Calcium alginate fiber and preparation method thereof

A technology of calcium alginate fiber and sodium alginate, applied in fiber processing, alginate rayon, pharmaceutical formulations, etc., can solve the problems of fiber size and the inability to encapsulate functional materials in the preparation process, and achieve repeatable experiments. The effect of strong property, uniform structure, simple and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of calcium alginate fiber, comprising the following steps:

[0034](1) Prepare oil phase or gas phase, sodium alginate solution and calcium chloride solution, and inject them into the inner phase fluid channel, middle phase fluid channel and outer phase fluid channel of the microfluidic device according to the inner, middle and outer phases;

[0035] (2) adjusting the fluid flow rate in the internal phase fluid channel described in step (1), so that the sodium alginate solution and the calcium chloride solution undergo a gelation reaction to generate calcium alginate fibers with a predetermined structure;

[0036] (3) Collect or wash the generated fibers to obtain calcium alginate fibers with a rod-shaped porous structure.

[0037] Wherein, in the step (1), the oil phase or the gas phase is injected into one of the internal phase fluid channels; in the step (2), the fluid flow rate in the internal phase fluid channel is adjusted so that it is greate...

Embodiment 1

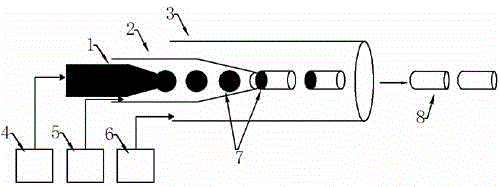

[0043] (1) The formation of the mixed state of sodium alginate solution and oil droplets: according to figure 1 As shown, the glass tubes A, B, and C are respectively glued to the glass slide, and then the glass tube A is inserted into the glass tubes B and C in turn, so that the pointed ends of the glass tubes A and B are used as the outflow ends. Then, when the glue is not completely dry, adjust the position between the glass tubes under the microscope so that the thin tube is in the middle of the thick tube. Inject methyl silicone oil KF-96 (50CS) into tube A through pump 1 and a 10ml syringe in the first liquid inlet power unit, and connect the needle to tube A through pump 2 and a 2.5ml syringe in the second liquid inlet power unit Push injection of 1wt% sodium alginate solution in tube B, and inject 2wt% calcium chloride solution in tube C through the pump 3 and 10ml syringe in the third liquid inlet power device, and make the flow rate of tube A relatively large. Under...

Embodiment 2

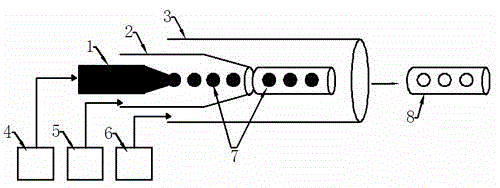

[0047] (1) The formation of the mixed state of sodium alginate solution and oil droplets: according to figure 2 As shown, the same apparatus as in Example 1 was used. Inject a mixture of methyl silicone oil KF-96 (50CS) and surfactant F108 (1wt%) at a volume ratio of 9:1 into tube A through pump 1 and a 10ml syringe connection needle in the first liquid inlet power unit Inject the 2wt% sodium alginate solution into tube B through the pump 2 in the second liquid inlet power unit and the 2.5ml syringe connection needle, and connect the needle through the pump 3 in the third liquid inlet power device and the 10ml syringe Inject 2wt% calcium chloride solution into tube C, and make the phase flow velocity of tube A smaller, and under the action of oil-water shear force, smaller oil droplets will be formed to fill the sodium alginate solution, and then pass through with the outer tube. Calcium chloride solution reacts to generate calcium alginate fibers containing many small oil d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com