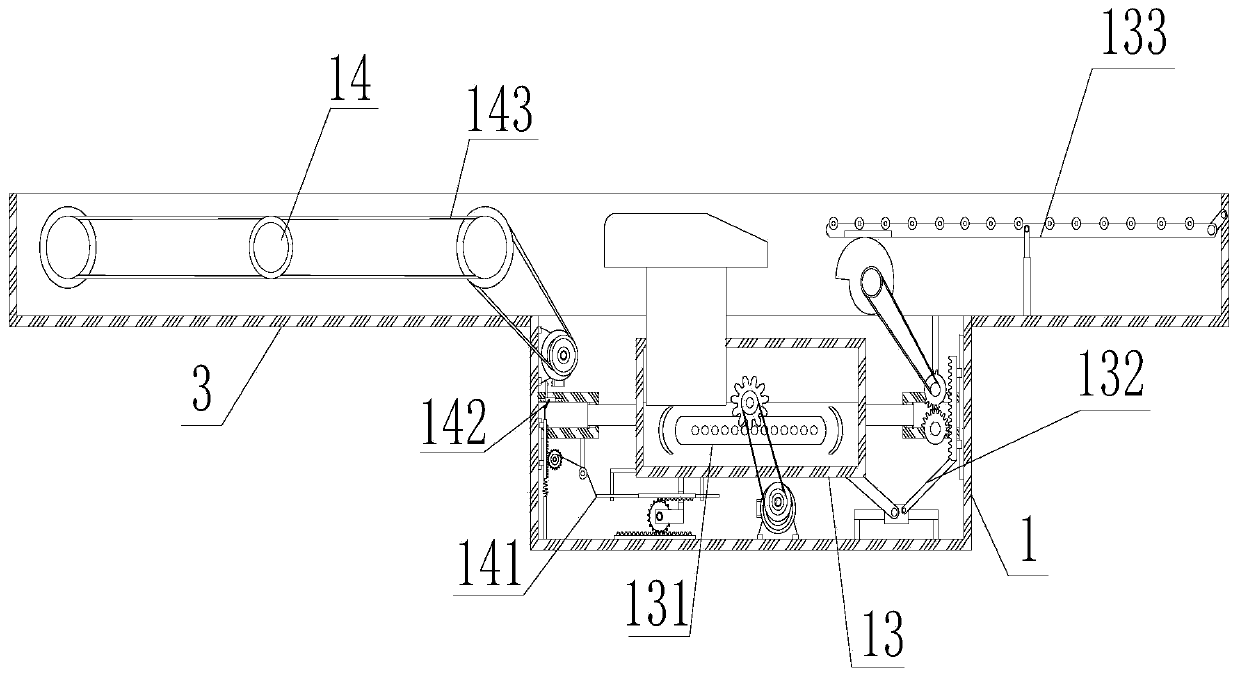

A cable folding and unfolding apparatus with a counting cut-off function for power line setting up

InactiveCN106099767AEasy to assemble and disassembleAccurately know the release lengthApparatus for cutting/splicing cablesApparatus for laying cablesEngineeringMechanical engineering

The invention discloses a cable folding and unfolding apparatus with a counting cut-off function for power line setting up. The cable folding and unfolding apparatus comprises a device main frame. The lower part of the device main frame is provided with a walking motor which cooperates with a wheel axle. The wheel axle is provided with a rear wheel, and the upper part of the device main frame is provided with a left frame and a right frame, wherein the right frame cooperates with an adjustment oil cylinder provided on a slide carriage. The upper part of the left frame is provided with a winding-and-unwinding motor. The upper part of the right frame is provided with a rotary shaft, and both the winding-and-unwinding motor and the rotary shaft are matched with shaft sleeves provided on both sides of a winding and unwinding frame. The device main frame is also provided with a counting frame. The counting frame is provided with a counting roller and a driven roller. The cable folding and unfolding apparatus with the counting cut-off function for power line setting up can perform folding and unfolding, calculate the meters of the unfolded part of a cable, so that operation personnel can accurately know the length of the unfolded part of the cable to prevent the unfolded part from being too long or too short; and a cutting device is provided, so that the cable cut-out is fast and convenient.

Owner:李从宾

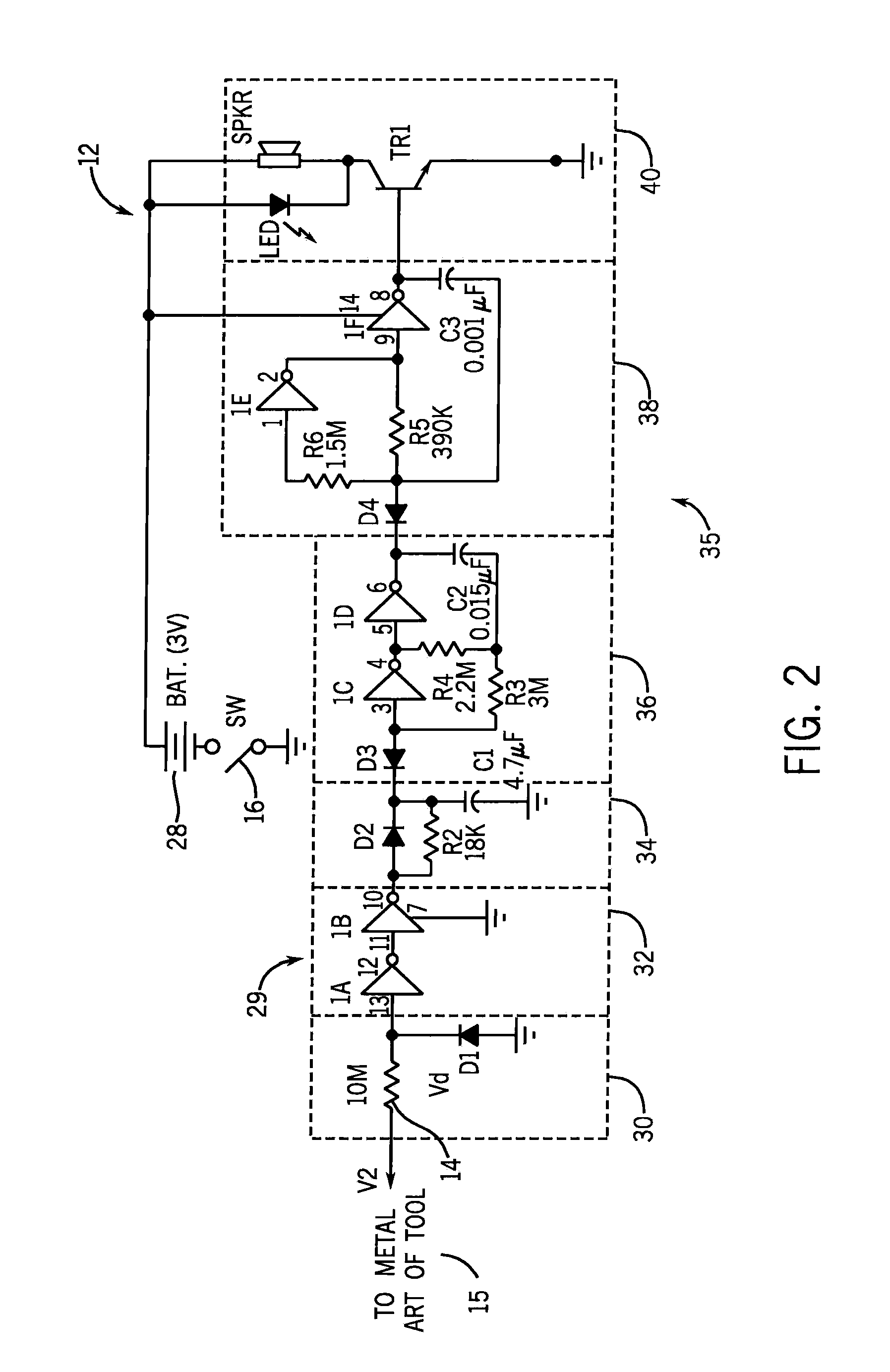

Voltage sensing hand tool

InactiveUS7468674B2Low costRaise security concernsApparatus for cutting/splicing cablesElectrical measurementsElectricityHand tool

