High-scratch-resistant water-based transparent ink composition and preparation method thereof

A technology of ink composition and transparent ink, which is applied in ink, household utensils, applications, etc., can solve the problems of less side branches, non-wear resistance, and insufficient film-forming compactness, so as to improve film-forming compactness and hardness , enhance the smoothness and feel, and improve the effect of anti-scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

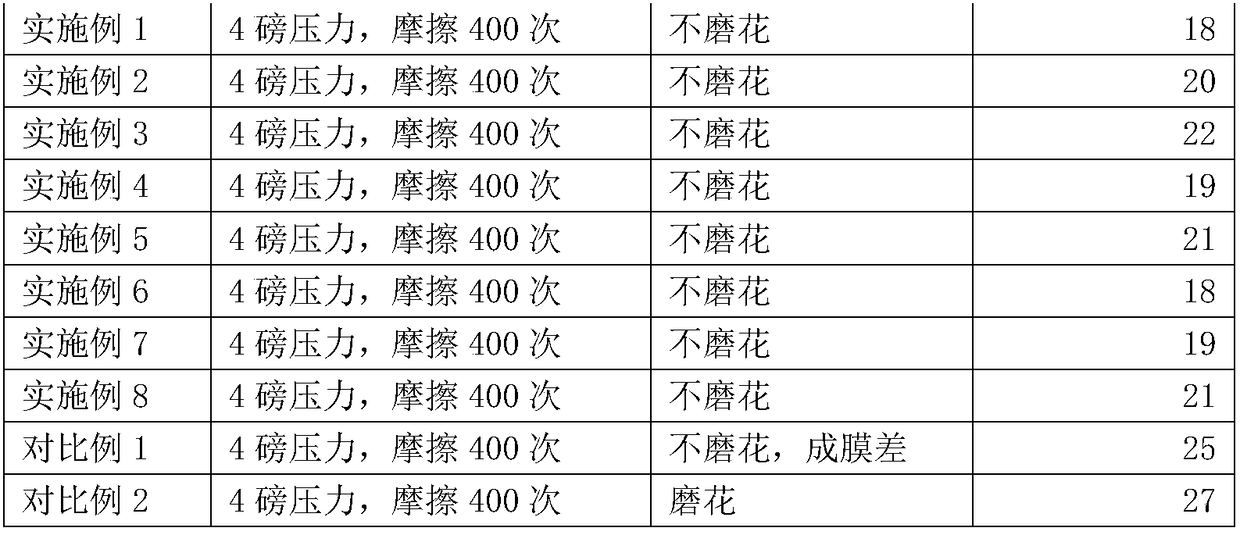

Embodiment 1

[0030] The smooth and scratch-resistant water-based varnish is prepared from the following components in parts by weight: 20% multifunctional styrene-acrylic acid copolymer soft emulsion, 34.5% styrene-acrylic acid copolymer hard emulsion, 30% High molecular weight solid acrylic resin 20%, water-based defoamer 0.3%, leveling agent 0.3%, 25% ammonia water 3%, dimethylethanolamine 1.0%, slip agent 0.3%, wax emulsion 8.0%, active amine 6.0%, Gas-phase nano silicon dioxide 0.6%, film-forming aid 1.5%, deionized water 4.0%, ethanol 0.5%. According to the ratio of the above components, first add high molecular weight solid acrylic resin, deionized water and defoamer into the container, stir in a high-speed stirring disperser with a speed of 400-1500 rpm, and slowly divide it into three times during the stirring process. Add ammonia water, add once every 20 minutes, stir for 2-8 hours until the solid resin is completely dissolved, then add the remaining components into the dissolved ...

Embodiment 2

[0032] The slippery and anti-scratch water-based varnish is prepared from the following components in parts by weight: multifunctional styrene-acrylic acid copolymer soft emulsion 20%, styrene-acrylic acid copolymer hard emulsion 33.2%, 30% High molecular weight solid acrylic resin 20%, water-based defoamer 0.3%, leveling agent 0.3%, 25% ammonia water 3%, dimethylethanolamine 1.0%, slip agent 0.3%, wax emulsion 8.0%, active amine 5.6%, Gas-phase nano silicon dioxide 1%, film-forming aid 1.5%, deionized water 9%, ethanol 0.8%. According to the ratio of the above components, first add high molecular weight solid acrylic resin, deionized water and defoamer into the container, stir in a high-speed stirring disperser with a speed of 400-1500 rpm, and slowly divide it into three times during the stirring process. Add ammonia water, add once every 20 minutes, stir for 2-8 hours until the solid resin is completely dissolved, then add the remaining components into the dissolved solid r...

Embodiment 3

[0034] The slippery and anti-scratch water-based varnish is prepared from the following components in parts by weight: multifunctional styrene-acrylic acid copolymer soft emulsion 25%, styrene-acrylic acid copolymer hard emulsion 29.2%, 30% High molecular weight solid acrylic resin 25%, water-based defoamer 0.3%, leveling agent 0.3%, 25% ammonia water 3%, dimethylethanolamine 1.0%, slip agent 0.3%, wax emulsion 5.0%, active amine 3%, Gas-phase nano silicon dioxide 1.6%, film-forming aid 1.5%, deionized water 4.0%, ethanol 0.8%. According to the ratio of the above components, first add high molecular weight solid acrylic resin, deionized water and defoamer into the container, stir in a high-speed stirring disperser with a speed of 400-1500 rpm, and slowly divide it into three times during the stirring process. Add ammonia water, add once every 20 minutes, stir for 2-8 hours until the solid resin is completely dissolved, then add the remaining components into the dissolved solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com