Patents

Literature

145results about How to "Evenly stacked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

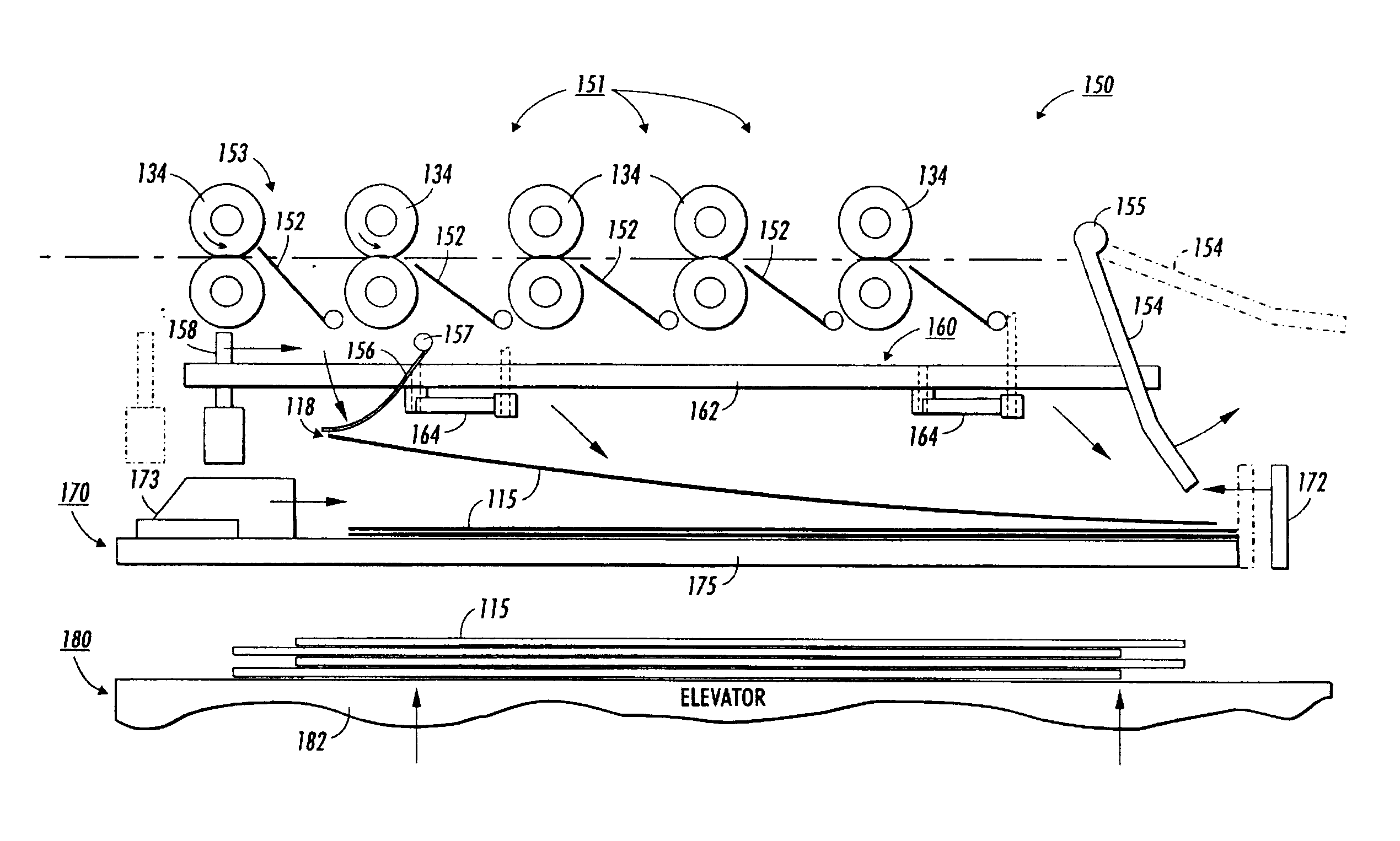

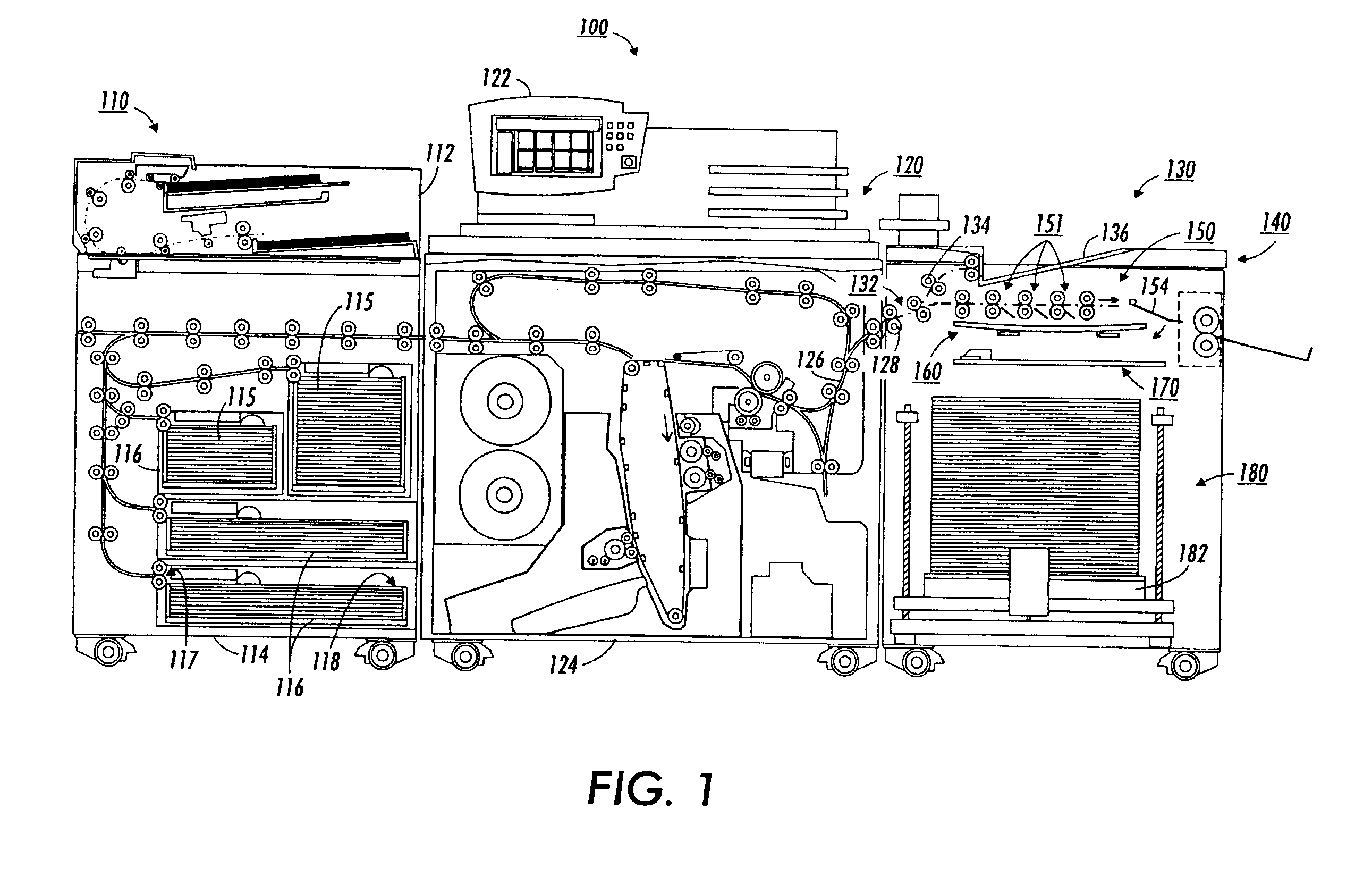

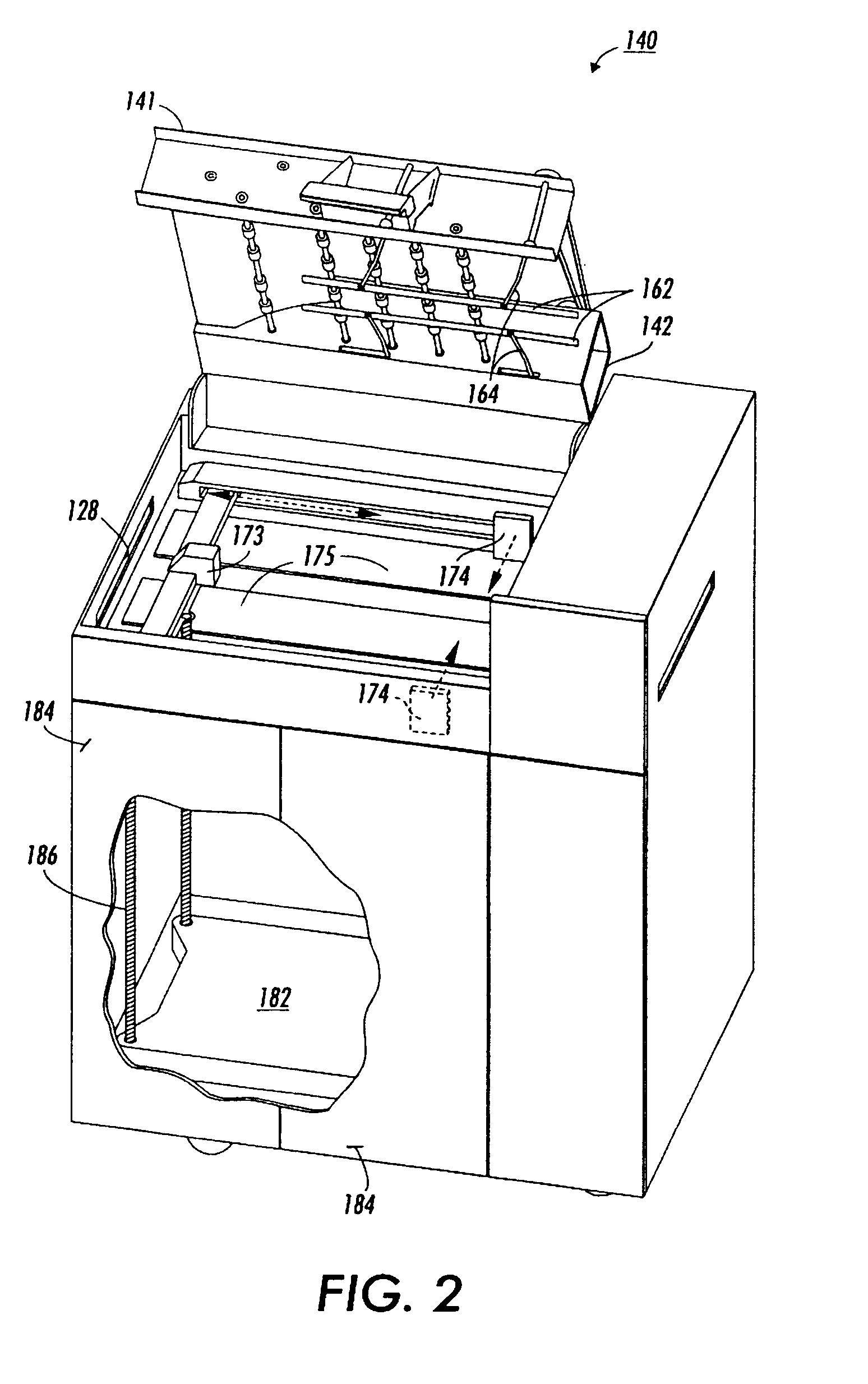

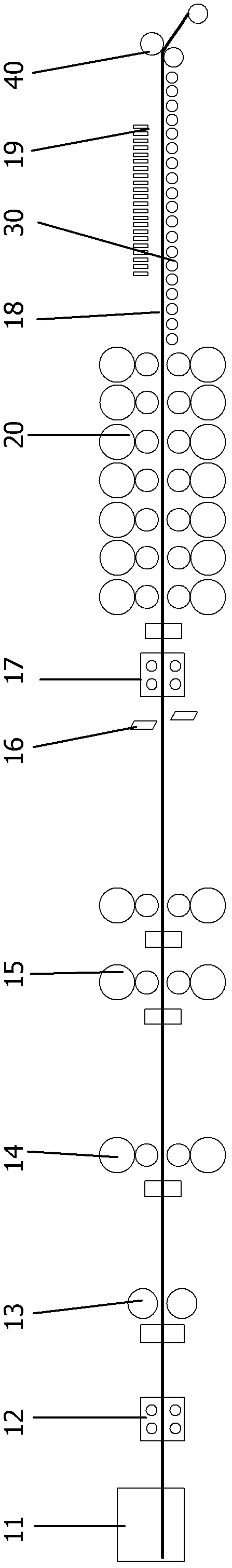

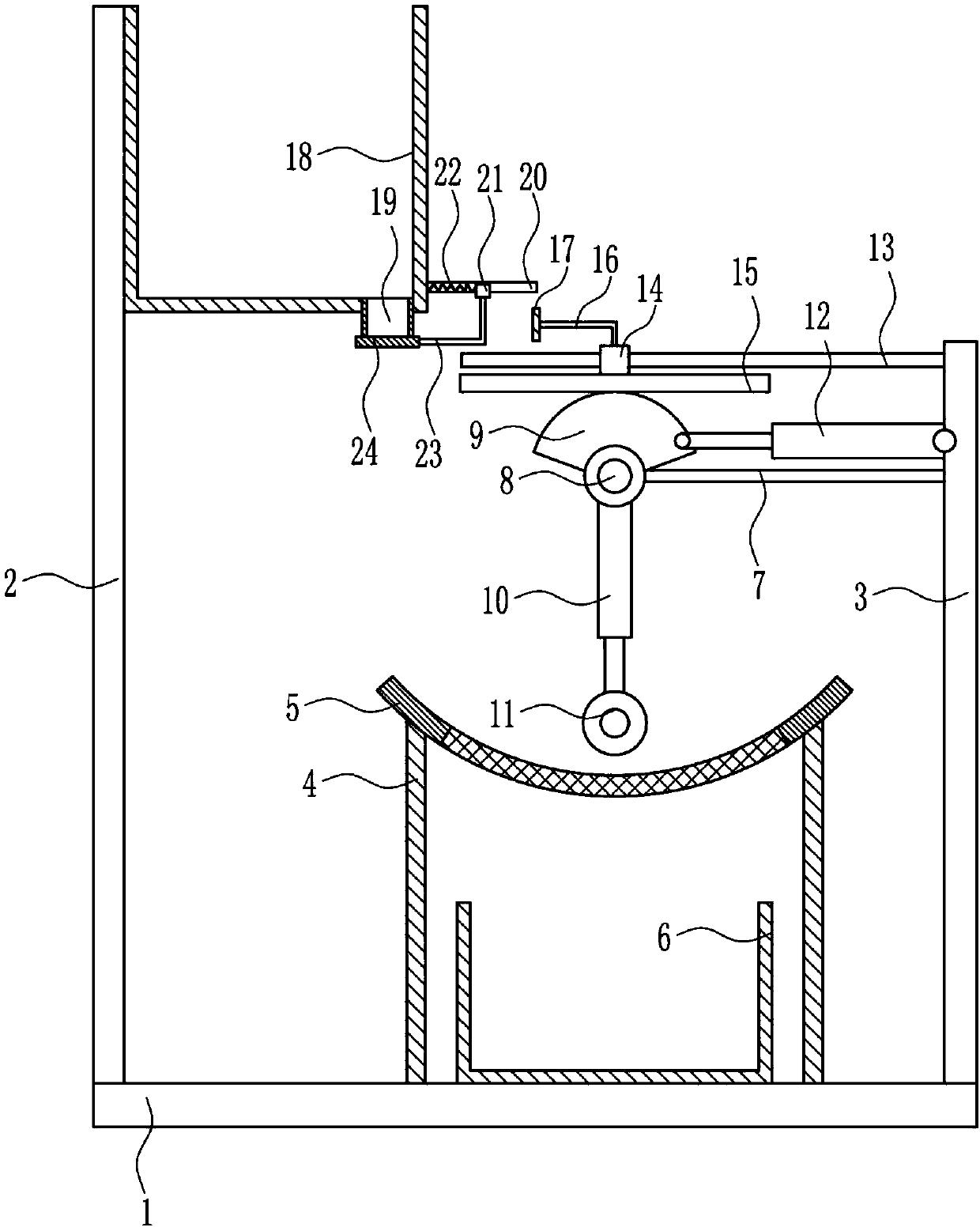

Systems and methods for trail edge paper suppression for high-speed finishing applications

InactiveUS6722650B1Prevent backward movementPrevent movementElectrographic process apparatusPile receiversLeading edgeEngineering

A paper sheet finishing system includes a sheet guiding mechanism having nip rollers to transport a sheet forward, at least one diverter gate through which the sheet passes when the at least one diverter gate is open, and a temporary compiler to support the sheet after the sheet passes the at least one diverter gate, a diverter member to travel in conjunction with the at least one diverter gate, and at least one rear suppressor member connected to the diverter member to push a trailing edge of the sheet forward and pitch a leading edge of the sheet downward after the sheet controllably descends past the temporary compiler with reduced flutter and improved positioning during compilation of the sheets.

Owner:XEROX CORP

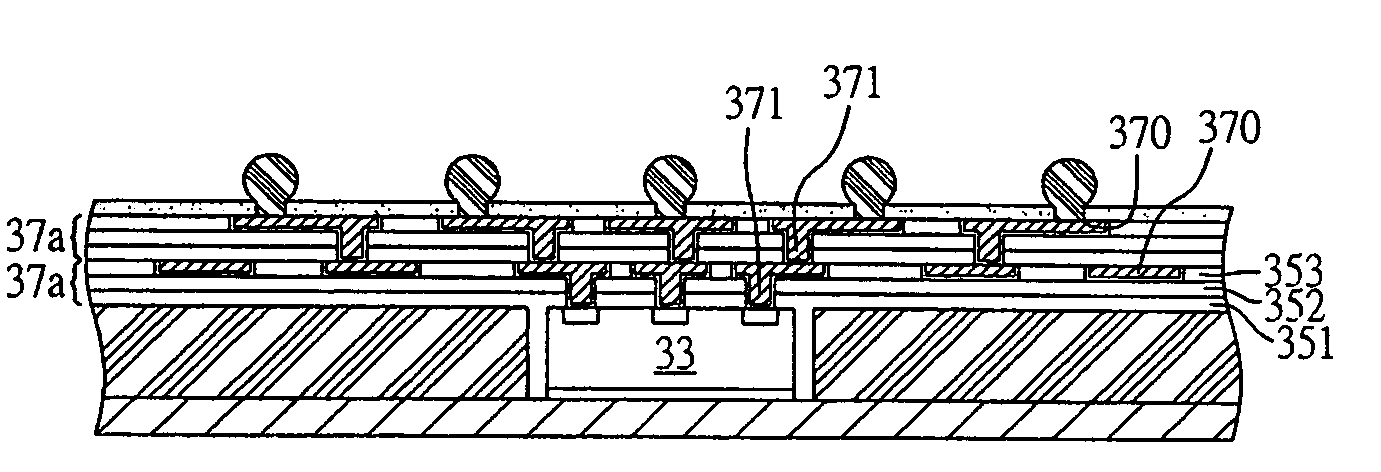

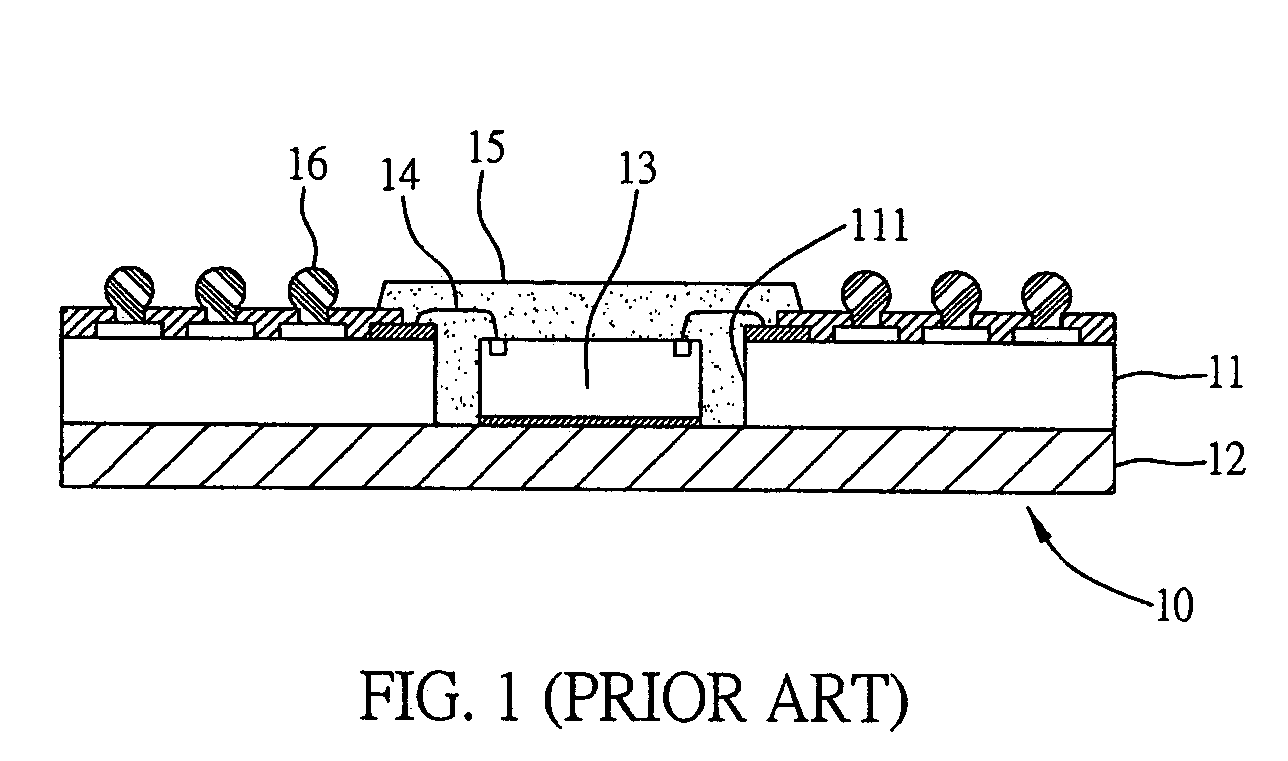

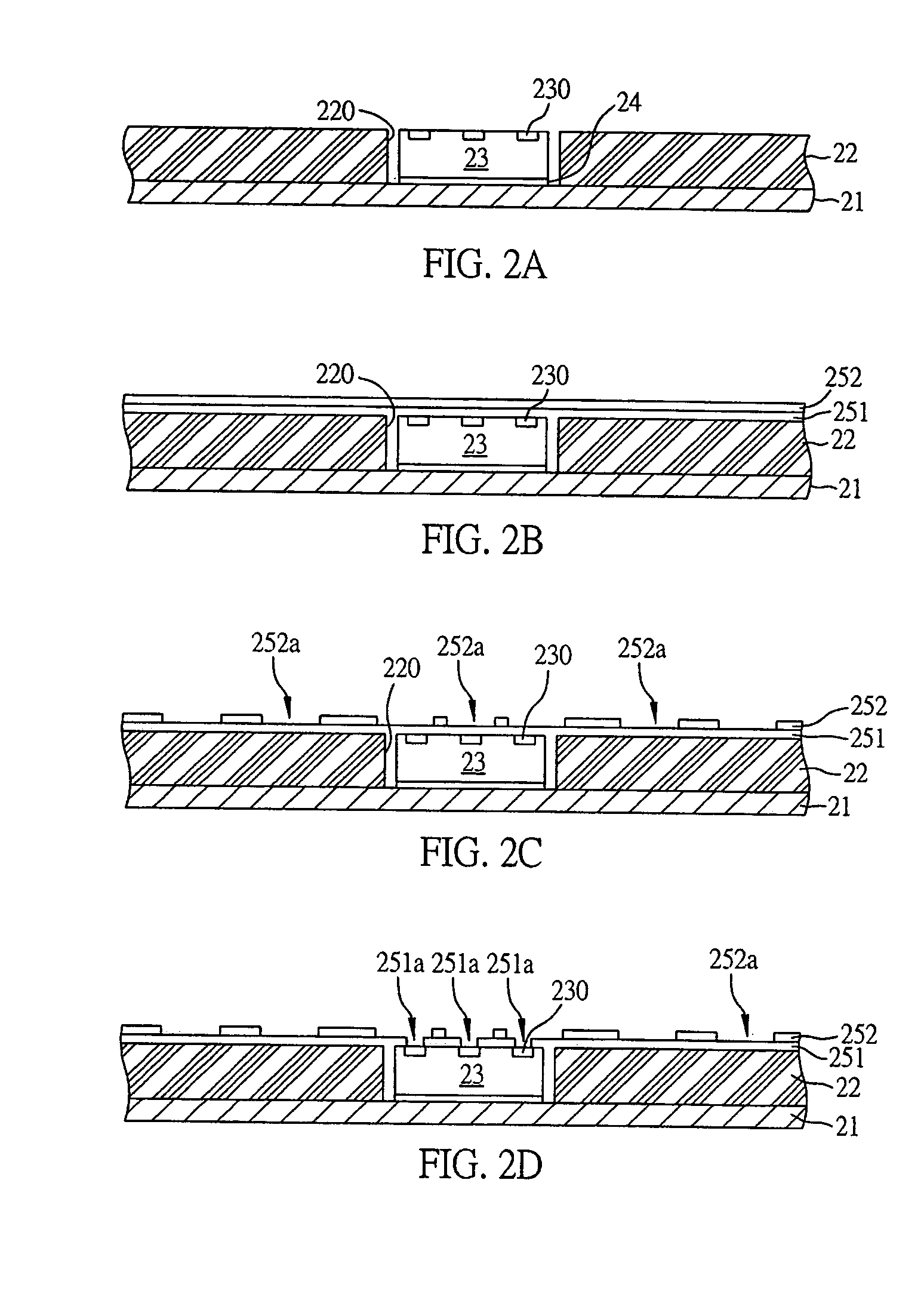

Superfine-circuit semiconductor package structure

InactiveUS20080006936A1Improve the level ofStrong adhesionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A superfine-circuit semiconductor package structure includes a carrier board, a support board having at least one through hole and mounted on the carrier board, at least one semiconductor chip received in the through hole of the support board and mounted on the carrier board, at least one circuit built-up structure electrically connected to the semiconductor chip and formed on the support board and the semiconductor chip, wherein the circuit built-up structure includes at least two insulating layers, a plurality of conductive vias formed in the lower insulating layer, circuit layer electrically connected to the conductive vias and flush with the upper insulating layer, and a plurality of conductive elements mounted on the circuit built-up structure, such that the semiconductor chip can be electrically connected to an external device through the circuit built-up structure and the conductive elements.