Owner:ECM IND LLC

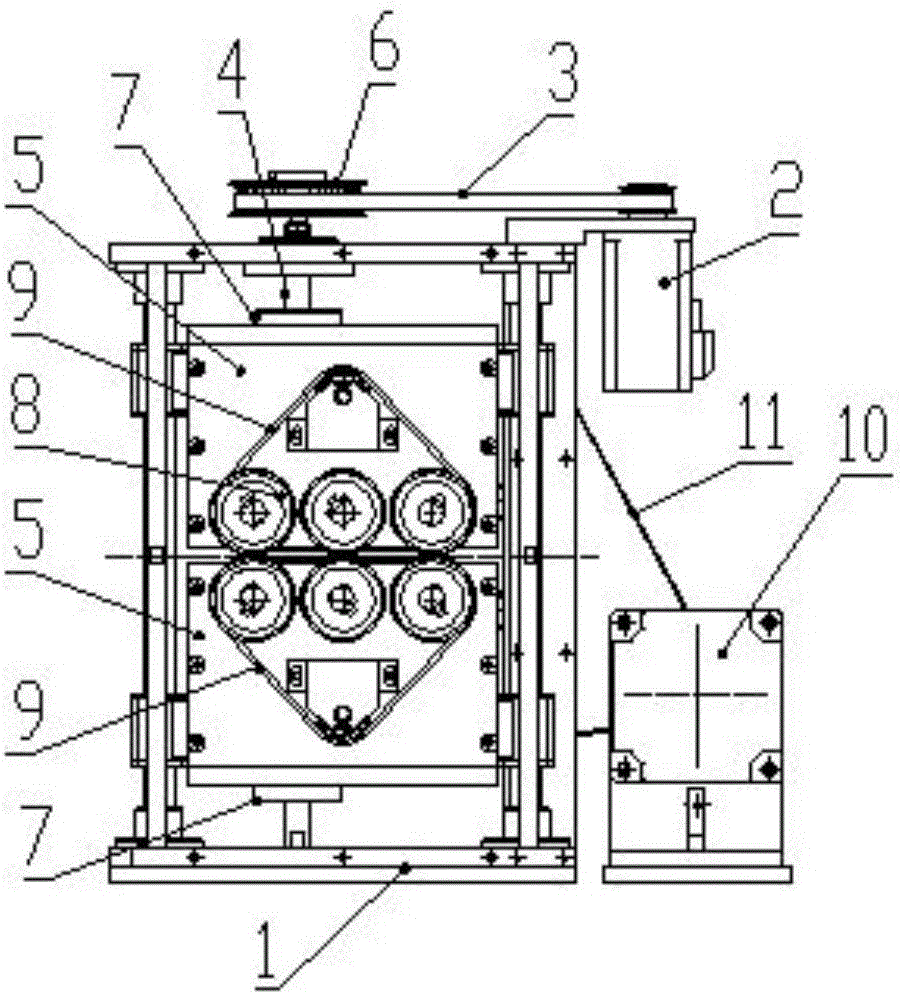

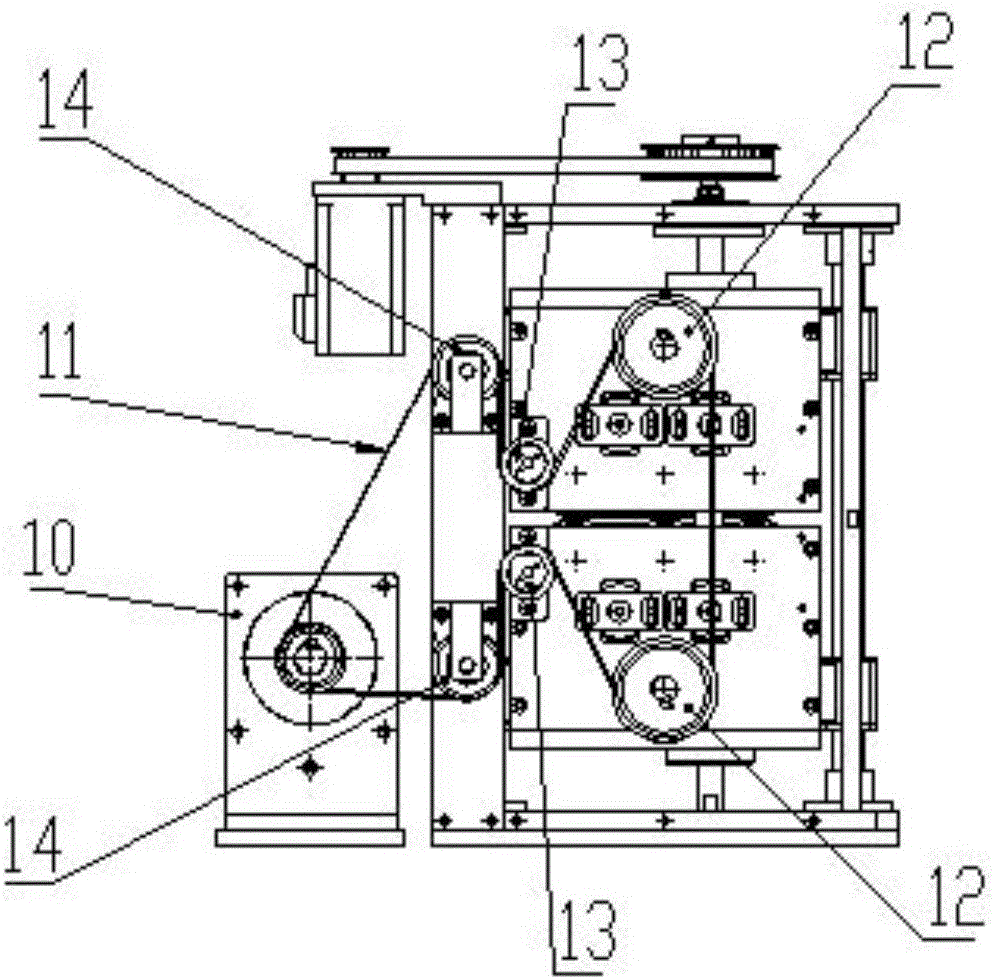

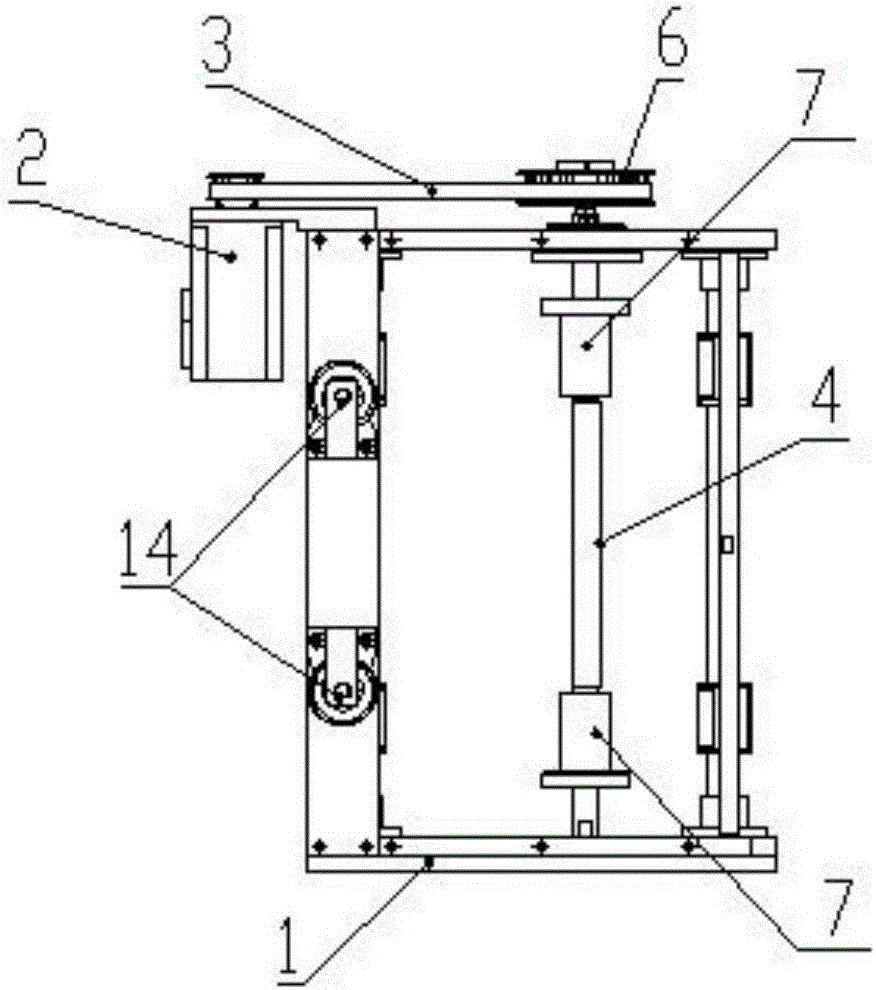

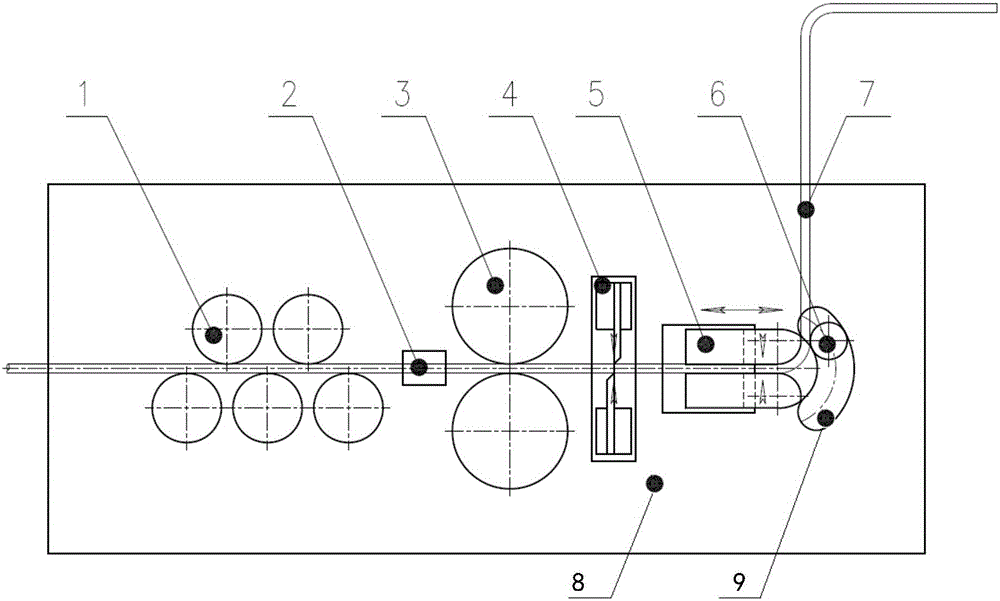

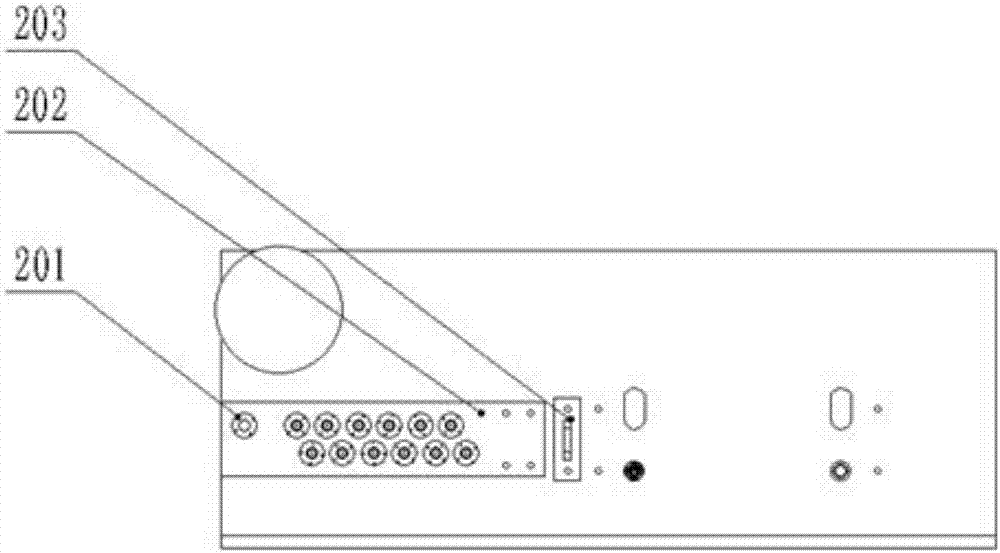

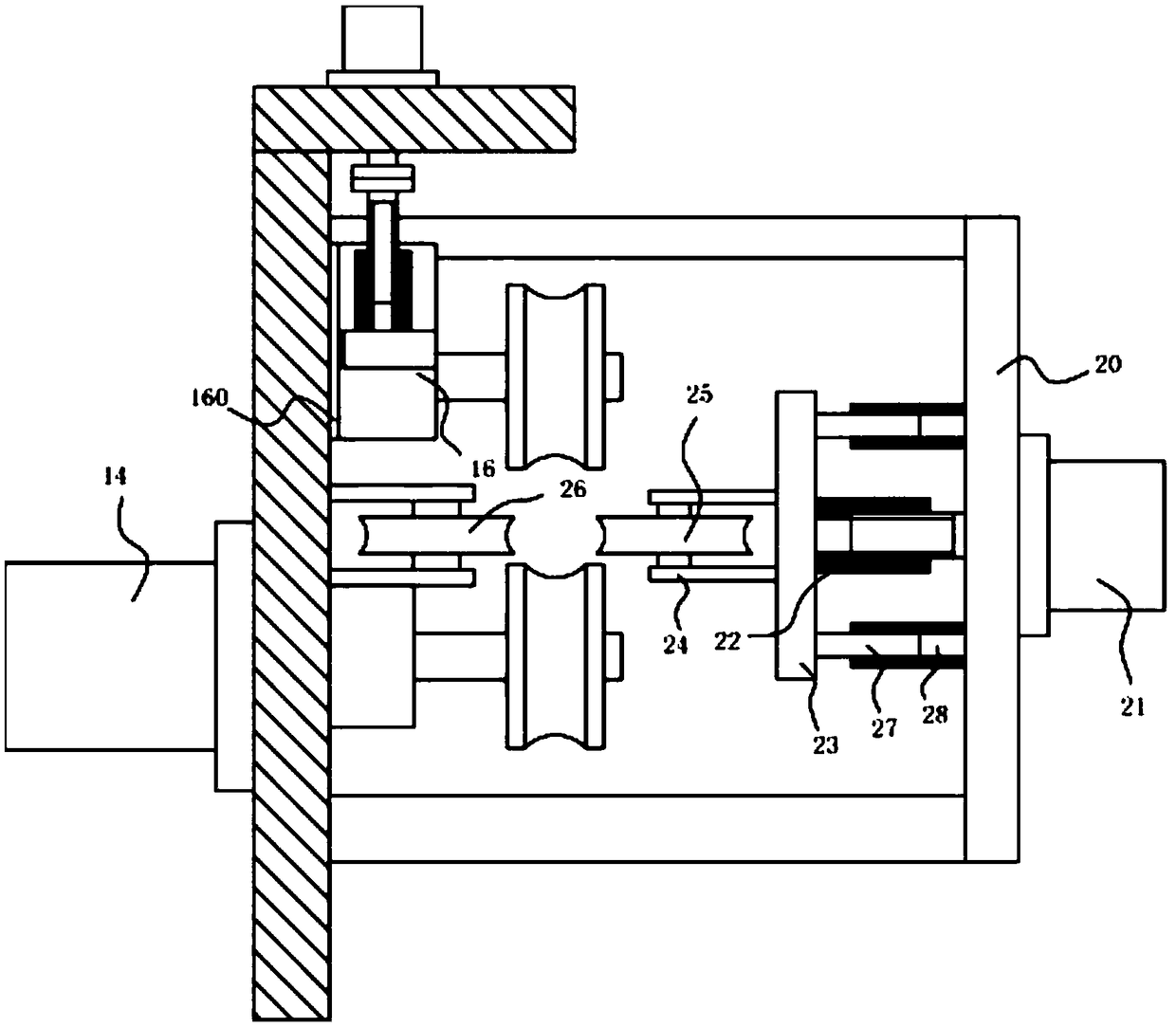

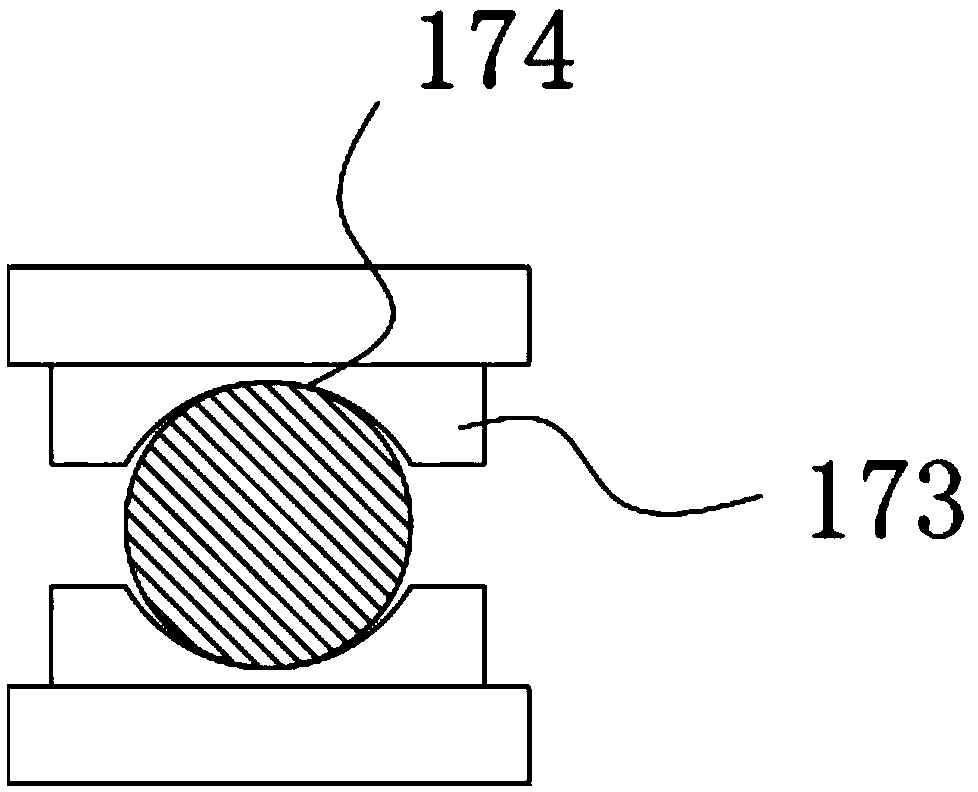

Wire stripping machine transmission mechanism with same power for multiple wheels and unchangeable center for different wire diameters

InactiveCN105775894AImprove length accuracyAvoid bevel phenomenonApparatus for cutting/splicing cablesFilament handlingMotor driveEngineering

The invention relates to a wire stripping machine transmission mechanism with the same power for multiple wheels and the unchangeable center for different wire diameters. A lifting motor drives a rotation wheel to rotate through a lifting drive belt, the rotation wheel drives a screw to rotate, and the screw drives two gearboxes to move in the opposite directions at the same time. All wire feeding wheels are driven through a set of motors and can be made to synchronously run, errors are reduced, and the upper wheels and the lower wheels are driven by one motor. After a wire is clamped, the position of the center face of the wire is not changed and is the same as the position of a cut center face. Wire feeding belts oppositely move at the same time, the moving distances are consistent, the types of machined wires cannot be affected by the diameters of the wires, all the wires can be machined, the wires are kept at the center position of a tool rest all the time, and the phenomenon of notch skew of a notch is avoided. One motor can drive two drive synchronous belt wheels to oppositely move at the same time in a drive belt winding direction manner while it is guaranteed that the driving torque is unchanged, the length precision of wire feeding is improved, and meanwhile the machining cost is reduced.

