Manufacturing method of flexible display device and flexible display device manufactured by adopting same

A flexible display device, flexible polymer technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor reliability, improve lifespan, reduce costs, and reduce pinholes and grain boundaries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing a flexible display device and the prepared flexible display device. The method for preparing the flexible display device includes the following steps:

[0040] Step 1: sequentially prepare at least one organic planarization layer and at least one inorganic barrier layer alternately arranged on the first flexible polymer substrate and the second flexible polymer substrate, and at least one layer alternately arranged Layer the organic planarization layer and at least one layer of the inorganic barrier layer to form a first water oxygen barrier layer and a second water oxygen barrier layer on the first flexible polymer substrate and the second flexible polymer substrate respectively. Barrier layer, the film-forming temperature of the inorganic barrier layer is 200-450°C;

[0041] Step 2: preparing an organic light-emitting diode on the side of the first flexible polymer substrate provided with the first water-oxygen barrier lay...

Embodiment 2

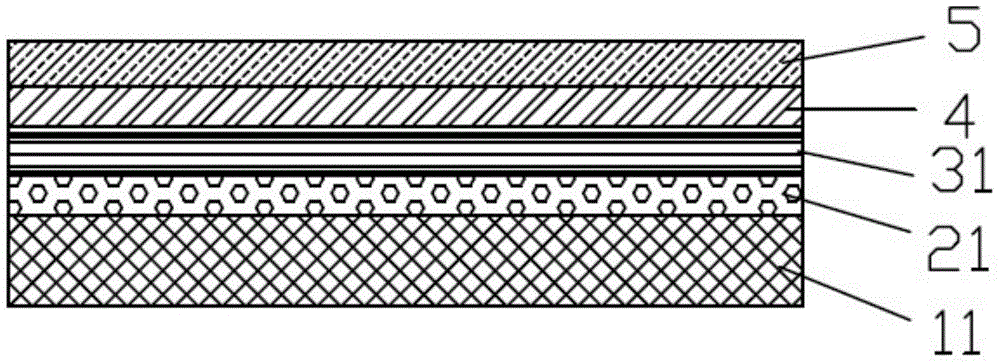

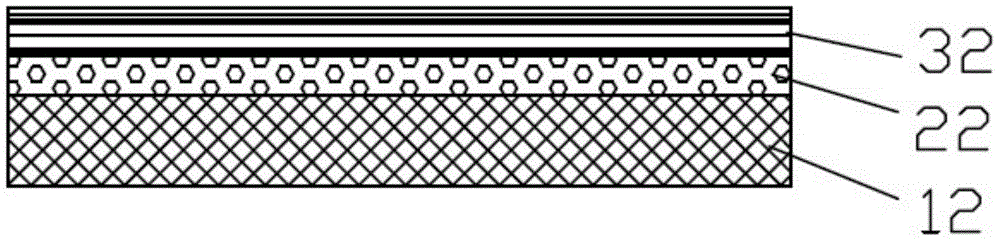

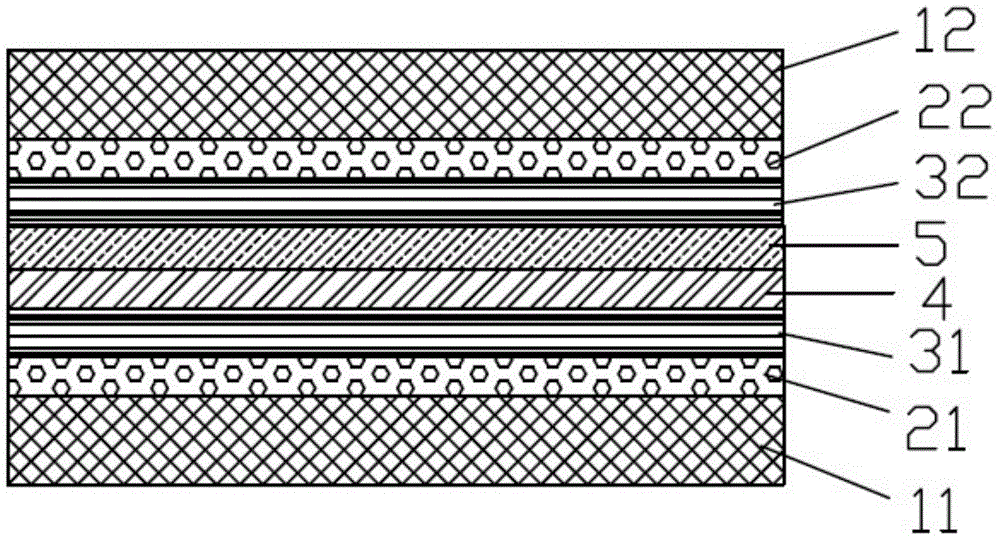

[0044] Such as Figures 1a-1d As shown, the present embodiment provides a method for preparing a flexible display device and the prepared flexible display device, and the method for preparing the flexible display device includes the following steps:

[0045] Step 1: Attach the first flexible polymer substrate 21 and the second flexible polymer substrate 22 to the first rigid carrier 11 and the second rigid carrier 12 respectively.

[0046] Step 2: If Figure 1a and Figure 1b As shown, on the first flexible polymer substrate 21 and the second flexible polymer substrate 22, at least one layer of organic planarization layer and at least one layer of inorganic barrier layer are sequentially prepared alternately, and the alternate At least one organic planarization layer and at least one inorganic barrier layer are provided to form a first water-oxygen barrier layer 31 and a second flexible polymer substrate 21 on the first flexible polymer substrate 21 and the second flexible po...

Embodiment 3

[0051] Such as Figure 2a-2d As shown, the present embodiment provides a method for preparing a flexible display device and the prepared flexible display device. The method for preparing the flexible display device specifically includes the following steps:

[0052] Step 1: Coating organic glue or inorganic glue on the first hard carrier 11 and the second hard carrier 12, and attaching the first flexible polymer substrate 21 and the second flexible polymer lining on the glue-coated surface respectively Bottom 22; the colloid is then cured by means of laser, ultraviolet light, etc., so that the first flexible polymer substrate 21 and the second flexible polymer substrate 22 are respectively attached to the first rigid carrier 11 and the second hard carrier 12. In this embodiment, organic glue is preferred, purchased from Nagase Corporation, Japan, model XNR5516Z, and cured by ultraviolet curing.

[0053] The first rigid carrier 11 and the second rigid carrier 12 are independe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com