LED (Light Emitting Diode) surface patch type encapsulating structure based on silicon base plate and encapsulating method thereof

A packaging method and packaging structure technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of increased wiring difficulty, difficult multi-chip modules, poor temperature resistance, etc., to reduce process cost and process difficulty , Convenient connection and packaging at will, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

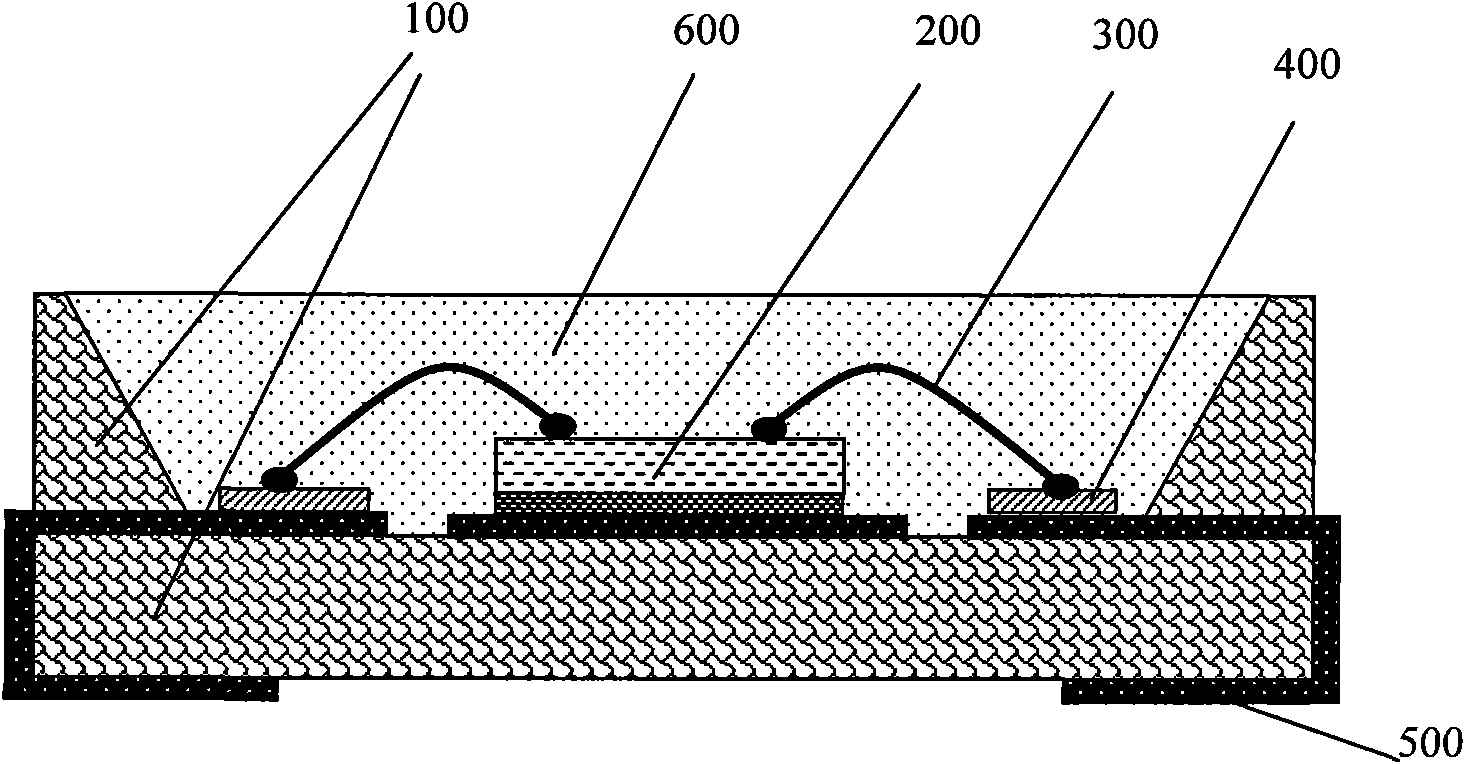

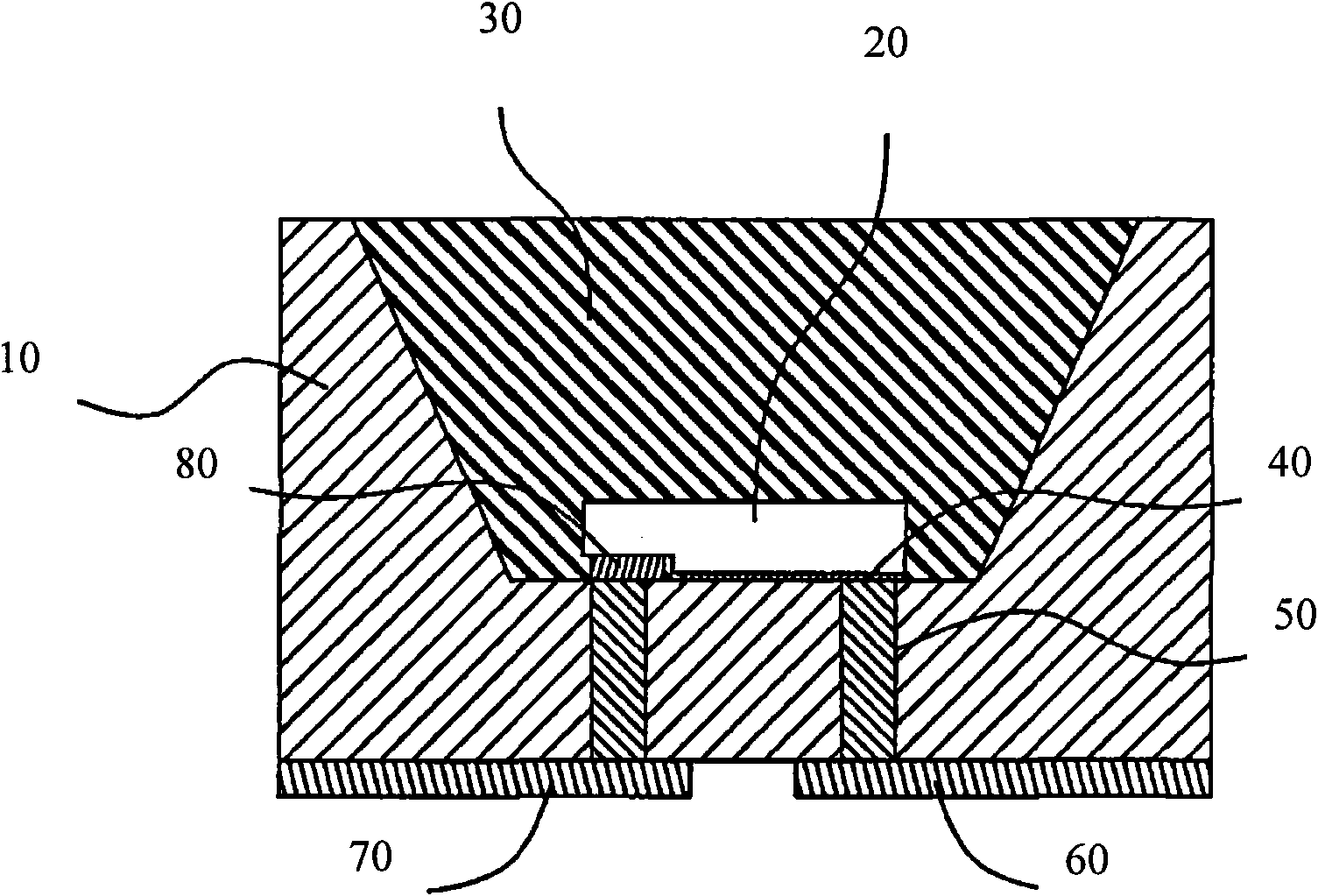