Owner:徐州领君自动化设备有限公司

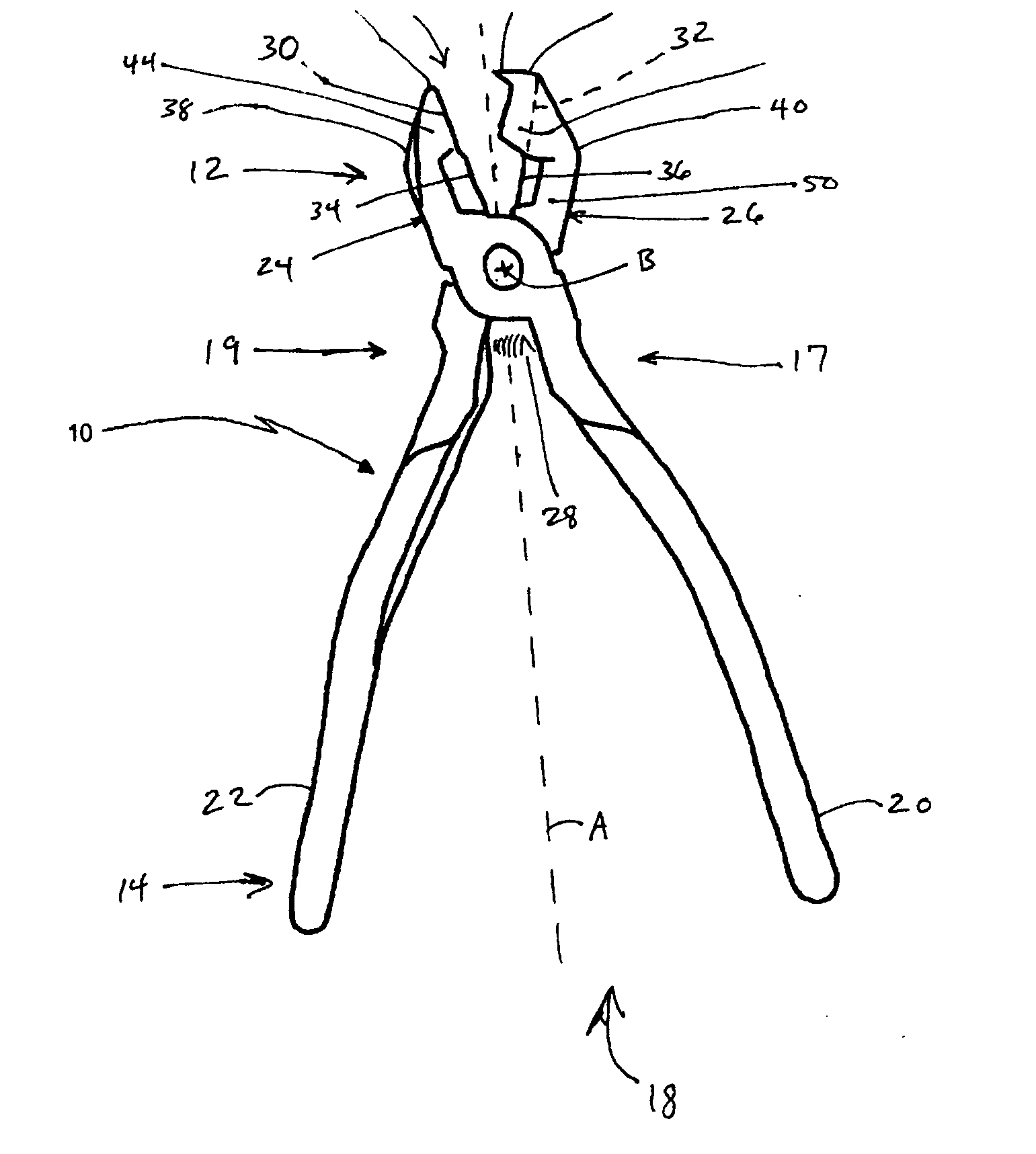

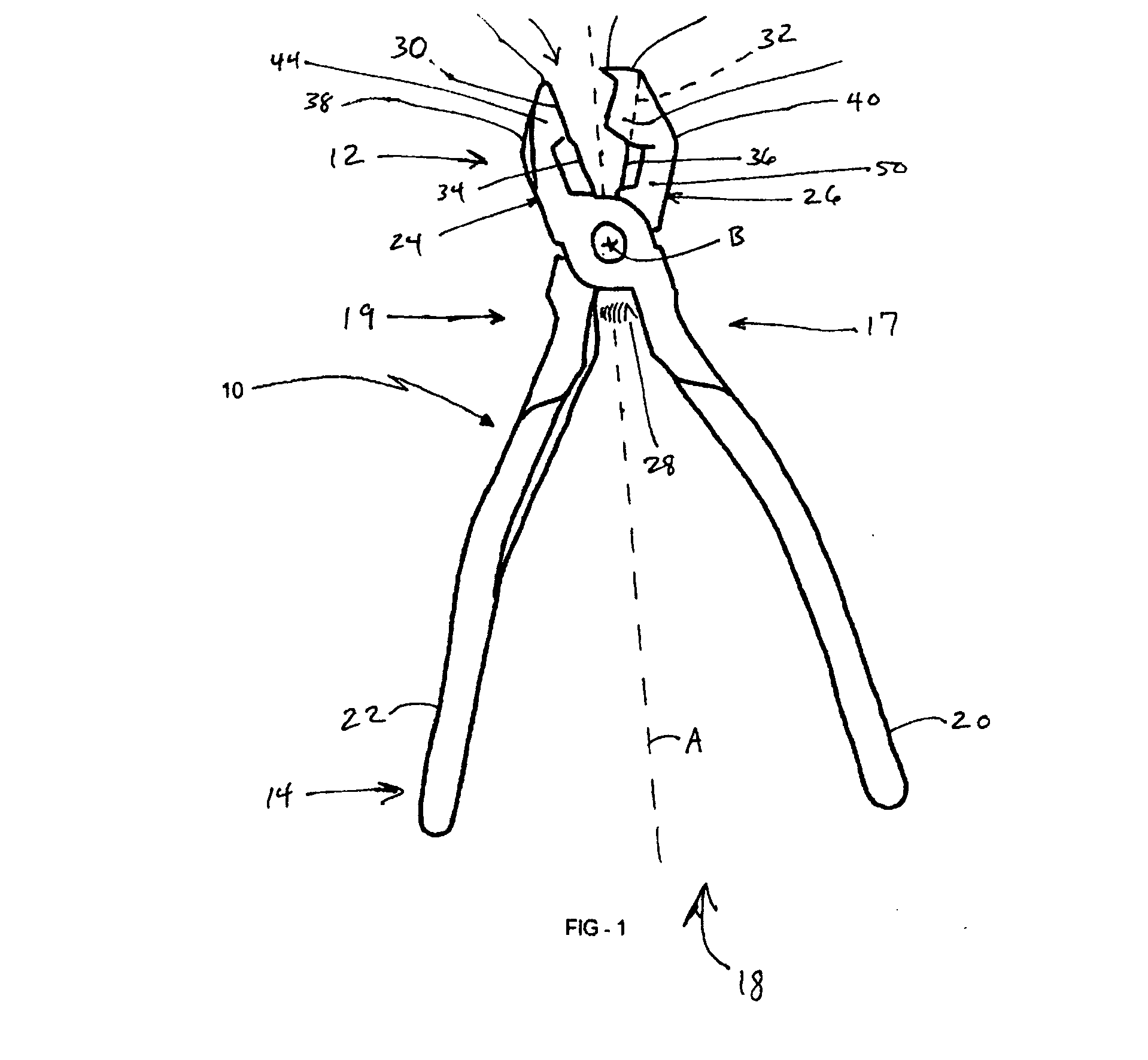

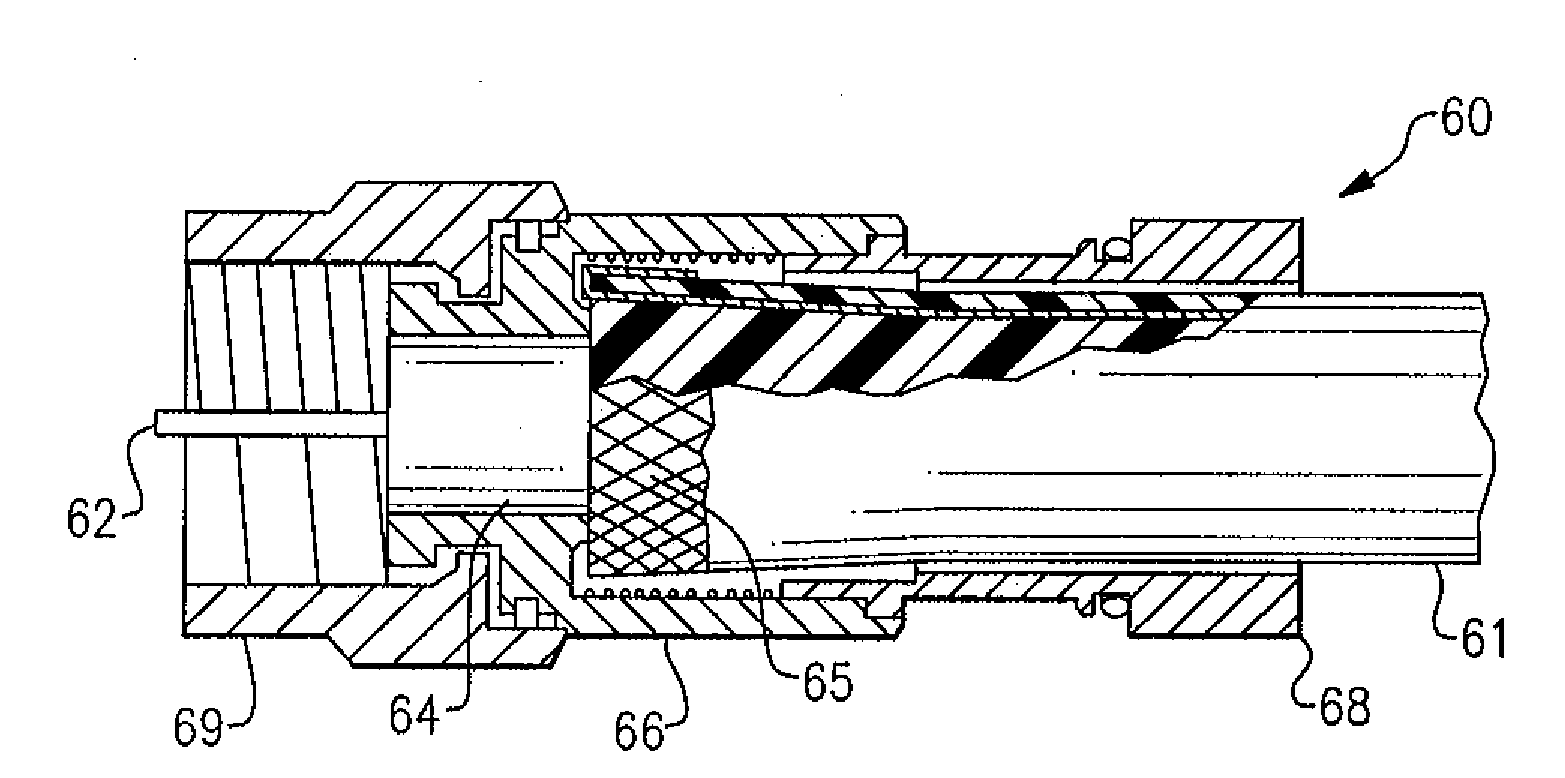

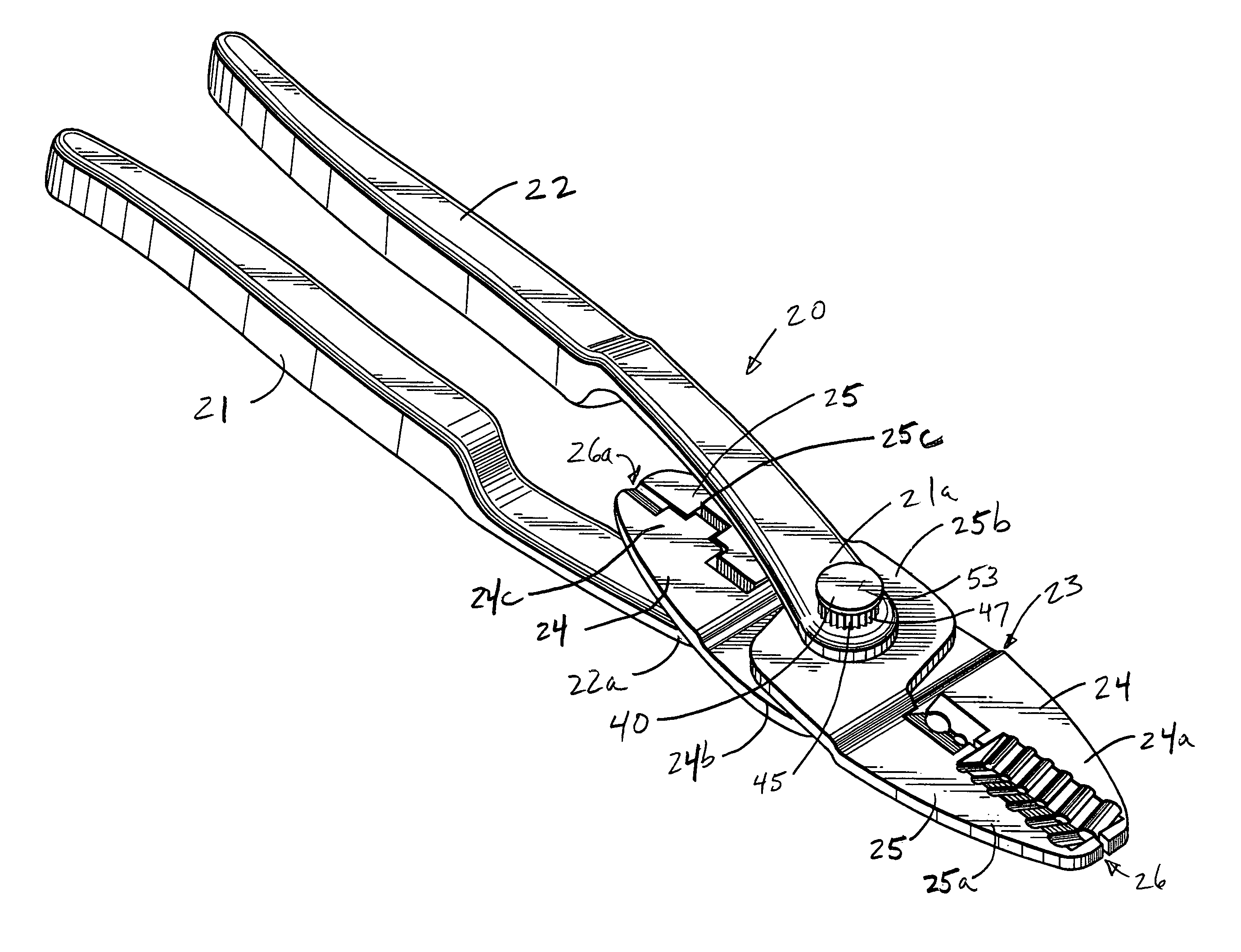

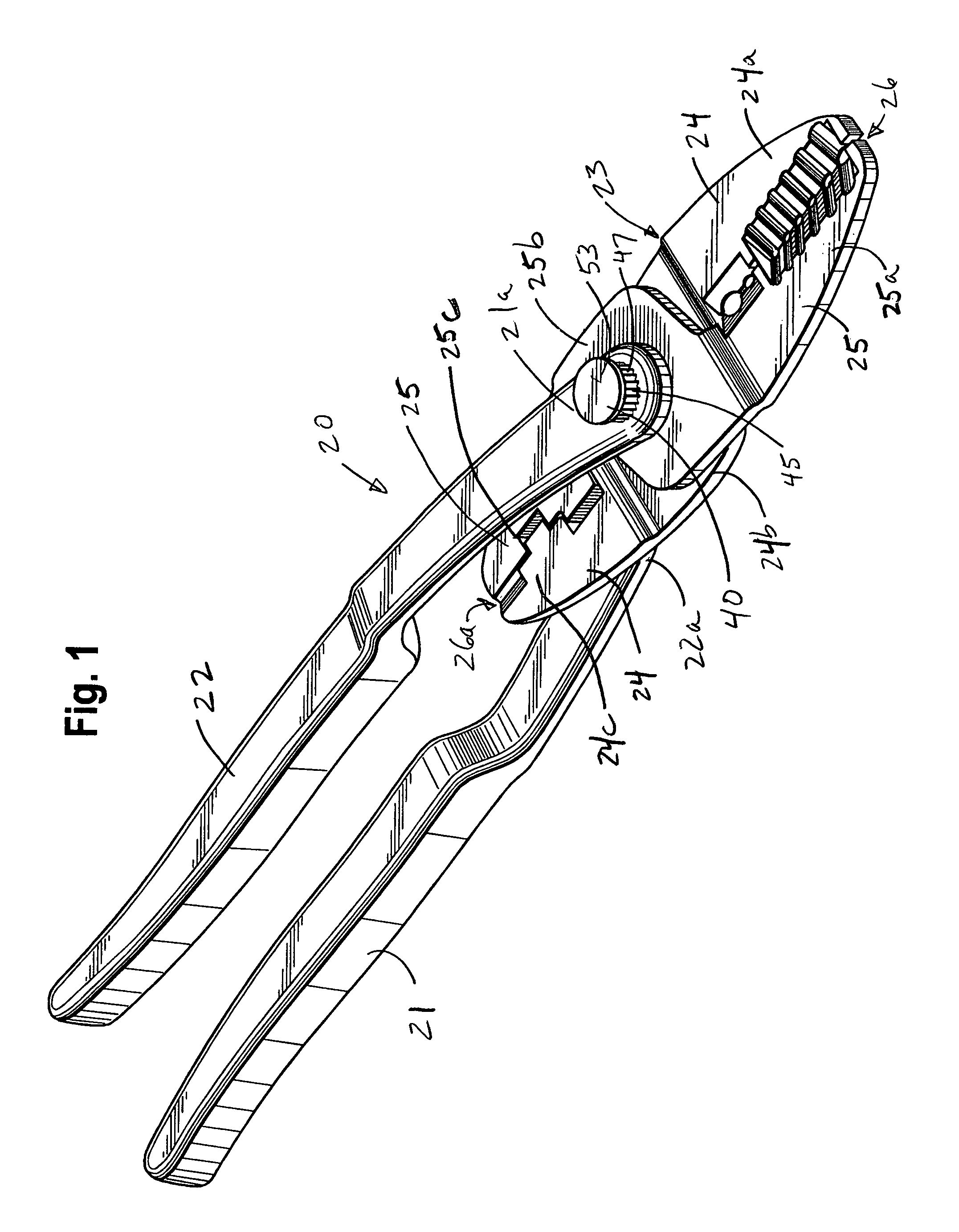

Pliers for cutting and holding straps and the like

A hand tool similar in design to the commonly known “linesman” pliers with the added capacity to control the cut material during and after the cutting operation. The addition and placement of a shear edge on the outside of the jaw assembly allows the invention to maintain control of the cut material and to further manipulate the material if needed. The invention also include a tine on the leading edge of the above mentioned shear edge to increase the capacity of the invention to gain initial control of the material to be processed.

