Quantum dot packaging body and application thereof

A technology of quantum dots and encapsulation, applied in semiconductor devices, manipulating single atoms, nanotechnology for materials and surface science, etc., can solve the problems of fragile glass tubes, reduced optical performance of quantum dots, and easy damage, etc., to achieve Easy to prepare, good water and oxygen barrier performance, and achieve the effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

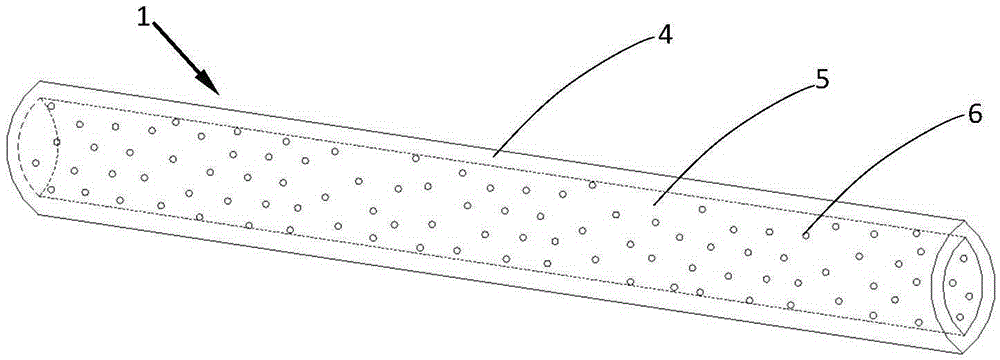

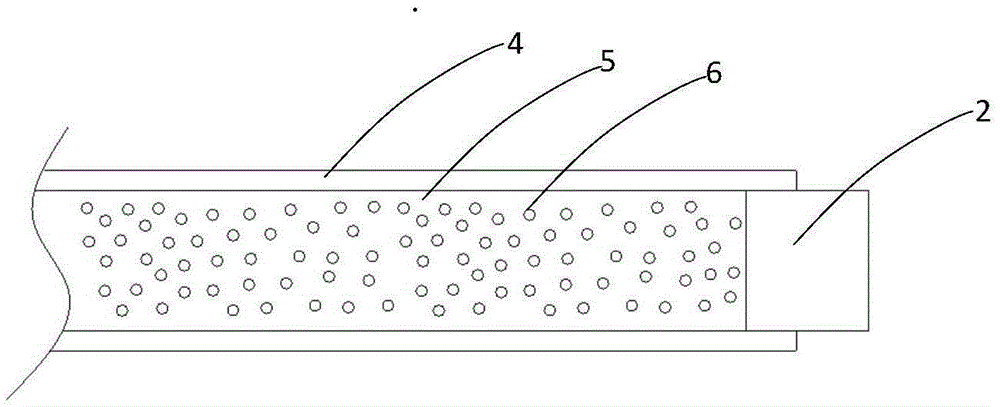

[0043] The preparation process of the tubular quantum dot glass body 3 mainly includes injecting, pouring or inhaling the second encapsulation medium before polymerization dispersed with quantum dots into the glass tube, and making the second encapsulation medium before polymerization by ultraviolet irradiation, heating or other means The packaging medium is polymerized and solidified, and the glass tube is sealed. The way of sealing includes using sealant or glass sintering. The sealant is preferably silicone rubber. In a specific embodiment, a part of the sealant is in the glass tube, thereby blocking the glass tube opening, such as image 3 shown. In a specific embodiment, the sealant completely wraps the glass nozzle, such as Figure 4 shown. In a specific embodiment, the glass of the glass nozzle is softened and reshaped by sintering to form a closed structure, such as Figure 5 shown. Of course, since the present invention also uses the first packaging medium 2, th...

Embodiment 1

[0060] Mix the quantum dots prepared in the oil phase with the shadowless glue, and rotate to evaporate the solvent to form a quantum dot dispersion; take 10 glass tubes with a cross-sectional outer diameter of 0.5 mm, an inner diameter of 0.3 mm, and a length of 20 cm, and pour them into the Inject the quantum dot dispersion. The injection method is as follows: put the quantum dot dispersion liquid in a brown bottle filled with argon gas sealed with a rubber stopper, insert the glass tube below the liquid level, and pressurize the brown bottle by introducing argon gas to form a pressure difference inside and outside the brown bottle. Aspirate the quantum dot dispersion into the glass tube. After the capillary is filled with quantum dot dispersion, put the glass tube under a UV lamp to cure. Both ends of the cured capillary were sealed with sealant under argon atmosphere. Disperse the cured glass tube in parallel in liquid shadowless glue, and cure it with ultraviolet light ...

Embodiment 2

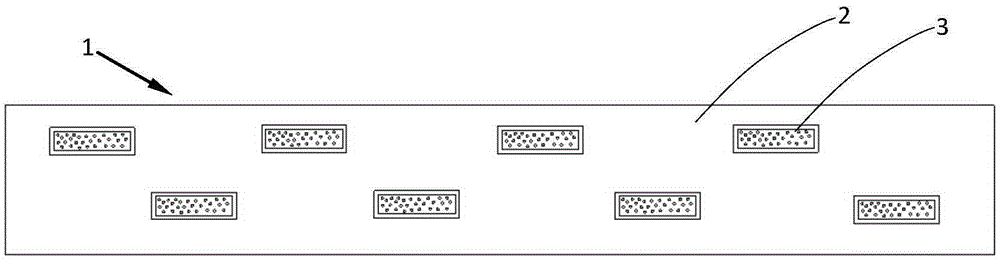

[0062]Mix the quantum dots prepared in the oil phase with the shadowless glue, and rotate to evaporate the solvent to form a quantum dot dispersion; take 10 glass tubes with a cross-sectional outer diameter of 0.5 mm, an inner diameter of 0.3 mm, and a length of 20 cm, and pour them into the Inject the quantum dot dispersion and cure with UV light. The injection method is the same as in Example 1. The above glass was photocut into glass tubules with a length of 1 cm by laser cutting. Arrange the small glass tubes with red light quantum dots and the glass pavilions with green light quantum dots in parallel according to the quantity ratio of 1:2, and the red and green alternate, and add shadowless glue and cure by ultraviolet light to form multiple tubes with a length of 1 cm and a width of Quantum dot package A2 with a height of 3 mm and a height of 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com