Preparation method of multicolor fluorescent carbon dots and application of multicolor fluorescent carbon dots in aspect of LED (light-emitting diode)

A technology of fluorescent carbon dots and carbon dots, which is applied in chemical instruments and methods, nano-optics, luminescent materials, etc., can solve the problems of difficult uniform dispersion, large particle size, and difficult to control, and achieve the effect of luminescence and encapsulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of blue light carbon dots is as follows:

[0042] 1. Weigh 0.192g of citric acid and 0.6g of urea, put them in a 20mL reaction kettle, add 10mL of N,N-dimethylformamide (DMF) into it, put them in an oven, raise the temperature to 140°C, and keep it warm for 12 hours , cooled naturally to obtain a blue light carbon dot solution.

[0043] 2. Put the solution obtained in step 1 into a centrifuge tube, set the rotation speed to 10000rpm, centrifuge for 10min, and take the supernatant.

[0044] 3. Add petroleum ether and ethyl acetate to the supernatant, and a precipitate appears in the solution.

[0045] 4. Centrifuge the solution in step 3 to obtain a precipitate, put it in an oven at 70°C for drying, and obtain a blue fluorescent carbon dot solid.

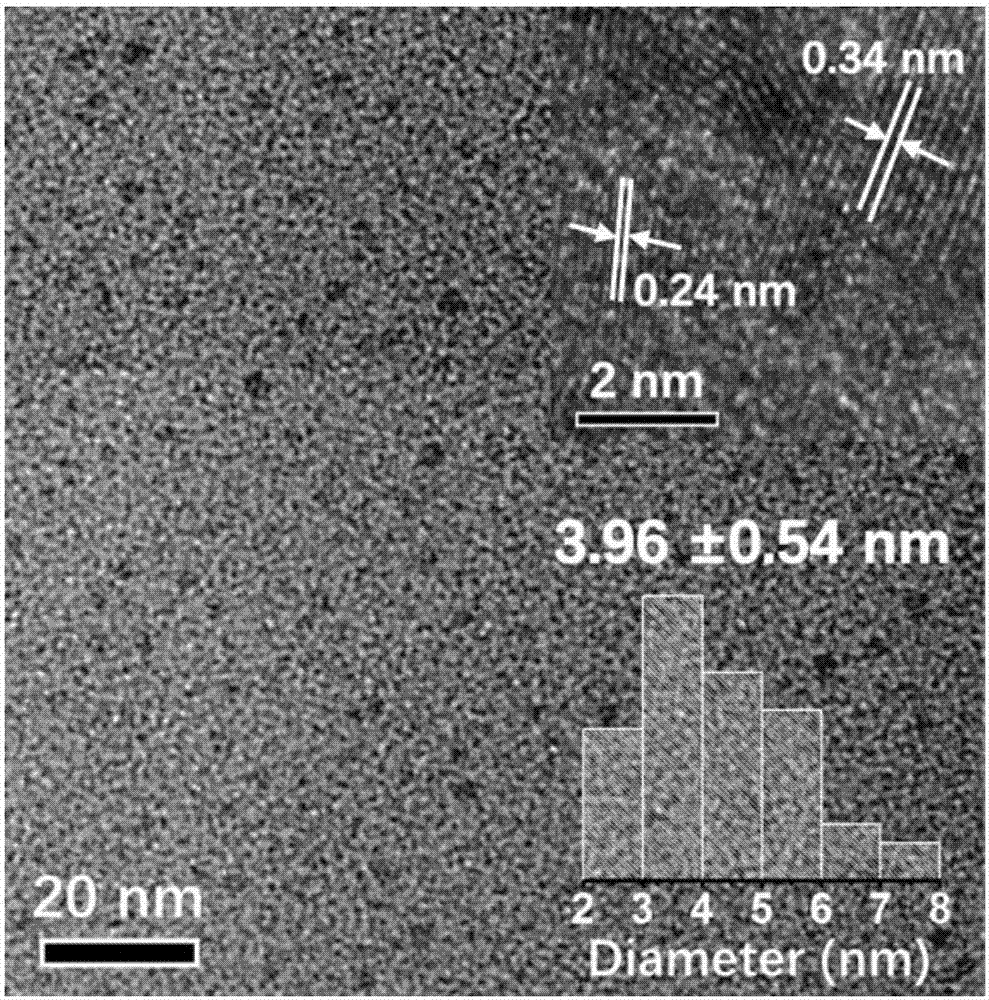

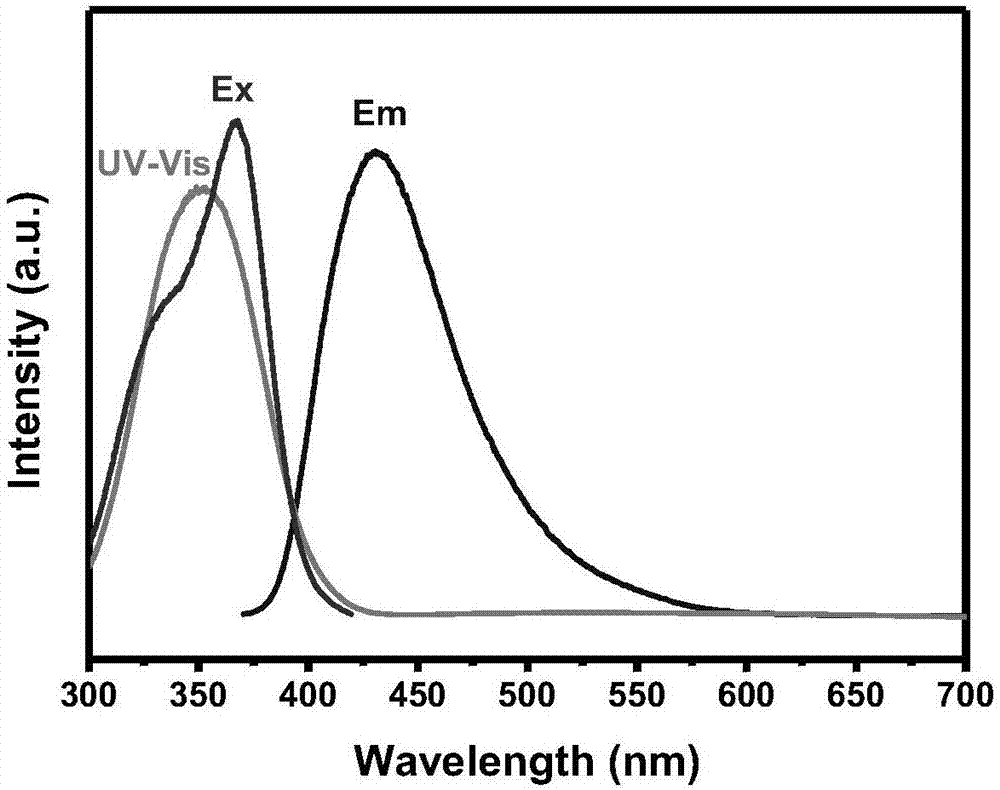

[0046] figure 1 This is the transmission electron microscope image and size distribution diagram of the blue-light carbon dots, from which it can be seen that the blue-light carbon dots are evenly dis...

Embodiment 2

[0049] The preparation method of green carbon dots is as follows:

[0050] 1. Weigh 0.576g of citric acid and 0.6g of urea, put them in a 20mL reaction kettle, add 10mL of N,N-dimethylformamide (DMF) into it, put them in an oven, raise the temperature to 160°C, and keep it warm for 12 hours , cooled naturally to obtain a green light carbon dot solution.

[0051] 2. Put the solution obtained in step 1 into a centrifuge tube, set the rotation speed to 10000rpm, centrifuge for 10min, and take the supernatant.

[0052] 3. Add petroleum ether and ethyl acetate to the supernatant, and a precipitate appears in the solution.

[0053] 4. Centrifuge the solution in step 3 to obtain a precipitate, put it in an oven at 70° C. to dry, and obtain a green fluorescent carbon dot solid.