Owner:PHOENIX PRECISION TECH CORP

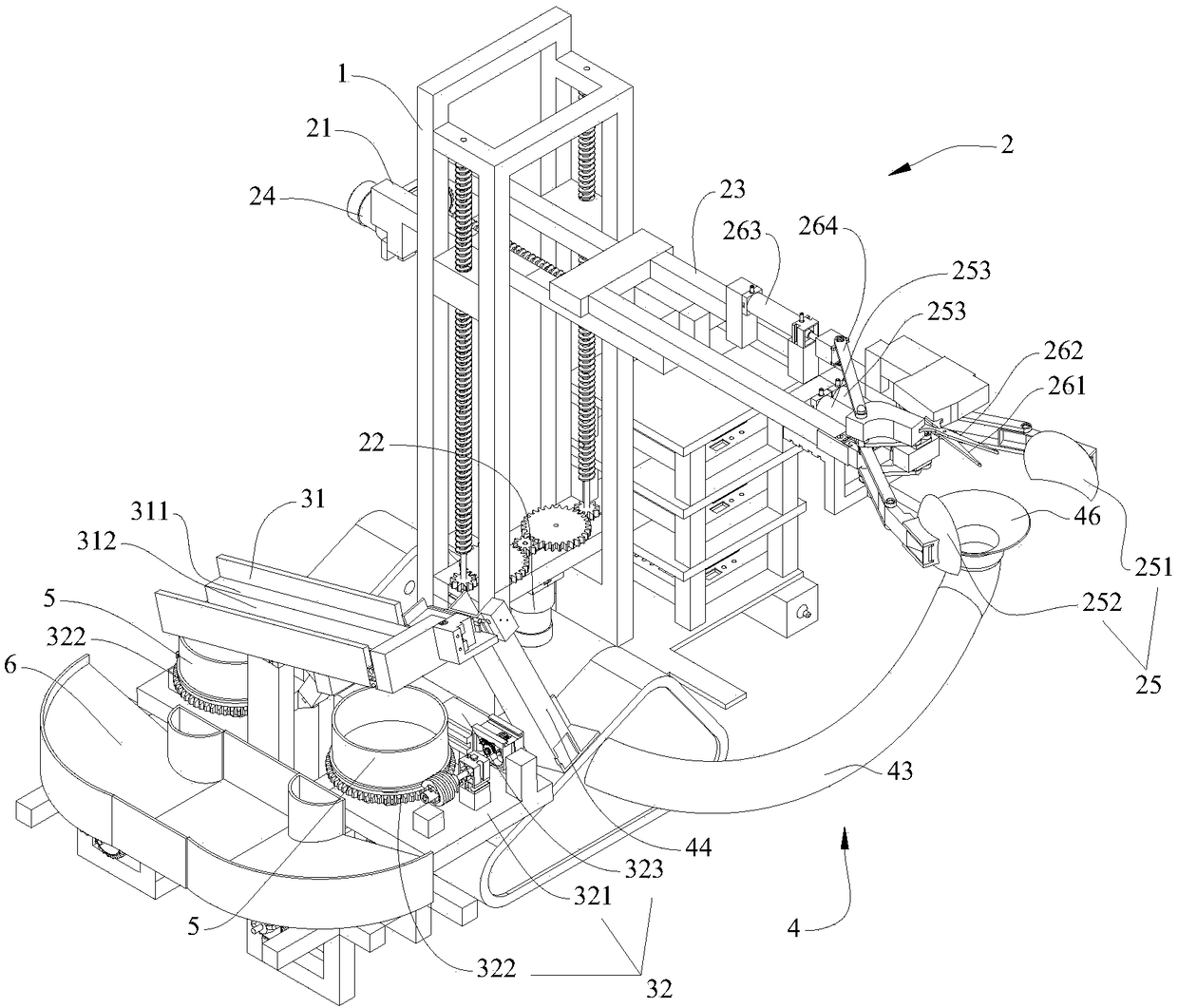

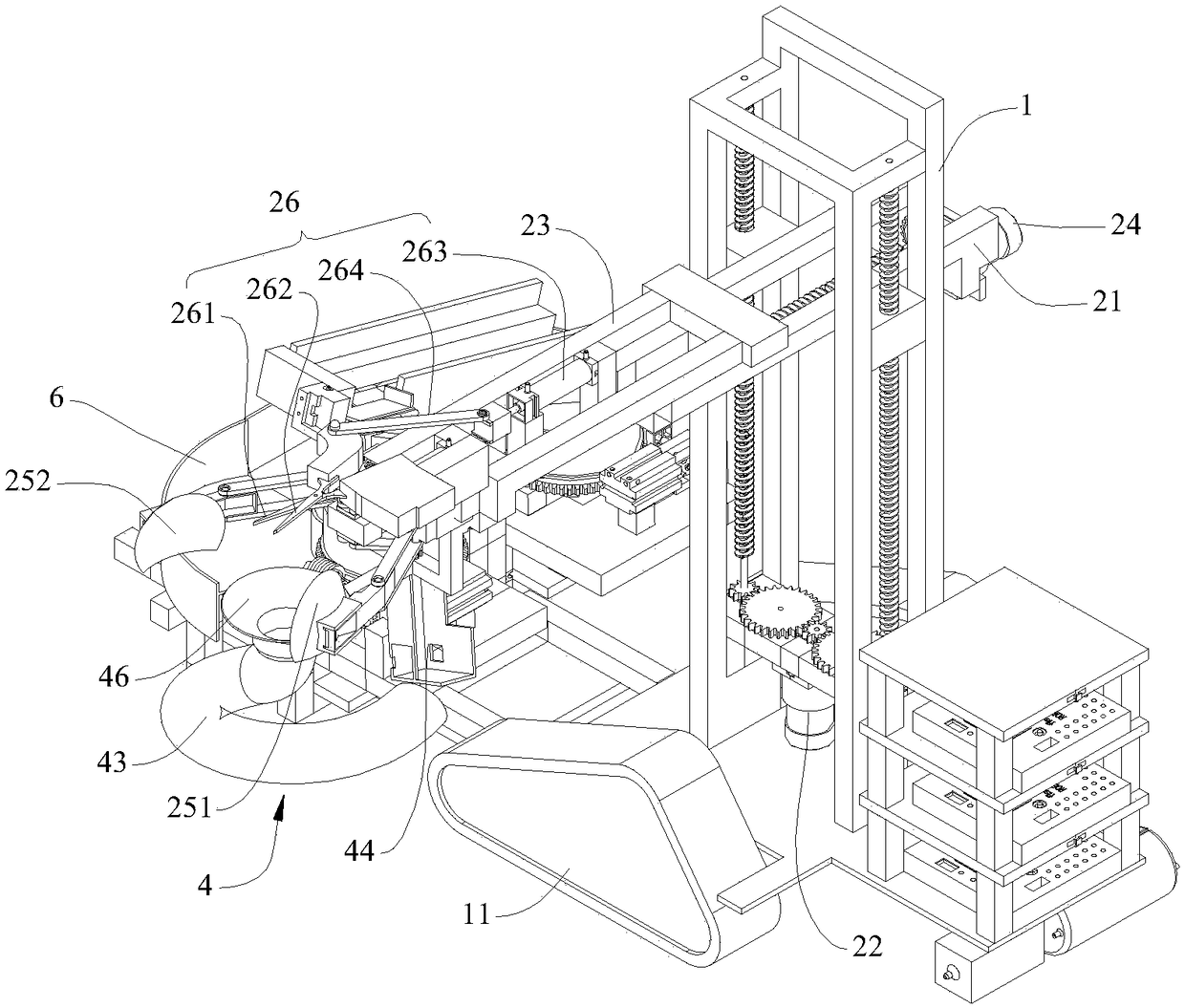

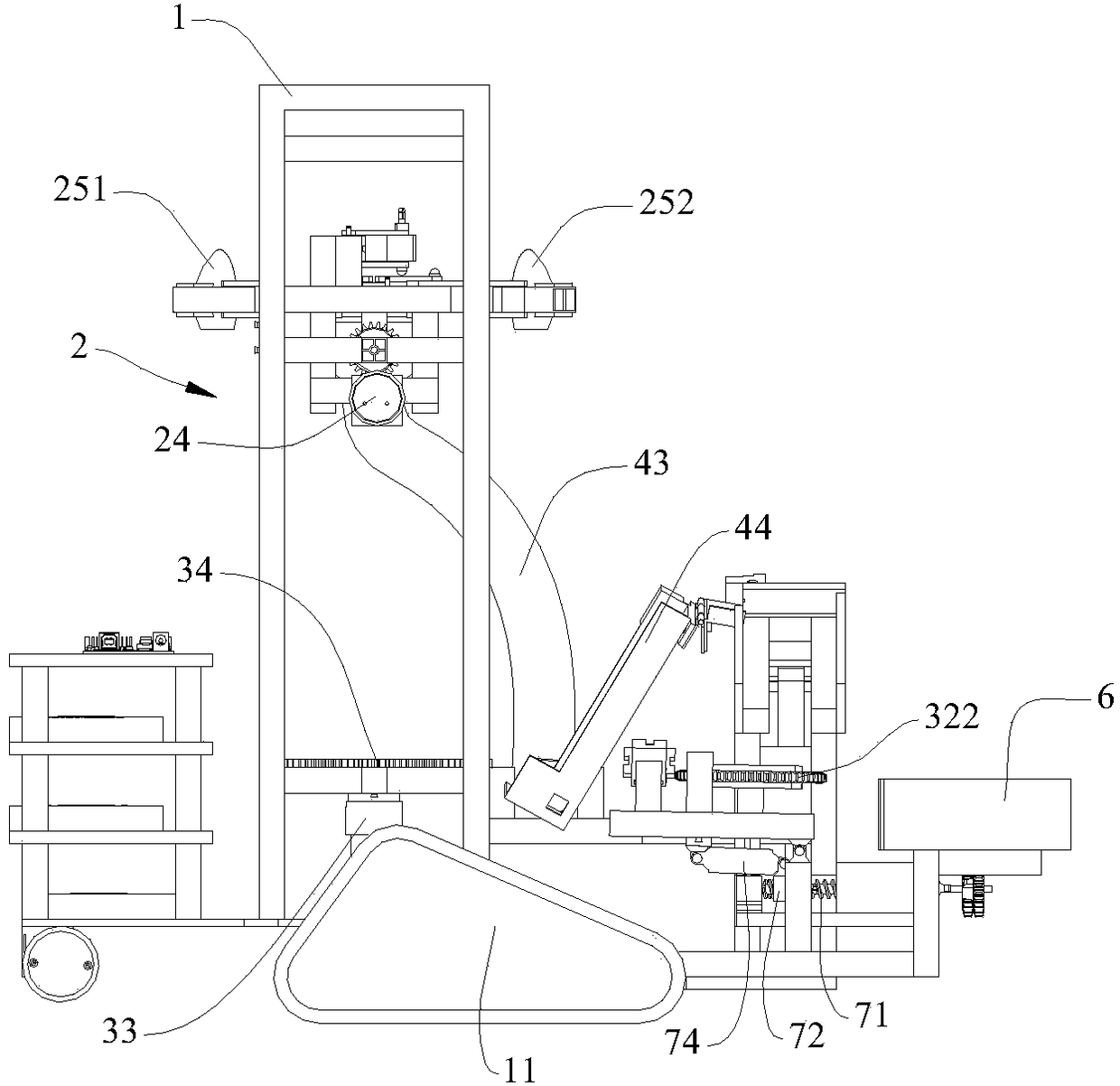

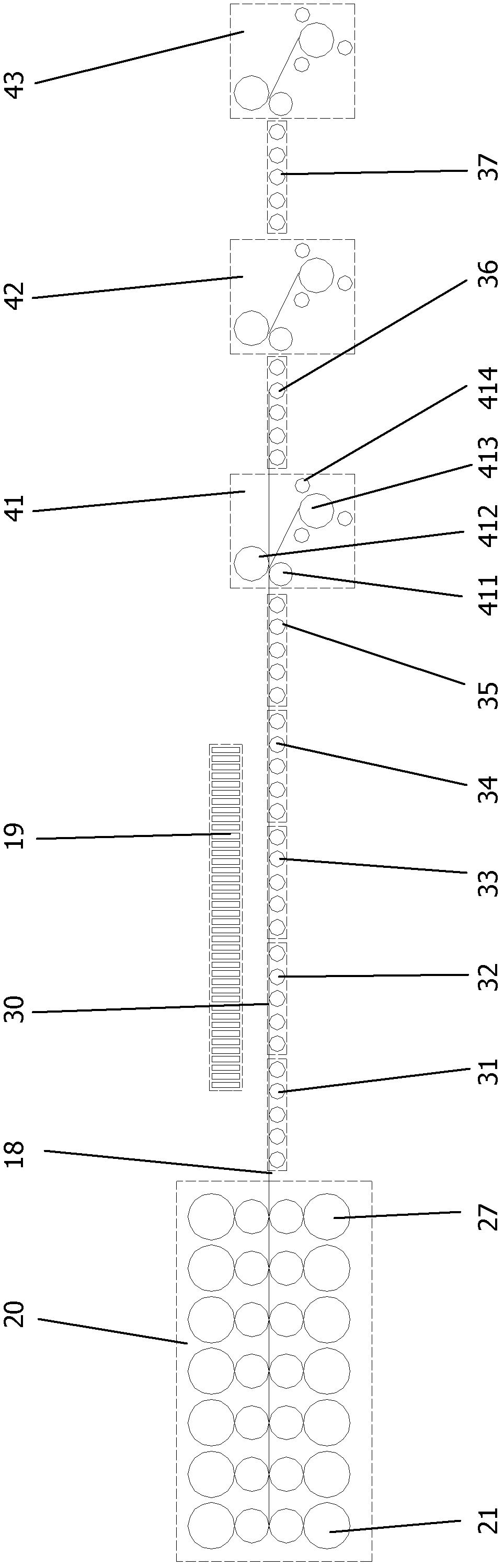

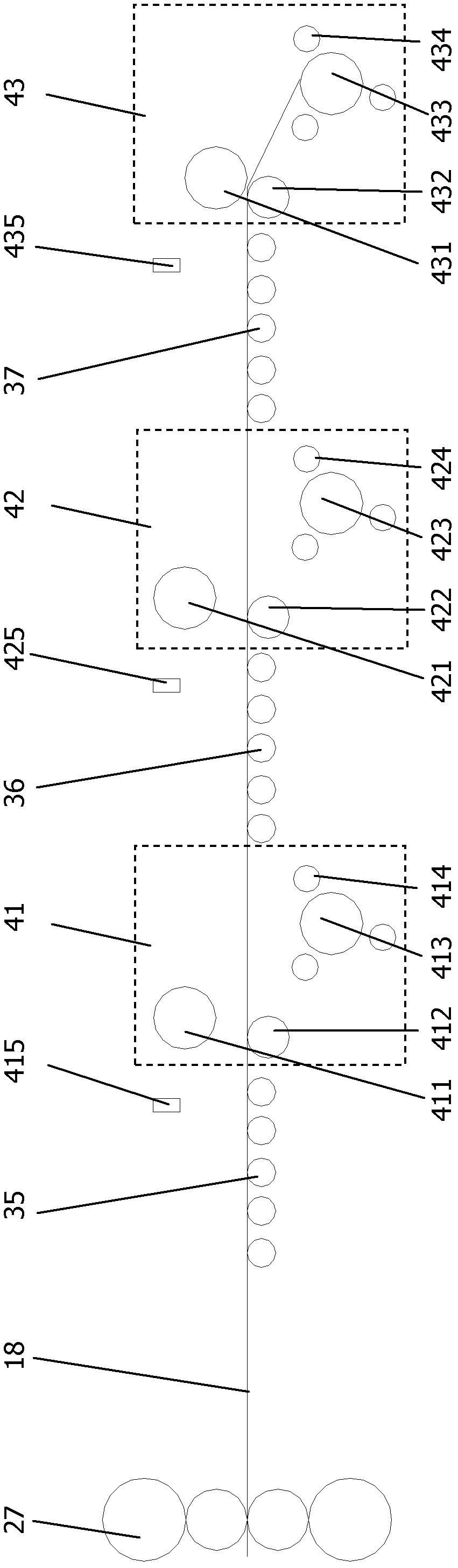

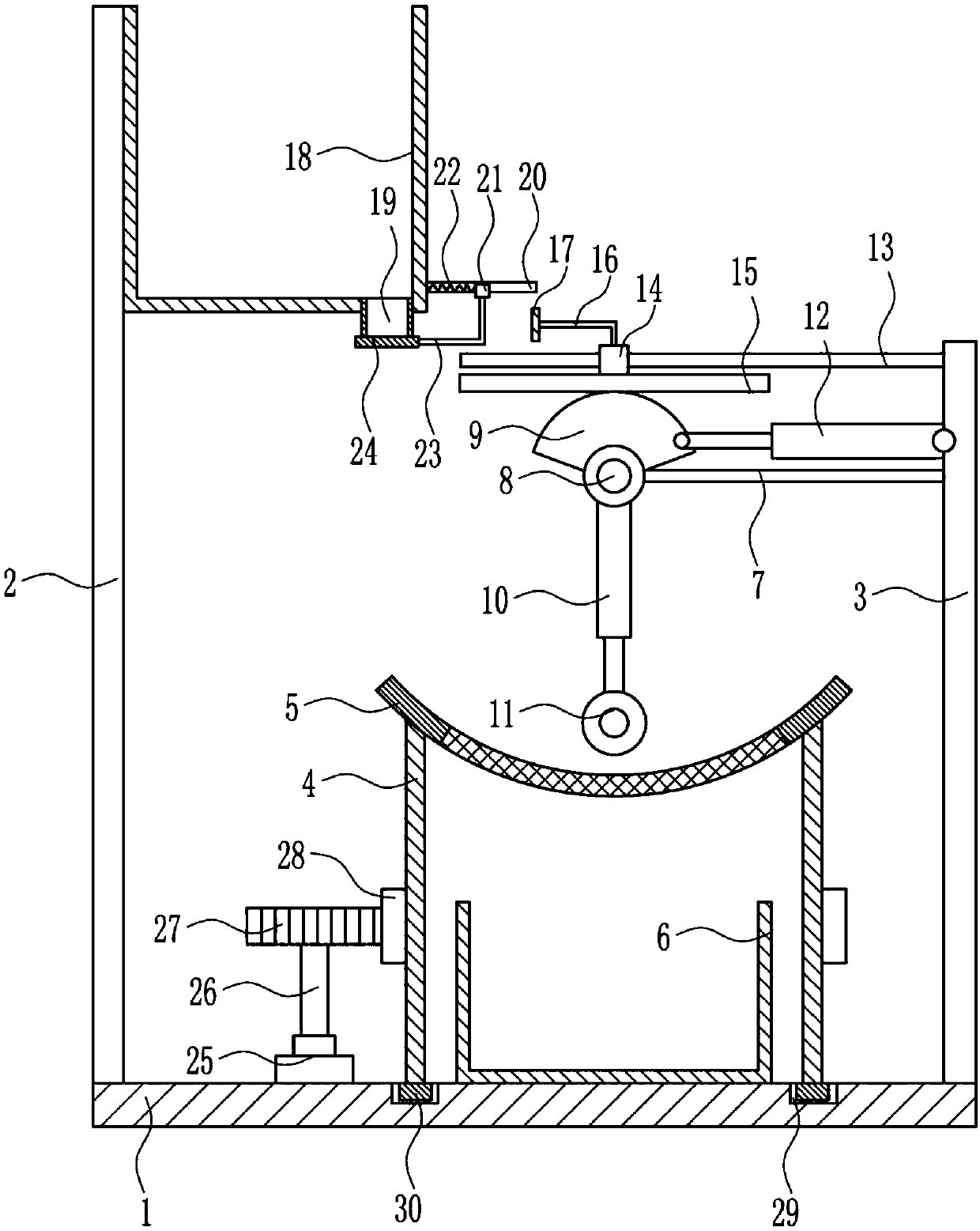

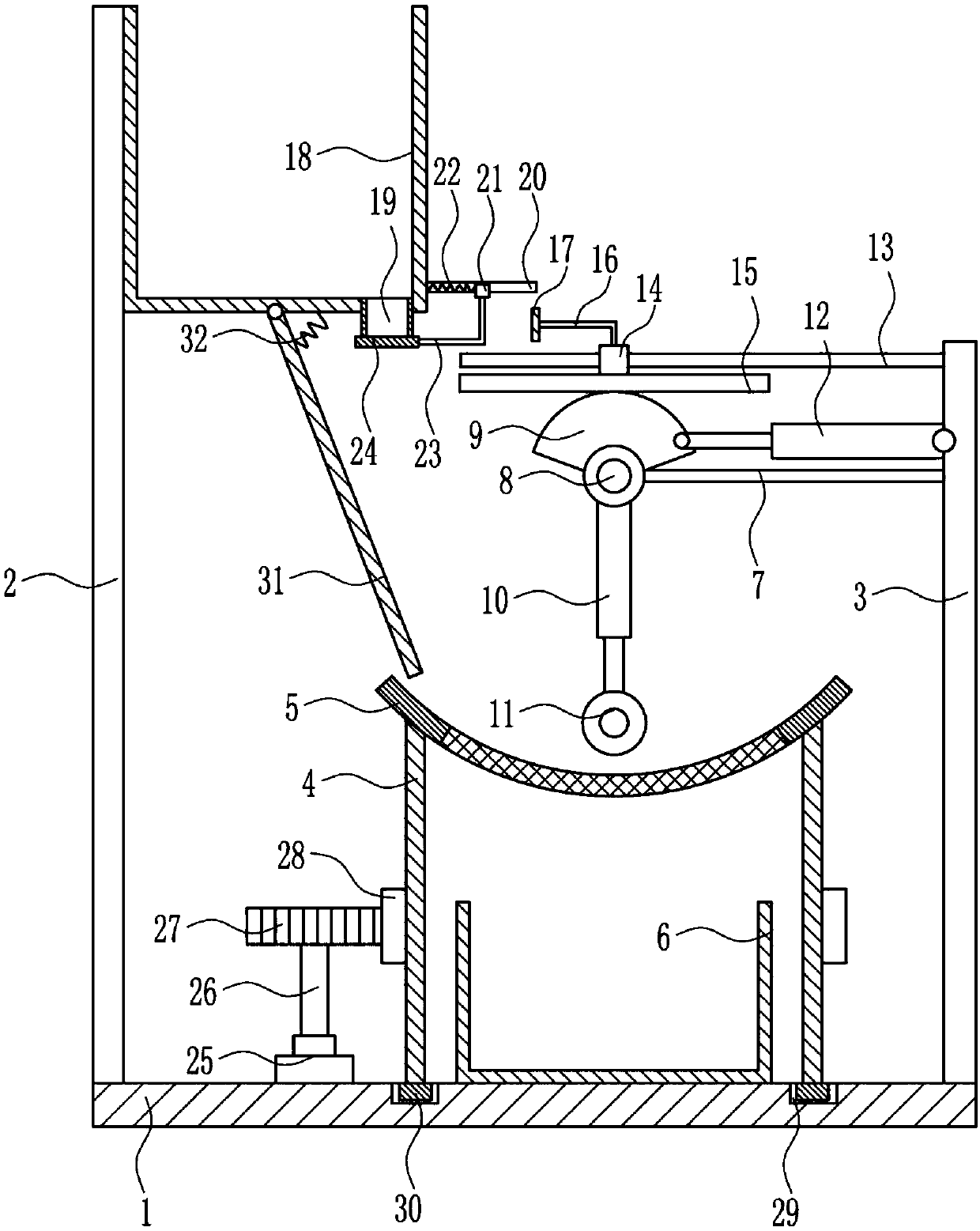

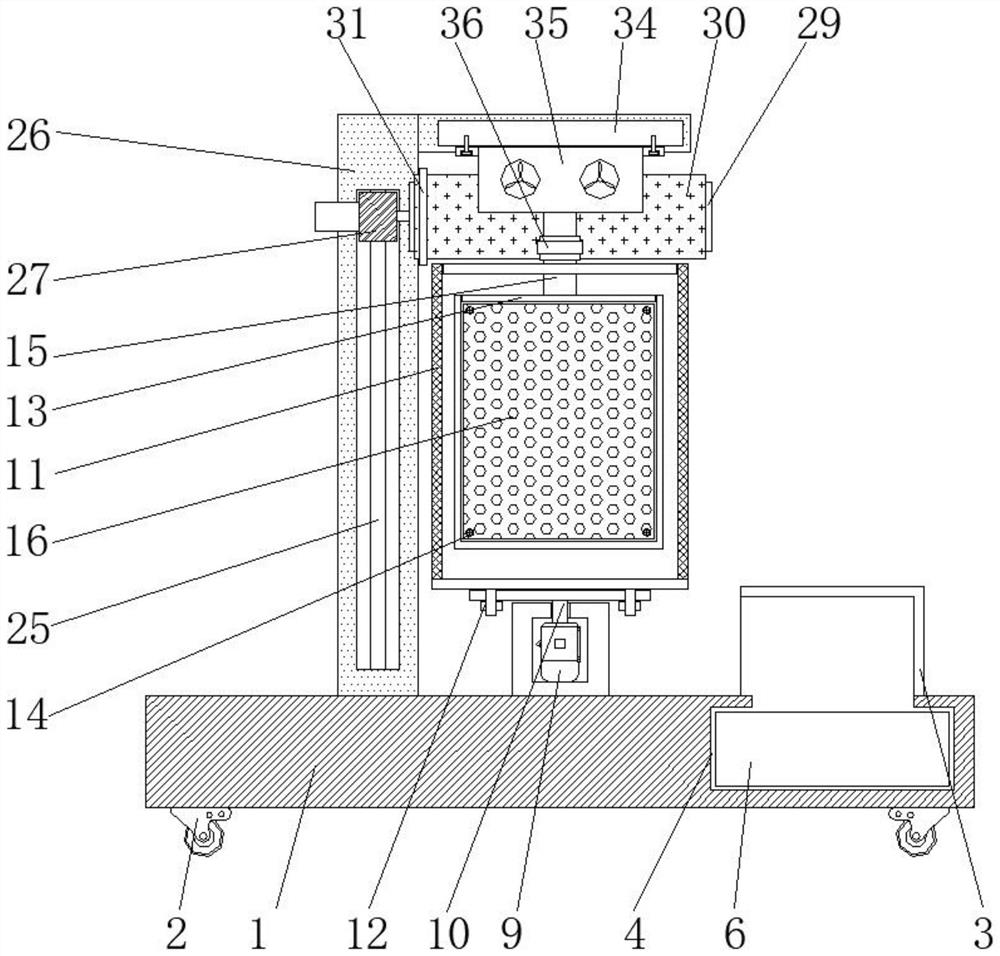

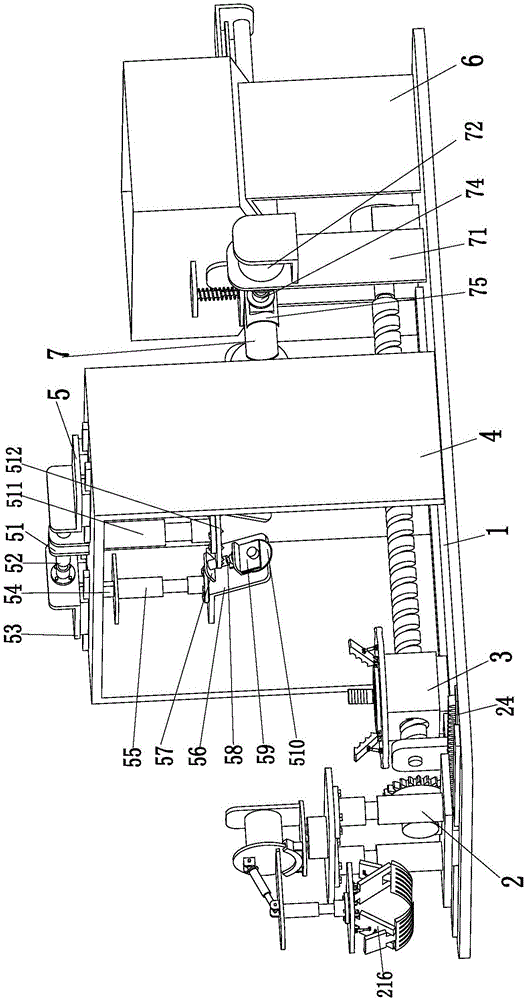

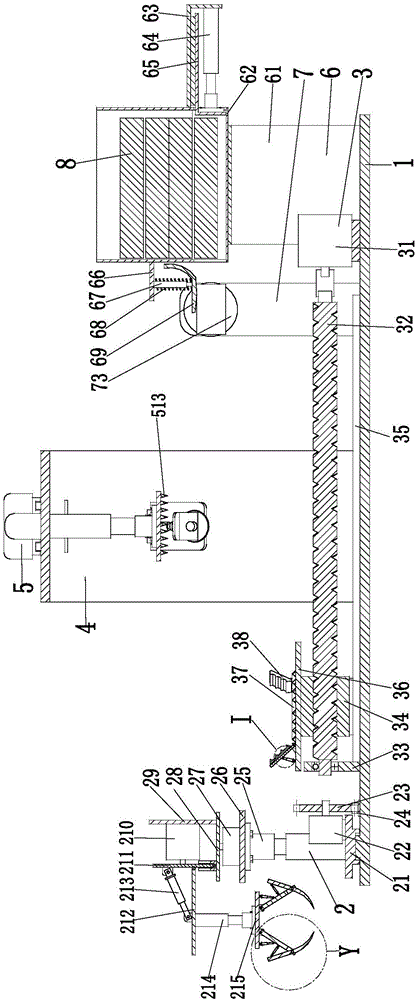

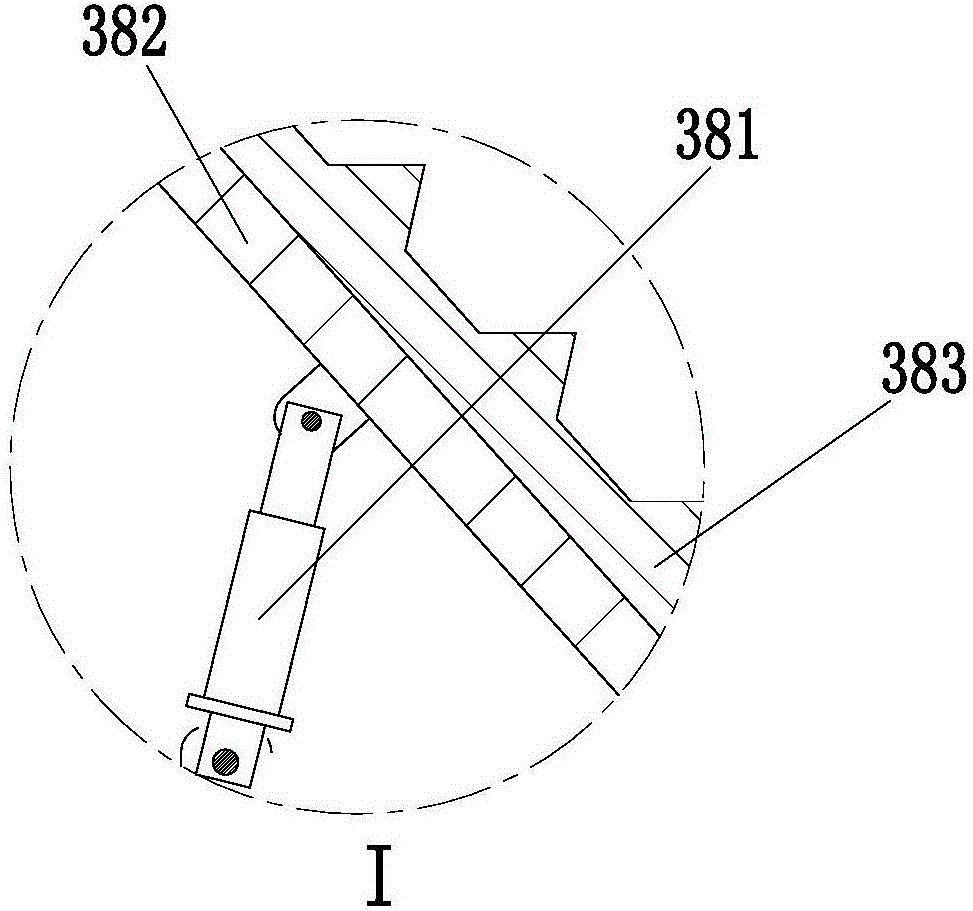

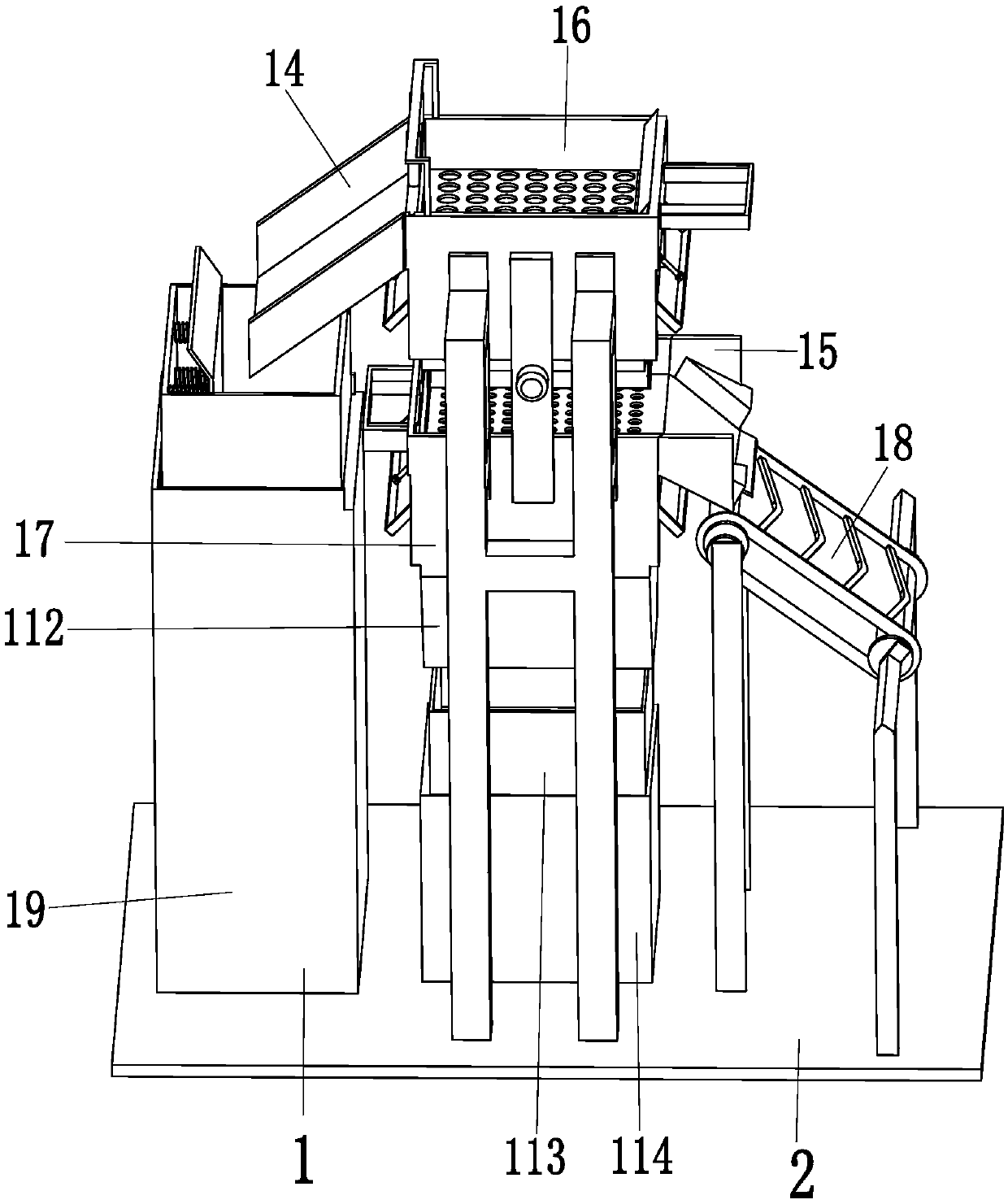

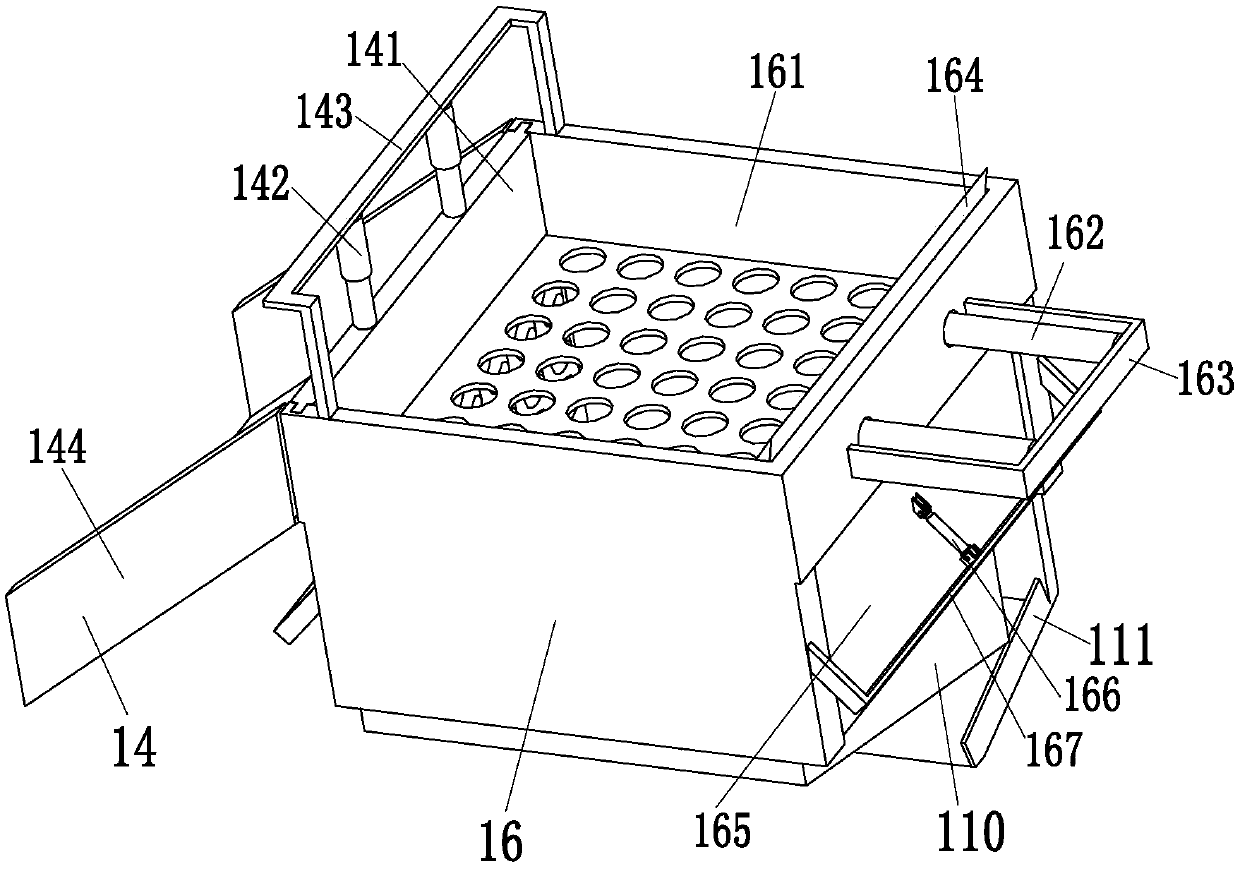

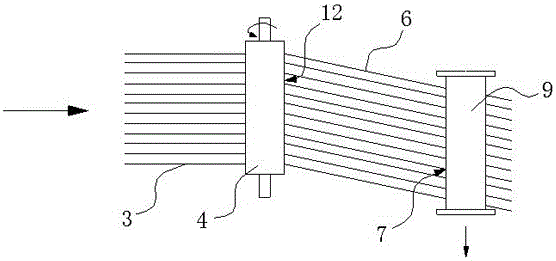

Automatic fruit picking equipment

The invention discloses automatic fruit picking equipment. The automatic fruit picking equipment comprises a mechanical device, wherein the mechanical device comprises a machine seat and a picking device, and further comprises a collecting device and a discharging device; the picking device comprises a lifting rack, a lifting driving mechanism, a base frame, a translating driving mechanism, a clamping jaw assembly and a scissors assembly; the lifting rack is arranged on the machine seat; the base frame is arranged on the lifting rack; the clamping jaw assembly and the scissors assembly are arranged at the front end of the base frame; the collecting device comprises a guiding table and collecting mechanisms; the collecting mechanisms are separately arranged below two ends of the guiding table; each collecting mechanism comprises a table seat, a rotating plate and a rotary driving piece; each rotary driving piece is used for driving the corresponding rotating