Patents

Literature

33results about How to "Increased cutting safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

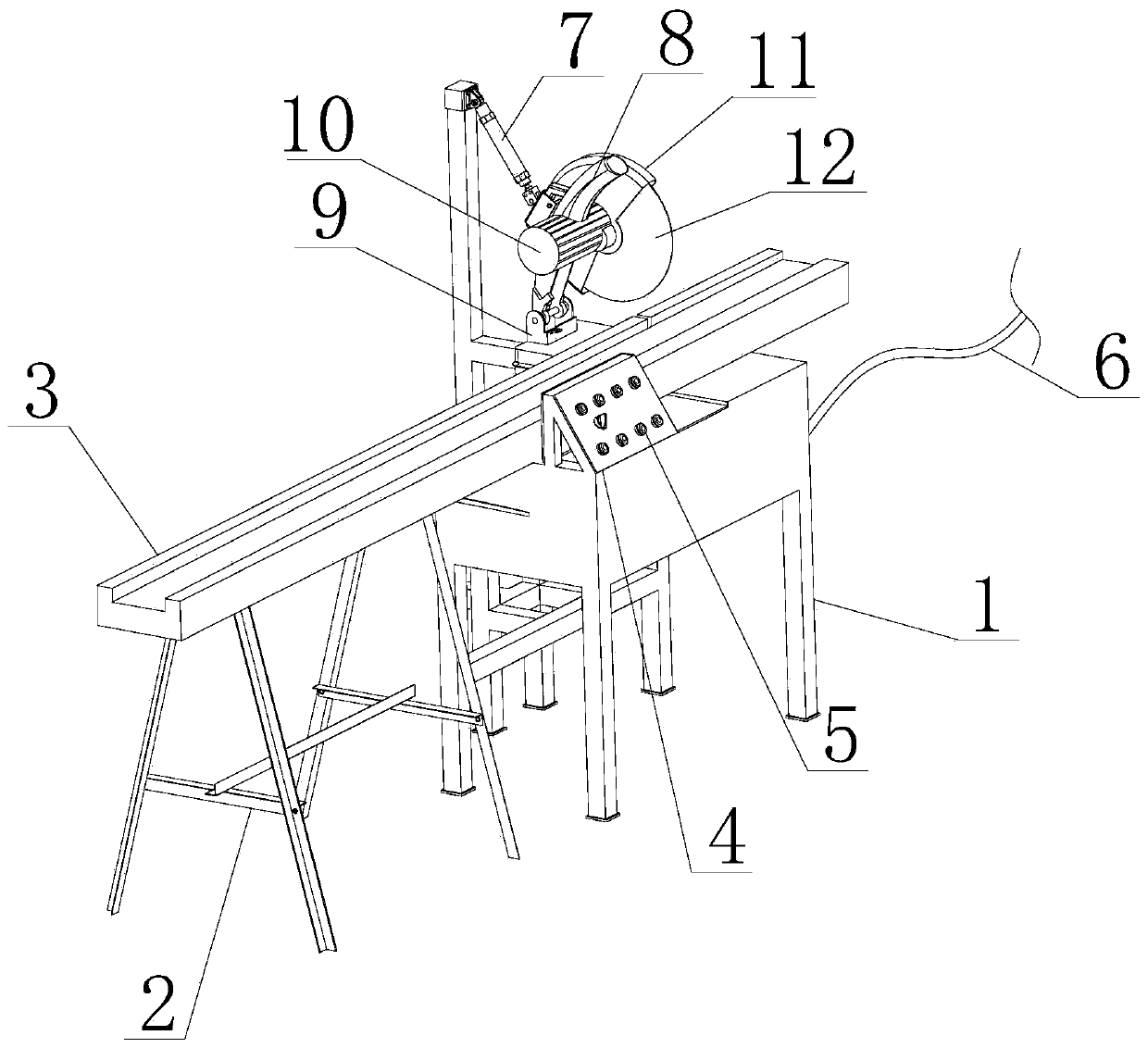

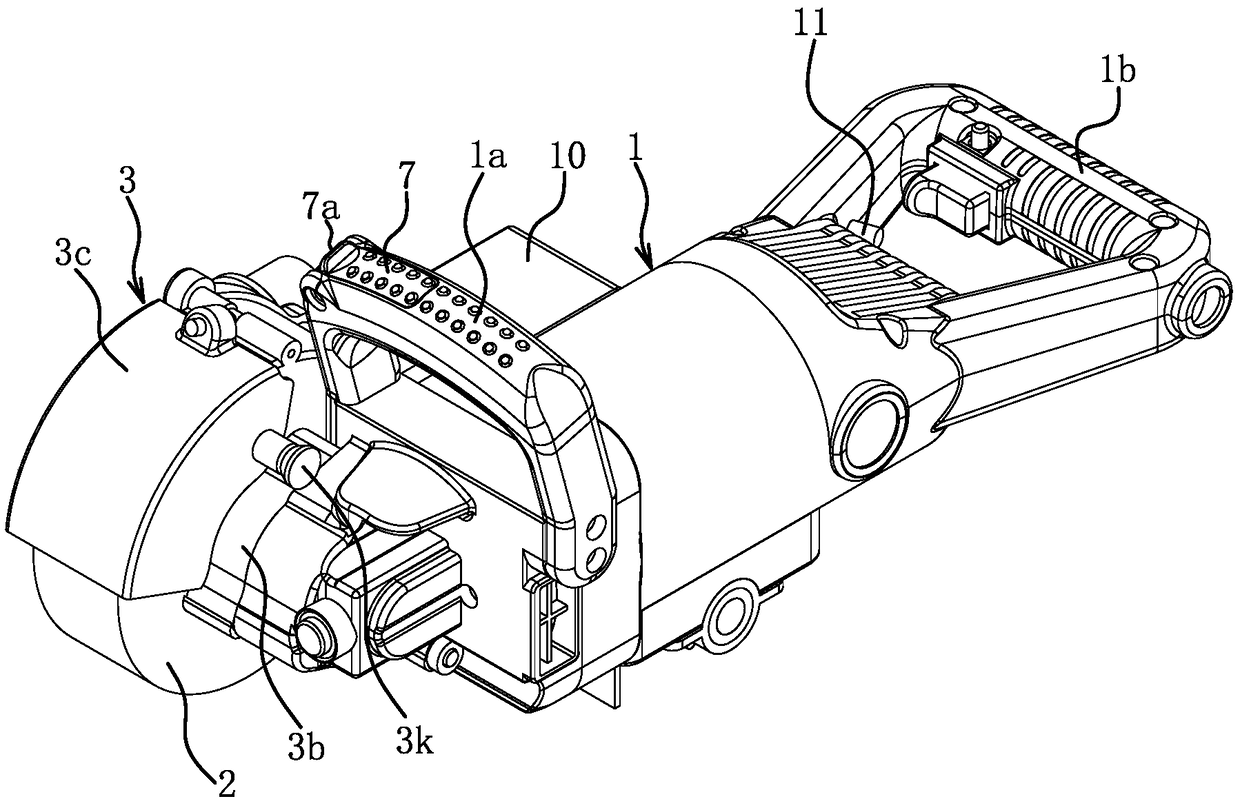

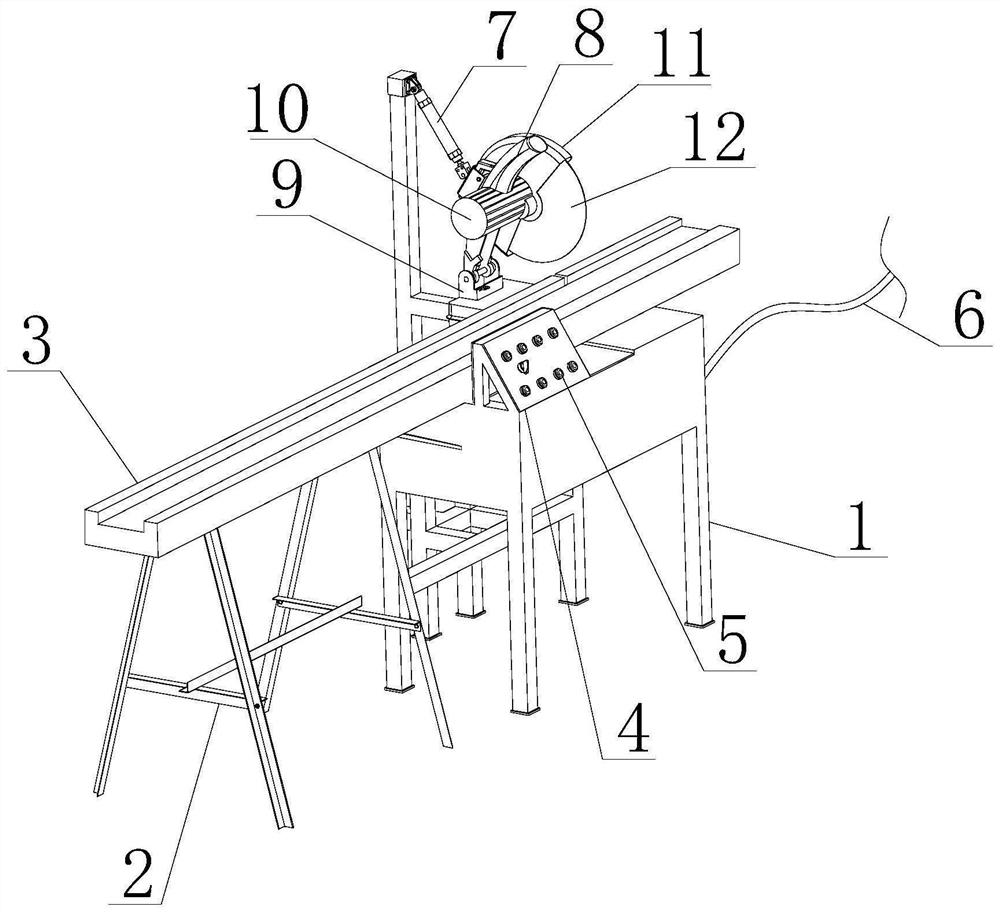

Novel cable cutting device for distribution line construction

ActiveCN110238324ASolve the problem of low cutting safetyIncreased cutting safetyApparatus for cutting/splicing cablesMotor driveGear drive