Owner:STEVENS MARK ANTHONY

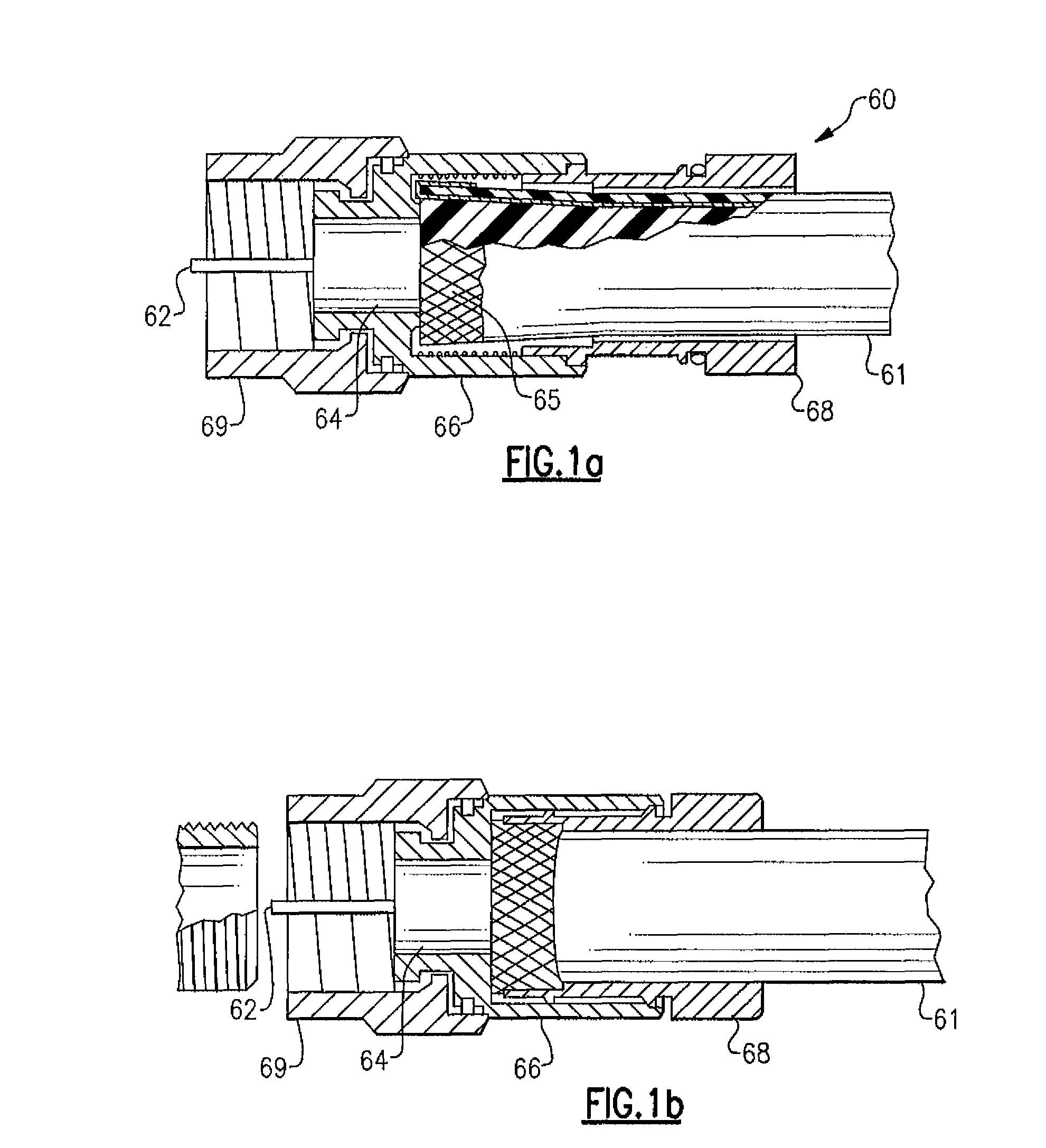

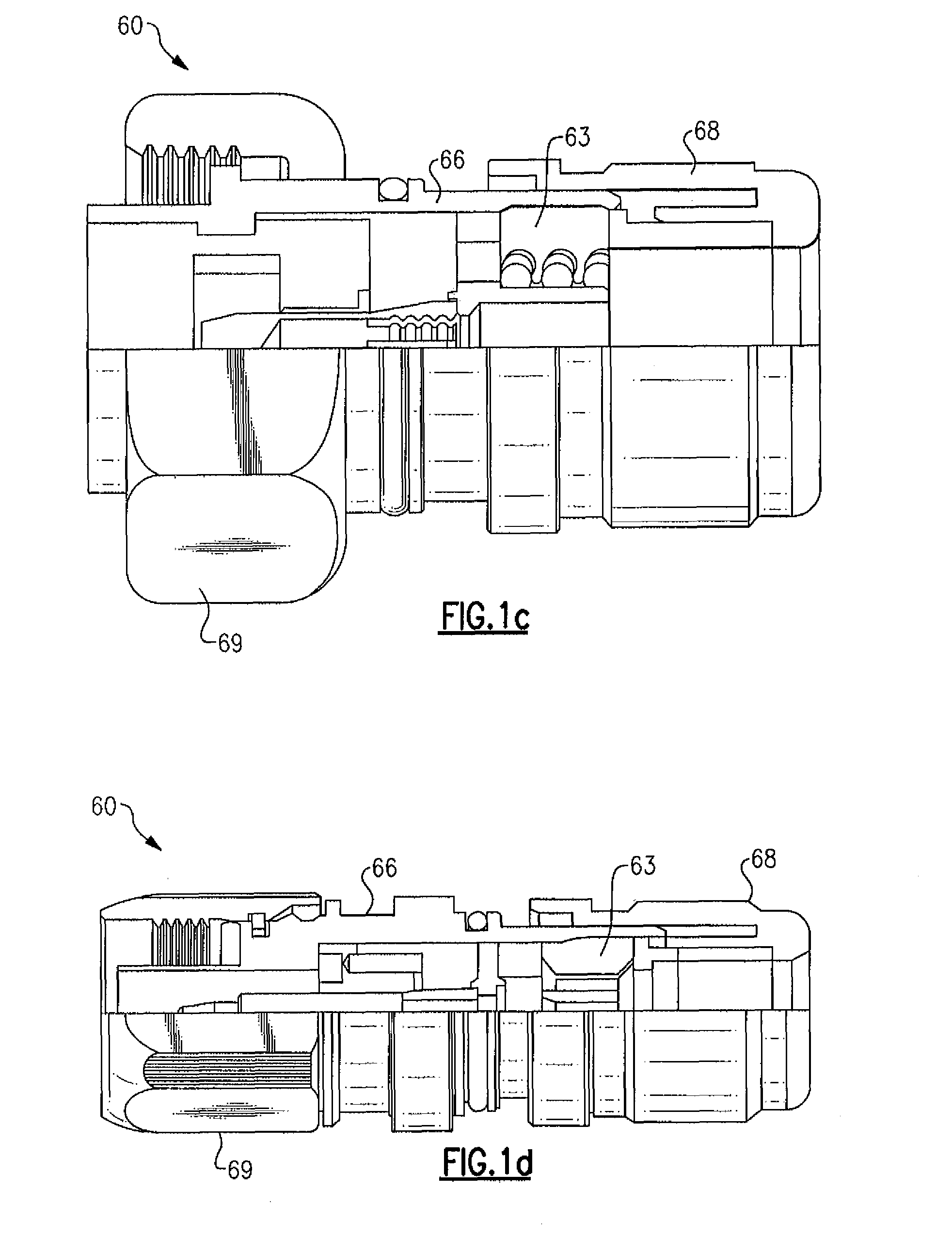

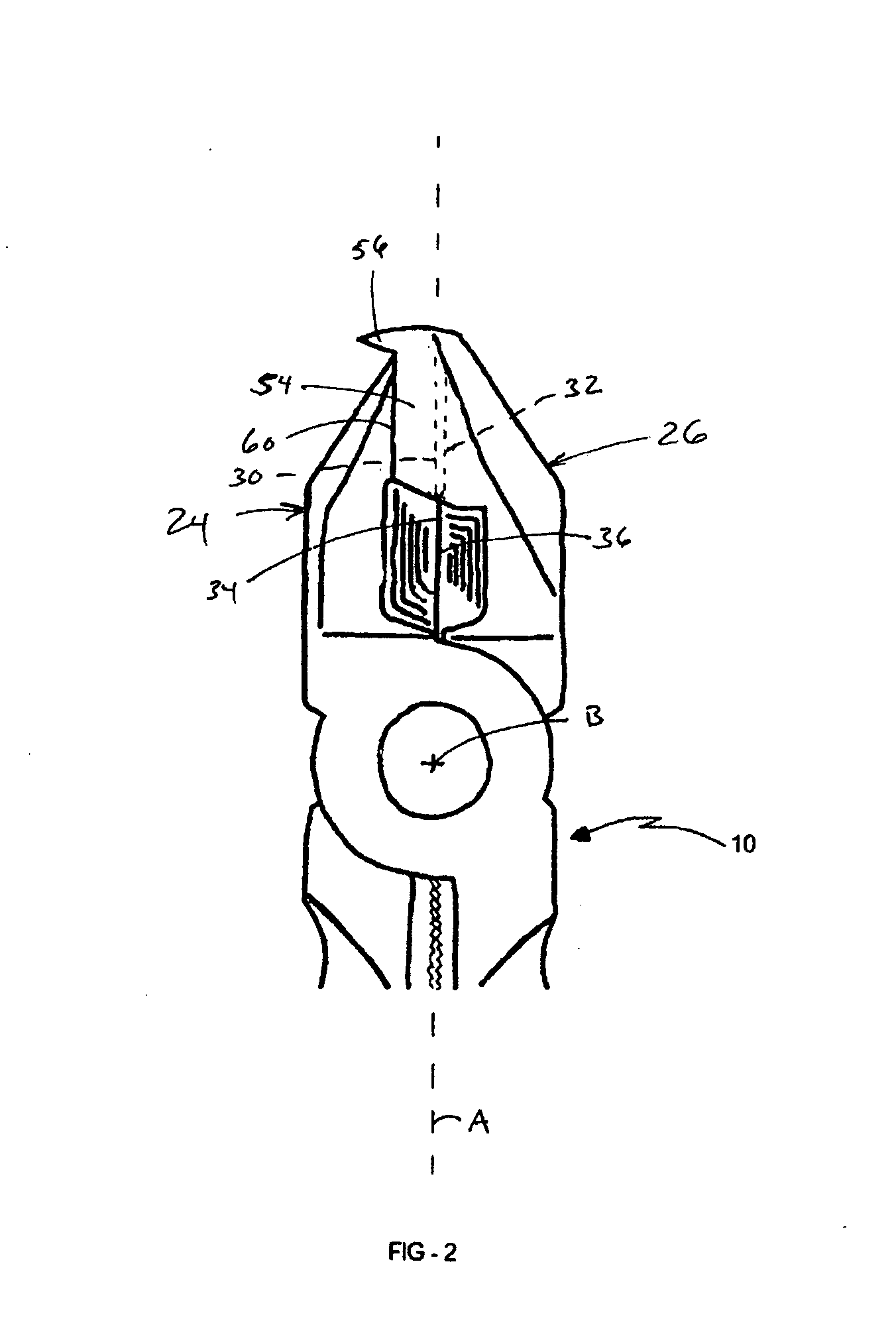

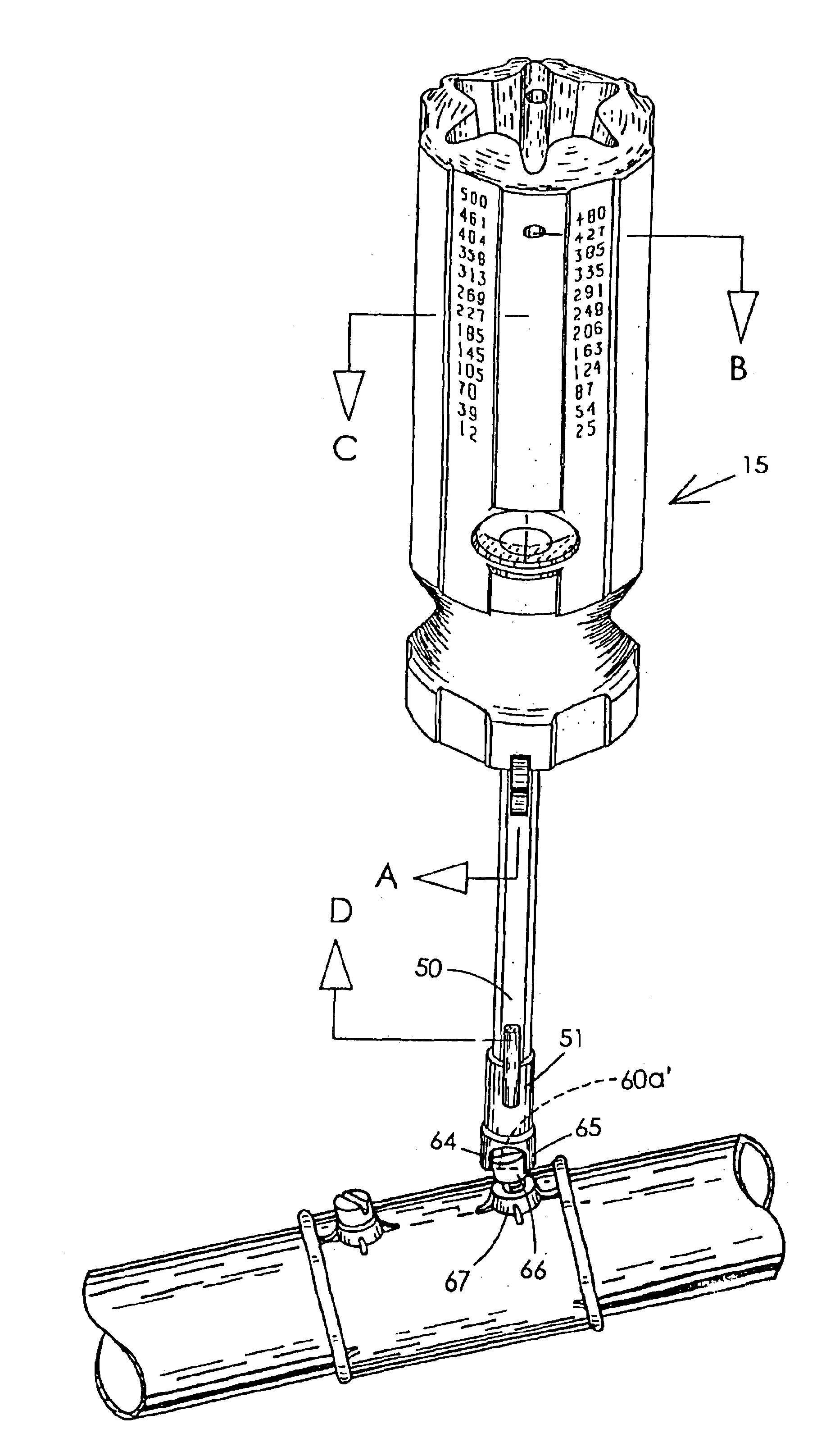

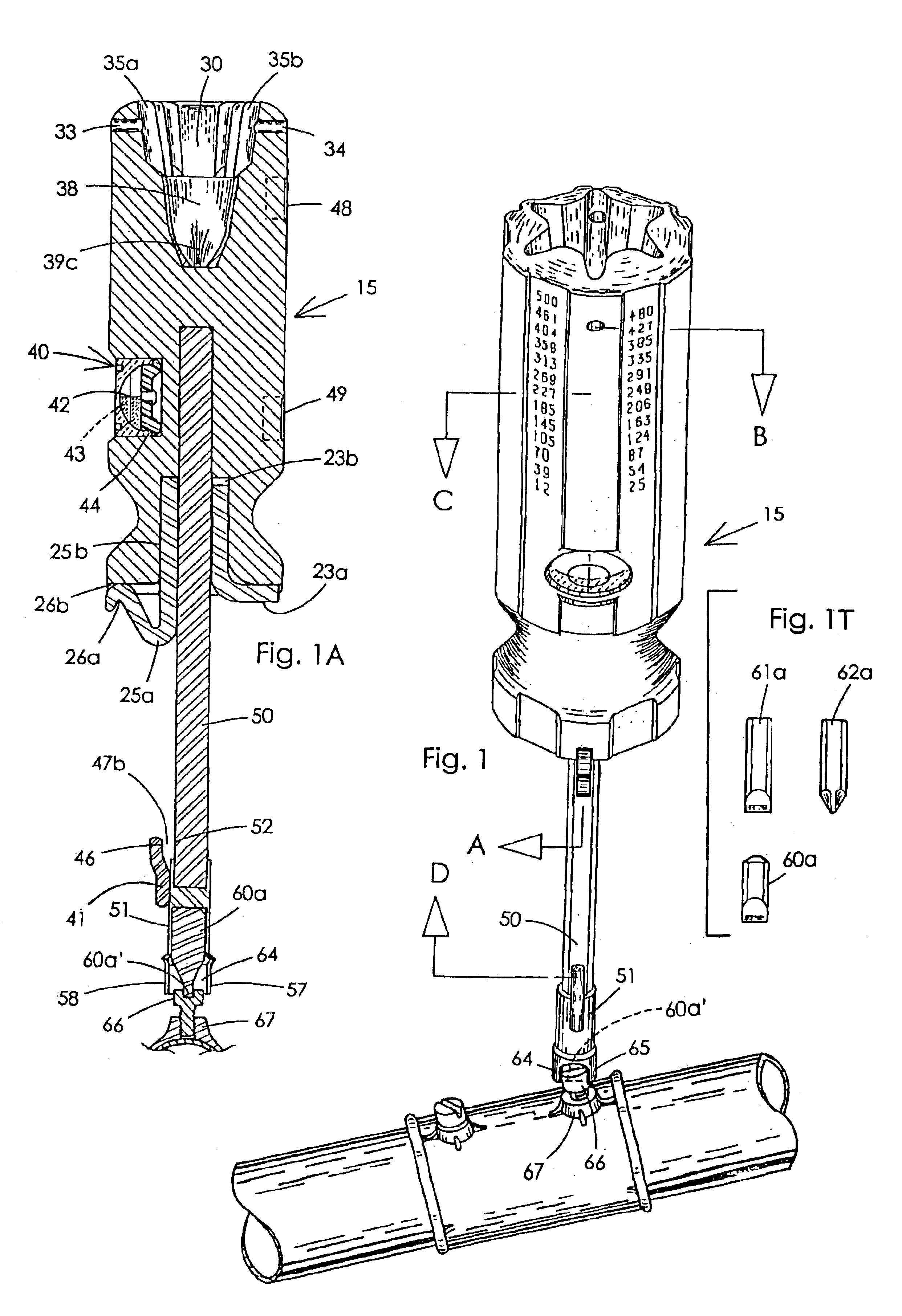

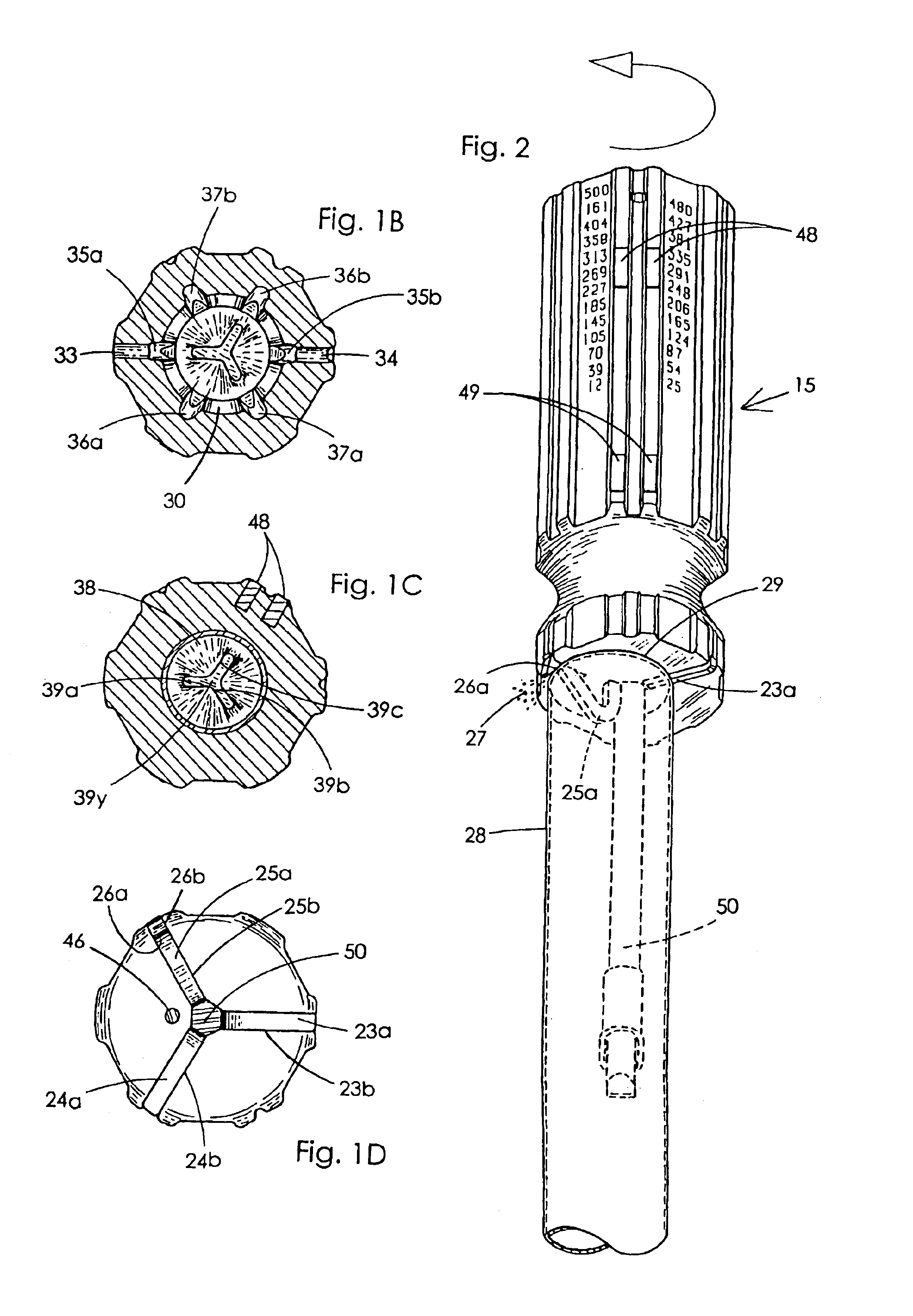

Hydraulic compression tool for installing a coaxial cable connector and method of operating thereof

InactiveUS20090064754A1Suitable for useShaping toolsElectrically conductive connectionsCoaxial cableCompression member

A hydraulic compression tool for securing a compression type cable connector to a prepared end of a coaxial cable. The tool can include a hydraulic assembly having an axially extendable ram, and a connector frame detachably attached to the hydraulic assembly. The connector frame can include a cable cradle configured to accommodate cables of various sizes and a sleeve for engaging a cable connector. The connector frame can further include a sliding guide structure attached to the cable cradle. The sliding guide structure can include a sliding bar and one or more sliding guides. The sleeve can be attached to the sliding bar. The sleeve can be configured to accommodate connectors of various sizes. Activating the hydraulic assembly can cause the ram to extend, which in turn can cause the sliding bar to move along the longitudinal axis of the cable connector compressing the compression member and connector body into operative engagement with the cable.

Owner:JOHN MEZZALINGUA ASSOC INC

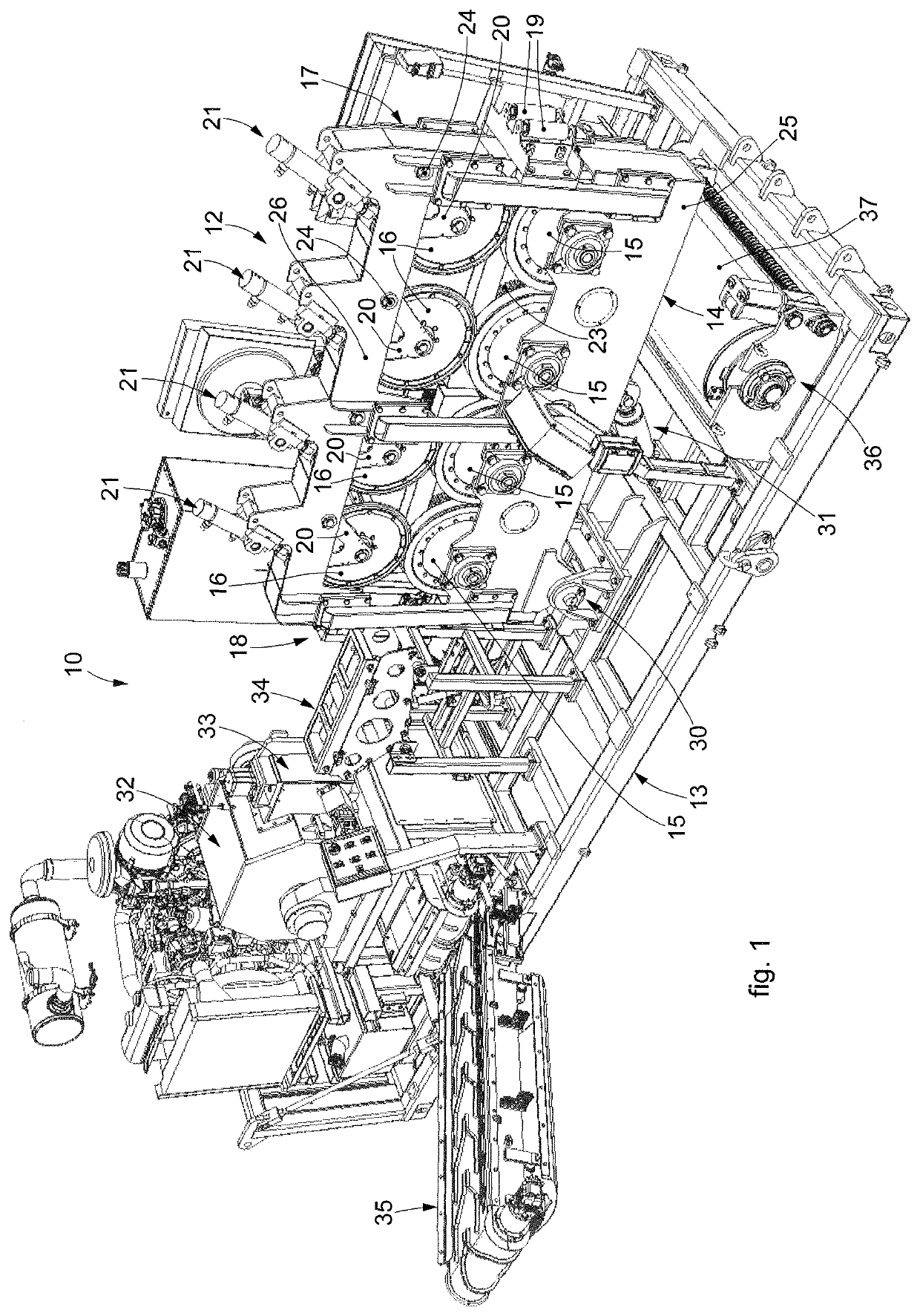

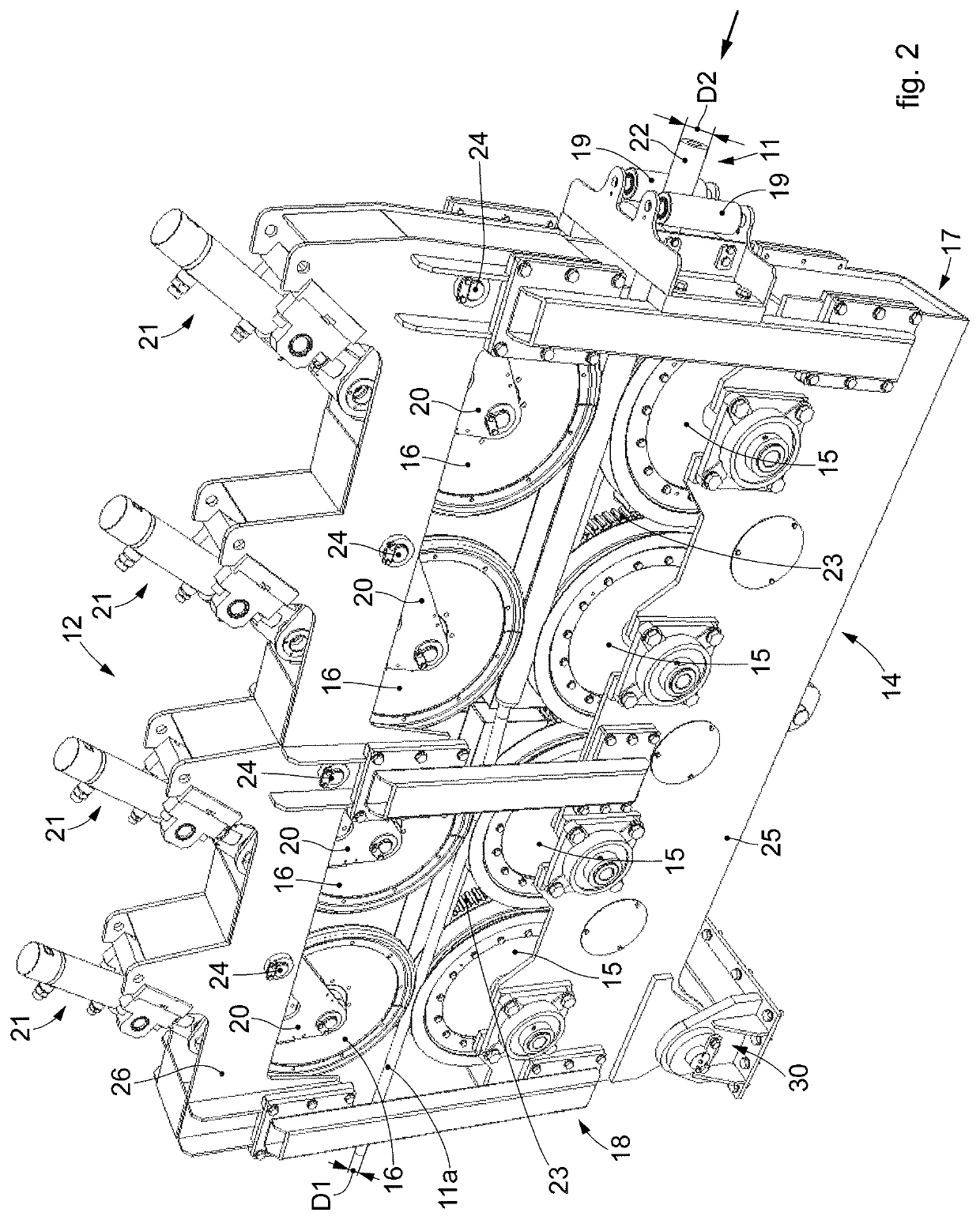

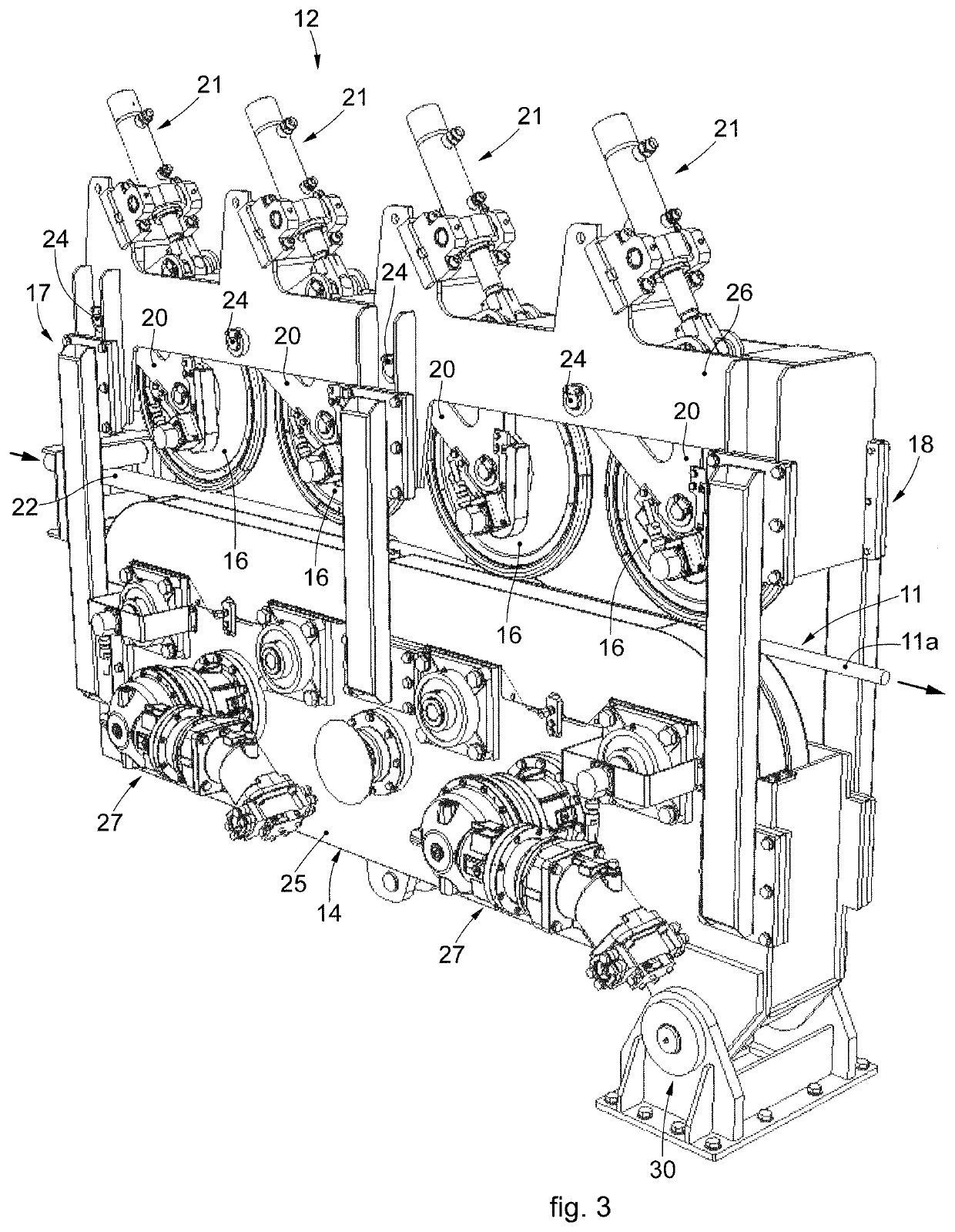

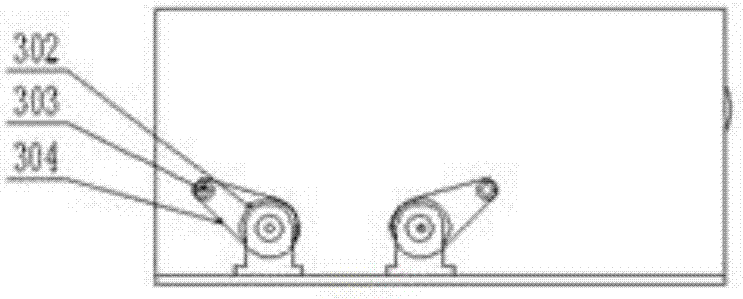

Cable recovery machine

ActiveUS20200255257A1Effective absorptionEffectively and uniformlyApparatus for cutting/splicing cablesFilament handlingControl theoryIdler-wheel

A cable recovery machine, comprising at least one traction module configured to hold and draw at least one cable, in particular of a cable laying plant; the traction module comprises a frame on which one or more traction wheels and one or more idle wheels are positioned; between the traction wheels and the idle wheels a space is defined for the passage and traction of the cable to be recovered; the idle wheels are provided with a support connected in a mobile manner to the frame of the traction module and provided with actuators configured to press the idle wheels against the cable that passes between them and the traction wheels, so that the space between the idle wheels and the traction wheels can be automatically adjusted on the basis of the external diameter (D1, D2) or thickness of the cable drawn

