Patents

Literature

370results about How to "Implement encapsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

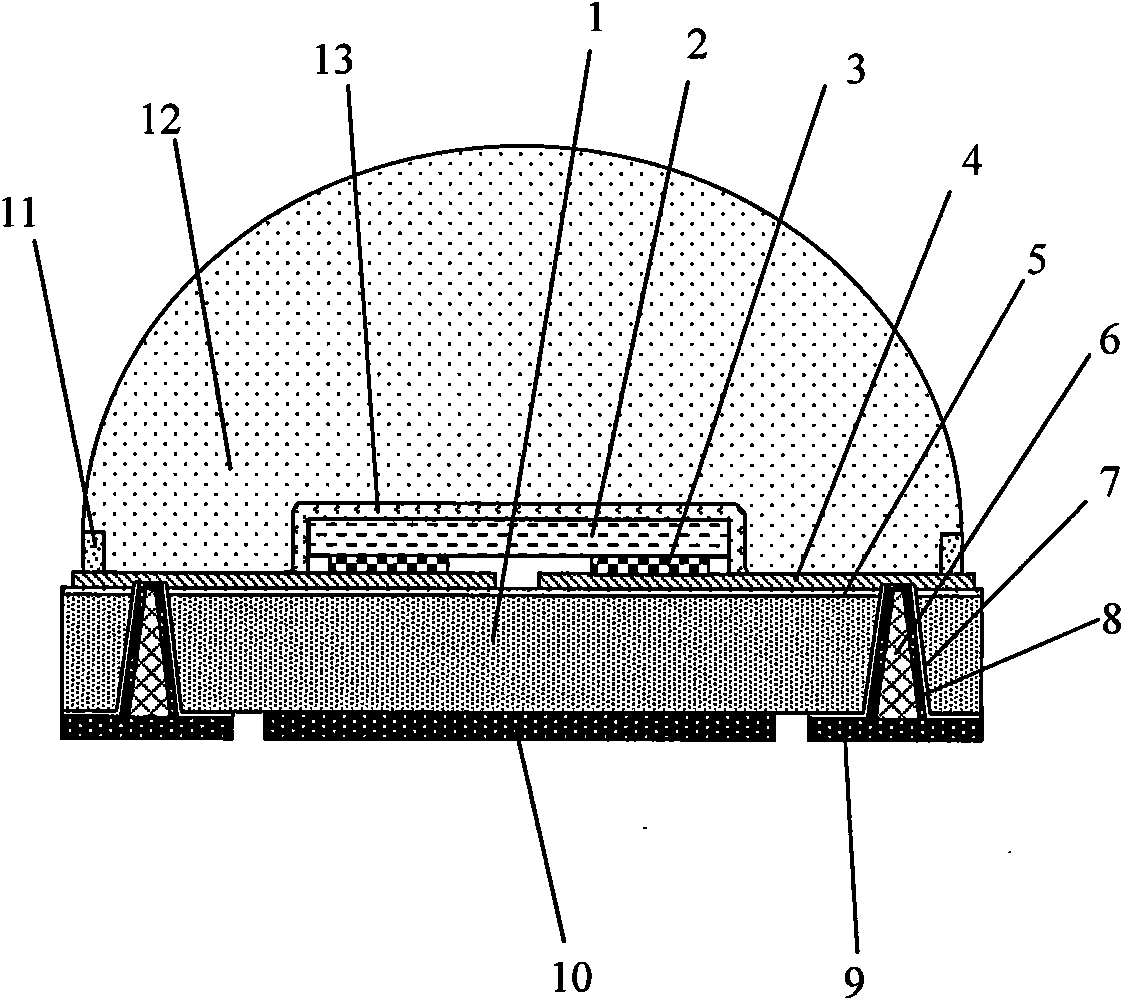

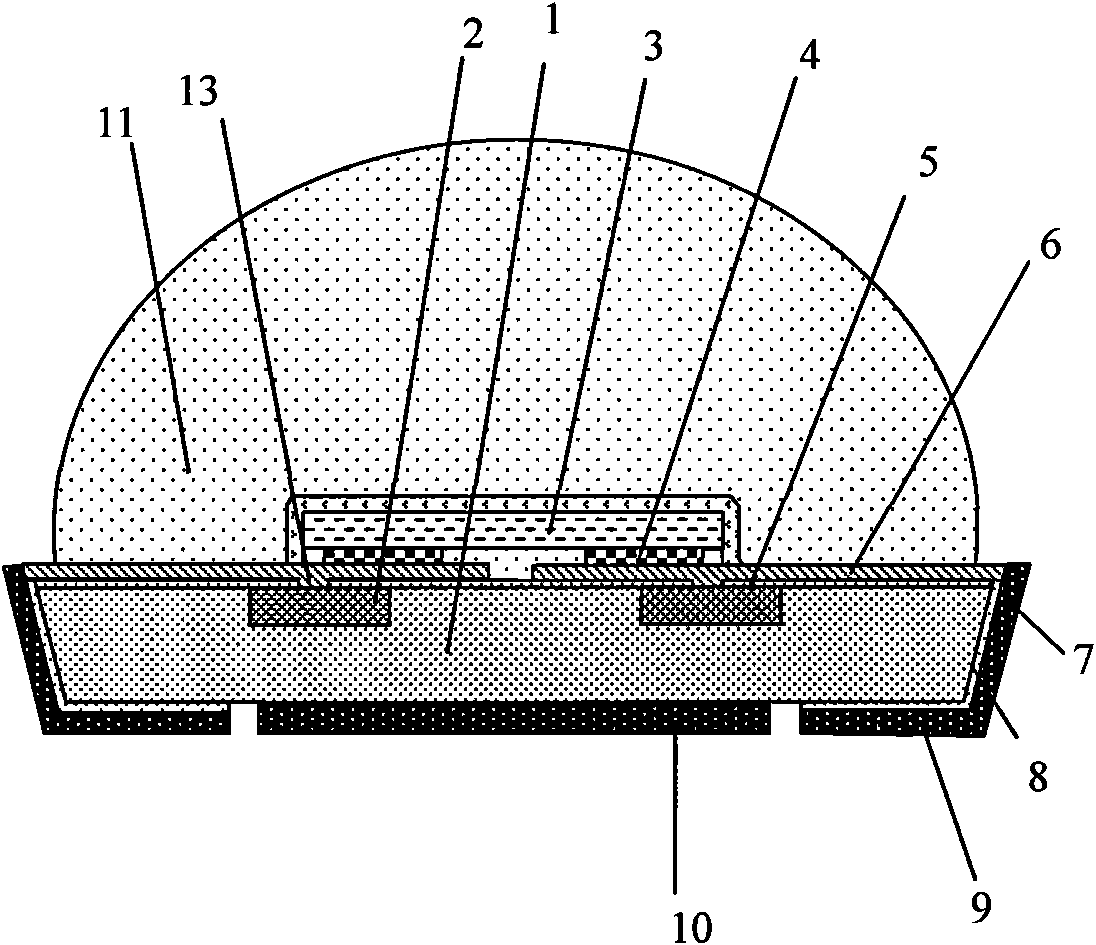

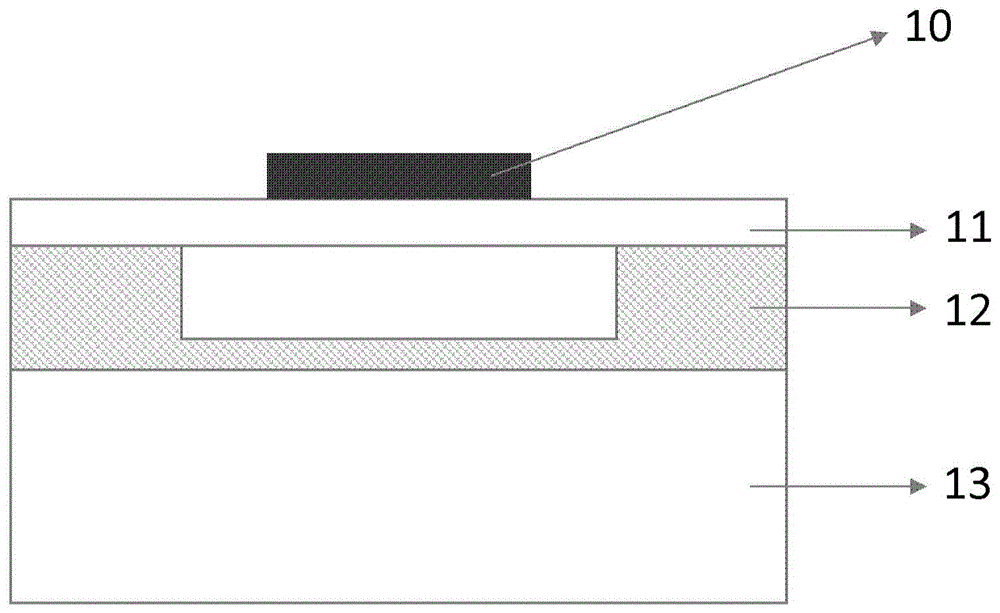

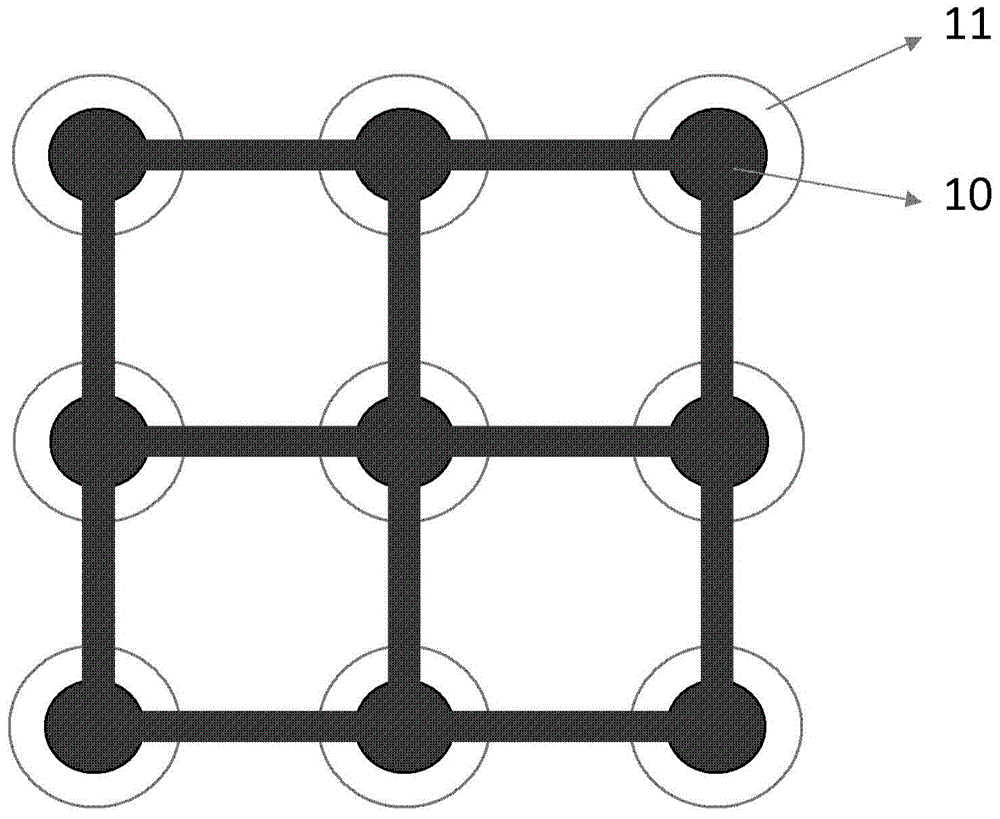

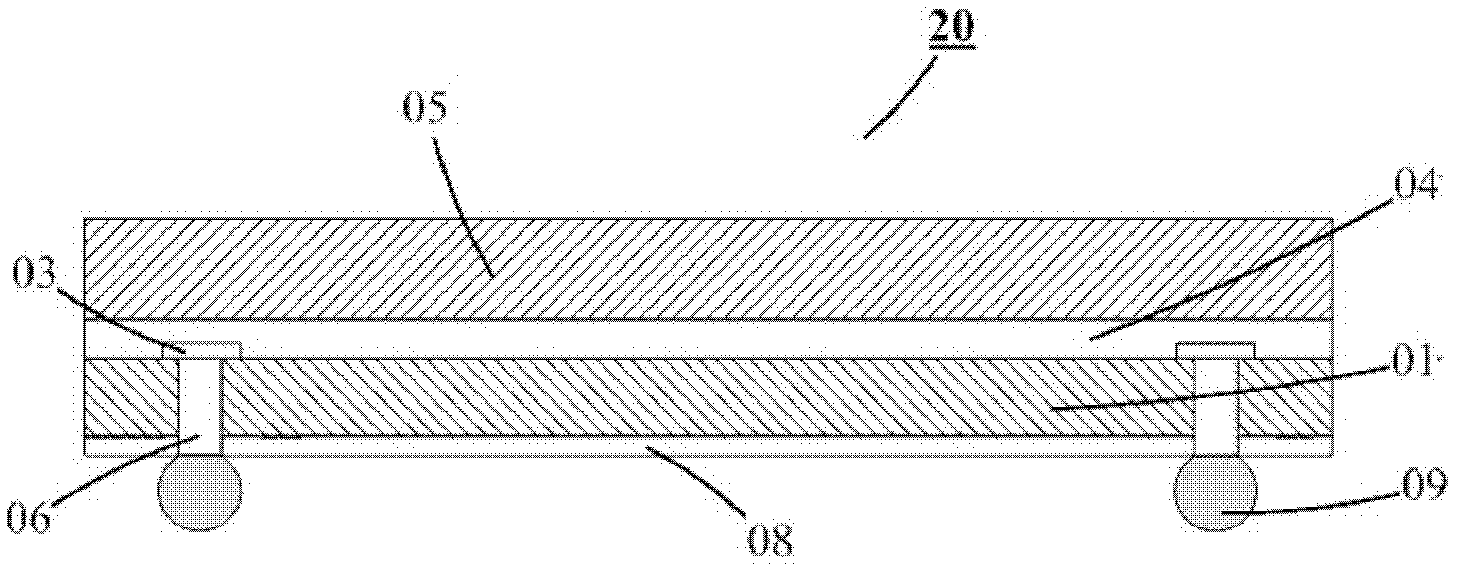

LED (Light Emitting Diode) surface patch type encapsulating structure based on silicon base plate and encapsulating method thereof

InactiveCN101997074AImprove cooling effectReduce volumeSolid-state devicesSemiconductor devicesInsulation layerHeat conducting

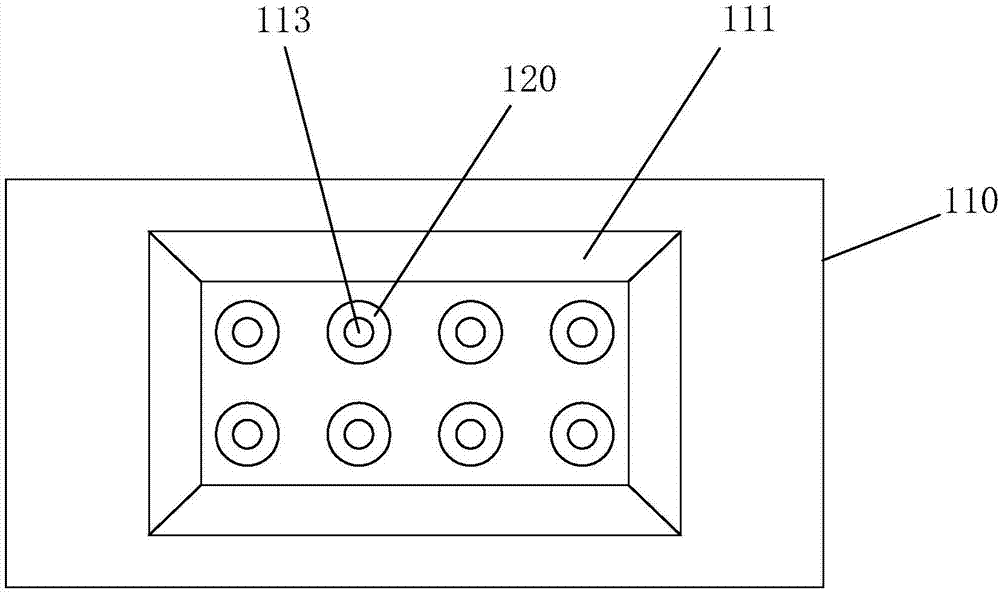

The invention relates to an LED (Light Emitting Diode) surface patch type encapsulating structure based on a silicon base plate, which comprises the silicon base plate, an LED chip, a circular ring convex wall and a lens, wherein the upper surface of the silicon base plate is a plane structure, an oxidation layer is covered on the upper surface of the silicon base plate, a metal electrode layer is arranged on the upper surface of the oxidation layer, the upper surface of the metal electrode layer is provided with metal convex points, a through hole penetrating through the silicon base plate is arranged below the metal electrode layer, an insulation layer covers the inner wall of the through hole and the partial lower surface of the silicon base plate, a metal connecting layer covers the surface of the insulation layer in the through hole, two electric conducting metal welding discs are respectively arranged at the lower surface of the silicon base plate and are insulated from the silicon base plate, a heat conducting metal welding disc is arranged at the lower surface of the silicon base plate, the LED chip is inversely arranged on the silicon base plate, and the LED chip and the metal electrode layer in the LED chip are isolated from the outside through the circular ring convex wall and the lens. The encapsulating structure has the advantages of good heat radiation effect and small size, also has high reliability because of no gold thread encapsulation, realizes the wafer level mass production encapsulation and hereby reduces the encapsulation cost.

Owner:APT ELECTRONICS

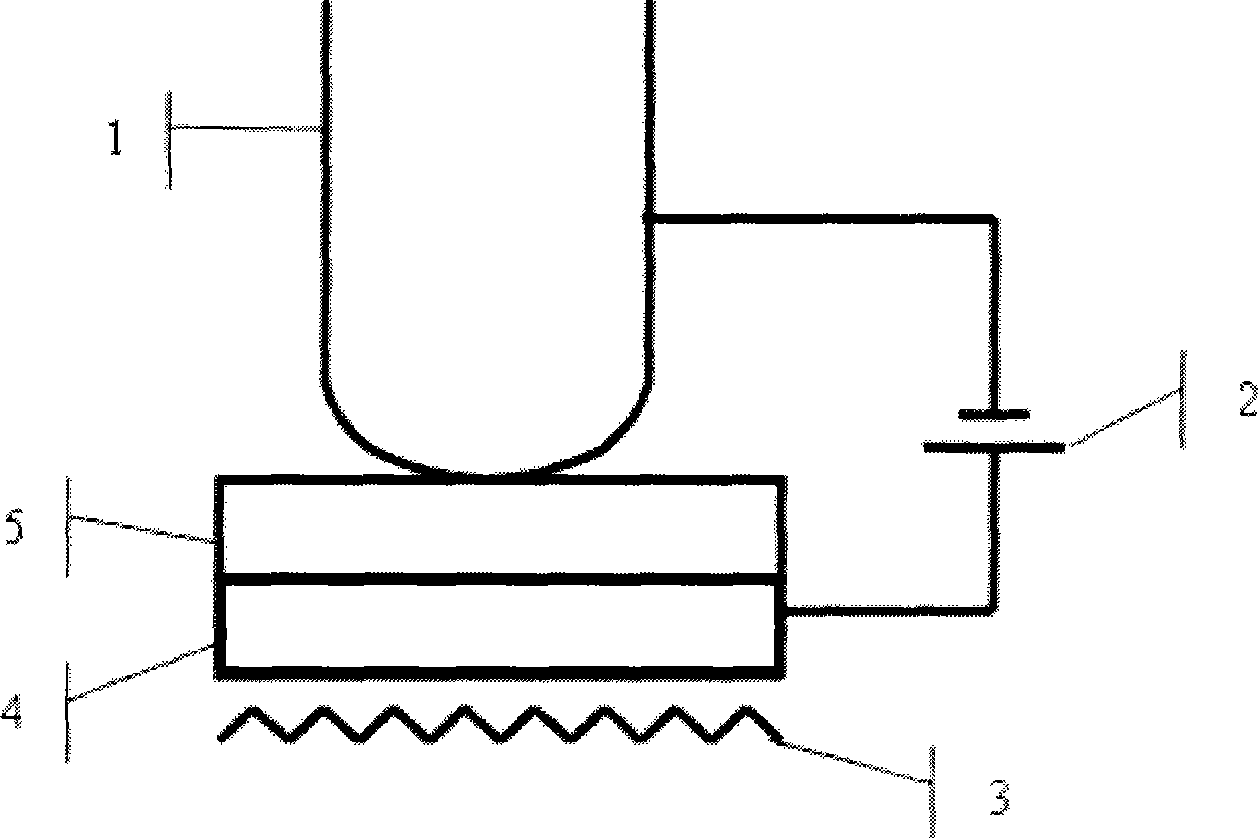

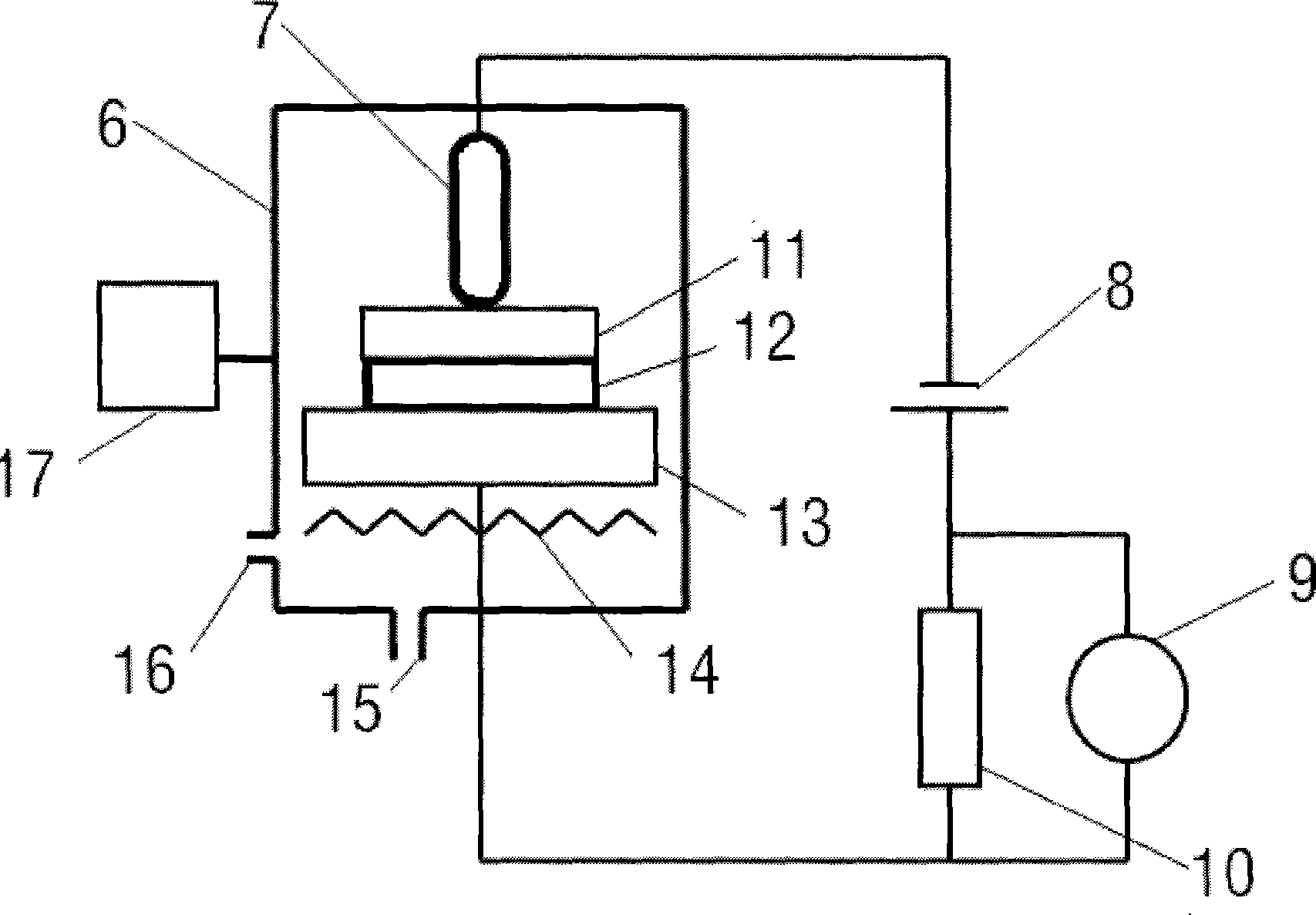

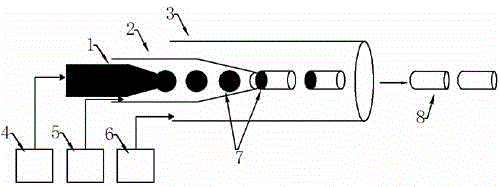

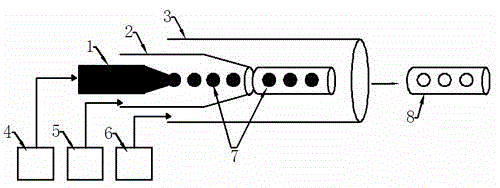

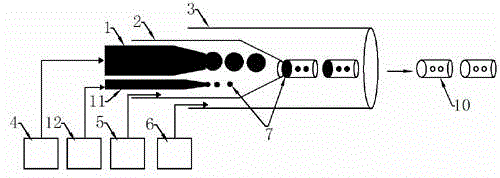

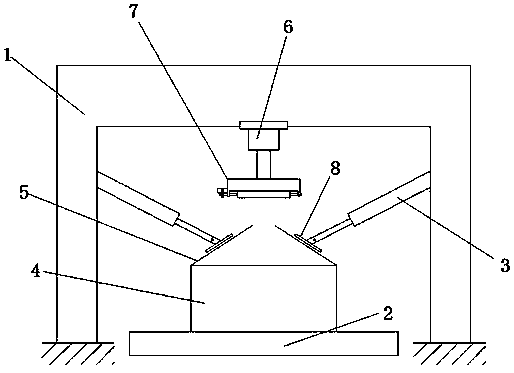

Miniature atomic air chamber encapsulation apparatus and technology method

InactiveCN101439843AImplement encapsulationAchieve bondingPrecision positioning equipmentSoldering apparatusChemical reactionRubidium

The invention discloses packaging equipment for a micro atomic gas chamber and a process technology method thereof. The equipment comprises a sample chamber, a pressure bar, a sample wafer, a sample stage, a heating wire, a temperature measurement probe, a vacuum pump connector, an inflation inlet, a direct-current high-voltage power supply, a voltmeter, a resistor, and other measurement and control devices. The method comprises: step 1, the selection of materials; step 2, the processing of the materials; step 3, the washing of the sample wafer; step 4, the bonding of a first surface; step 5, the bonding of a second surface; and step 6, the detection of a sample, and is a method which closes metal rubidium generated by adopting an in-situ chemical reaction method in a micro gas chamber. The method has the advantages that the special equipment is a common high vacuum system which is based on an anode bonding technology principle and adopts a relatively cheap mechanical pump, namely molecular pump air-bleed set; at the same time, inert gas is used to take measures such as the repeated inflation to the vacuum system to clean, the high temperature baking to the local sample wafer to remove gas and so on, to lighten the influence of residual gas and adsorbed gas as far as possible, particularly lighten the oxidation of rubidium.