plate to rotate; and the discharging device is provided with a feeding opening and a discharging opening. The automatic fruit picking equipment is high in degree of automation, and can adapt to fruit picking in various environments; and a basket can be automatically changed when the collected fruits are arranged uniformly and the basket is filled with the fruits.

Owner:SUZHOU UNIV

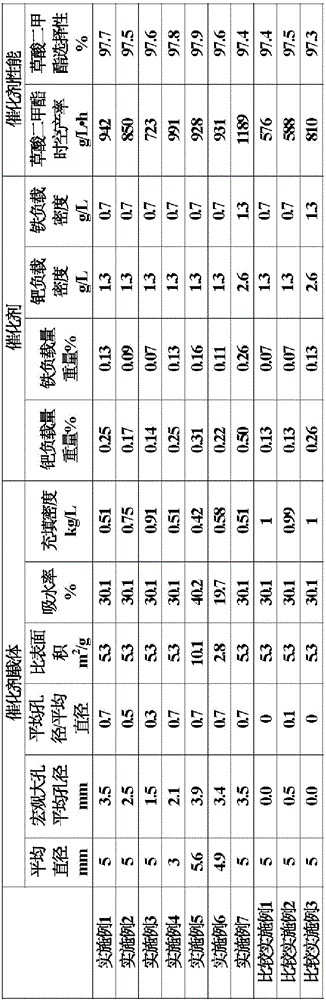

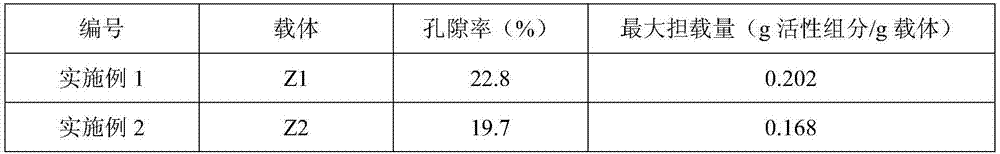

Catalyst carrier and catalyst comprising the same

ActiveCN106457227AEasy to fillEvenly stackedCatalyst carriersCatalyst activation/preparationOxalateGas phase

The invention relates to a catalyst carrier used in a process of coupling and synthesizing dialkyl oxalates through gas phase catalysis of carbon monoxide, the catalyst carrier comprises micro pores and one or more macro pores which can pass through the catalyst carrier, wherein the ratio of the average pore size of the macro pores and the average diameter of the catalyst carrier is more than 0.2. The invention also relates to the catalyst carrier and a catalyst which comprises activated components and an optional additive and is loaded on the catalyst carrier. The catalyst can effectively perform gas phase catalysis on carbon monoxide to couple and generate the dialkyl oxalates, the heat dissipation is improved, the pressure drop is reduced, the usage amount of precious metal such as palladium is reduced, the usage cost of the catalyst and the production cost of the dialkyl oxalates are reduced, so that the industrial mass production of the dialkyl oxalates can be contributed to realize.