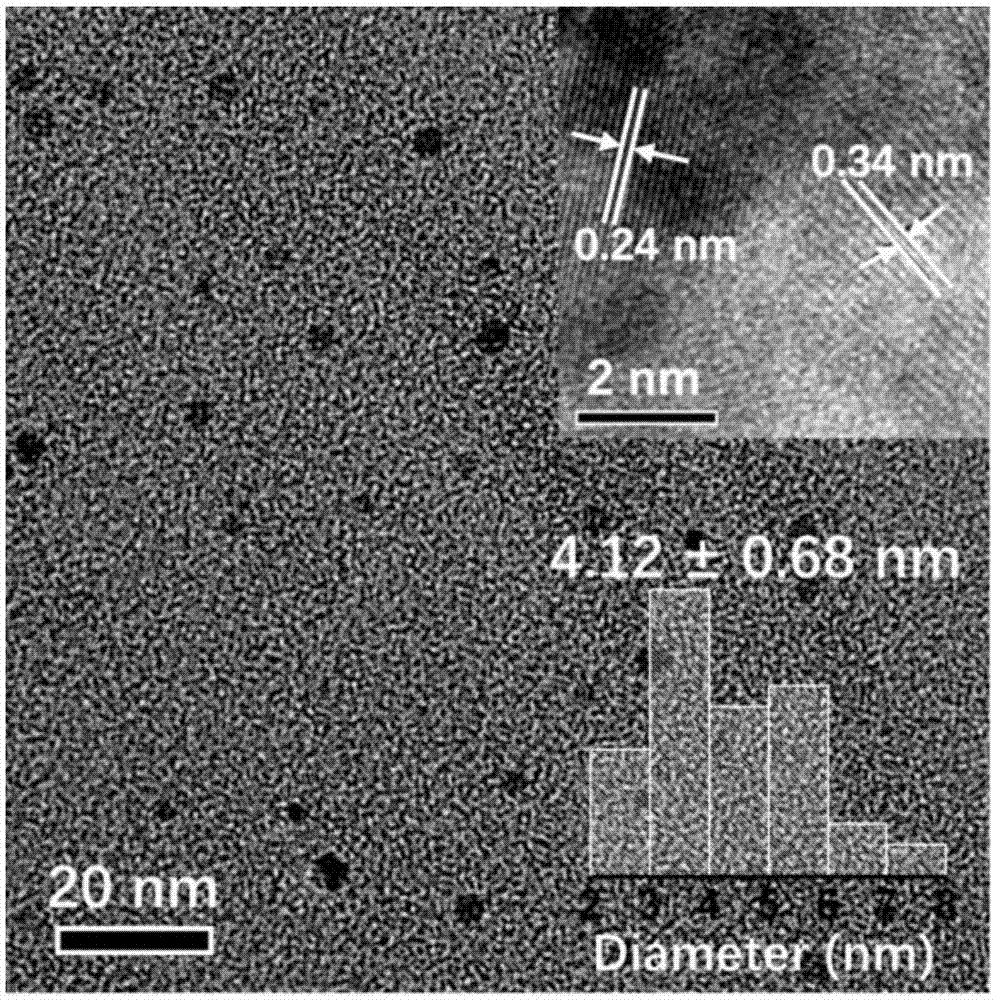

[0054] image 3 This is the transmission electron micrograph and size distribution diagram of the green carbon dots obtained, from which it can be seen that the green carbon dots are evenly dispersed. It ...

Embodiment 3

[0057] The preparation method of red light carbon dots is as follows:

[0058] 1. Weigh 1.44g citric acid and 0.6g urea, put them in a 20mL reaction kettle, add 10mL N,N-dimethylformamide (DMF) into it, put them in an oven, raise the temperature to 200°C, and keep it warm for 12 hours , cooled naturally to obtain a red light carbon dot solution.

[0059] 2. Put the solution obtained in step 1 into a centrifuge tube, set the rotation speed to 10000rpm, centrifuge for 10min, and take the supernatant.

[0060] 3. Add petroleum ether and ethyl acetate to the supernatant, and a precipitate appears in the solution.

[0061] 4. Centrifuge the solution in step 3 to obtain a precipitate, put it in an oven at 70°C for drying, and obtain a red fluorescent carbon dot solid.

[0062] Figure 5 This is the transmission electron microscope image and size distribution diagram of the red-light carbon dots, from which it can be seen that the red-light carbon dots are evenly dispersed. It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com