Owner:PEKING UNIV

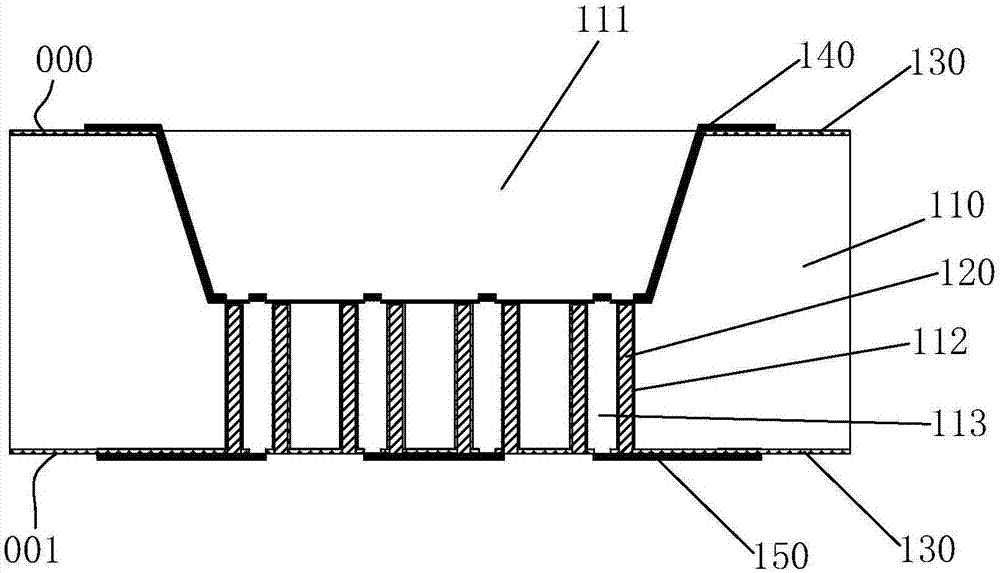

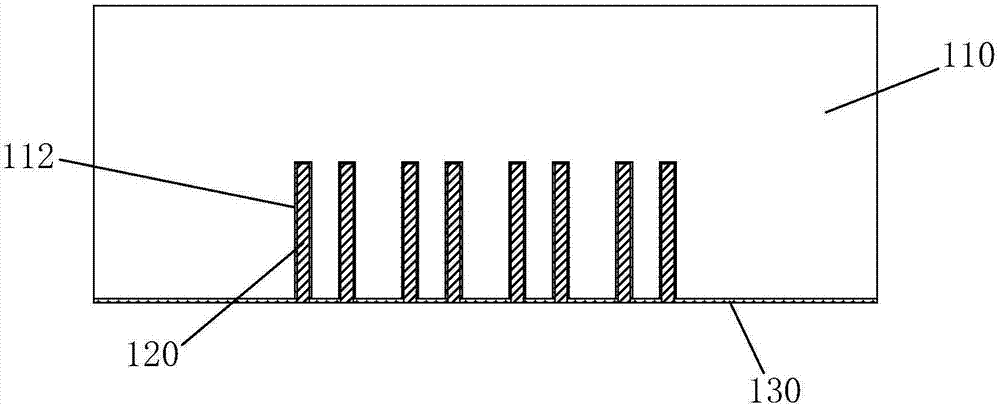

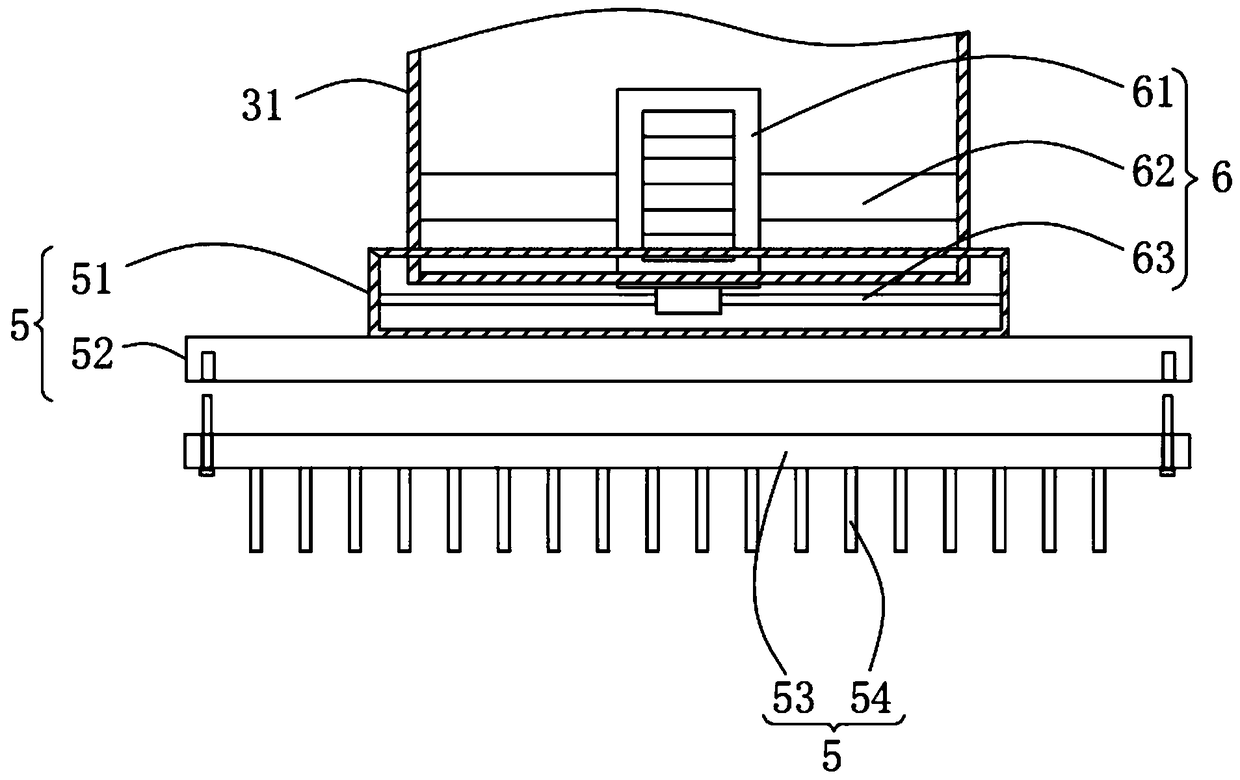

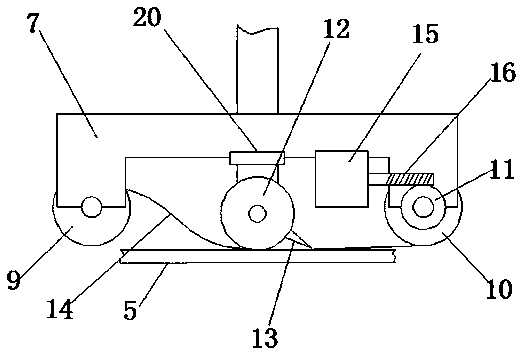

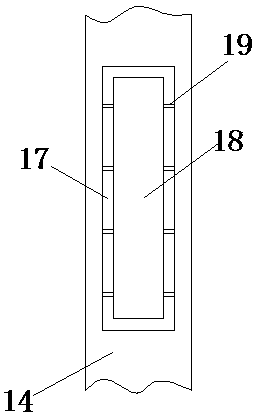

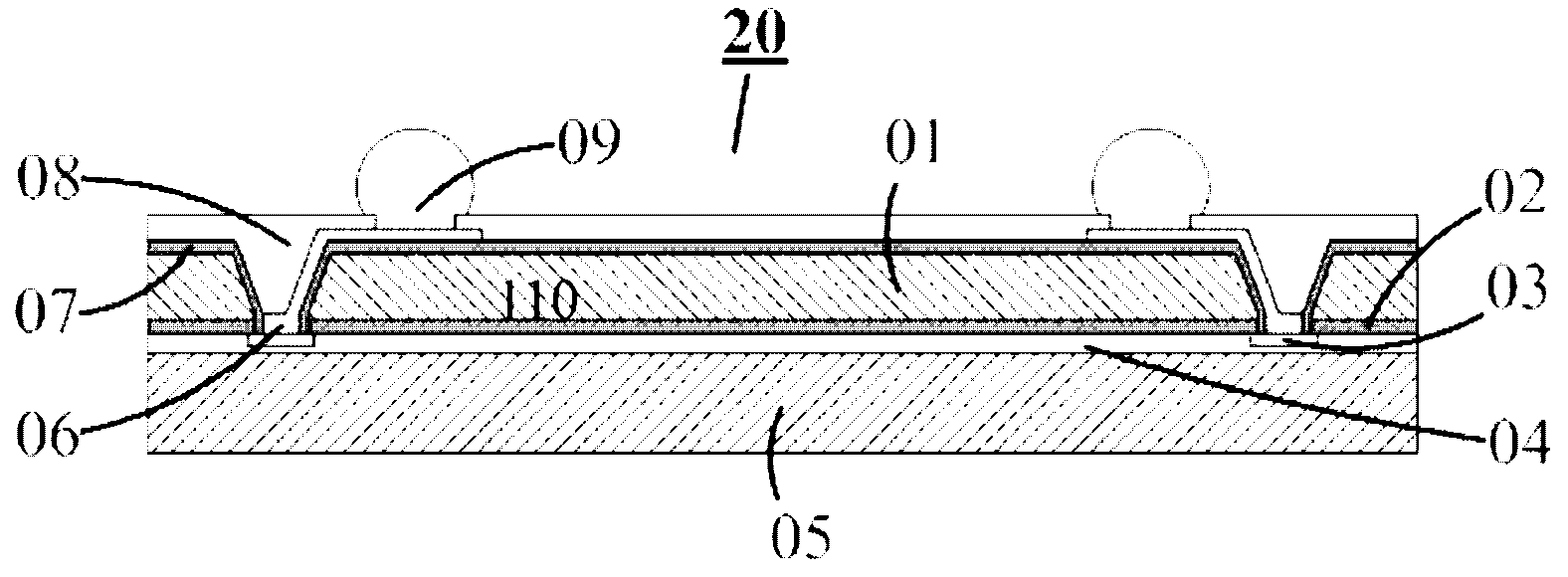

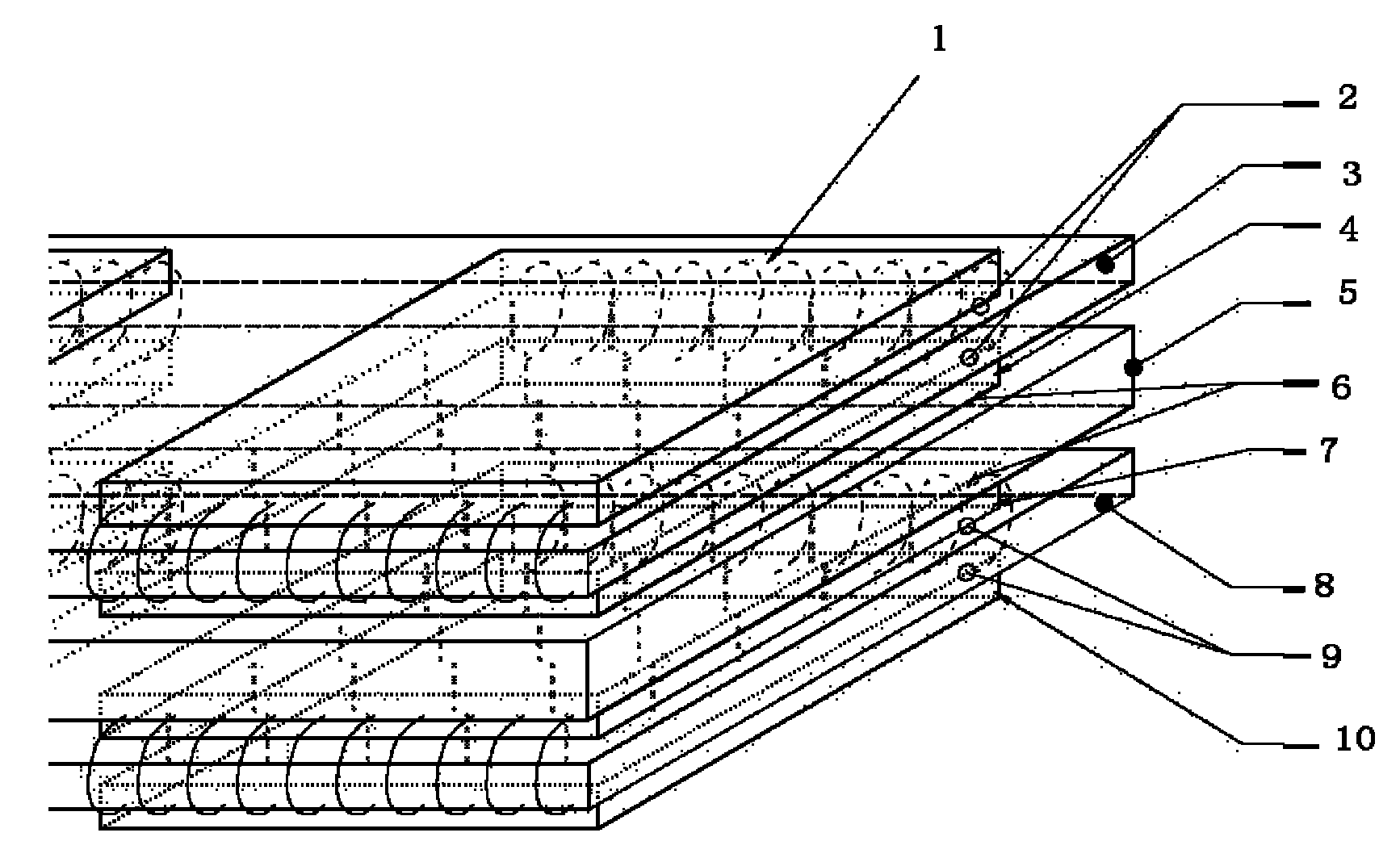

Embedded fan-out type silicon pinboard applied to three-dimensional system-level packaging and manufacturing method

PendingCN107452689AMiniaturizationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesHigh densityInterconnection

The invention discloses an embedded fan-out type silicon pinboard applied to three-dimensional system-level packaging. The front side of a silicon substrate is provided with a concave cavity whose side wall has certain gradient, the reverse side is provided with a vertical interconnection structure extending to the bottom of the concave cavity, and the vertical interconnection structure includes a plurality of mutually independent conductive columns; the front side of the silicon substrate and the side wall and the bottom of the concave cavity are provided with first metal interconnection layers used for being connected with a microelectronic chip bonding pad placed in the concave cavity and manufacturing a front side leading-out end; and the reverse side of the silicon substrate is provided with a second metal interconnection layer to be used for manufacturing a reverse side leading-out end, the first metal interconnection layers and the second metal interconnection layer are insulated from the silicon substrate, and the conductive columns are electrically connected with the first metal interconnection layers and the second metal interconnection layer. The invention also discloses a manufacturing method of the embedded fan-out type silicon pinboard and application to packaging, by use of the concave cavity combined with the vertical interconnection structure, application to three-dimensional system packaging is further realized on the basis of meeting requirements of high density, small size and low cost, thereby improving product performance.

Owner:XIAMEN UNIV

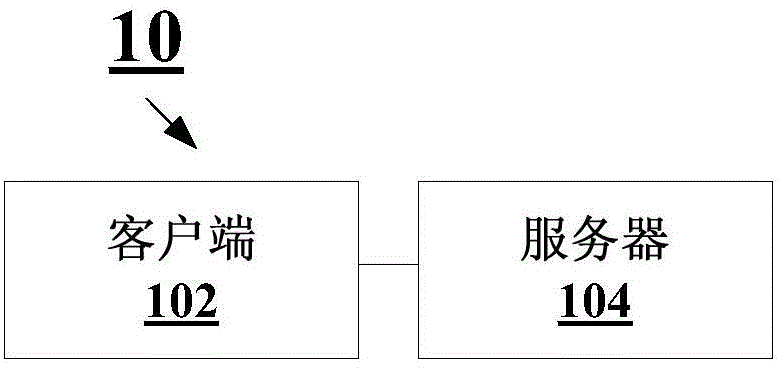

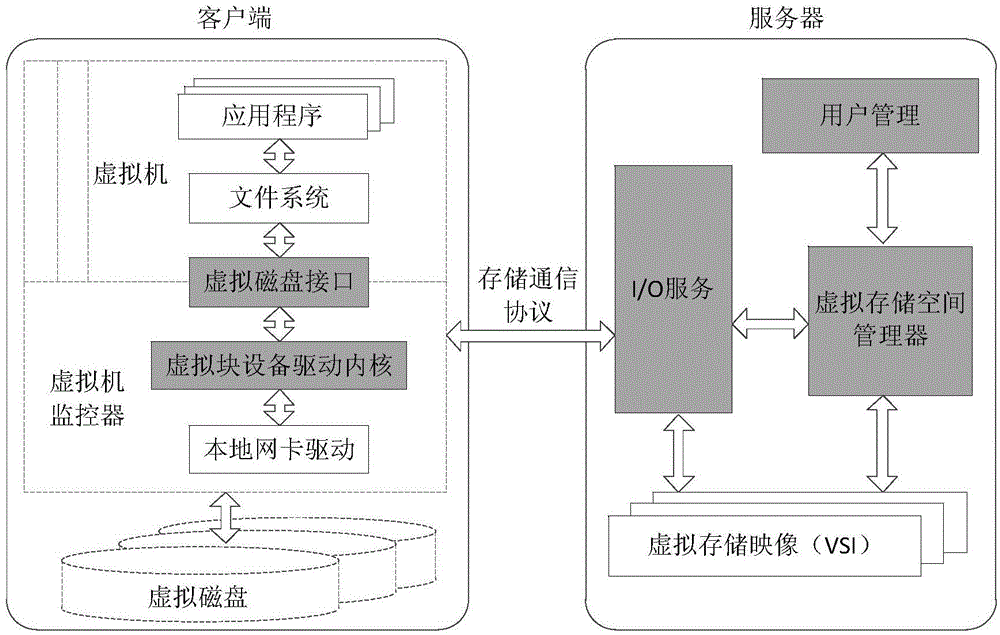

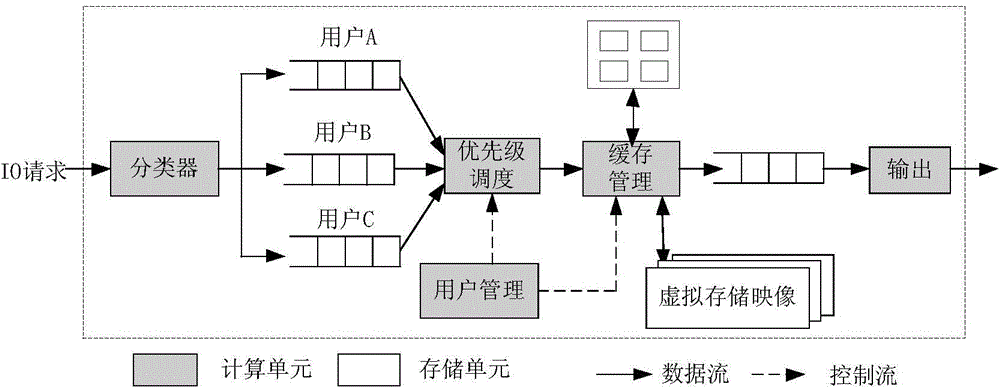

Network block device storage system and method for virtual machine

ActiveCN104636077AAchieve accessAccess request fulfillmentInput/output to record carriersTransmissionOperational systemFile system

The invention relates to a network block device storage system and method for a virtual machine. The method includes the steps that responses to execution conducted by users to application programs are made and a virtual machine operation system calls a virtual disk interface to send virtual disk reading and writing requests; the virtual disk interface transmits the reading and writing requests to a virtual block device drive unit; the virtual block device drive unit dispatches the reading and writing requests according to the I / O request types; according to the dispatching sequence, the reading and writing requests are packaged into network messages and the network messages are sent to a server through a storage communication protocol; the server receives the network messages sent by the multiple users, wherein the network messages carry IP addresses distributed to the users; parameters in the network messages are extracted and according to the extracted parameters, corresponding VSI serial numbers are searched for; through a file system and the corresponding VSI serial numbers, reading or writing operation is conducted on a corresponding region on a physical disk of the server. By the adoption of the network block device storage system and method for the virtual machine, packaging of intra-kernel services of the virtual machine is provided for the users and meanwhile network block device storage of the multiple users is supported.