Owner:HIGHCHEM

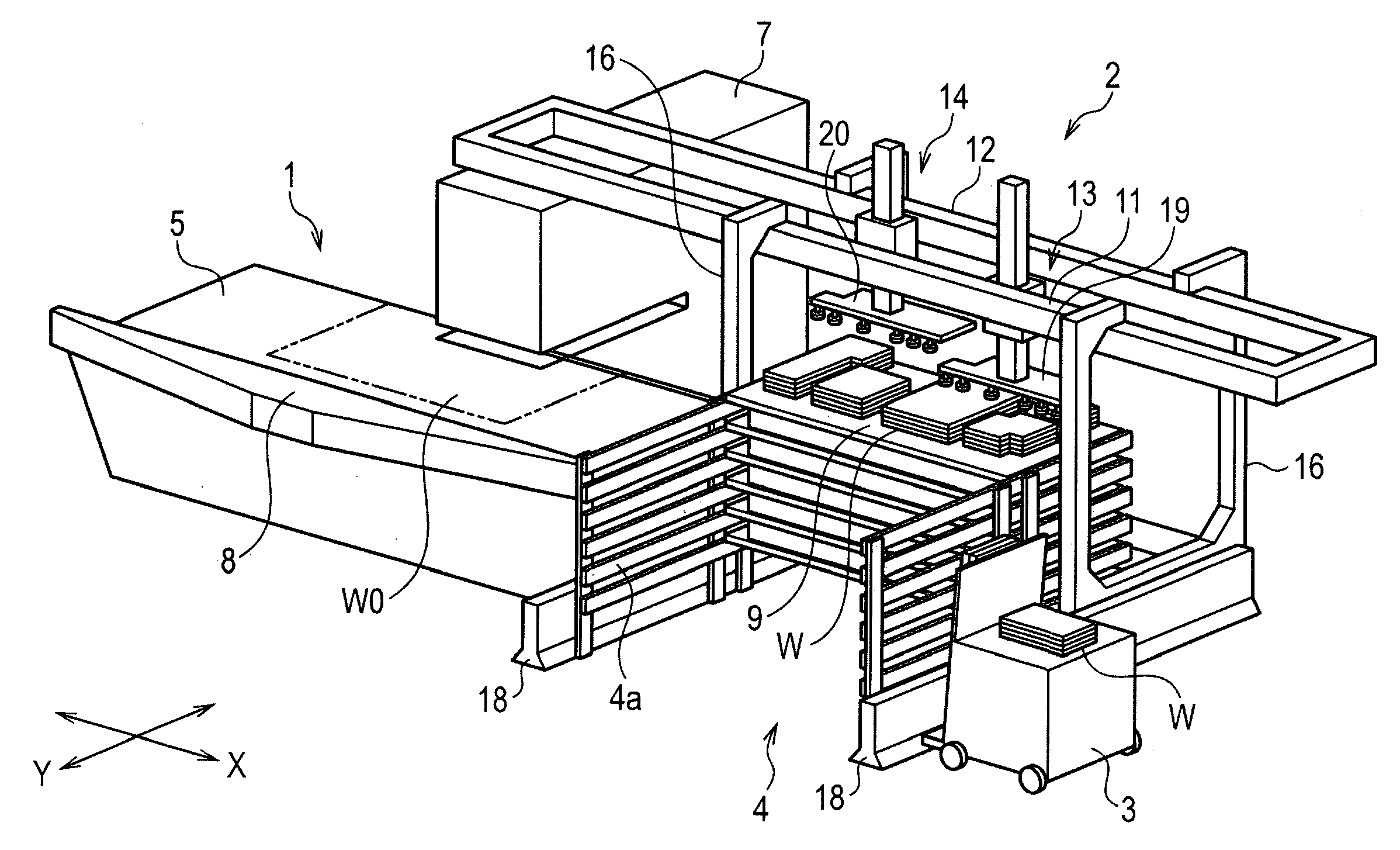

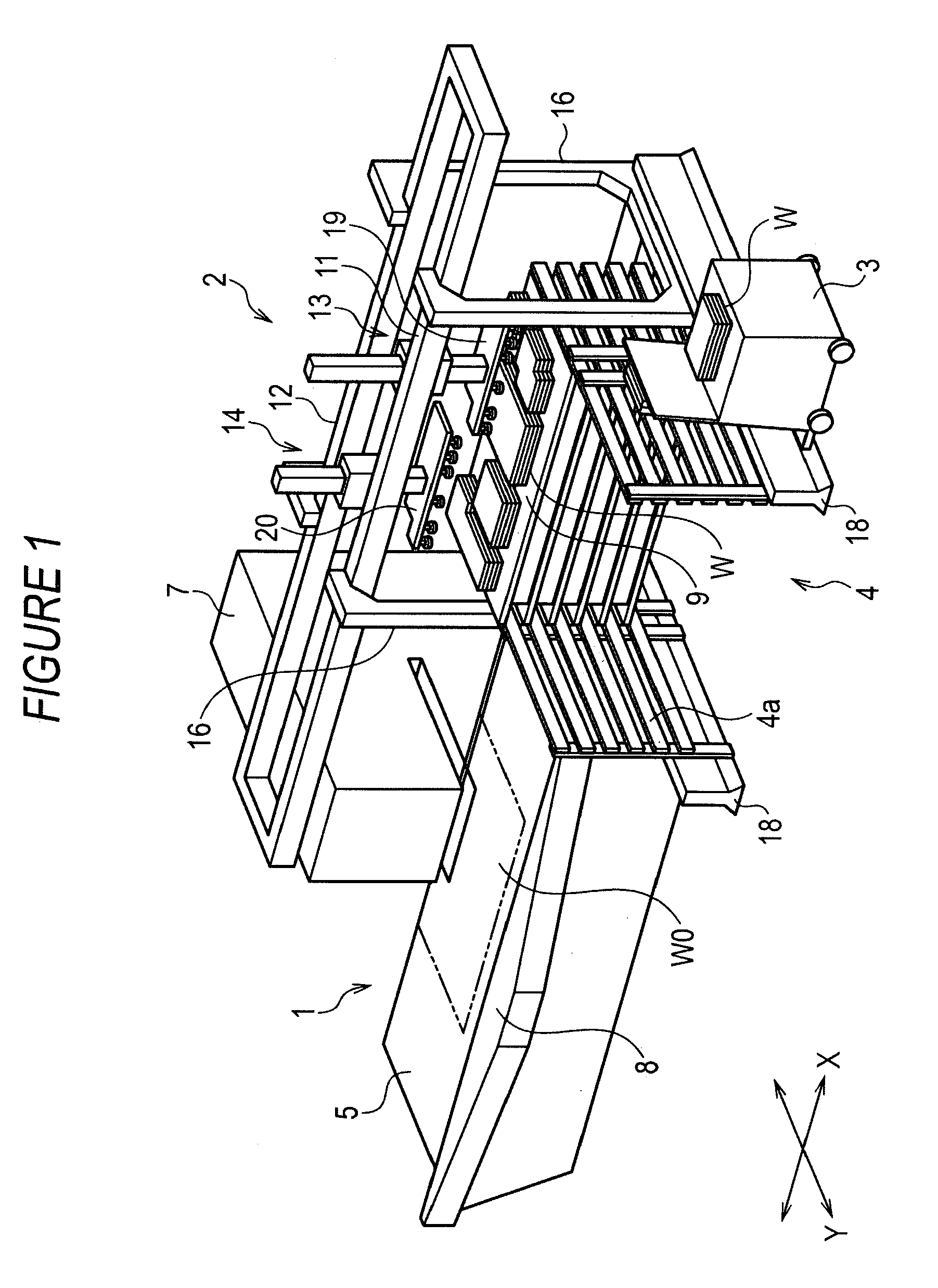

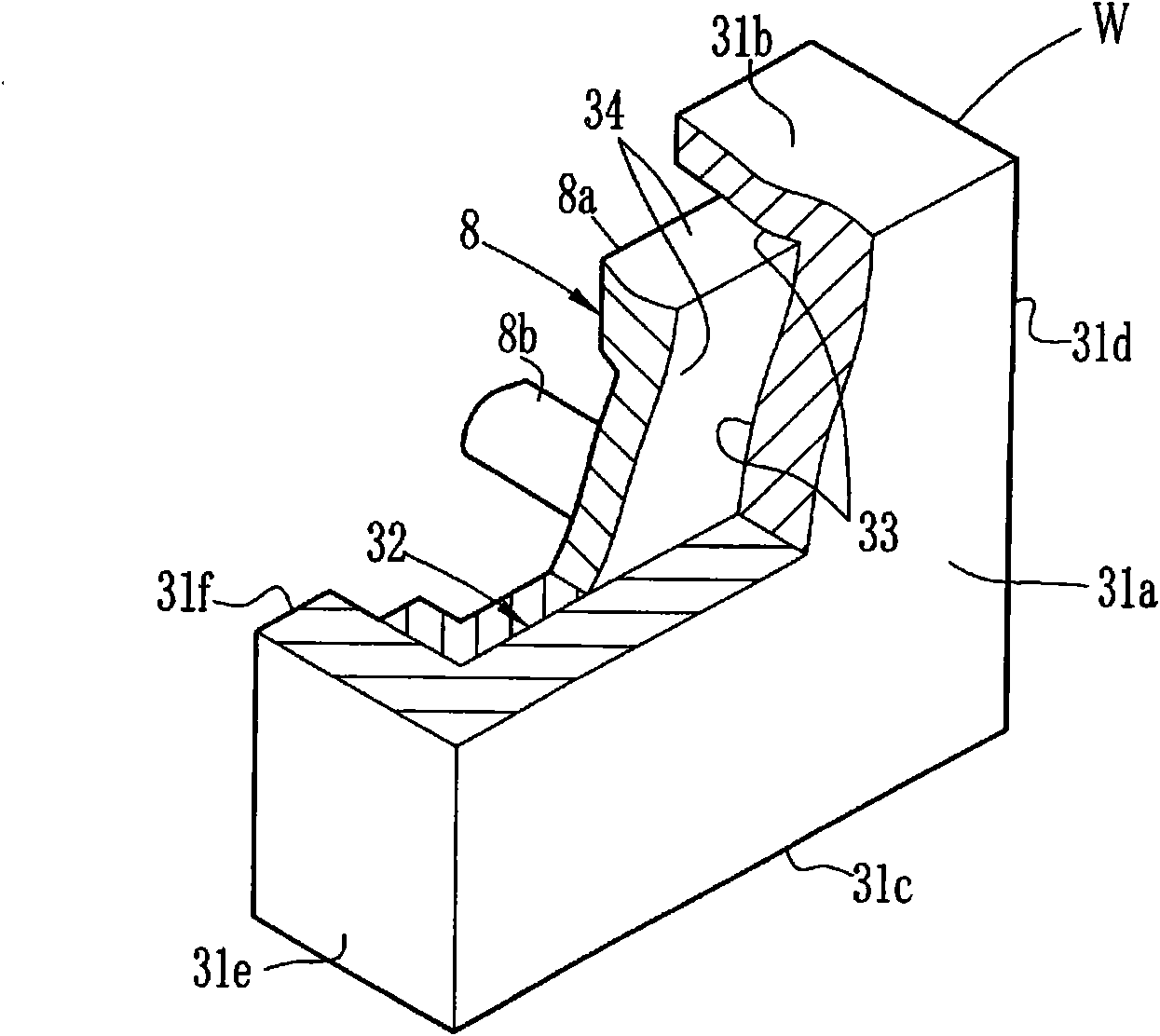

Plate material conveying device

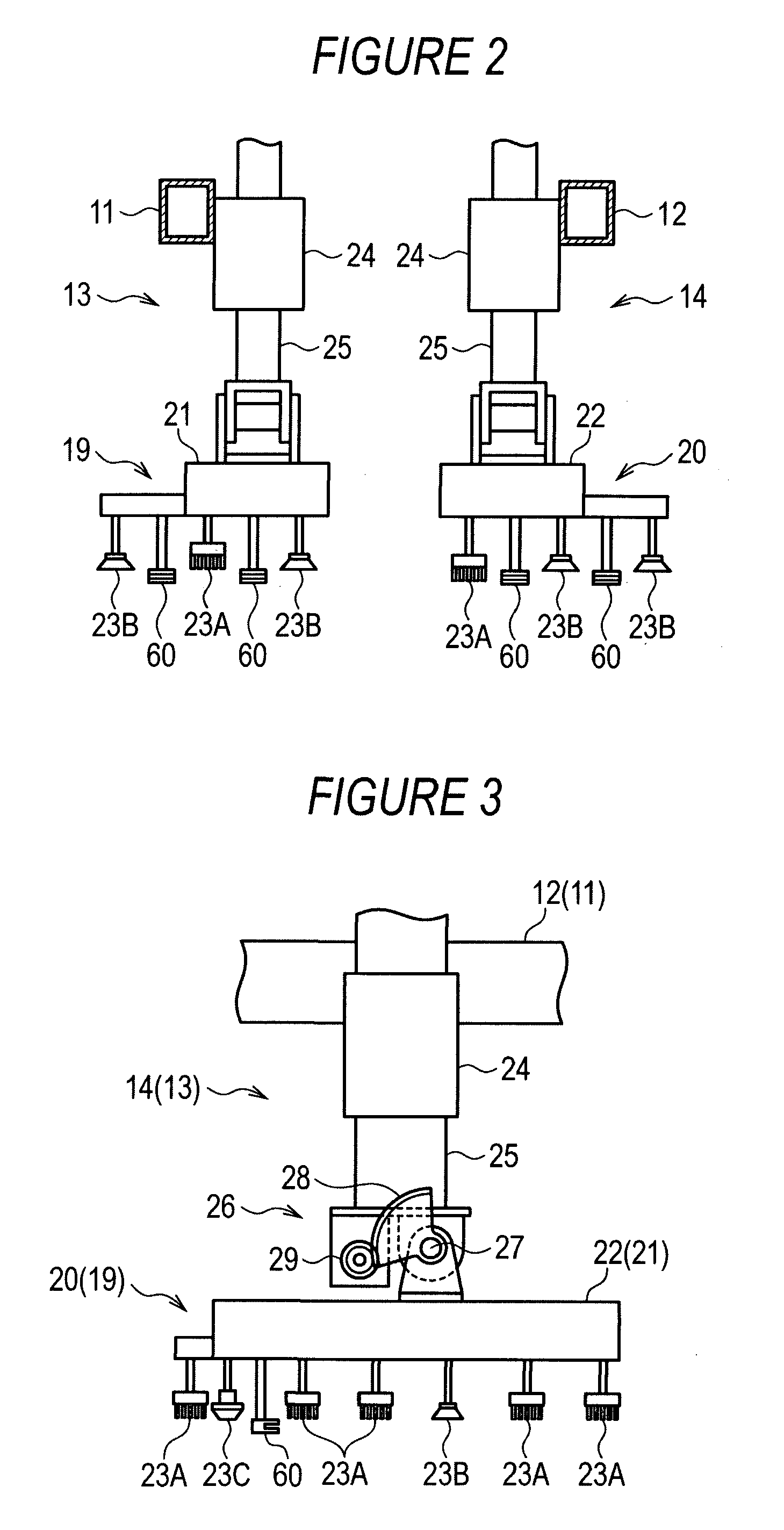

InactiveUS20090263218A1Efficiently conveyedSimple materialProgramme-controlled manipulatorGripping headsTurning framesEngineering

The present invention provides a plate material conveying device including a compact traveling member to enable an increase in plate material conveyance speed and a reduction in time required for acceleration and deceleration and to allow small plate materials to be more efficiently conveyed, the plate material conveying device further enabling one of a gripper and a suction type plate material holder to be selected for conveyance of a plate material. Traveling members 13, 14 are provided on respective tracks 11, 12 so as to travel freely along the respective tracks 11, 12. Each of the traveling members 13, 14 has a plate material holder support frame 21, 22 supporting suction type plate material holders 23A, 23B, 23C. The plate material holder support frame 21, 22 has a frame main body 21a, 22a, and a turning frame 21b, 22b which is turnable in a substantially horizontal direction with respect to the frame main body 21a, 22a and which is turnable to a position where the supported plate material planarly overlaps the adjacent track. Each of the turning frames 21b, 22b has a gripper 60 gripping an end of the plate material. An opening of the gripper is configured to face a central side of the plate material.

