A kind of cutting method of fiber grade polypropylene pipe

A polypropylene pipe and cutting method technology, applied in metal processing, plastic recycling, recycling technology and other directions, can solve problems such as affecting the normal production of winding pipes, low cutting efficiency, affecting cleaning, etc., to improve cutting efficiency and its quality, The effect of improving handling efficiency and quality, and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

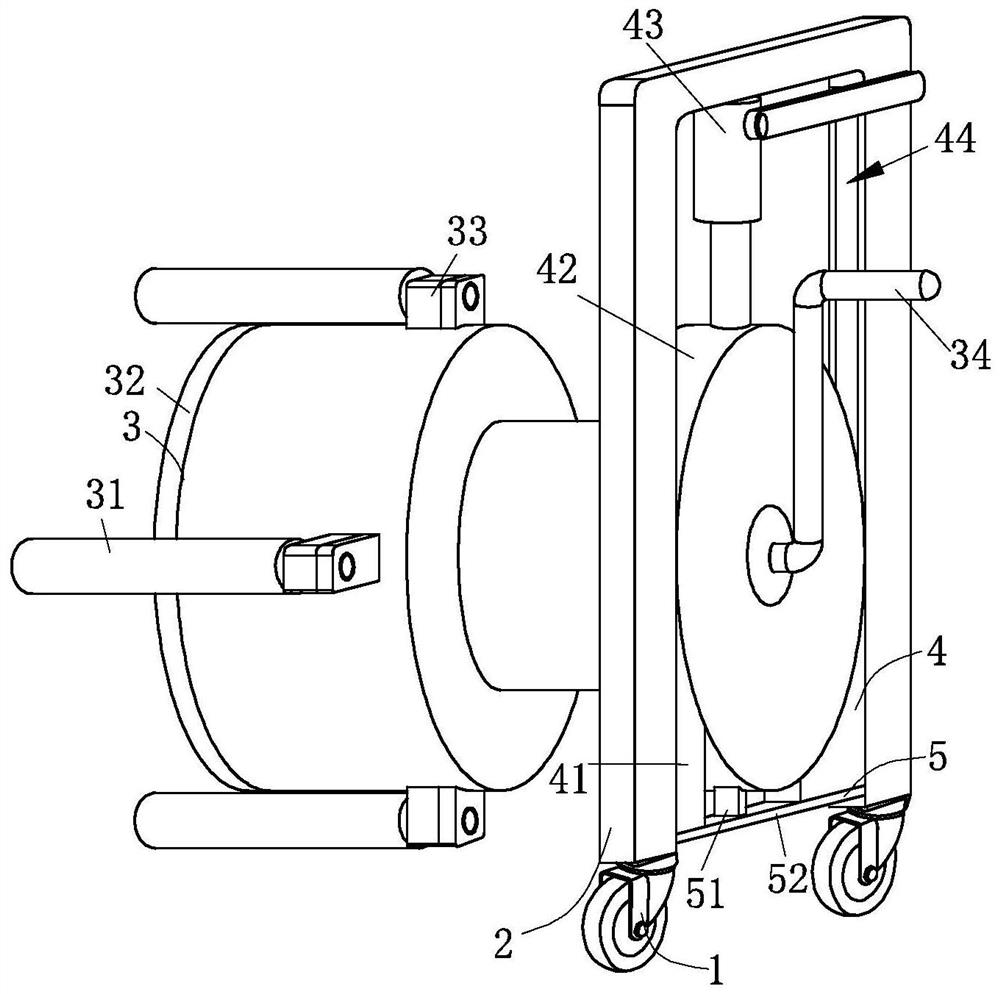

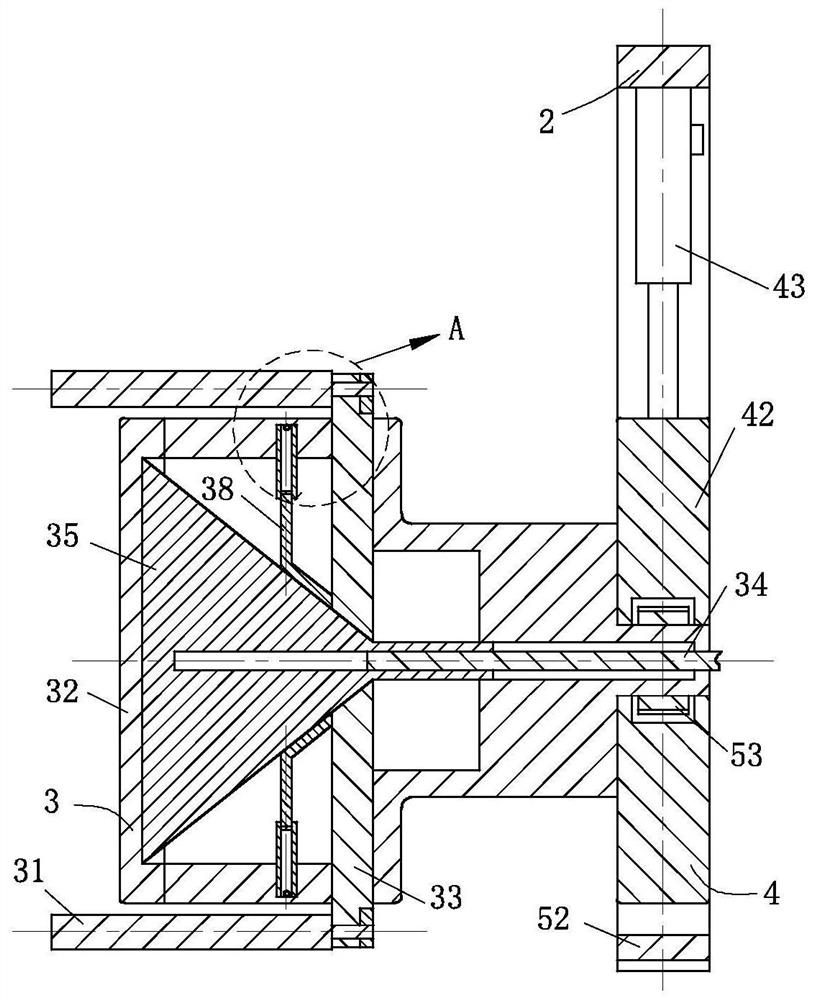

[0026] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

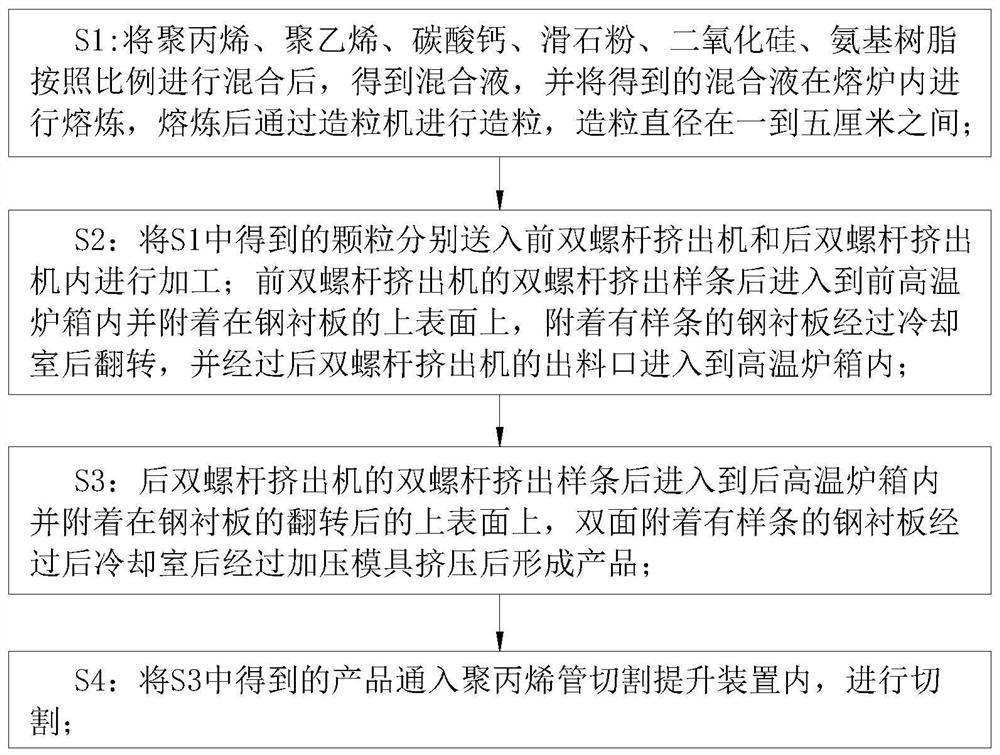

[0027] like Figure 1-Figure 6 As shown, a fiber-grade polypropylene pipe cutting method of the present invention comprises the following steps:

[0028] S1: after polypropylene, polyethylene, calcium carbonate, talc, silicon dioxide, and amino resin are mixed in proportion, a mixed solution is obtained, and the obtained mixed solution is smelted in a melting furnace, and is carried out by a granulator after the smelting Granulation, the granulation diameter is between one and five centimeters, and the polypropylene material is made small in size through granulation, which is convenient for later processing;

[0029] S2: The pellets obtained in S1 are respectively sent to the front twin-screw extruder and the rear twin-screw extruder for pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com