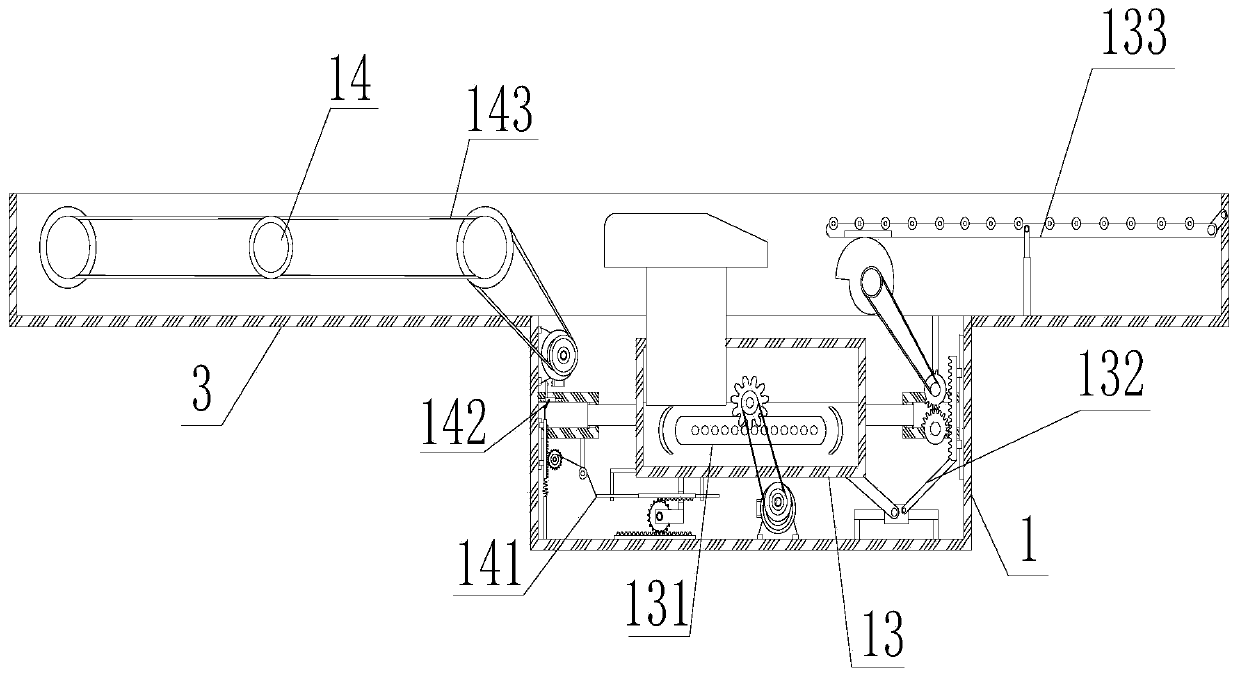

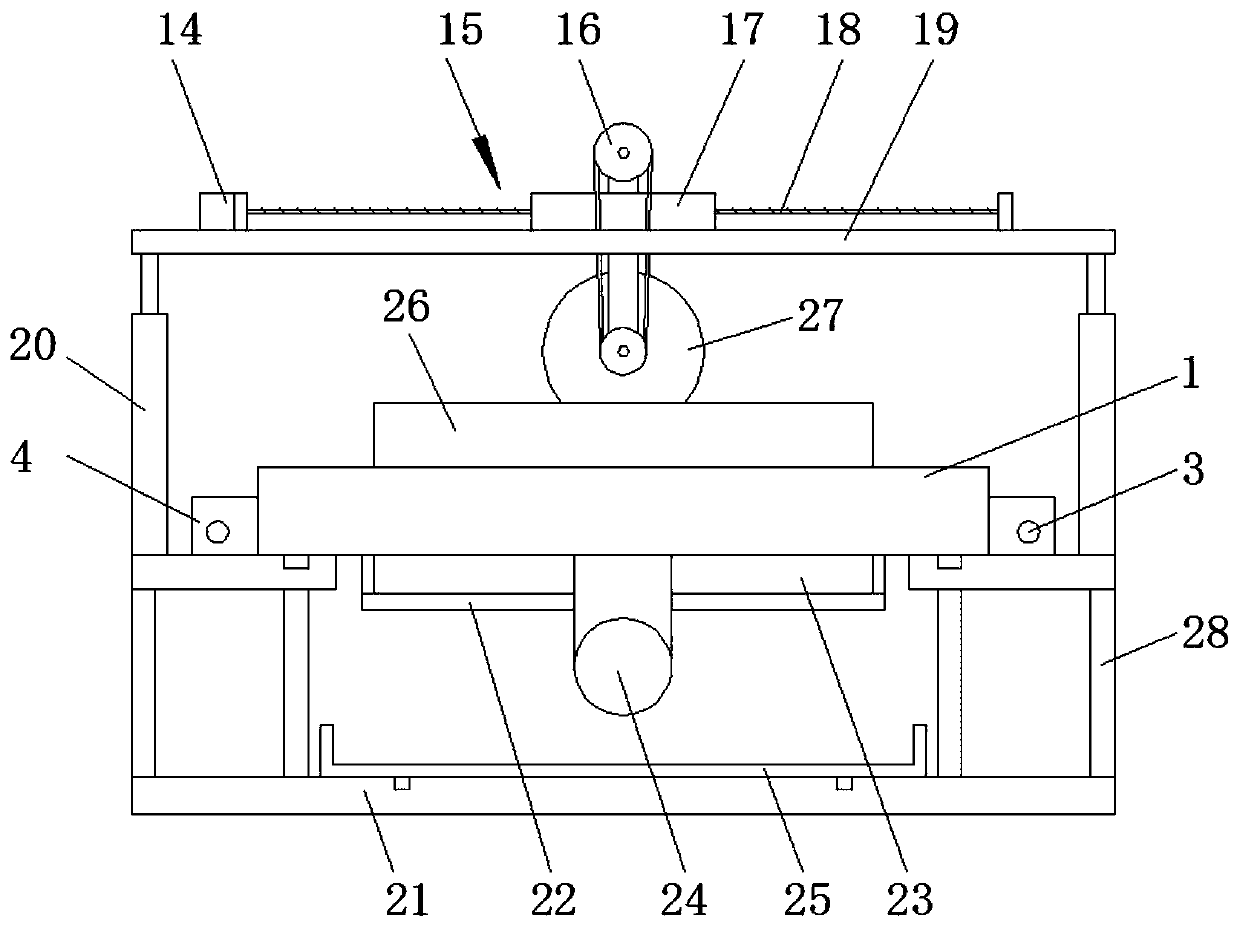

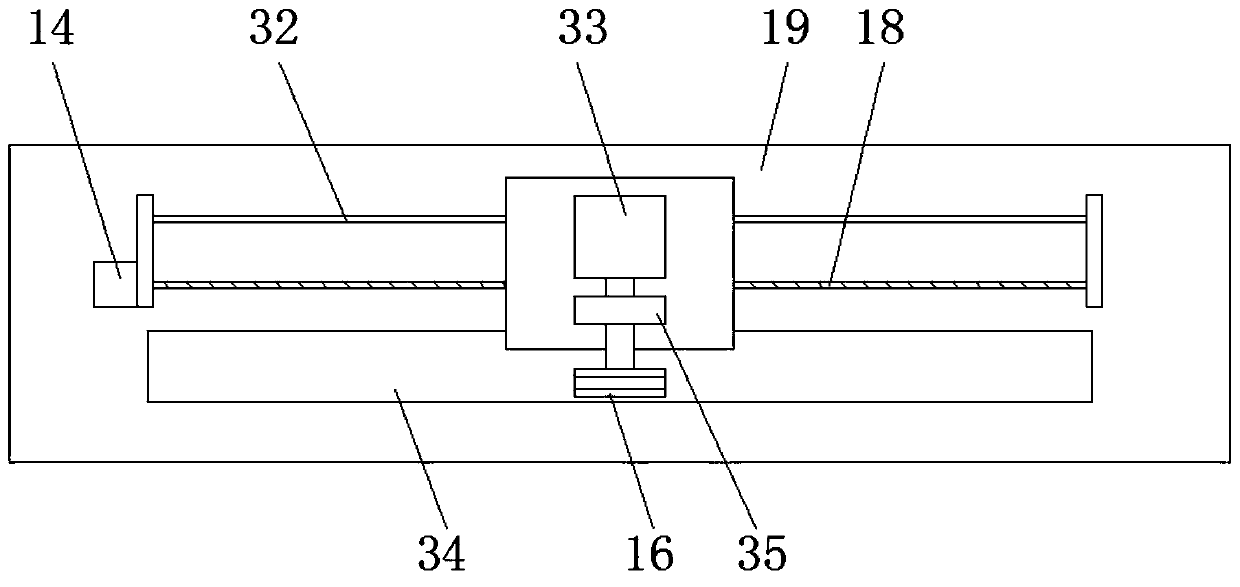

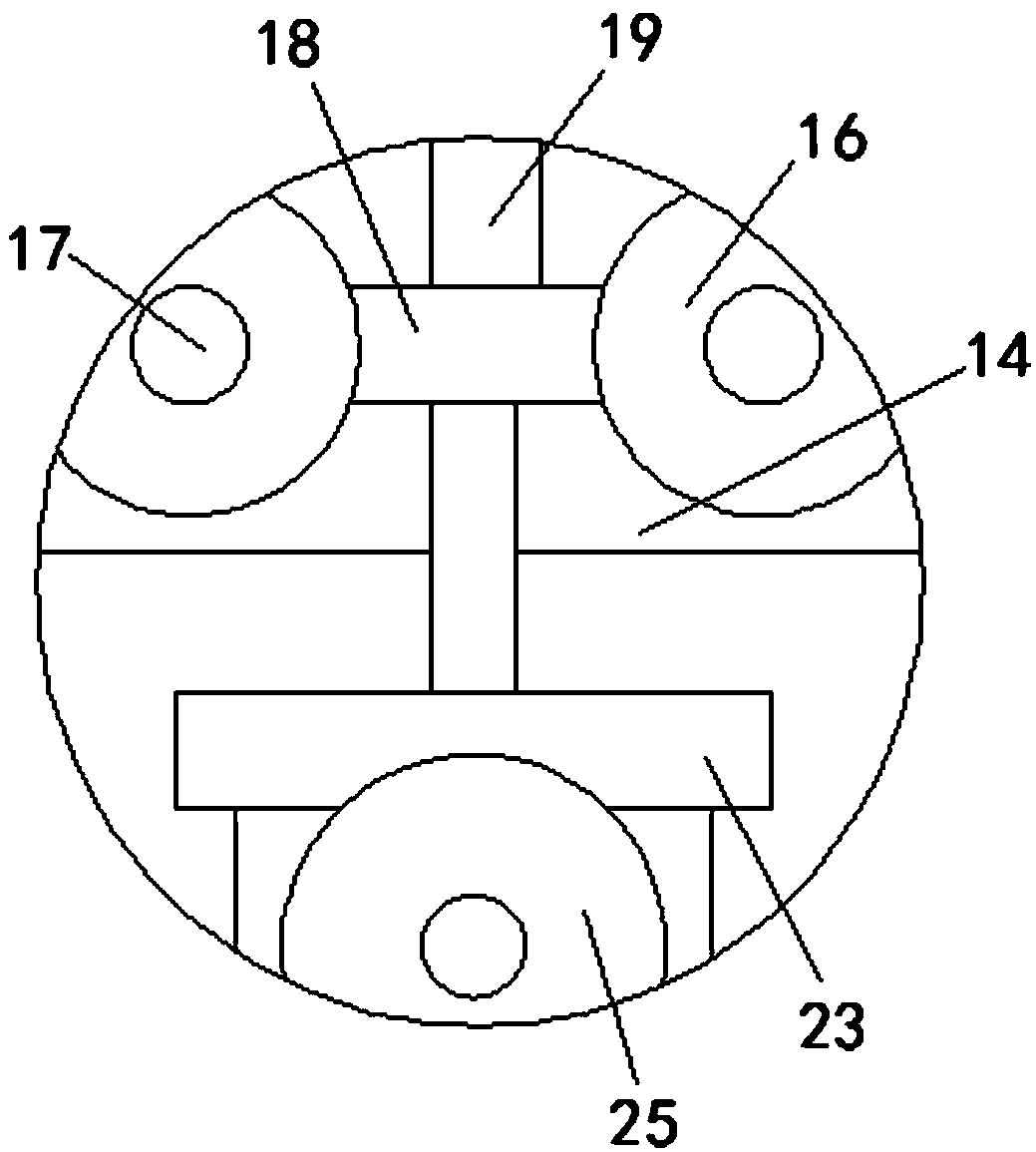

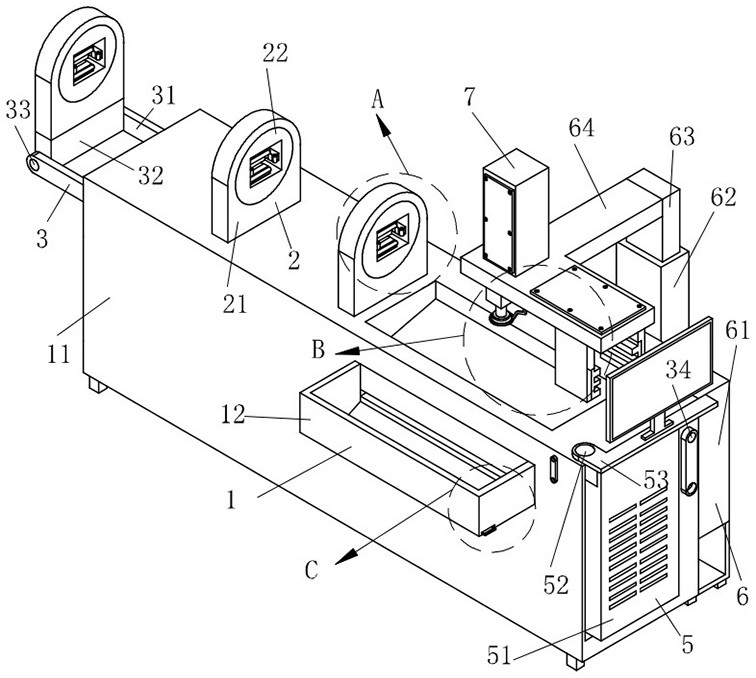

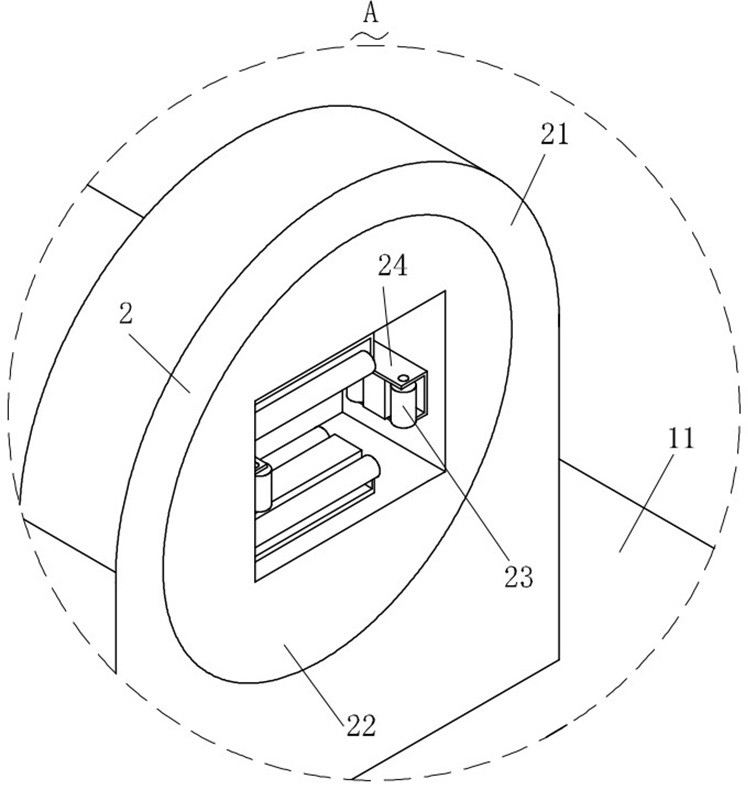

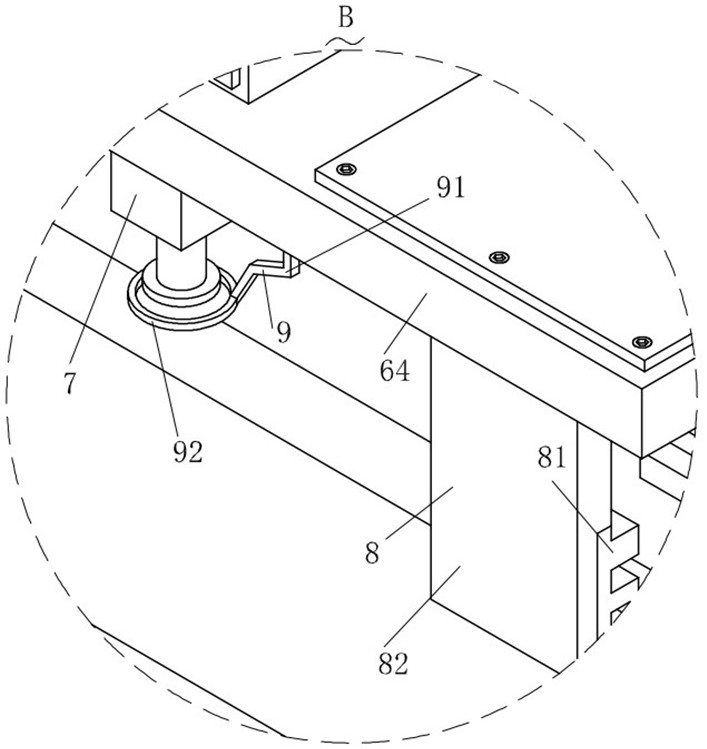

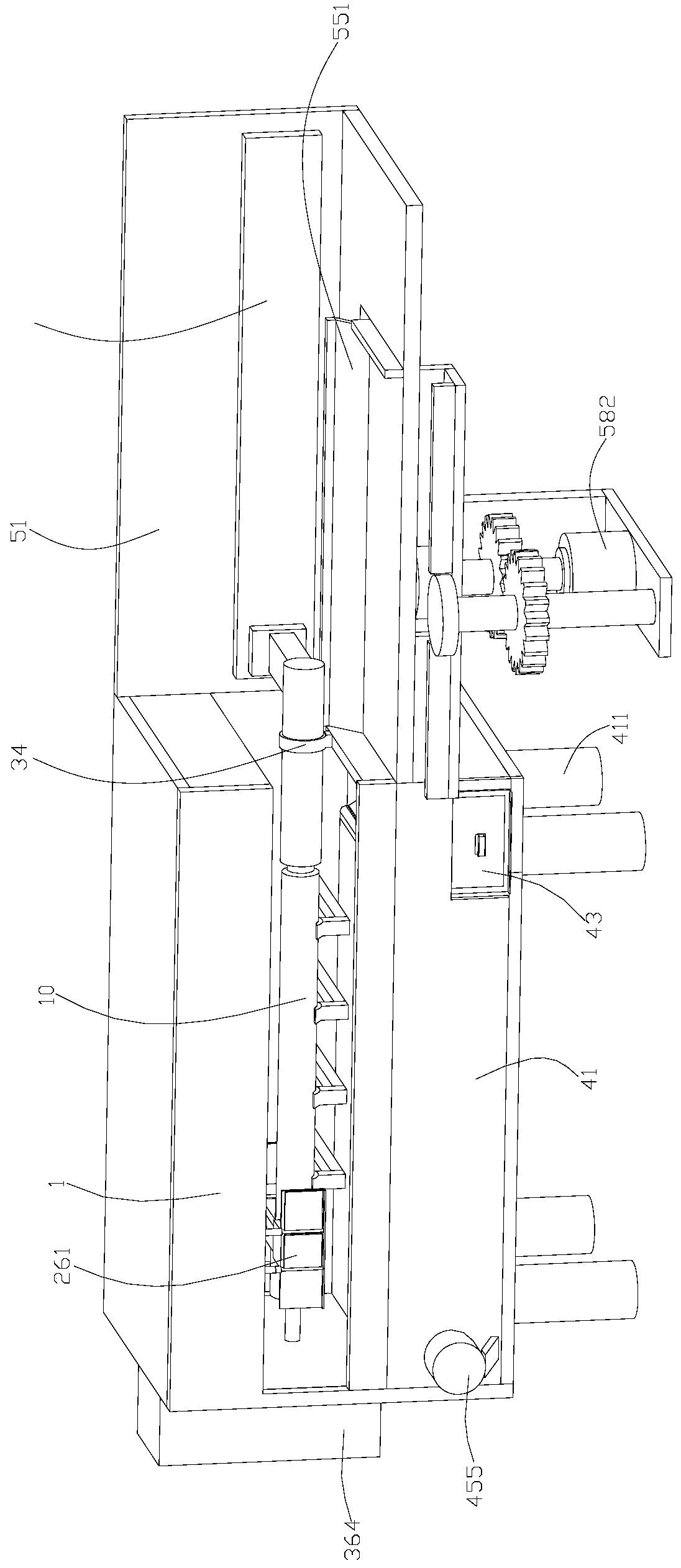

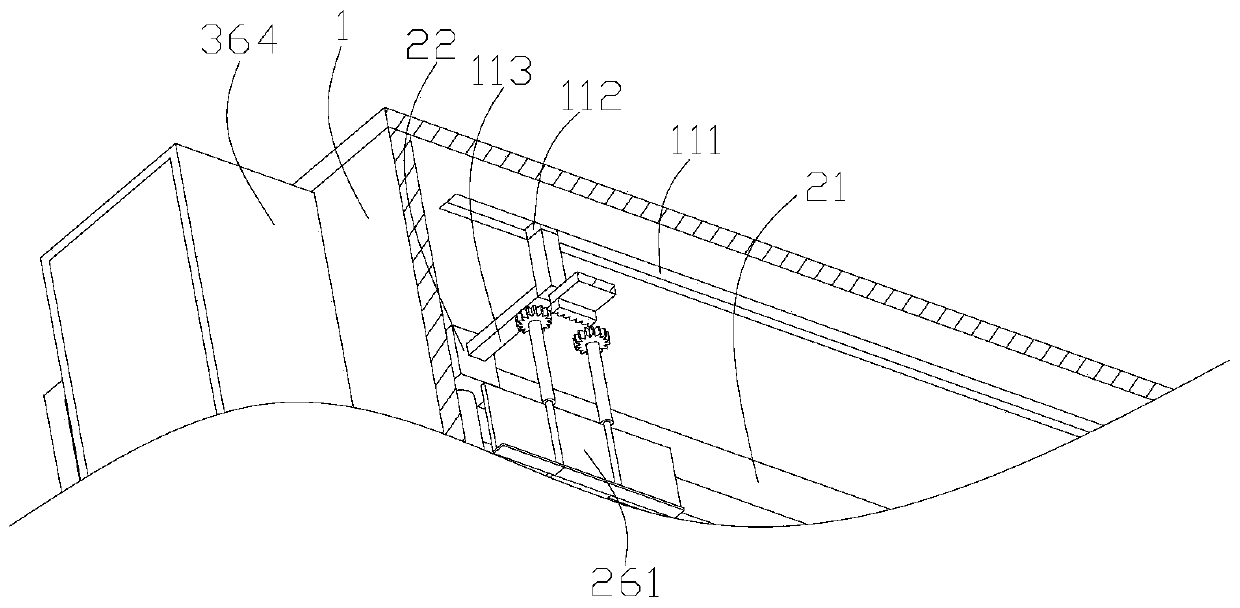

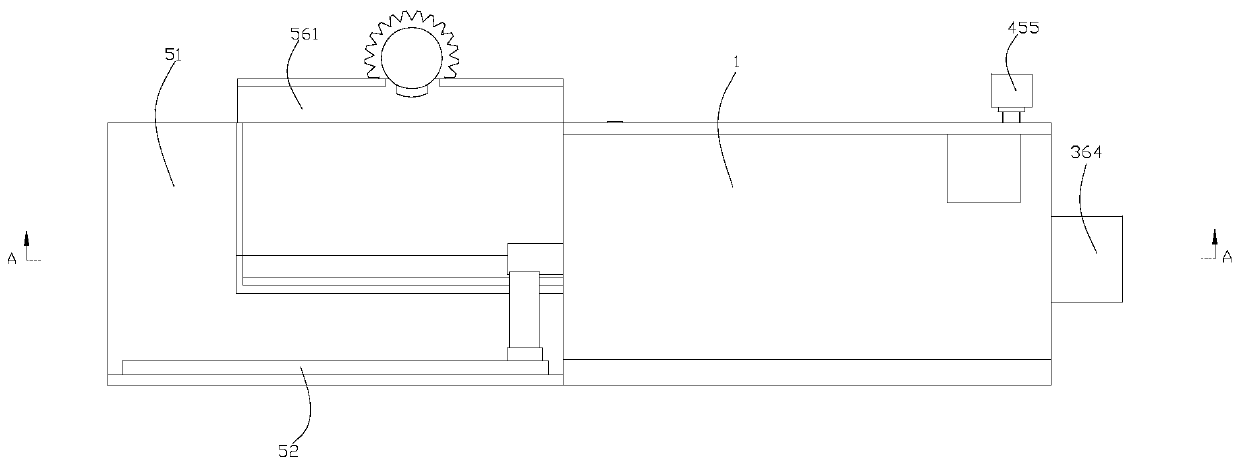

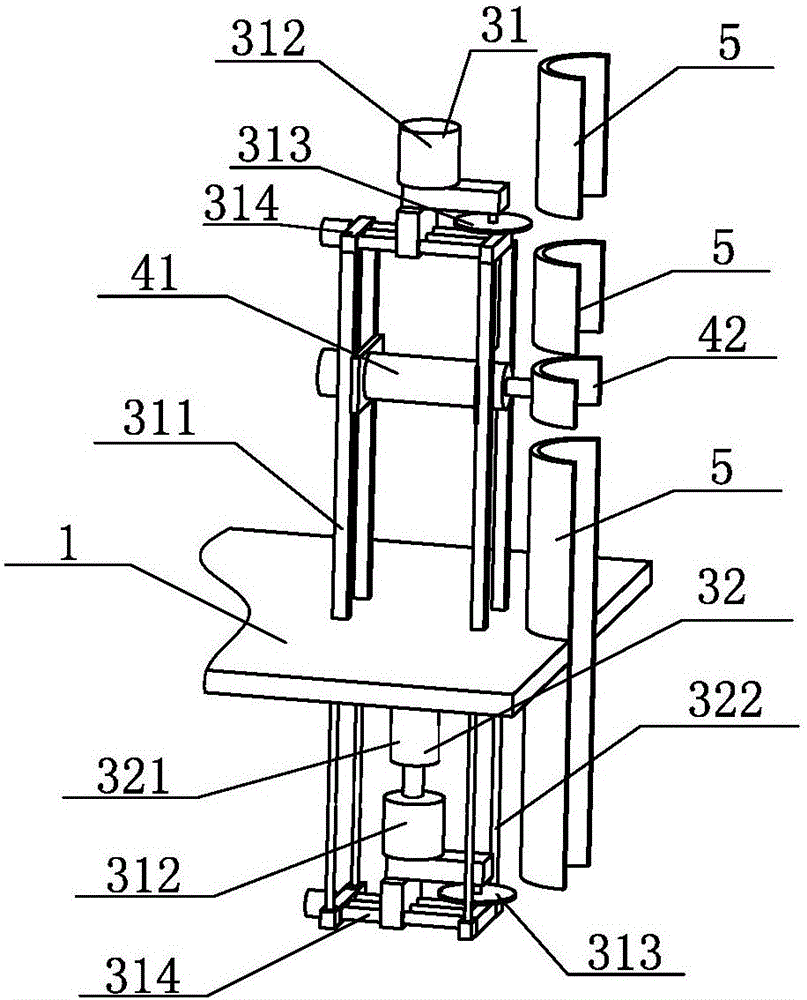

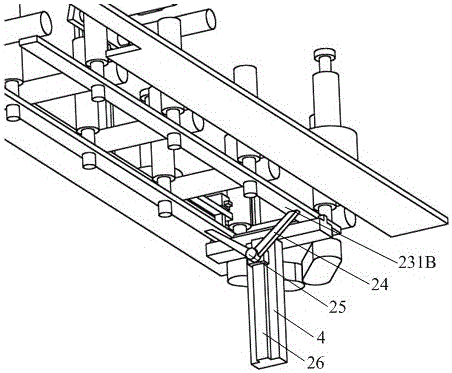

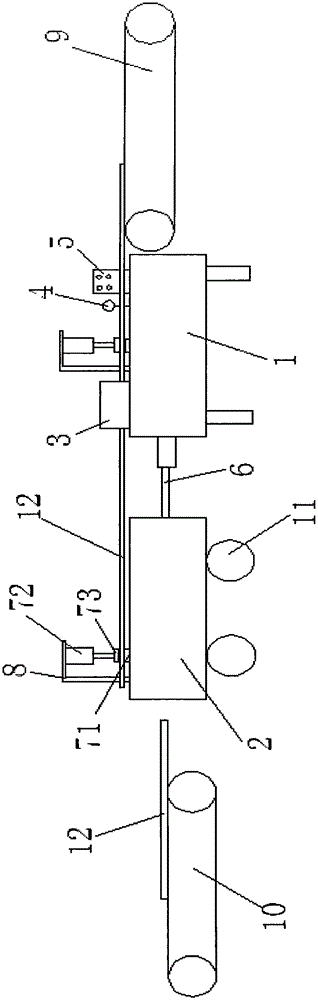

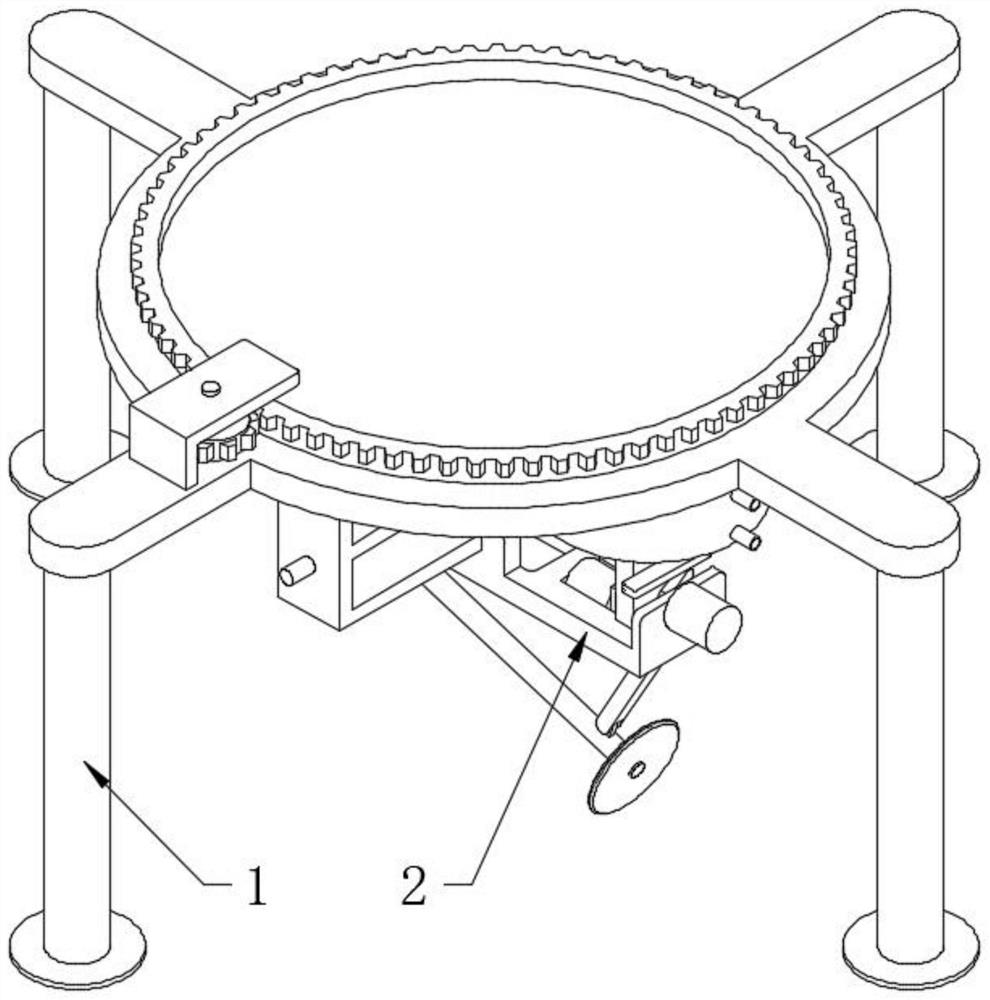

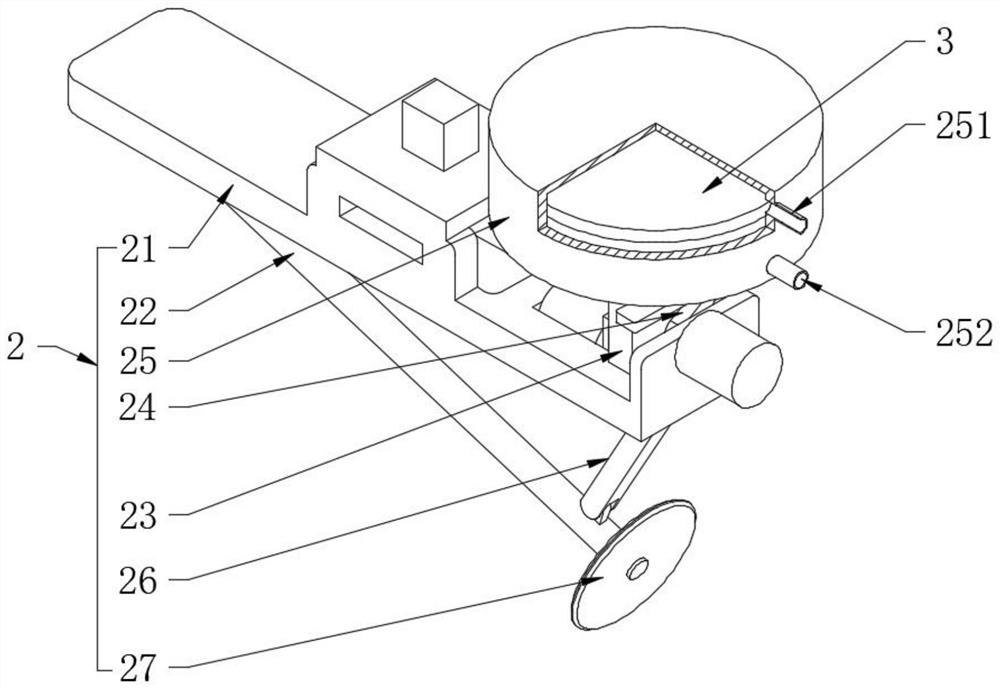

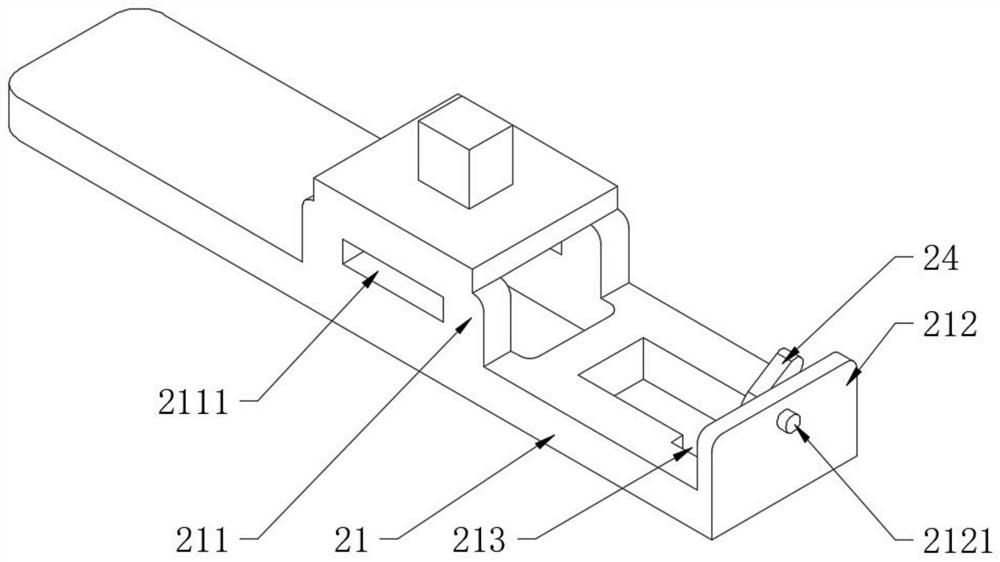

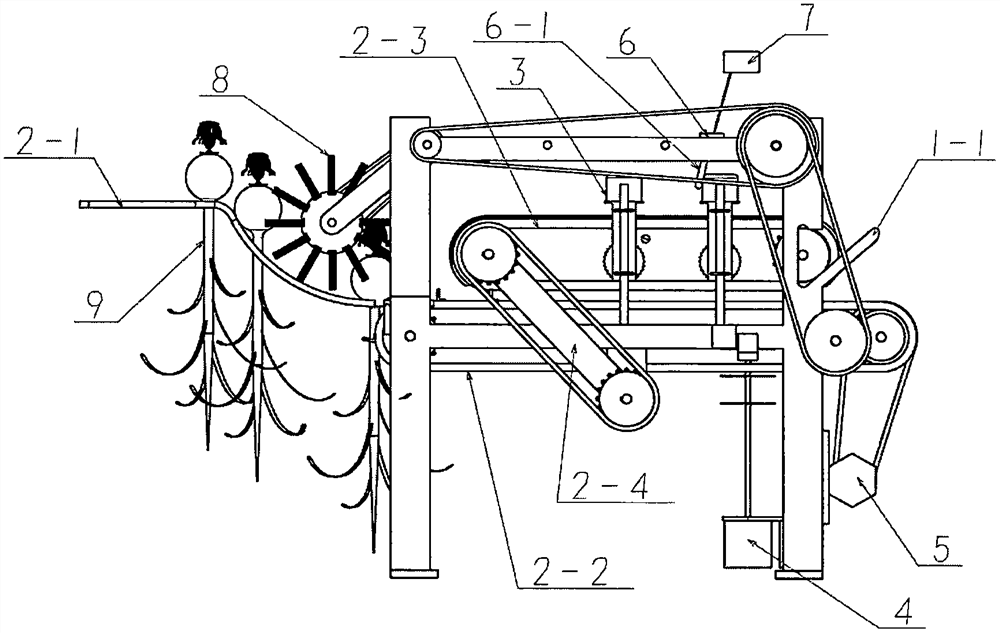

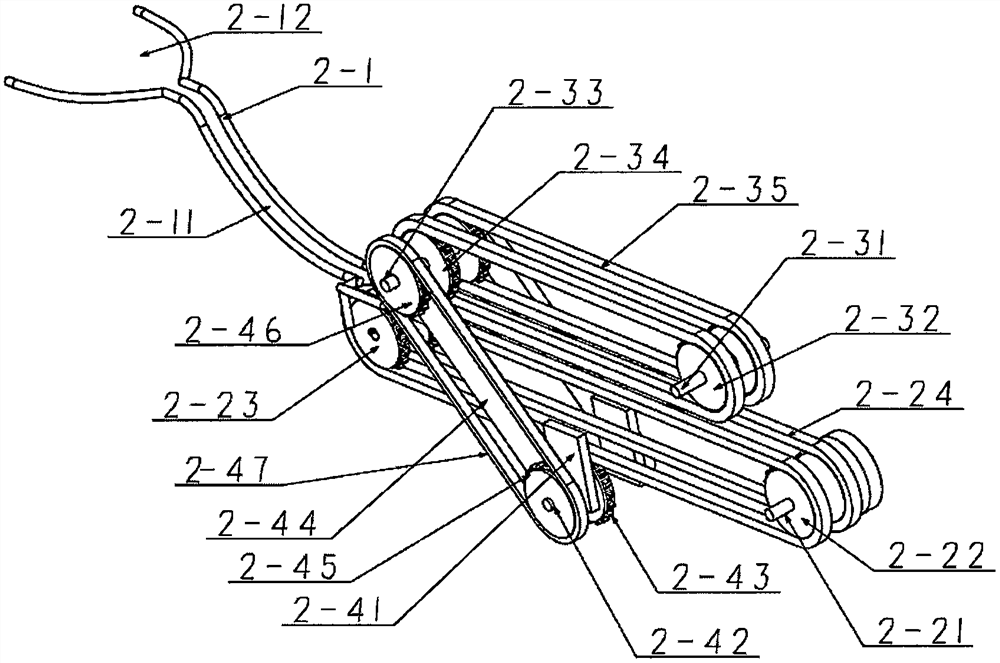

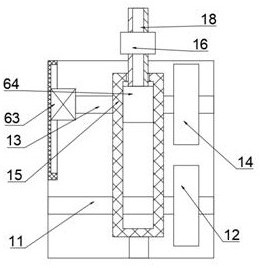

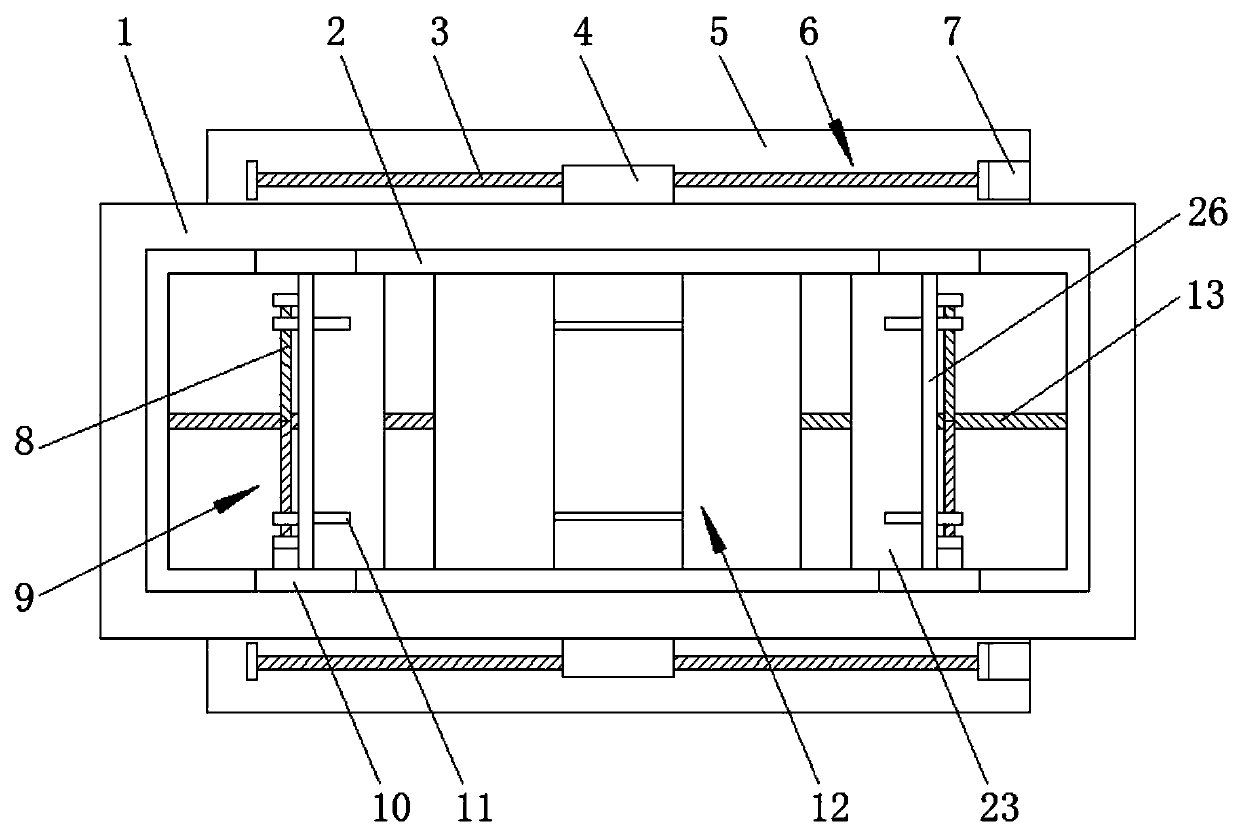

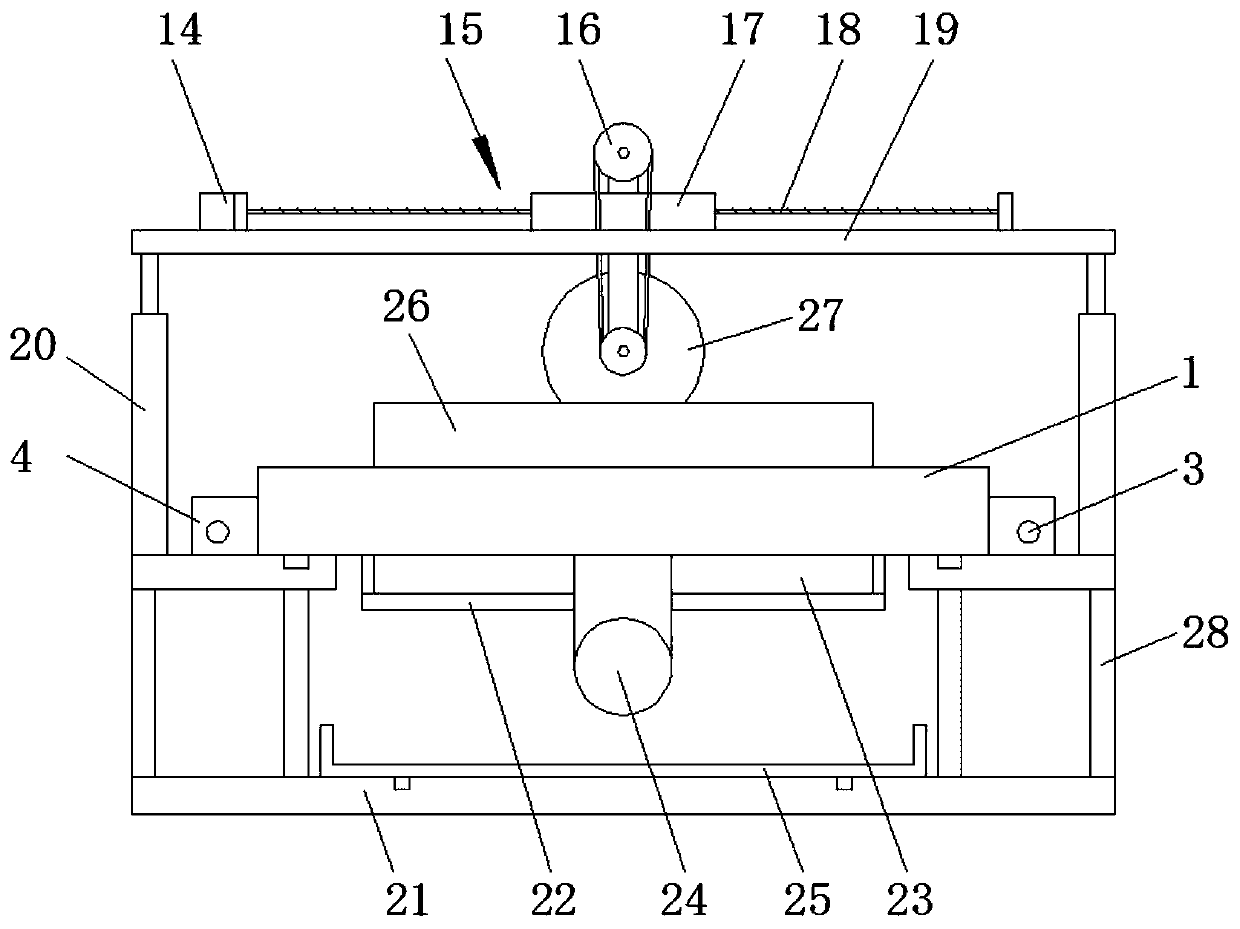

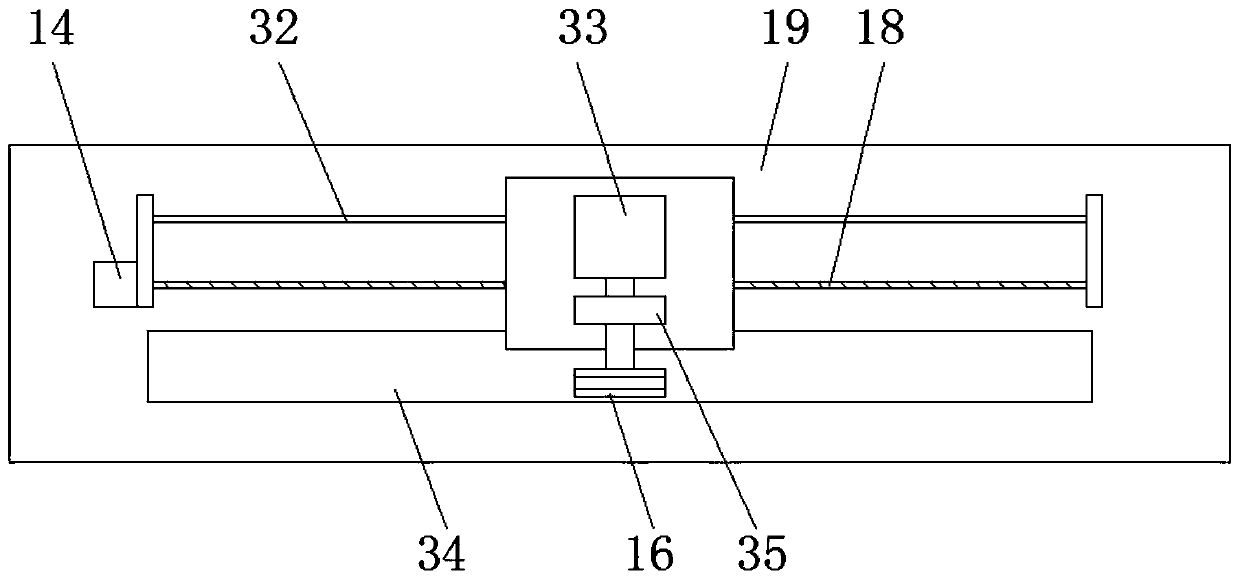

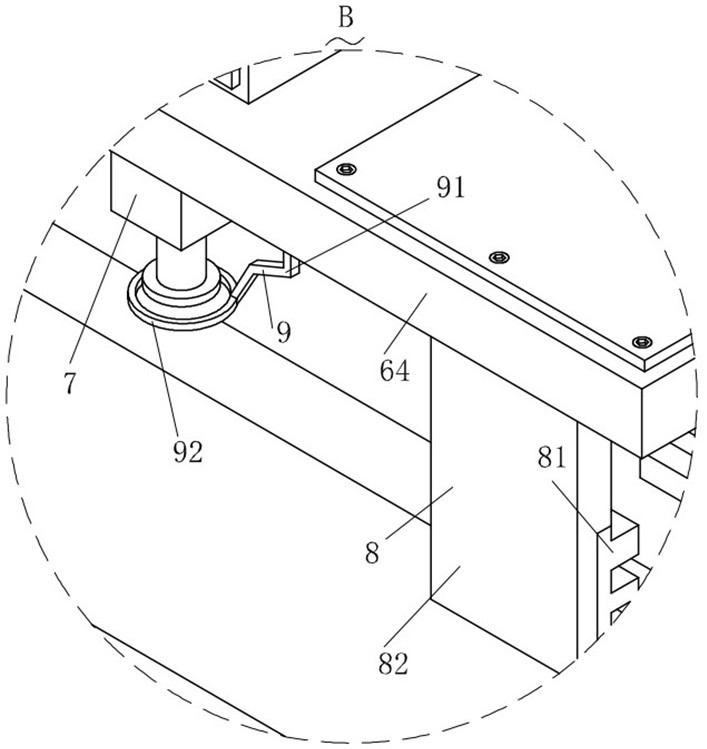

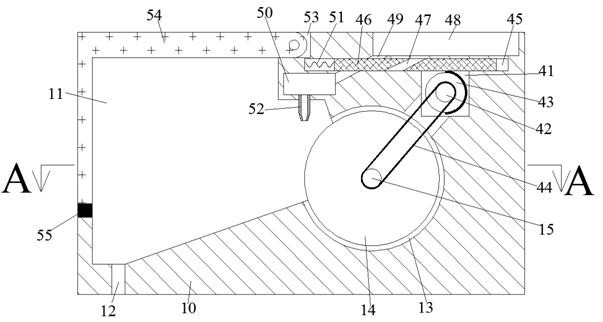

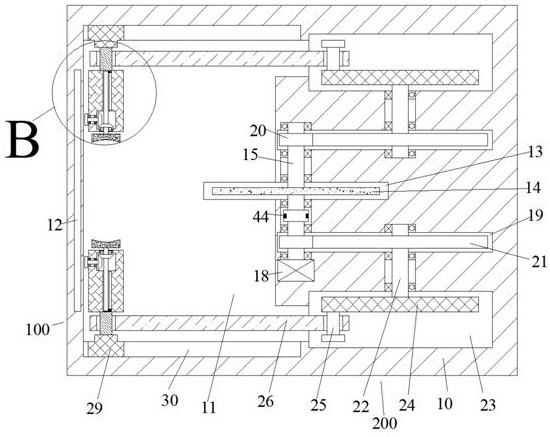

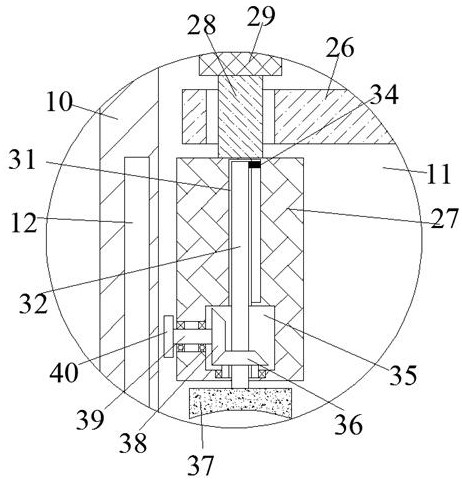