Owner:CHINA TELECOM CLOUD TECH CO LTD

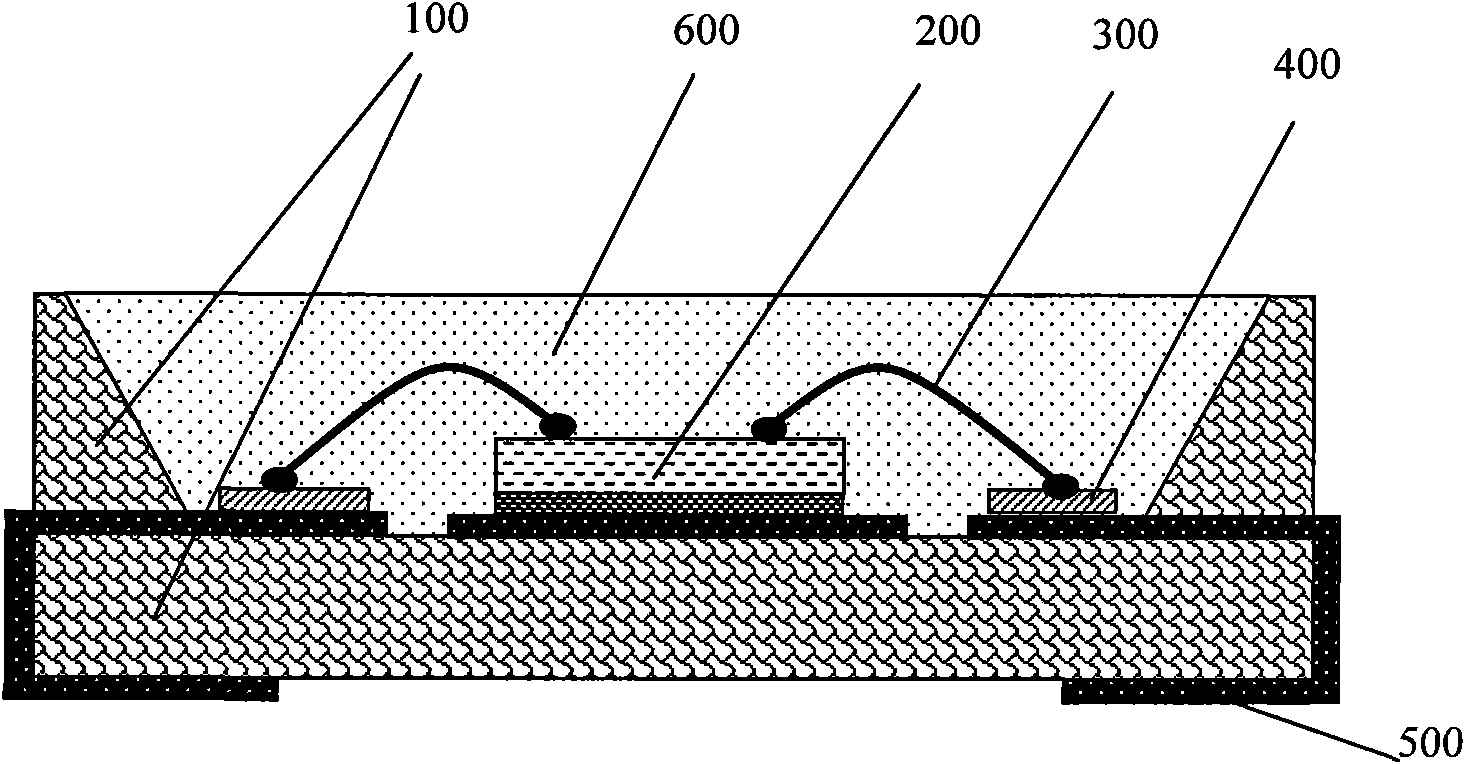

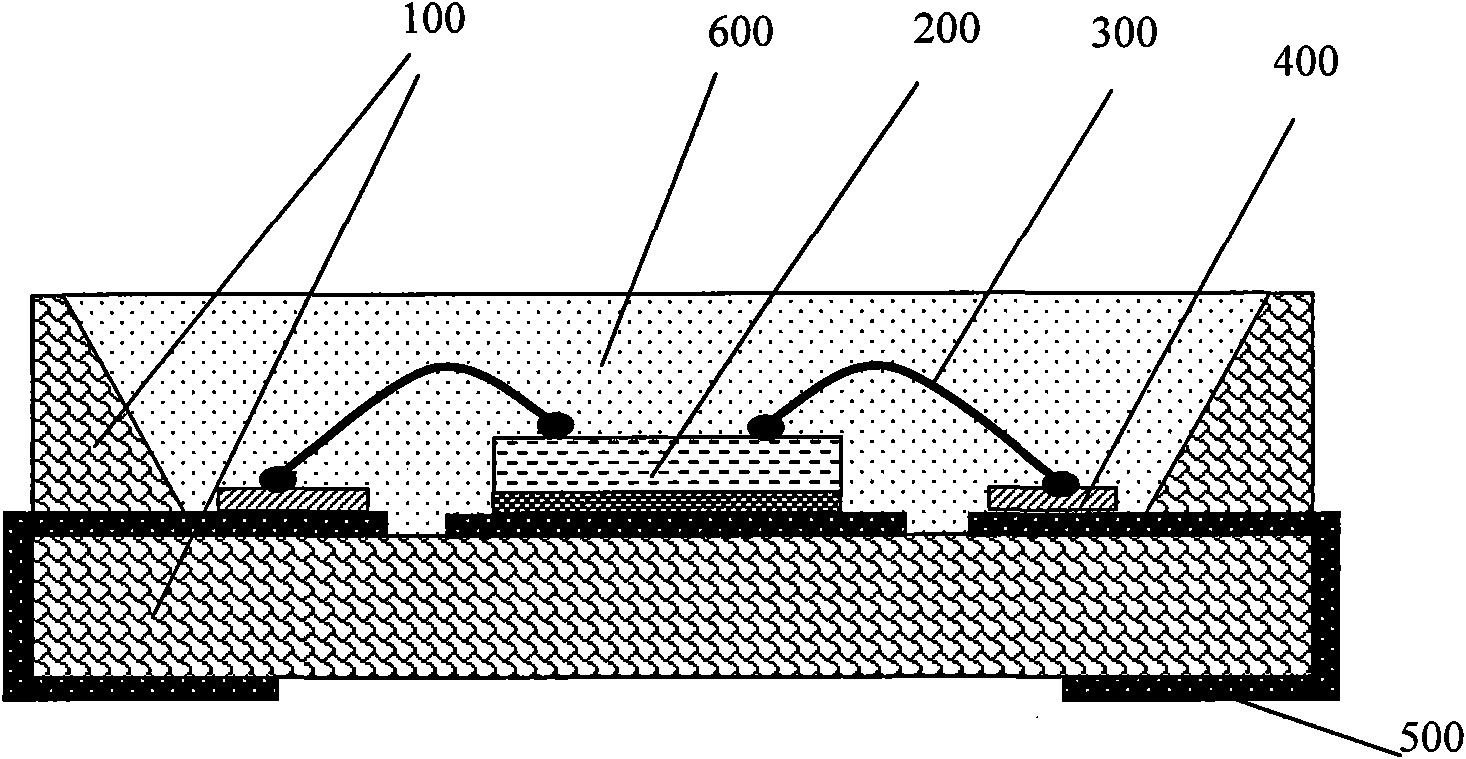

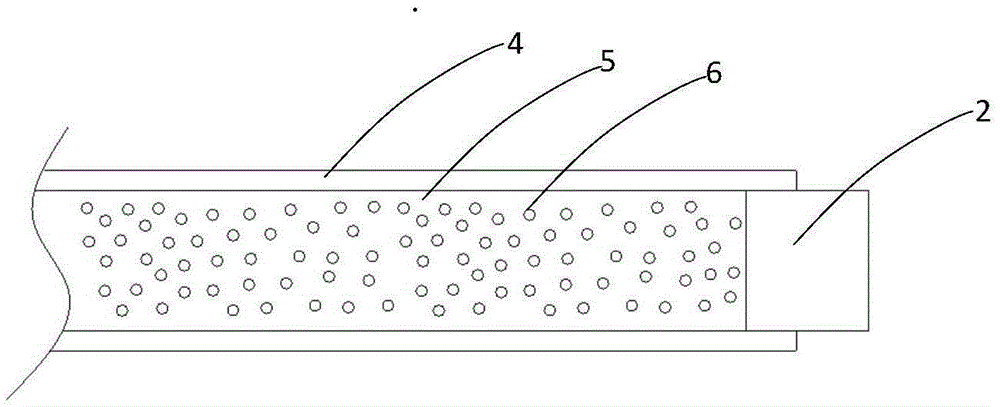

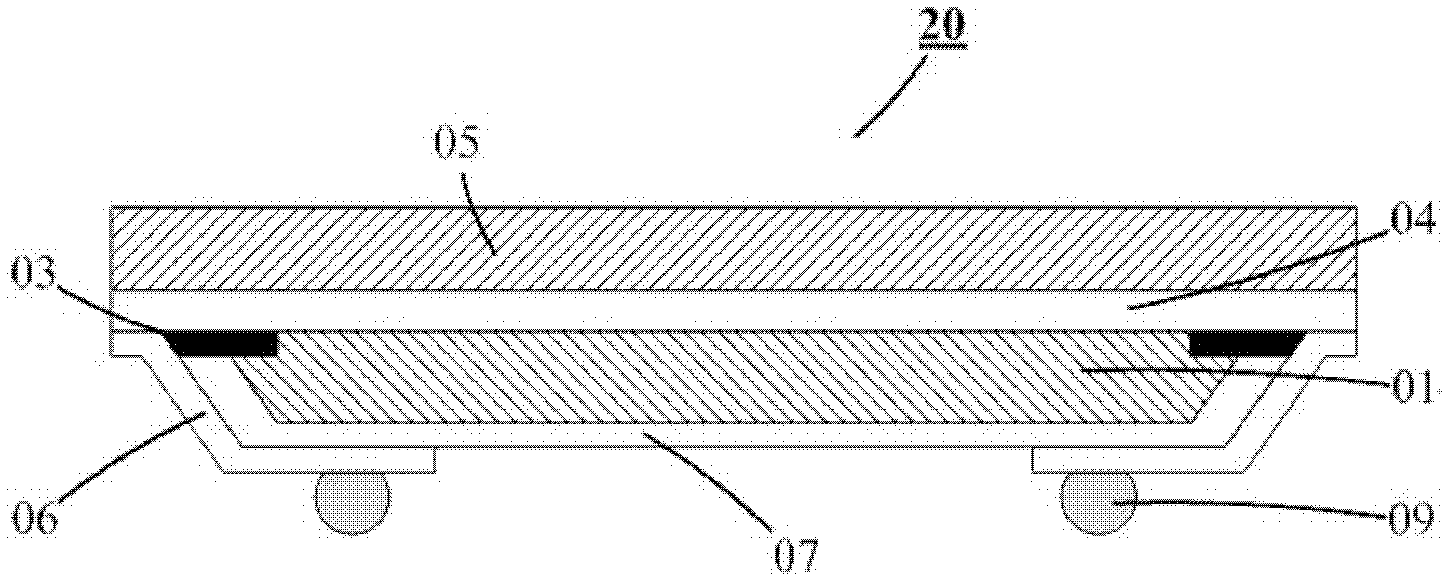

LED surface mounting structure for silicon substrate integrated with functional circuits and packaging method thereof

InactiveCN101958389AImprove cooling effectReduce volumeSolid-state devicesSemiconductor devicesHeat conductingSurface mounting

The invention relates to an LED surface mounting structure for a silicon substrate integrated with functional circuits, which comprises the silicon substrate and an LED chip. The upper surface of the silicon substrate has a planar groove-free structure; an oxidation layer cover the upper surface of the silicon substrate; a metal electrode layer is arranged on the upper surface of the oxidation layer; the upper surface of the metal electrode layer is provided with metal salient points; the LED chip is inversely arranged on the silicon substrate; the lower surface of the silicon substrate is provided with two conductive metal pads which are electrically connected with the metal electrode layer on the upper surface of the silicon substrate through metal leads arranged on the side wall of the silicon substrate; a heat conducting metal pad is arranged on the lower surface of the silicon substrate corresponding to the underside of the LED chip; and the upper surface of the silicon substrate is integrated with peripheral functional circuits required by the LED. The structure has the advantages of good radiating effect and small volume, LED driving and protecting functional circuits are directly integrated in the silicon substrate, wafer-scale industrial packaging is realized and the packaging and lamp cost is reduced.

Owner:APT ELECTRONICS

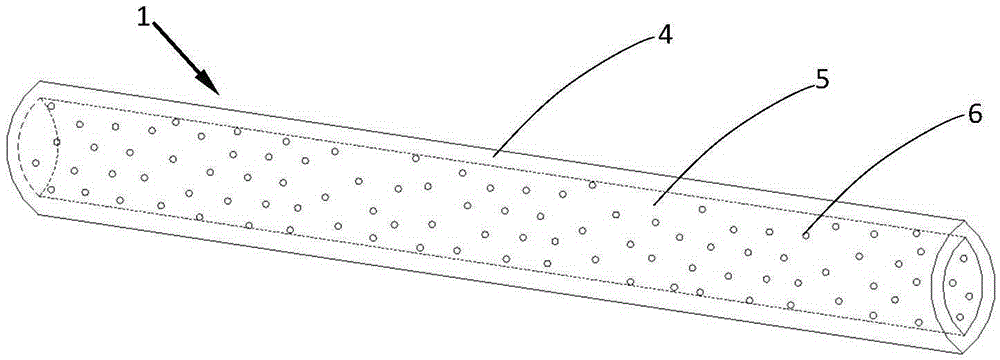

Calcium alginate fiber and preparation method thereof

InactiveCN103820880AUniform structureThe preparation method is simple and safeFilament/thread formingAlginate artificial filamentsFiber structureWater dynamics

The invention discloses a calcium alginate fiber and a preparation method thereof. The fiber is calcium alginate hydrogel with a porous structure, a rodlike structure or a rodlike and porous compound structure; the diameter of the fiber is 100-500mu m. According to the preparation method, on the basis of the action of hydrodynamics and by use of the chemical principle that sodium alginate reacts with calciumchloride to generate the calcium alginate hydrogel and the design of a microfluid device, sodium alginate solution and calciumchloride solution are mixed to generate gelation reaction; fibers with different structures and different sizes are generated by adjusting the flow velocity of internal-phase fluid. The preparation method disclosed by the invention has the advantages of simplicity, safety, lower cost and strong experimental repeatability; in the preparation process, a high-voltage electric field is not mentioned, so that the damage to cells is avoided and cell encapsulation can be realized. The prepared fiber structure has the advantages of uniformity, size controllability, good biocompatibility and broad application prospect; the prepared fiber structure can be directly applied to the fields of biomedicines such as cell culture and drug delivery.

Owner:SOUTHEAST UNIV

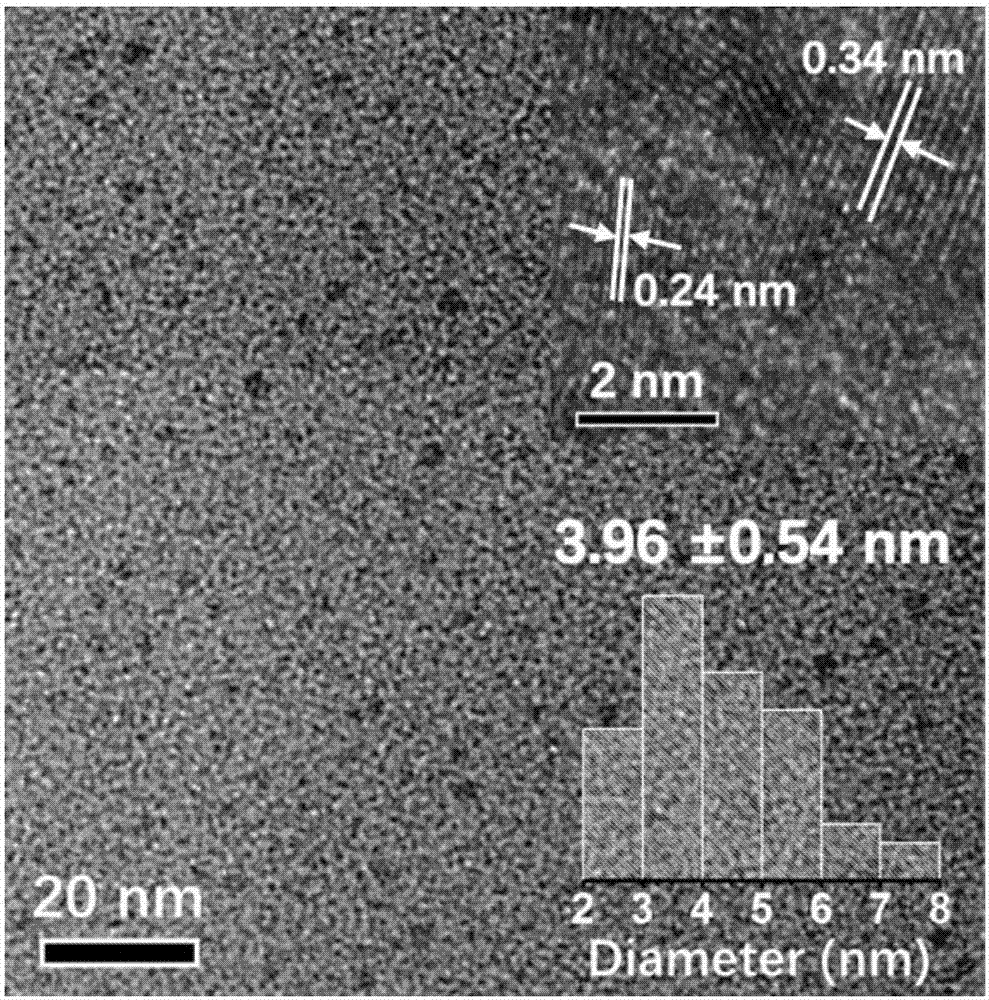

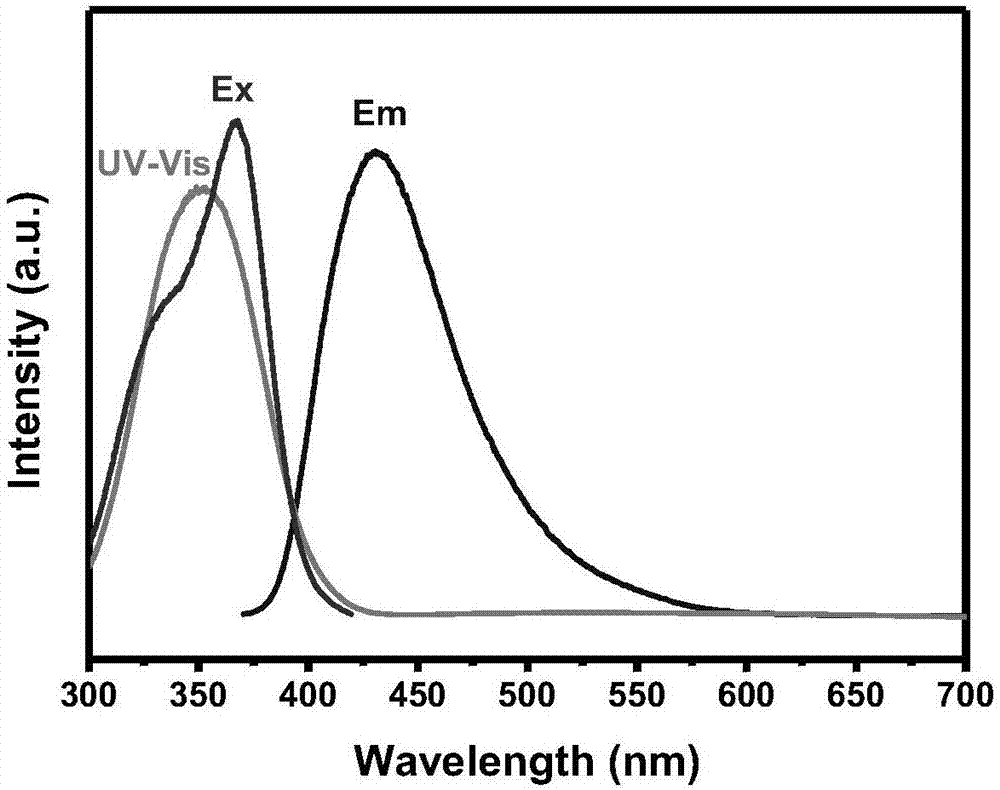

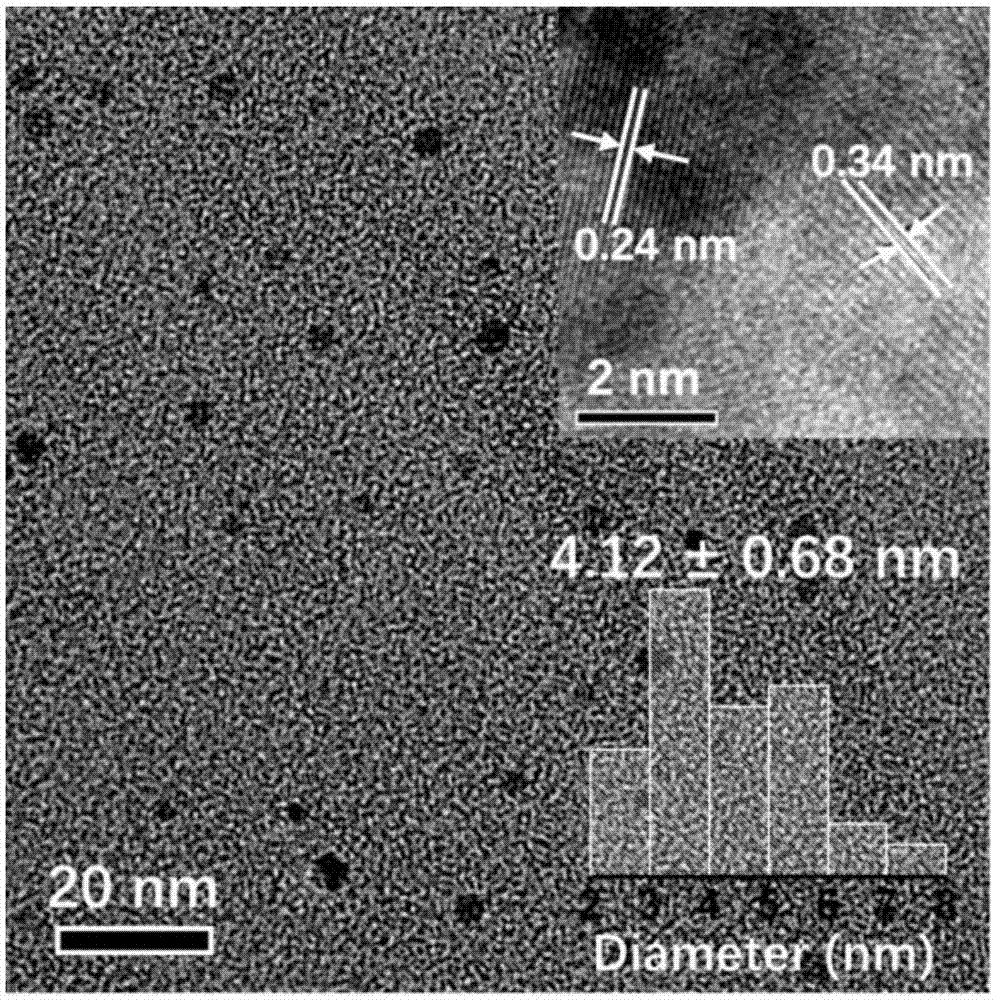

Preparation method of multicolor fluorescent carbon dots and application of multicolor fluorescent carbon dots in aspect of LED (light-emitting diode)

InactiveCN107418569ACheap way to prepareCheap manufacturingMaterial nanotechnologyNanoopticsEpoxyN dimethylformamide

The invention discloses a preparation method of multicolor fluorescent carbon dots and application of the multicolor fluorescent carbon dots in the aspect of LED (light-emitting diode), and relates to the field of luminescent materials. The efficient multicolor fluorescent carbon dots can be obtained through regulating the proportion and reaction temperature of a reactant. The carbon dots are prepared by the following method: citric acid and urea, in different proportions, are dissolved in N,N-dimethylformamide, the reaction temperature is controlled to be 140 to 200 DEG C to carry out solvothermal reaction, the fluorescent carbon dots with the maximum emission peak covering 400 to 650nm are obtained, and the fluorescent carbon dots with the fluorescence quantum efficiency all being 10% or above are obtained, wherein the blue light is 52%, the green light is 35% and the red light is 13%. The carbon dots can be used as luminescent powder of an LED to be directly added into an encapsulating material epoxy resin of the diode, and used for preparing LED devices with blue light, green light, red light and white light.

Owner:BEIJING UNIV OF TECH

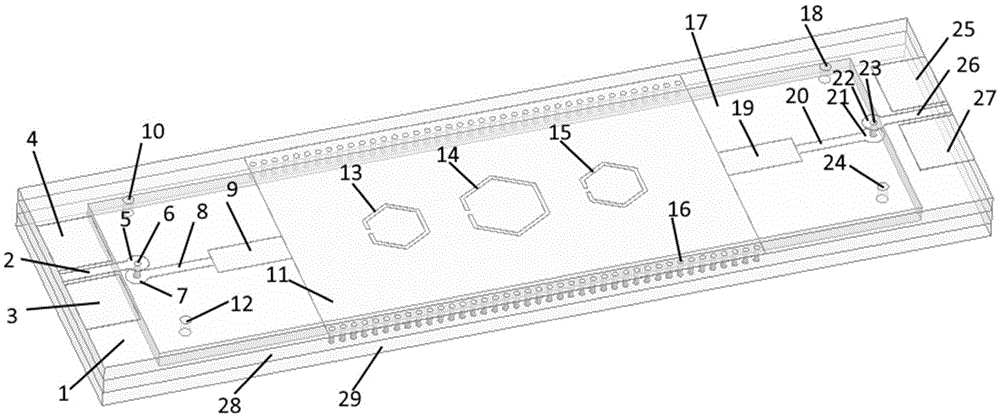

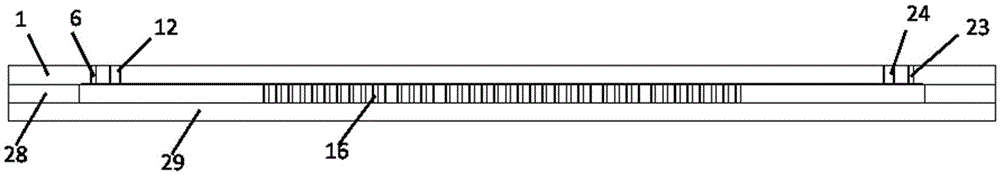

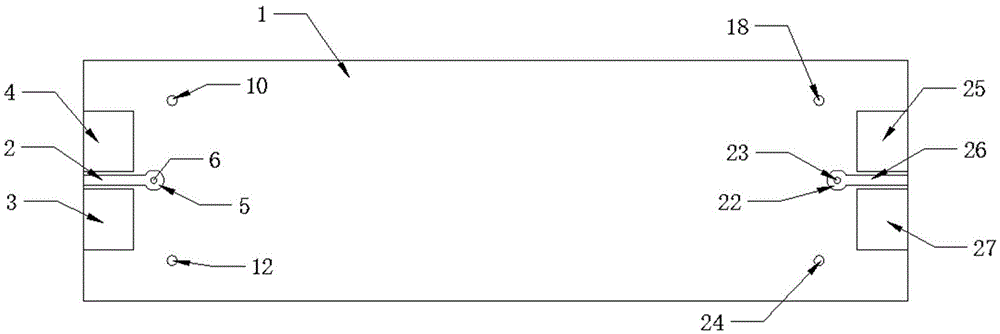

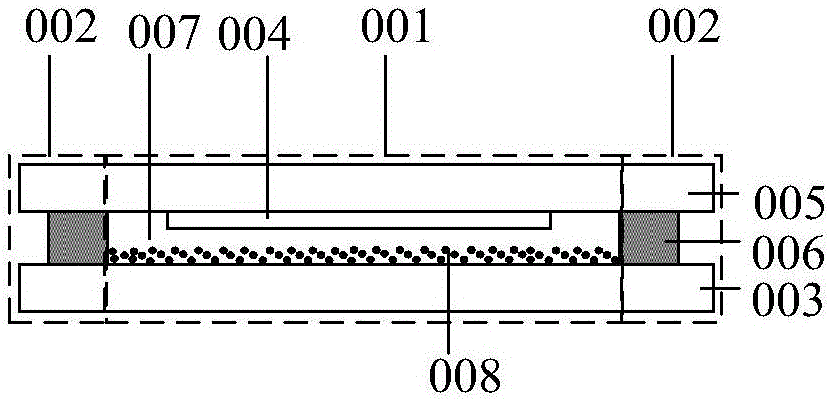

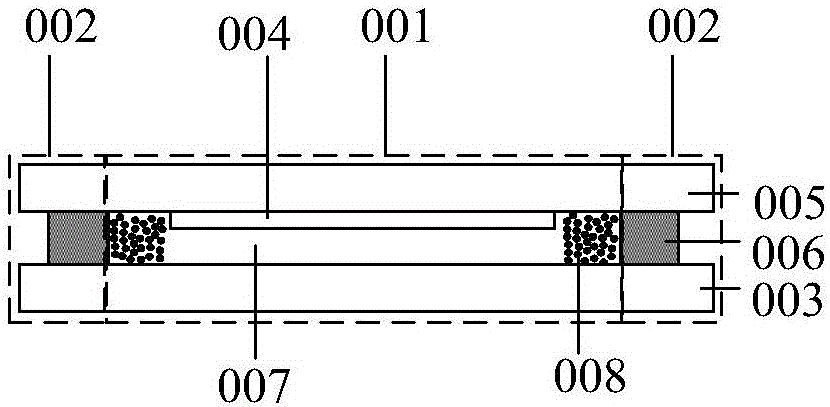

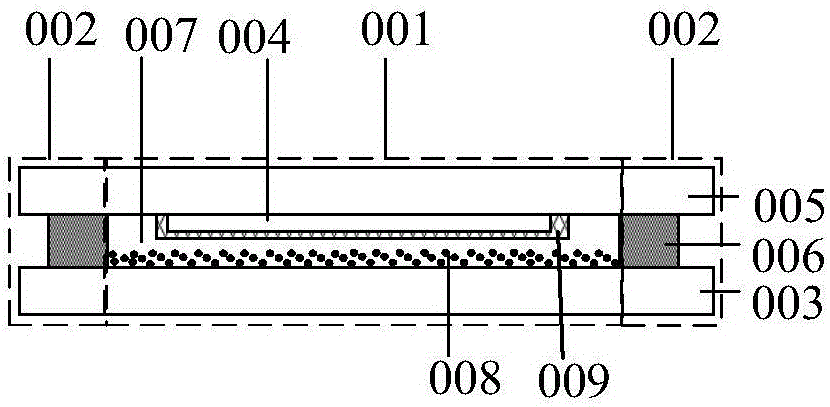

Substrate integrated waveguide microwave tunable filter based on liquid crystal material

InactiveCN105489987AOvercome Impedance MismatchAddressing Impedance MismatchesWaveguide type devicesSatelliteLiquid crystal

The invention discloses a substrate integrated waveguide microwave tunable filter based on a liquid crystal material, wherein the substrate integrated waveguide microwave tunable filter belongs to the technical fields of wireless communication, satellite communication, radar system, etc. Particularly the invention relates to a filter based on the liquid crystal material. The filter settles a problem of liquid crystal material leakage in an existing packaging process. The filter settles a problem of impedance mismatch in manners of interlayer through hole interconnection and strip line stepped impedance transformation. A modulating voltage is added through direct contact type feeding. A bandpass filter is realized through etching an open resonance ring structure on an upper-surface metal layer of a substrate integrated waveguide. The upper-surface metal layer of the substrate integrated waveguide is reversed for contacting with the liquid crystal material, thereby forming the substrate integrated waveguide tunable filter based on the liquid crystal material. The substrate integrated waveguide microwave tunable filter settles the problem of liquid crystal leakage in a traditional packaging method and has effects of impedance matching and continuous adjustable frequency response of the filter.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

