Preparation method of flame-retardant fluorocarbon aluminum veneer for furniture decoration

A technology for flame-retardant fluorocarbon aluminum veneer and furniture, which is applied to the device, coating, anti-corrosion coating and other directions of coating liquid on the surface. Complexity and other issues, to achieve the effect of improving safety, good effect, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

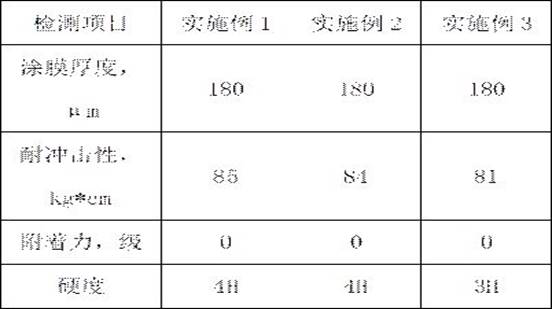

Embodiment 1

[0018] The present invention proposes a method for preparing a flame-retardant fluorocarbon aluminum plate for furniture:

[0019] 1. Sheet Metal Processing: Select 3.2mm thick aluminum alloy panel for sheet metal processing;

[0020] 2, pretreatment: degreasing: The aluminum alloy panel obtained by step 1 is degreased by degreasing liquid at 75 ° C for 3 min; water washing; acid washing: acid washing is 2.5 min under room temperature; water washing; passivation: The chromium passivation solution is passivated to the surface of the aluminum plate; water washing; drying; dried at a temperature below 60 ° C, a chemical treatment layer of 28 μm thickness in the aluminum alloy surface;

[0021] 3, spraying: The surface of the chemical layer surface of the chemical treatment layer obtained by step 2 is formed to form a fluorocarbon primer layer, and the thickness of the primer layer is 22 μm; at room temperature for 5 min, drying under 165 ° C; continuing Spray fluorocarbon noodles for...

Embodiment 2

[0028] The present invention proposes a method for preparing a flame-retardant fluorocarbon aluminum plate for furniture:

[0029] 1. Sheet Metal Processing: Select 4mm thick aluminum alloy panel for sheet metal processing;

[0030] 2, pre-treatment: degreasing: The aluminum alloy panel obtained by step 1 is degreased by degreasing liquid at 50 ° C for 5 min; water is washed; acid washing: acid washing is carried out at room temperature; water washing; passivation: adopt chromium The passivation liquid is passivated to passivate the aluminum sheet surface; water washing; drying; drying at a temperature of 30 μm thickness at a temperature of less than 60 ° C, a chemical treatment layer of 30 μm thickness;

[0031] 3, spraying: the surface of the chemical layer surface of the chemical treatment layer obtained by step 2 is formed to form a fluorocarbon primer layer, and the thickness of the primer layer is 15 μm; at room temperature at room temperature, drying under 160 ° C; Continue...

Embodiment 3

[0038] The present invention proposes a method for preparing a flame-retardant fluorocarbon aluminum plate for furniture:

[0039] 1. Sheet Metal Processing: Select 2mm thick aluminum alloy panel for sheet metal processing;

[0040] 2, pretreatment: degreasing: The aluminum alloy panel obtained by step 1 is degreased by degreasing fluid at 80 ° C for 2 min; water washing; acid washing: acid washing is acid washing at room temperature; water washing; passivation: adopt chromium The passivation liquid is passed to passivate the surface of the aluminum plate; water washing; drying; drying at a temperature of less than 60 ° C, a chemical treatment layer of 25 μm thickness is obtained at the surface of the aluminum alloy;

[0041] 3, spraying: The surface of the chemical layer surface of the chemical treatment layer obtained by step 2 is formed to form a fluorocarbon primer layer, and the thickness of the primer layer is 25 μm; at room temperature for 4 min, drying under 180 ° C; conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com