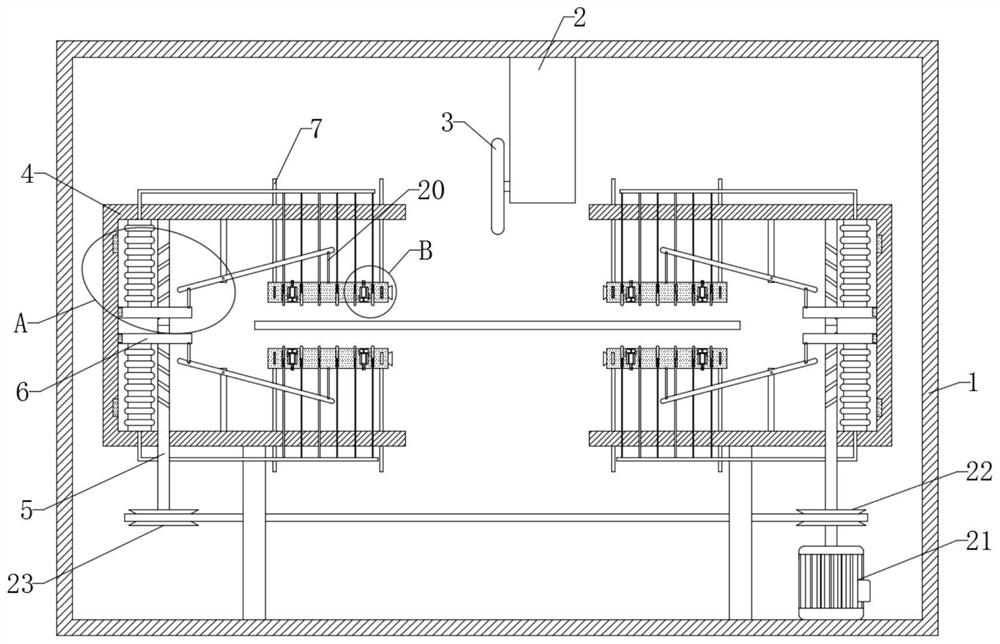

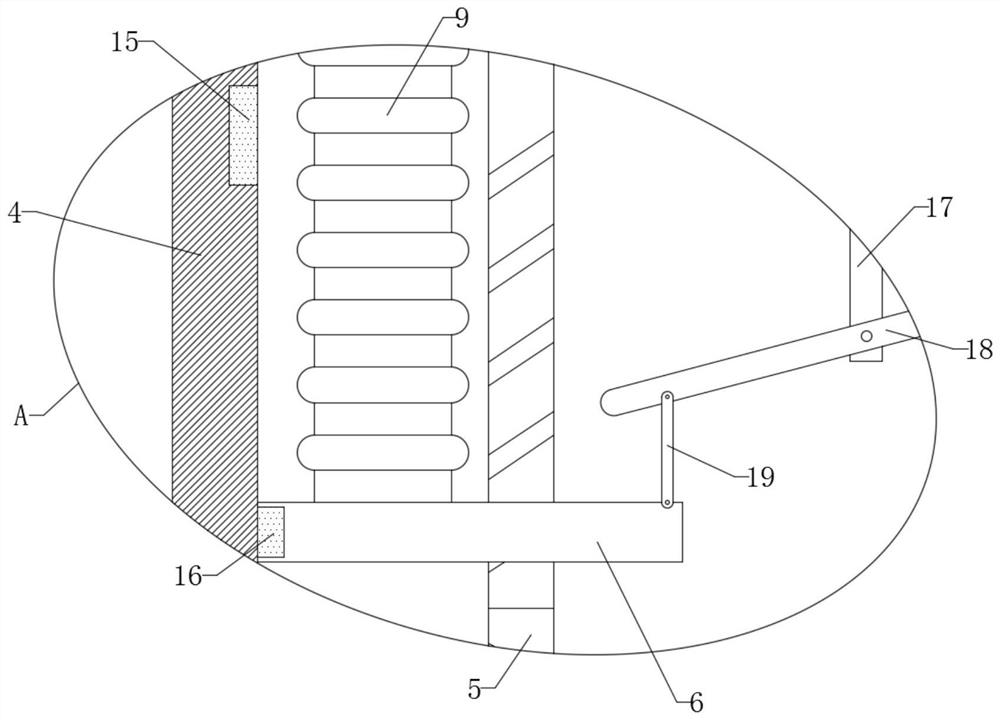

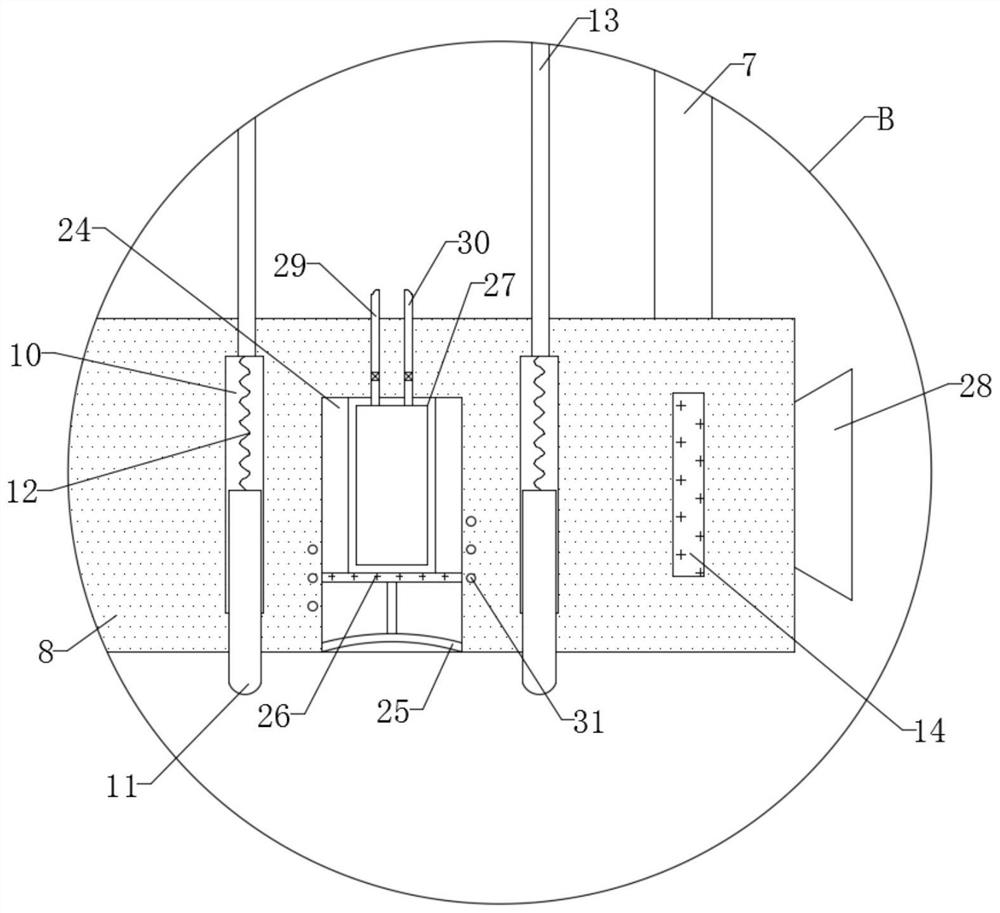

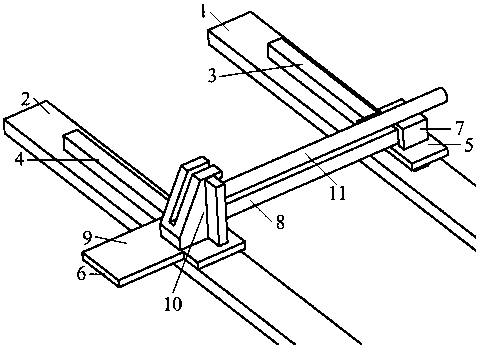

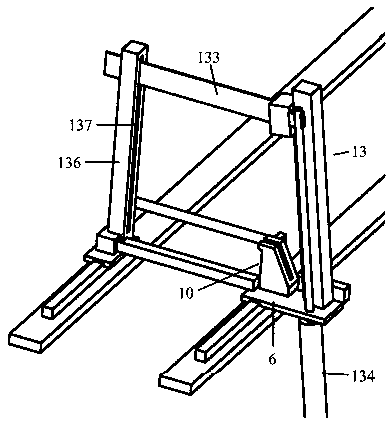

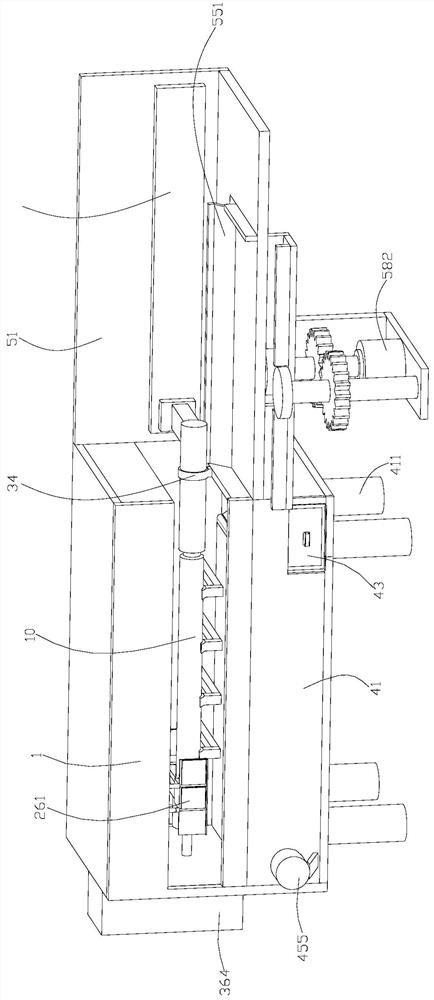

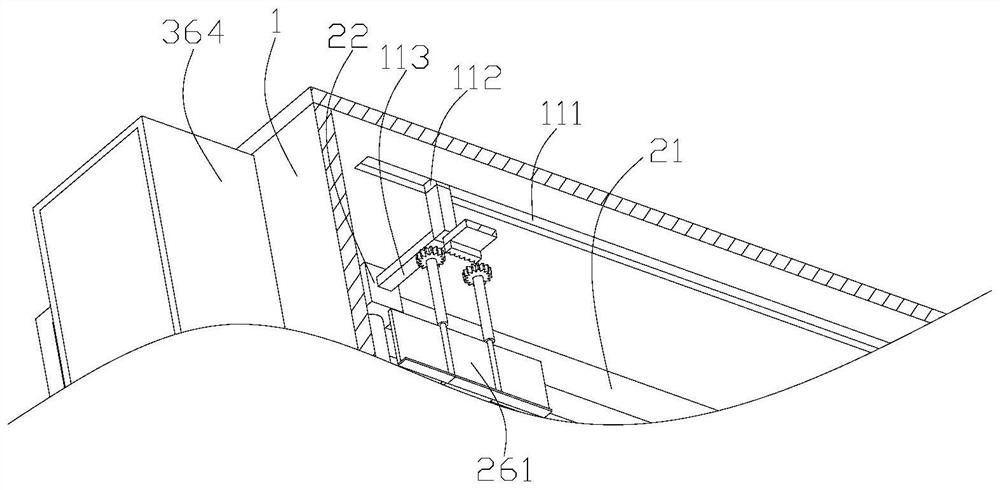

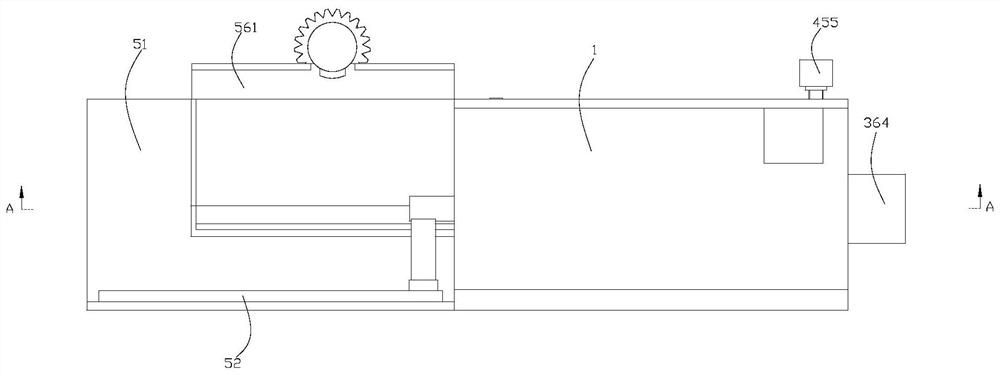

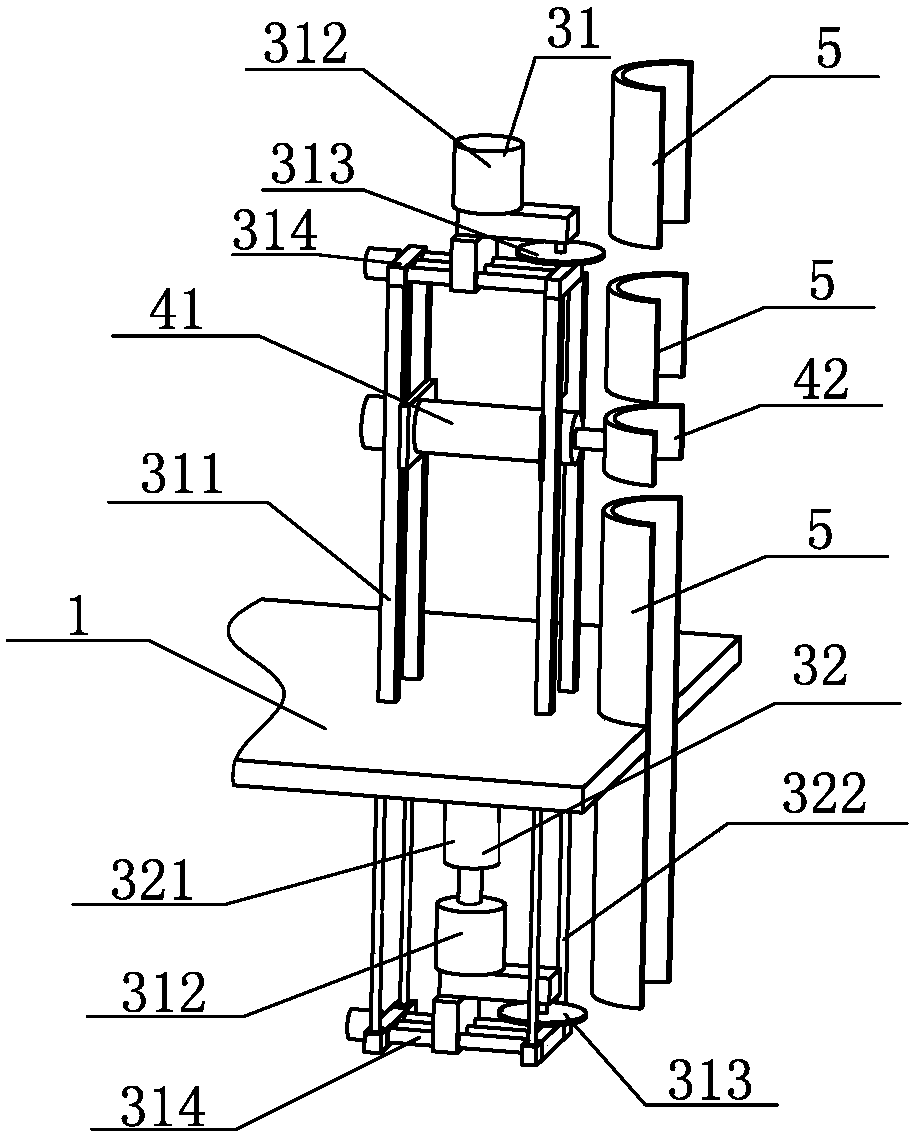

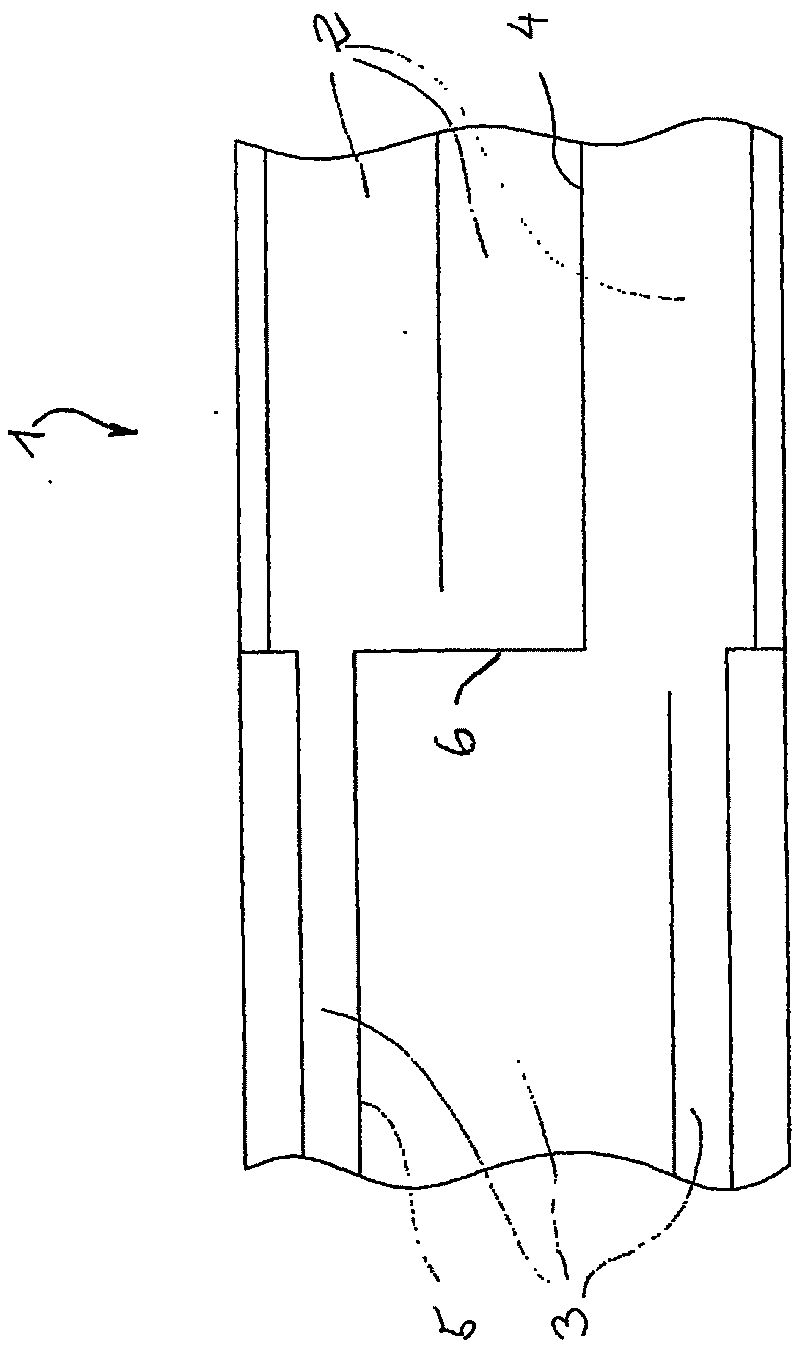

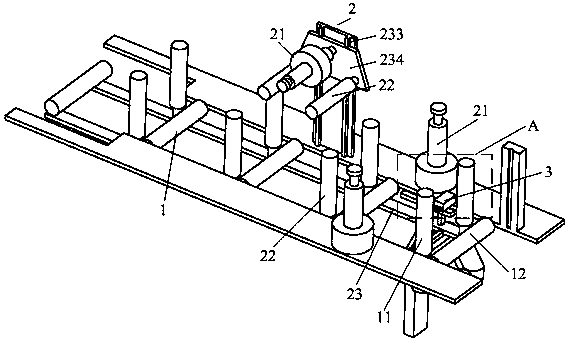

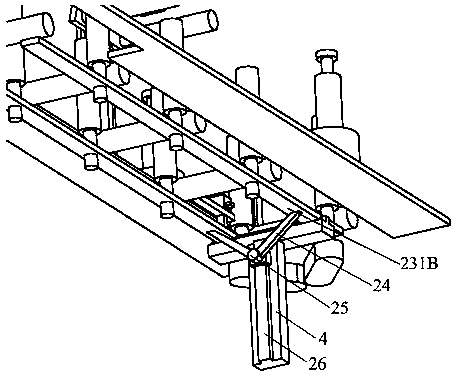

The invention discloses a novel cable cutting device for distribution line construction. The novel cable cutting device comprises a conveying device and a feeding device. The conveying device is arranged inside a support frame, a conveying mechanism transmits a cable to the right end, then the cable is transported to the upper end and enters a cutting area, meanwhile, a sliding frame on the conveying mechanism pushes a swinging mechanism, the swinging mechanism drives a cam to rotate, a material guiding plate conveys the cut cable, and therefore the