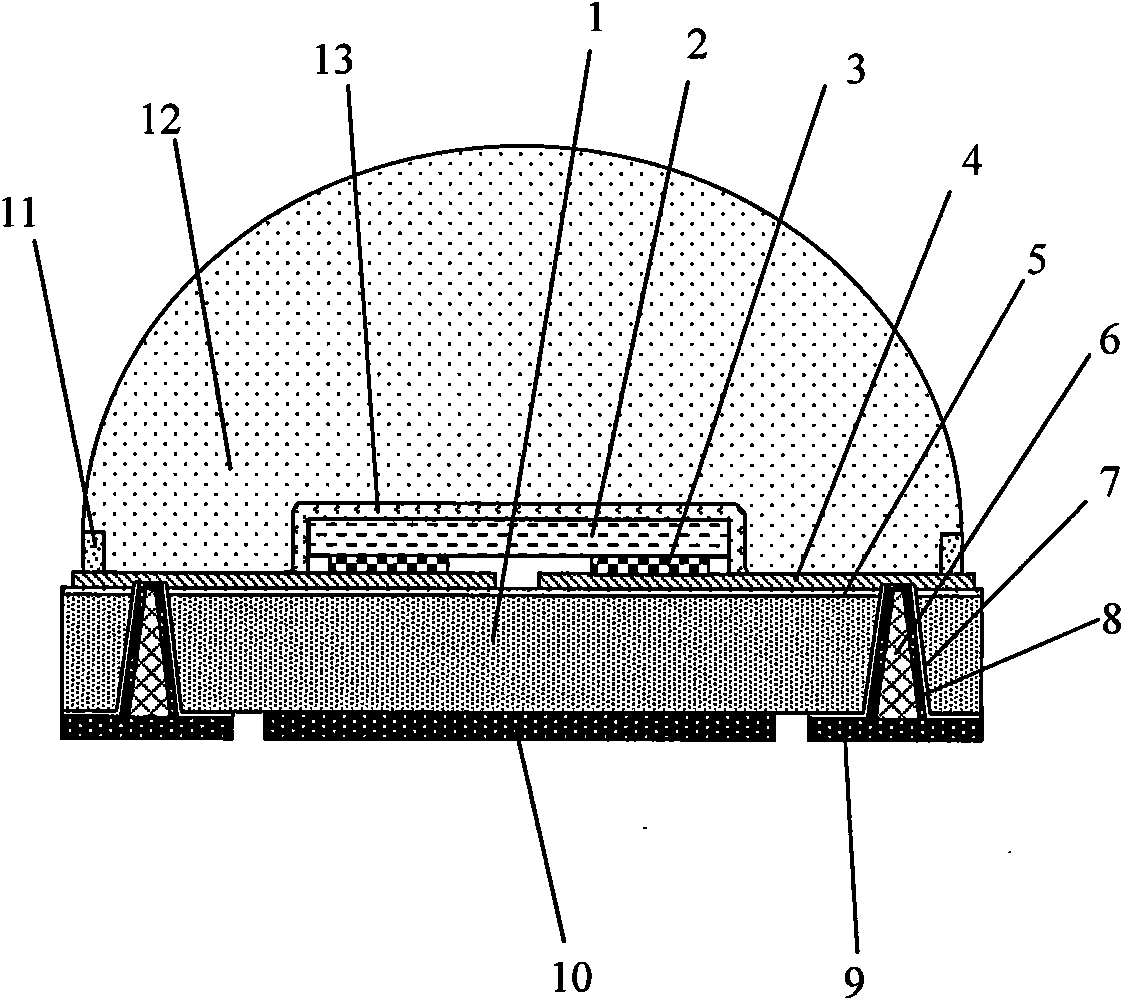

[0022] Please also see image 3 , Figure 4 and Figure 5 , which are respectively a schematic cross-sectional view, a top view and a bottom view of the silicon substrate-based LED packaging structure of the present invention. The LED packaging structure includes a silicon substrate 1 , an LED chip 2 and a lens 12 . Specifically, the upper surface of the silicon substrate 1 is a planar structure without grooves. An oxide layer 5 covers the upper surface of the silicon substrate 1 . Two metal electrode layers 4 respectively used to connect positive and negative electrodes are disposed on the upper surface of the oxide layer 5 and are insulated from each other. Metal bumps 3 are respectively provided on the upper surface of the metal electrode layer 4 . The LED chip 2 is flip-chip mounted on the silicon substrate 1 , and the positive and negative poles of the LED chip 2 are respectively connected to two metal bumps 3 , so as to be electrically connected to the metal electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com