Owner:TESMEC

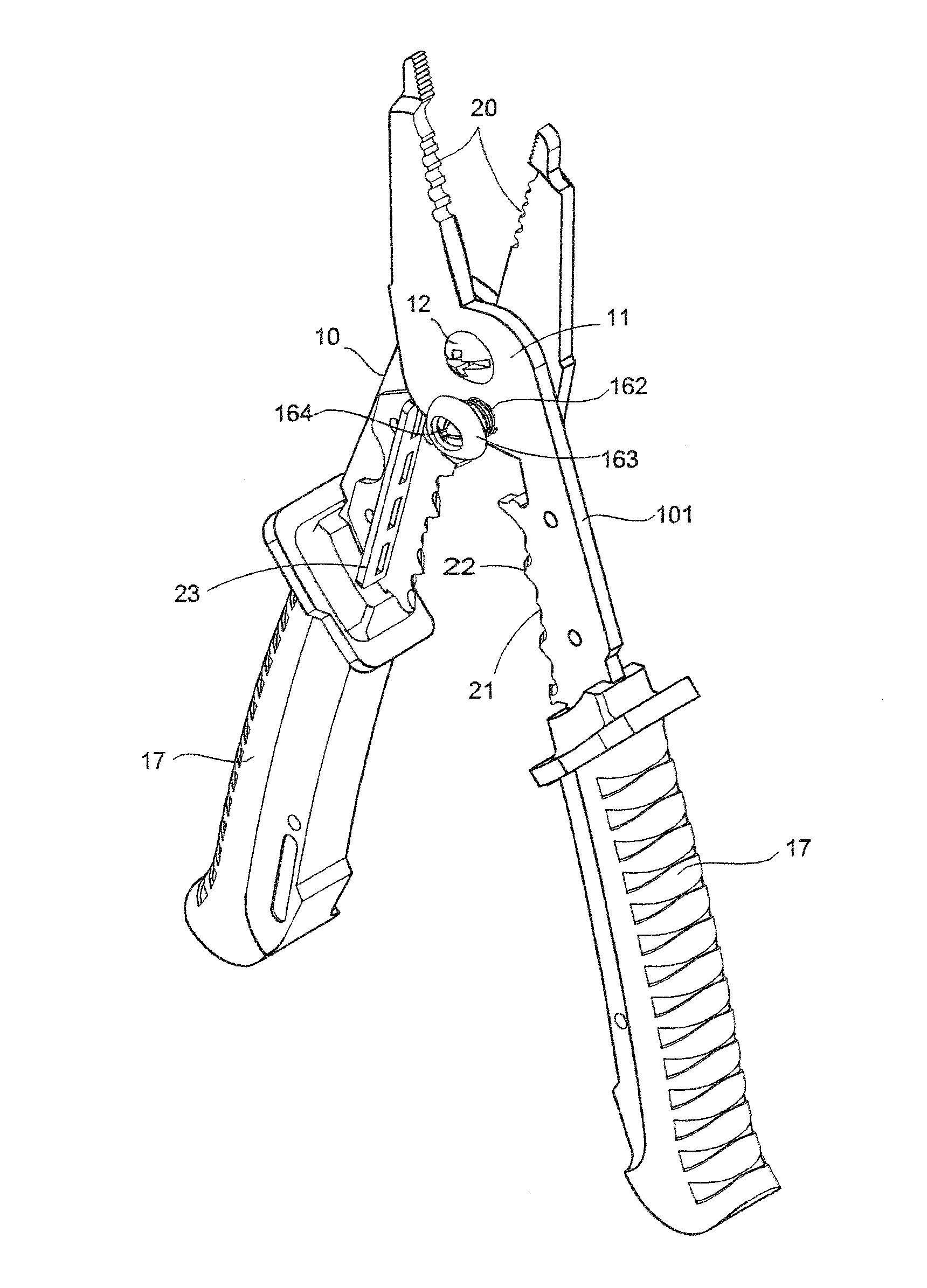

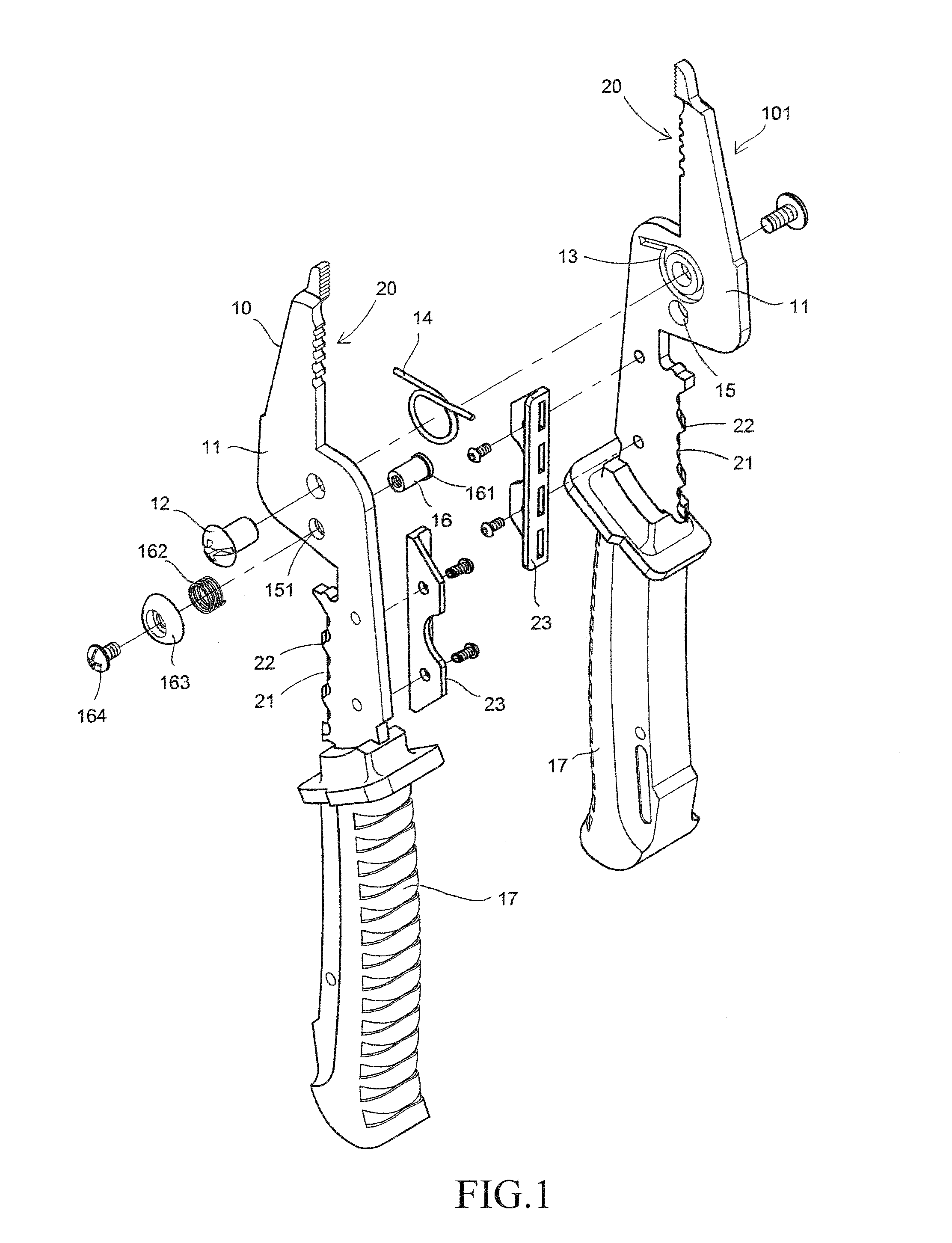

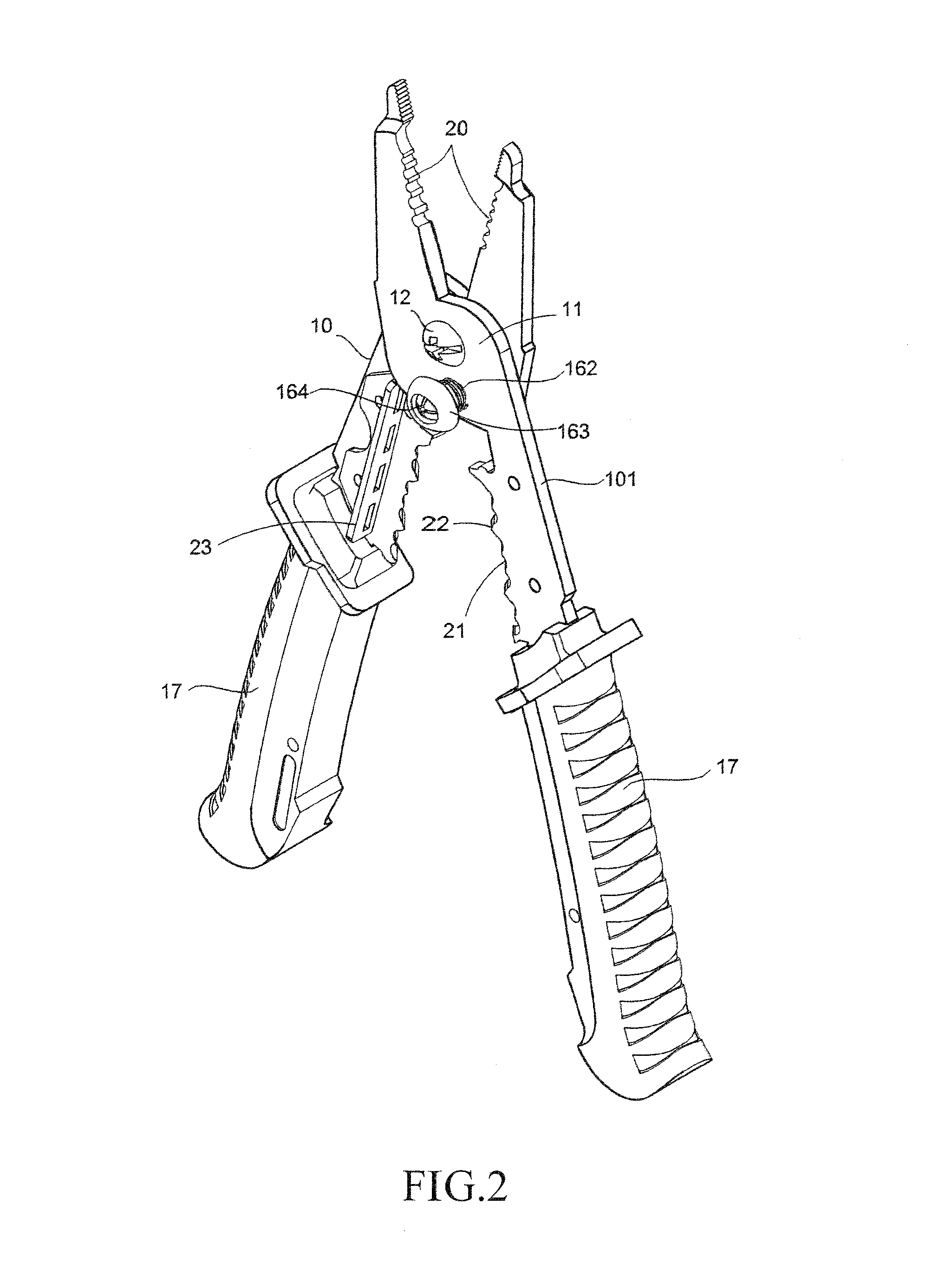

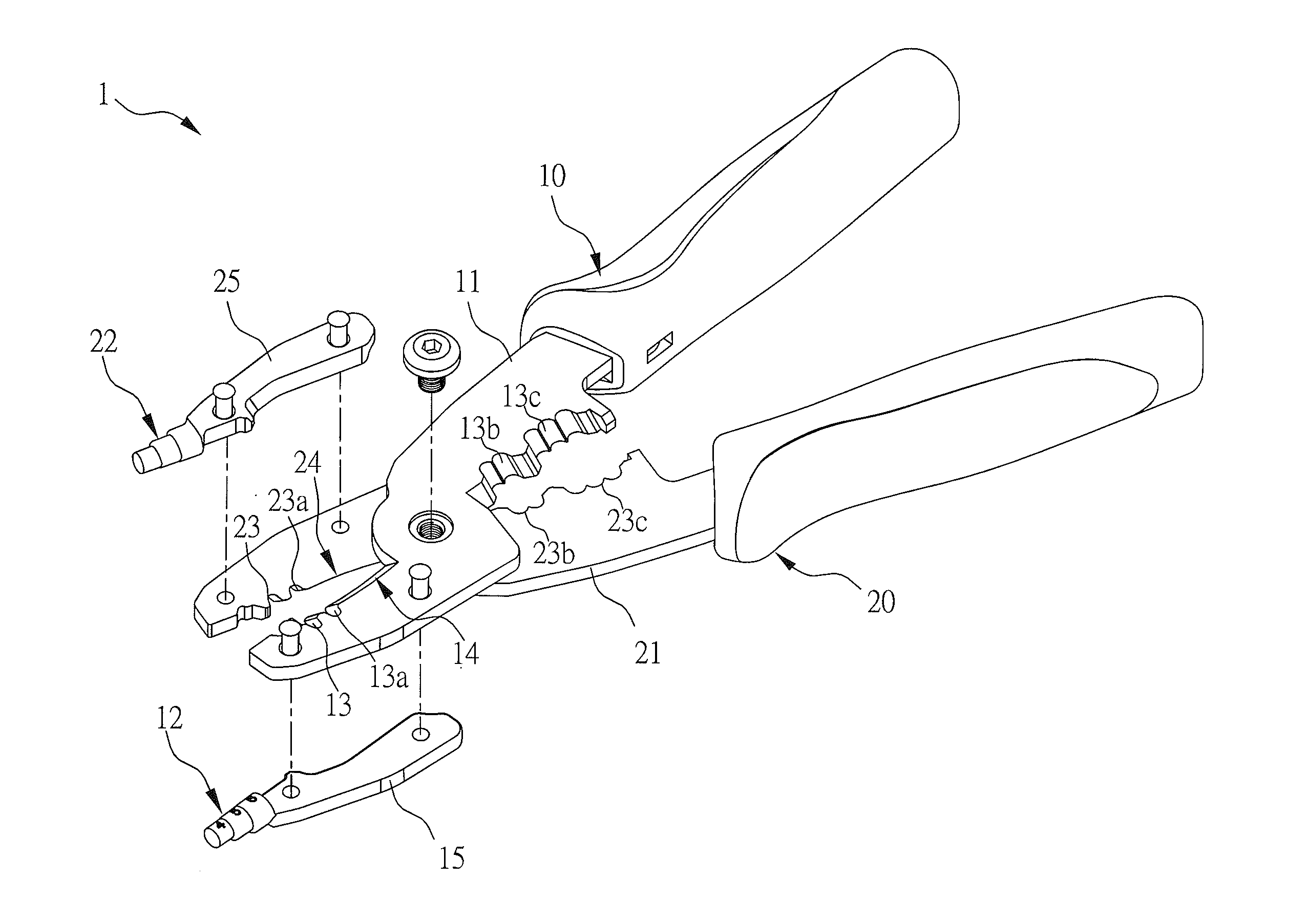

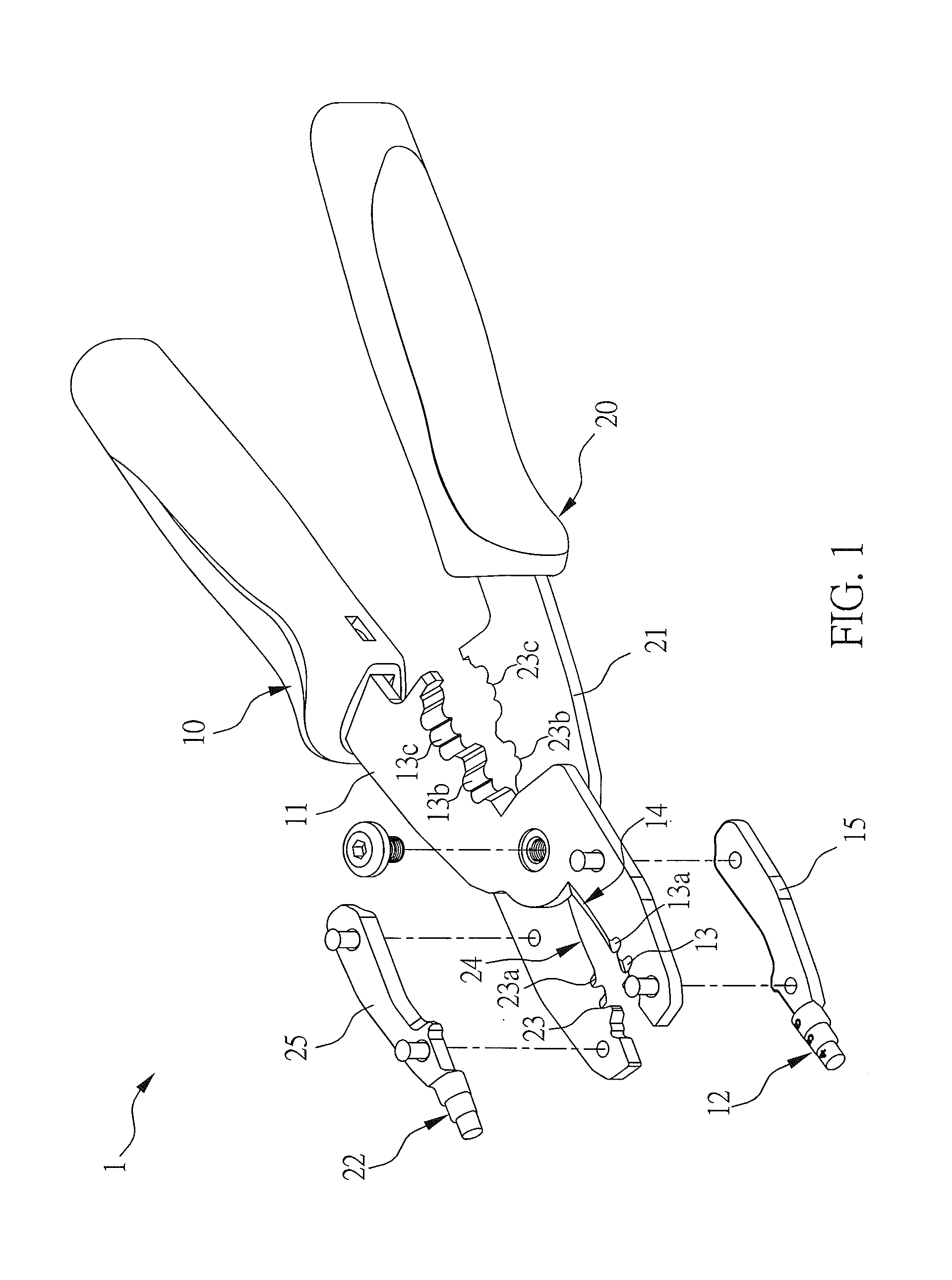

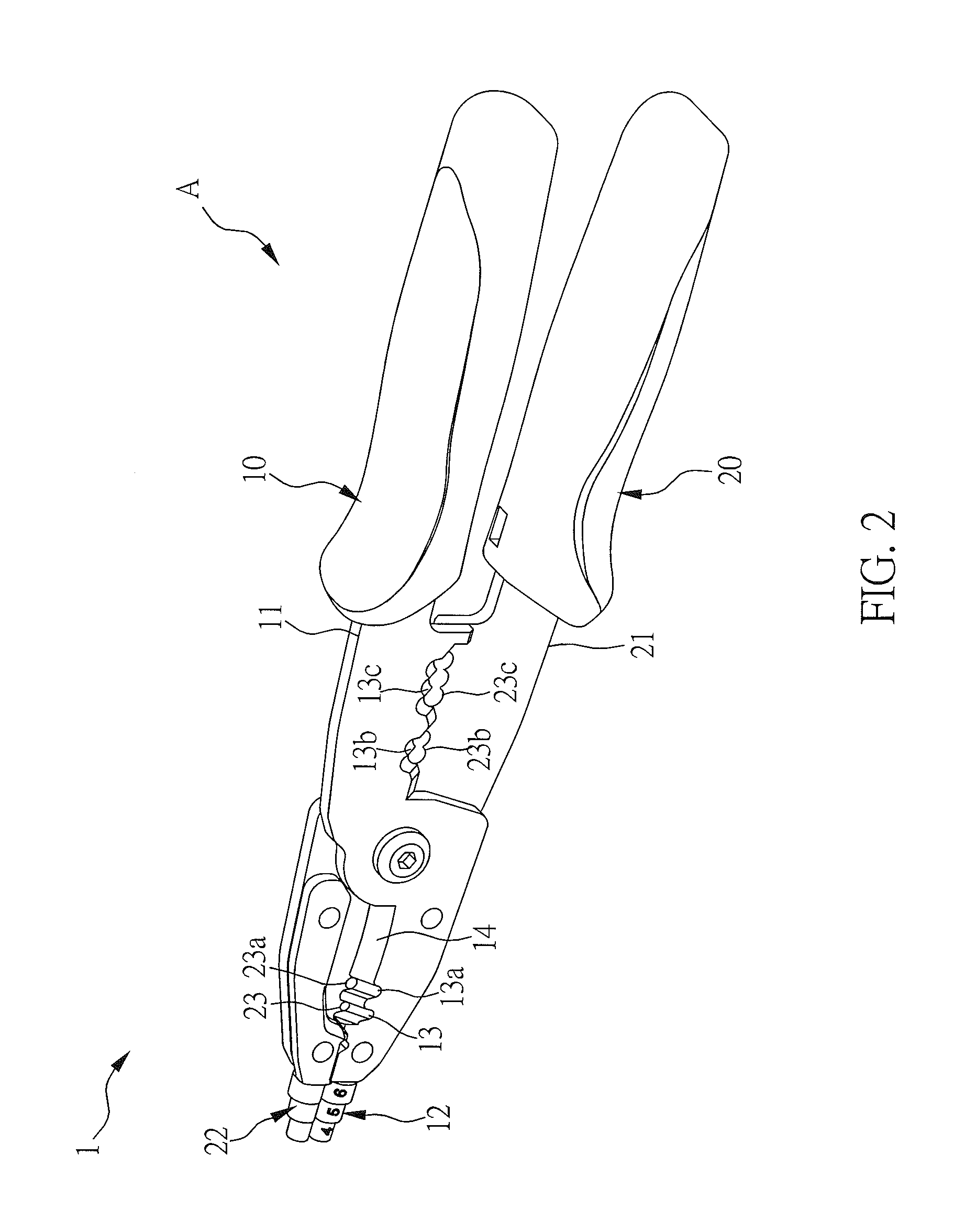

Locking structure of multifunctional stripping/cutting pliers

InactiveUS20130228047A1Easy to press operationSafely arrangedApparatus for cutting/splicing cablesApparatus for removing/armouring cablesEngineeringInsertion site

Multifunctional stripping / cutting pliers are provided for stripping and cutting multi-wire and multi-core electrical cable. The stripping / cutting pliers have plate like bodies that are pivoted in an opposing manner and form in pivot disks thereof a receiving slot in which a spring is received in a concealed arrangement. A stepped hole is provided to extend through a middle portion of the pivoted bodies at a lower side of the insertion site of the spring for receiving a positioning pin to extend therein so as to provide an easy depression operation from the outside of the bides to realize locking. Through the concealed and position-returning arrangement of the spring of the stripping / cutting pliers and assisted by simple depression that achieves locking, the cutting operation of the stripping / cutting pliers can provides the effects of being easy, being practical, and operation and locking safety.