advantages that the cable can be quickly pushed to the cutting area to be cut and the cutting safety is increased are achieved. The feeding device is arranged inside the support frame, when the sliding frame moves to the left end, the driving mechanism is driven to move to the left end, the driving mechanism drives a winding gear to rotate through a traction rope, the winding gear drives a motor starting mechanism to conduct transmission, a third motor is started, the third motor drives a conveyor belt to transmit the cable, and therefore the advantages that the cable is quickly transmitted and the cutting efficiency is increased are achieved.

Owner:CHONGQING ELECTRIC POWER COLLEGE

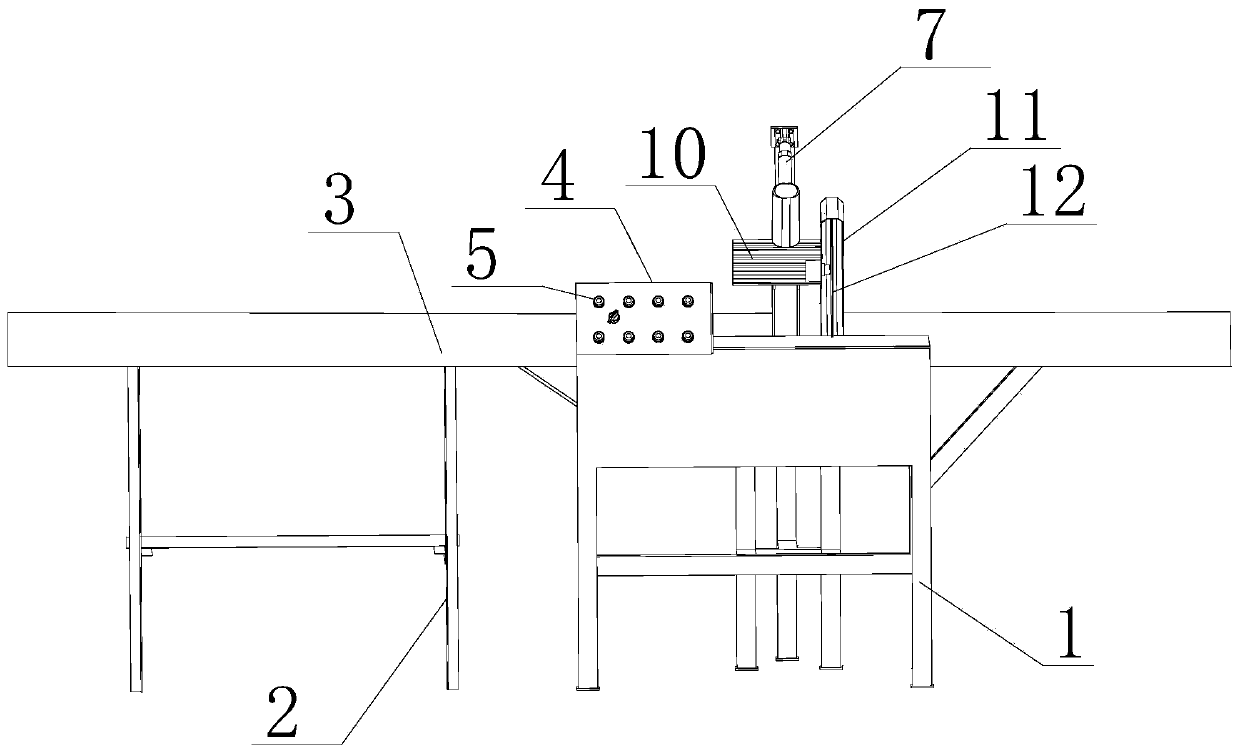

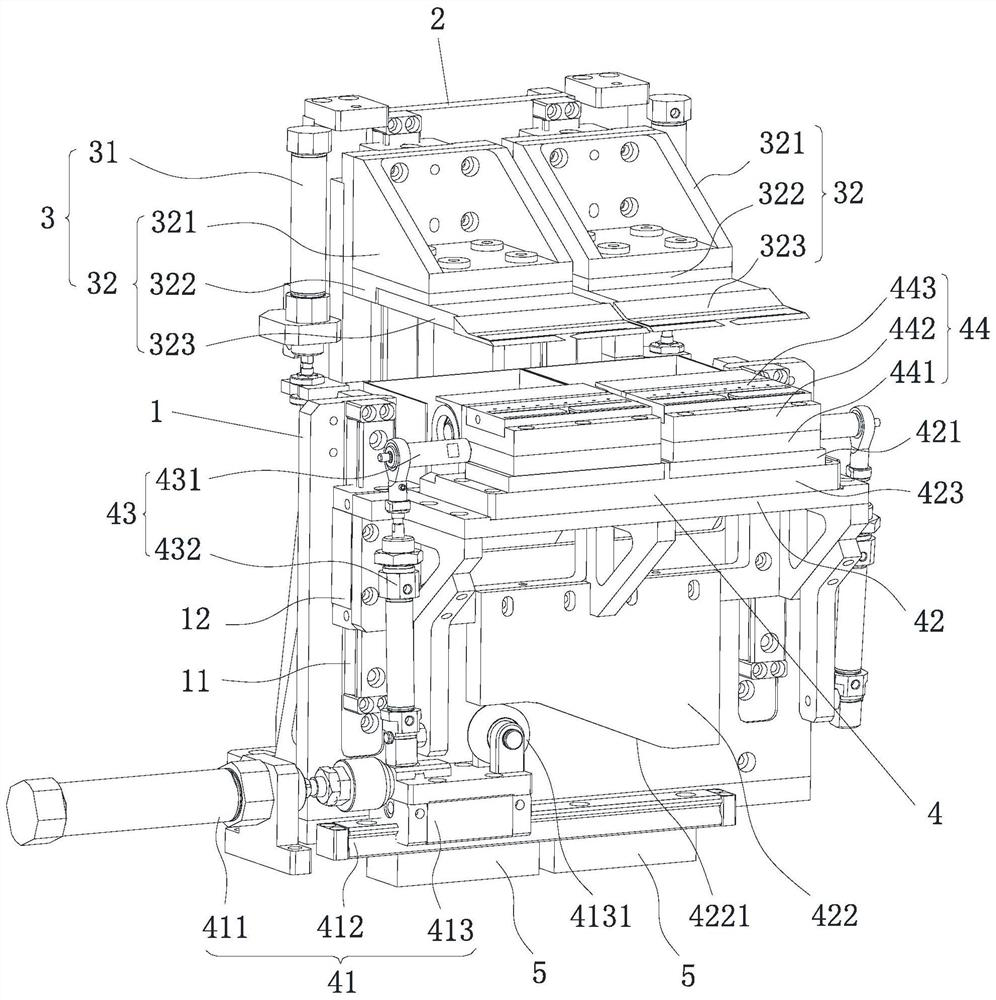

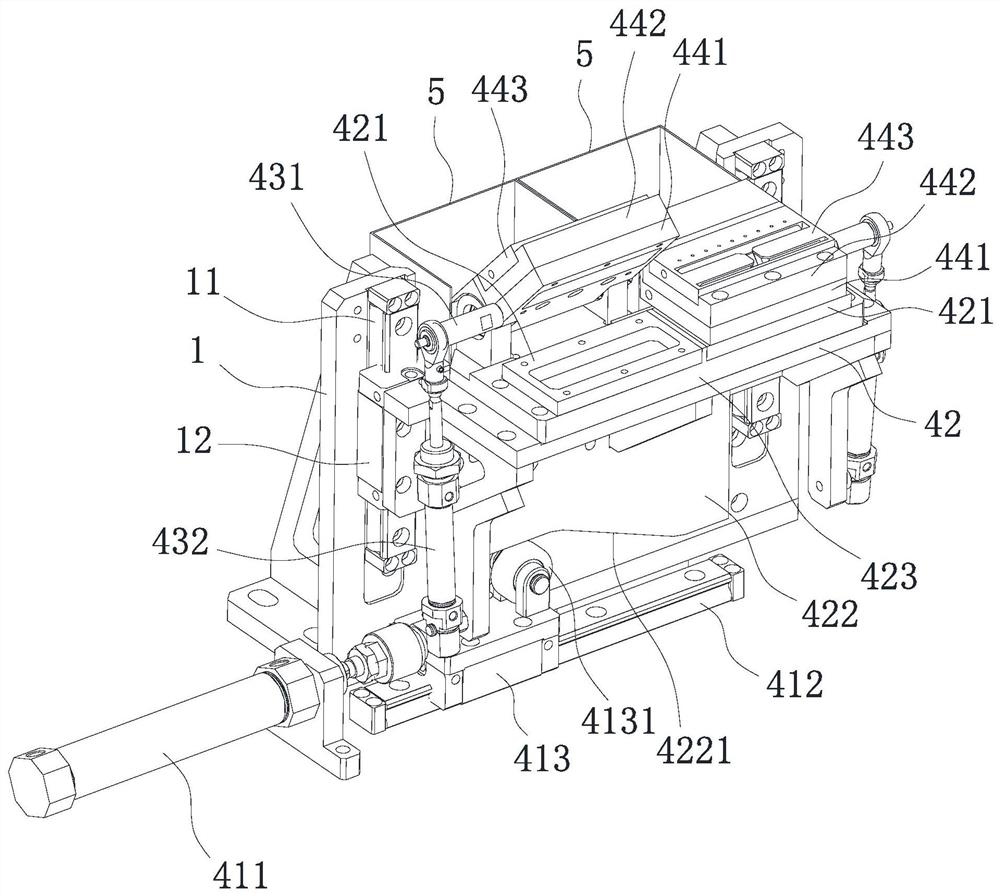

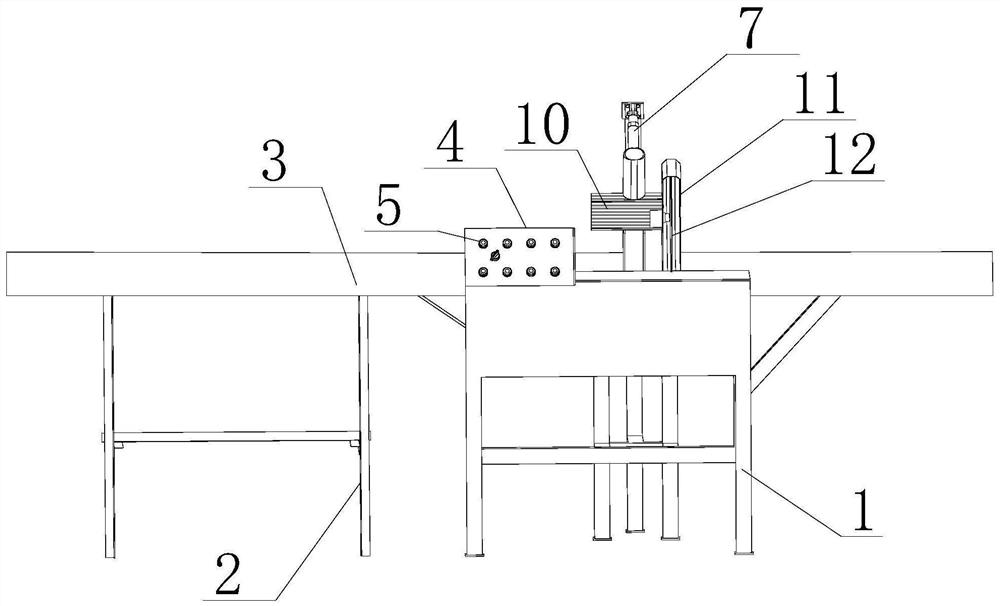

Cutting device for electrical equipment production and cutting method

InactiveCN110153489AReasonable structural designConvenient whereaboutsShearing machinesShearing machine accessoriesEngineeringElectrical equipment