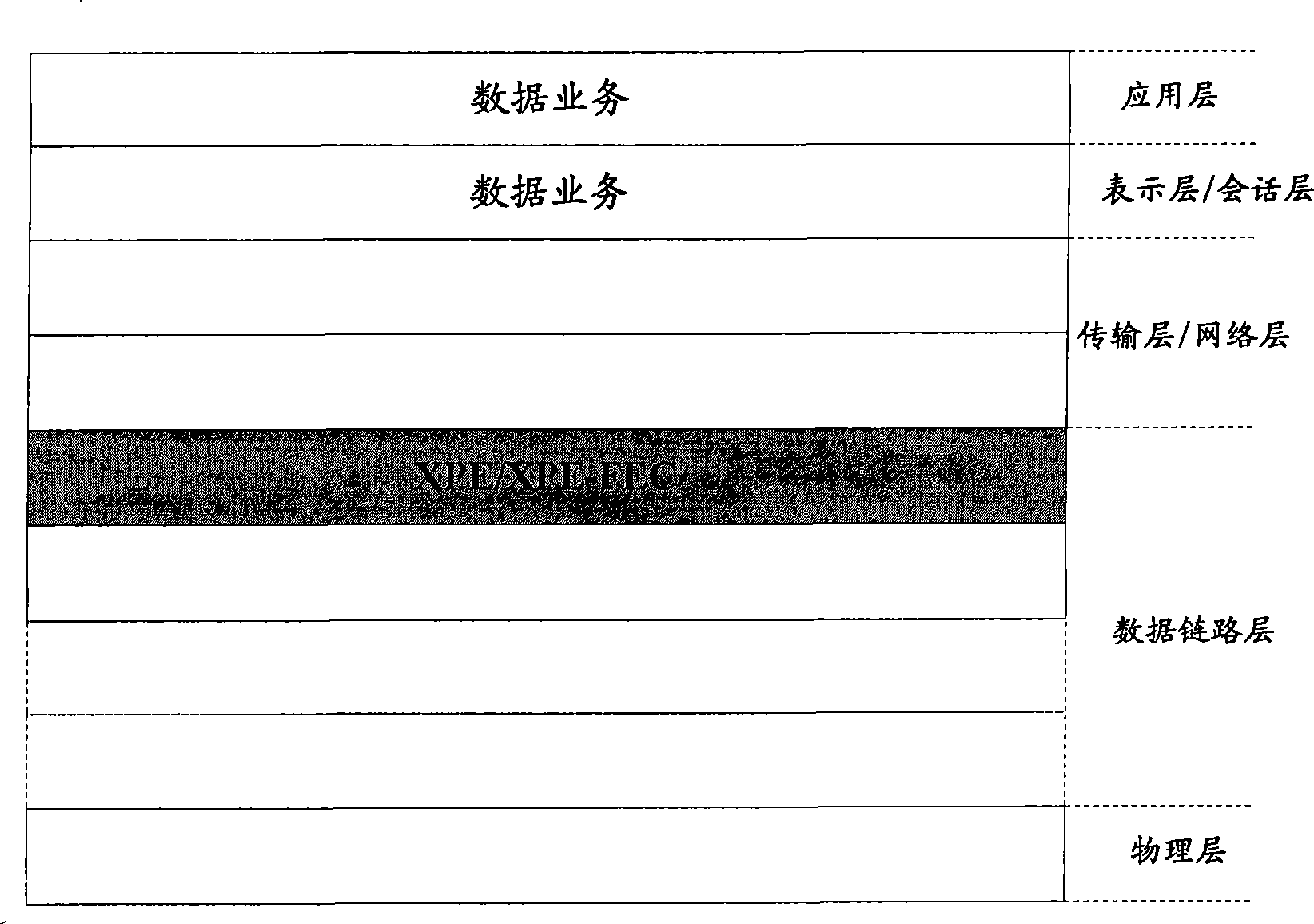

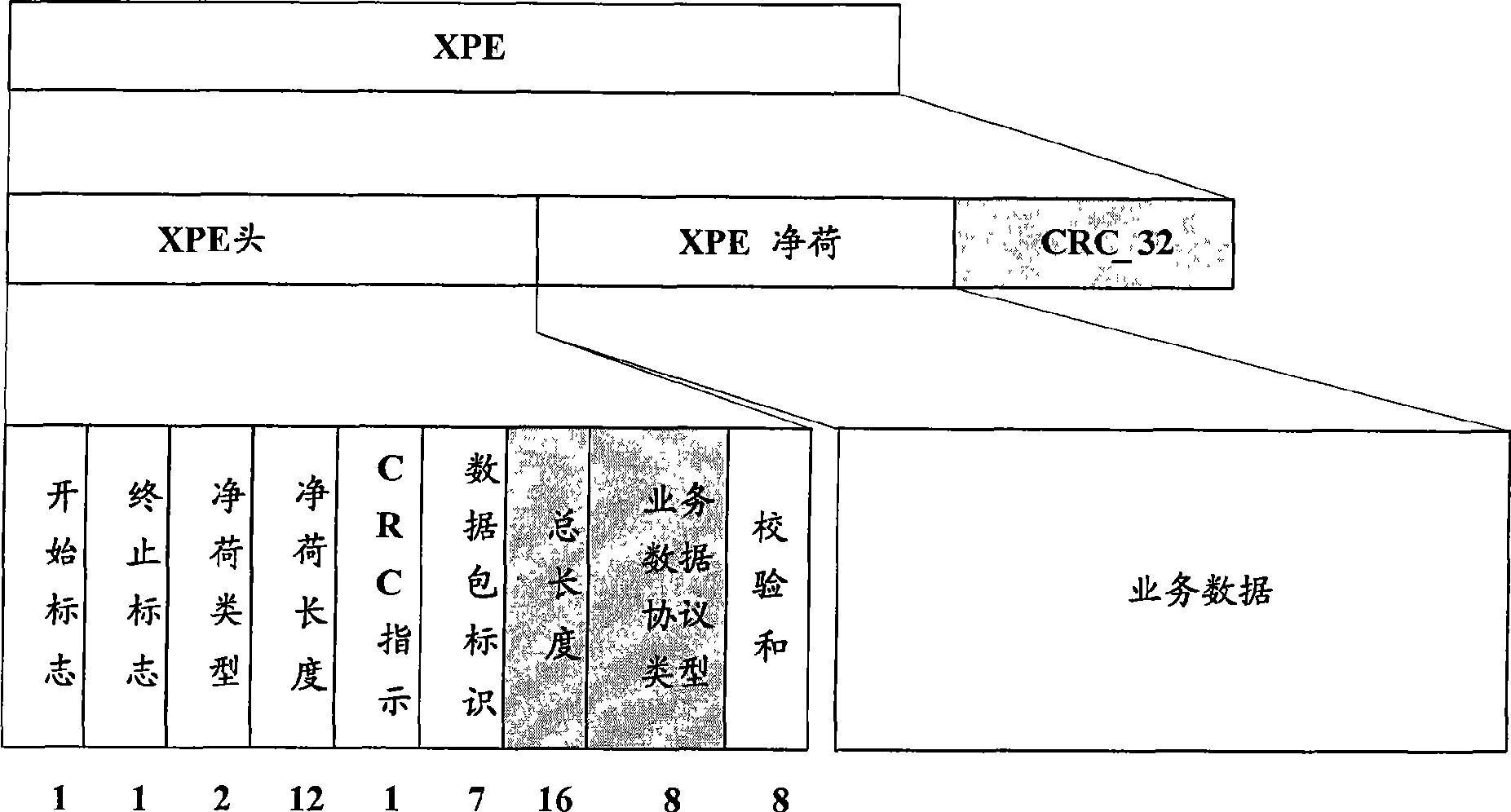

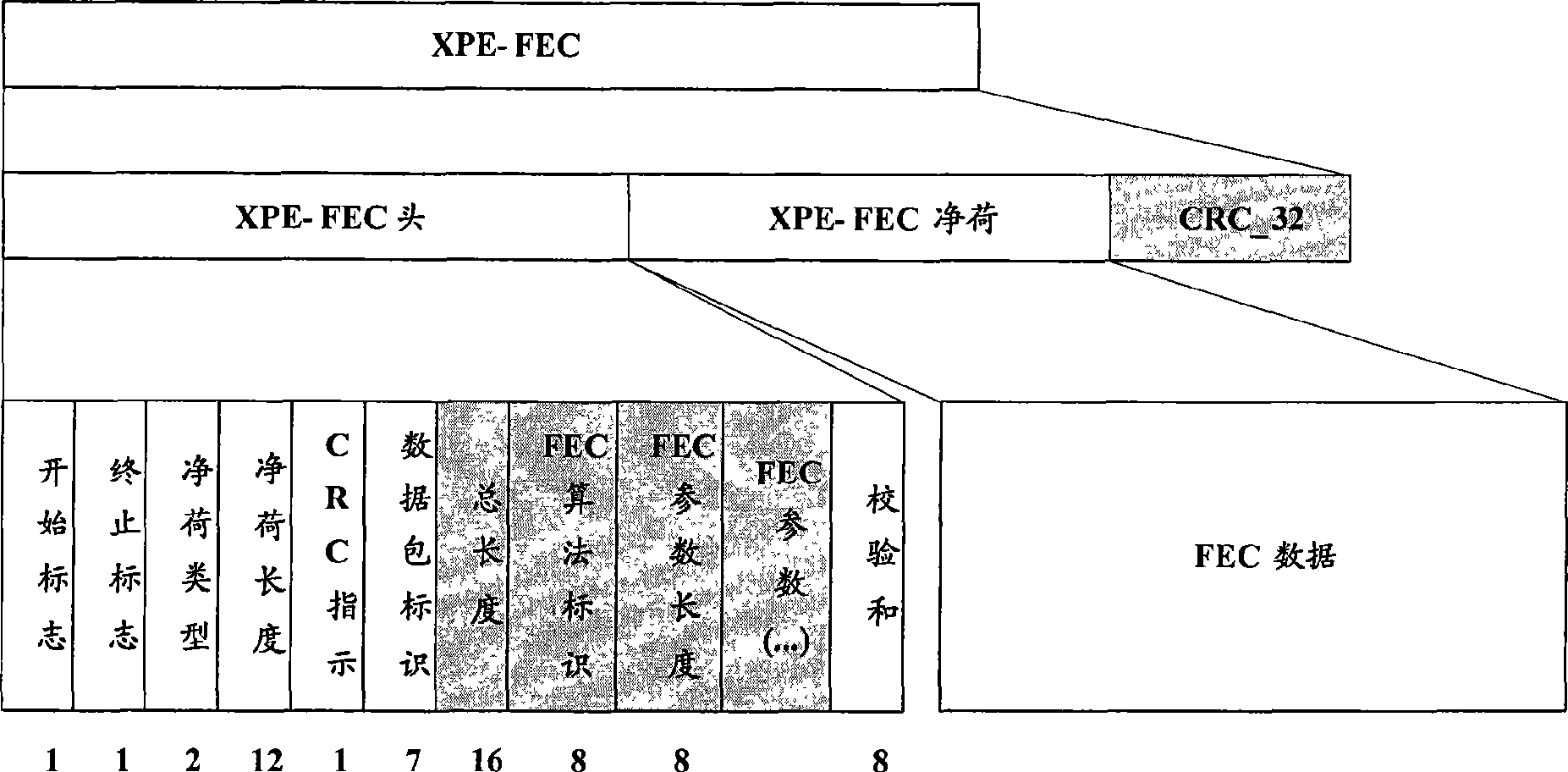

Multi-protocol service data package parsing method, receiving terminal and sending terminal

InactiveCN101459654AResolve Compatible TransportsImplement encapsulationData switching networksNetwork packetLink data

The invention provides a multi-protocol service data packaging and analyzing method, a receiving end and a sending end, wherein the packaging method comprises: creating a data packet which comprises two parts of tips and payloads when a data link layer has service data which needs transmitting, storing the service data into the part of payloads in the data packet, assigning value to each field in the tips of the data packet, thereby realizing the package of the service data. The service data of different modes can be uniformly packed into an XPE / XPE-FEC bag and can be transmitted through defining an XPE bag and an XPE-FEC bag in a link data layer and through applying the technical scheme, and the package of multi-protocol data can be realized, users can conveniently and rapidly receive multi-mode service data, and compatible transmission of the multi-mode service data can be effectively solved.

Owner:LENOVO MOBILE COMM TECH

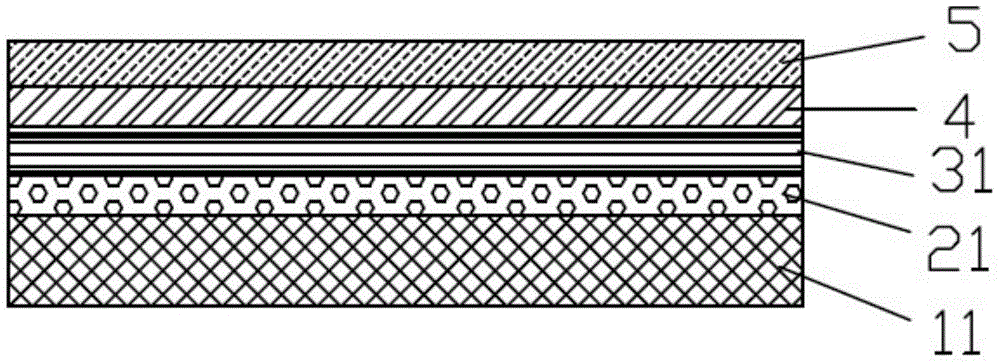

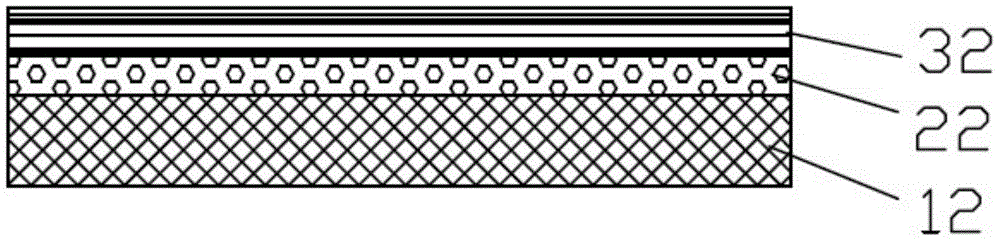

Manufacturing method of flexible display device and flexible display device manufactured by adopting same

InactiveCN104576970AImprove film densityReduce pinholes and grain boundariesSolid-state devicesSemiconductor/solid-state device manufacturingPolymer substrateEngineering

The invention provides a manufacturing method of a flexible display device. In the manufacturing method, a water and oxygen barrier layer is directly arranged on a flexible polymer substrate, and then arranged on an organic light-emitting diode in a bonding manner, so that the film-forming compactness of the inorganic barrier layer can be improved, and accordingly the water vapor and oxygen permeation preventing capability of the water and oxygen barrier layer is improved, degradation and deterioration of various materials in the organic light-emitting diode are prevented and the service life of the flexible display device is prolonged; the manufacturing process of the organic light-emitting diode and the manufacturing process of the water and oxygen barrier layer are not required to be sequentially carried out, the water and oxygen barrier layers on a first flexible polymer substrate and a second flexible polymer substrate can be manufactured synchronously or manufactured on the same flexible polymer substrate, and a cutting process is performed as required, so that a production process can be simplified and purposes of improving the production efficiency and reducing the cost are achieved. The invention further provides the flexible display device manufactured by the manufacturing method. The flexible display device is relatively long in service life.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

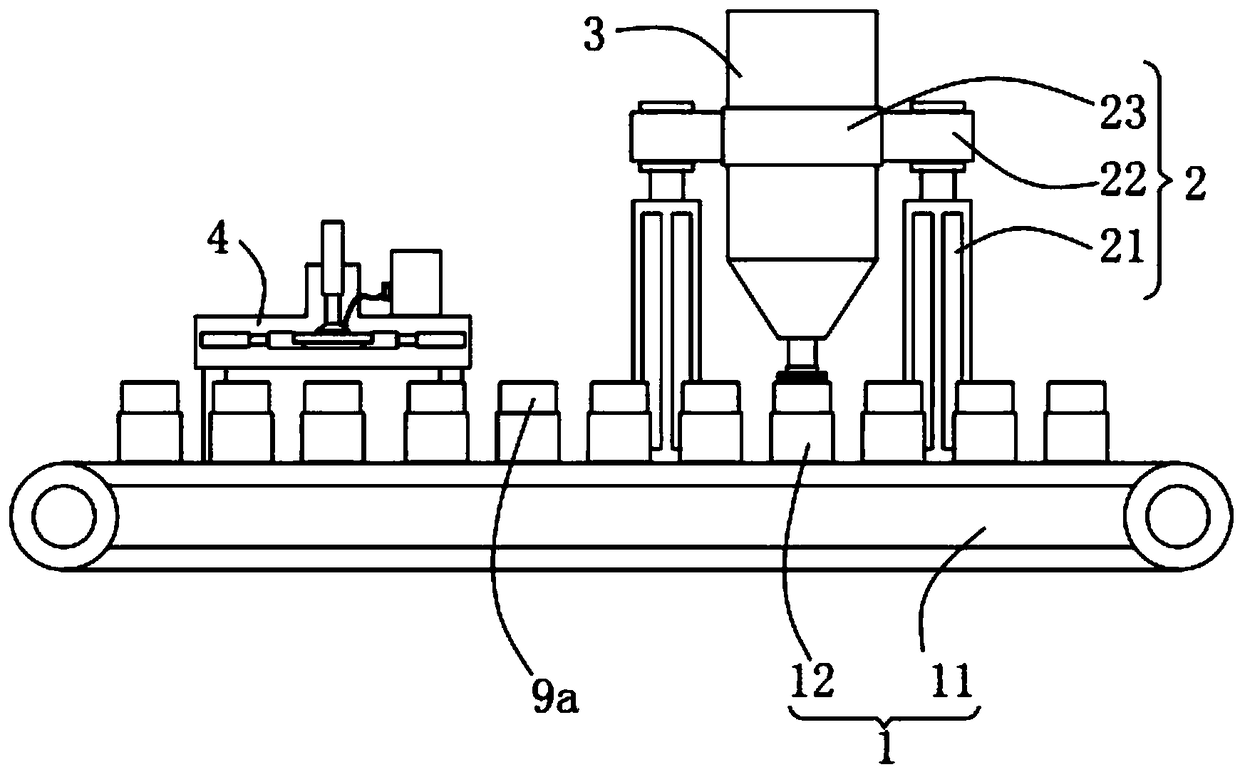

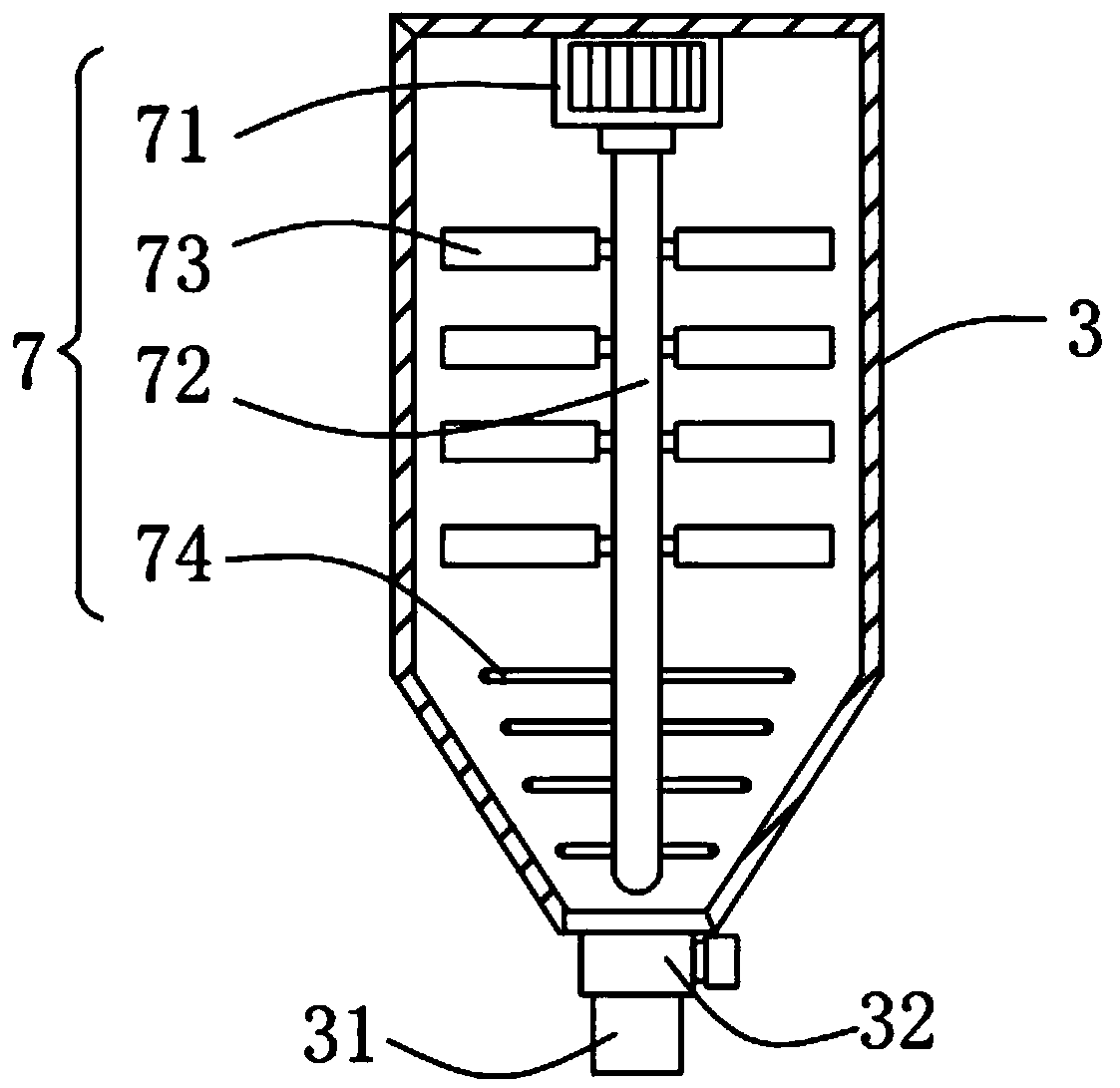

Powder material packaging machine

ActiveCN109335113AEvenly stackedQuick unloadingRotary stirring mixersSolid materialPackaging TankEngineering

The invention relates to the technical field of food processing equipment, in particular to a powder materials packaging machine. The powder material packaging machine comprises a conveying mechanism,a lifting mechanism, a material storage cylinder, a sealing mechanism, a flattening mechanism, a rotating mechanism, a stirring mechanism and a feeding mechanism. According to the machine, a discharging pipe can be driven to move upwards gradually from the bottom layer in a packaging tank through the lifting mechanism, so that the materials are gradually accumulated from bottom to top, and the accumulation is more uniform; meanwhile, the rotating mechanism can drive the flattening mechanism to rotate, a shifting rod can shift and scatter the materials, a flattening plate can flatten the materials, so that the powder materials can fully fill the whole packaging tank; in the discharging process, stirring blades can stir the top area of the packaging tank, stirring rods which are distributedin a funnel shape can stir the outlet area of the packaging tank, so that the discharging is more rapid and the blockage is prevented; and automatic feeding and packaging can be realized.