Owner:YANG SHYI DONG

Special tool for 10KV circuit live-wire work robot drainage wire connecting work

ActiveCN110021898AAvoid clutterBeautiful lengthApparatus for cutting/splicing cablesApparatus for joining/termination cablesEngineeringElectrical and Electronics engineering

The invention discloses a special tool for 10KV circuit live-wire work robot drainage wire connecting work. The special tool comprises a cable stretch-in end and a cable stretch-out end, wherein a puncture cable clamp is positioned between the cable stretch-in end and the cable stretch-out end. The special tool comprises a substrate, and is characterized by comprising a drainage wire shearing mechanism installed on the substrate, wherein the drain wire shearing mechanism comprises an electric cutter; and the electric cutter is positioned at the cable stretch-out end. According to the special tool, robot live-wire wiring work can be realized, manual live-wire wiring work also can be realized, and the special tool has the function of shearing unnecessary drainage wires.

Owner:山东乐普韦尔自动化技术有限公司

Handle multi-purpose tool

InactiveUS7051392B2Apparatus for cutting/splicing cablesContact member assembly/disassemblyEngineeringCalculator

A handle multi-tool of particular utility to electricians for performing many operations involved in electrical installations in which a number of different tools are necessary, such as: pliers, channel locks, multi-tip screw driver, level, wire nut driver, scraper, measuring tape, calculator, level, and plum bob. All of them may be partially or totally replaced by this handle multi-tool, the shape and weight of which resembles a common screwdriver.

Owner:DOMINGUEZ ARMANDO

Indexable pliers-type tool

ActiveUS7451673B1Facilitate angular modificationApparatus for cutting/splicing cablesPliersEngineering

An indexable pliers-type tool with selectable first and second jaw tool structures comprising opposing jaw elements having first and second portions with handles, the first portions defining a first tool structure, the second portions defining a second tool structure, the jaw elements are adapted to be pivotally moveable relative to each other about an axis, each handle has a handle aperture therein coaxial with jaw apertures, and a pivot pin is disposed axially through the jaw apertures and the handle apertures and is axially movable between locked and unlocked positions, wherein when the pin is in the locked position, the first or second tool structure can be used, and when the pin is disposed in the unlocked position, the jaw elements can be rotated for tool structure selection.

Owner:SNAP ON INC

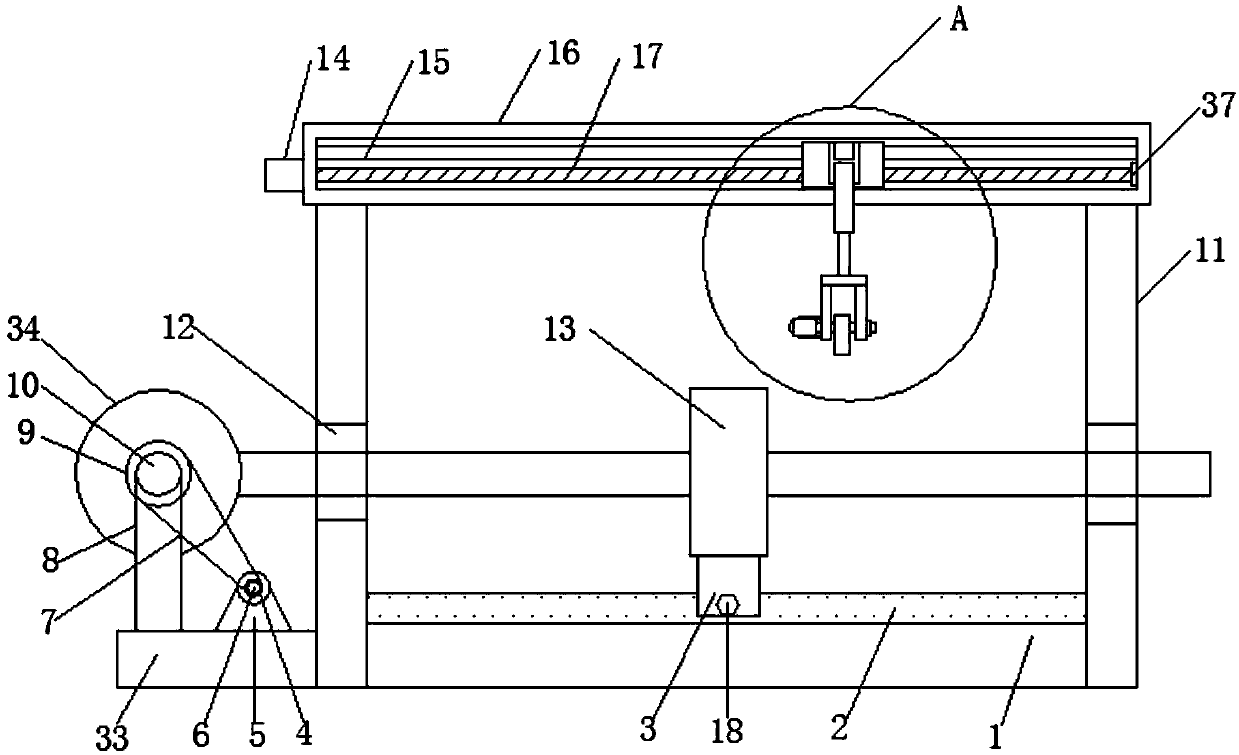

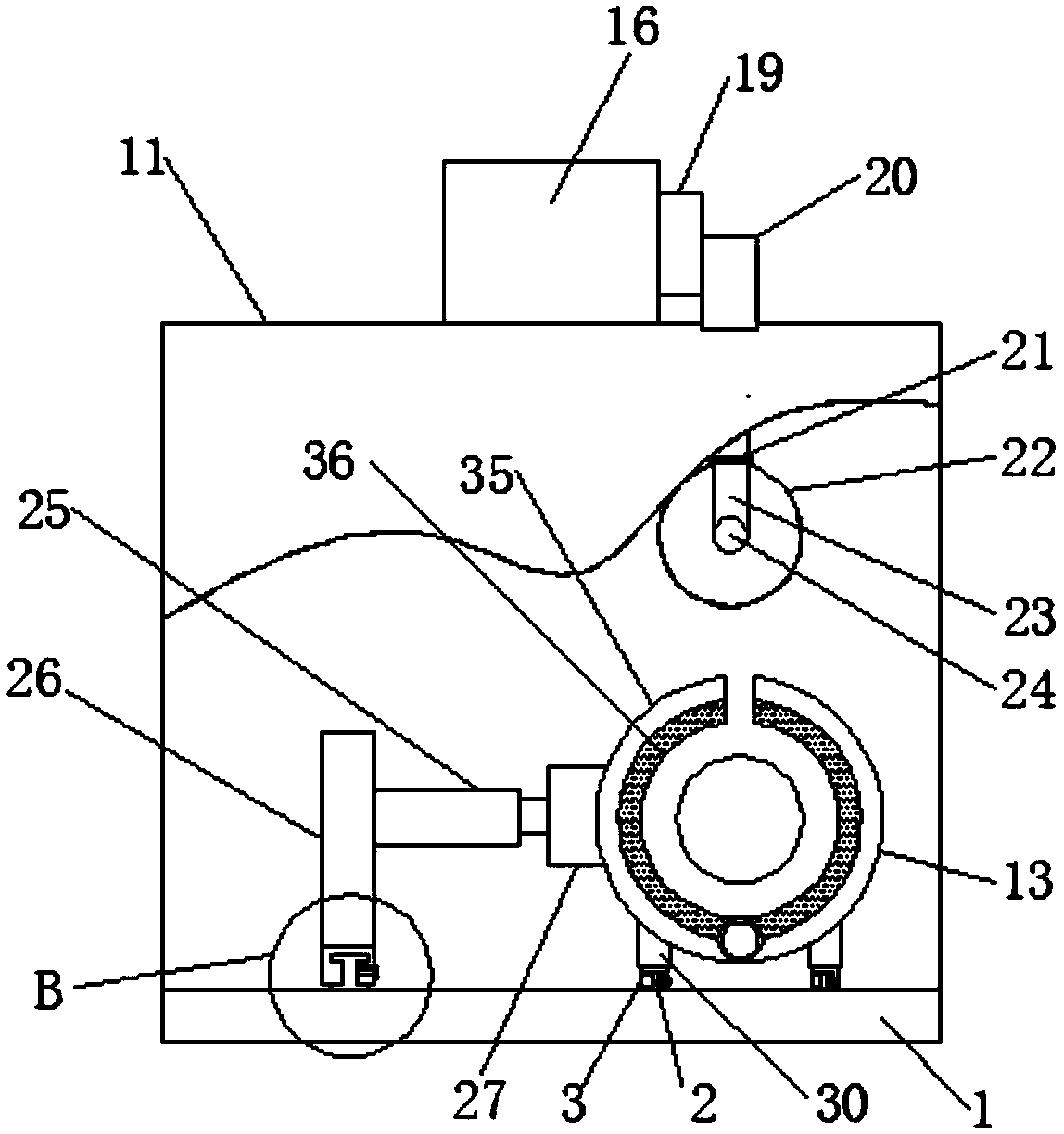

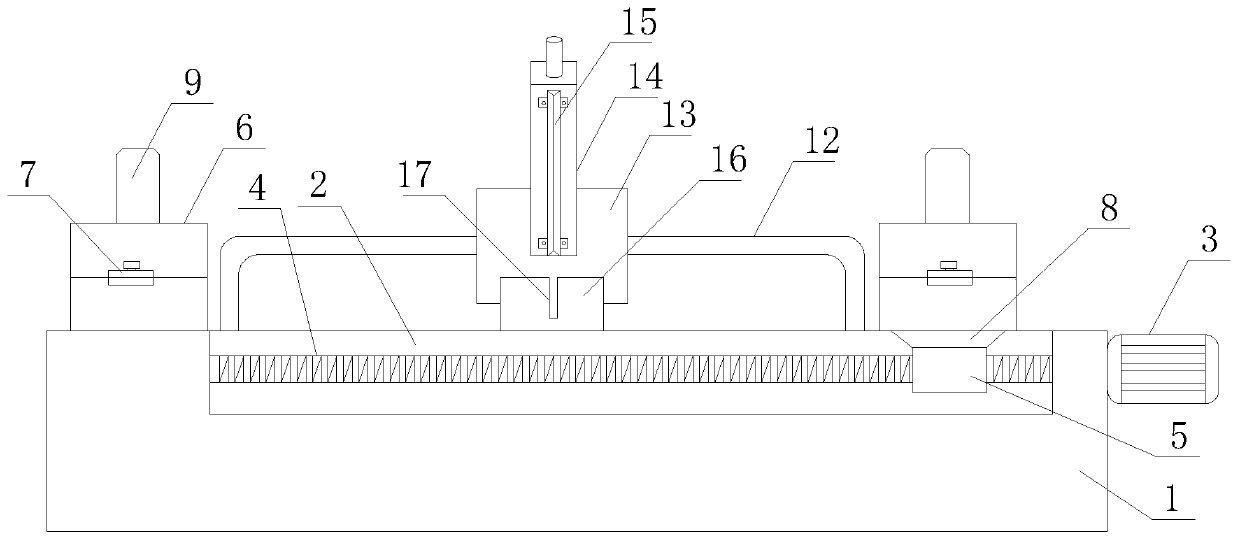

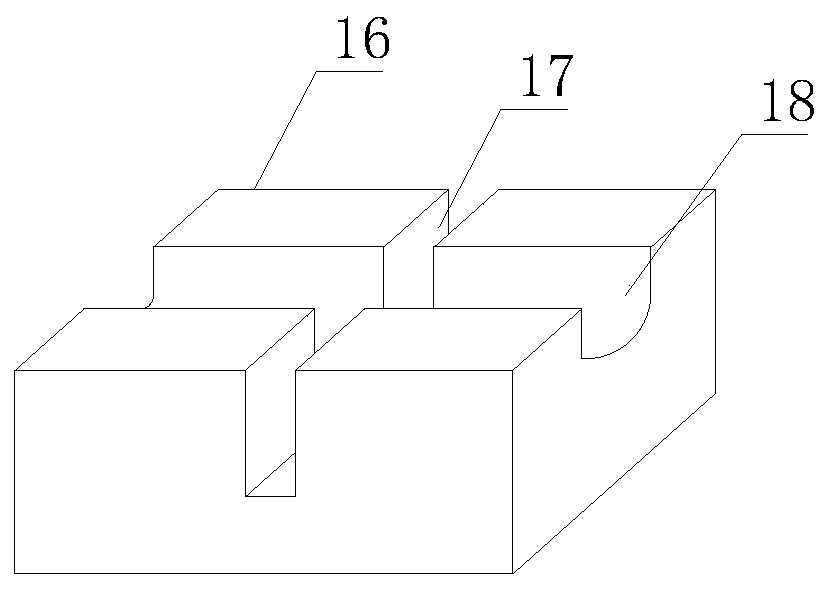

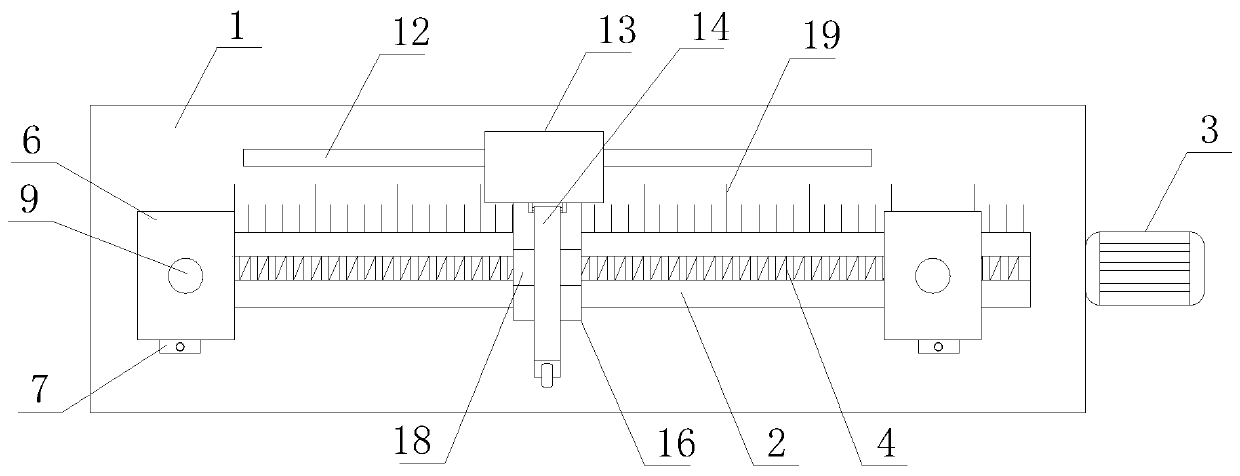

Cutting device for cable production

InactiveCN110216225ANeat cutChange spacingApparatus for cutting/splicing cablesElectric cablesMachining

The invention relates to the technical field of cable production equipment, in particular to a cutting device for cable production. The cutting device comprises a machining table, wherein a mounting groove is formed in the top end of the machining table; a lead screw motor is installed on the outer wall of one side of the machining table, and a lead screw is installed at the output end of the leadscrew motor; the lead screw extends into the mounting groove, and a lead screw nut is slidably connected to the outer wall of the lead screw; a connecting block is welded to the top end of the lead screw nut; and cable clamping mechanisms are arranged at the top of the machining table. According to the device, the defects in the prior art are overcome, and the distance between the two cable clamping mechanisms can be changed by starting the lead screw motor; since one cable clamping mechanism is fixed on the machining table, therefore the cables can be tensioned and straightened, then the cable can be cut through a cutter, and the cables are always kept in a straightening state in the cutting process, so that the cables are cut in order, the cutting surface is flat, and the cutting effectis good.