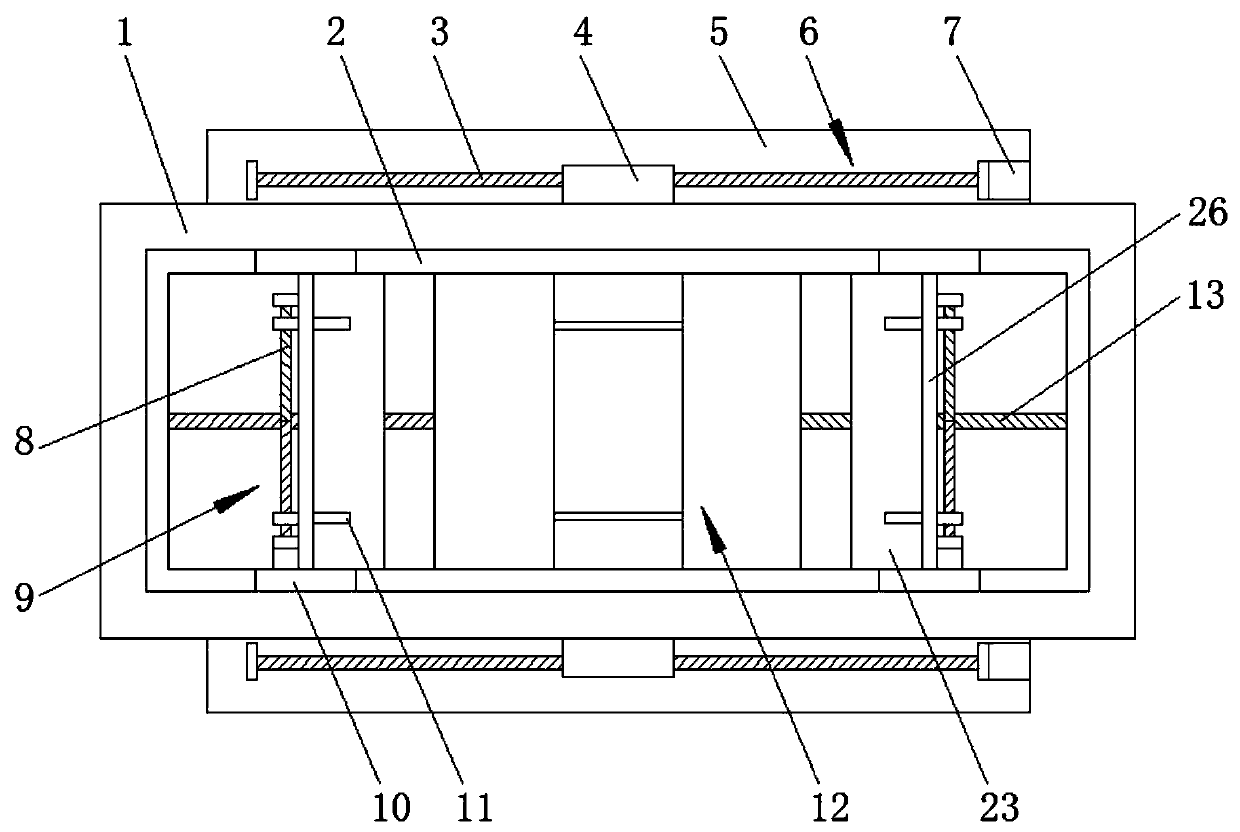

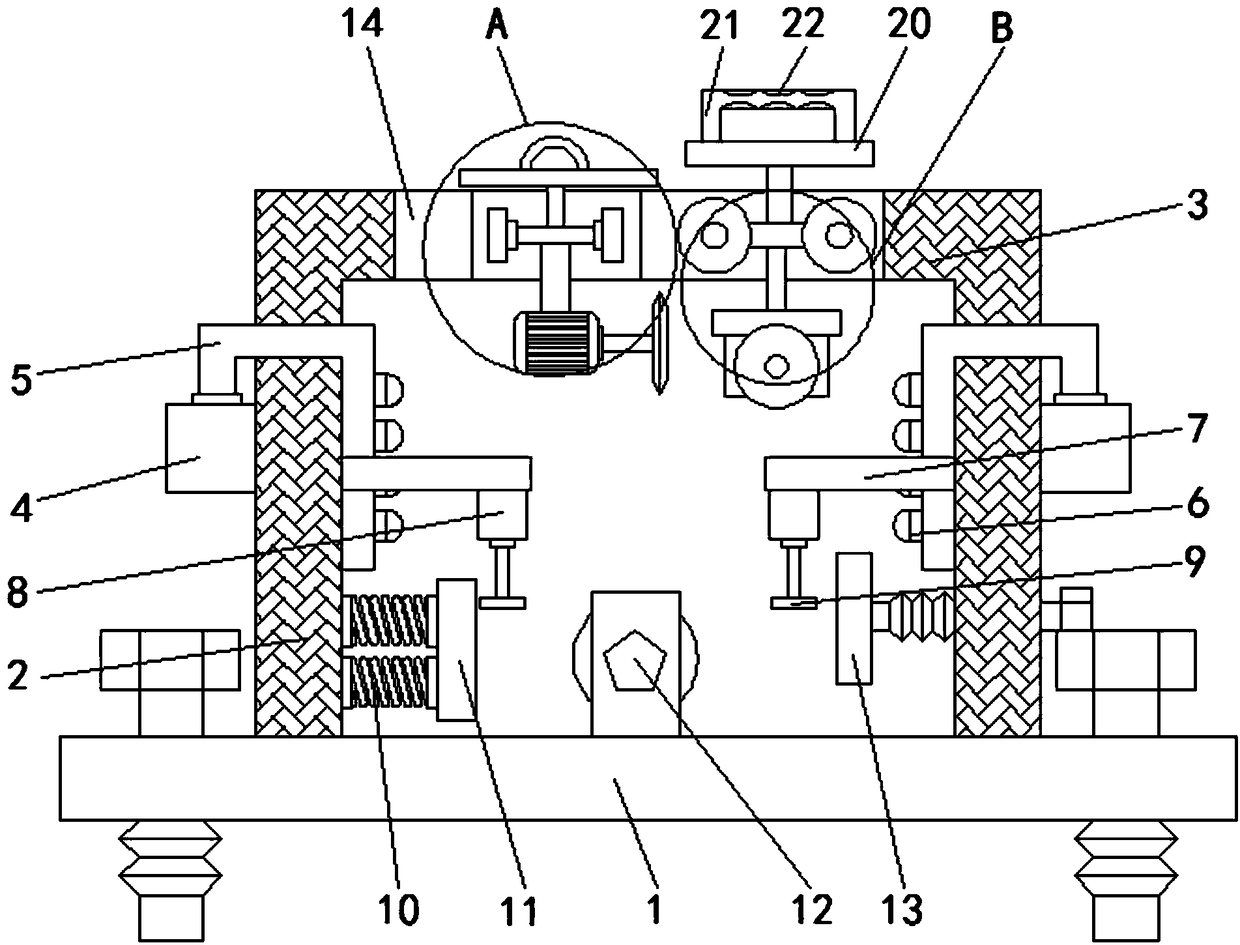

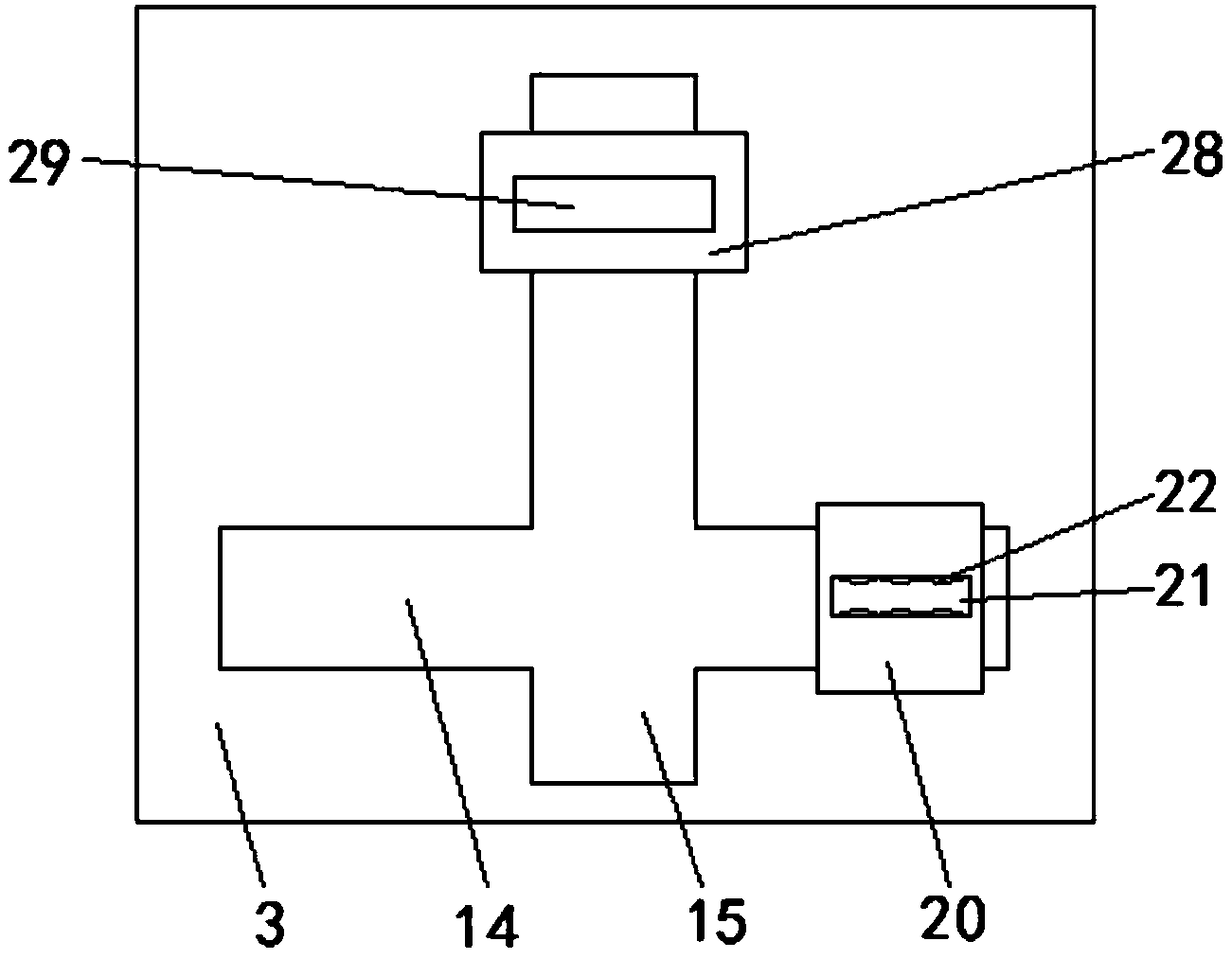

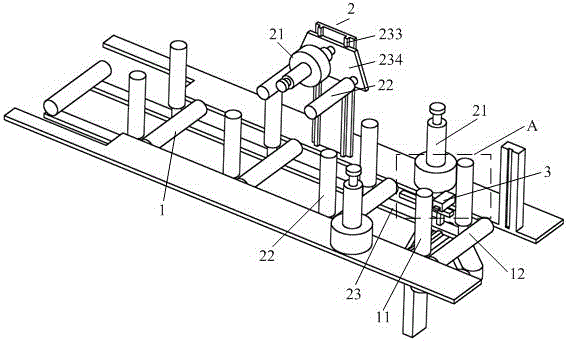

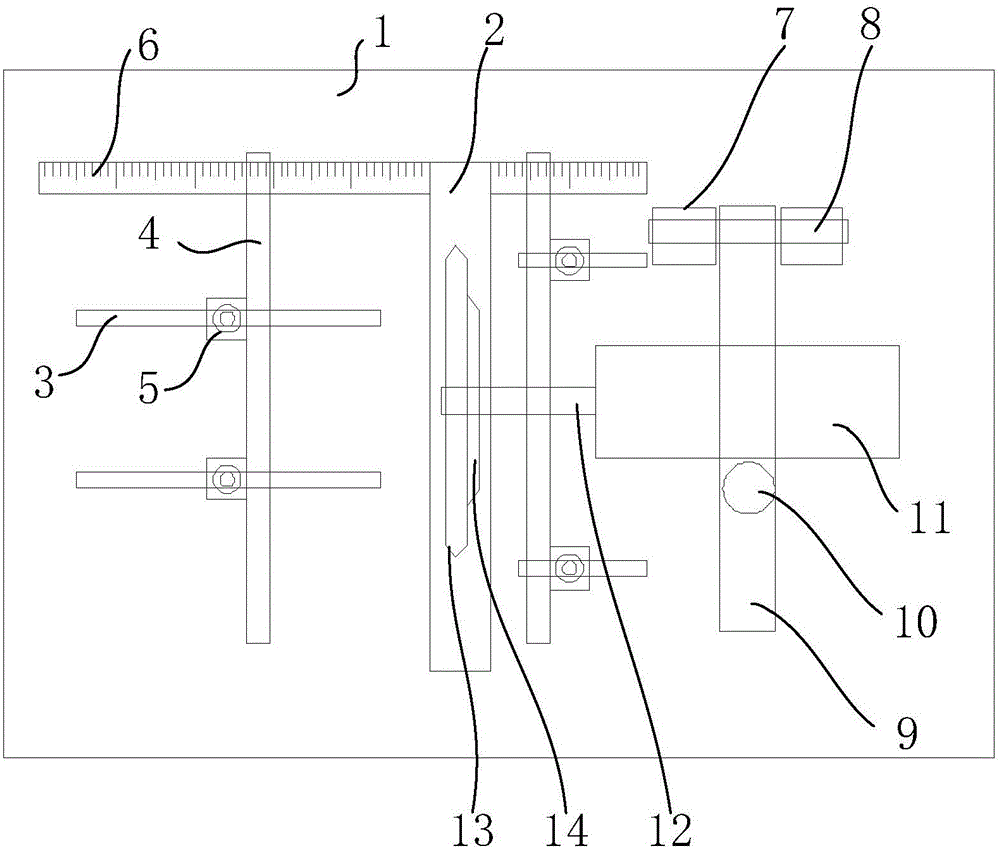

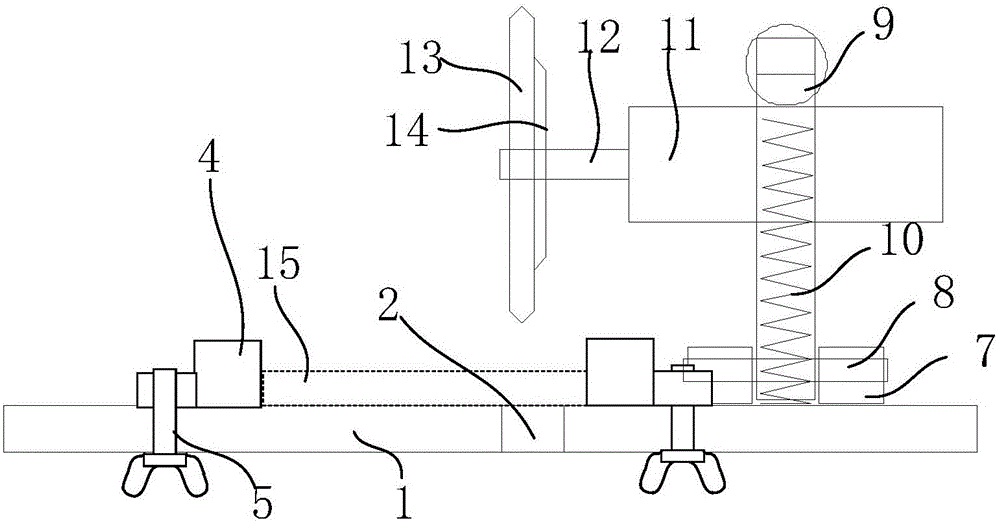

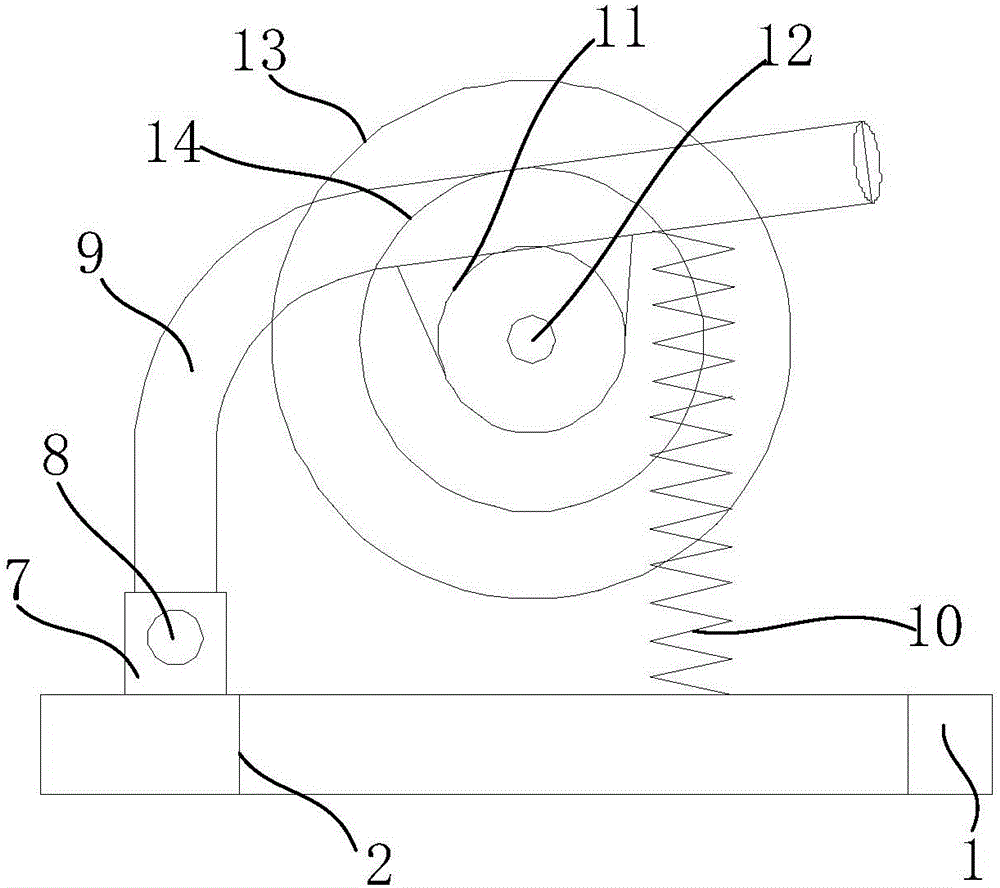

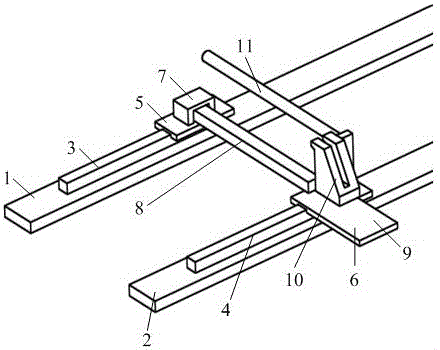

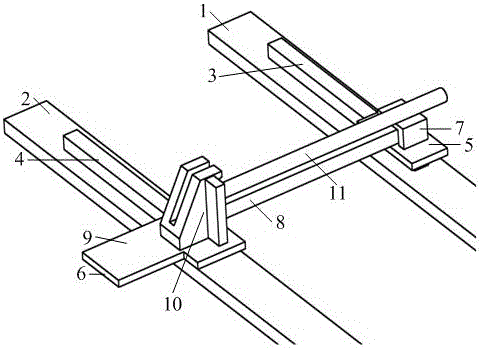

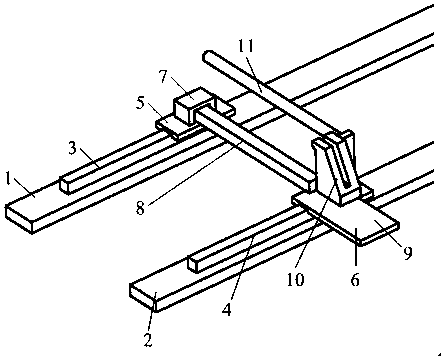

The invention discloses a cutting device for electrical equipment production. The cutting device comprises a movable framework, a longitudinal clamping assembly, a transverse clamping assembly, a workpiece moving assembly, a pre-bearing table, a movable cutting assembly and a top beam, wherein the longitudinal clamping assembly and the transverse clamping assembly are arranged at the interior of the movable framework, the transverse clamping assembly comprises two transverse clamping plates which are synchronously and reversely moved in sliding grooves, a longitudinal clamping assembly is arranged on each of the two transverse clamping plates, ech longitudinal clamping assembly comprises two longitudinal clamping plates which are synchronously and reversely moved, the pre-bearing table isfixed on the bottom end surface of the movable framework between the two transverse clamping plates through a side plate, the pre-bearing table comprises a pre-bearing plate and a limiting strip, andlifting plates used for lifting a to-be-cut workpiece on the pre-bearing plate are fixed at the bottom ends of the opposite side surfaces of the two transverse clamping plates. The cutting device forthe electrical equipment production has the advantages of being reasonable in structural design, practical, reliable and the like, and can be widely popularized and used.

Owner:QINGDAO HUANGHAI UNIV

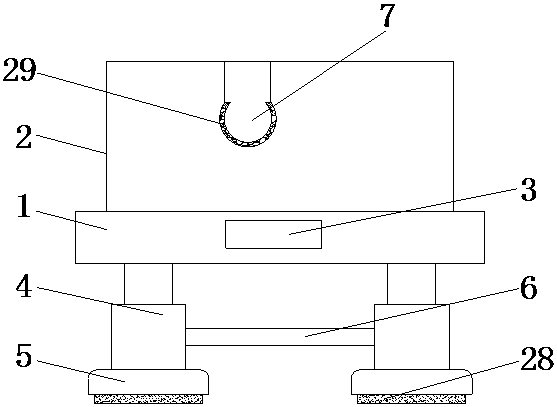

Safe wood cutting device for construction engineering

ActiveCN108466332AAvoid harmImprove securityGuide fencesProfiling/shaping machinesArchitectural engineeringMachining process

The invention relates to the technical field of construction processing equipment and discloses a safe wood cutting device for construction engineering. The device comprises a base, two supporting plates are symmetrically and fixedly connected to the left and right sides of the top of the base, and the tops of the two supporting plates are fixedly connected through a mounting plate; dust suction machines are fixedly connected to the sides, away from each other, of the two supporting plates; dust suction pipes are fixedly connected to dust inlet ends of the tops of the dust suction machine. According to the safe wood cutting device for construction engineering, through arrangement of a first sliding slot, a second sliding slot, a first roller, a second roller, an operating handle and a pushing handle, the function of indirectly controlling a cutting structure to work is achieved, the safety performance of the whole machining process is improved by indirect control, the upper and lower positions of the cutting structure are limited better, the situation that workers are hurt due to violent shaking in the cutting process is avoided, correspondingly the workers can safely perform cutting work, and therefore the effect of improving the overall cutting safety performance is achieved.

Owner:莱芜市文林土工材料有限公司

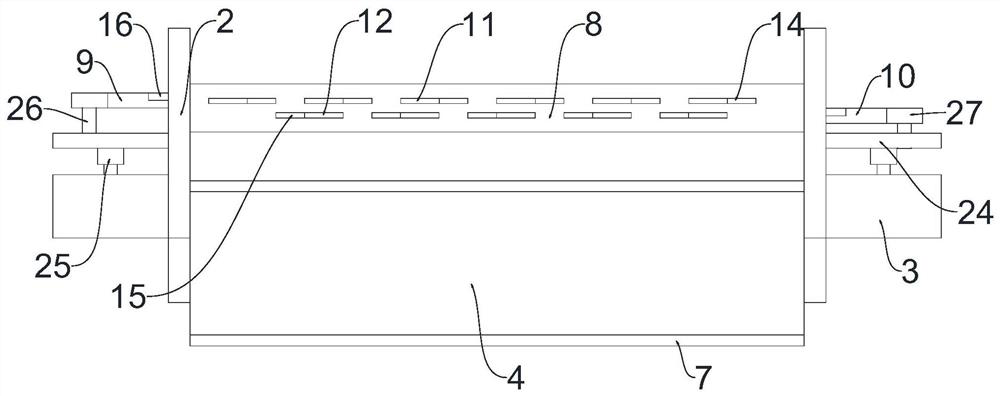

Multi-angle adjustable laser cutting machine

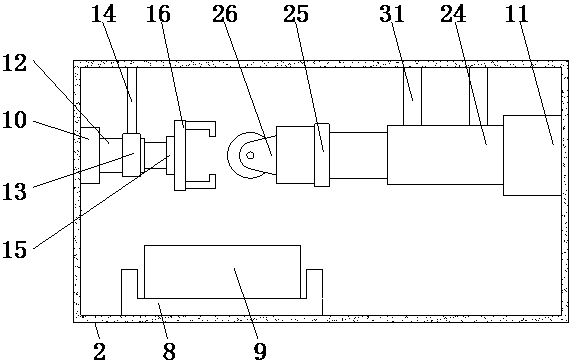

ActiveCN113369678AEasy to fold and storeImprove operational stabilityLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the technical field of laser cutting, in particular to a multi-angle adjusting laser cutting machine. The multi-angle adjusting laser cutting machine comprises a supporting structure, a length adjusting structure is arranged on the supporting structure, and rotating structures used for guiding a steel frame are arranged on the length adjusting structure and the supporting structure, a driving structure for driving one of the rotating structures is arranged on the supporting structure; the supporting structure is provided with a moving structure used for adjusting a position of a laser cutting head, and the laser cutting head is fixed to the moving structure, a storage structure for fixing a computer is arranged on the supporting structure; a position of the rotating structure on the length adjusting structure can be conveniently adjusted through the length adjusting structure, then supporting range can be conveniently adjusted, steel frames with different lengths can be conveniently cut, operation stability is improved, meanwhile, the rotating structure on the length adjusting structure can be conveniently folded and stored, and space utilization efficiency is greatly improved.

Owner:XUZHOU YIZHONG FORGING EQUIP

Iron rod polishing equipment with convenient discharge function

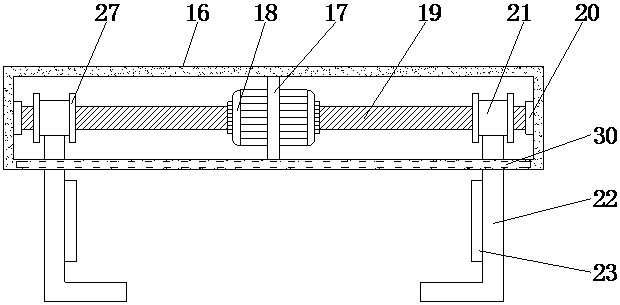

ActiveCN109909861AImprove grinding efficiencyAvoid harmGrinding carriagesPolishing machinesScrapElectromagnet

The invention discloses iron rod polishing equipment with a convenient discharge function. The iron rod polishing equipment comprises a box body, a grinding device arranged in the box body, a clampingdevice used for clamping an iron rod, a waste chip collecting device arranged at the outer bottom of the box body, and a discharging device used for discharging the iron rod; and the discharging device comprises a frame body arranged on one side of the box body, a third driving piece arranged on the frame body, a fixing rod with one end connected with the third driving piece, a dragging rod connected with the other end of the fixing rod, a material receiving assembly arranged on the frame body and a transmission assembly matched with the material receiving assembly, wherein a second electromagnet is arranged at one end of the dragging rod. According to the equipment, the iron rod can be comprehensively and efficiently polished, in the polishing process, scrap iron fallen from the iron rodcan be removed in time, polished iron rod can be discharged automatically, the polishing efficiency is improved, in addition, operation is simple in the whole process, discharging is rapid and stable, and the safety is high.