Owner:台州佑辅机械实业有限公司

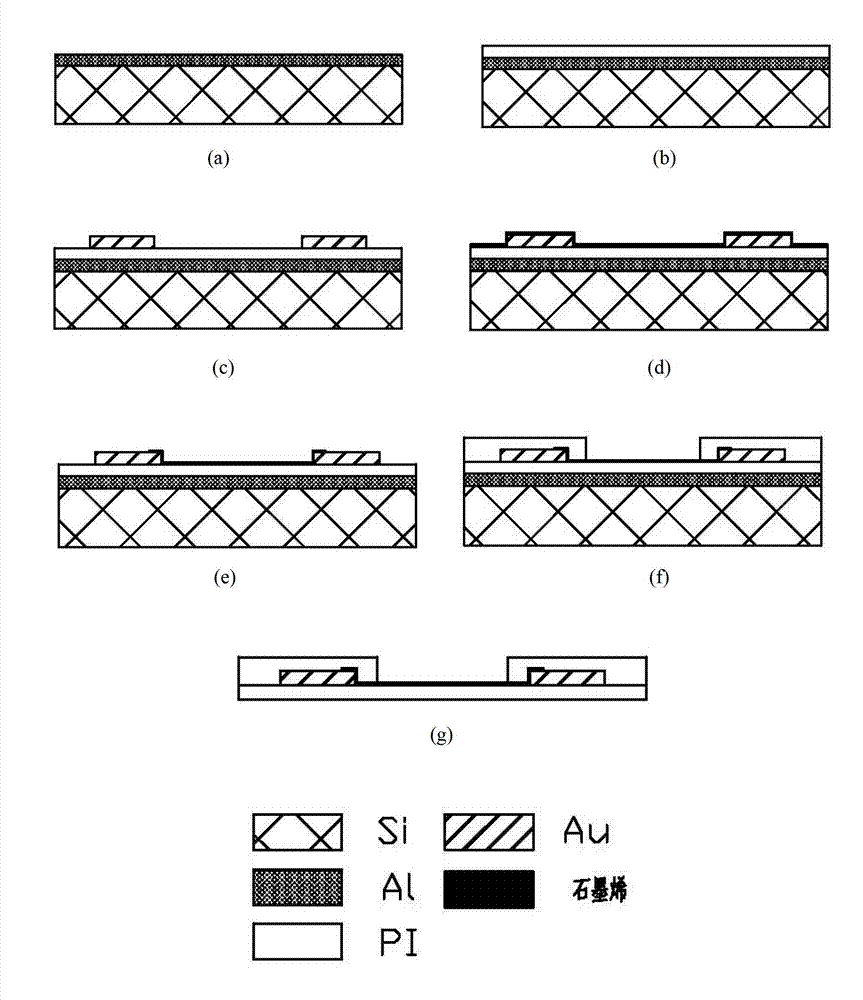

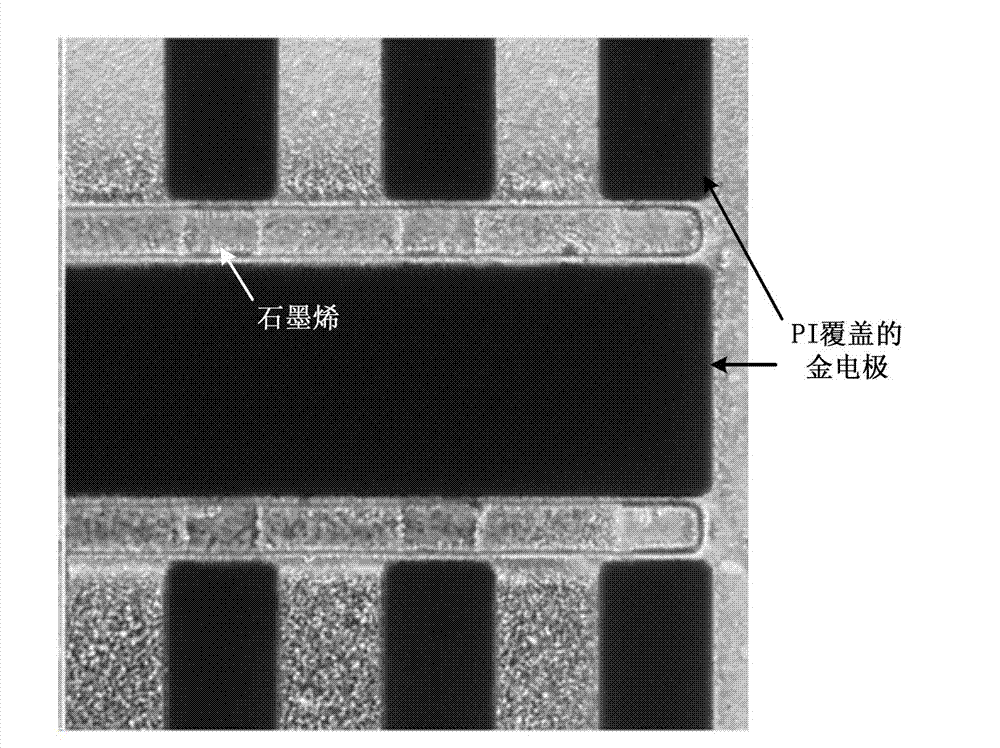

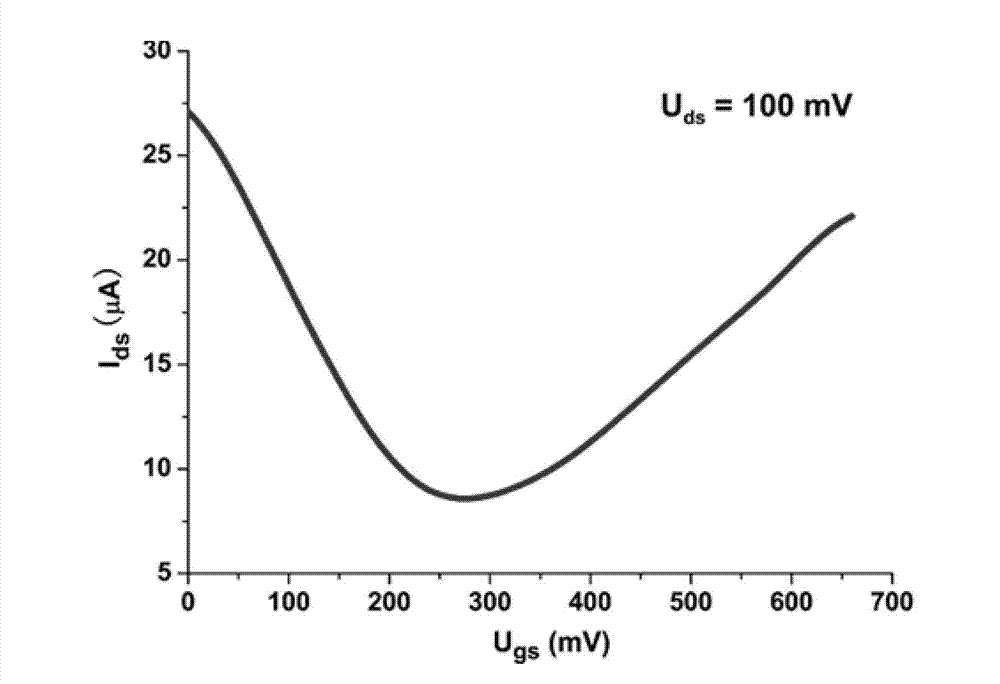

Preparing method and detecting method of liquid grid type grapheme field-effect tube based on polyimide (PI)

ActiveCN103199020AFacilitated releaseReduce contact resistanceTransistorSemiconductor/solid-state device manufacturingField-effect transistorPhotoresist

The invention relates to a preparing method and a detecting method of a liquid grid type grapheme field-effect tube based on polyimide (PI). The methods are characterized in that an aluminum layer is deposited on a silicon substrate to be used as a sacrificial layer, PI photoresist is coated on the aluminum layer in a spin mode to be used as a substrate of a flexible field-effect tube, a commercialized grapheme / polymethyl methacrylate thin film is transferred to a titanium / gold electrode which is deposited on the PI substrate in advance to form good ohmic contact, AZ 4620 photoresist is used as a mask layer for grapheme patterning, grapheme is etched through oxygen plasma, and an insulating layer is manufactured on the surface of the patterned grapheme through the PI photoresist to form a liquid grid type structure. The field-effect tube is in the liquid grid type structure, so that machining steps can be reduced, further surface decoration on the surface of the grapheme is convenient, and accordingly specific detection on various biological signals is achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

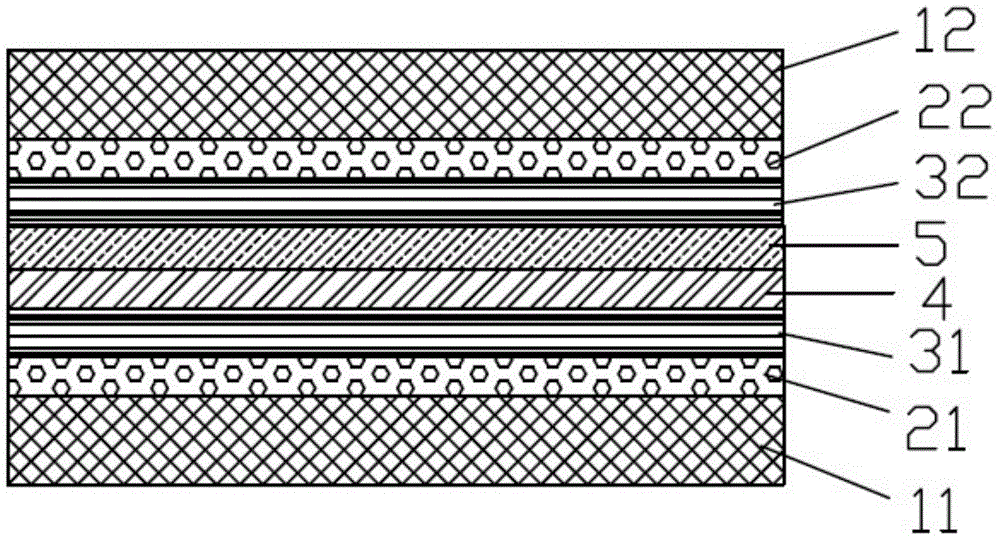

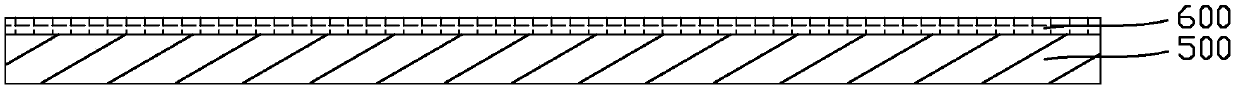

OLED display panel encapsulation method and encapsulation structure

InactiveCN107644946AImplement encapsulationRealize functionSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayOxygen barrier

The invention provides an OLED display panel encapsulation method and encapsulation structure. According to the OLED display panel encapsulation method provided by the invention, a film encapsulationlayer for water and oxygen barrier is independently fabricated with respect to an OLED substrate; a number of annular first grooves and a number of annular first protrusions are formed on the first inorganic barrier layer of the film encapsulation layer and the OLED substrate through photolithography; and a vacuum bonding method is used to bond the OLED substrate and the film encapsulation layer through meshing of a number of first protrusions and a number of first grooves and an adhesive layer, so as to realize the functions of film encapsulation and flexible display. The technical problem that the existing OLED film encapsulation process is complex is effectively solved. Particles, holes and other badness caused by a diaphragm plate and increased cost in the production process are prevented. Low membranous density caused by low temperature film formation and other technical problems are solved. The film encapsulation layer and the OLED substrate are manufactured independently, whichis beneficial to improving the product yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

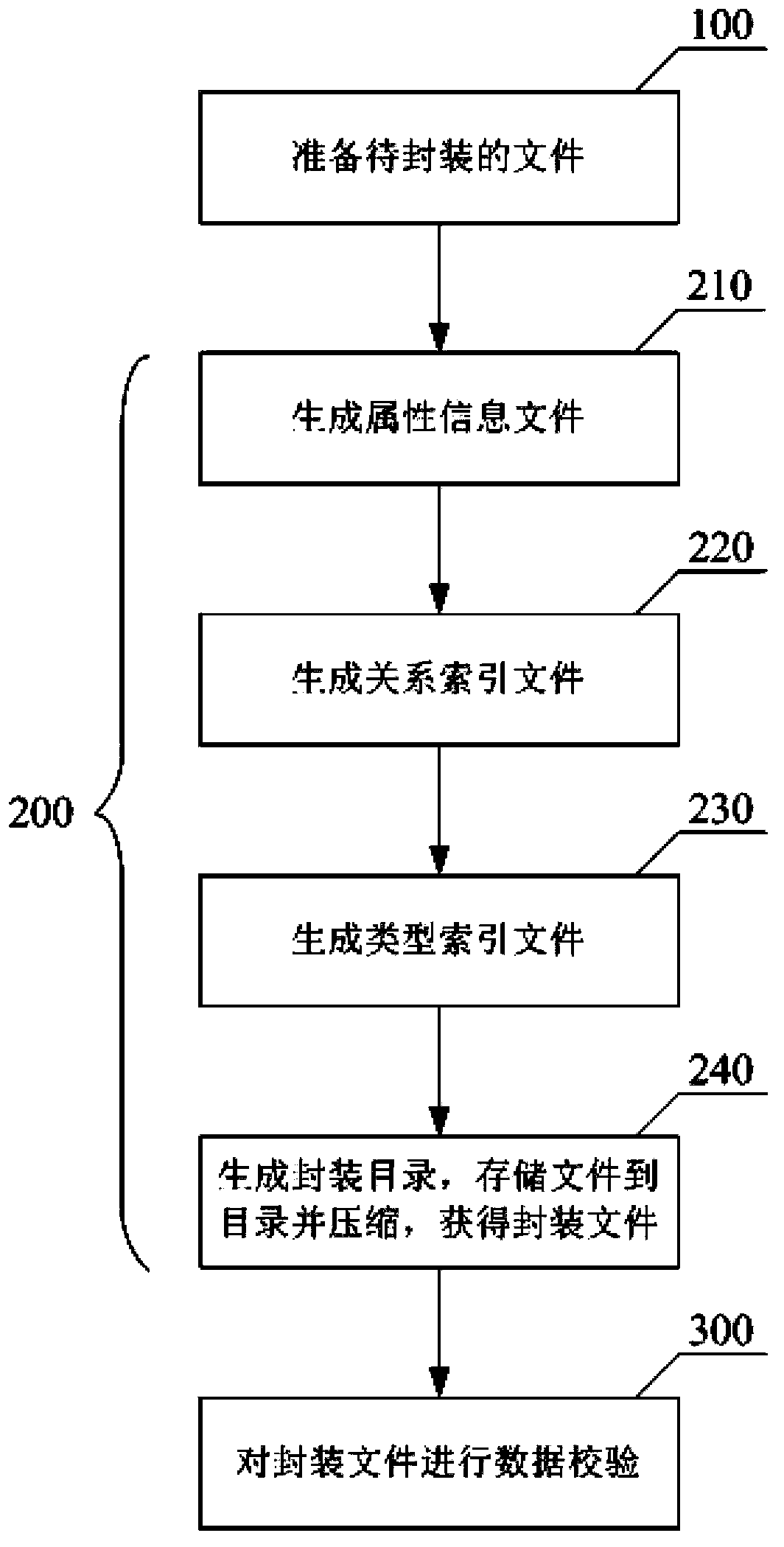

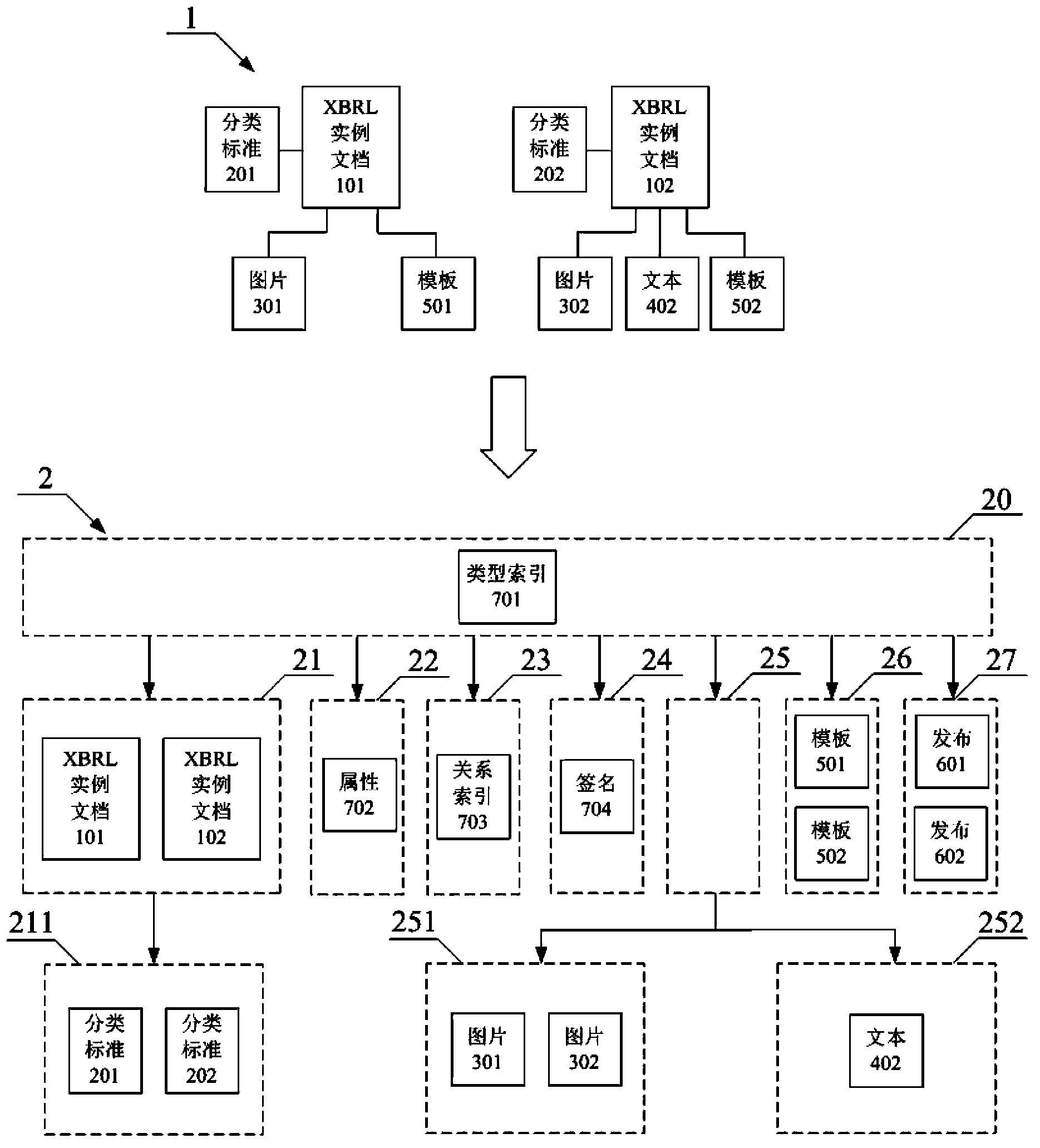

Method for encapsulating XBRL (extensible business reporting language) instance documents

ActiveCN103885925AReduce complexityImprove application efficiencySpecial data processing applicationsRelevant informationEngineering

The invention discloses a method for encapsulating XBRL (extensible business reporting language) instance documents. The method includes preparing a required-to-be-encapsulated files; at least generating attribute information files, relation index files and type index files; generating encapsulation directories; storing the required-to-be-encapsulated files and the generated files in the various corresponding directories and compressing the files to obtain encapsulated files; verifying data of the encapsulated files. Each required-to-be-encapsulated file contains at least one XBRL instance document. Each encapsulation directory at least contains a root directory, an instance document directory, an attribute information directory and a relation index directory. The method has the advantages that the encapsulation directories which are of multilayer structures are generated, the various files are respectively stored in the various corresponding directories, accordingly, the XBRL instance documents and relevant information of the XBRL instance documents can be structurally encapsulated in a standardized manner, and electronic organizational structures and forms of the XBRL instance documents and the relevant information can be unified.

Owner:INFORMATION CENT OF CHINA SECURITIES REGULATORY COMMISSION +1

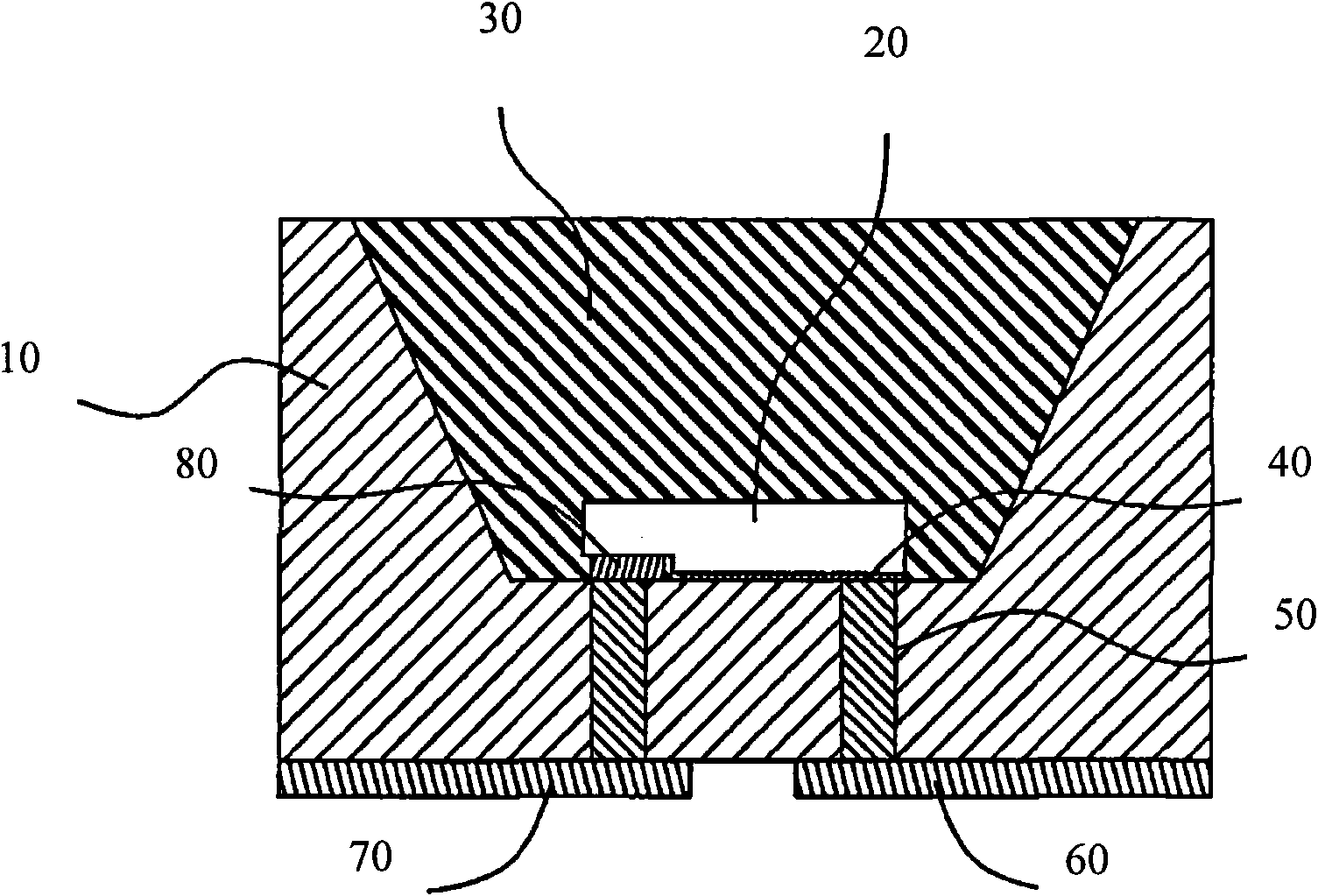

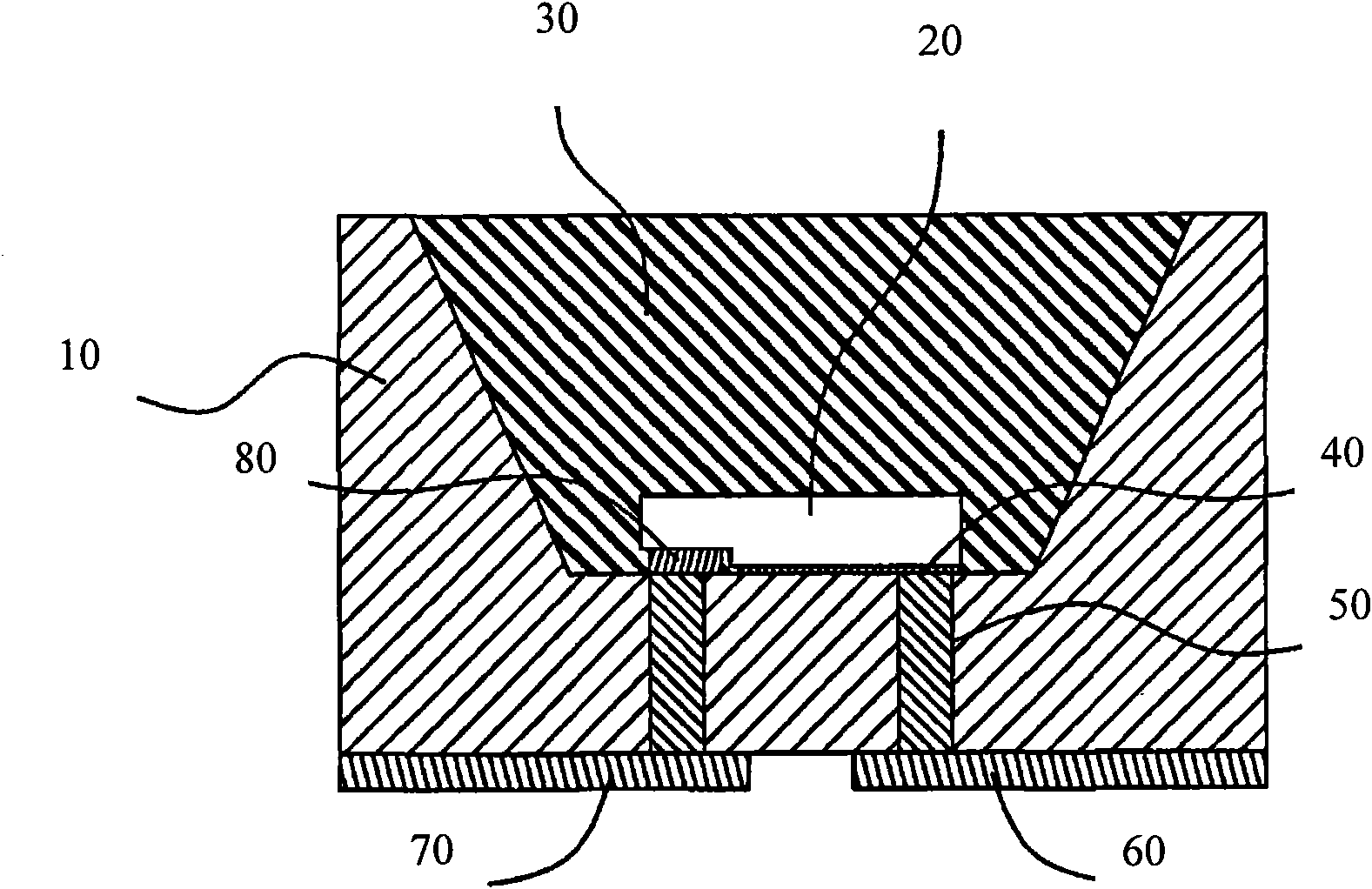

Method and chip for integrating micro electromechanical system device and integrated circuit

ActiveCN101355038AEnabling Wafer Level IntegrationImplement encapsulationSemi-permeable membranesSemiconductor/solid-state device detailsIntegrated approachIntegrated circuit

The invention provides an integration method and an integrated chip for a micro-electronic-mechanical-system device and an integrated circuit. The method comprises the following steps of: firstly, providing a first chip provided with a first electric connection point and the MEMS device, and a second chip provided with a second electric connection point and the integrated circuit; then, generating a first additional conductive point on the first electric connection point, and simultaneously generating a first package ring surrounding the MEMS device; generating a second additional conductive point on the second electric connection point, and simultaneously generating a second package ring on the second chip; finally, leading the first chip and the second chip in abutting joint, leading the first additional conductive point and the second additional conductive point to be fused in abutting joint to complete the electric connection of the MEMS device and the integrated circuit, simultaneously, leading the first package ring and the second package ring to be fused in abutting joint to package the MEMS device in the ring, thereby reducing the package cost, simultaneously shortening the electric connection route between the MEMS device and the integrated circuit, and effectively reducing stray capacitance and coupling inductance.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Display panel and manufacturing method thereof

ActiveCN106848105AImplement encapsulationRealize functionSolid-state devicesSemiconductor/solid-state device manufacturingState of artMagnetite Nanoparticles

The embodiment of the invention discloses a display panel and a manufacturing method thereof. According to the scheme, on one hand, magnetic nanoparticles with water absorption are distributed on the side, away from an OLED device, in the perpendicular film direction in a packaging layer or on the periphery of the area where the OLED device is located in the film direction; on the other hand, due to the fact that the magnetic nanoparticles with the water absorption have magnetism, in the packaging waterproofing technology, the magnetic nanoparticles with the water absorption can be doped in packaging materials, the magnetism is applied to induce the magnetic nanoparticles to the side away from an OLED device or the periphery of the area where the OLED device is located, and therefore a person only needs to conduct one-time coating on the packaging materials doped with the magnetic nanoparticles with the water absorption; compared with the double coating mode in the prior art, the technology is simple, and the technology complexity is lowered.