Owner:MURATA MASCH LTD

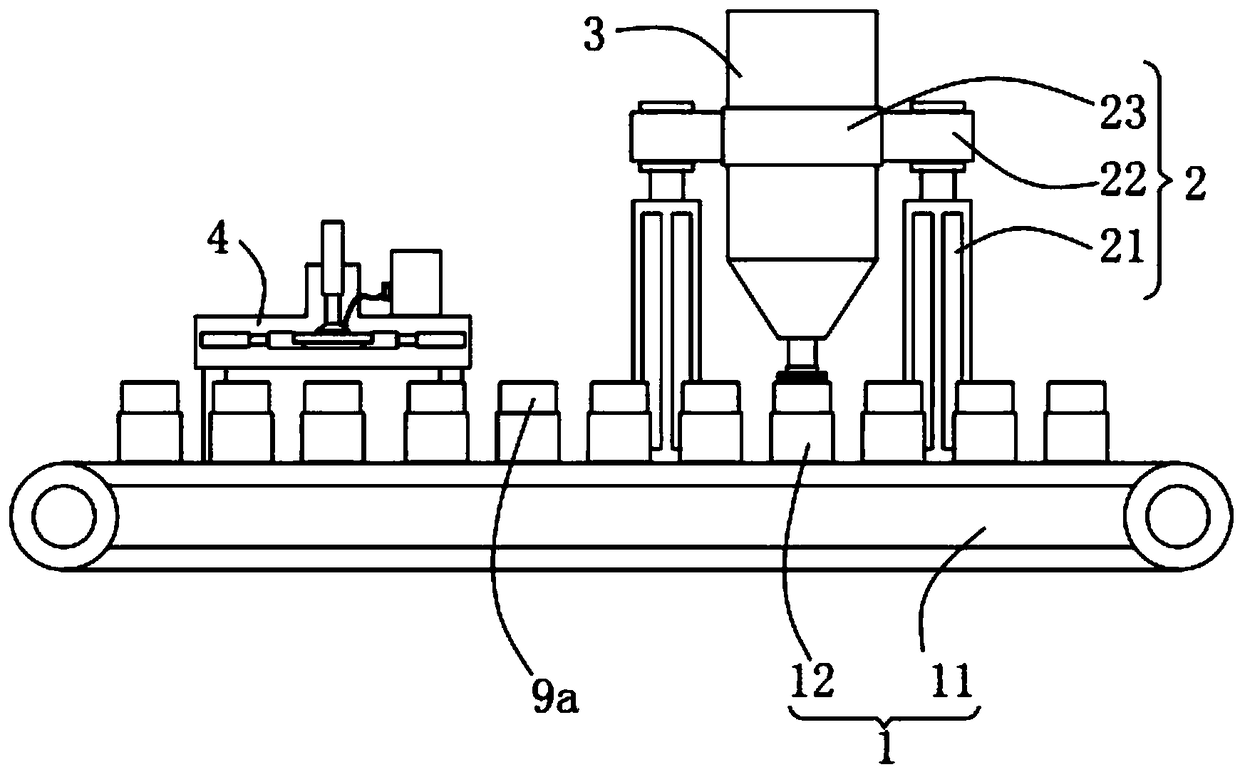

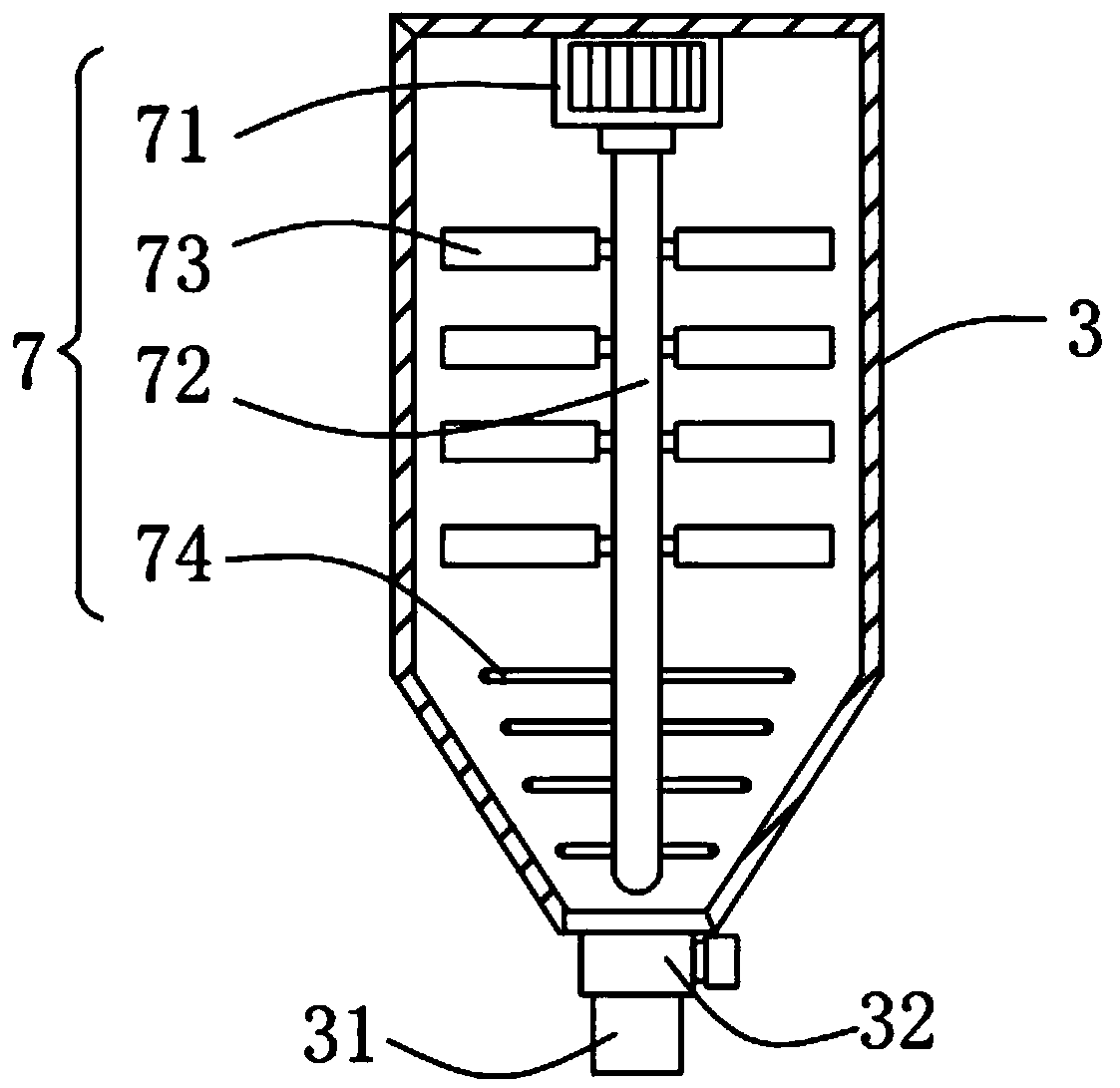

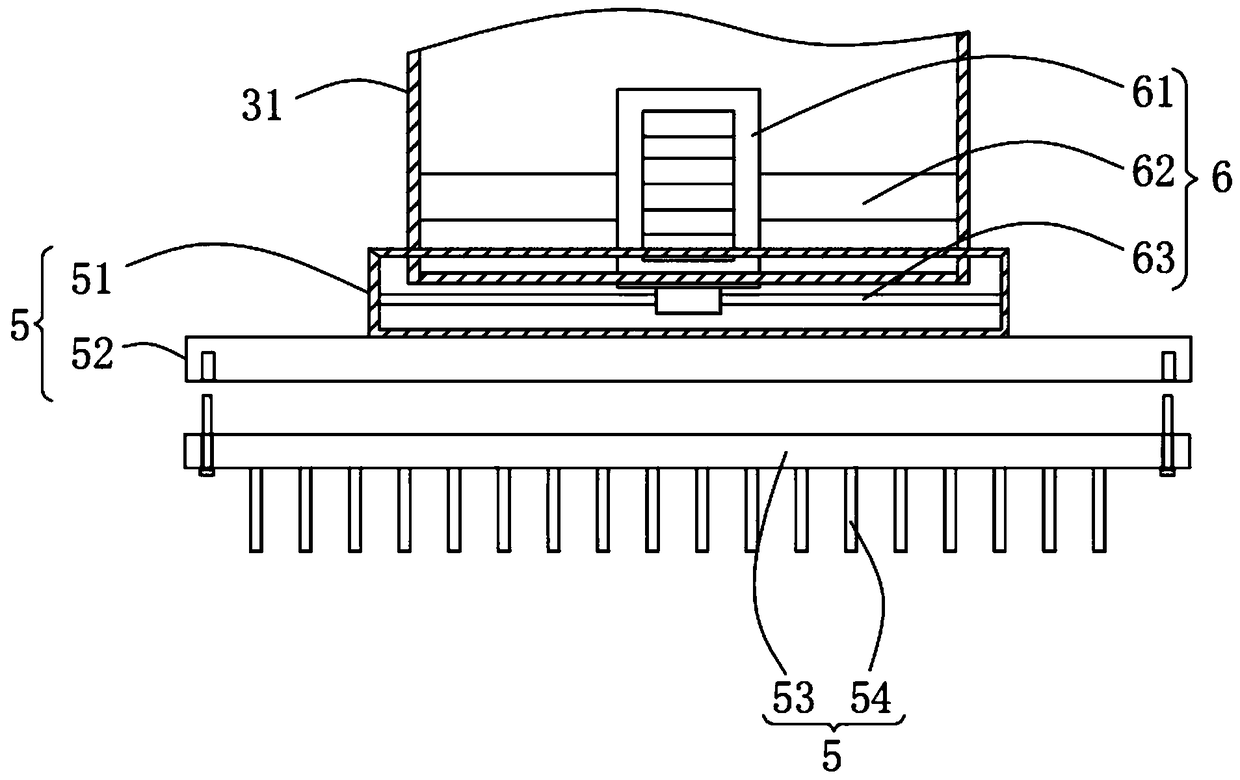

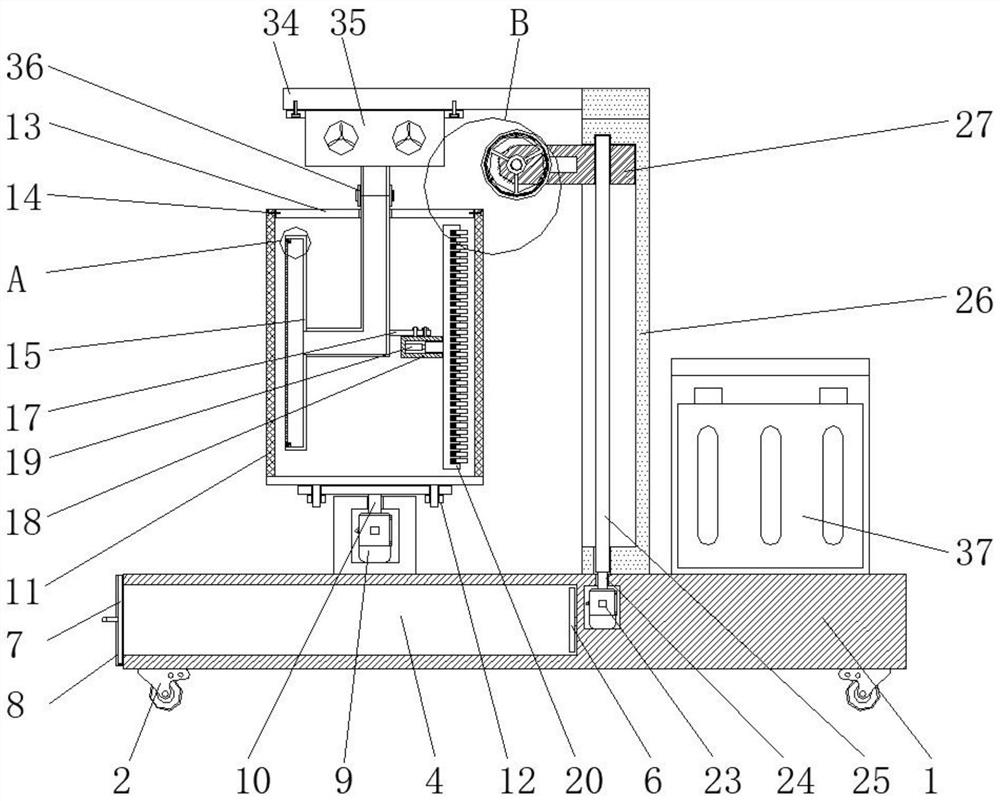

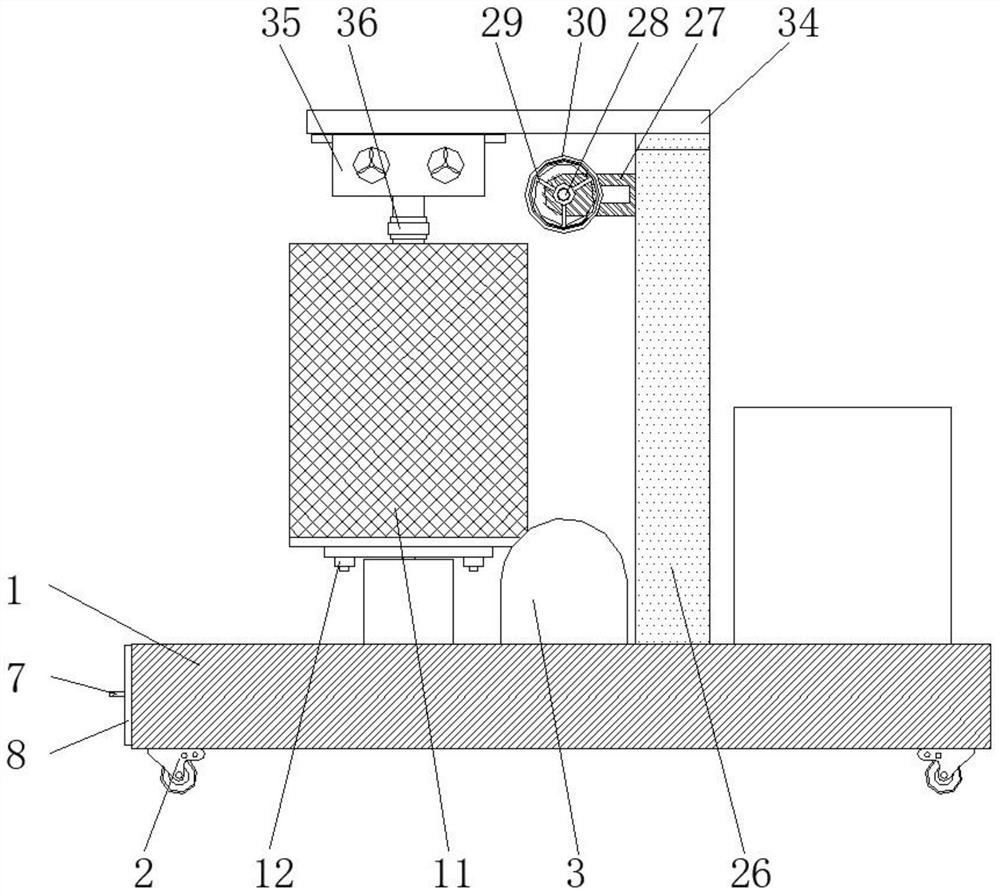

Powder material packaging machine

ActiveCN109335113AEvenly stackedQuick unloadingRotary stirring mixersSolid materialPackaging TankEngineering

The invention relates to the technical field of food processing equipment, in particular to a powder materials packaging machine. The powder material packaging machine comprises a conveying mechanism,a lifting mechanism, a material storage cylinder, a sealing mechanism, a flattening mechanism, a rotating mechanism, a stirring mechanism and a feeding mechanism. According to the machine, a discharging pipe can be driven to move upwards gradually from the bottom layer in a packaging tank through the lifting mechanism, so that the materials are gradually accumulated from bottom to top, and the accumulation is more uniform; meanwhile, the rotating mechanism can drive the flattening mechanism to rotate, a shifting rod can shift and scatter the materials, a flattening plate can flatten the materials, so that the powder materials can fully fill the whole packaging tank; in the discharging process, stirring blades can stir the top area of the packaging tank, stirring rods which are distributedin a funnel shape can stir the outlet area of the packaging tank, so that the discharging is more rapid and the blockage is prevented; and automatic feeding and packaging can be realized.

Owner:台州佑辅机械实业有限公司

Halting method for scrap steel of hot rolling coilers

ActiveCN103223418AAutomatic judgment of steel scrap accidentsAvoid issues that delay downtimeRolling safety devicesMetal rolling arrangementsStrip steelMaterials science

A halting method for scrap steel of hot rolling coilers comprises an automatic coiler halting method and an automatic roller bed halting method. The automatic coiler halting method comprises the following steps: determination is performed according to detection and logic, and when the head of strip steel does not to reach the coilers yet and if a motor of a pinch roll or a winding drum of one coiler trips, the standby state of another coiler is shifted to the using state automatically; and determination is performed based on detection and logic, and when the head of the strip steel is gripped by the coilers and if the motor of a pinch roll or a winding drum of one coiler trips, all the coilers are halted automatically. According to the automatic roller bed halting method, the rolling state is divided into five types, and different roller bed halting processes are selected and executed automatically according to different rolling states and strip steel types. The halting method can perform automatic determination and halt on the scrap steel of the coilers, and adopts different roller bed halting methods according to automatic analysis of a strip steel rolling step, therefore, the strip steel can be accumulated uniformly on the rolling bed, and a scrap steel accident is prevented from expanding.

Owner:BAOSHAN IRON & STEEL CO LTD

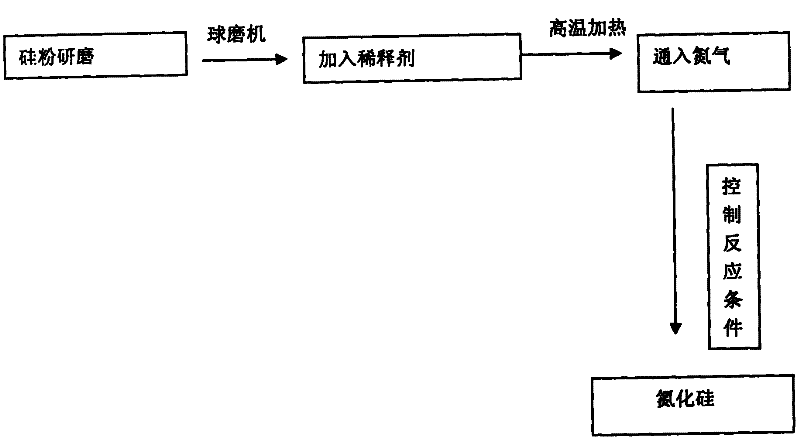

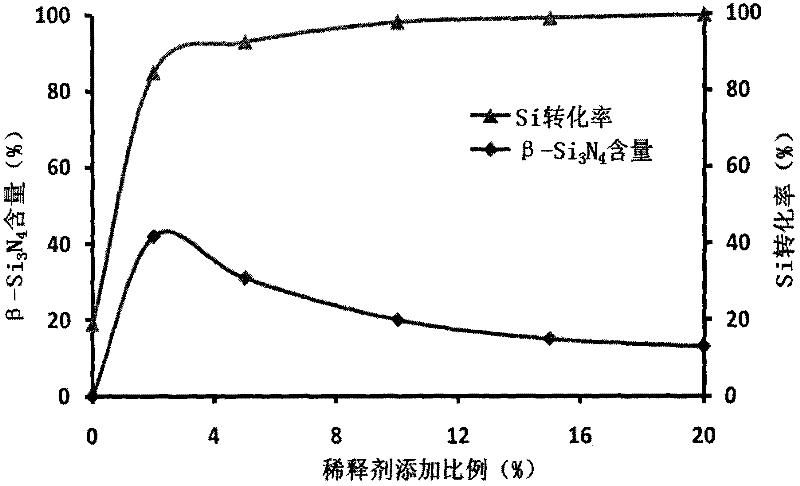

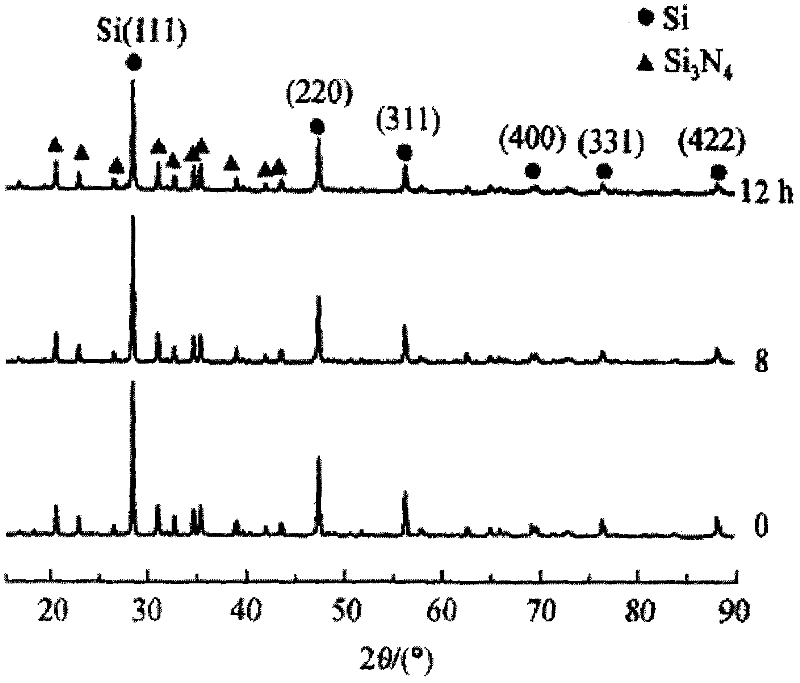

Production method of high-content alpha-crystal form silicon nitride powders

InactiveCN102173396ASmall granularityImprove defectsNitrogen compoundsChemical industryInorganic ChemicalSolid reaction

The invention discloses a production method of silicon nitride powders, in particular relates to a novel production method of silicon nitride powders with high content of alpha-Si3N4, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: firstly pre-treating powdery raw materials by mechanical activation, and feeding a mixed diluting agent of alpha-Si3N4 and non-crystalline Si3N4 during the direct nitridation of silicon powders at a high temperature under normal pressure. By controlling the addition ratio of the diluting agent and the nitridation time and temperature, the silicon nitride powders with high content of alpha-Si3N4 are synthesized. The process improves the activity of solid-phase reactants, promotes the reaction between Si and N2, does not need high-temperature and high-pressure conditions, is easy to operate, adopts easily-available raw materials, increases the purity of products, has a low coat and a high efficiency, and is environment-friendly and energy-saving. The process is economical and highly-efficient and suitable for large-scale production.