Owner:安徽伟迈信息技术有限公司

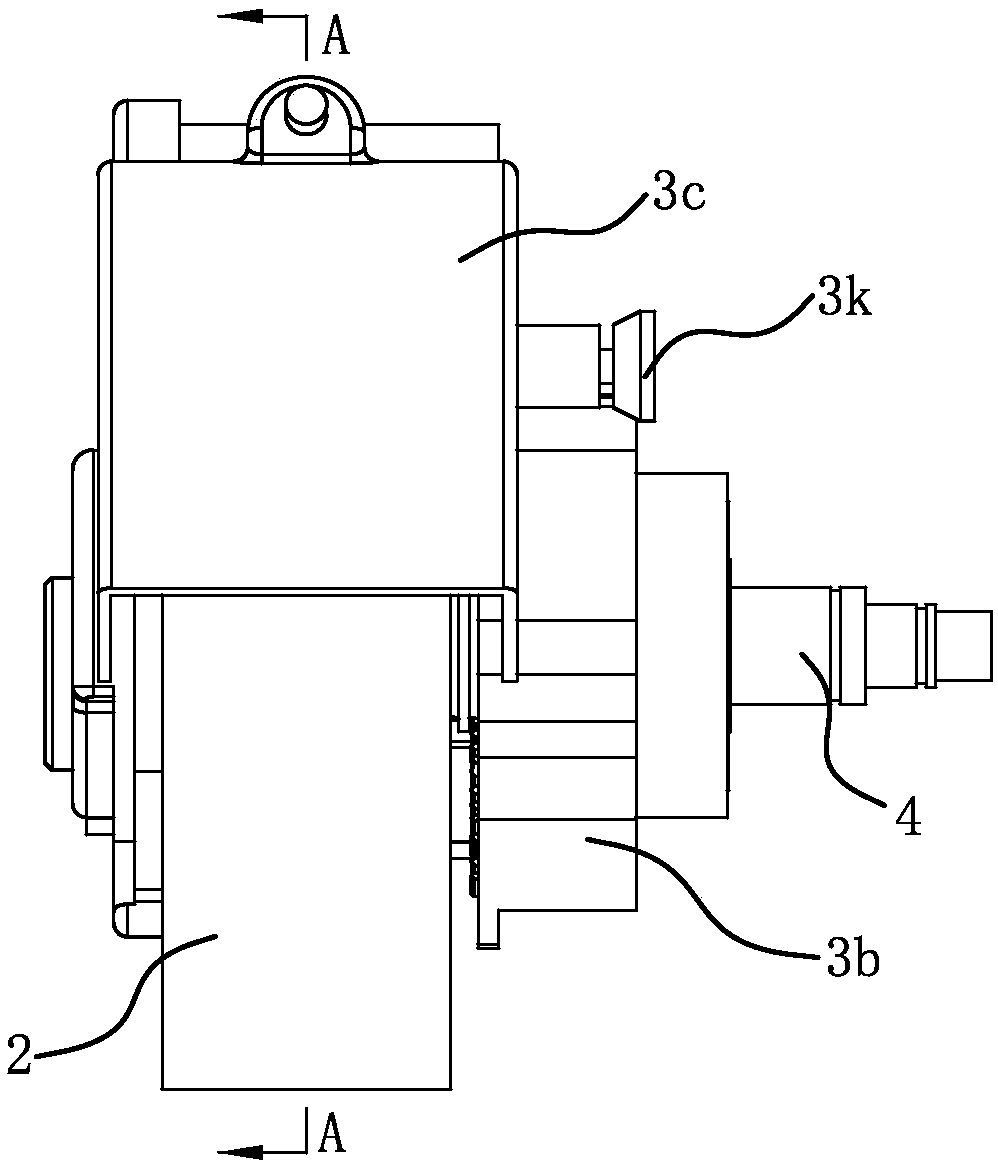

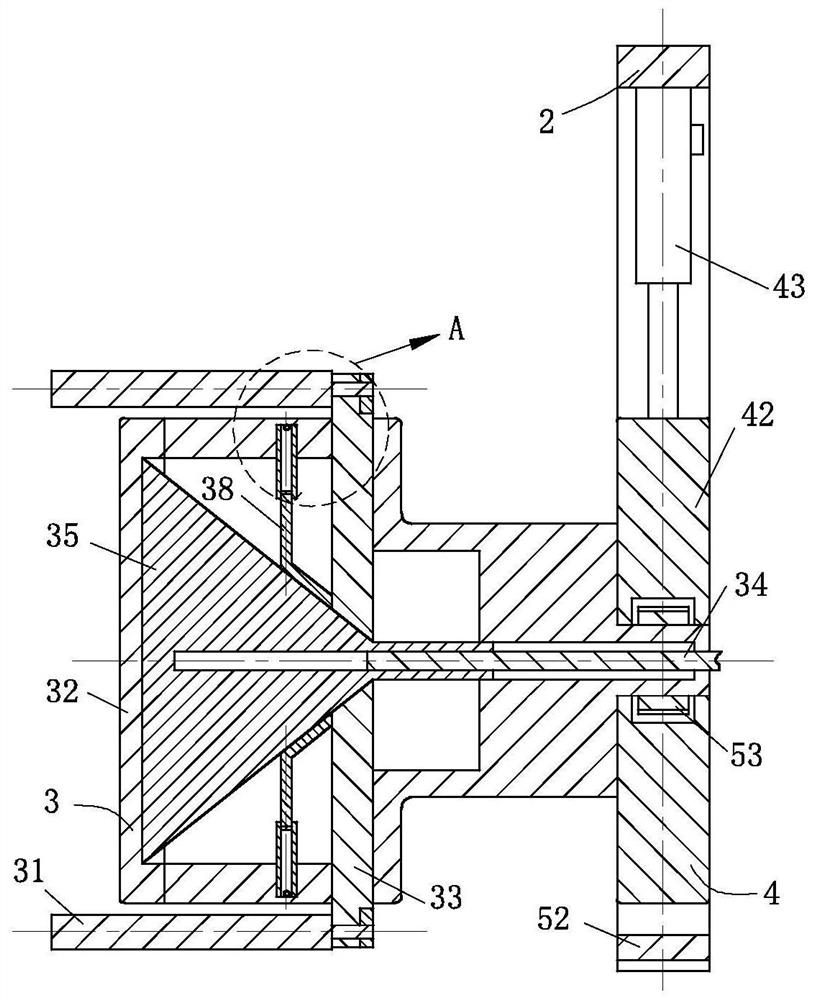

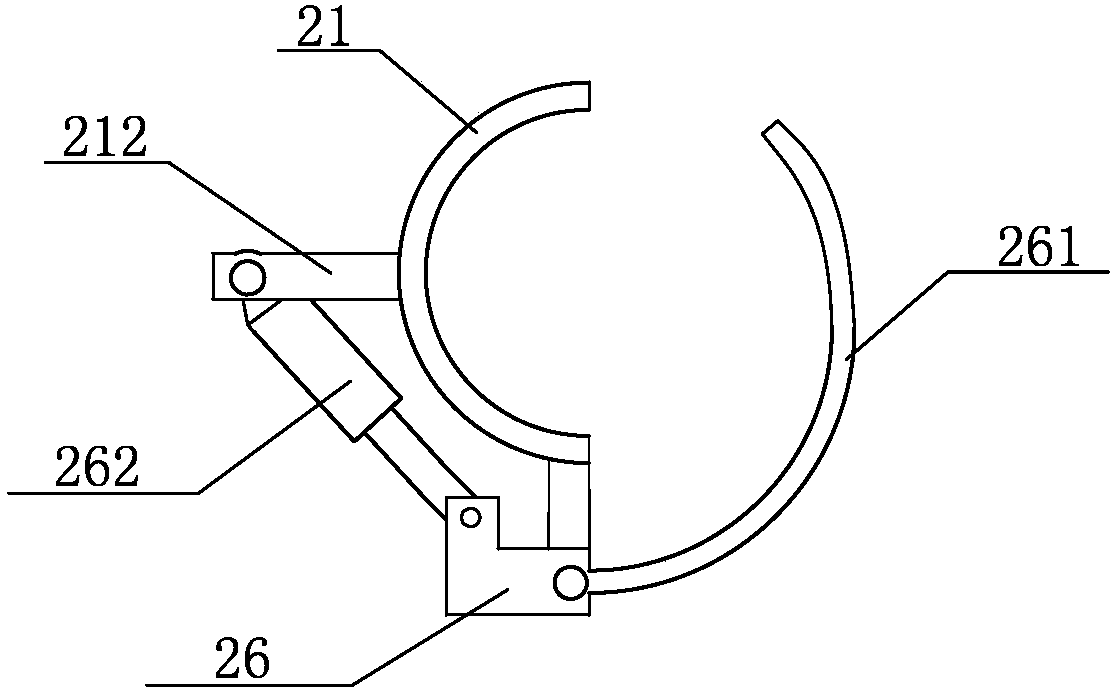

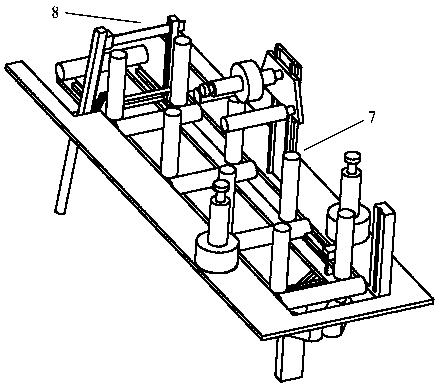

Device for vertically cutting concrete pole in segmented mode

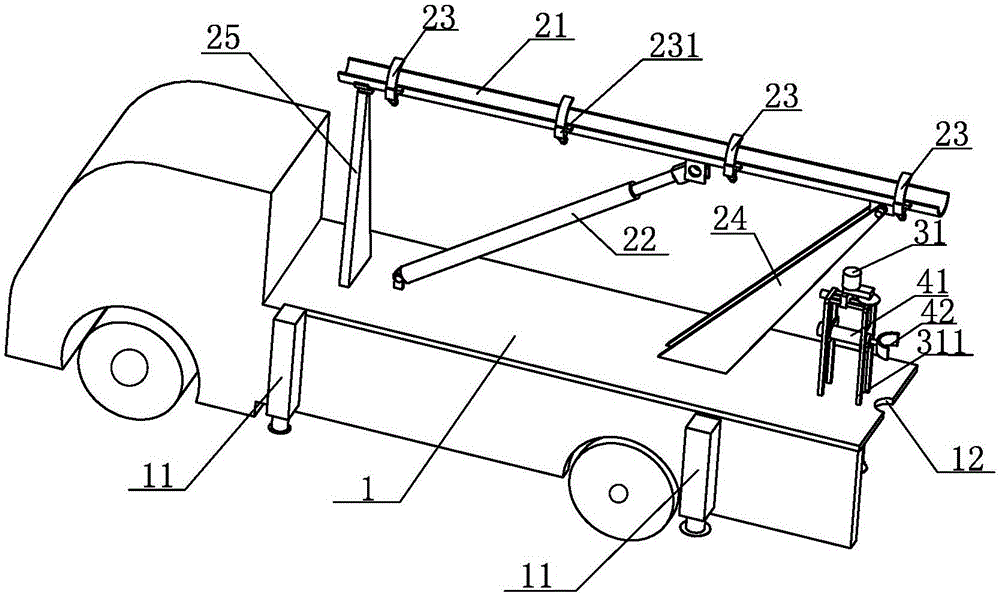

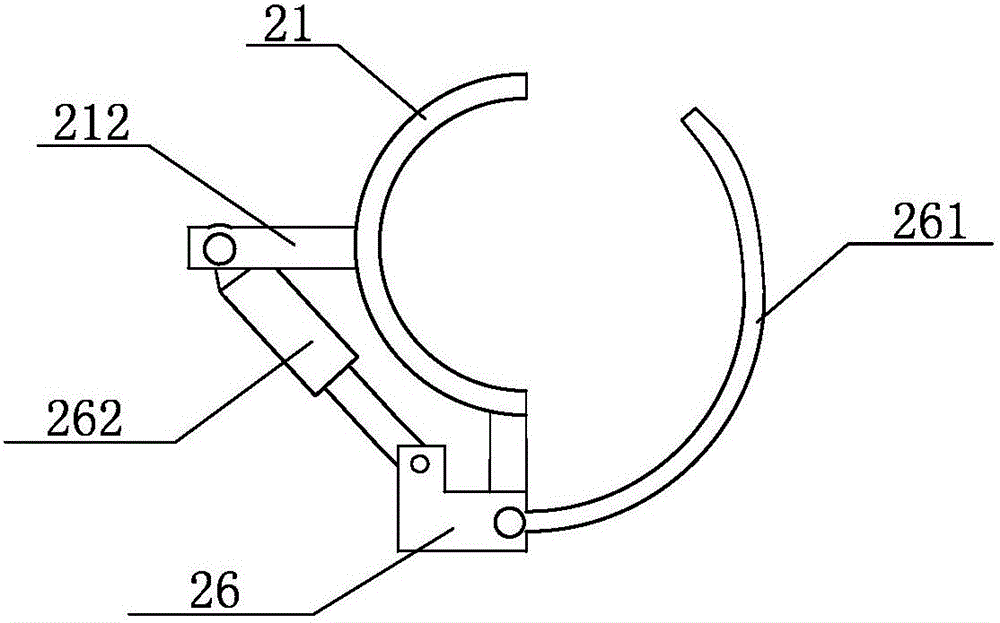

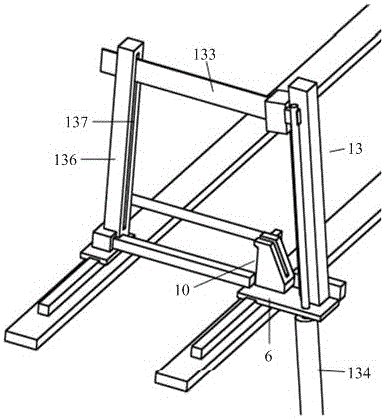

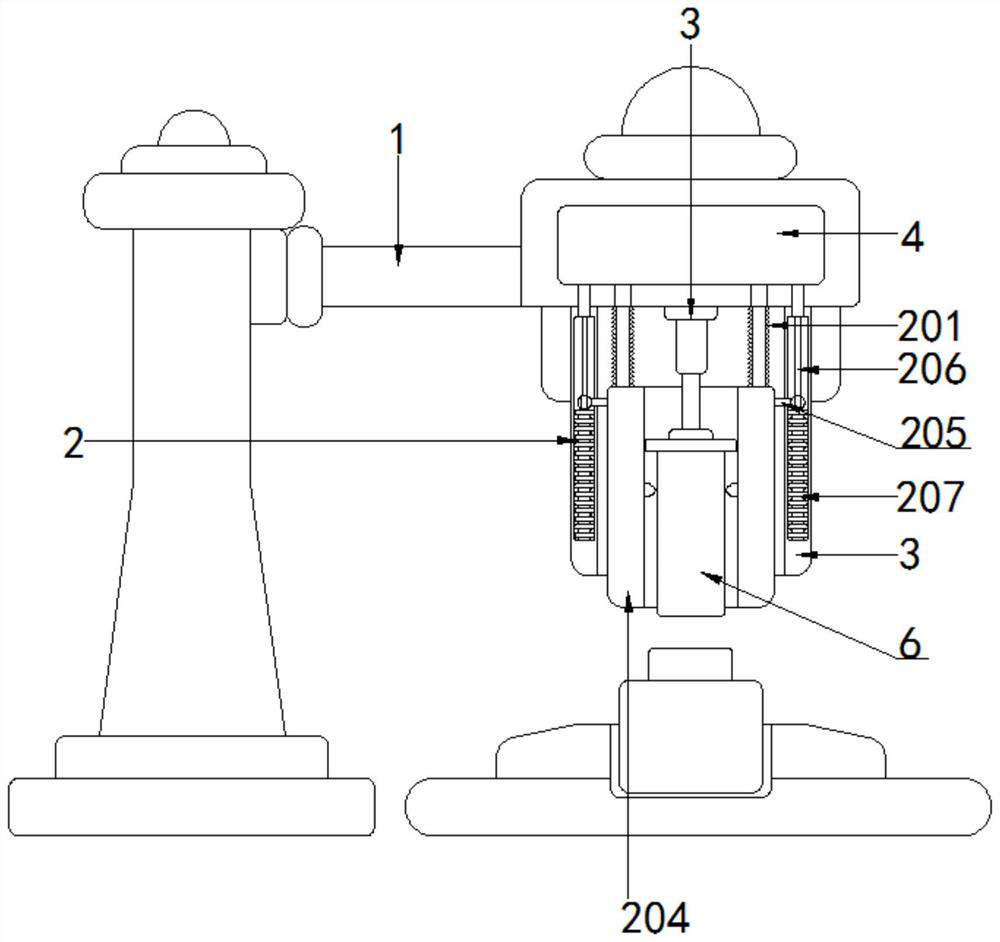

ActiveCN106273004AIncreased cutting safetyAvoid leaningWorking accessoriesStone-like material working toolsDrive motorEngineering

The invention provides a device for vertically cutting a concrete pole in a segmented mode. The device comprises a vehicle-mounted chassis, a surrounding device and a cutting mechanism; telescopic hydraulic support legs are oppositely arranged on the two sides of the vehicle-mounted chassis, the surrounding device comprises an arc-shaped surrounding plate, a first hydraulic oil cylinder, a rotating support frame and a flatwise placing support frame, the cutting mechanism comprises an upper cutting device and a lower cutting device, the upper cutting device and the lower cutting device each comprises a cutting assembly, and each cutting assembly comprises a driving motor, a cutting blade and a screw transmission mechanism, wherein the driving motor adopts belt transmission to drive the cutting blade, and the driving motor and the cutting blade are both fixedly arranged on a mobile sliding block of the screw transmission mechanism. According to the device, the arc-shaped surrounding plate can vertically fix the waste concrete pole, the pole cannot be tilted after the bottom end of the pole is cut off, and therefore accidents are avoided; the cutting mechanism can achieve segmented cutting on the pole along with continuous downward movement of the pole in the arc-shaped surrounding plate, and the cut pole is beneficial for transportation.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

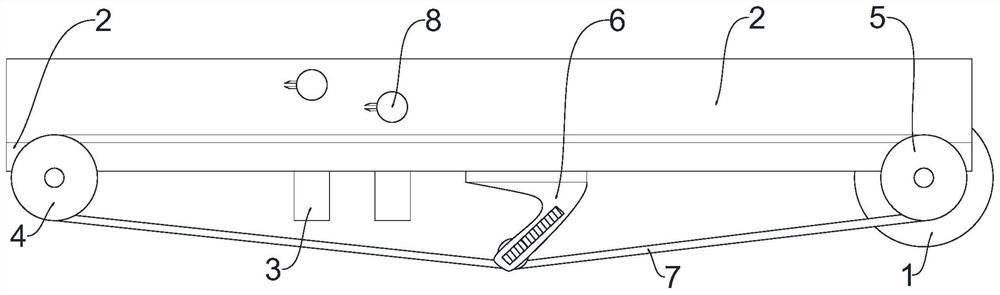

Full-automatic aluminum product laminating machine

ActiveCN106240897AImprove film application efficiencyFacilitate automatic breakingPackagingTectorial membraneEngineering

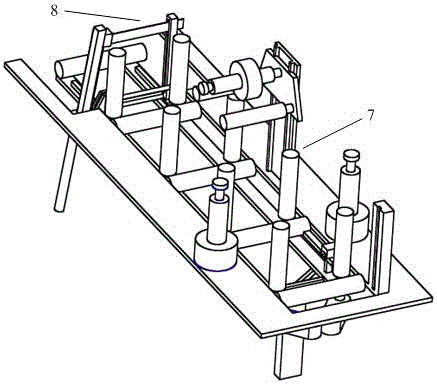

The invention provides a full-automatic aluminum product laminating machine. The full-automatic aluminum product laminating machine comprises a laminating mechanism and a protective film cutting-off mechanism. The laminating mechanism comprises conveying mechanisms, laminating assemblies arranged on the laminating side of aluminum products and feeding interval limiting mechanisms. Each laminating assembly comprises a rotating sleeve and laminating rollers. The laminating rollers are arranged on moving mechanisms. When laminating is conducted, the moving mechanisms can drive the laminating rollers to be attached to the lamination surfaces of the aluminum products, and laminating can be continuously conducted on the aluminum products of different sizes and shapes. In this way, the full-automatic aluminum product laminating machine is high in laminating efficiency and wide in application range. A cutter installed on a cutter installation platform can synchronously move along with the aluminum products, the cutter is always aligned to the interval between every two adjacent aluminum products in the cutting process, and therefore both the cutting efficiency and the cutting safety are improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

Automatic reset two-directional clamping-type grinder

InactiveCN106042197ARealize fixed distance cuttingPrevent movementEdge grinding machinesWorking accessoriesEngineeringDrive motor

The invention discloses an automatic reset two-way clamping grinding machine, which comprises a table top with a cutting groove, at least two clamping guide grooves set on the table tops on both sides of the cutting groove and perpendicular to the direction of the cutting groove , the clamping bars straddling all the clamping guide grooves on the same side of the cutting groove, the adjusting screws connected to the corresponding clamping bars through each clamping guide groove, and the scale set along the direction of the clamping guide groove , the fixed shaft frame arranged beside the cutting groove on the table, the rocker arm frame connected with the fixed shaft frame, the force spring, the driving motor, as well as the cutting disc and the grinding disc. The invention realizes the clamping and fixing of tiles during cutting by setting clamping strips on the cutting table of the cutting machine, avoids the movement of tiles due to cutting force, improves cutting safety, and uses the adjustable function of the clamping strips to change the tiles The positioning distance can achieve fixed-distance cutting of tiles, reducing the special marking process during tile cutting and improving work efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

Automatic cutting device

InactiveCN106695975AShorten the lengthIncrease flexibilityMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic cutting device. The automatic cutting device comprises a first rack, a second rack, a controller, a first clamping device, a second clamping device, a cutting assembly, a displacement sensor and a telescopic device. The first rack and the second rack are sequentially arranged from front to rear. The cutting assembly and the first clamping device are arranged on the first rack. The second clamping device is arranged on the second rack. The displacement sensor is in output connection with the controller. The controller is in output connection with the first clamping device, the second clamping device and the cutting assembly. The telescopic device is located between the first rack and the second rack. The automatic cutting device has the beneficial effects of being high in cutting precision, flexibility and efficiency, capable of lowering the cutting strength and good in cutting safety and is applied to the technical field of cutting.

Owner:刘程杰

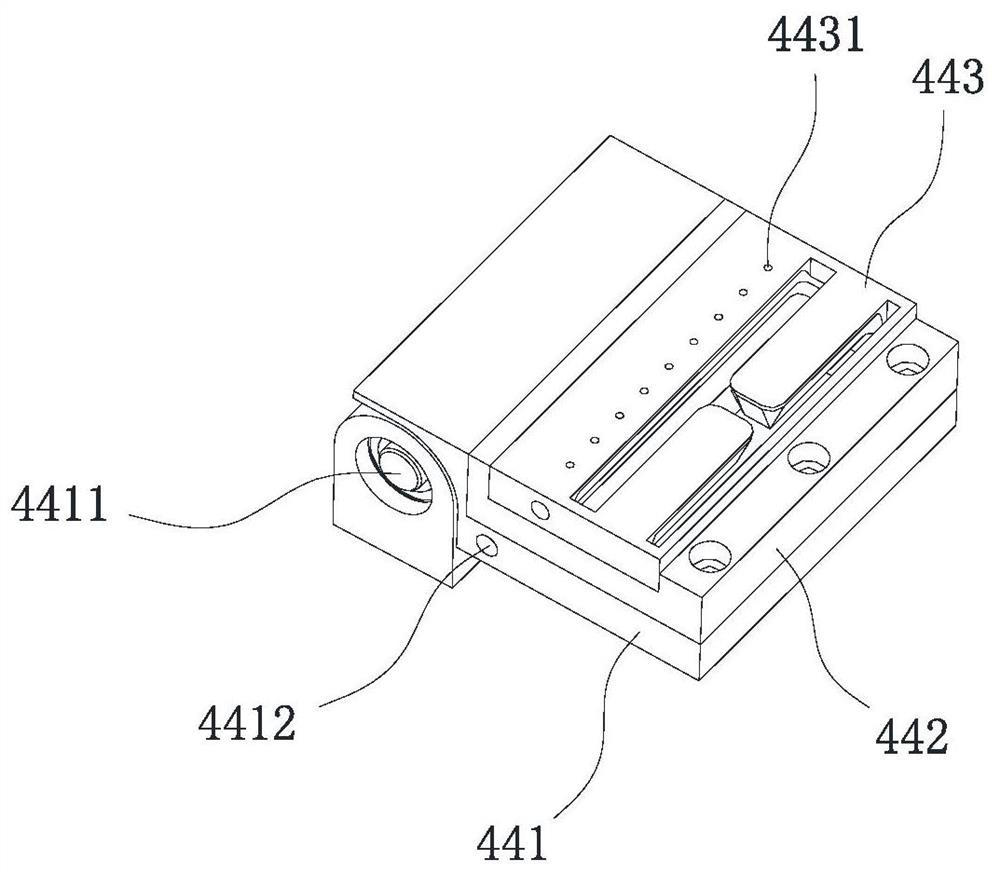

Protection film breaking mechanism for aluminum material film pasting machine

ActiveCN106335678AImprove cutting efficiencyIncreased cutting safetyPackagingMechanical engineeringEngineering

The invention discloses a protection film breaking mechanism for an aluminum material film pasting machine. The protection film breaking mechanism comprises a cutter holder and a cutter. The aluminum material film pasting machine comprises a left horizontally-moving plate and a right horizontally-moving plate, wherein the left horizontally-moving plate and the right horizontally-moving plate can horizontally get close to or be away from each other. The cutter holder comprises a left slide base and a right slide base, wherein the left slide base and the right slide base can slide relative to the left horizontally-moving plate and the right horizontally-moving plate correspondingly. A slide block is arranged on the left slide base. A guide column extending towards the left slide base is arranged on the right slide base. The slide block is sleeved with the guide column in a connected manner. A cutter installation platform is arranged on the right slide base. A movement assembly is arranged on the cutter installation platform and is used for driving the cutter installation platform and aluminum materials to synchronously move. The cutter installed on the cutter installation platform and the aluminum materials can synchronously move. In the cutting process, the cutter is kept aligned with the gap between the front aluminum material and the aluminum material behind all the time. The cutting efficiency is improved, and the cutting safety is also improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

Municipal road damaged asphalt pavement cutting and cleaning equipment

The invention discloses municipal road damaged asphalt pavement cutting and cleaning equipment. The equipment comprises a cutting positioning seat and a circulating punching and rolling cutting devicearranged at the lower part of the cutting positioning seat, and the cutting positioning seat is used for controlling the rotating and linear motion of the circulating punching and rolling cutting device. According to the municipal road damaged asphalt pavement cutting and cleaning equipment, the circulating punching and rolling cutting device is mounted, and comprises a rectangular bearing plate,a suspension pipe, a circular punching combination, a cam, a balance weight body, a connecting rod and a hobbing cutter which are horizontally distributed, the suspension pipe is distributed in an inclined manner, the hobbing cutter is rotatably connected to the free end of the suspension pipe, the circular punching combination can apply inertia counter-acting force of the balance weight body tothe hobbing cutter and then is matched with the hobbing cutter to roll the road surface to achieve the effect of cutting the road surface, and the equipment is small in size, convenient to operate, high in flexibility, high in cutting safety and free of pollution.