Owner:BOE TECH GRP CO LTD

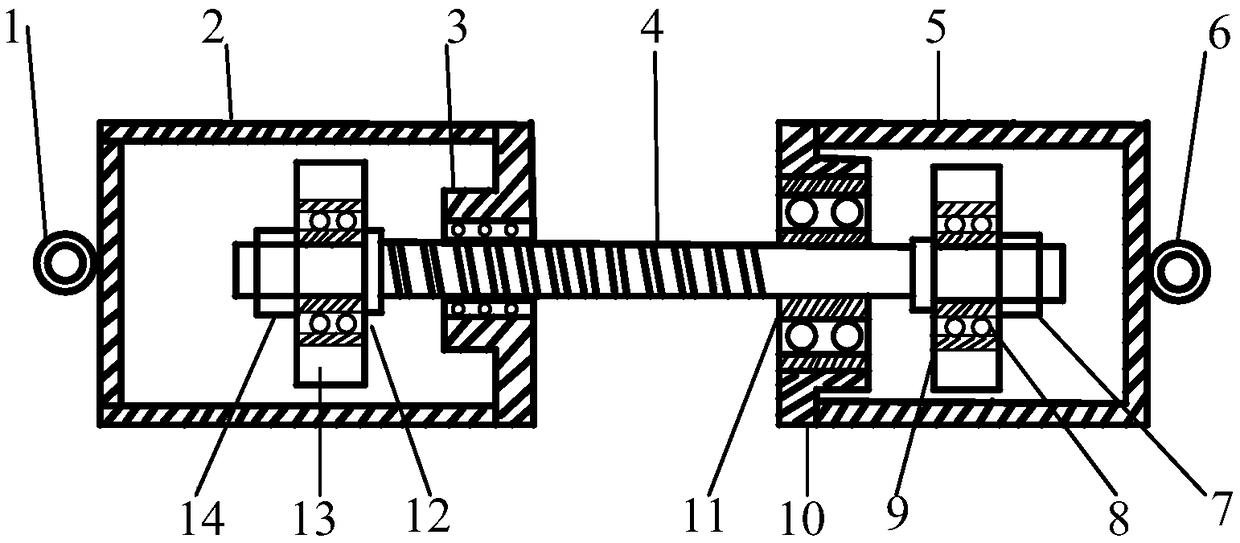

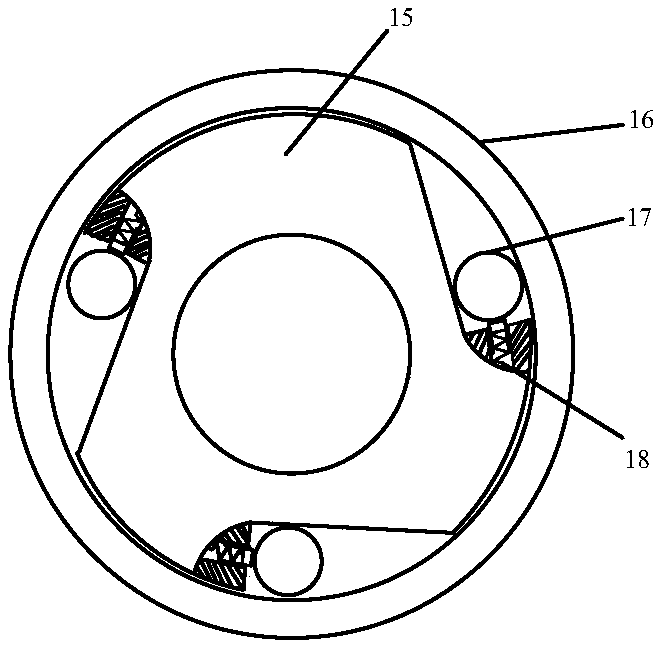

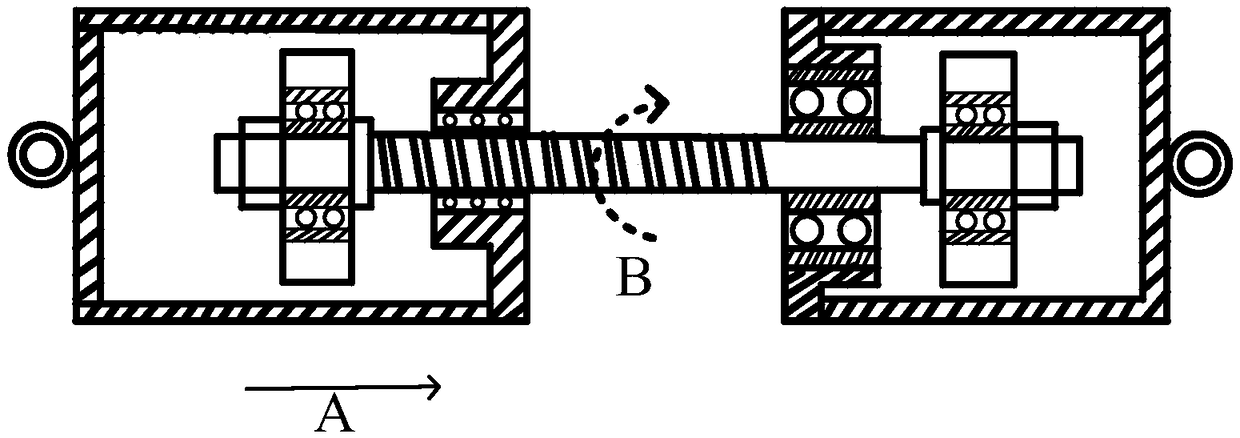

Stable-switching ball screw type inerter device

ActiveCN109253210AAchieve the desired effectReduce nonlinear factorsRotating vibration suppressionResilient suspensionsBall screwFlywheel

The invention provides a stable-switching ball screw type inerter device. The stable-switching ball screw type inerter device comprises a first mounting part, a second mounting part, a first cylinderbarrel, a second cylinder barrel, a screw nut, a screw, a flywheel A, a flywheel B, a one-way clutch A and a one-way clutch B and is characterized in that the screw is mounted between the first cylinder barrel and the second cylinder barrel in a penetrating manner, one end of the screw is rotatably mounted in the first cylinder barrel, and the other end of the screw penetrates the screw nut fixedly mounted on the second cylinder barrel and is coordinated with the screw; the first mounting part is mounted at the left end of the first cylinder barrel, and the second mounting part is fixedly mounted at the right end of the second cylinder barrel; when the motion direction of the nut instantly changes, only one of the two flywheels synchronously rotates along with the screw, flywheel impact, caused by rotation direction change, on the screw during switching is avoided effectively, stable switching is achieved, influence of nonlinear factors is small, and the performance of the inerter device is improved effectively.

Owner:JIANGSU UNIV

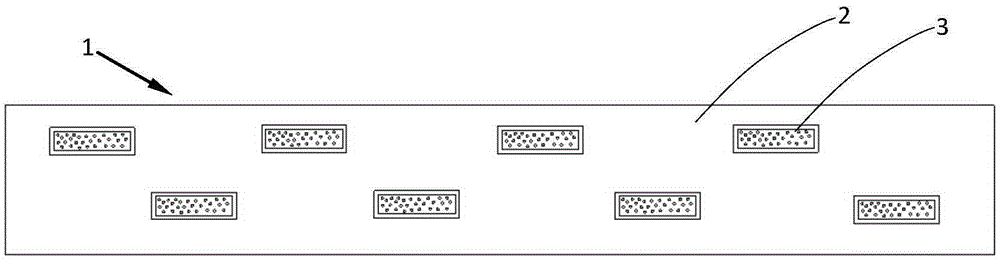

Quantum dot packaging body and application thereof

InactiveCN105565264AImprove water and oxygen barrier performanceImprove overall lifespanMaterial nanotechnologyIndividual molecule manipulationDisplay deviceQuantum dot

The present invention discloses a quantum dot packaging body which comprises a first packaging medium which is optically transparent and at least two quantum dot glass bodies dispersed in the first packaging medium. Each quantum dot glass body comprises glass located at the outer layer, a second packaging medium which is optically transparent and located at the inner layer, and at least one type of quantum dots dispersed in the second packaging medium. The first packaging medium consists of high polymer materials. By packaging the packaging body quantum dots in the glass body with a certain volume, the fragile disadvantages of glass tubes are avoided, and at the same time, a relative high luminous efficiency is kept. The present invention also discloses a light-emitting device, a backlight module and a display device. The present invention also discloses a preparation method of the quantum dot packaging body.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

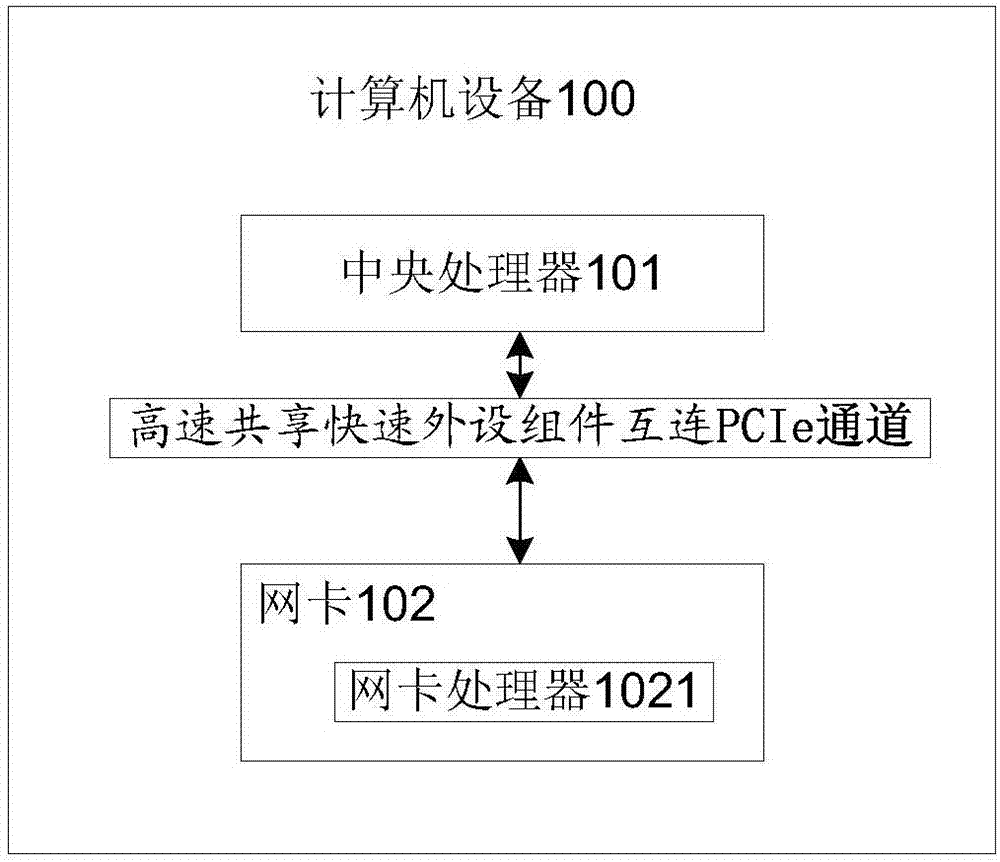

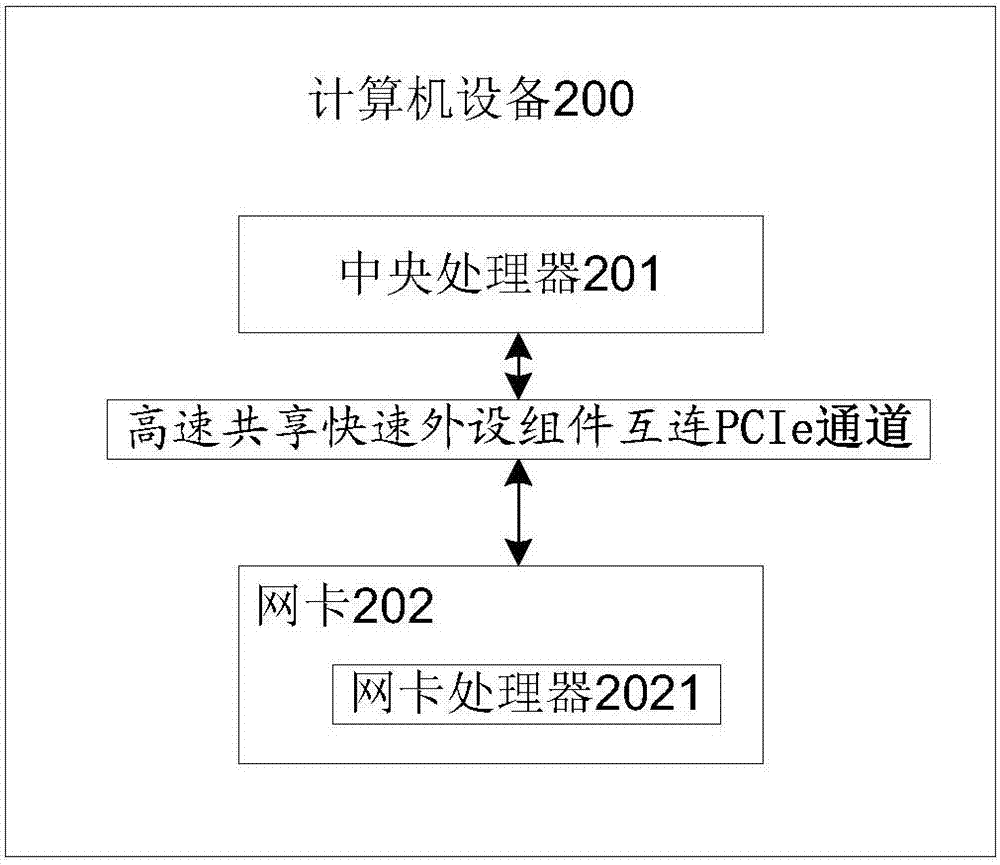

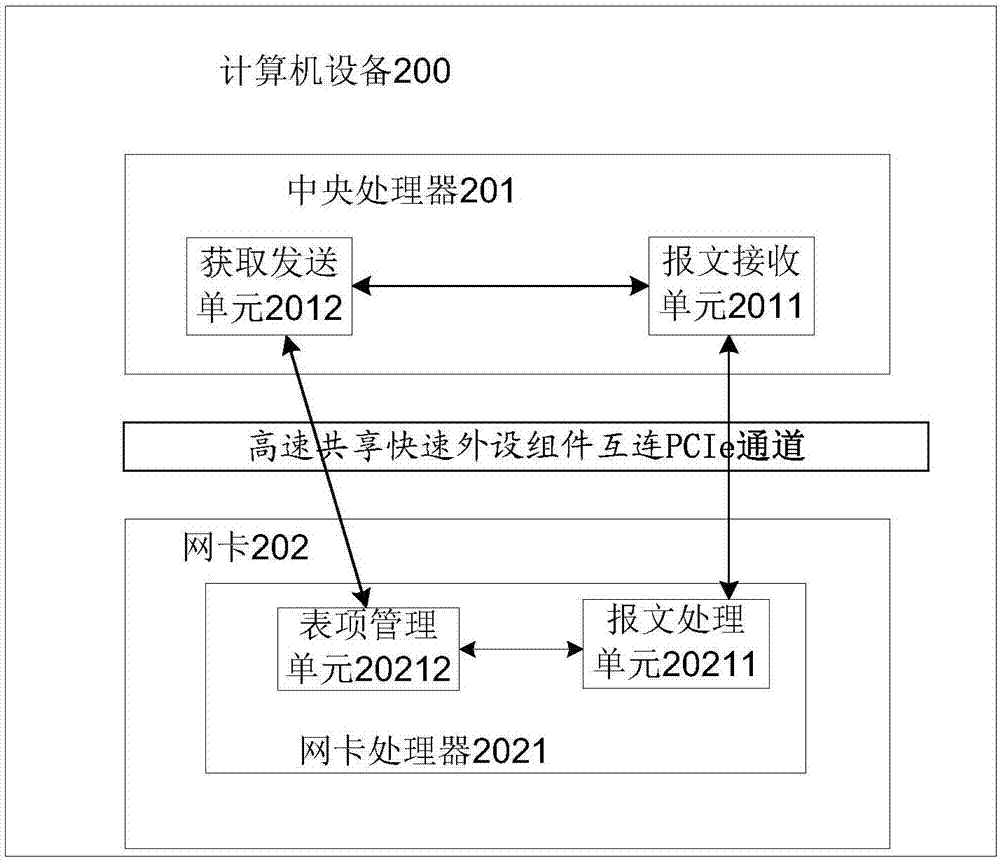

Method for sending virtual extensible local area network packet, computer device, and readable medium

ActiveCN107113240AImplement encapsulationRealize sendingProgram controlNetworks interconnectionEmbedded systemComputer equipment

Provided in an embodiment of the present invention are a method for sending a VxLAN packet, a computer device, and a computer readable medium for resolving a problem in which existing techniques are unable to forward VxLAN packets with network cards. The method for forwarding a VxLAN packet provided in the embodiment of the present invention comprises: after a network card has received a first packet, determining whether encapsulation information for performing VxLAN encapsulation on the first packet is saved in the network card; if so, performing the VxLAN encapsulation on the first packet, and sending the same; and if not, requesting the encapsulation information from a central processing unit, saving the same, and sending a packet obtained after performing the VxLAN encapsulation on the first packet. The invention enables a network card to perform the VxLAN encapsulation on a received packet and send the same.

Owner:HUAWEI TECH CO LTD

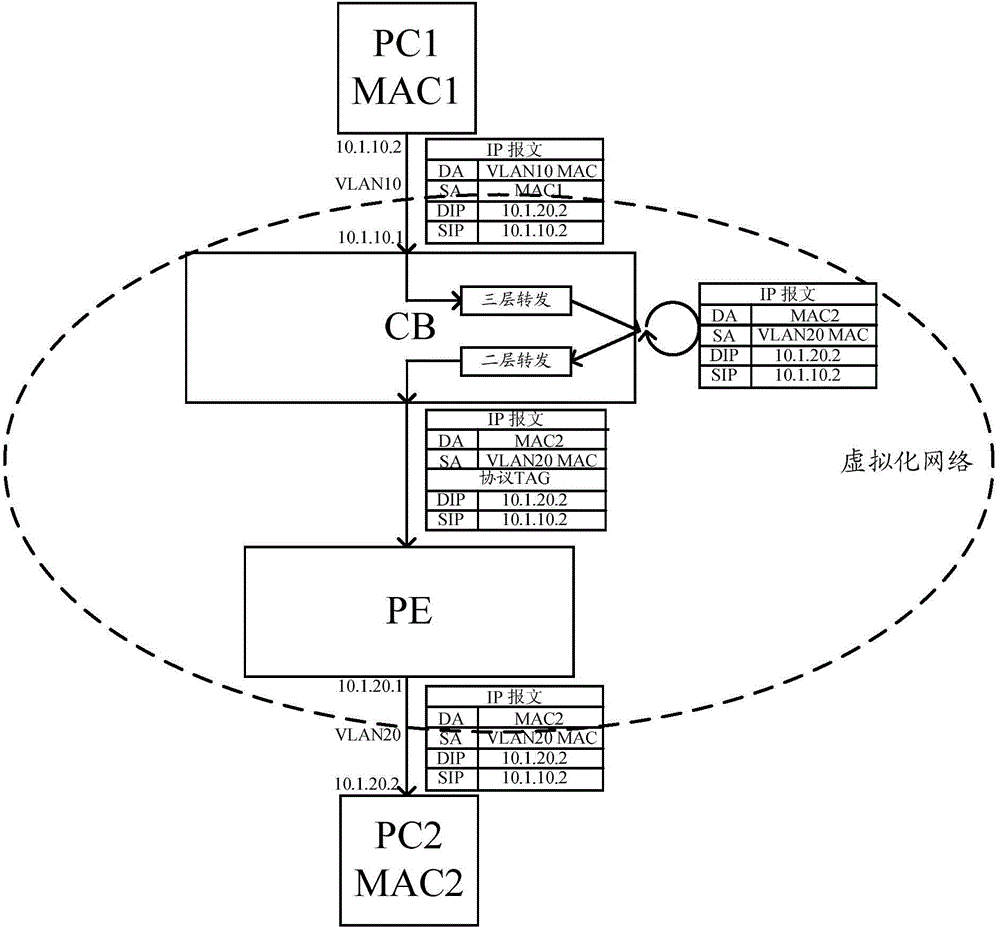

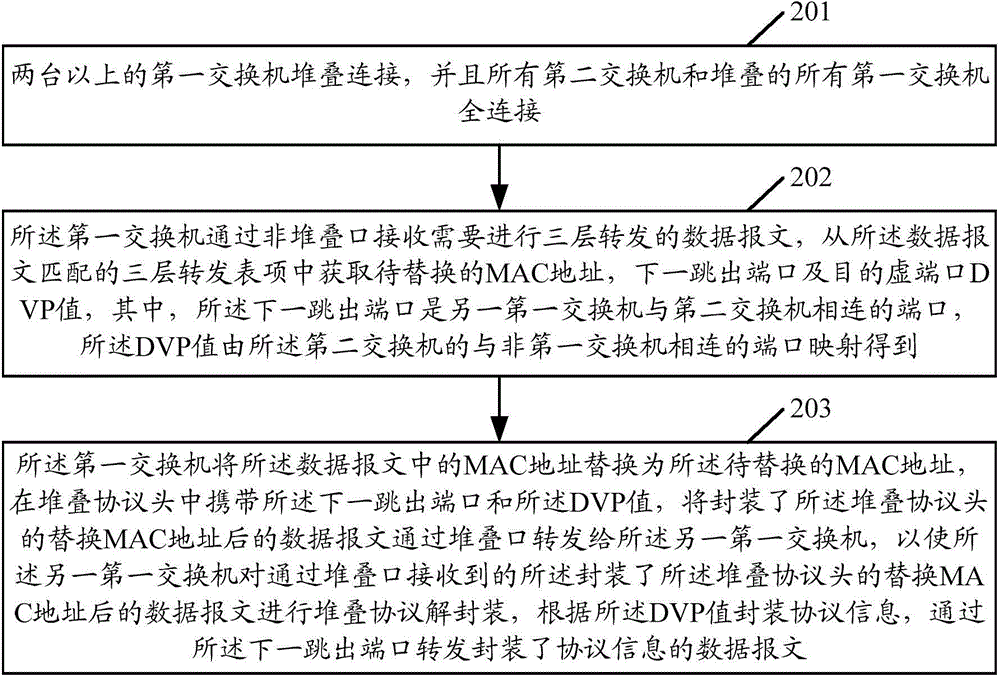

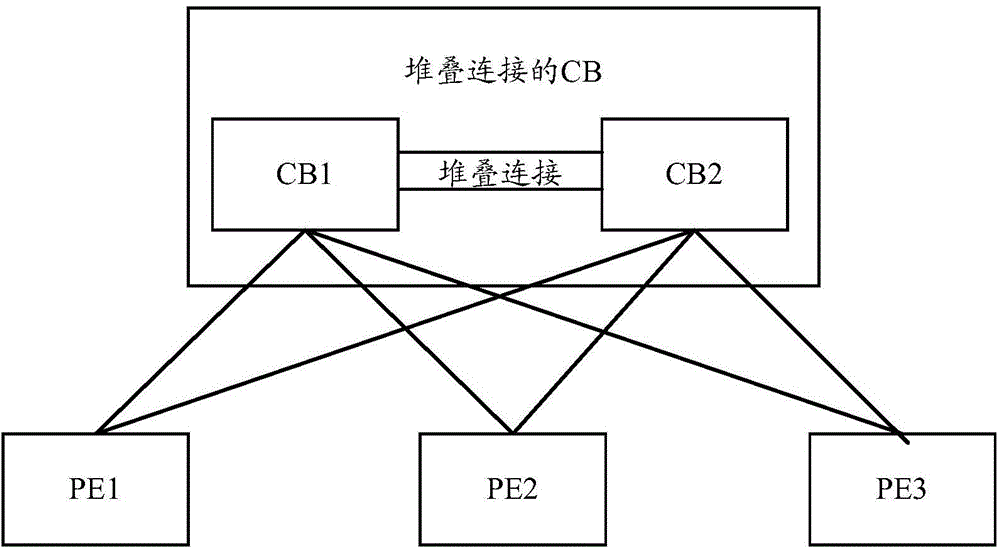

Method and device for realizing third tier forwarding and packaging protocol information in Internet

ActiveCN104639440AImplement encapsulationImprove forwarding efficiencyData switching networksThe InternetMedia access control

The invention discloses a method and a device for realizing third tier forwarding and packaging protocol information in Internet. More than two first exchangers are in stacking connection; all second exchangers are in full connection with all the first exchangers; the first exchangers receive a data message with the need of carrying out third tier forwarding through a non-stackable port; an MAC (Media Access Control) address to be replaced, a next step-out port and a destination virtual port DVP value are obtained from third tier forwarding table items matched with the data message; the next step-out port is a port where the another first exchanger is connected with the second exchanger; the DVP value is obtained by mapping of a port, which is not connected with each first exchanger, of the corresponding exchanger; the MAC address in the data message is replaced by the MAC address to be replaced; a stacking protocol head carries the next step-out port and the DVP value; the data message which is packaged with the stacking protocol head and has the replaced MAC address is transferred to the other first exchanger by a stackable port.

Owner:NEW H3C TECH CO LTD

An OLED device structure and 3D printing technology based multiple-spray-head printing method thereof

InactiveCN104409651AImplement encapsulationEliminates the hassle of refilling materials multiple timesSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionFilling materials

The invention aims to provide an OLED device structure including a glass substrate arranged in a bottom layer. The OLED device structure is characterized in that an anode layer, a hole transport layer, an organic light emitting layer, an electron injection buffer layer, a cathode layer and an encapsulation thin film layer are arranged in turn on the glass substrate. In the invention, a print head is provided with multiple spray heads for simultaneous printing, three-dimensional models of an OLED device and a package film are pre-designed by a computer, scanning paths of the structure of each layer are positioned precisely on a heating substrate, and then the OLED device is printed, and a heating process is performed by a heating solidification device during printing. The method is simplified as compared with the traditional device printing method, and can be used to carry out the moulding and packaging of the device by one time. The method eliminates troubles of repeatedly filling materials, and reduces greatly working hours. The moulded device rotates 90 degrees as compared with a device traditionally printed layer upon layer, and the film package of the OLED device is realized.