Owner:GONGYI CITY HONGTAI SILICON NITRIDE MATERIAL

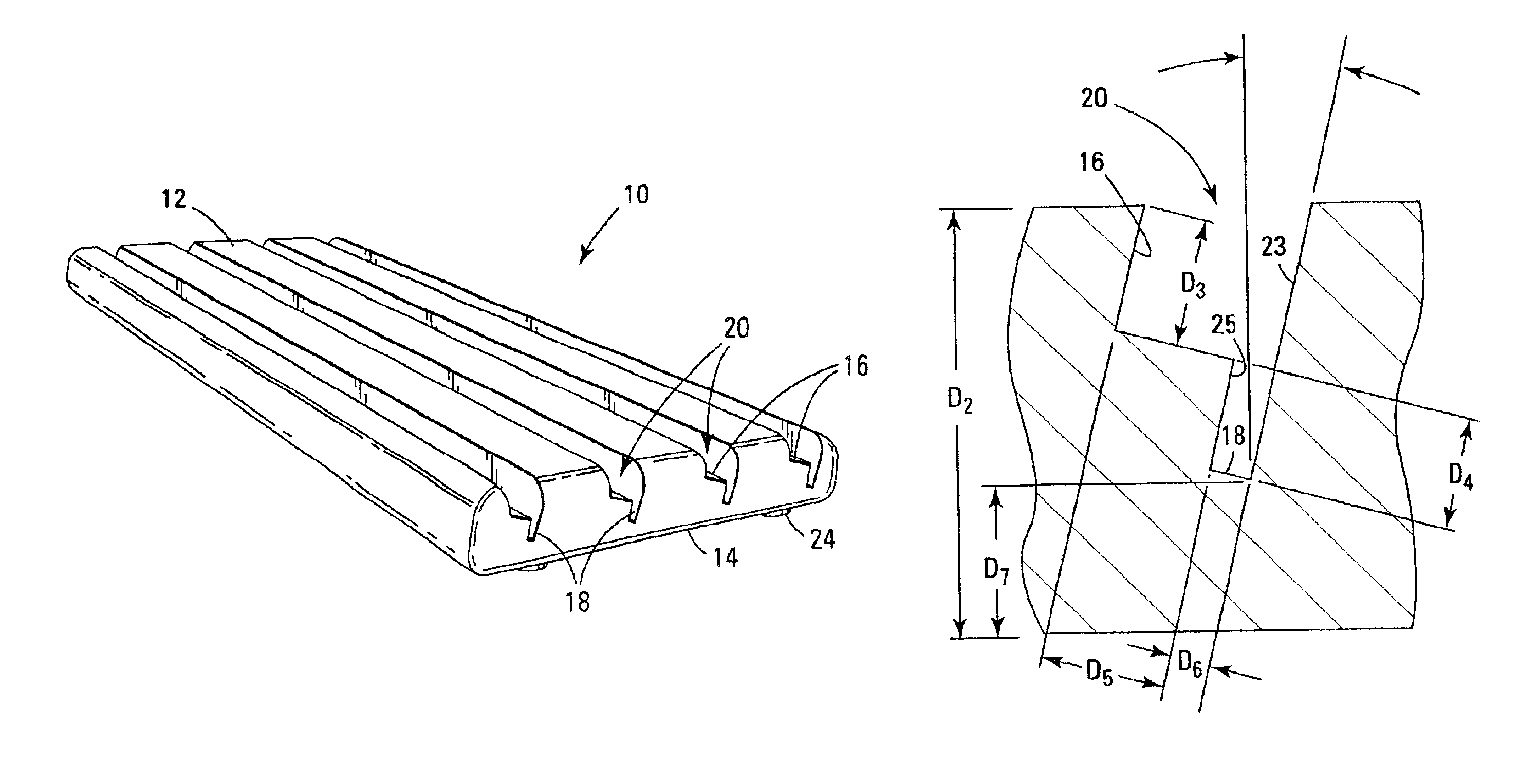

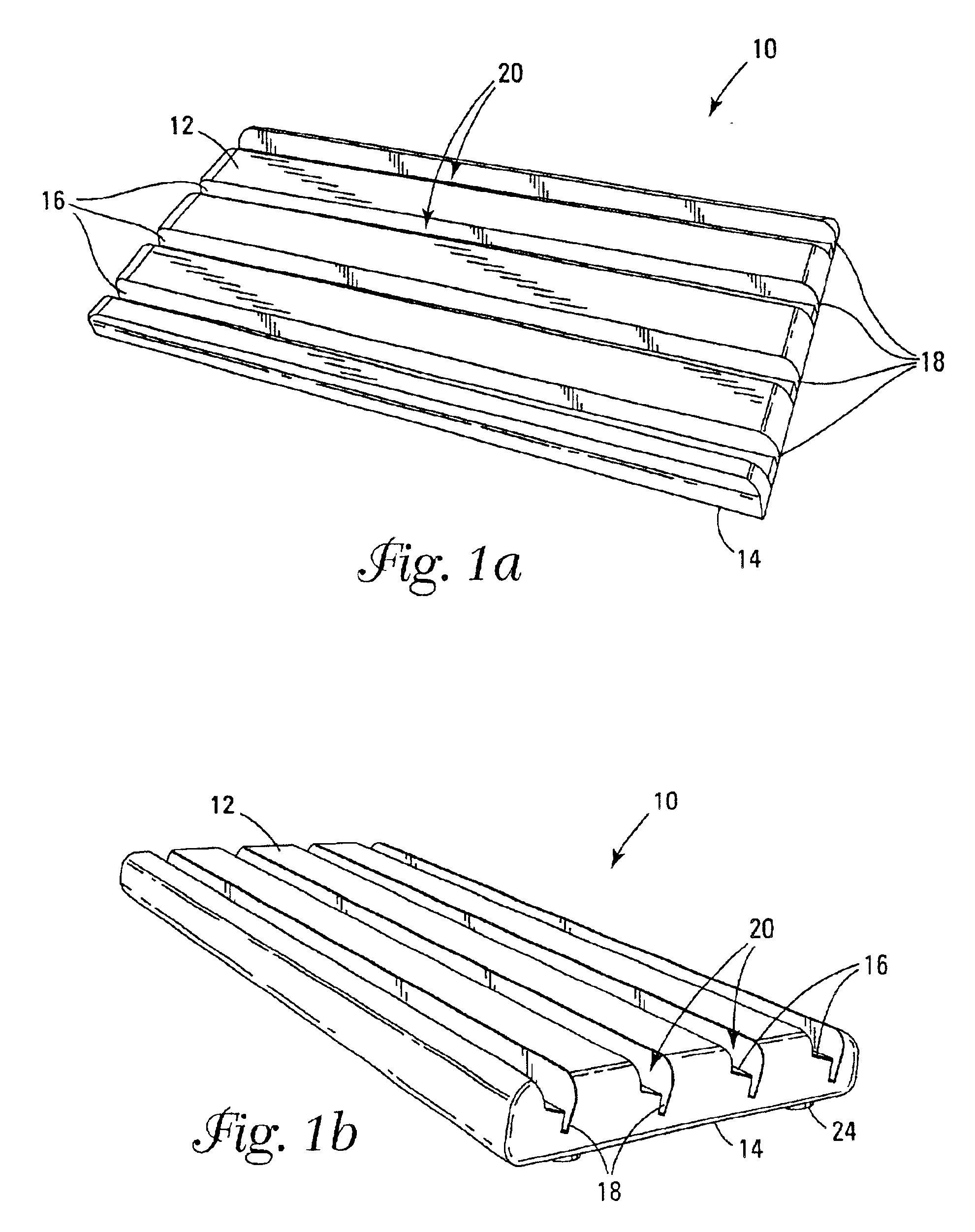

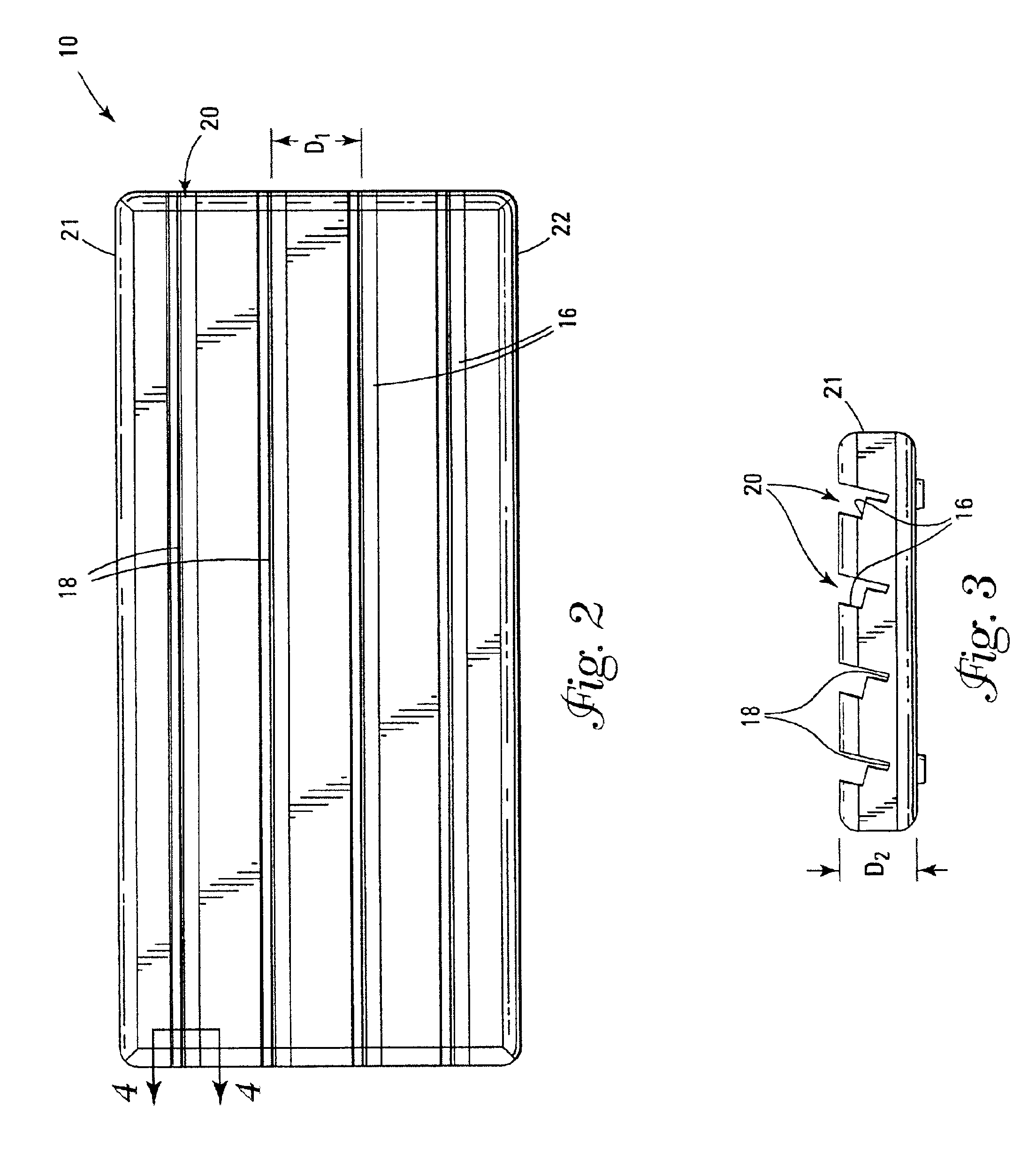

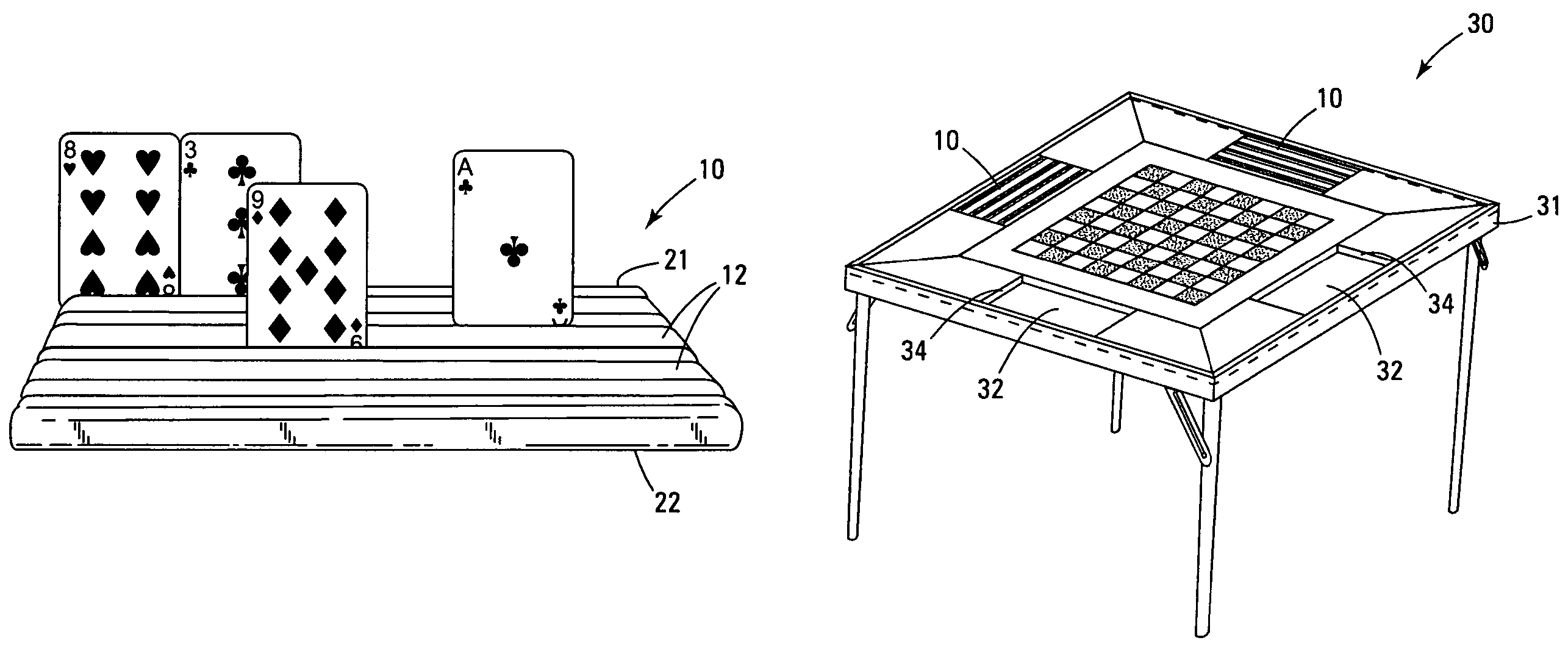

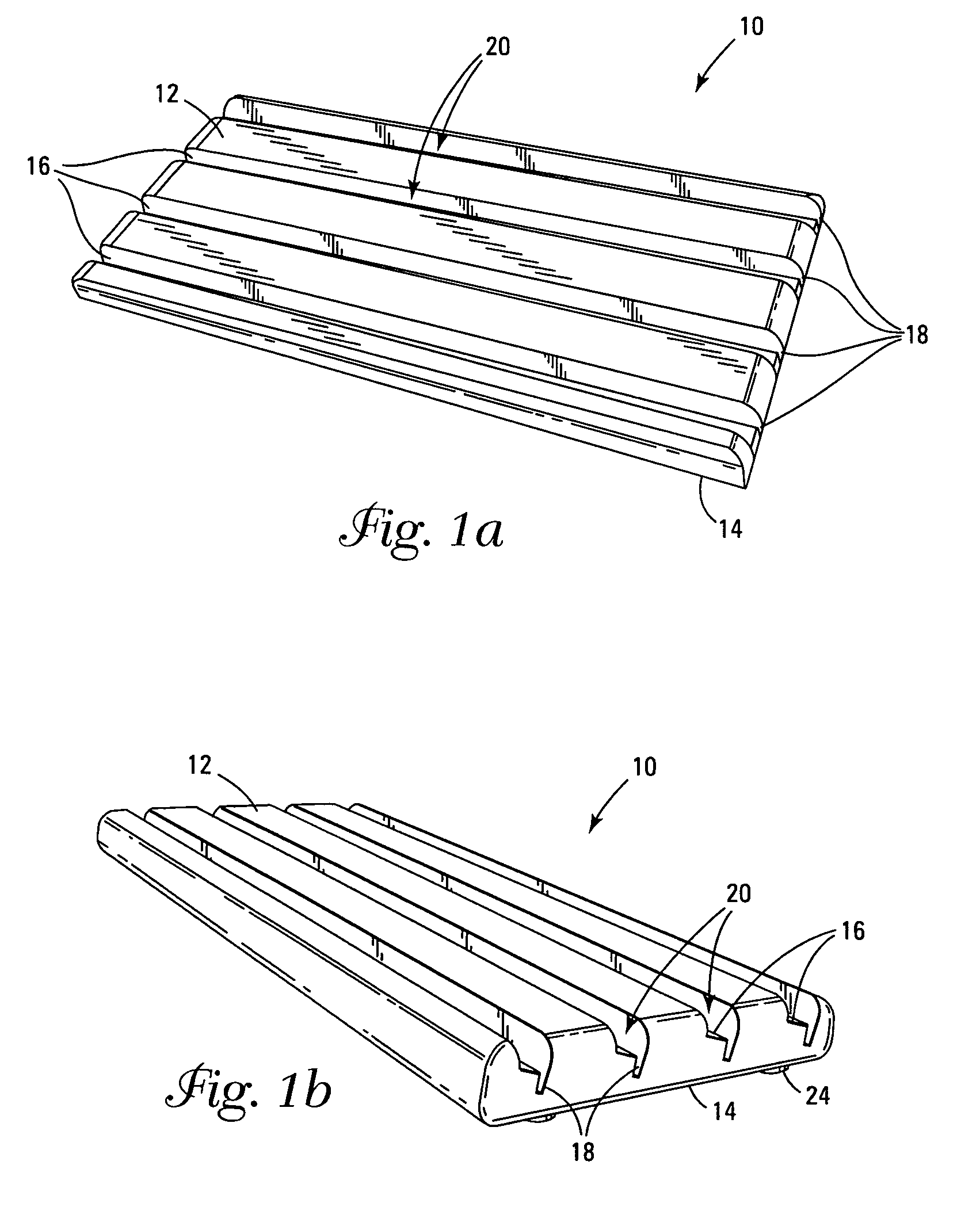

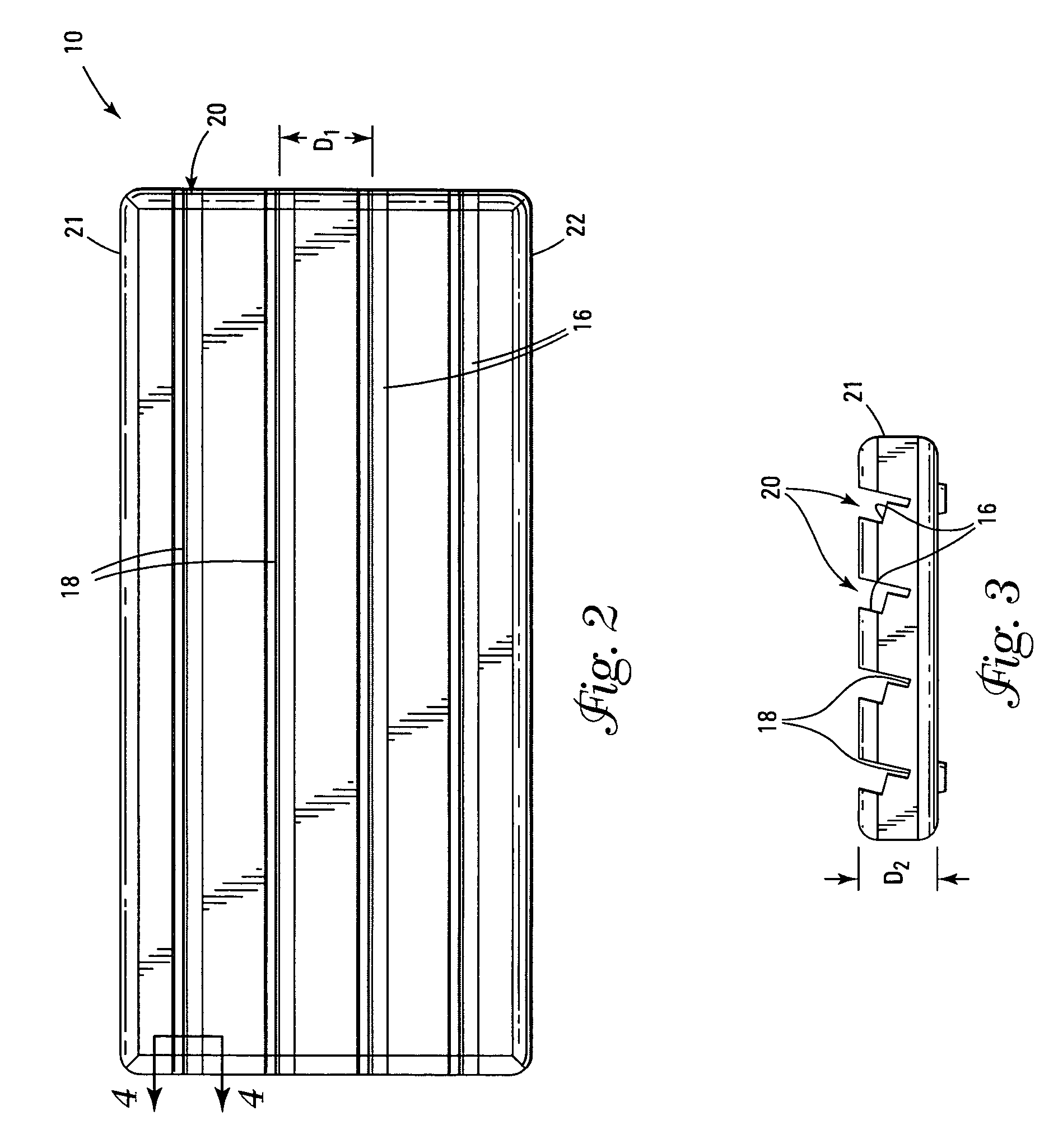

Slotted game board and gaming table

InactiveUS6854730B2High friction vibrational dampeningStable supportBoard gamesCard gamesPlaying cardEngineering

A game board for supporting cards and gaming pieces such as dominos. The game board includes a board that has first and second major surfaces and first and second sets of slots. The first set of slots is sized and configured for supporting gaming pieces like dominos and is disposed within the first major surface of the game board. The second set of slots is sized and configured for supporting playing cards. The second set of slots is disposed on the first major surface of the game board but within the first set of slots to form a set of compound slots. The game board could be used on a gaming table that has multiple recessed areas for receiving and supporting each game board flush with the top surface of the table.