Owner:李诗义

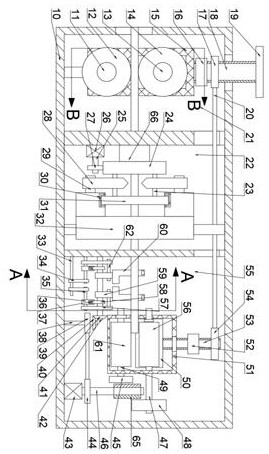

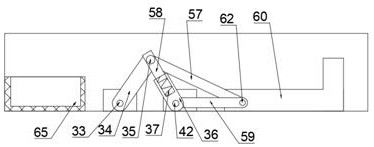

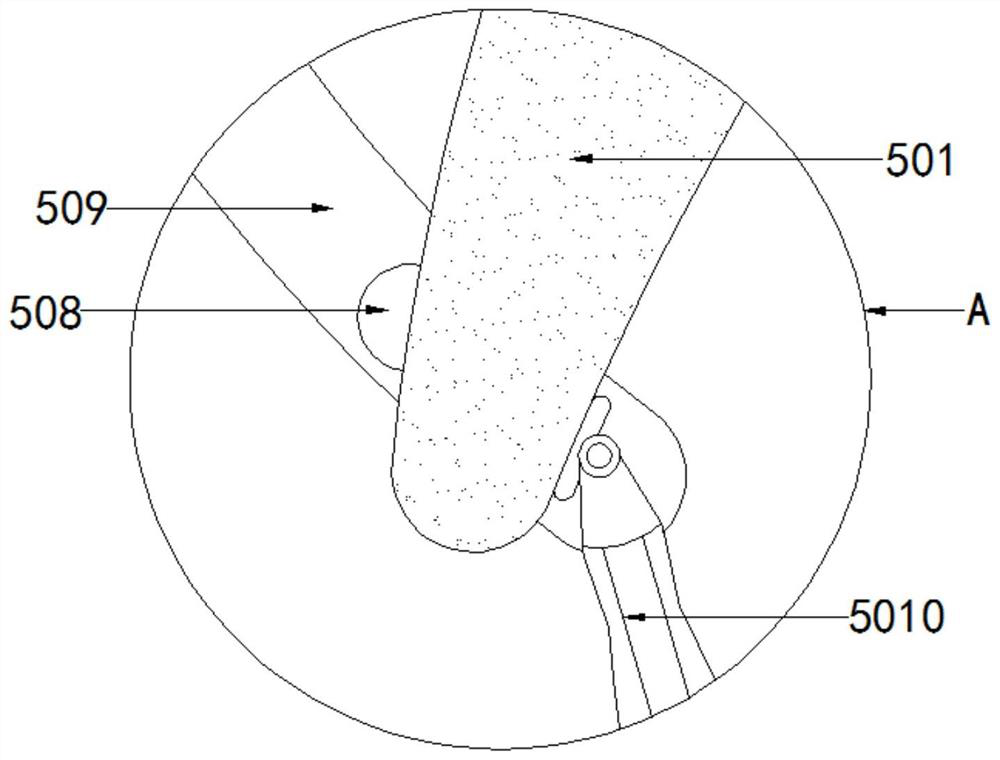

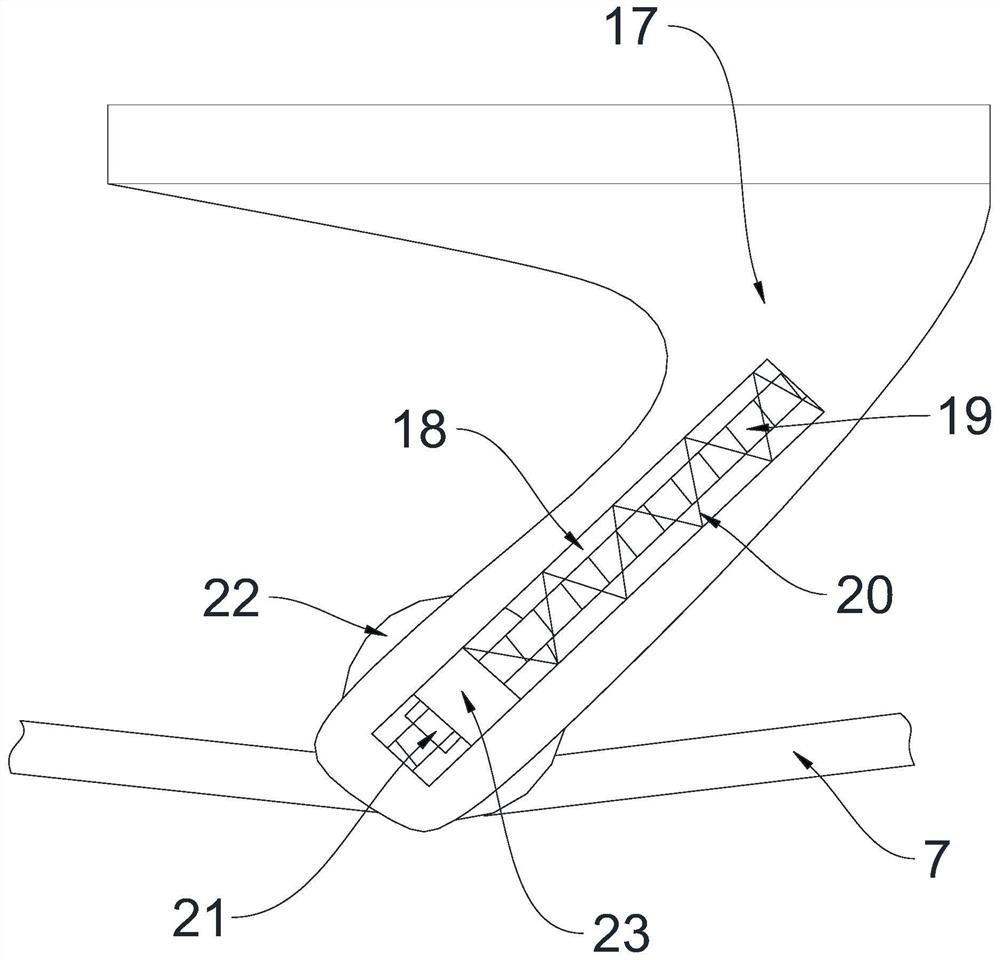

Inverted hanging type garlic rhizome cutting device and cutting machine

PendingCN112931904ASimple structureIncreased efficiency in cutting garlic rhizomesFood treatmentData transportEngineering

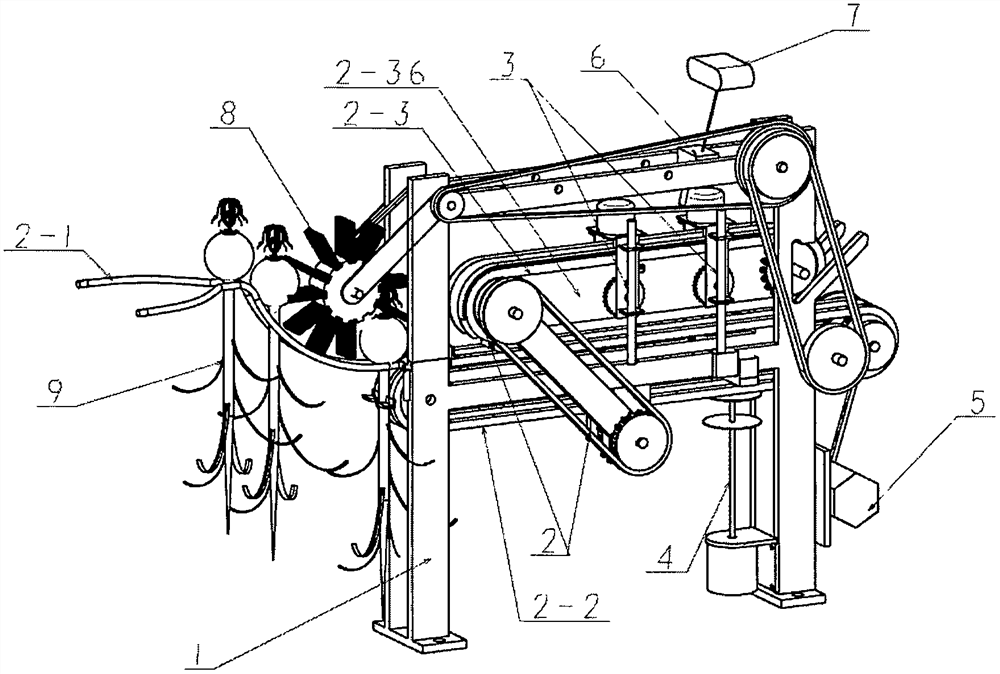

The invention relates to the field of agricultural harvesting machinery, in particular to an inverted hanging type garlic rhizome cutting device and a cutting machine. The inverted hanging type garlic rhizome cutting device is characterized in that a clamping and conveying device is installed in the middle of a left-right symmetrical rack, and at least two root cutting assemblies which can be sequentially installed on the upper side of a garlic clamping and conveying route in a floating mode are installed above the clamping and conveying device; a stalk cutting device is mounted in the middle of the lower part of the clamping and conveying device; a garlic bulb size detection device is mounted near the clamping and conveying device; a data transmission device electrically connected with the garlic bulb size detection device is arranged at one end of the garlic bulb size detection device; an impurity removing device is arranged at the front end of the rack and at an inlet of the clamping and conveying device; and the garlic bulb size detection device is used for detecting the size of the garlic bulb in the process of clamping and conveying the garlic, and transmitting the size to the database through the data transmission device. The inverted hanging type garlic rhizome cutting device can accurately position and cut root hair and stalks, and is simple and compact in structure and high in adaptability.

Owner:王振

Polishing machine suitable for reinforcing steel bar shearing edge surfaces with different calibers

InactiveCN112475141AFlat section of steel barImprove work efficiencyRevolution surface grinding machinesGrinding drivesGrindingElectric machinery

The invention discloses a polishing machine suitable for reinforcing steel bar shearing edge surfaces with different calibers. The polishing machine comprises a shell, a grinding cavity is formed in the shell, a grinding motor is fixedly arranged on the lower side wall of the grinding cavity, a grinding motor shaft is rotationally arranged at the upper side of the grinding motor, a grinding motorwheel is fixedly arranged at the lower side of the grinding motor shaft, and a collecting chamber is fixedly mounted at the upper side of the grinding motor shaft. The polishing machine suitable for the reinforcing steel bar shearing edge surfaces with the different calibers can effectively and rapidly shear steel bars in a fixed-size manner, the shearing surfaces are smooth, the machine is suitable for the steel bars in different sizes, annular grinding is conducted on the shearing bent surfaces, the section of each steel bar is smoother, the machine is suitable for subsequent installation and use, the steel bar machining work efficiency is improved, manpower is saved, meanwhile, a cutter is hidden in the machine body, and steel bar cutting safety is improved.

Owner:ZHENGZHOU TIETOU MASCH TECH CO LTD

A steel bar cutting device with stable clamping function

Owner:佛山市顺德区海众金属制品有限公司

Cutting device and cutting method for electrical equipment production

InactiveCN110153489BReasonable structural designConvenient whereaboutsShearing machinesShearing machine accessoriesEngineeringElectric equipment

The invention discloses a cutting device for electrical equipment production. The cutting device comprises a movable framework, a longitudinal clamping assembly, a transverse clamping assembly, a workpiece moving assembly, a pre-bearing table, a movable cutting assembly and a top beam, wherein the longitudinal clamping assembly and the transverse clamping assembly are arranged at the interior of the movable framework, the transverse clamping assembly comprises two transverse clamping plates which are synchronously and reversely moved in sliding grooves, a longitudinal clamping assembly is arranged on each of the two transverse clamping plates, ech longitudinal clamping assembly comprises two longitudinal clamping plates which are synchronously and reversely moved, the pre-bearing table isfixed on the bottom end surface of the movable framework between the two transverse clamping plates through a side plate, the pre-bearing table comprises a pre-bearing plate and a limiting strip, andlifting plates used for lifting a to-be-cut workpiece on the pre-bearing plate are fixed at the bottom ends of the opposite side surfaces of the two transverse clamping plates. The cutting device forthe electrical equipment production has the advantages of being reasonable in structural design, practical, reliable and the like, and can be widely popularized and used.

Owner:QINGDAO HUANGHAI UNIV

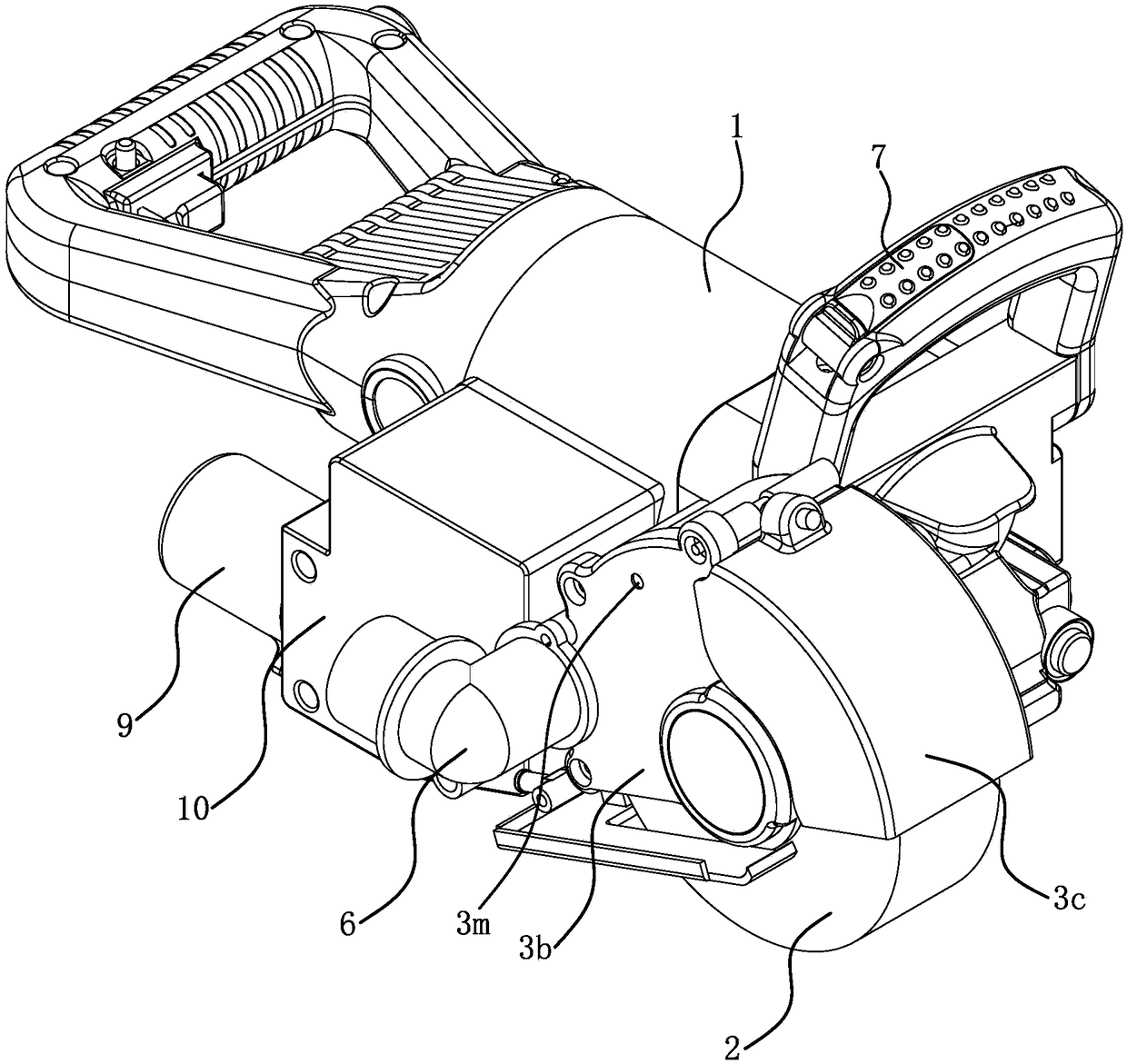

Grooving machine without cutting dead angle

ActiveCN106381985BBig angleAvoid affecting normal slottingWorking accessoriesBuilding constructionsEngineeringMechanical engineering

The invention provides a grooving machine without a cutting dead angle, belonging to the technical field of decoration engineering, and solving the problem that the structures and variety of the existing grooving machines without the cutting dead angle are not complete. The grooving machine without the cutting dead angle comprises a case and a saw blade shield, wherein the saw blade shield comprises a fixed shield and a movable shield; the fixed shield is fixedly connected with the case, the movable shield is rotatably connected with a first rotating shaft, the first rotating shaft is fixedly connected with a second rotating shaft, and the second rotating shaft is rotatably connected with the fixed shield; and a locking structure is arranged between the movable shield and the fixed shield for ensuring positioned connection of the movable shield and the fixed shield when the fixed shield and movable shield are arranged sequentially along an arc, and also ensuring positioned connection of the movable shield and the fixed shield when the movable shield is sleeved outside the fixed shield. The grooving machine without the cutting dead angle can ensure that the grooving machine is suitable for cutting planes as well as cutting corners, i.e. the grooving machine without the cutting dead angle has the advantage of no cutting dead angle.

Owner:芜湖邦胜不锈钢制品有限公司

A multi-angle adjustable laser cutting machine

ActiveCN113369678BEasy to fold and storeImprove operational stabilityLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the technical field of laser cutting, in particular to a multi-angle adjustable laser cutting machine, including a support structure, the support structure is provided with a length adjustment structure, and both the length adjustment structure and the support structure are provided with a A rotating structure that guides the steel frame, the supporting structure is provided with a driving structure for driving one of the rotating structures; the supporting structure is provided with a moving structure for adjusting the position of the laser cutting head, and the laser cutting head is fixed on Mobile structure; the support structure is provided with a storage structure for fixing the computer; it is convenient to adjust the position of the rotating structure on the length adjustment structure through the length adjustment structure, thereby facilitating adjustment of the support range and cutting of steel frames of different lengths , improves the operational stability, and at the same time facilitates the folding and storage of the rotating structure on the length adjustment structure, thereby greatly improving the space utilization efficiency.

Owner:XUZHOU YIZHONG FORGING EQUIP

A crystal cutting device

ActiveCN110202705BSimple structureEasy to operateWorking accessoriesFine working devicesCooling fluidRock crystal

The invention discloses a cutting device for crystal, which comprises a machine body. A cutting cavity with an inclined lower end wall is arranged in the body. A front and back symmetrical clamping device is arranged in the cutting cavity, and the clamping devices face each other. The movement is used to clamp the crystal raw material. A discharge groove is connected between the lower side of the cutting chamber and the outside world. The invention has a simple structure and is easy to operate. The rotation of the cutter can drive the movement of the crystal raw material, so that the raw material can be cut easily. During the movement and the rotation of the cutter, a quantitative amount of coolant is added to the cutting part to reduce the cutting temperature. This device is fully automated during the cutting process, and the cutting safety is high.

Owner:禹城正大塑业有限公司

Intelligent anti-static stable tempered glass cutting equipment

ActiveCN114770774AAvoid damageImprove practicalityWorking accessoriesStone-like material working toolsStructural engineeringToughened glass

The intelligent anti-static stable tempered glass cutting equipment comprises a shell, a cutting knife is installed on the top of the shell through a control mechanism, a stabilizing mechanism is arranged in the shell, and the stabilizing mechanism comprises two U-shaped plates fixedly connected to the bottom of the shell through two fixing rods; the inner walls of the two U-shaped plates are rotationally connected with two bidirectional lead screws correspondingly, the side walls of the bidirectional lead screws are in threaded connection with two sliding blocks, and the side walls of the sliding blocks are attached to the side walls of the U-shaped plates. By arranging the stabilizing mechanism, flexible clamping of the clamping rods to tempered glass is changed into rigid clamping, the tempered glass is prevented from being damaged, meanwhile, the multiple clamping rods are movably connected into the strip-shaped cavity, when the surface height of the tempered glass is changed, the clamping rods can be clamped in the strip-shaped cavity, and therefore the tempered glass can be clamped in the strip-shaped cavity. At the moment, the moving-out lengths of the clamping rods in contact with the surface of the tempered glass are correspondingly changed, so that the tempered glass in different shapes can be fixed, and the practicability of the tempered glass fixing device is improved.

Owner:邢台浩达玻璃制品有限公司

A protective film breaking mechanism of an aluminum film laminating machine

ActiveCN106335678BImprove cutting efficiencyIncreased cutting safetyPackagingTectorial membraneEngineering

The invention discloses a protection film breaking mechanism for an aluminum material film pasting machine. The protection film breaking mechanism comprises a cutter holder and a cutter. The aluminum material film pasting machine comprises a left horizontally-moving plate and a right horizontally-moving plate, wherein the left horizontally-moving plate and the right horizontally-moving plate can horizontally get close to or be away from each other. The cutter holder comprises a left slide base and a right slide base, wherein the left slide base and the right slide base can slide relative to the left horizontally-moving plate and the right horizontally-moving plate correspondingly. A slide block is arranged on the left slide base. A guide column extending towards the left slide base is arranged on the right slide base. The slide block is sleeved with the guide column in a connected manner. A cutter installation platform is arranged on the right slide base. A movement assembly is arranged on the cutter installation platform and is used for driving the cutter installation platform and aluminum materials to synchronously move. The cutter installed on the cutter installation platform and the aluminum materials can synchronously move. In the cutting process, the cutter is kept aligned with the gap between the front aluminum material and the aluminum material behind all the time. The cutting efficiency is improved, and the cutting safety is also improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

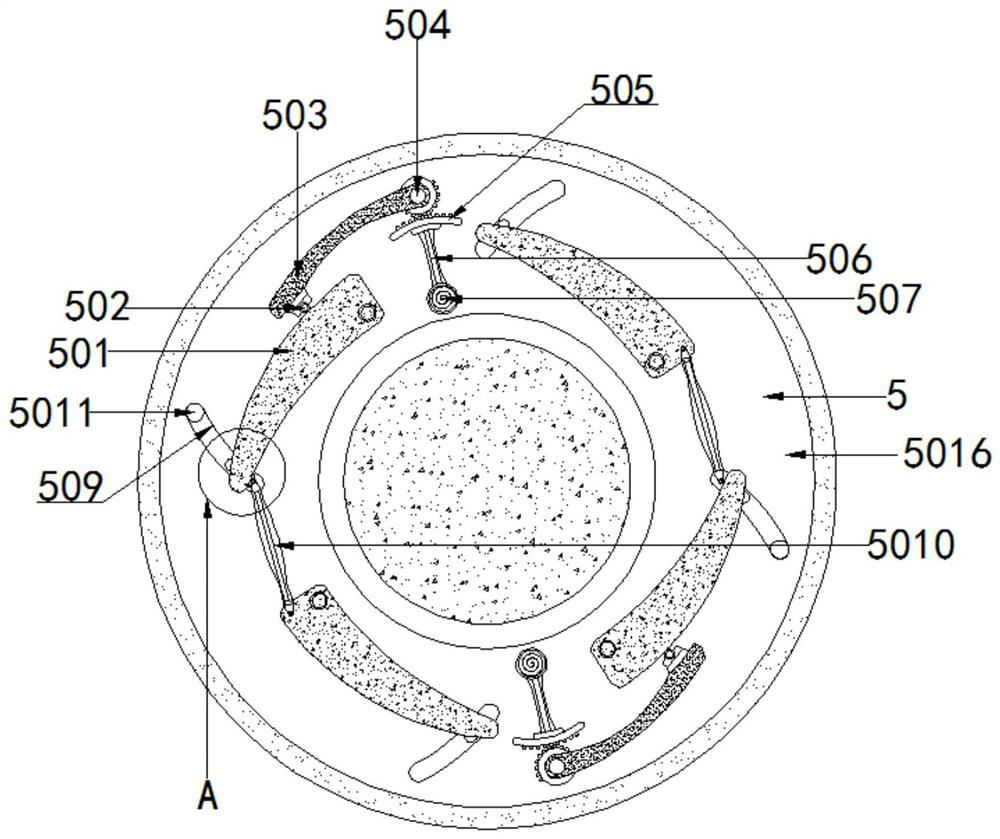

Capsule packaging equipment

ActiveCN112456411AComplete cutting sectionImplement encapsulationDecorative coversClosure decorative/protective coversMedical equipmentCoil spring

The invention relates to the technical field of medical equipment, and discloses capsule packaging equipment. The capsule packaging equipment comprises a packaging table, a bottle opening shaping assembly, an electric telescopic rod, a cutting assembly and a moving column; an air pump is fixedly installed on the inner wall of the top end of the packaging table; the inner wall of the packaging table is movably connected with the outer wall of the bottle opening shaping assembly; and the outer wall of the packaging table is fixedly equipped with the inner wall of the top end of the electric telescopic rod. According to the capsule packaging equipment provided by the invention, the electric telescopic rod moves to drive the moving column to move to abut against a medicine bottle opening, thenthe air pump inflates the bottle opening shaping assembly to start working, a negative-pressure air bag is compressed to the maximum position, a cutter head continues to move downwards, and then an electromagnetic block is powered on; the cutting assembly starts to work, blades are collectively opened, annular cutting is conducted on an aluminum foil with a shaped bottle opening, the air pump stops working after annular cutting is completed, the aluminum foil returns to the starting position under the action of a coil spring, the negative-pressure air bag and a negative-pressure telescopic rod, and therefore the effects of capsule packaging, aluminum foil cutting section completeness and cutting safety improvement are achieved.