Owner:FUZHOU UNIV

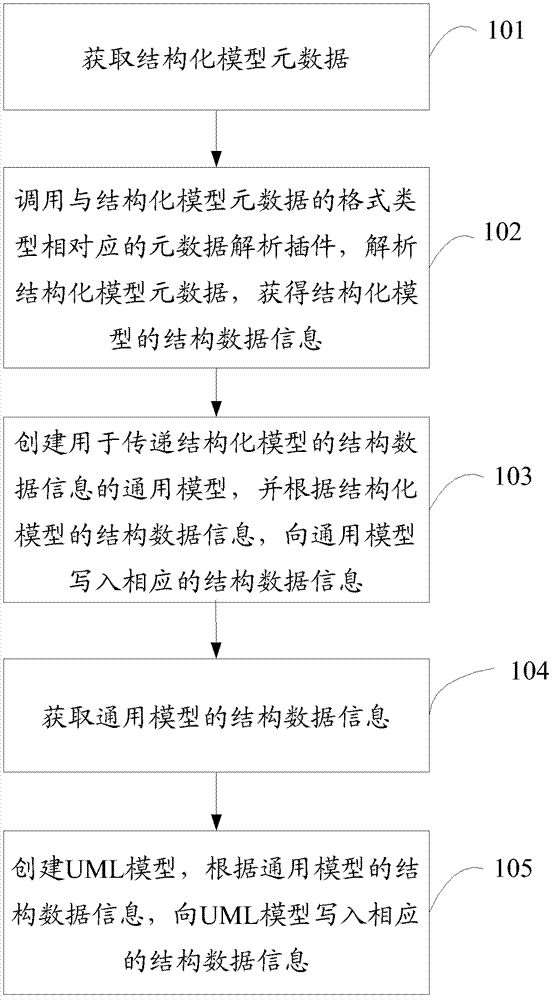

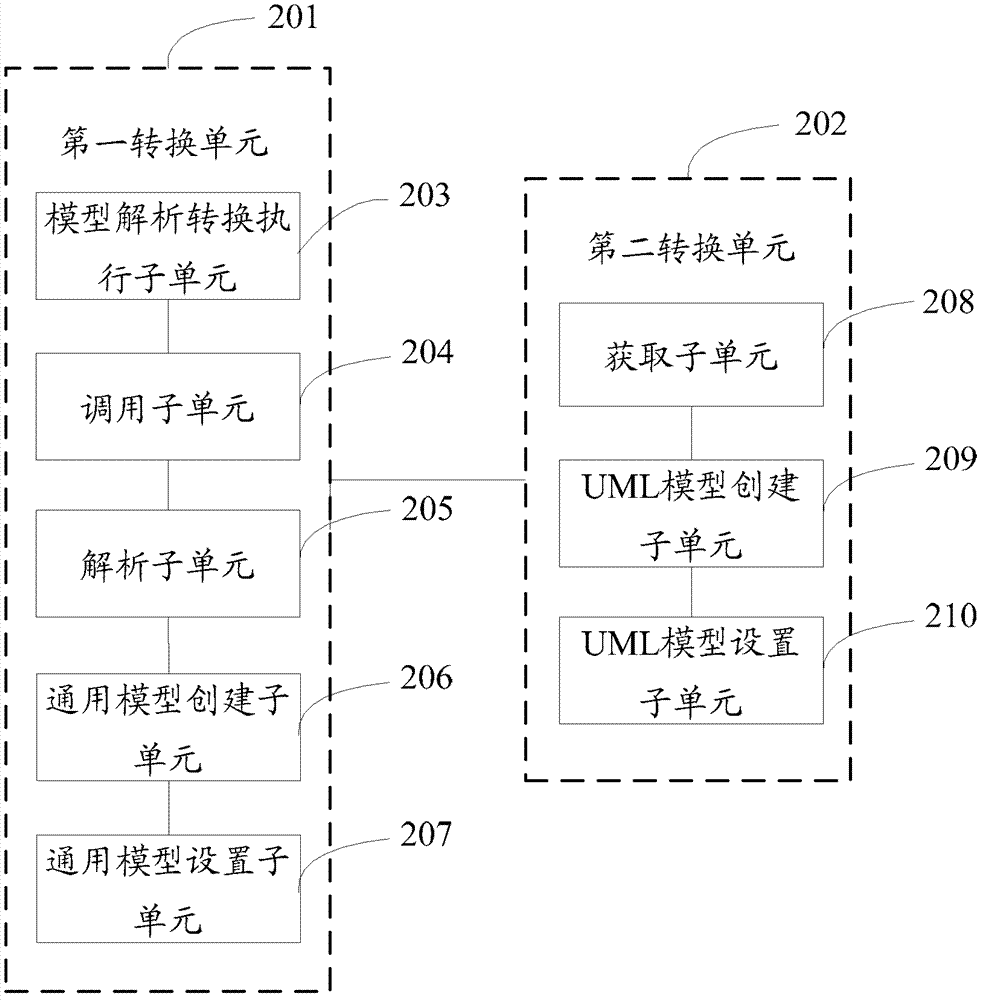

Model conversion method and device

ActiveCN103092594AImplement encapsulationSpecific program execution arrangementsData informationTheoretical computer science

The invention discloses a model conversion method. The model conversion method includes acquiring structural model metadata, calling metadata analysis plugins corresponding to format types of the structural model metadata, and analyzing the structural model metadata to acquire structured data information of a structural model; establishing a universal model for transmitting the structured data information of the structural model; writing the corresponding structured data information in a universal model according to the structured data information of the structural model; acquiring structured data information of the universal model; establishing a unified modeling language (UML) model, and writing the corresponding structured data information in the UML model according to the structured data information of the universal model. Besides, the invention further discloses a corresponding model conversion device. The model conversion method and device are used for converting the structural model to the UML model, conversion logics of the universal model and the UML model can be packaged, and packaging and extension of the conversion logics of the structural model in different metadata formats and the universal model are supported.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

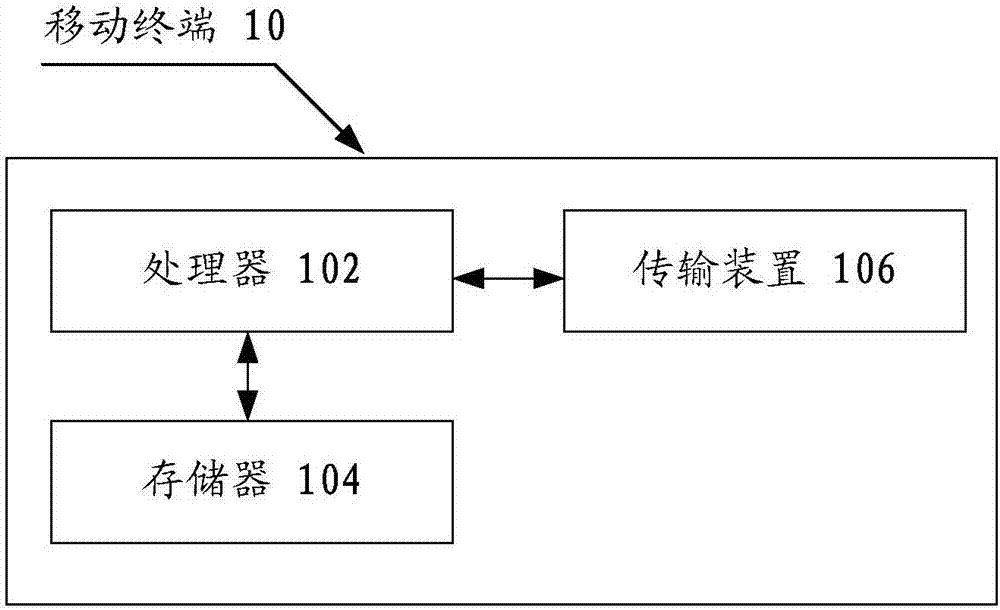

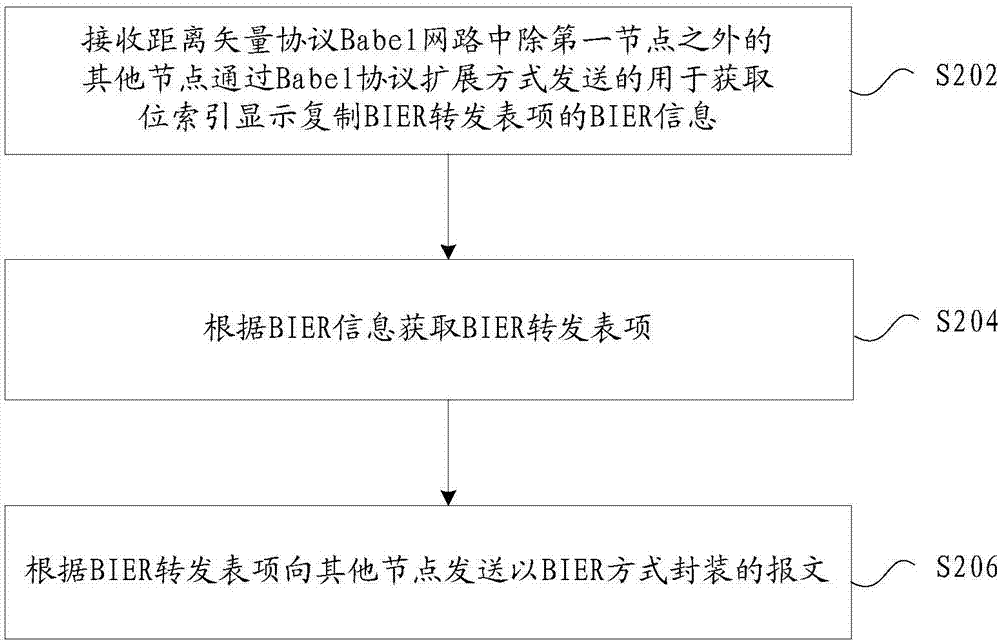

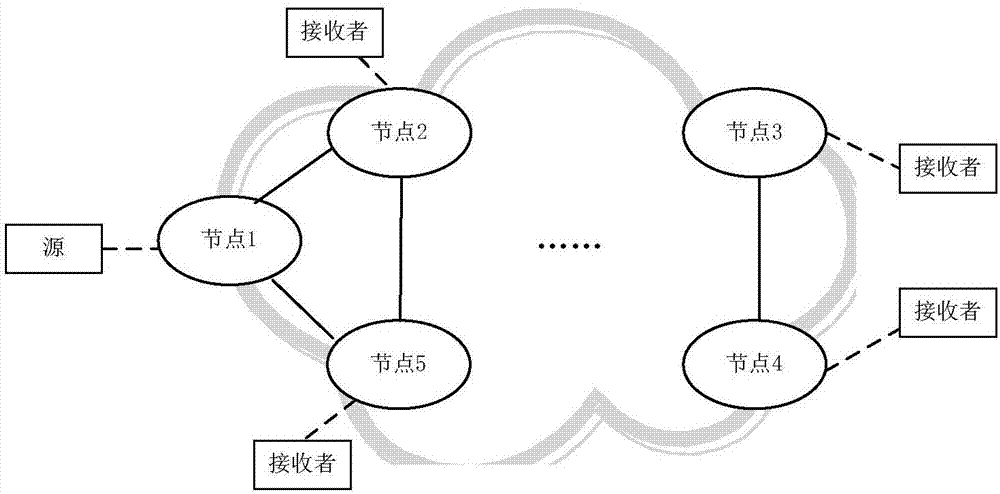

Message transmission method, message transmission device and node

ActiveCN107968750AImplement encapsulationRealize forwardingData switching networksProtocol for Carrying Authentication for Network AccessPromotion effect

The invention provides a message transmission method, a message transmission device and a node. The method comprises the following steps of receiving BIER information which is sent by other nodes except a first node in a distance vector protocol Babel network through a Babel protocol extension mode and is used for acquiring bit indexed explicit replication (BIER) forwarding entries; acquiring theBIER forwarding entries according to the BIER information; and sending messages encapsulated in a BIER mode to other nodes according to the BIER forwarding entries. According to the message transmission method, the message transmission device and the node, a problem that related information of a BIER technology cannot be transferred in a network running a BEL routing protocol in the correlation technique can be solved, and a very important promotion effect is achieved on the development of multicast technologies and networks.

Owner:ZTE CORP

Method for storing electronic book format

InactiveCN102073624AImplement encapsulationAchieve protectionSpecial data processing applicationsTime limitElectronic book

The invention designs a book format which can protect copyrights of digital books. The format can be used for storing characters, pictures, formulas, tables and other elements; in order to avoid users copying and transferring digital books at random, the format also stores all kinds of safety verification and data protection information; for a user authorized to download books, the format limits the user to read the books at the current computer downloading the books, tracks the book resource reading time limit of the user according to a user type and a user buying period to ensure that electronic books beyond a valid period cannot be read by the user; and therefore, the original copyrights of electronic books can be protected to the largest extent, the loss of book resources can be avoided, and the legitimate interests of merchants can be protected.

Owner:李成龙

Device used for carton folding and packaging

PendingCN107738779AImplement encapsulationPrecise alignmentWrapper twisting/gatheringAdhesive beltClassical mechanics

The invention relates to the technical field of packaging box production, in particular to a device used for carton folding and packaging. The device comprises a mounting support, a conveying belt isarranged at the bottom of the mounting support, a carton is placed on the conveying belt, the side wall of the mounting support is fixedly connected with a pair of first electric cylinders, the ends of power rods of the first electric cylinders are connected with a movable plate, the movable plate is in contact with a cover plate on the carton, the top of the mounting support is fixedly connectedwith a second electric cylinder, the end of a power rod of the second electric cylinder is fixedly connected with a pressing plate, the side, away from the second electric cylinder, of the pressing plate is provided with a first roller and a second roller, the first roller and the second roller are connected with adhesive tape in a winding manner, strip through holes are evenly formed in the adhesive tape, and according to the device used for carton folding and packaging, a bonding strip can be automatically pasted on the middle gap. Carton packaging is achieved, compared with an existing manual adhesive tape bonding manner, the efficiency is higher, manual operation is not needed, the packaging cost is reduced, the adhesive tape is accurately aligned with the middle gap of the carton, andthe packaging quality is ensured.

Owner:阜宁县华强纸品有限公司

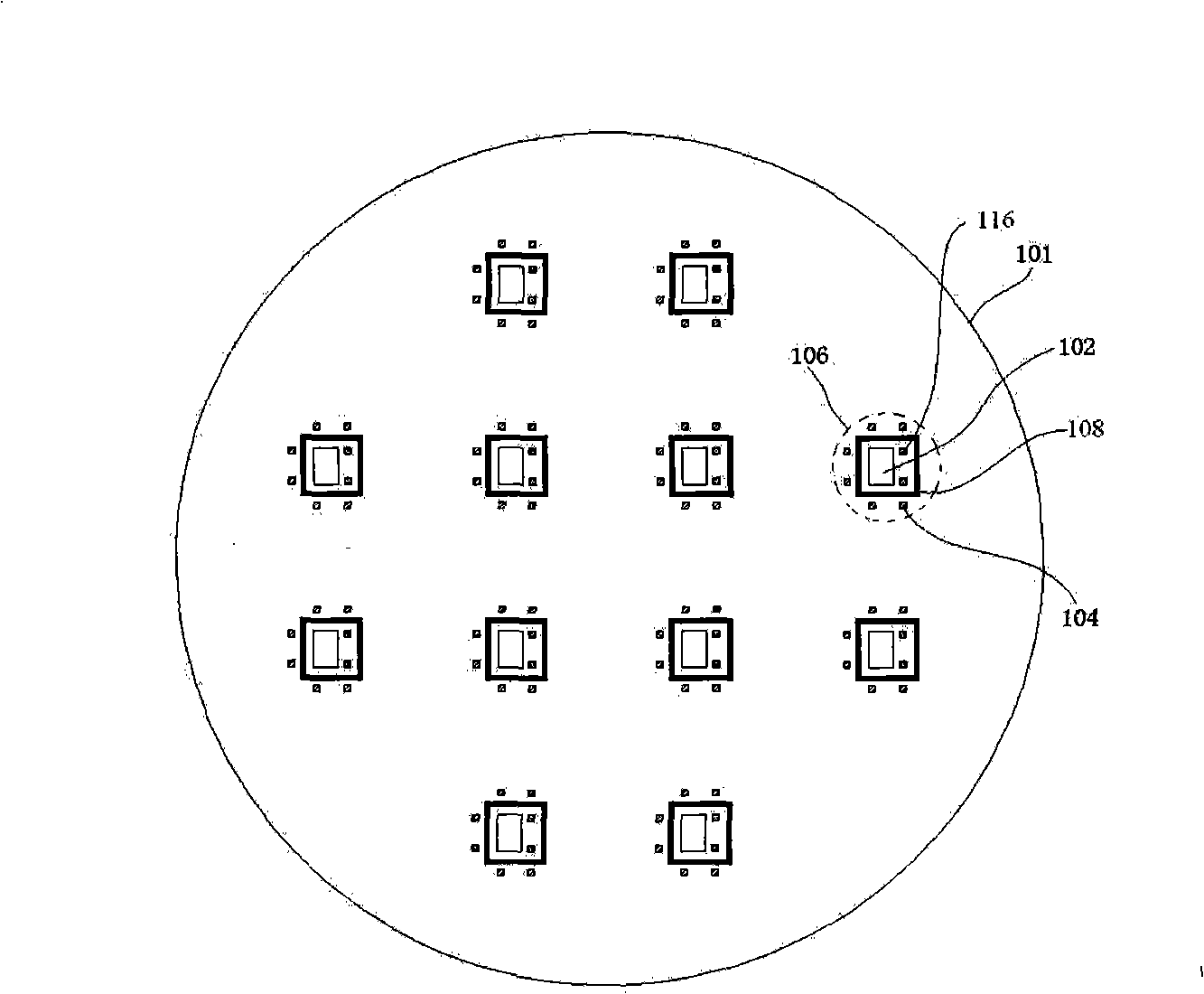

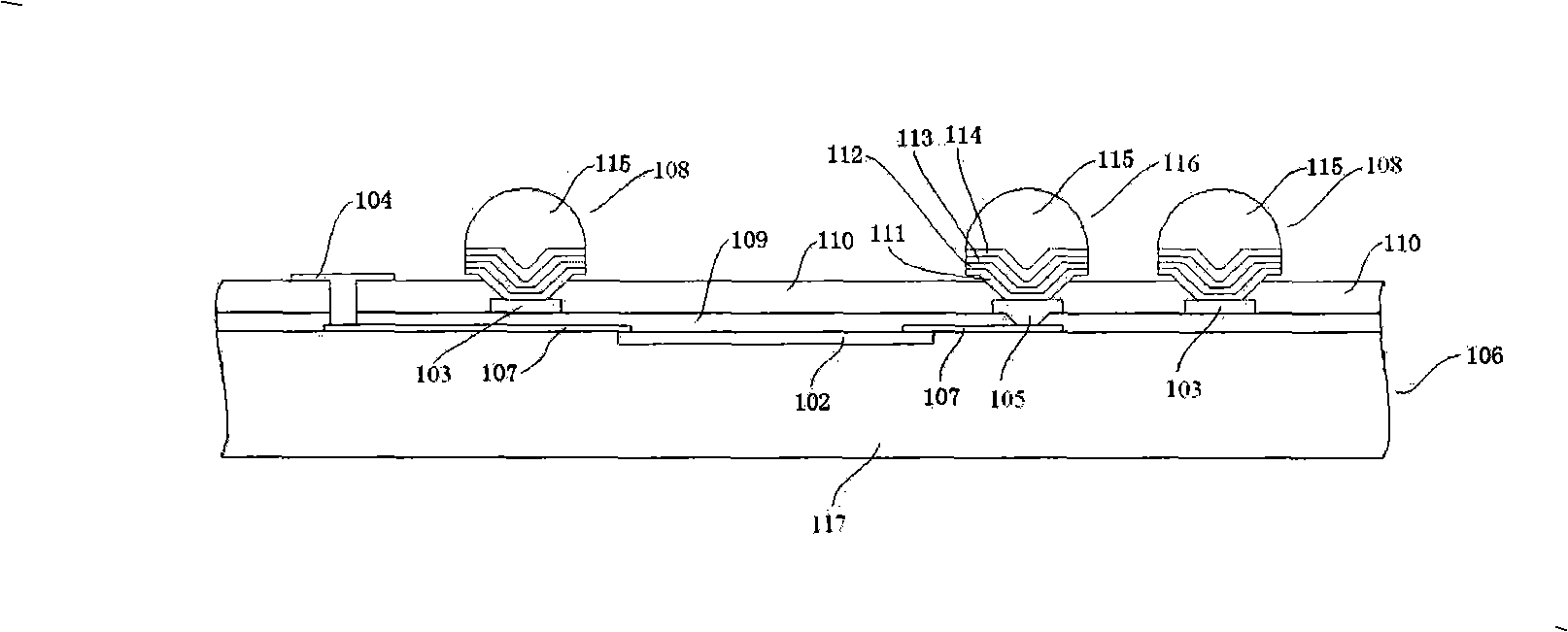

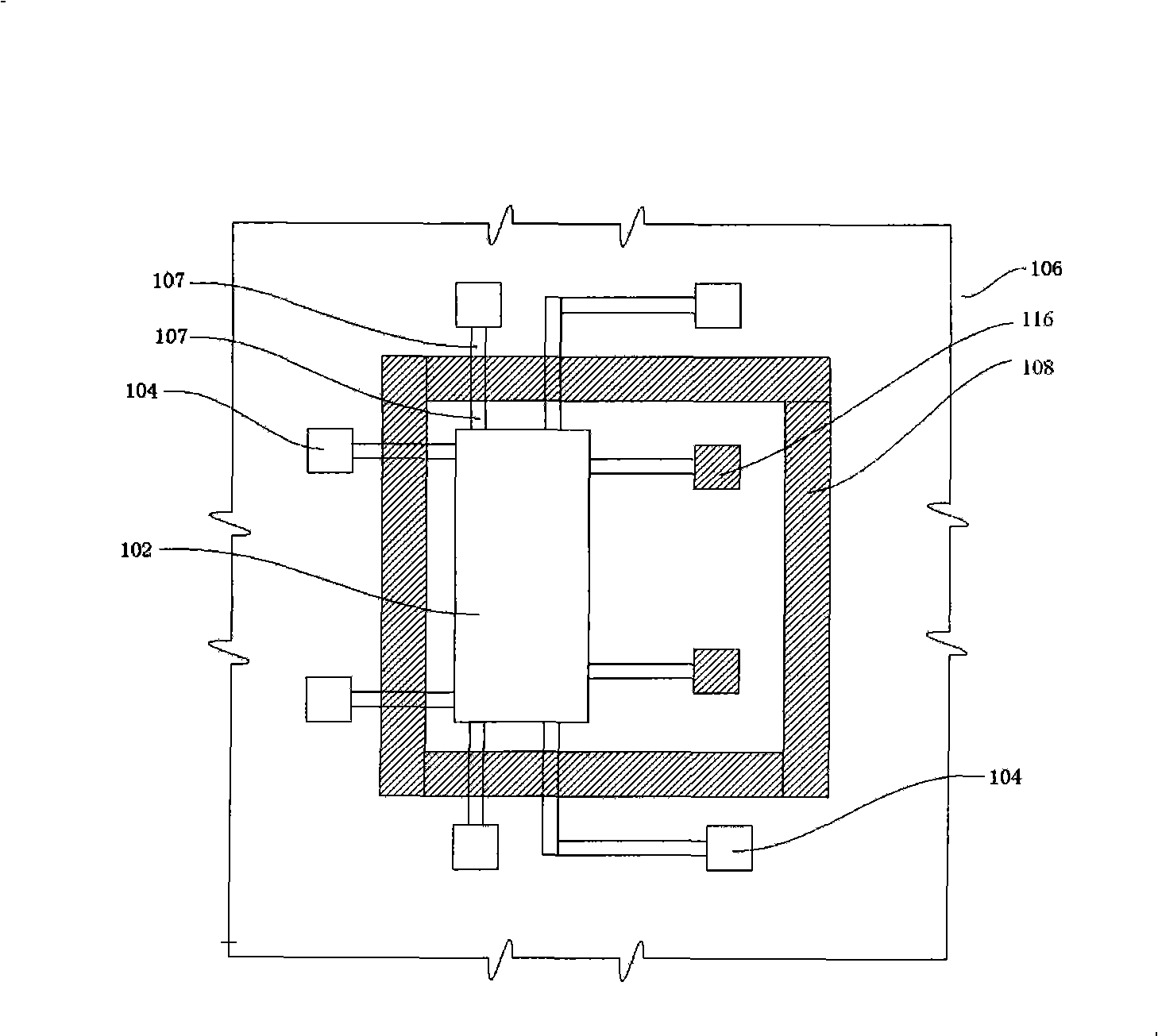

Capacitive ultrasonic sensor and manufacturing method thereof

InactiveCN104655261AImprove reliabilityImprove thickness uniformitySubsonic/sonic/ultrasonic wave measurementDecorative surface effectsUltrasonic sensorMiniaturization

The invention discloses a capacitive ultrasonic sensor. The capacitive ultrasonic sensor comprises a low-resistivity silicon substrate, a silicon oxide layer formed on the low-resistivity silicon substrate, a two-dimensional cavity array structure formed in the silicon oxide layer, a diaphragm formed above the two-dimensional cavity array structure and an upper electrode formed by deposition of metal aluminum on the diaphragm, wherein the upper electrode is a graph array, and graphs in the graph array of the upper electrode and the graphs in the two-dimensional cavity array structure are distributed in a one-to-one correspondence manner and mutually connected together. According to the capacitive ultrasonic sensor disclosed by the invention, wet process and dry process surface activation treatment is performed on the silicon substrate and an SOI (silicon-on-insulator) chip, a low-temperature silicon chip direct bonding technology is adopted, and the prepared capacitive ultrasonic sensor has the advantages of miniaturization, high reliability, good repeatability, relatively few process steps, short manufacturing period and the like; furthermore, the process temperature is relatively low, and the capacitive ultrasonic sensor is easy to be integrated with an IC (integrated circuit) for realizing integral packaging of the chip.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

