Method and chip for integrating micro electromechanical system device and integrated circuit

A technology of micro-electromechanical systems and integrated circuits, applied in the direction of electric solid-state devices, chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of high packaging cost, overall performance degradation, and multiple interference Signal and other issues, to achieve the effect of reducing packaging cost, reducing volume, and reducing packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method for integrating MEMS devices and integrated circuits and the formed integrated chips of the present invention will be described in detail below through specific embodiments.

[0035] see figure 1 and Figure 13 , the integration method of MEMS device and integrated circuit of the present invention mainly comprises the following steps:

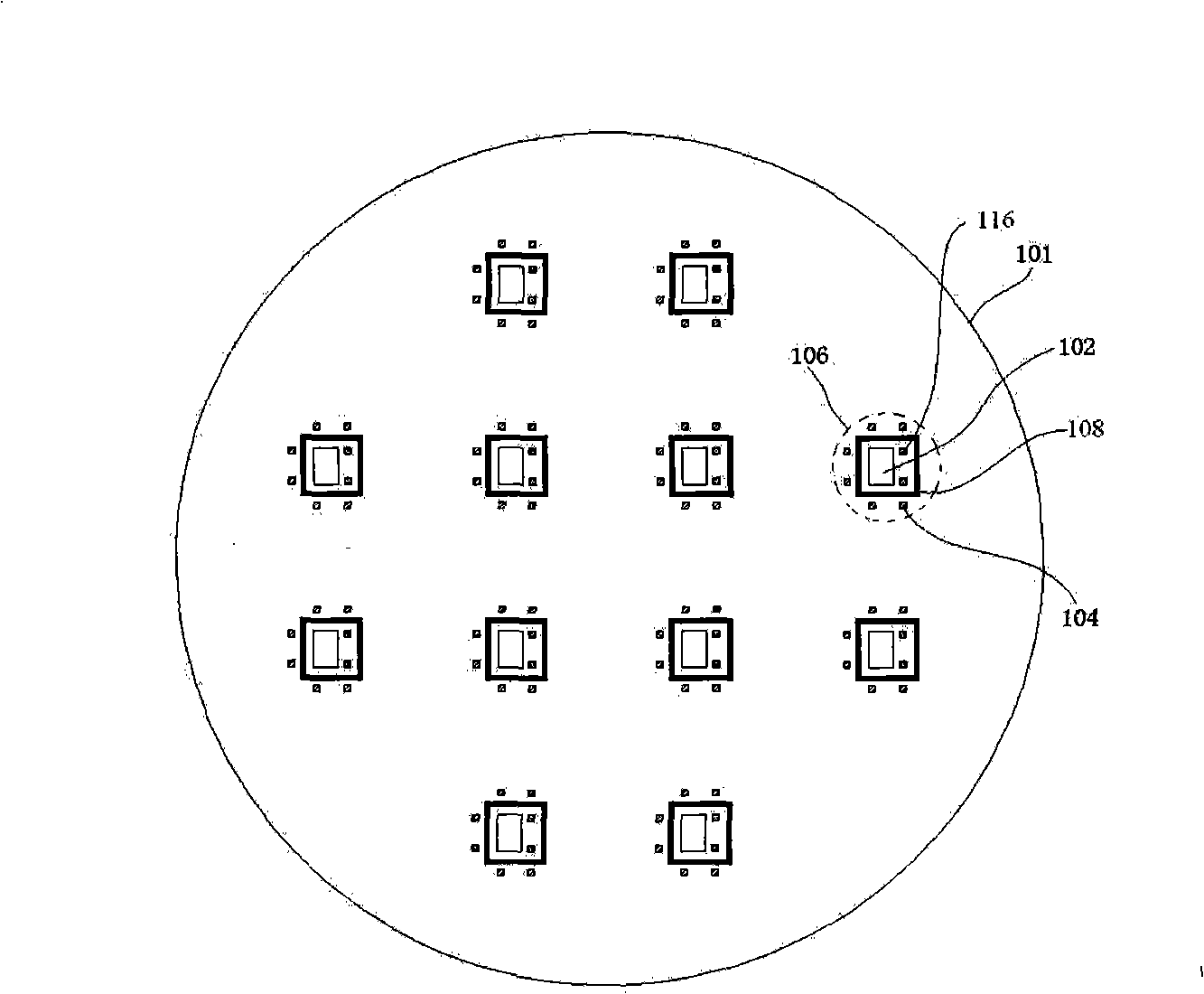

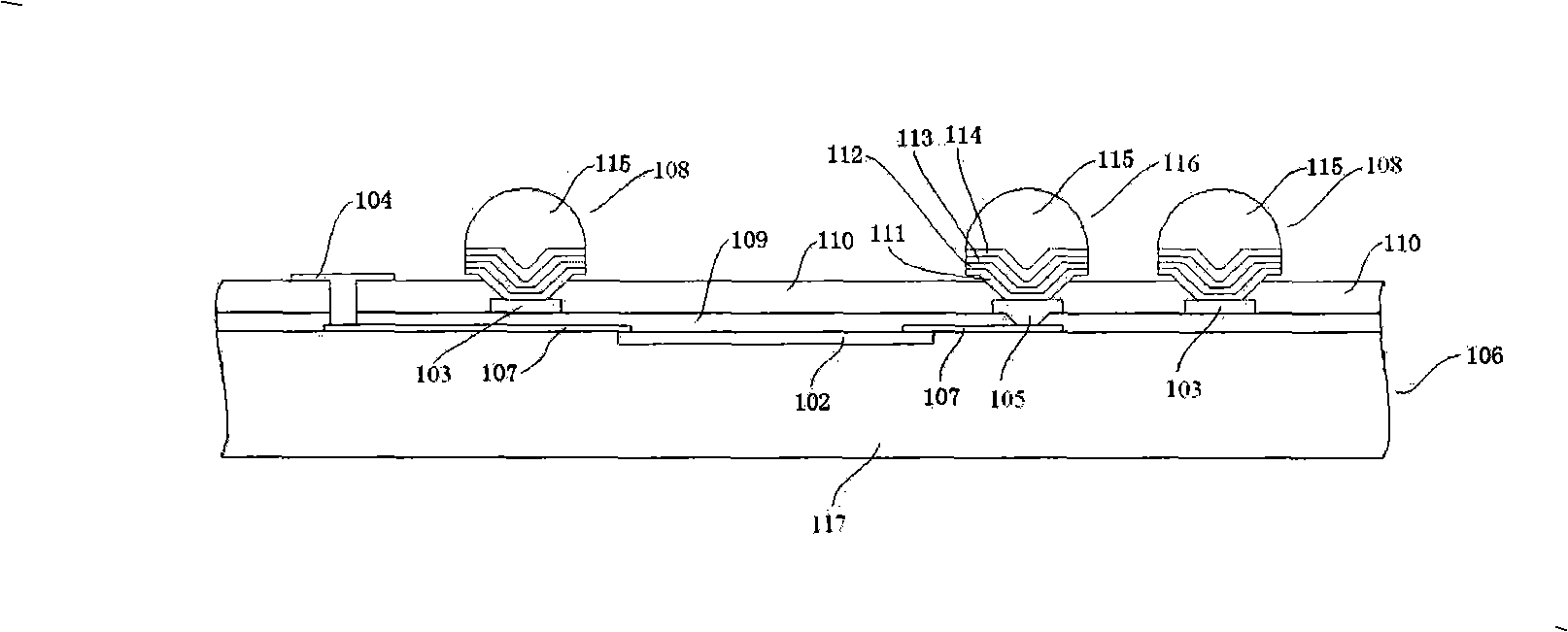

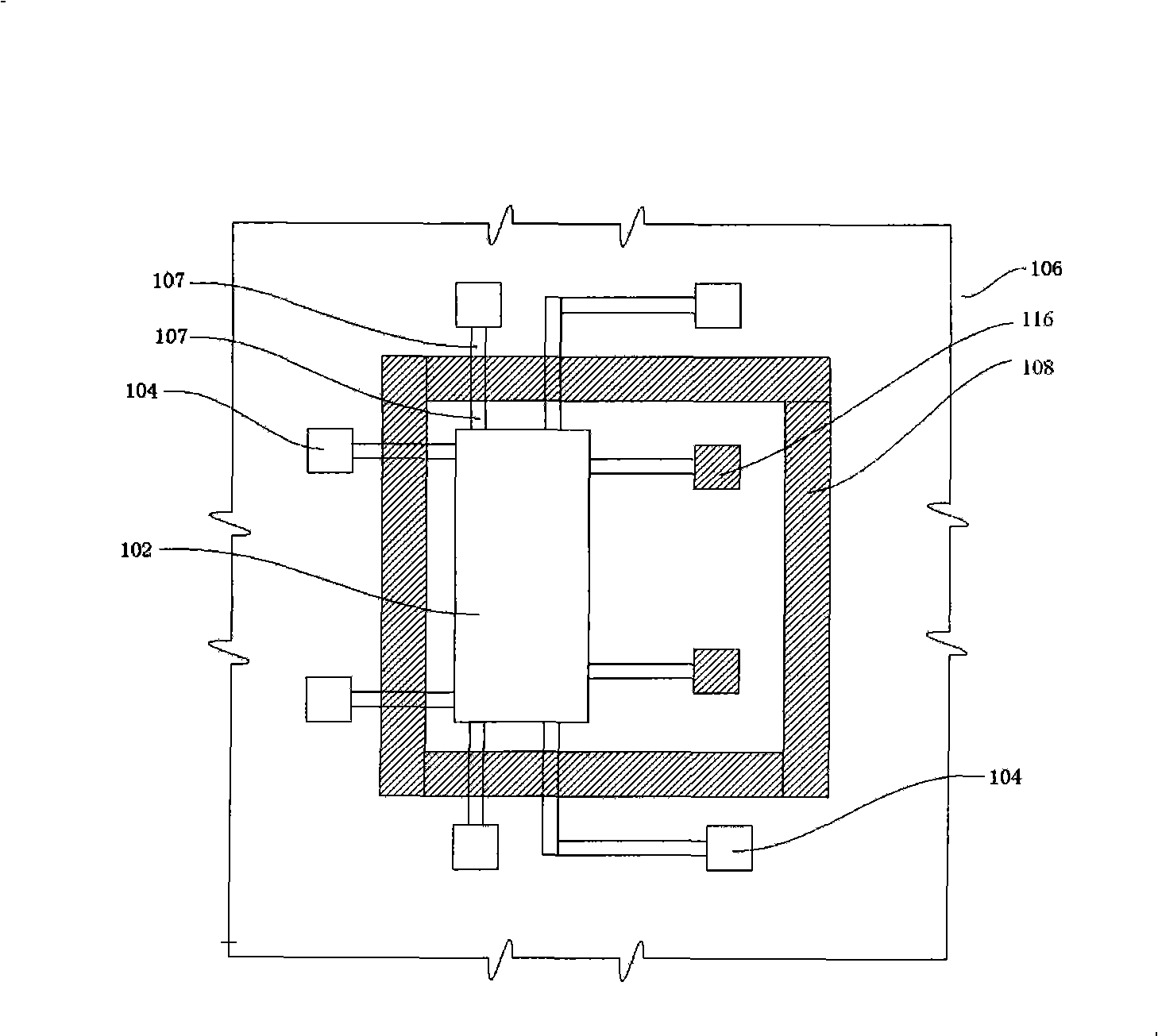

[0036] The first step: provide a first wafer 201 and a second wafer 101 respectively, such as Figures 4 to 6 As shown, the first wafer 201 has a plurality of first chips, that is, MEMS device units 205, each MEMS device unit 205 is composed of 3 layers, the bottom layer is a silicon substrate 208, and the silicon substrate There is a silicon oxide layer 216 on the silicon oxide layer 208, and a device layer 206 is on the silicon oxide layer 216. A narrow groove 219 is obtained by photolithography and etching to form a MEMS device such as a comb-tooth capacitance accelerometer 202. The accelerometer A release hole 215 is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com