Owner:BRAUN LOUIS F

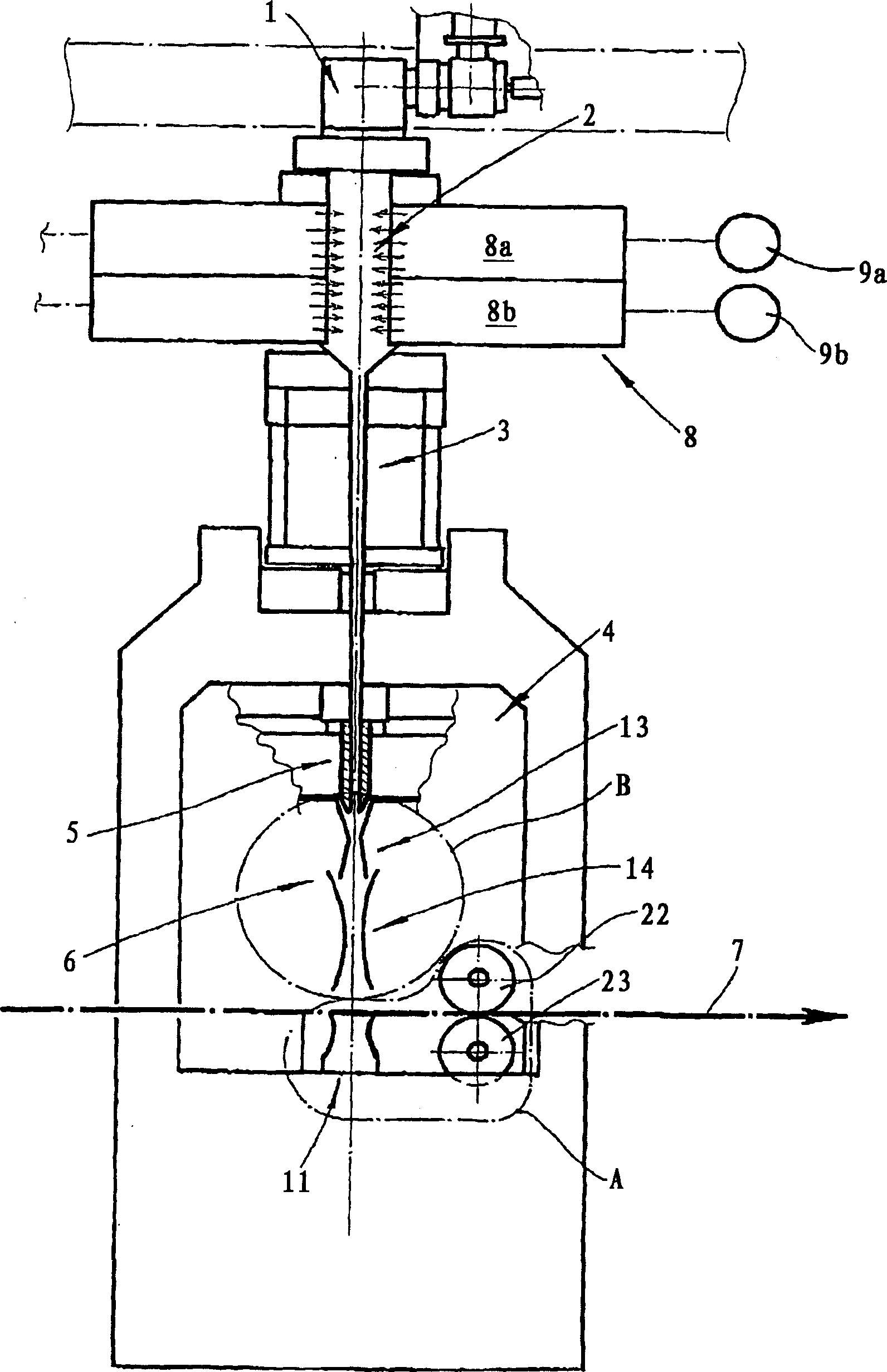

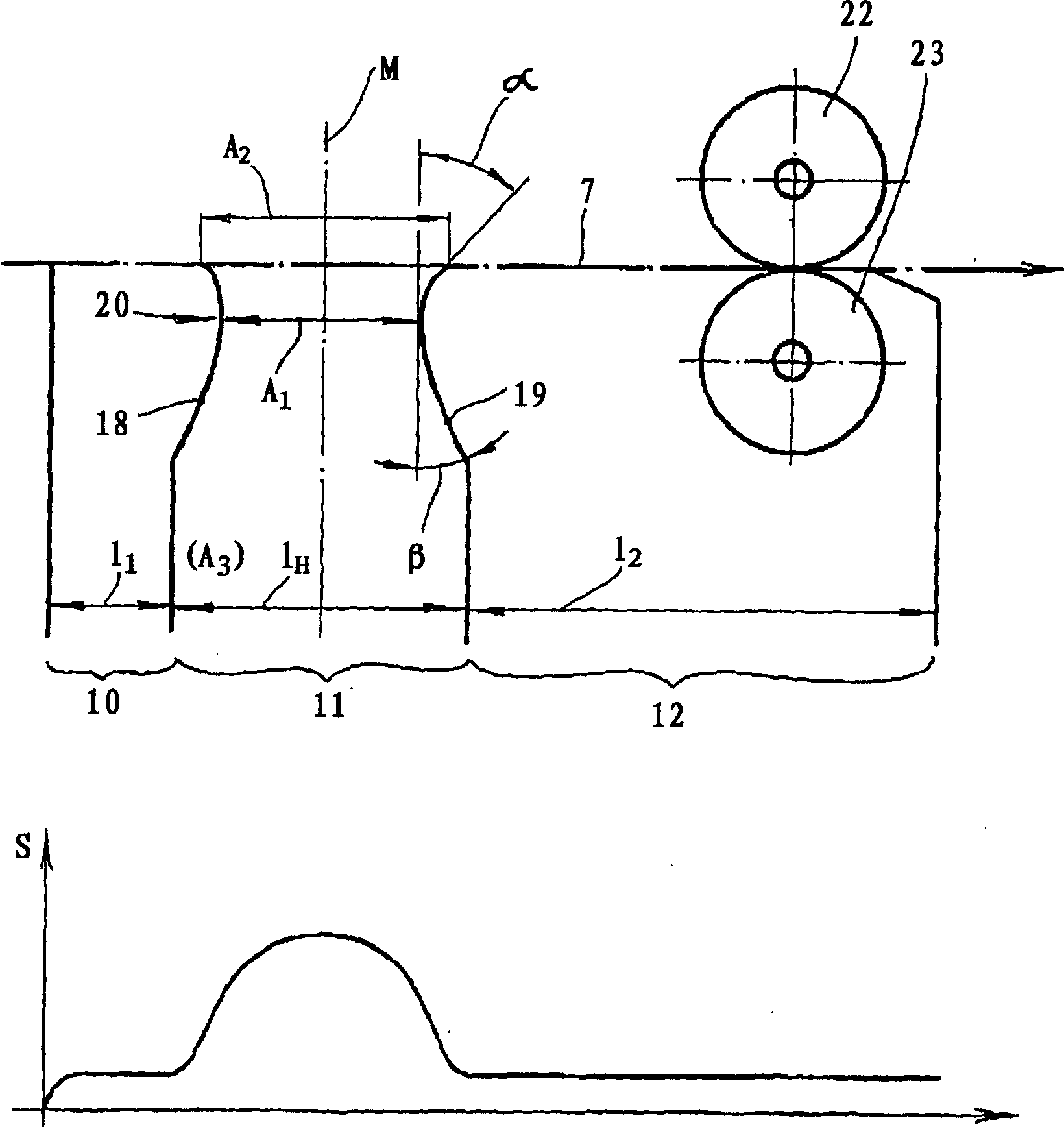

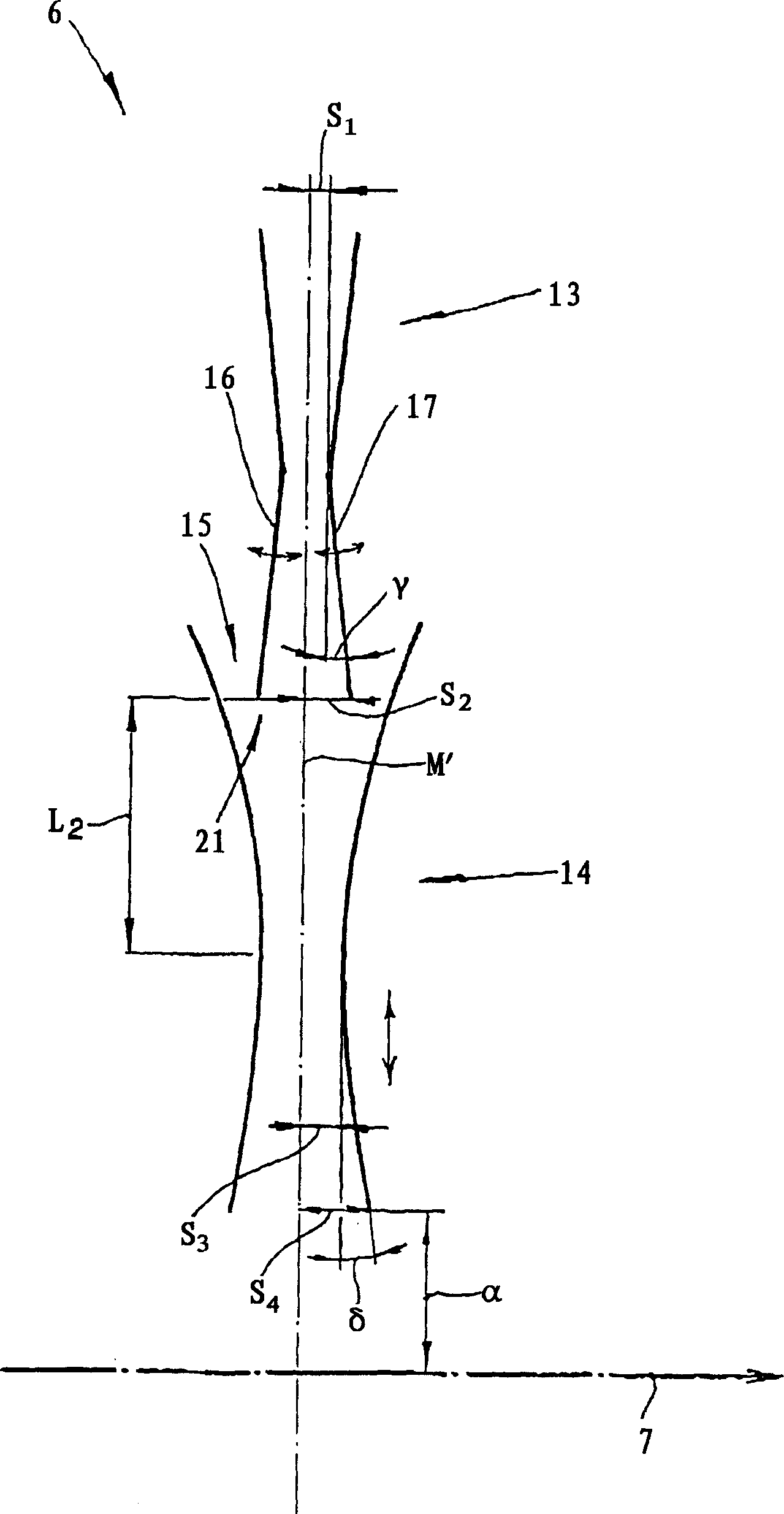

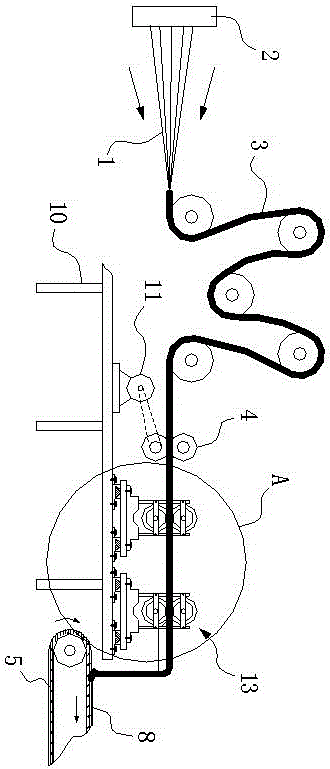

Equipment for continuously producing adhesive non-woven fabric web

InactiveCN1441105AEffective delivery reliabilityFunction increaseMelt spinning methodsNon-woven fabricsThermoplasticWoven fabric

A spun-bond web production apparatus comprises a spinneret for producing descending thermoplastic synthetic resin filaments; receiving device for receiving filaments; continuously movable collecting foraminous belt; and at least two mutually independently controllable suction zones beneath the belt for drawing air and including a primary suction zone at which a greater part of the filaments are drawn onto the belt. A spun-bond web production apparatus comprises a spinneret (1) for producing descending thermoplastic synthetic resin filaments; receiving device below the spinneret and receiving filaments for aerodynamically stretching the filaments; continuously movable collecting foraminous belt (7) displaceable longitudinally in a web-producing direction below the receiving device to produce a spun-bond web; and at least two mutually independently controllable suction zones (11) beneath the belt for drawing air through and in succession in the web-producing direction, and including a primary suction zone at which a greater part of the filaments are drawn onto the belt and at least one other suction zone.

Owner:莱芬豪舍有限责任两合公司机器制造厂

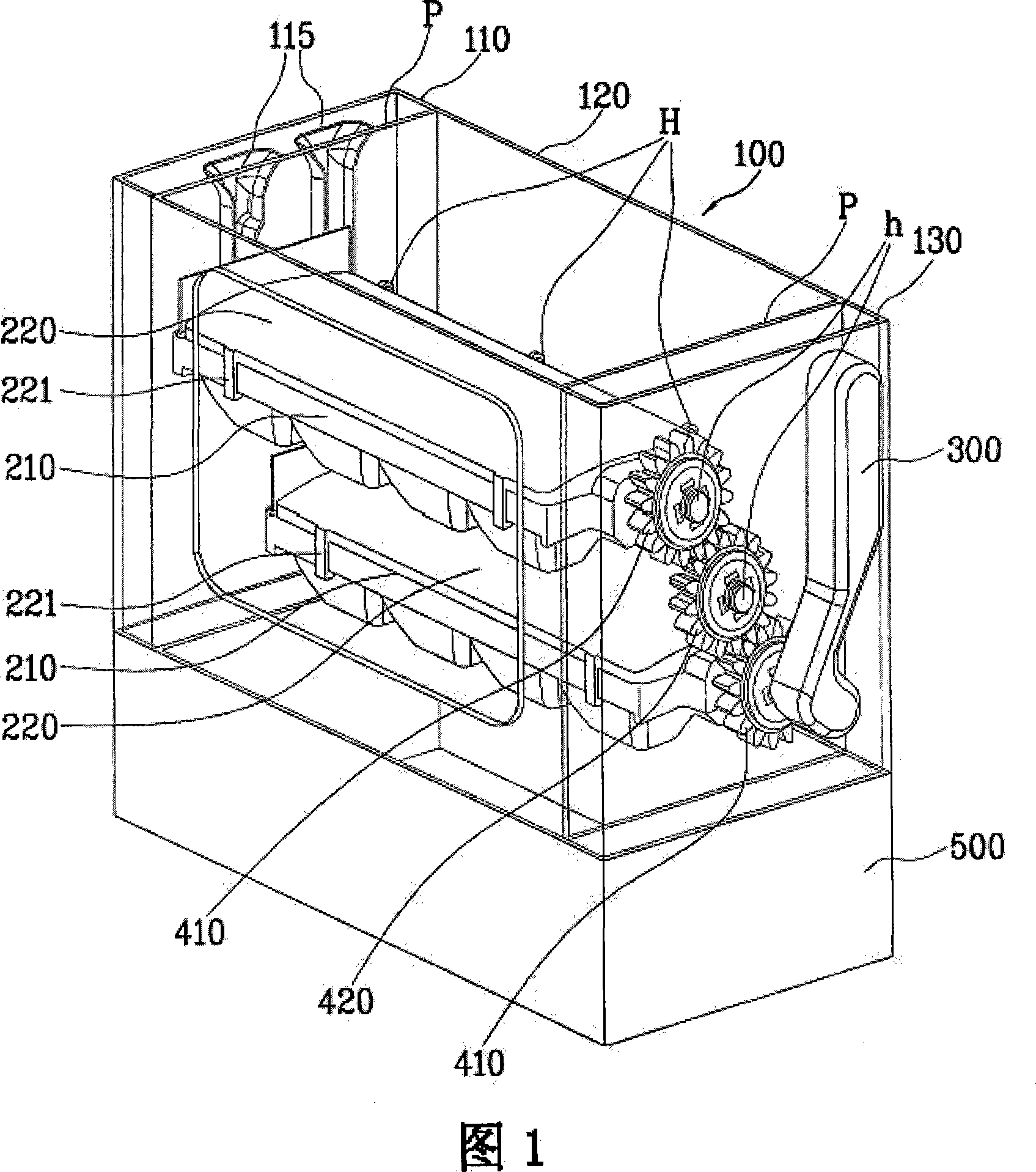

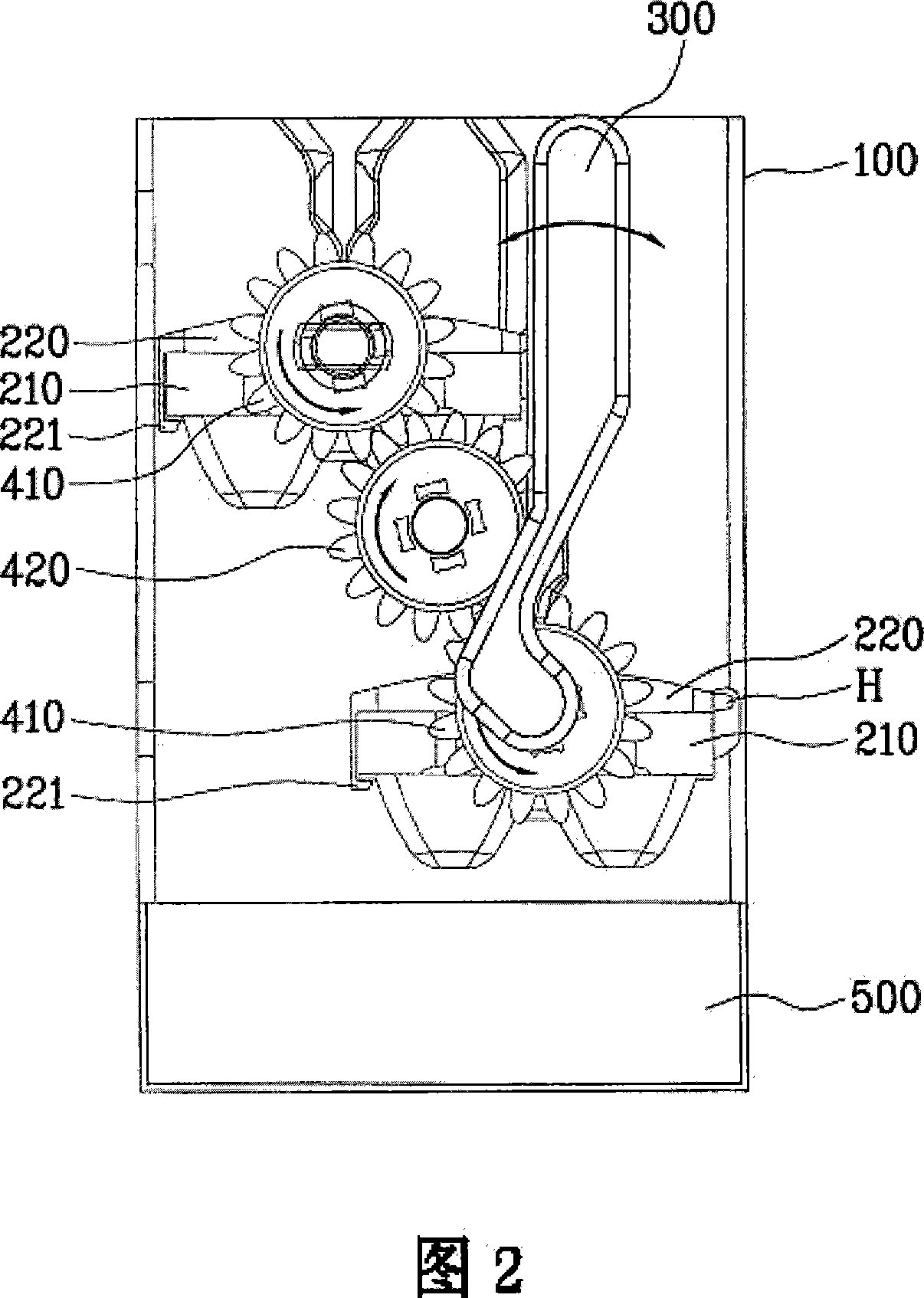

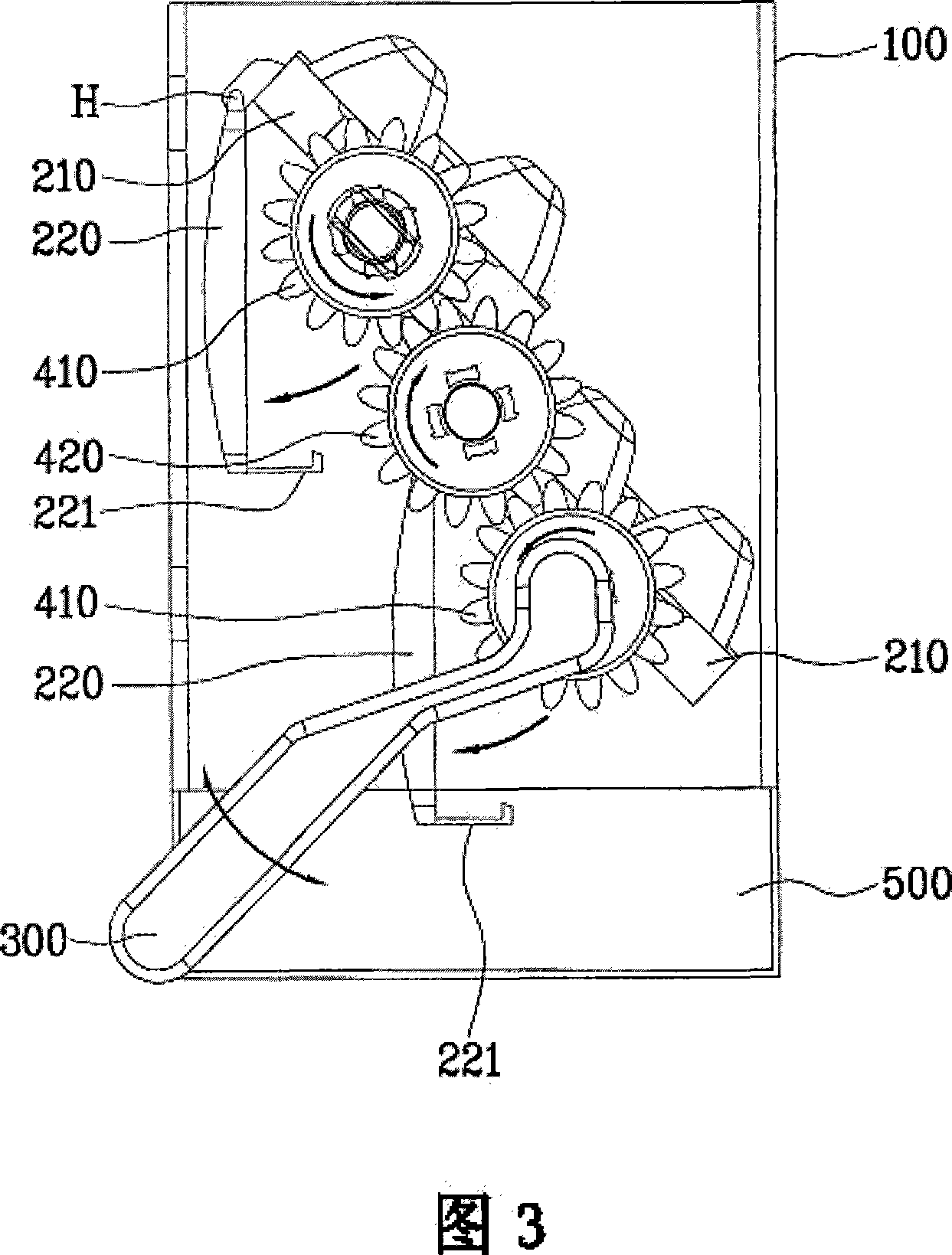

Ice tray assembly and refrigerator having the same

ActiveCN101082458AEvenly stackedLighting and heating apparatusIce productionRefrigerator carCoupling

The present invention relates to an ice making tray member and a refrigerator equipped with the ice making tray member, through which ice cubes stored in a plurality of ice making trays can be taken out from the ice making tray without any disturbance by one operation. To this end, the present invention provides an ice-making tray component, which is characterized in that it includes: a plurality of ice-making trays: arranged up and down in the casing, connected by an interlocking device so as to be able to rotate simultaneously; The ice trays are connected so that the ice trays can be rotated. Moreover, the present invention also provides a refrigerator equipped with an ice-making tray component, which is characterized in that it includes: a plurality of ice-making trays: installed in a housing arranged on the inner surface of the refrigerator door in the shape of an up and down oblique line; and driving The device is connected to the above-mentioned ice making tray so that the ice making tray can be rotated.

Owner:LG ELECTRONICS INC

Dry powder raw material grinding device for producing fire extinguisher

InactiveCN108672054AGrind evenlyGrinding speed is fastSievingScreeningFire extinguisherGrinding wheel

The invention relates to a powder grinding device, in particular to a dry powder raw material grinding device for producing a fire extinguisher. The dry powder raw material grinding device for producing the fire extinguisher is high in smashing efficiency, smashing is uniform, and raw materials are not stacked easily in the smashing process. According to the technical scheme, the dry powder raw material grinding device for producing the fire extinguisher comprises a bottom plate, a left support, a right support, a round supporting plate, a grinding box, a collecting box, a supporting rod, a first rotating shaft, a fan-shaped gear, an air cylinder, a grinding wheel, an electric pushing rod and the like. The left support is arranged on the left side of the top of the bottom plate. The rightsupport is arranged on the right side of the top of the bottom plate. The round supporting plate is arranged in the middle of the top of the bottom plate. According to the dry powder raw material grinding device, the electric pushing rod serves as the main power source to drive the grinding wheel to swing to carry out grinding, meanwhile, by means of mutual cooperation of the fan-shaped gear and arack, a baffle moves left and right indirectly, the raw materials are discharged intermittently, the raw materials are ground while being discharged, and the raw materials are not stacked easily in the grinding process.

Owner:胡智晶

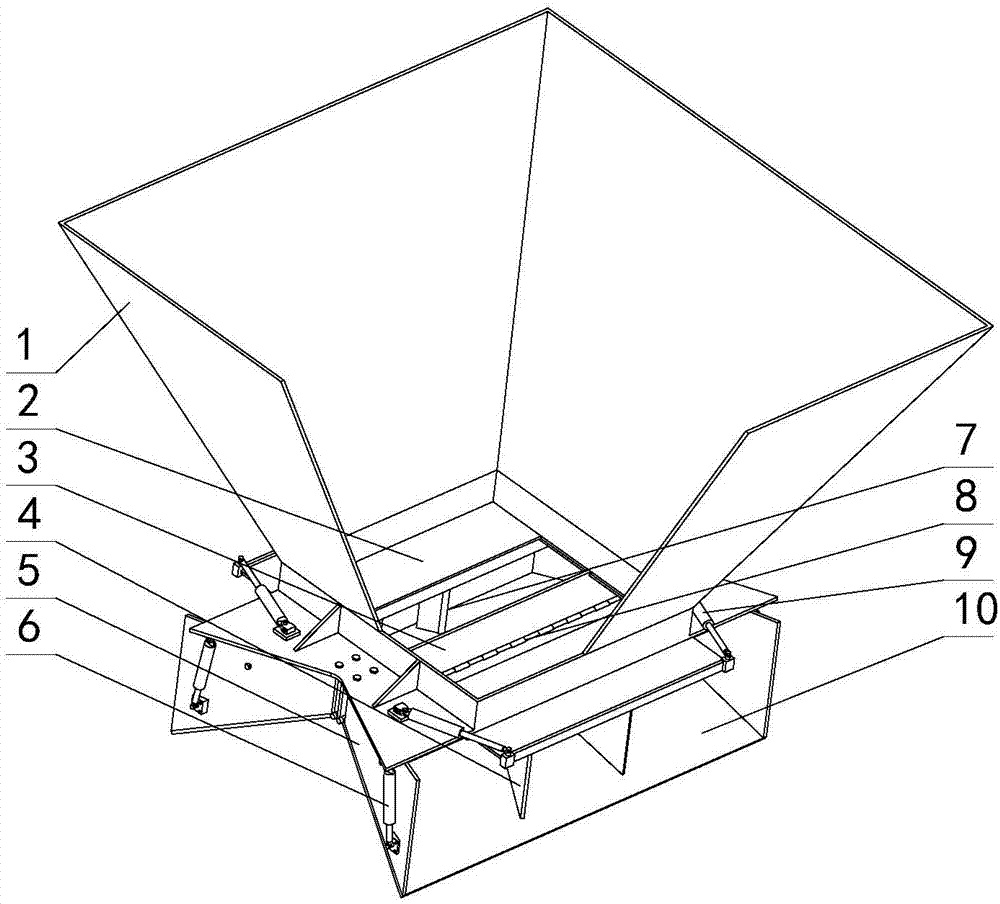

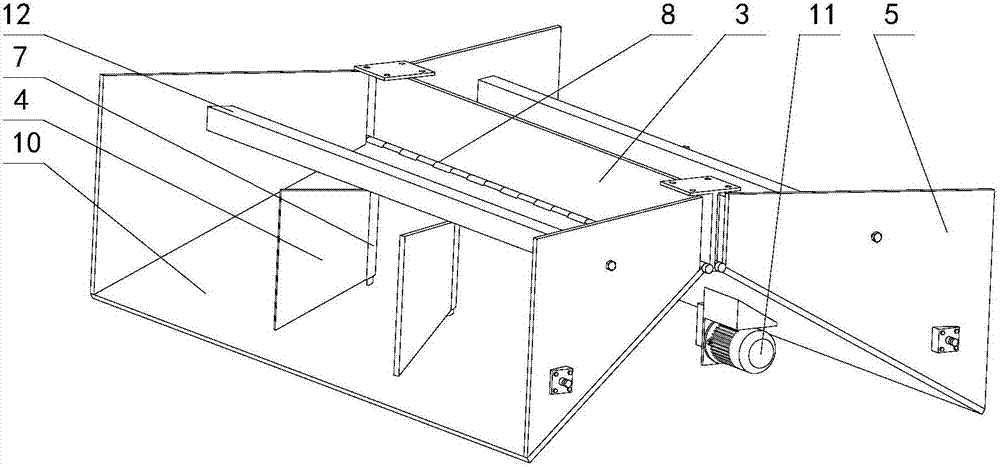

Discharging hopper capable of achieving flat heaping of fallen materials

InactiveCN107380762AImprove work efficiencyReduce manufacturing costConveyorsLarge containersElectrical and Electronics engineeringMaterial flow

The invention discloses an unloading hopper for realizing the flat accumulation of blanking, which is characterized in that it comprises a hopper, a vertically arranged partition is arranged in the middle of the discharge opening at the lower part of the hopper, and material guide grooves are symmetrically arranged on both sides of the partition , the chute is movably connected with the partition plate through the first rotating shaft, the chute is provided with a chute to communicate with the discharge port, and the discharge port is symmetrically arranged on the top of the chute An opening control panel, the opening control panel of the discharge port is slidingly connected with the discharge hopper, and by controlling the opening and closing of the control panel of the discharge port opening, the openings of the material guide ports of the two material guide grooves are realized. Compared with the conventional unloading hopper, the unloading hopper provided by the present invention has added a material guide groove and a material distribution plate, and by adjusting the angle of the material guide groove and the material distribution plate, the direction and flow rate of the material flow can be changed, which can effectively change the flow rate of the material. The stacking state of the material can be realized, so as to realize the uniform and flat accumulation of the material blanking, and there is no need to artificially level the stockpile, thereby improving the operating efficiency and reducing the production cost.