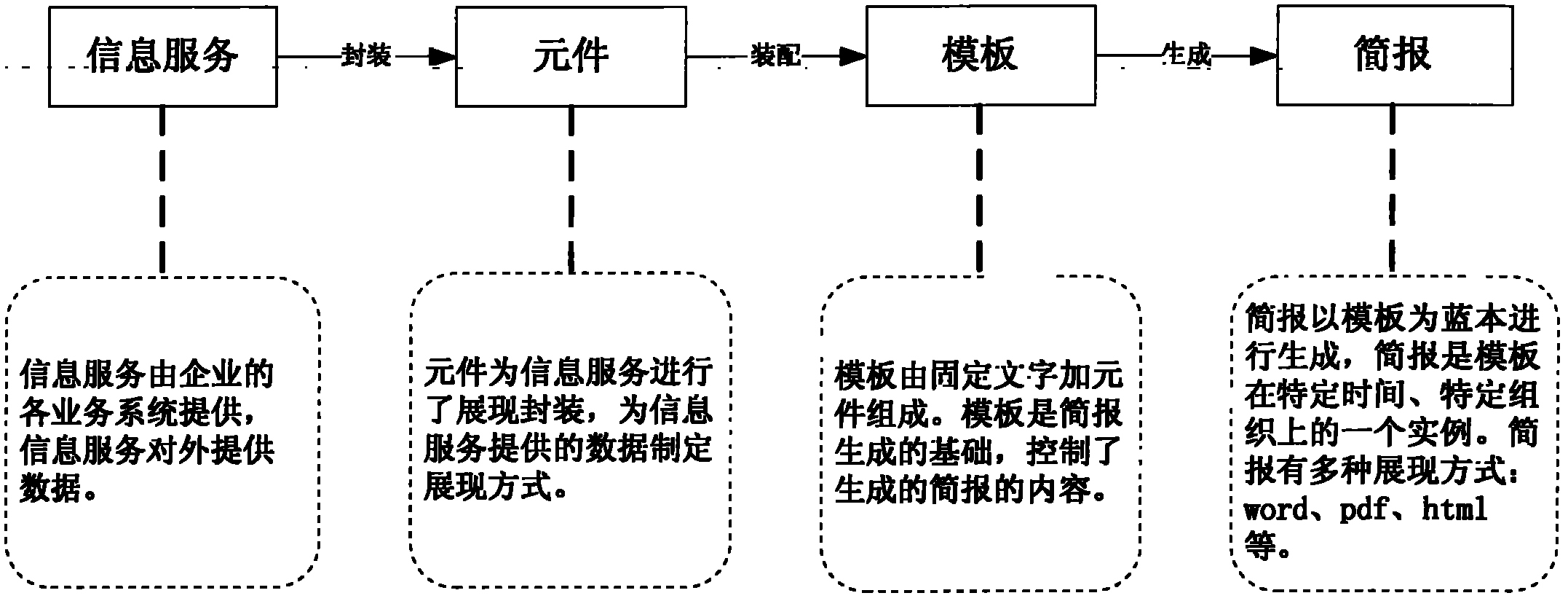

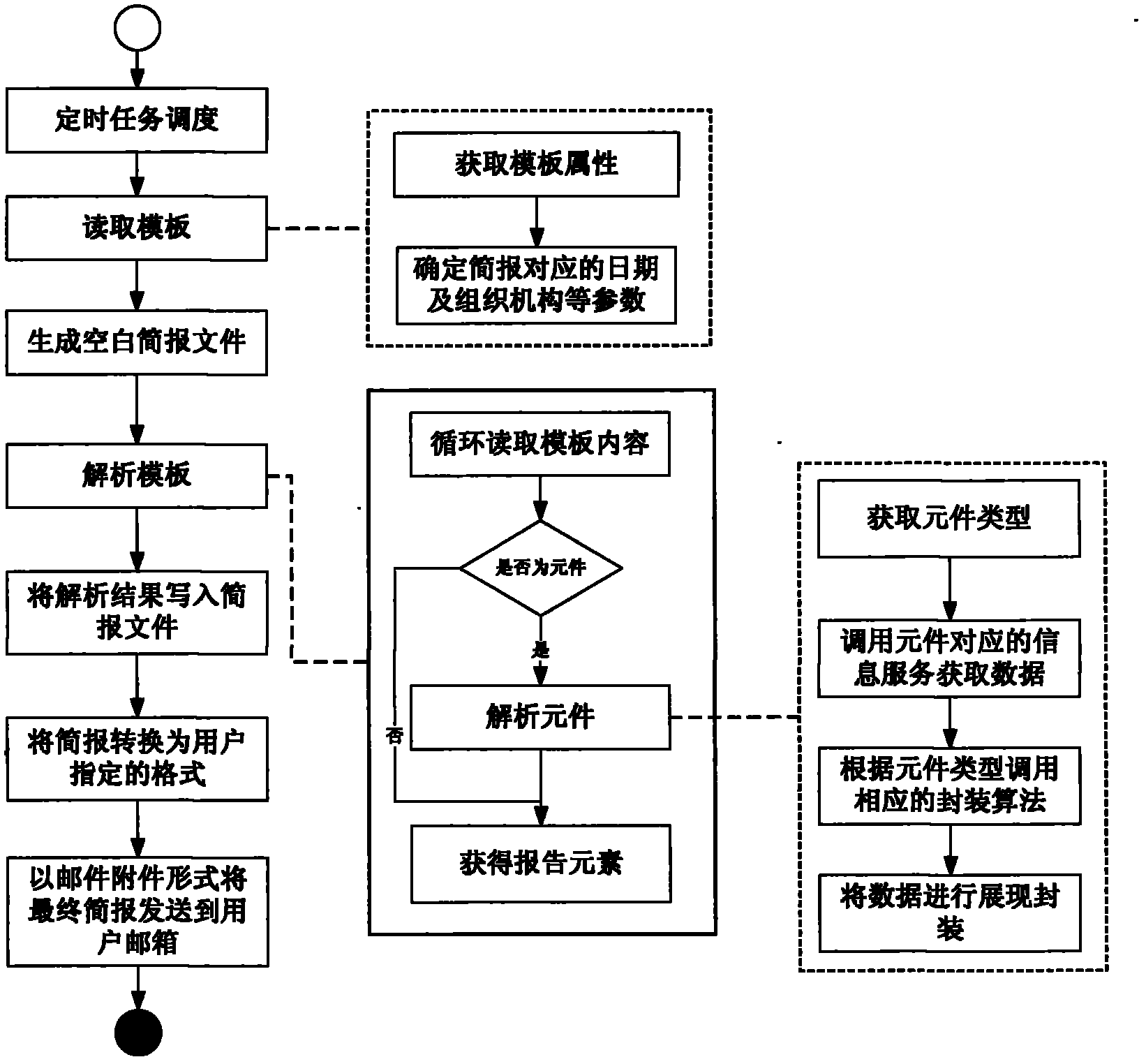

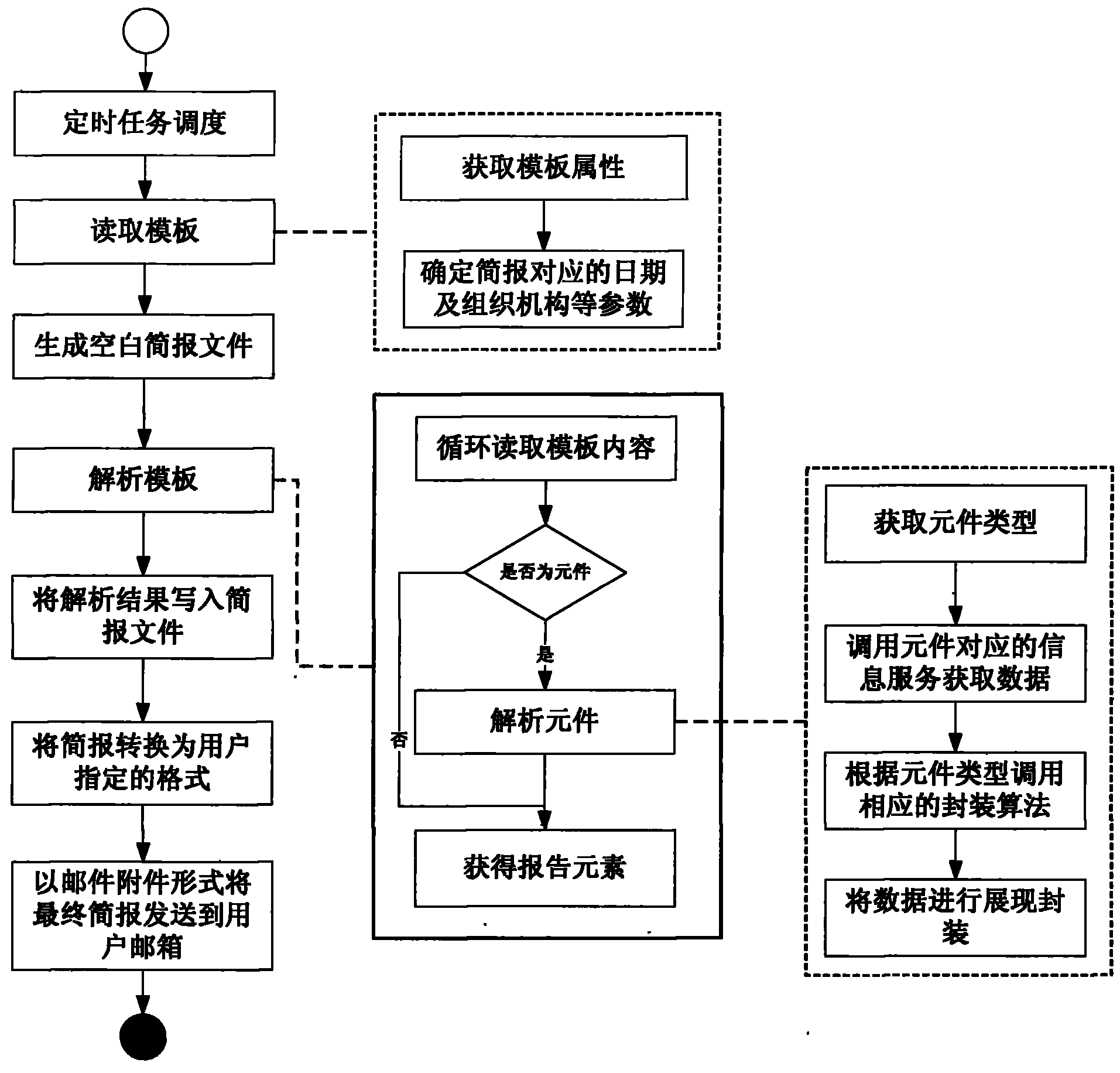

Automatic intelligent briefing generation method

The invention provides an automatic intelligent briefing generation method and discloses a method for automatically generating enterprise analysis reports by an information system. By the method, the capability that a user freely customizes a report as required is realized via free assembly of elements by fully using information services of the conventional service system of an enterprise. The generated time and the generated format of the report can be appointed according to the requirement of the user, so the automatic system generation of the analysis reports of the enterprise is realized; and the working efficiency of enterprise analyzers is improved greatly, and a great amount of labor cost is saved.

Owner:INSPUR SOFTWARE CO LTD

Wafer-level chip size encapsulation technology for GaAs (gallium arsenide) CCD (Charge Coupled Device) image sensor

ActiveCN102509718AImprove interconnect densityFirm packagingDecorative surface effectsSemiconductor/solid-state device manufacturingInterconnection densityCharge couple device

The invention relates to a wafer-level chip size encapsulation technology for a GaAs (gallium arsenide) CCD (Charge Coupled Device) image sensor. The technology is characterized by comprising the following steps of: (1) firstly bonding a glass wafer and a GaAs wafer through a resin adhesive so as to protect the active surface of a chip and improve the strength of a chip wafer; (2) manufacturing a trapezoidal-slot structure by a wet corrosion or physical method so as to reduce the lining thickness of a chip interconnection area; (3) manufacturing vertical interconnected through holes by a dry etching technology so as to expose a pad on the active surface of the chip; (4) sputtering seed-layer metal and electroplating, and manufacturing a hole metalizing and RDL layer to realize circuit interconnection from the active surface to the back surface of the chip; (5) manufacturing a passivation layer, a UBM layer and raised points; and (6) finally scribing to form an independent encapsulation chip. As the trapezoidal-slot structure on the back realizes thickness reduction only in the area with the pad, the cost is effectively lowered; and through the interconnection of the vertical through holes, the encapsulation interconnection density can be improved, and the signal transmission path is shortened.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

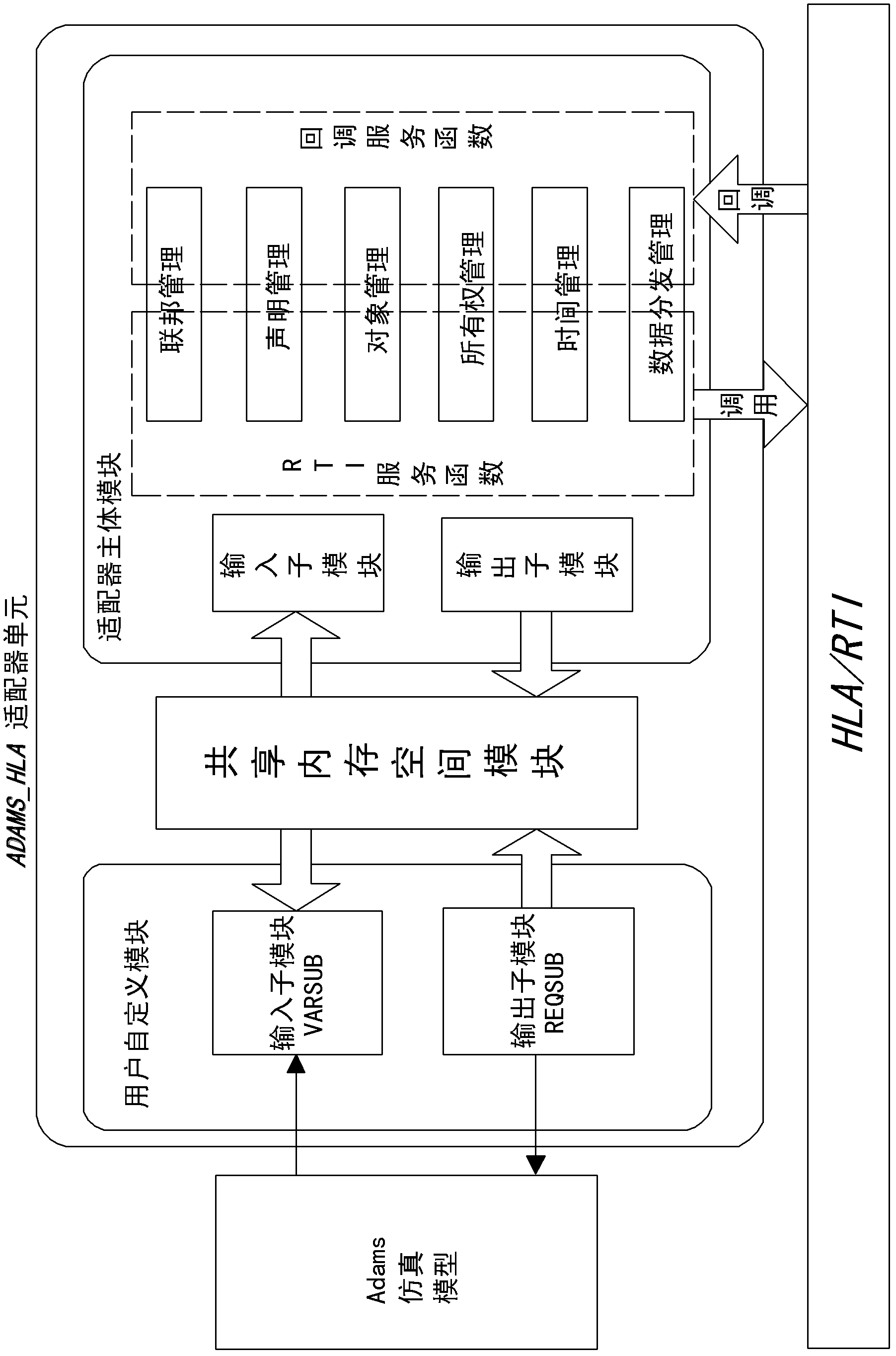

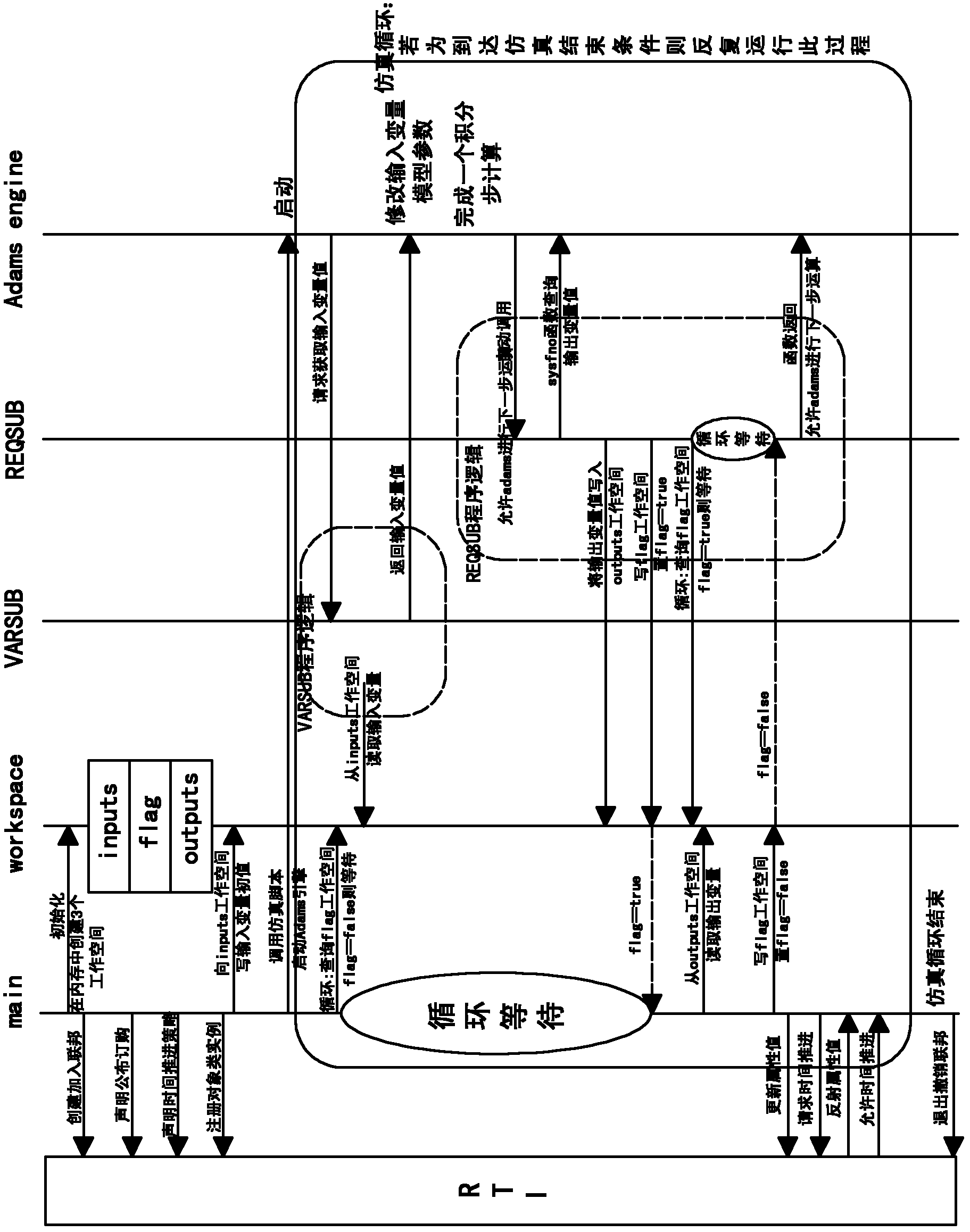

HLA (Human Leukocyte Antigen)-based Adams simulation model integrated platform and method

InactiveCN102915386AEasy to useGood effectSpecial data processing applicationsReusabilityHuman leukocyte antigen

The invention discloses an HLA (Human Leukocyte Antigen)-based Adams simulation model integrated platform, to solve the defect in the prior art that an Adams simulation model is hard to be subjected to HLA integration. The HLA-based Adams simulation model integrated platform comprises a simulation model unit, an adaptor unit and an HLA system, wherein the simulation model unit comprises at least one Adams simulation module; the adaptor unit comprises a user defined module, a shared memory space module and a main body module; and the user defined module comprises an input sub-module and an output sub-module. The invention discloses an HLA-based Adams simulation model integrated method. With the adoption of the HLA-based Adams simulation model integrated method, the advantages of a commercial simulation software solver are maintained, the packaging of an Adams model is realized under the condition that the simulation model needs not to be modified or is slightly configured, and the reusability of the Adams model is greatly improved.

Owner:TSINGHUA UNIV

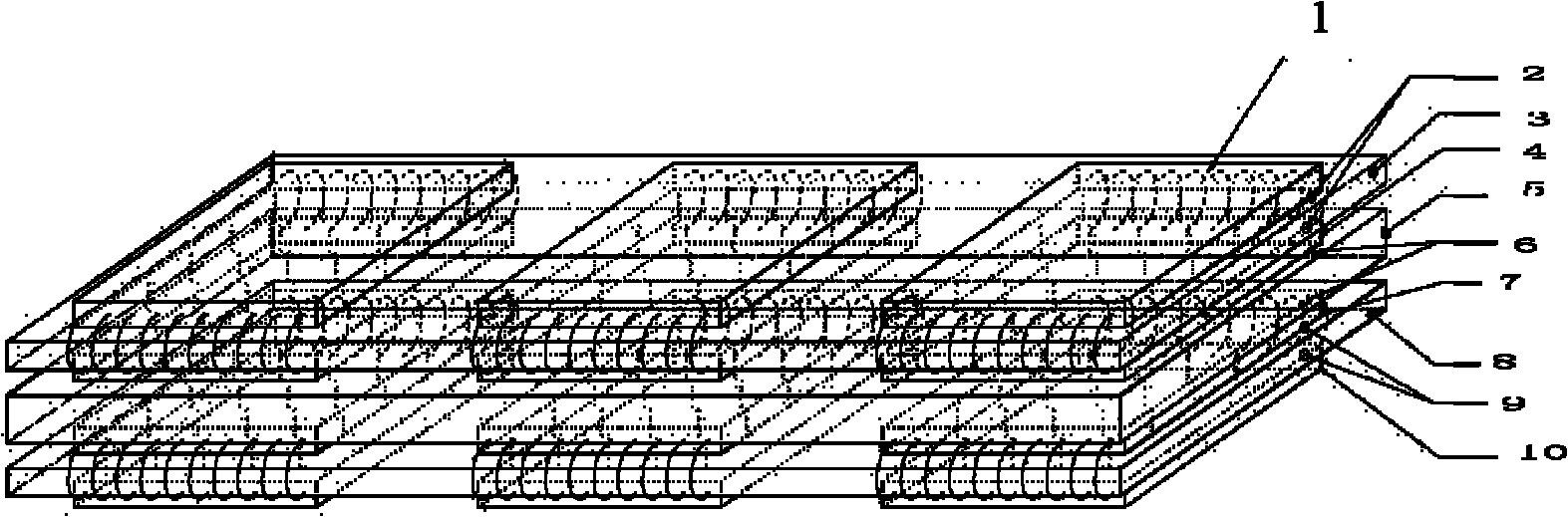

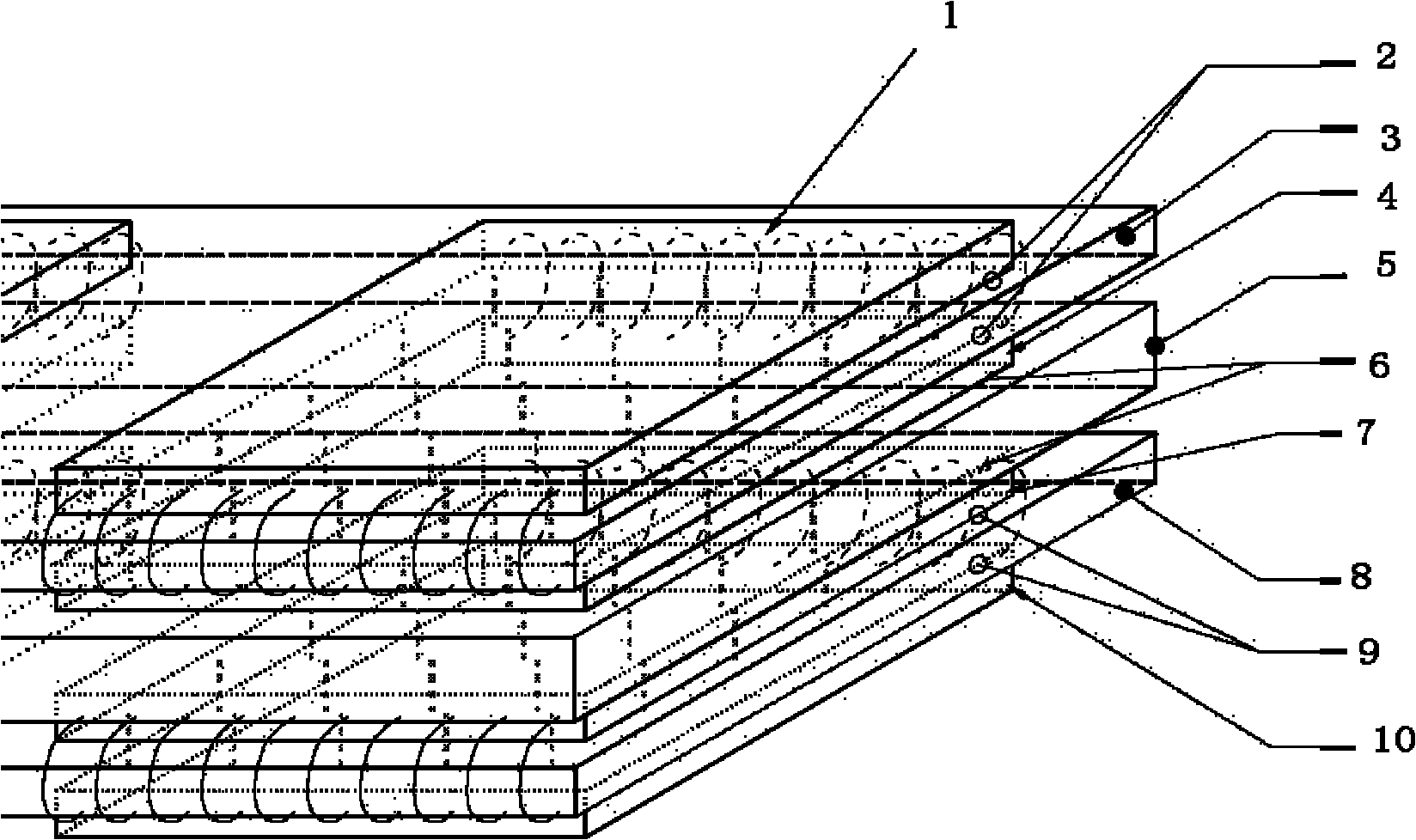

Method for packaging multi-laminated multi-chip on flexible circuit board and packaging chipset

InactiveCN101847590AExcellent dielectric propertiesEnabling Package ManufacturingSemiconductor/solid-state device detailsSolid-state devicesConductive pasteInter layer

The invention relates to a method for packaging a multi-laminated multi-chip on a flexible circuit board by adopting FUTCP (Flexible Ultra-thin Three-dimensional Chip Package) and a packaging chipset. Two packaging chips are bound on a middle-layer (bottom) flexible circuit terminal, two packaging chips which are bound on the same symmetrical position of an upper-layer (top) flexible circuit terminal are mutually connected through ACAF (Anisotropic Conductive Adhesives and Films), the chips are stacked, mutually connected and packaged by using NCP (Non-conductive paste), and a chip stacking assembly is packaged by adopting a high-frequency LCP (Liquid Crystal Polymer) chip to bond the multilayer chip and simultaneously solidified; the edge bend of each packaging chip which is connected with the upper-layer (top) flexible circuit is connected with the two middle-layer (bottom) packaging chips in the packaging process so as to form a stacking layer, and the four chips are packaged on the flexible circuit board.

Owner:SHENZHEN DANBOND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com