Owner:HUBEI OULY PHARMA

Cavity-variable cherry tomato slicing device

ActiveCN104325492BAvoid cumbersomeImprove the pressing effectMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of cutting devices of cherry tomatoes, in particular to a variable-cavity cherry tomato slicing device. The slicing device comprises a bottom disk, a disk cover and a cutter, wherein the bottom disk is used for accommodating the cherry tomatoes, and is provided with a concave part; the disk cover is used for pressing the cherry tomatoes, and is provided with a concave part; the cutter is used for cutting the cherry tomatoes; a lower connecting part extends from one side of the bottom disk; an upper connecting part which corresponds to the lower connecting part extends from one side, which corresponds to the lower connecting part, of the disk cover; the lower connecting part is hinged to the upper connecting part; a spring is further arranged between the lower connecting part and the upper connecting part; an accommodating space for accommodating the cherry tomatoes is formed between the bottom disk and the disk cover; a gap between one side, which is far away from the lower connecting part, of the bottom disk and one side, which is far away from the upper connecting part, of the disk cover is greater than the thickness of the cutter. The variable-cavity cherry tomato slicing device has the advantages of high cutting safety, high efficiency, good pressing effect, and easiness and convenience in operation.

Owner:王远志

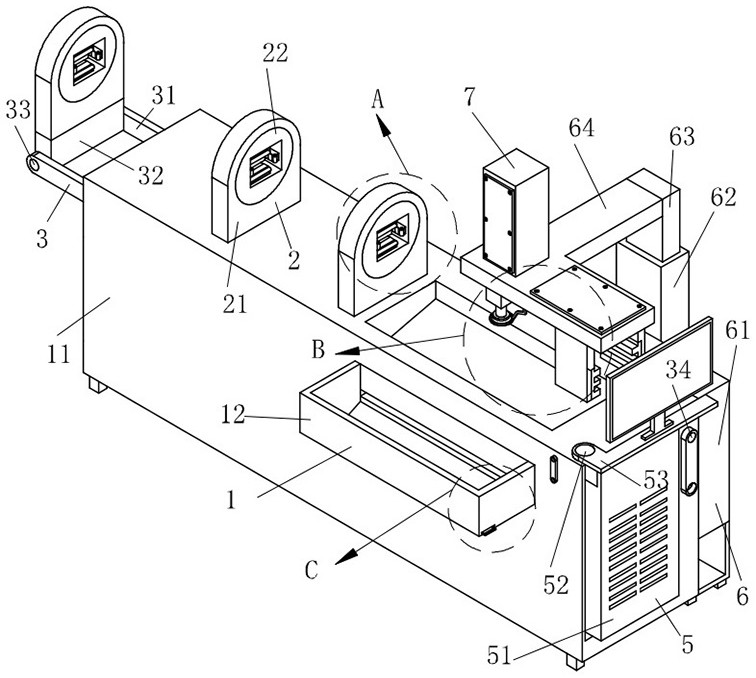

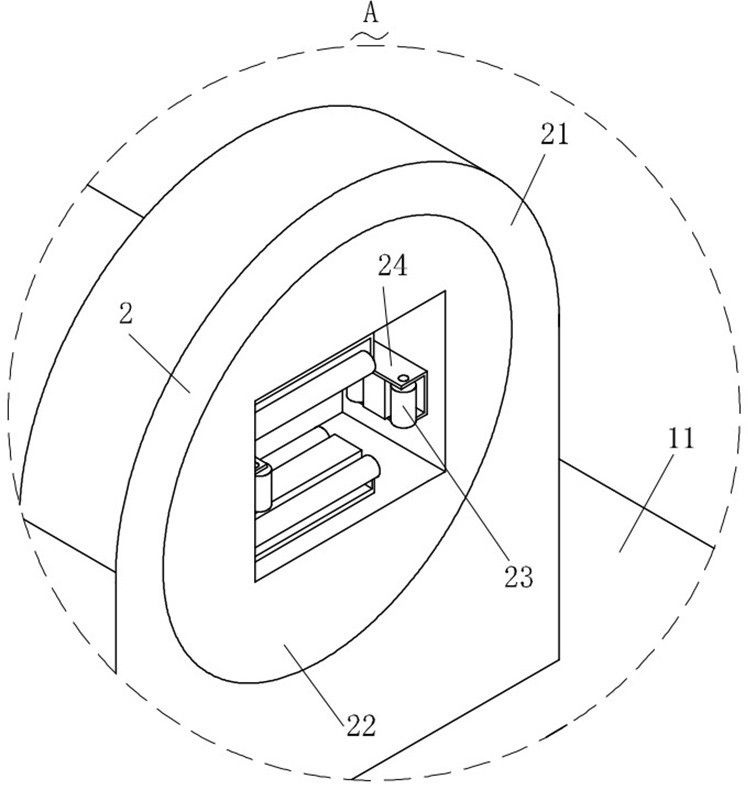

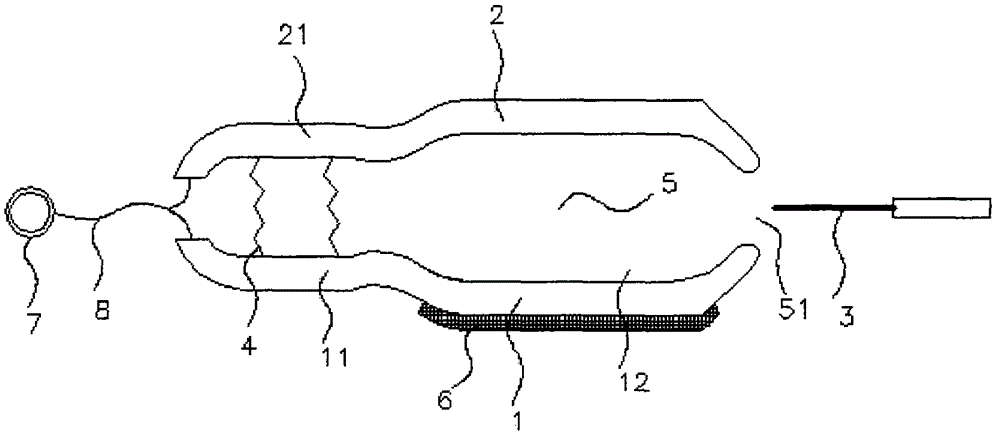

Laser cutting tooling and laser cutting production line for soft pack battery tabs

ActiveCN110640331BPrevent splashIncreased cutting safetyCell component detailsWelding/soldering/cutting articlesProduction lineEngineering

Owner:深圳市大族锂电智能装备有限公司

A kind of iron bar polishing equipment convenient for unloading

ActiveCN109909861BEfficient grinding and polishingAffect the grinding effectGrinding carriagesPolishing machinesPolishingStructural engineering

The invention discloses iron rod polishing equipment with a convenient discharge function. The iron rod polishing equipment comprises a box body, a grinding device arranged in the box body, a clampingdevice used for clamping an iron rod, a waste chip collecting device arranged at the outer bottom of the box body, and a discharging device used for discharging the iron rod; and the discharging device comprises a frame body arranged on one side of the box body, a third driving piece arranged on the frame body, a fixing rod with one end connected with the third driving piece, a dragging rod connected with the other end of the fixing rod, a material receiving assembly arranged on the frame body and a transmission assembly matched with the material receiving assembly, wherein a second electromagnet is arranged at one end of the dragging rod. According to the equipment, the iron rod can be comprehensively and efficiently polished, in the polishing process, scrap iron fallen from the iron rodcan be removed in time, polished iron rod can be discharged automatically, the polishing efficiency is improved, in addition, operation is simple in the whole process, discharging is rapid and stable, and the safety is high.

Owner:安徽伟迈信息技术有限公司

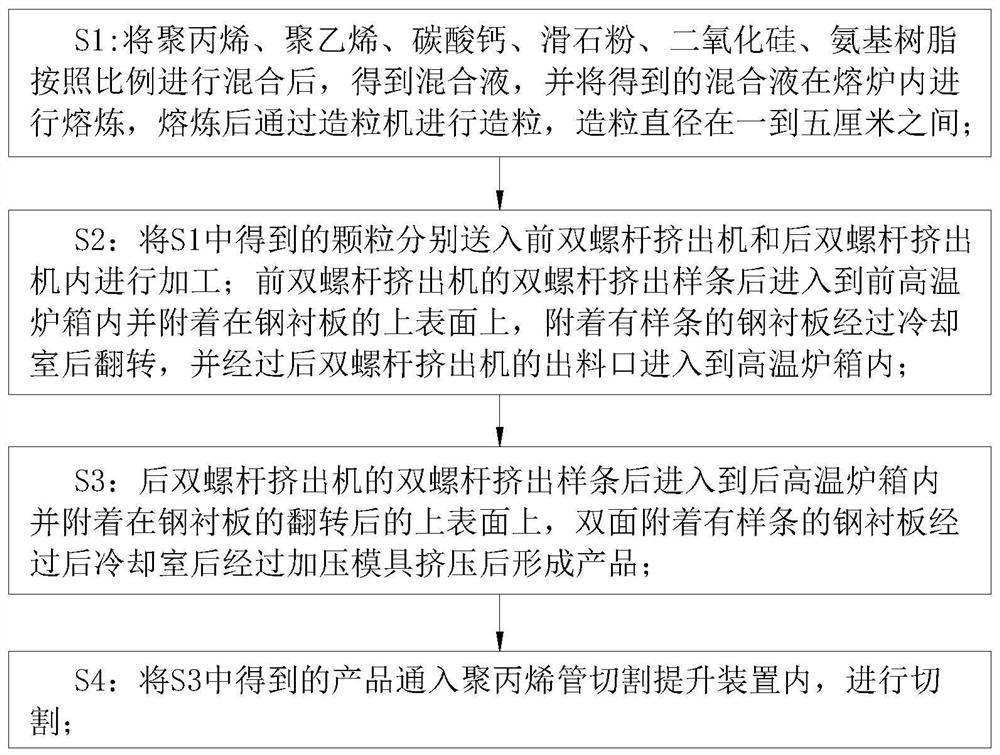

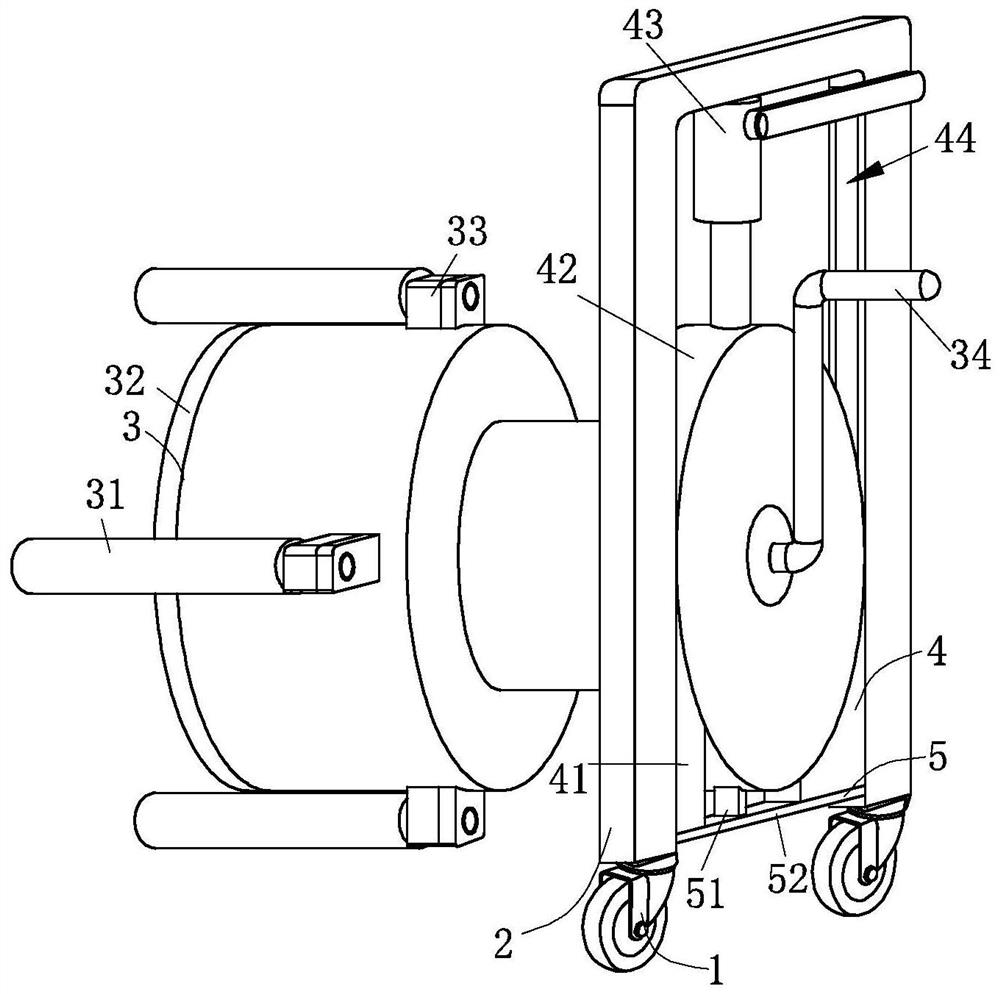

A kind of cutting method of fiber grade polypropylene pipe

ActiveCN110341080BEasy to liftVersatilityPlastic recyclingMetal working apparatusFiberStructural engineering

Owner:赵雪莉

Vertical Segment Cutting Concrete Pole Device

ActiveCN106273004BAvoid leaningPlay an auxiliary guiding roleWorking accessoriesStone-like material working toolsEngineeringPole piece

The invention provides a device for vertically cutting a concrete pole in a segmented mode. The device comprises a vehicle-mounted chassis, a surrounding device and a cutting mechanism; telescopic hydraulic support legs are oppositely arranged on the two sides of the vehicle-mounted chassis, the surrounding device comprises an arc-shaped surrounding plate, a first hydraulic oil cylinder, a rotating support frame and a flatwise placing support frame, the cutting mechanism comprises an upper cutting device and a lower cutting device, the upper cutting device and the lower cutting device each comprises a cutting assembly, and each cutting assembly comprises a driving motor, a cutting blade and a screw transmission mechanism, wherein the driving motor adopts belt transmission to drive the cutting blade, and the driving motor and the cutting blade are both fixedly arranged on a mobile sliding block of the screw transmission mechanism. According to the device, the arc-shaped surrounding plate can vertically fix the waste concrete pole, the pole cannot be tilted after the bottom end of the pole is cut off, and therefore accidents are avoided; the cutting mechanism can achieve segmented cutting on the pole along with continuous downward movement of the pole in the arc-shaped surrounding plate, and the cut pole is beneficial for transportation.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

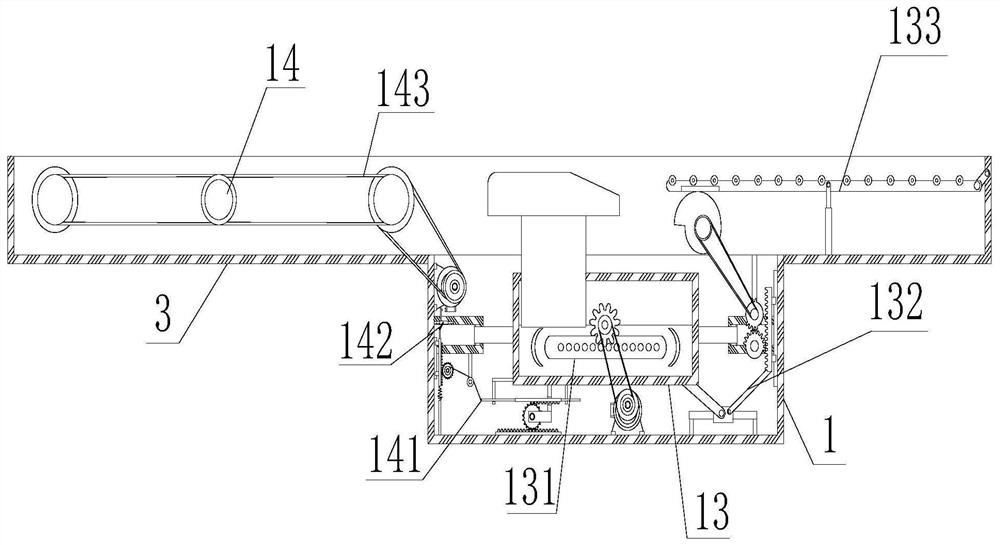

Conveying and cutting mechanism for pesticide processing and production

ActiveCN112058419AStable supportImprove transmission efficiencyConveyorsGrain treatmentsAgricultural scienceAgricultural engineering

The invention relates to the technical field of pesticide processing and production, in particular to a conveying and cutting mechanism for pesticide processing and production. The conveying and cutting mechanism comprises a conveying motor, a transverse guide rail and an adjusting motor. An inner conveying mechanism driven by a conveying motor and an inner cutting mechanism controlled by an adjusting motor are movably mounted on the upper surface of the transverse guide rail. The conveying and cutting mechanism for pesticide processing and production is composed of the inner conveying mechanism which is driven by the conveying motor and the inner cutting mechanism which is controlled by the adjusting motor mounted on the transverse guide rail. Transmission of pesticide raw materials can be controlled by the inner conveying mechanism. In the transmission process, the pesticide raw materials are cut and crushed, so that the functional integration level is improved greatly. The conveyingand cutting mechanism is simple and convenient to operate and convenient to unload and fix and the later maintenance cost is lowered. As multiple cutting blades are matched to cut the pesticide raw materials, the cutting efficiency is improved, and meanwhile, splashing generated by rotary cutting is avoided, so that the cutting safety is improved.

Owner:江苏东南植保有限公司 +1

A new type of cable cutting device for distribution line construction

ActiveCN110238324BSolve the problem of low cutting safetyIncreased cutting safetyApparatus for cutting/splicing cablesGear driveGear wheel

The invention discloses a new type of cable cutting device for power distribution line construction, which includes a conveying device and a feeding device. The conveying device is arranged inside the support frame, and the conveying mechanism conveys the cable to the right end, and then conveys the cable to the upper end. Entering the cutting area, at the same time, the sliding frame on the conveying mechanism pushes the swinging mechanism, so that the swinging mechanism drives the cam to rotate, so that the material guide plate can convey the cut cable, so that the cable can be quickly pushed to the cutting area for cutting. The advantage of increasing cutting safety; by setting the feeding device inside the support frame, when the sliding frame moves to the left end, the driving mechanism moves to the left end, the driving mechanism drives the winding gear to rotate through the traction rope, and the winding gear drives the motor to start the mechanism Transmission is carried out, and the third motor is started, so that the third motor drives the conveyor belt to transmit the cable, thereby achieving the advantages of fast transmission of the cable and increasing the cutting efficiency.

Owner:CHONGQING ELECTRIC POWER COLLEGE

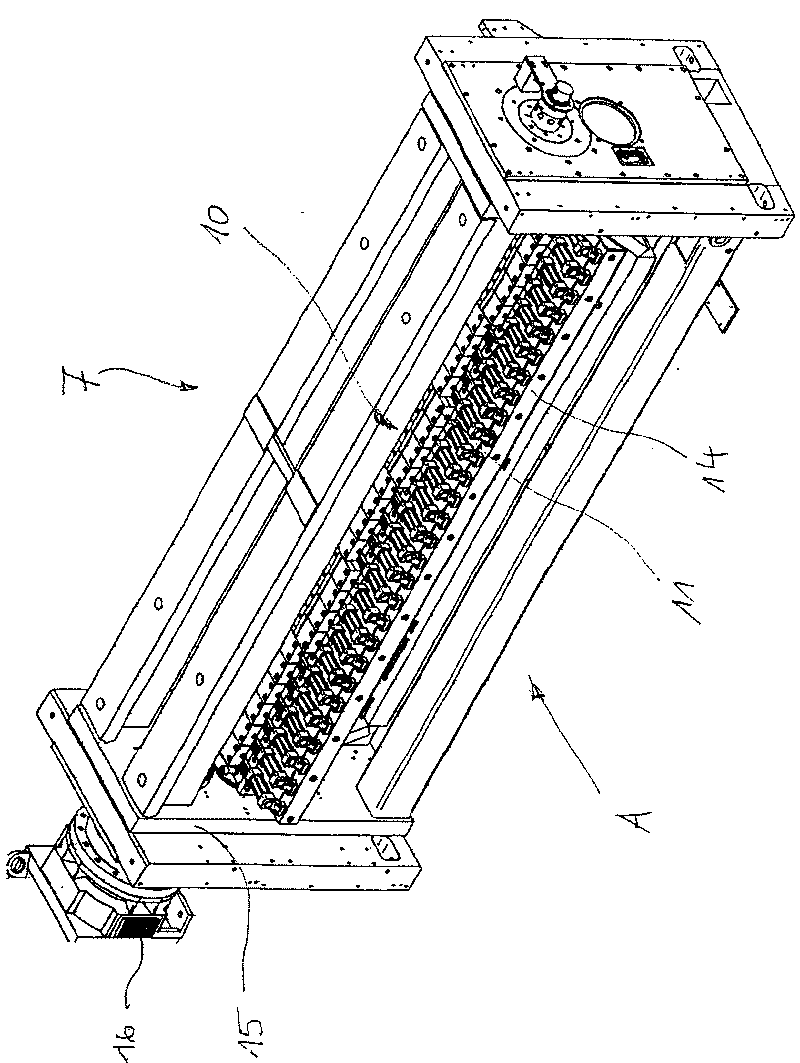

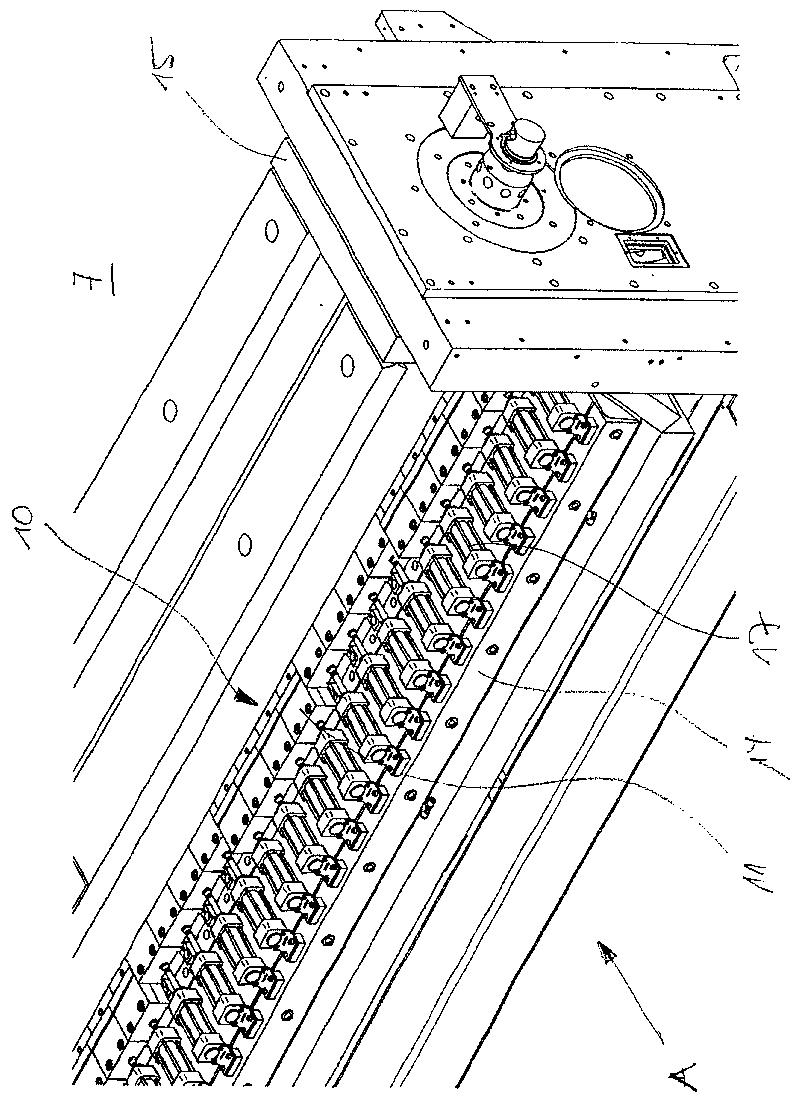

Device for cutting track-like material as well as method for producing cross sections in a track-like material

InactiveCN1640634BIncreased cutting safetySmall space requirementBox making operationsPaper-makingMechanical engineeringEngineering

The present invention relates to a device 7 for cutting track-like material 1 as well as a method for producing transverse cuts 6 in a track-like material 1 in a continuous operating process. To increase the service life of the device 7 and to improve the cut reliability, it is proposed that the counter-tool 10 to the cutting tool 8 form, in the active position (cutting position), a blunt counter-surface 12 for the cutting tool 8, which counter-surface is in direct contact with the track-like material 1 and is not cuttable.

Owner:BHS波纹纸加工机械及设备有限公司

A fully automatic aluminum film sticking machine

ActiveCN106240897BImprove film application efficiencyFacilitate automatic breakingPackagingTectorial membraneEngineering

The invention provides a full-automatic aluminum product laminating machine. The full-automatic aluminum product laminating machine comprises a laminating mechanism and a protective film cutting-off mechanism. The laminating mechanism comprises conveying mechanisms, laminating assemblies arranged on the laminating side of aluminum products and feeding interval limiting mechanisms. Each laminating assembly comprises a rotating sleeve and laminating rollers. The laminating rollers are arranged on moving mechanisms. When laminating is conducted, the moving mechanisms can drive the laminating rollers to be attached to the lamination surfaces of the aluminum products, and laminating can be continuously conducted on the aluminum products of different sizes and shapes. In this way, the full-automatic aluminum product laminating machine is high in laminating efficiency and wide in application range. A cutter installed on a cutter installation platform can synchronously move along with the aluminum products, the cutter is always aligned to the interval between every two adjacent aluminum products in the cutting process, and therefore both the cutting efficiency and the cutting safety are improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com