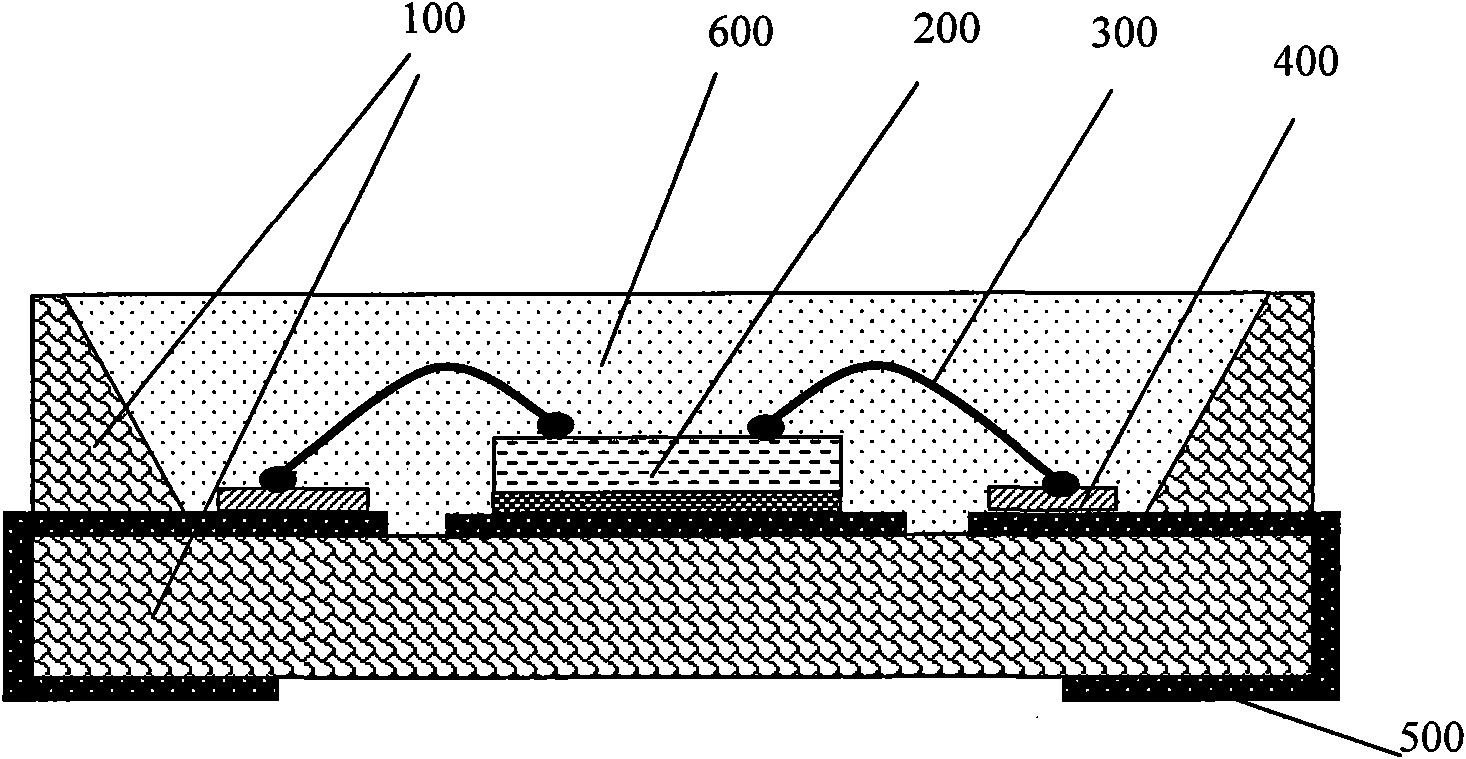

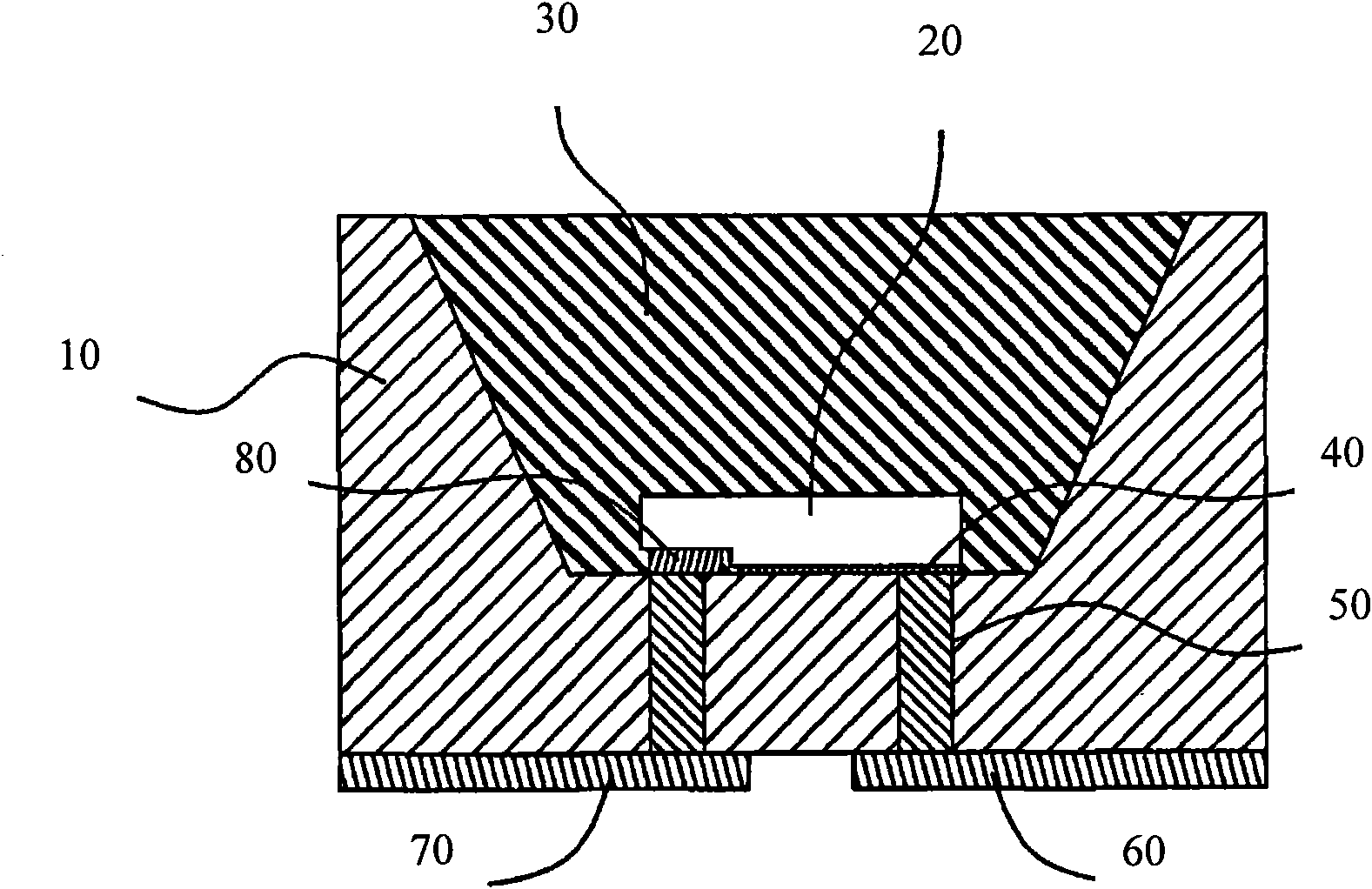

LED surface mounting structure for silicon substrate integrated with functional circuits and packaging method thereof

A technology of LED packaging and functional circuits, applied in circuits, electrical components, electric solid devices, etc., can solve problems such as unsatisfactory heat dissipation, difficult miniaturization, poor temperature resistance, etc., to achieve high integration and reduce Process cost and process difficulty, the effect of packaging cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