Owner:ANHUI TIANMING CABLE

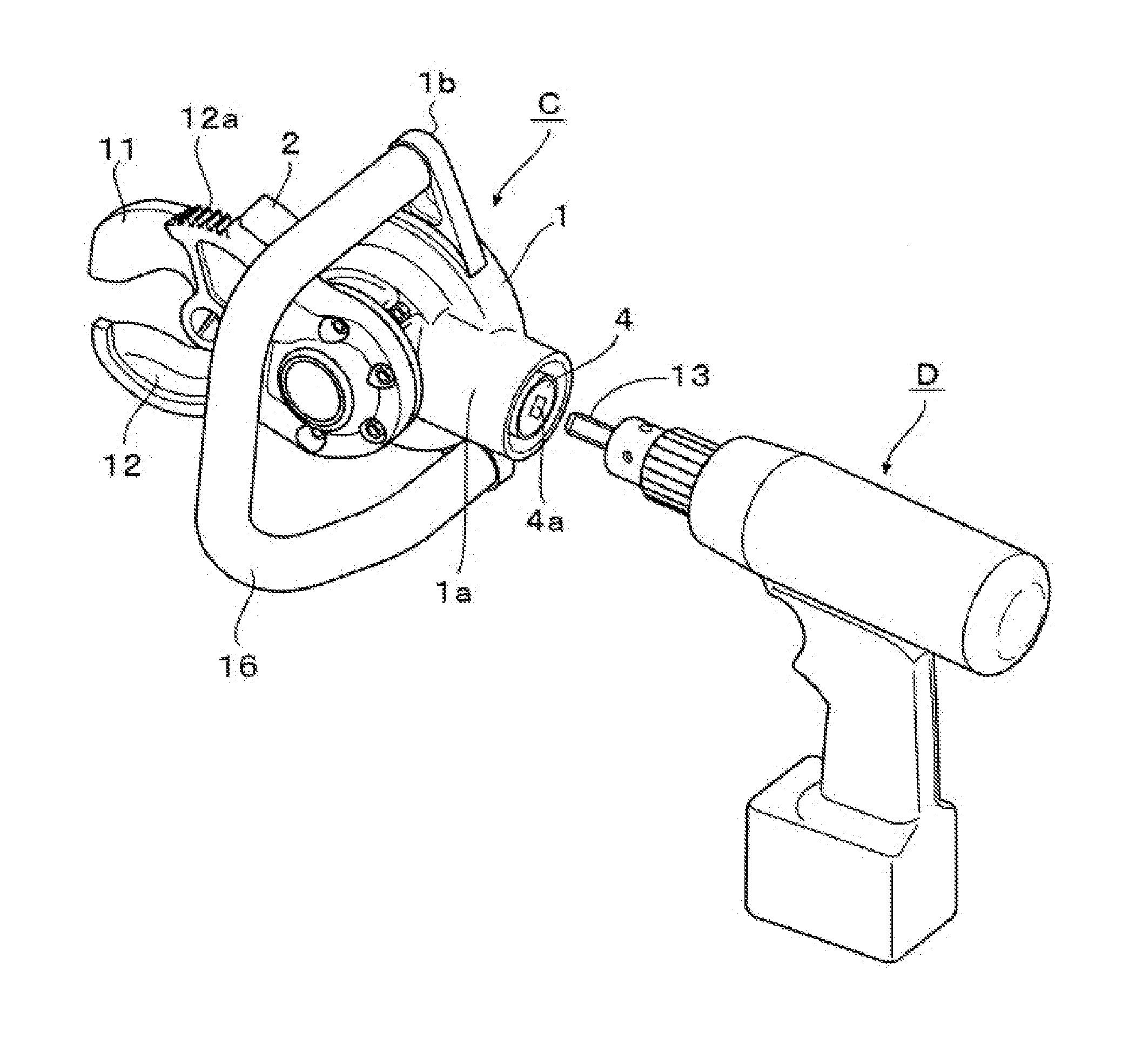

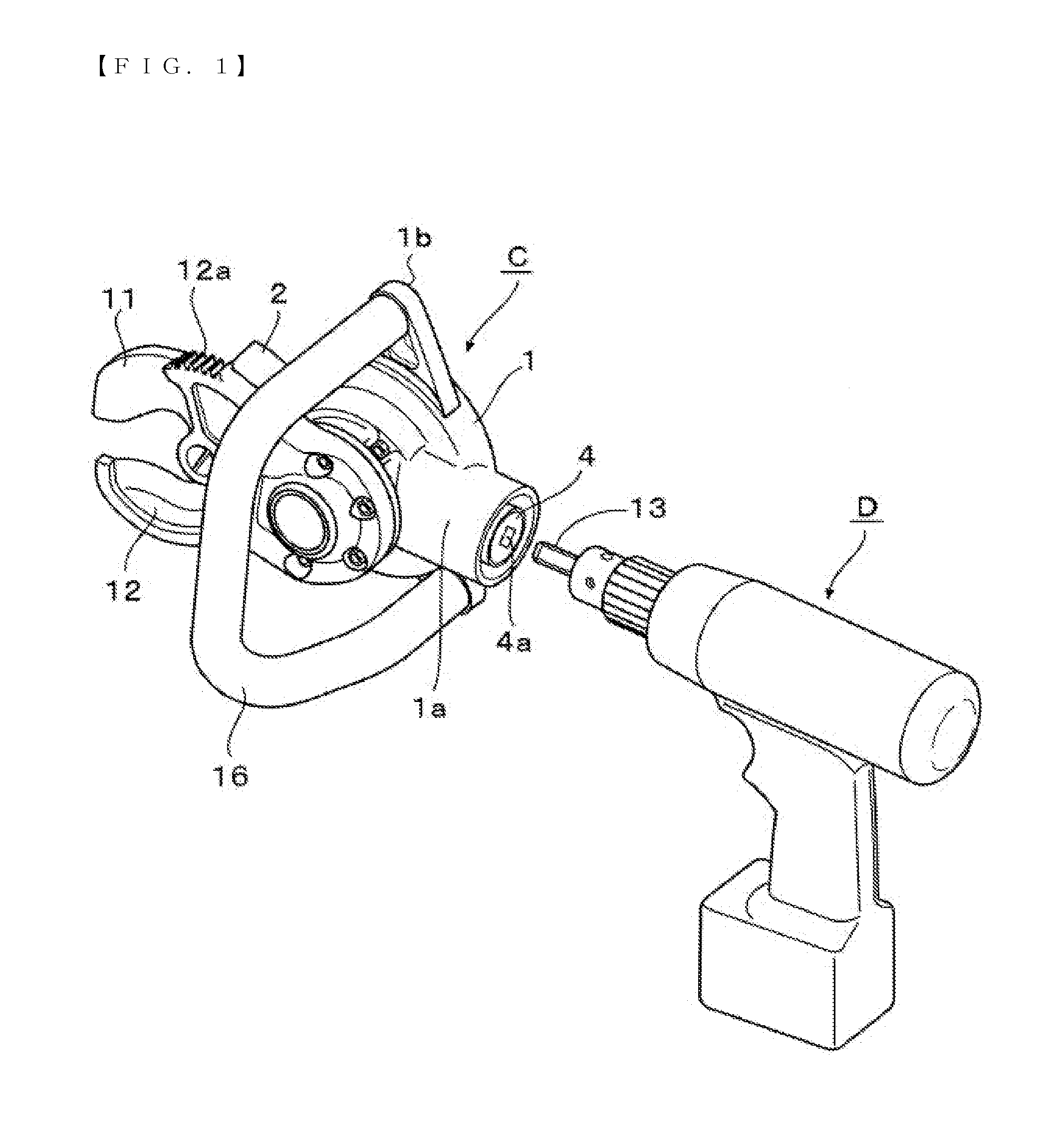

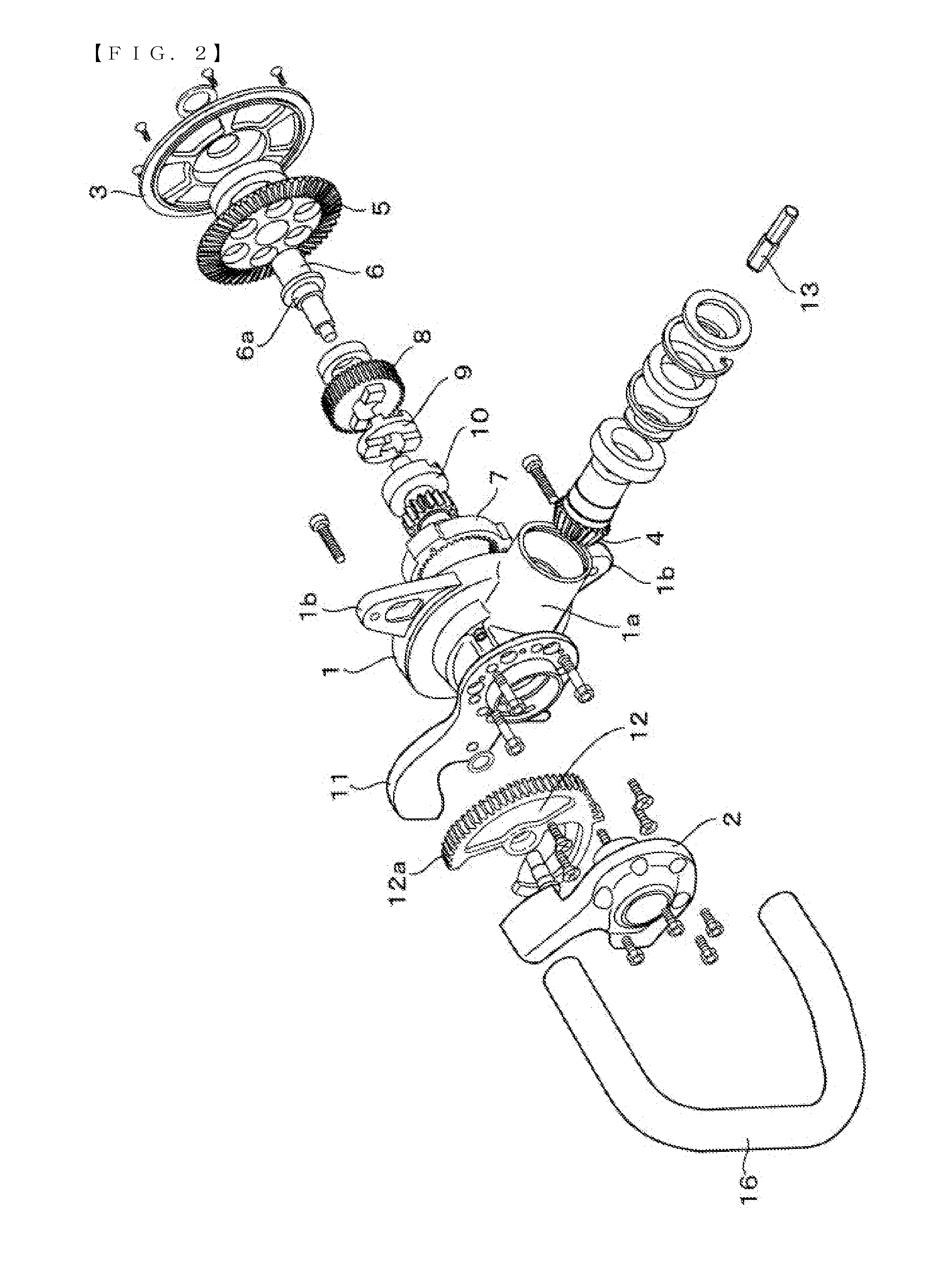

Electric cable cutter

InactiveUS20140007433A1Reduce thicknessSmall sizeApparatus for cutting/splicing cablesCuttersDrive shaftCoupling

Owner:TOA INTERSYST

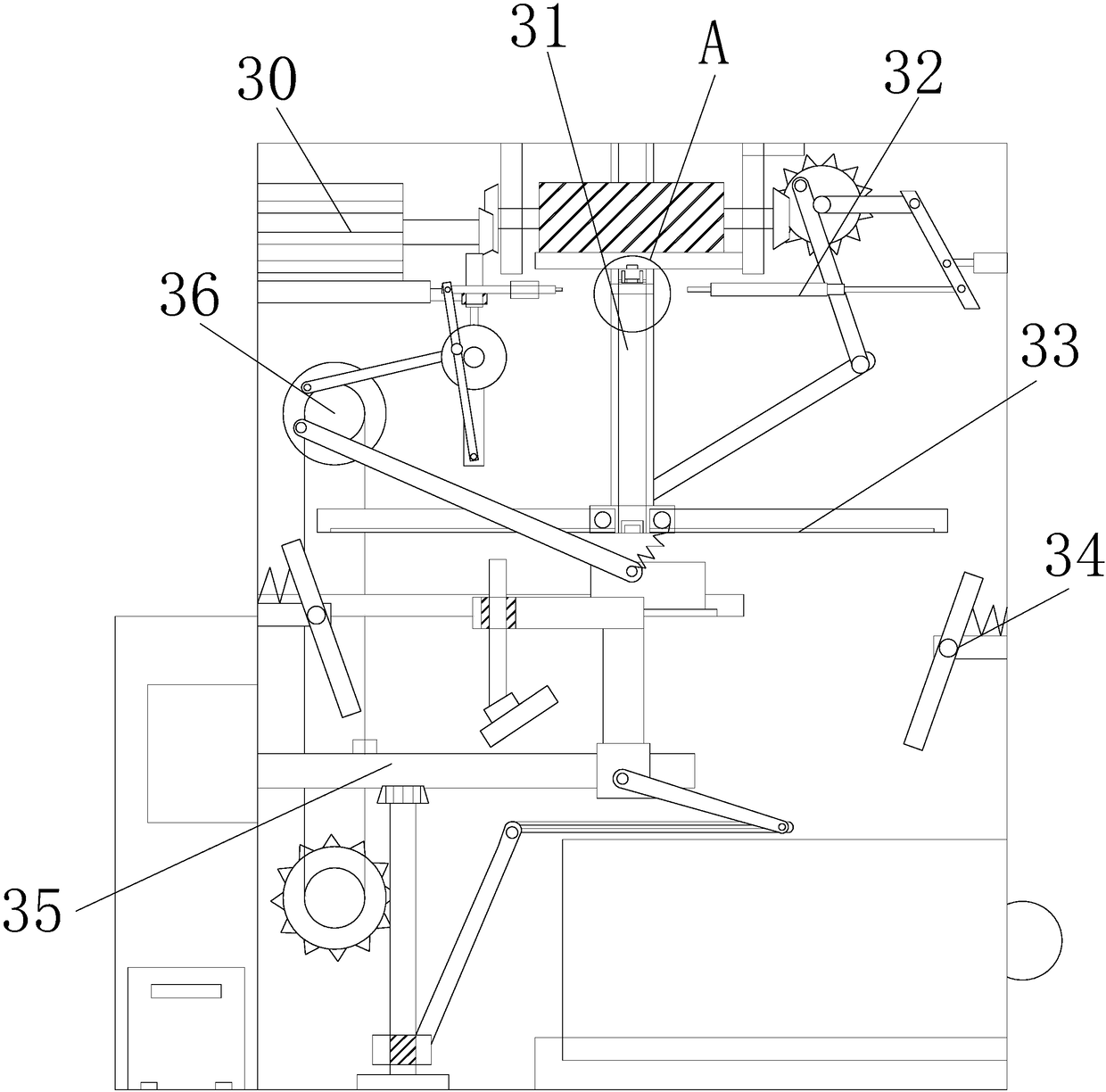

Automatic wire processing device

ActiveCN106451258AThe functional indicators are consistentApparatus for cutting/splicing cablesApparatus for removing/armouring cablesEngineeringElectric wire

The invention discloses an automatic wire processing device which comprises a base. An automatic wire leading mechanism, a wire peeling and cutting mechanism and a wire bending mechanism are sequentially arranged on the base, the automatic wire leading mechanism controls a wire to be processed to pass the wire peeling and cutting mechanism and the wire bending mechanism, different preset positions of the wire to be processed are respectively peeled, cut and bent by the wire peeling and cutting mechanism and the wire bending mechanism, the automatic wire leading mechanism, the wire peeling and cutting mechanism and the wire bending mechanism are respectively and controllably connected with a main control module, the main control module controls the automatic wire leading mechanism to drive the wire to sequentially pass the wire peeling and cutting mechanism and the wire bending mechanism, controls the wire peeling and cutting mechanism to peel and cut the wire at an appropriate moment by the aid of passed rate and needed wire appearances and controls the wire bending mechanism to bend the wire at the appropriate position, so that a directly-obtained finished product wire to be connected meets requirements of preset wire appearances, the wire is effectively and accurately processed, and uniformity of function indexes of construction wires is ensured.

Owner:STATE GRID ZHEJIANG JIANDE POWER SUPPLY +2

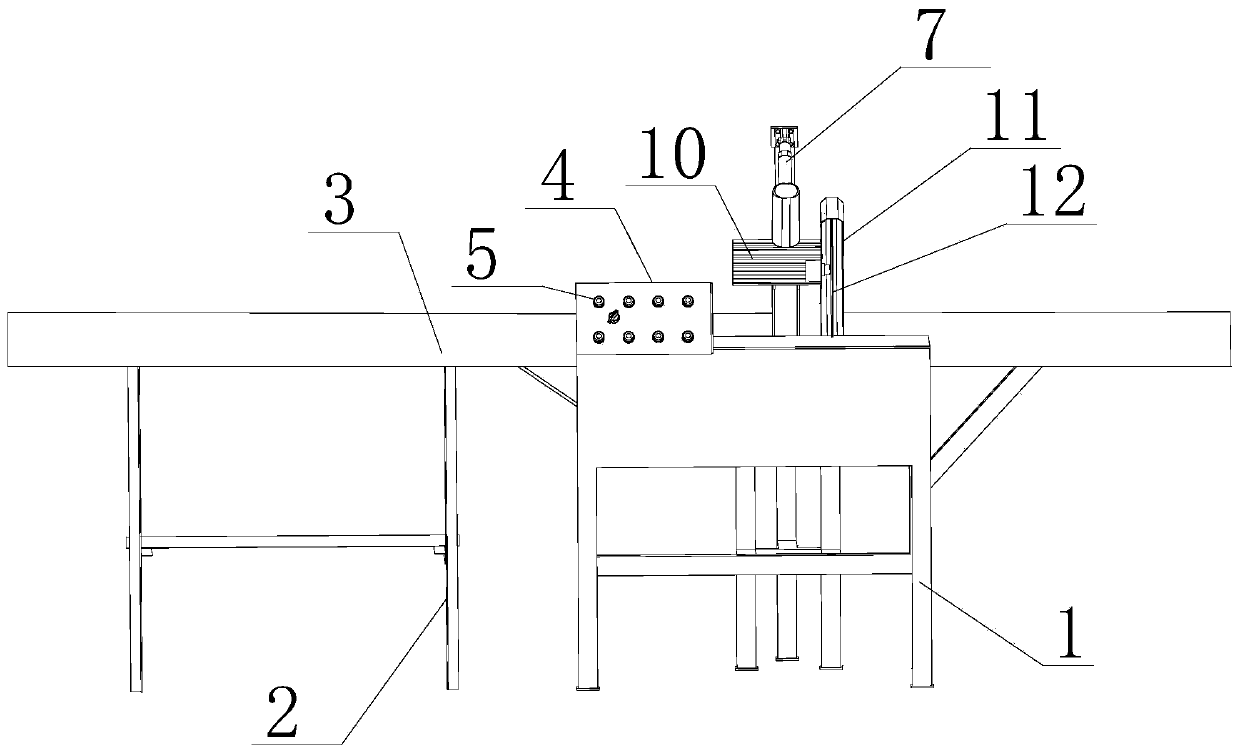

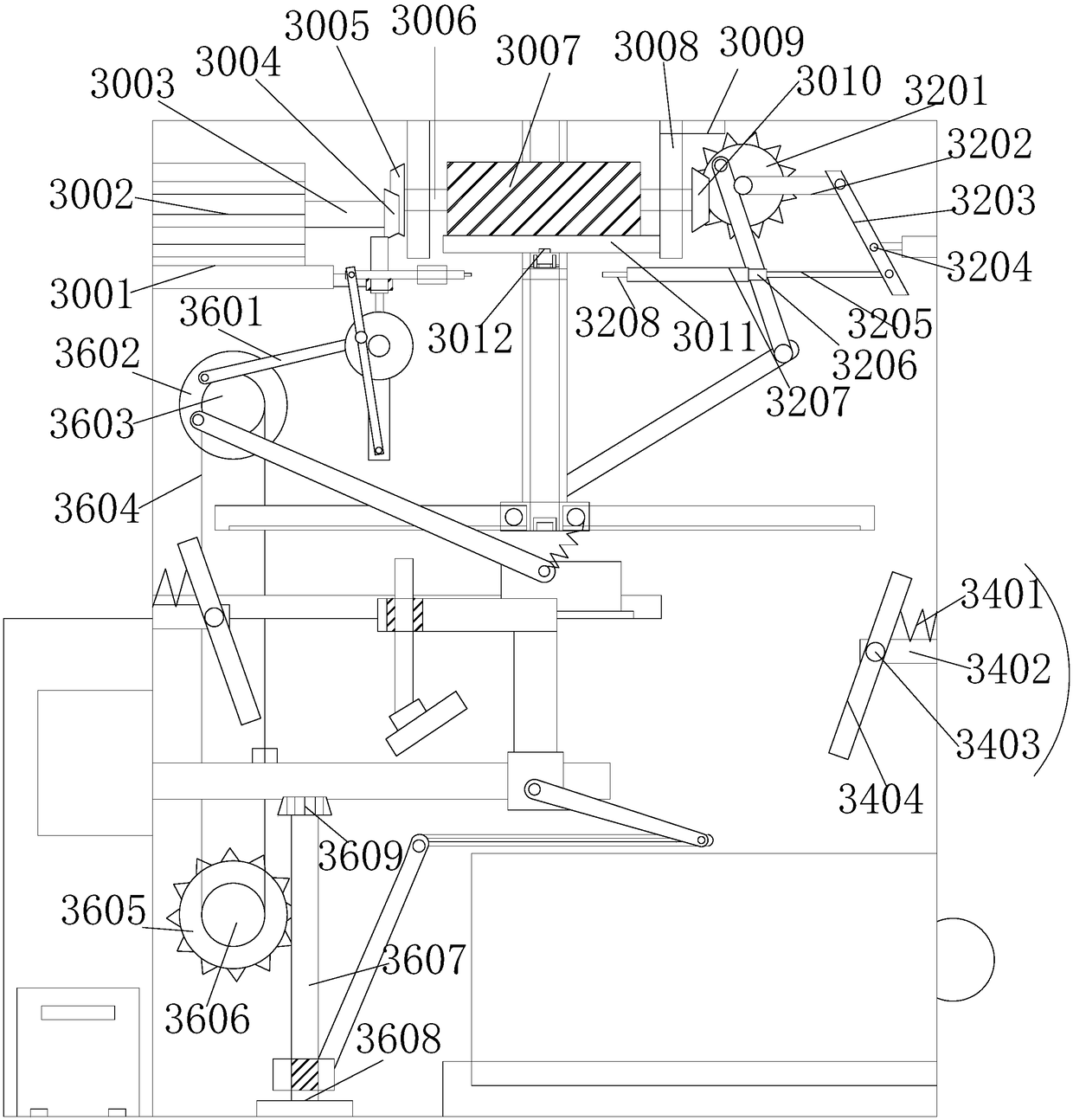

Novel cable cutting device for distribution line construction

ActiveCN110238324ASolve the problem of low cutting safetyIncreased cutting safetyApparatus for cutting/splicing cablesMotor driveGear drive

The invention discloses a novel cable cutting device for distribution line construction. The novel cable cutting device comprises a conveying device and a feeding device. The conveying device is arranged inside a support frame, a conveying mechanism transmits a cable to the right end, then the cable is transported to the upper end and enters a cutting area, meanwhile, a sliding frame on the conveying mechanism pushes a swinging mechanism, the swinging mechanism drives a cam to rotate, a material guiding plate conveys the cut cable, and therefore the advantages that the cable can be quickly pushed to the cutting area to be cut and the cutting safety is increased are achieved. The feeding device is arranged inside the support frame, when the sliding frame moves to the left end, the driving mechanism is driven to move to the left end, the driving mechanism drives a winding gear to rotate through a traction rope, the winding gear drives a motor starting mechanism to conduct transmission, a third motor is started, the third motor drives a conveyor belt to transmit the cable, and therefore the advantages that the cable is quickly transmitted and the cutting efficiency is increased are achieved.