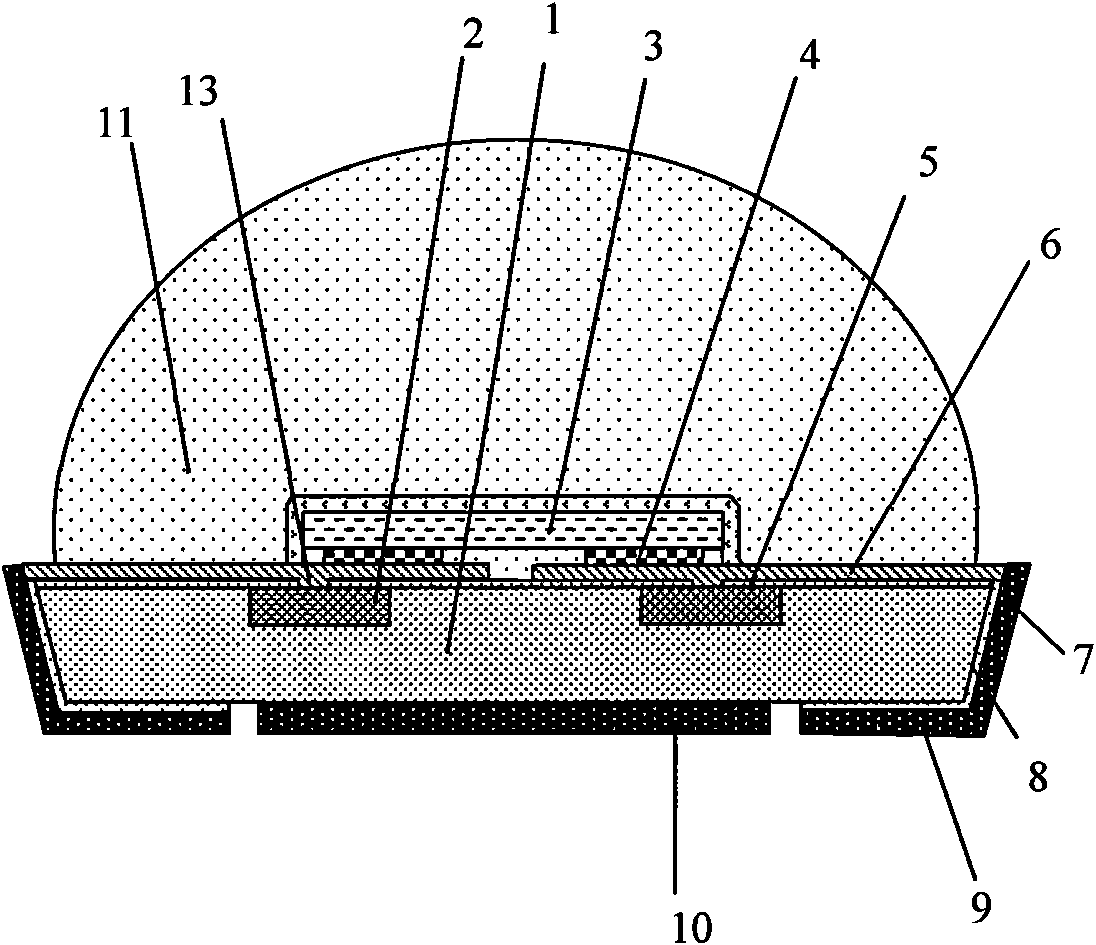

[0051] The method of integrating the electrostatic protection circuit on the silicon substrate 1 will be described in detail below.

[0052] It is specifically realized in the above step S2. An electrostatic protection circuit 2 and a metal electrode layer 6 are formed on a silicon substrate 1 . For the top view and equivalent circuit diagram of the specific electrostatic protection circuit, please refer to Figure 12 , the circuit is connected in parallel with the two electrodes of the LED chip. The production process is as follows: select a P-type doped silicon substrate 1 with a certain resistivity, first perform a thermal oxidation process on the surface to form an oxide layer 5, and then open a window for the doping position by photolithography etching, and use ion implantation or The diffusion process forms an N-type heavily doped region 2 at the window position, and the doping concentration and depth are determined according to the required PN junction reverse breakdo...

Embodiment 2

[0054] The method for integrating another electrostatic protection circuit on the silicon substrate 1 will be described in detail below.

[0055] It is specifically realized in the above step S2. An electrostatic protection circuit 2 and a metal electrode layer 6 are formed on a silicon substrate 1 . For the top view and equivalent circuit diagram of the specific electrostatic protection circuit, please refer to Figure 13 , the circuit is connected in parallel with the two electrodes of the LED chip. Select an N-type doped silicon substrate 1 with a certain resistivity, first perform a thermal oxidation process on the surface to form an oxide layer 5, and then open a window where the doping position needs to be etched by photolithography, and use ion implantation or diffusion process at the window position Form a P-type heavily doped region 2, the doping concentration and depth are determined according to the required PN junction reverse breakdown voltage; while doping, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com