Owner:CHONGQING ELECTRIC POWER COLLEGE

Cutting, stripping and crimping all-in-one tool

InactiveUS20120204413A1Line/current collector detailsApparatus for cutting/splicing cablesHDMIEngineering

A tool includes lower and upper members which are connected together so that the tool can be moved to an open position or to a closed position. The tool has a number of cutting blades and surfaces which allow a user to cut or strip a HDMI cable. The tool also has a pair of platforms which hold an associated laced wire guide and mated terminal block therein. The tool can be used to terminate the cut and stripped HDMI cable with the mated wire guides and terminal block.

Owner:FOCUS STRATEGIES CAPITAL ADVISORS LLC +1

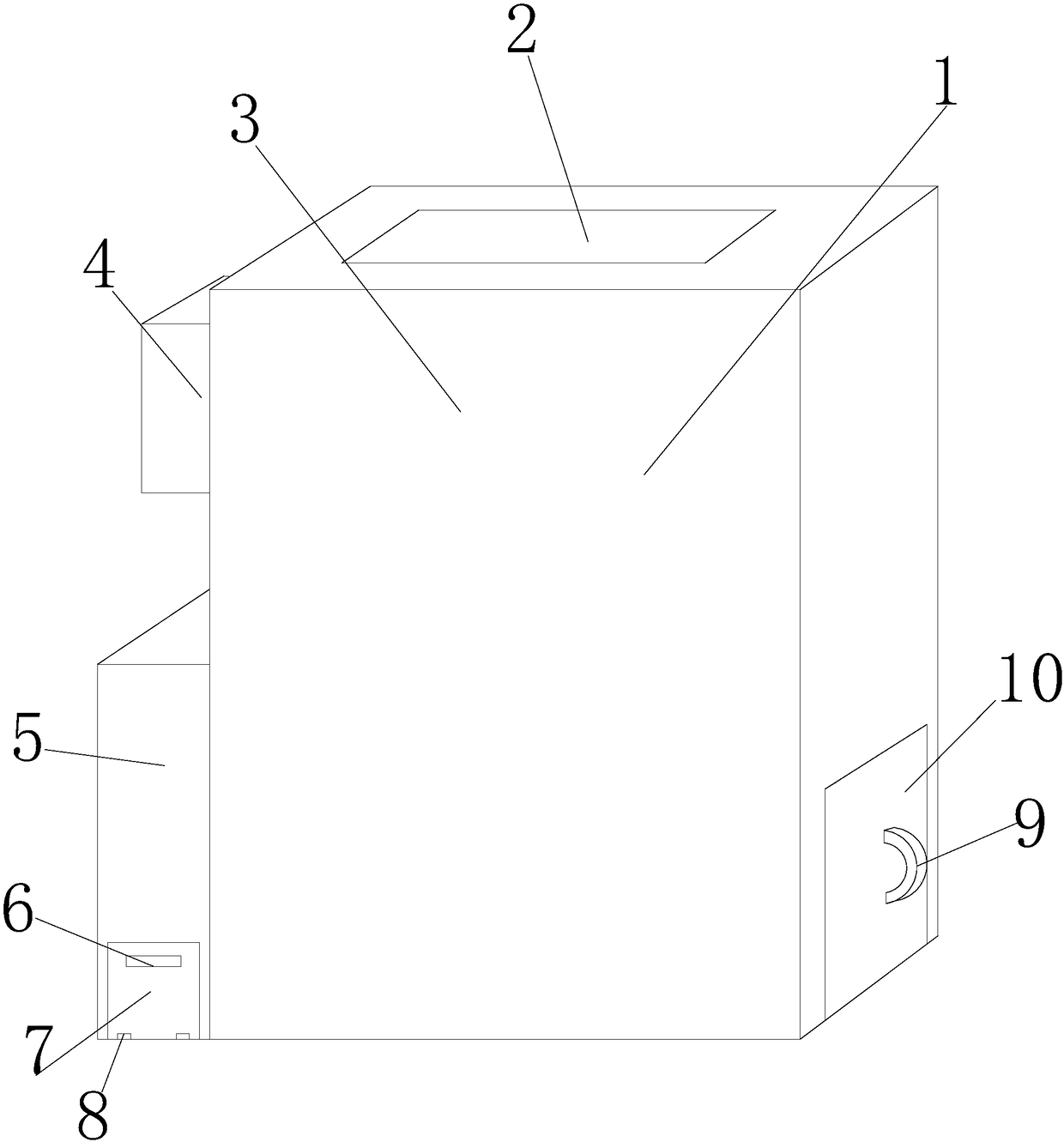

Electric power efficient cable cutting apparatus

The invention discloses an electric power efficient cable cutting apparatus. The electric power efficient cable cutting apparatus comprises a box body, a replacement window, an efficient cable cuttingapparatus, a control electrical box, an extension block, a rectangular groove, a first collection box, a sliding rail, a U-shaped handle and a second collection box; the box body is of a cuboid structure, and the replacement window is formed in the top of the box body; the replacement window is embedded in the top end of the box body in a hinge connection manner; the efficient cable cutting apparatus is mounted in the box body in a movable connection manner; the control electrical box is mounted on the left upper part of the box body and electrically connected with the efficient cable cuttingapparatus; and the extension block is arranged on the left end plane of the box body and fixedly connected into an integrated structure. By virtue of the electric power efficient cable cutting apparatus, a cutting blade can be pushed to cut a cable accurately through a blade groove to enable the cut cable sections to be equal in lengths and to be maintained in a U-shaped telescopic rod, and a collecting rod drives the cables left and right to be collected in two directions, and the cables can be wound or straightened so as to be used and carried by a working staff conveniently.

Owner:安徽安发特交通工程集团有限公司

Wire harness stripping device in low-voltage box

ActiveCN110797808AShorten the production cycleImprove efficiencyApparatus for cutting/splicing cablesApparatus for removing/armouring cablesElectric machineEngineering

The invention relates to the technical field of wire harness processing equipment, and particularly relates to a wire harness stripping device in a low-voltage box, which comprises an L-shaped substrate. A mounting shaft is rotationally arranged on the left side of the L-shaped substrate; a guide roller group and a conveying roller group are respectively arranged at the right lower part of the mounting shaft; the guide roller group and the conveying roller group are horizontally arranged and are both rotationally connected to the side wall of the L-shaped substrate; a motor for driving one roller in the conveying roller group to rotate is mounted on the rear side wall of the L-shaped substrate; a positioning block is arranged on the right side of the conveying roller group; an opening is formed in the side wall of the L-shaped substrate; the opening, the positioning block and the conveying roller group are aligned in the horizontal position; first telescopic air cylinders are symmetrically arranged on the two sides of the opening; and the first telescopic air cylinders are fixed to the side wall of the L-shaped substrate. Continuous operation of wire harness cutting and stripping can be achieved, the production cycle of an enterprise is shortened, the benefits of the enterprise are improved, and the wire harness stripping device is suitable for further application and popularization.

Owner:XIAMEN MINGHAN ELECTRIC

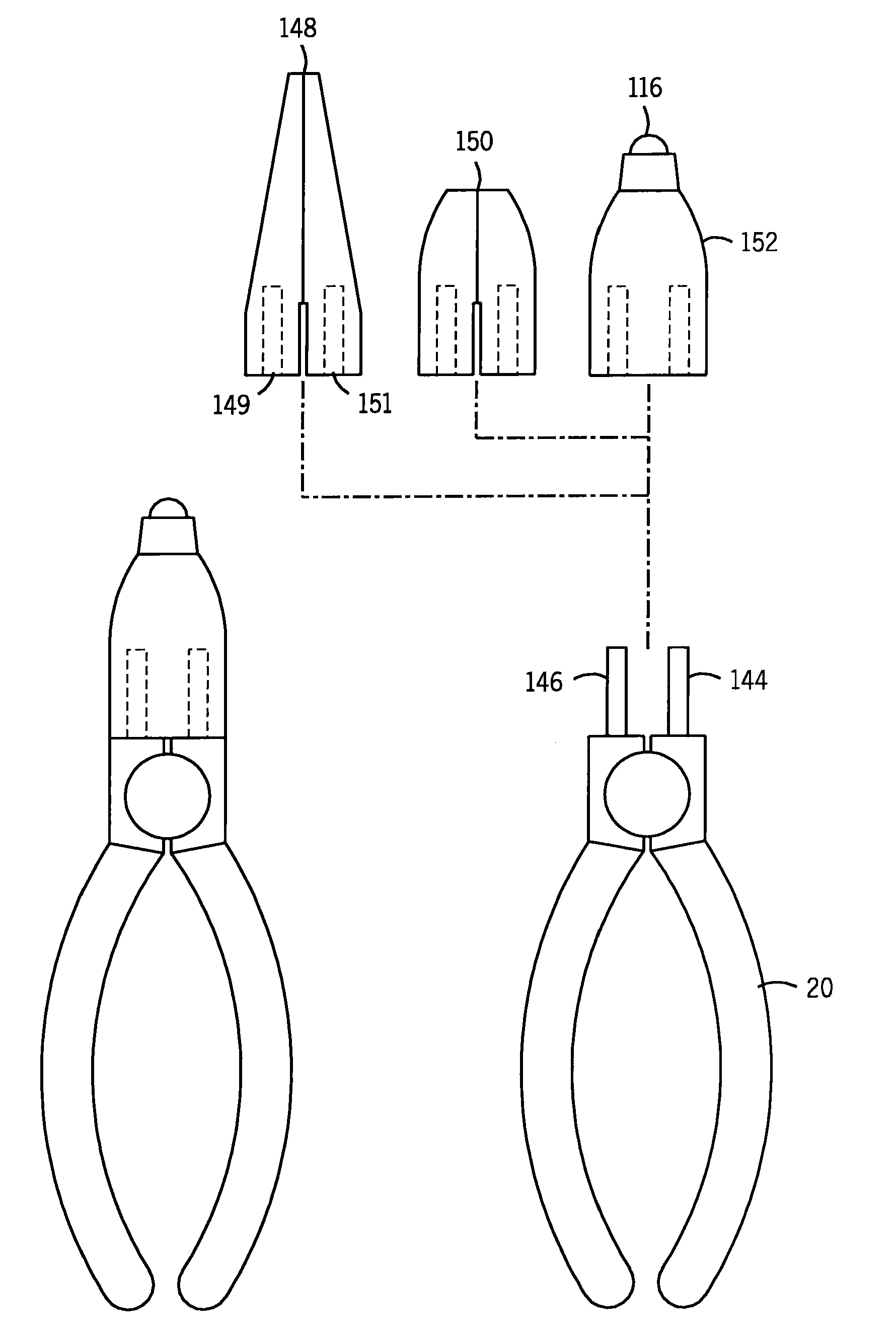

Wire Treatment Pliers Set

InactiveUS20160181772A1Line/current collector detailsApparatus for cutting/splicing cablesEngineering

Owner:HANLONG INDAL

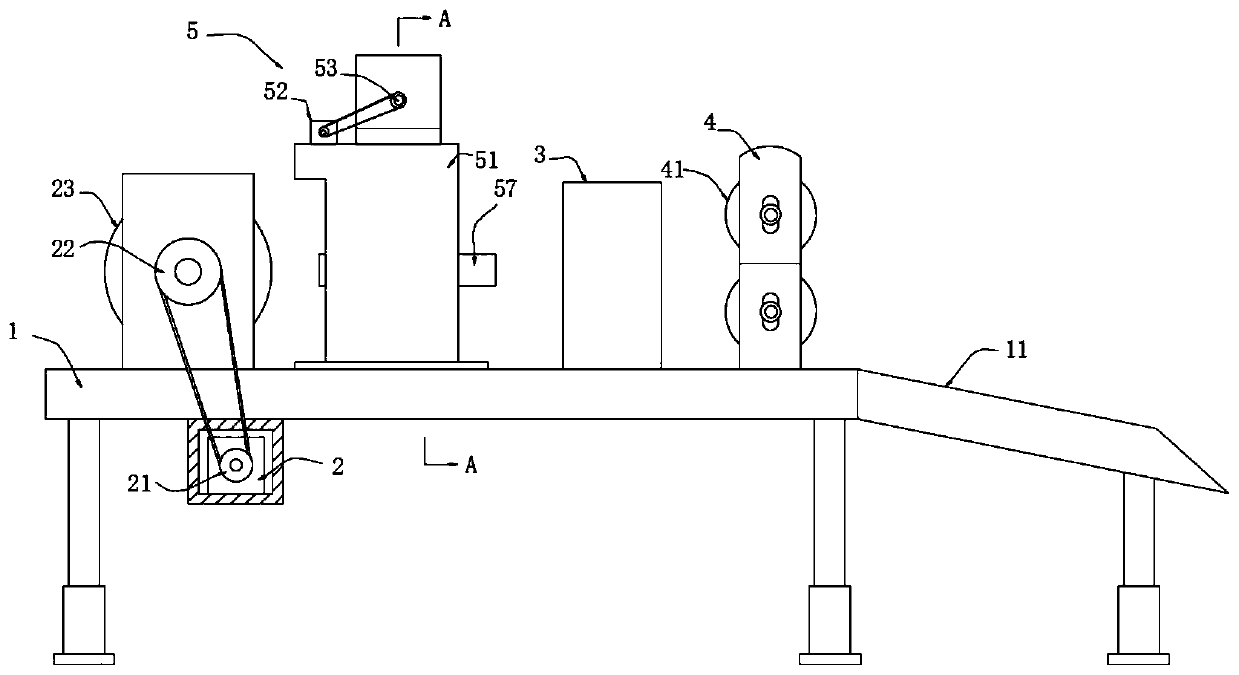

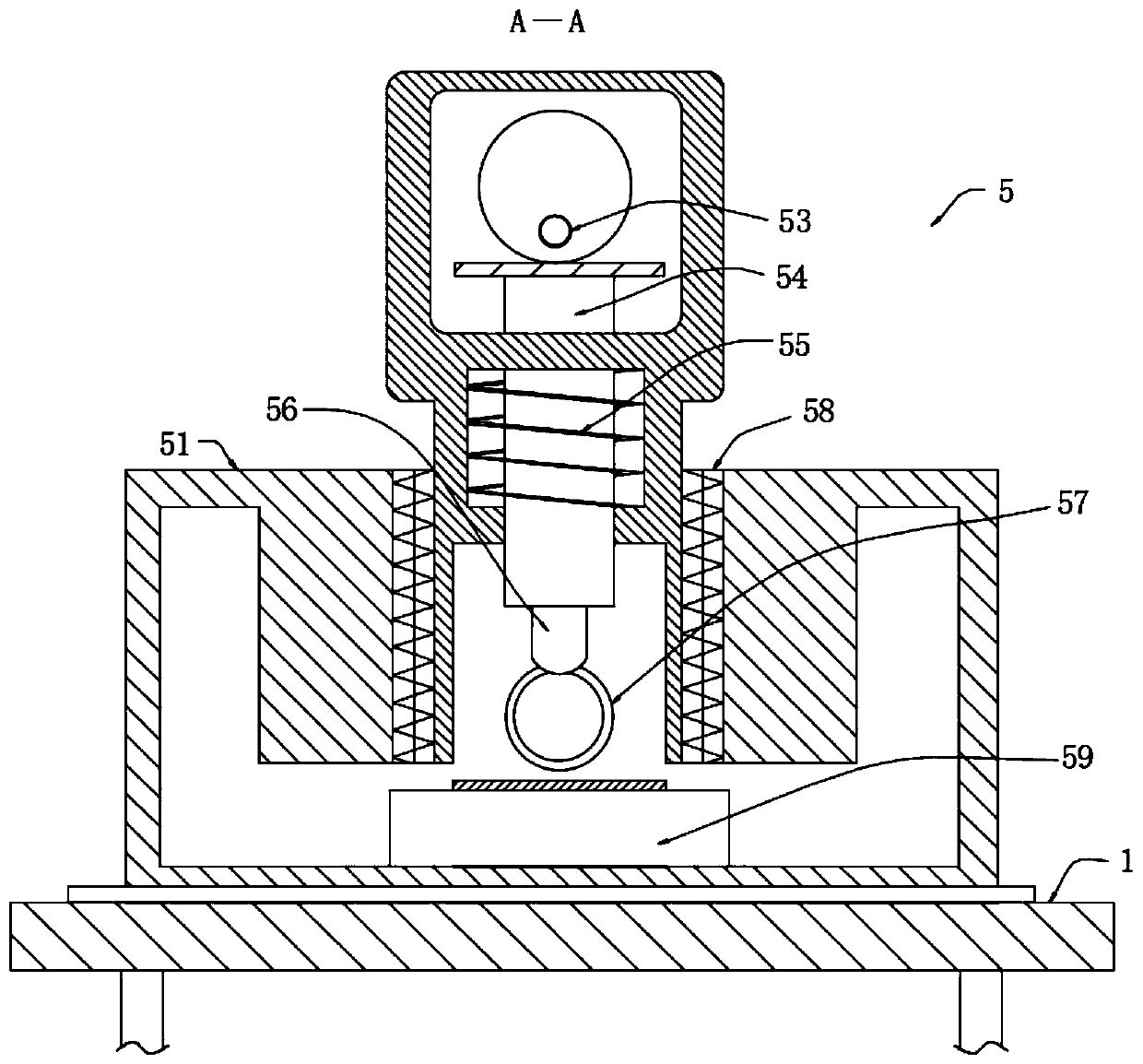

Cutting and stripping device for waste flat electric wires

InactiveCN107994516AImprove work efficiencyImprove efficiencyApparatus for cutting/splicing cablesBasic electric elementsDrive shaftEngineering

The invention discloses a cutting and stripping device for waste flat electric wires. The device comprises a base, wherein a rack body is arranged on the base, a reel is arranged on the rack body, a guide mechanism is arranged below the reel, and the guide mechanism is horizontally and sequentially connected with a drive mechanism and a cutting and stripping mechanism; the drive mechanism comprises a pair of roller drive mechanisms, each roller drive mechanism comprises a stepping motor fixed in the rack body, each stepping motor is connected with a rotary shaft, two ends of each rotary shaftpenetrate through the rack body and are connected with a small belt pulley and a driving roller respectively, a driven shaft is arranged below each rotary shaft, one end of each driven shaft is fixedon the rack body through a bearing, a bearing block is arranged at the other end, two ends of each driven shaft are connected with a large belt pulley and a driven roller respectively, the small beltpulleys are connected with the large belt pulleys through belts, and the driving rollers and the driven rollers are matched. The cutting and stripping device has the characteristics that the working efficiency is high, the labor intensity is reduced and the stripping effect is better.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Cable stripping and cutting machining device

ActiveCN111049070AEasy to moveRealize cutting workApparatus for cutting/splicing cablesApparatus for removing/armouring cablesWire cuttingStructural engineering

The invention discloses a cable stripping and cutting machining device. The device comprises a mounting bracket, a wire stripping mechanism and a wire cutting mechanism; the wire stripping mechanism and the wire cutting mechanism are both installed on the mounting bracket; the wire stripping mechanism is arranged on the right side of the wire cutting mechanism; and a wire winding roller is arranged on the left side of the wire cutting mechanism. With the cable stripping and cutting machining device of the invention adopted, problems such as infirm fixation of a cable, failure to automaticallystrip or cut the cable, and failure to automatically wind the cable during existing cable stripping can be solved. The wire stripping mechanism is adopted; the wire stripping mechanism can perform automatic wire stripping on a cable; the wire stripping mechanism is reasonable in structural arrangement and firm in fixation; the stripped cable can enter the wire cutting mechanism; the cable can be cut off through the up-down reciprocating work of a cutter; and therefore, the machining efficiency of the cable is greatly improved, and tedious manual operation is avoided. The cable stripping and cutting machining device has high practicability and is convenient to use and popularize.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

Reinforced cable cutting mechanism with guide wheels

InactiveCN108655305AStable deliveryGood effectApparatus for cutting/splicing cablesDrive motorWall plate

The invention discloses a reinforced cable cutting mechanism with guide wheels. A main bottom plate is included, and a vertical plate is fixed to the top face of the main bottom plate; a horizontal extending plate is fixed to the top face of the vertical plate; the lower portions of the front wall faces of the left side and the right side of the vertical plate are each hinged to a lower rolling wheel through a bearing; two driving motors are fixed to the rear wall face of the vertical plate; a middle supporting frame is fixed to the middle portion of the front wall face of the vertical plate;a guiding adjusting motor is fixed to the middle portion of the front wall face of a front wall plate of the middle supporting frame; an output shaft of the guiding adjusting motor penetrates the middle supporting frame and is connected with a transverse screw sleeve in a screwed manner; an adjusting plate is fixed to the rear end of the transverse screw sleeve; the upper portion and the lower portion of the rear wall face of the adjusting plate are each fixedly provided with an extending plate; and the two ends of a center rotating shaft of a main guide wheel are hinged to the two extending plates through bearings. The reinforced cable cutting mechanism with the guide wheels can be used for normal conveying of a cable, supporting and limiting conveying is performed through upper rolling wheels, the lower rolling wheels, the main guide wheel and an auxiliary guide wheel, and the reinforced cable cutting mechanism with the guide wheels is stable in conveying and good in effect.

Owner:佛山慧创正元新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com