Owner:WUHAN UNIV OF TECH

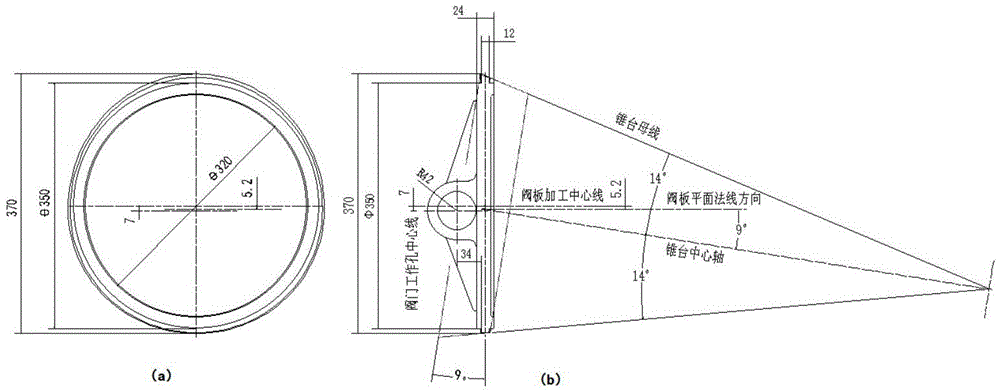

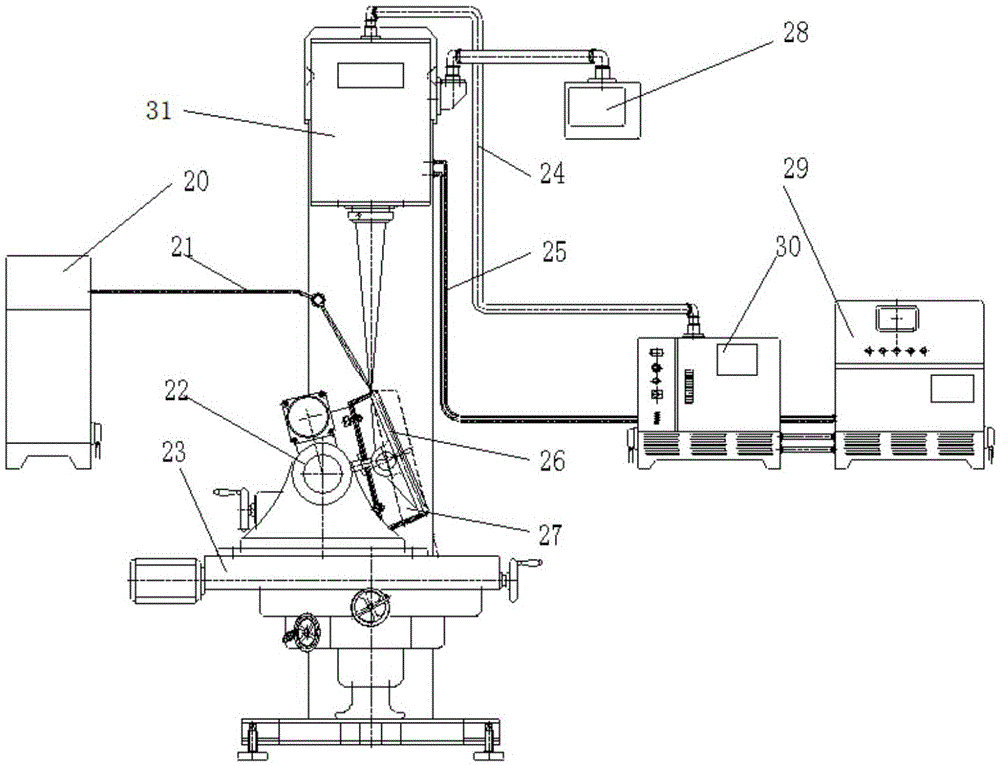

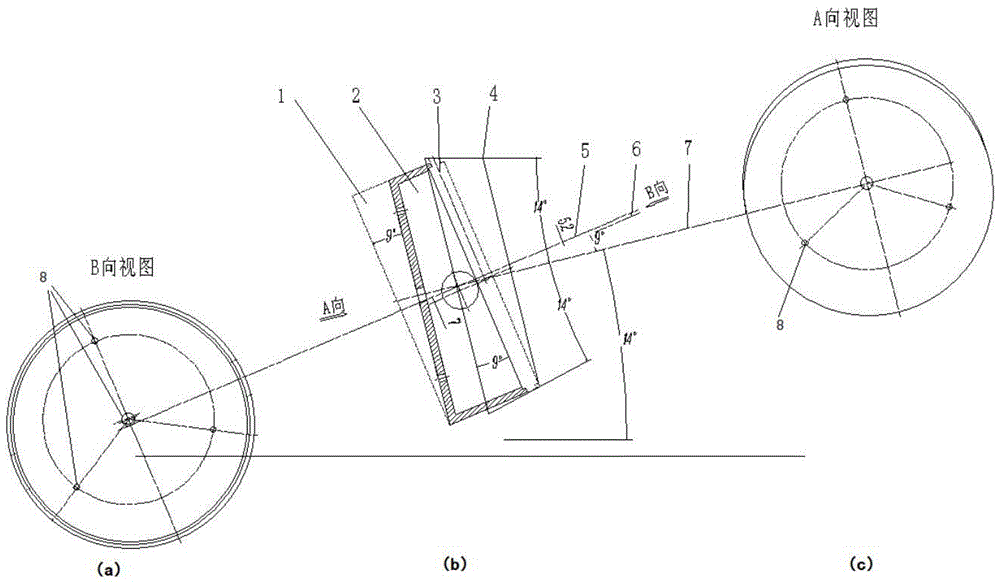

Laser cladding device for inclined frustum-shaped valve plate sealing faces of large valves

ActiveCN105483694AFacilitate transmissionImprove sealing surface qualityMetallic material coating processesEngineeringFrustum

The invention discloses a special clamp for inclined frustum-shaped valve plates, a laser cladding device and a corresponding laser cladding method, and belongs to the laser cladding field of semiconductor laser units. According toclamps for the valve plates in the prior art, in the laser cladding process, cladding is not uniform due to the inclined frustum shape of the valve plates, and some positions cannot be subjected to cladding. The special clamp comprises a side wall and a bottom surface, wherein the side wall is cylindrical, the bottom surface is oval, and an angle is formed between the bottom surface and the side wall and is equal to the included angle between the central axis of the inclined frustum shape of the valve plates and the plane normal of the valve plates; for cladding of the inclined frustum-shaped valve plates, powder accumulation is more uniform, the cladding surface is horizontal, the whole inclined frustum-shaped surface can be subjected to cladding, and cladding is more uniform.

Owner:HUAZHONG UNIV OF SCI & TECH

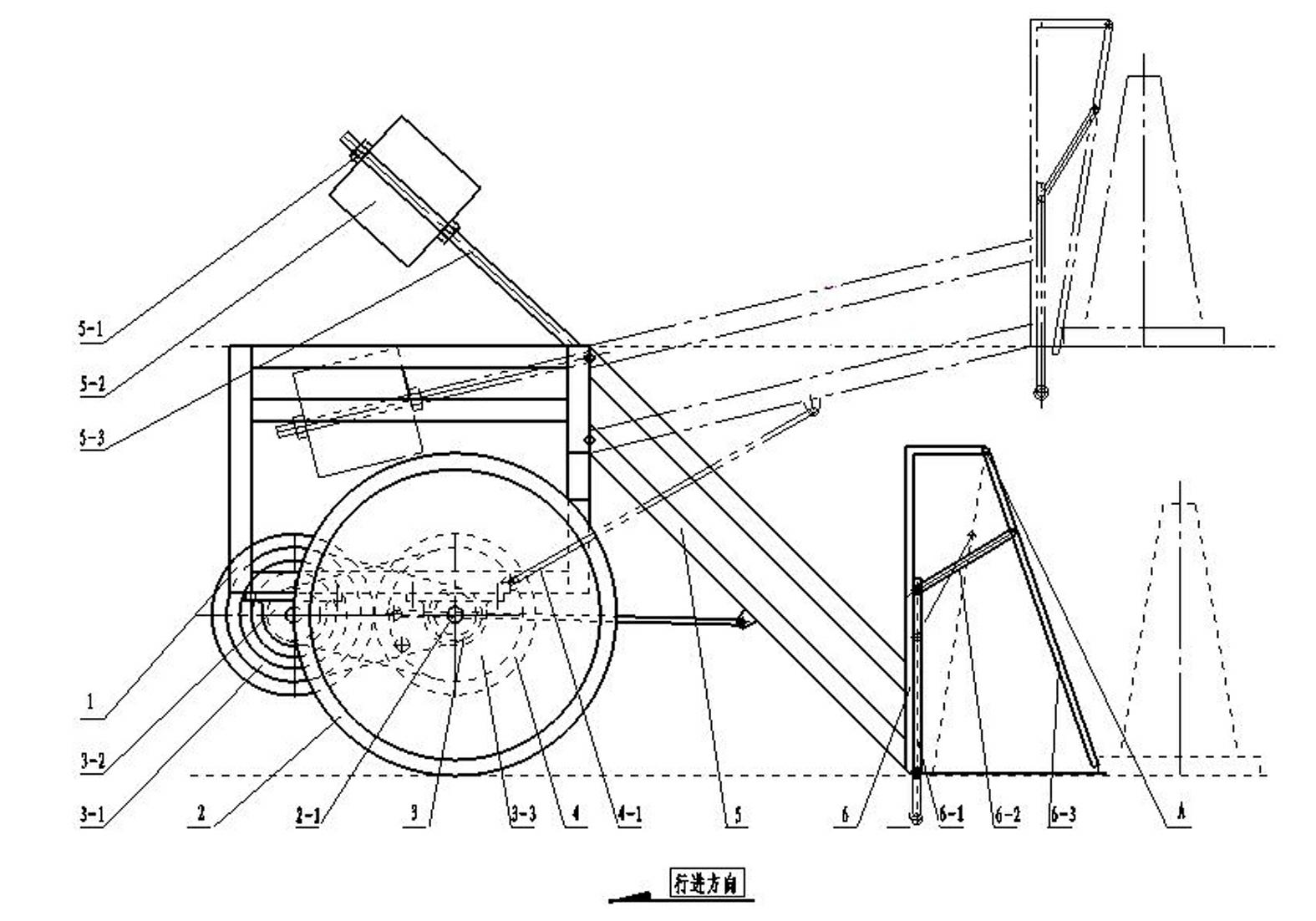

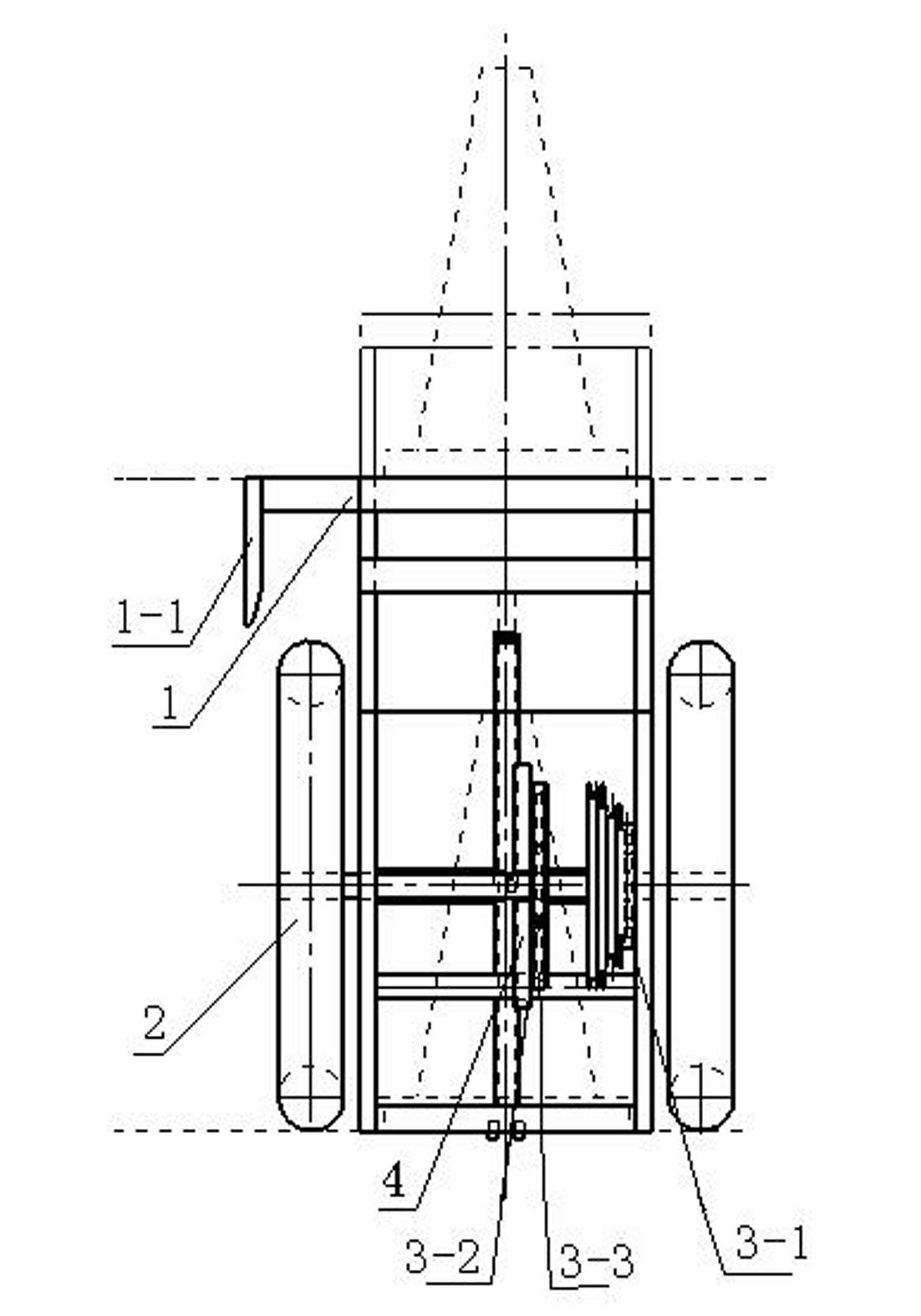

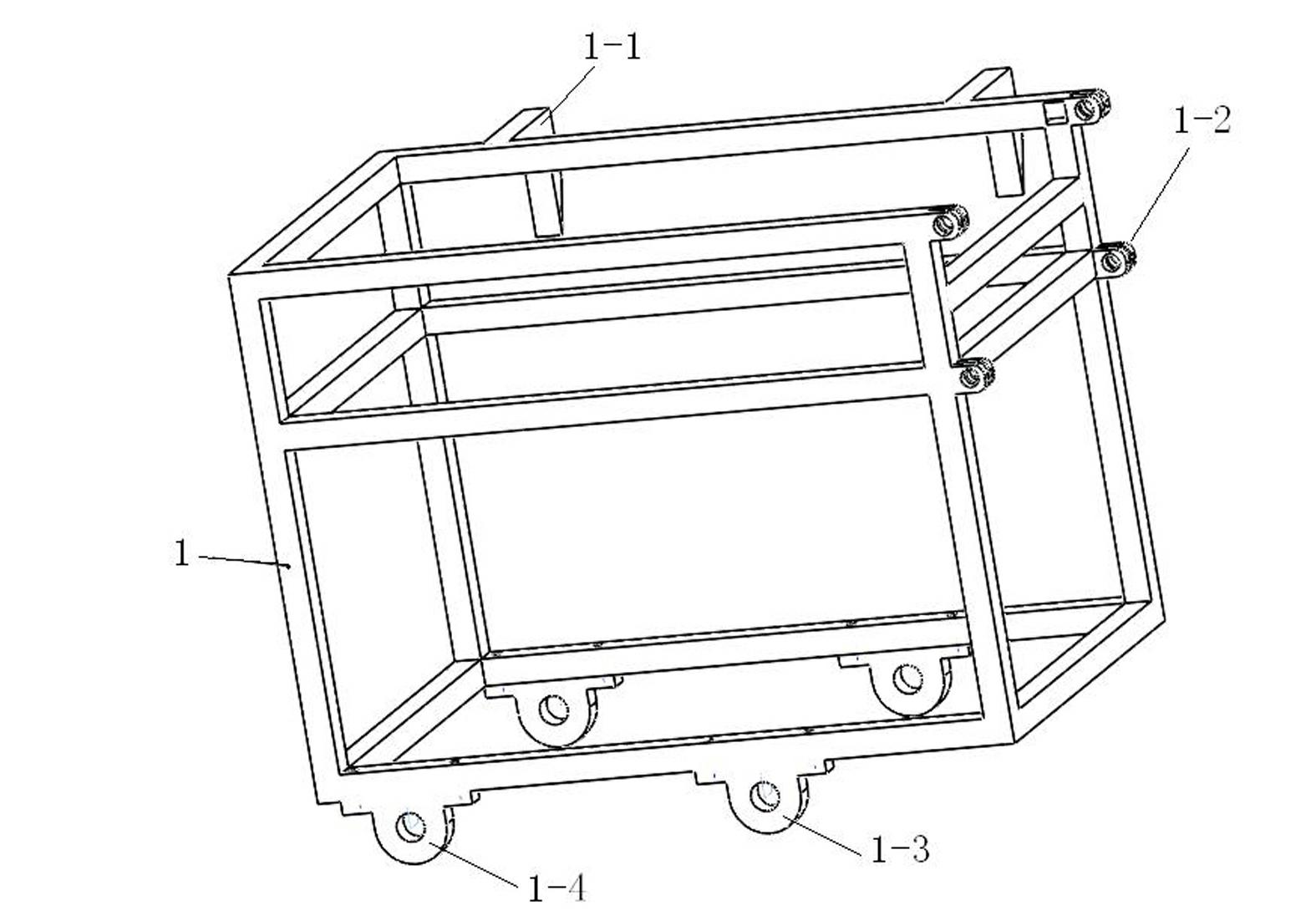

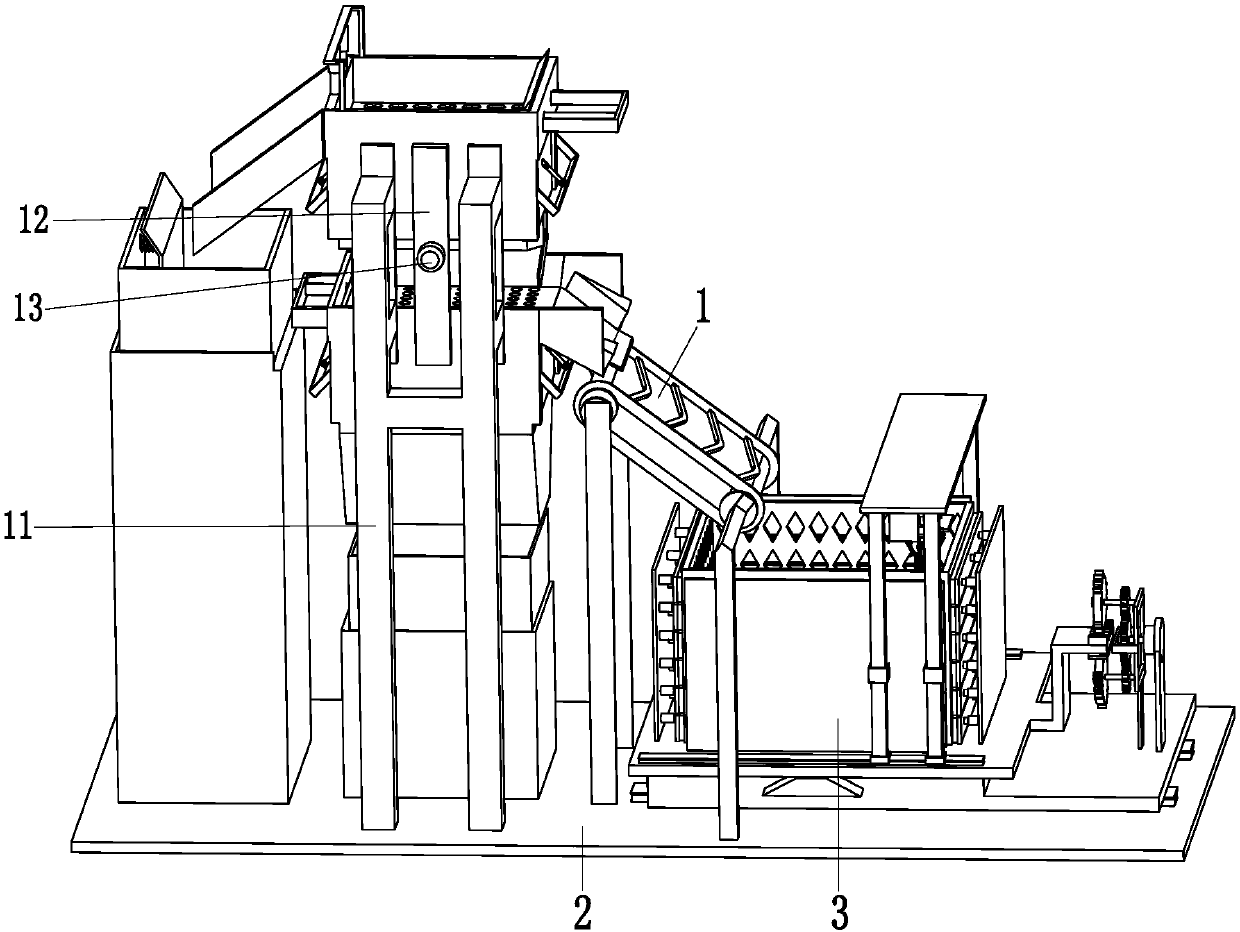

Stacking device for traffic cones

The invention discloses a stacking device for traffic cones, comprising a rack fixed on a travelling unit, wherein a connecting hook used for being hung on a ledge plate of an operating vehicle is arranged at one side of the rack, and a connecting fulcrum used for bearing a lifting mechanism is arranged at the rear side of the rack; and the stacking device further comprises the travelling unit, a speed change mechanism, a crank-connecting rod mechanism, and the lifting mechanism, wherein a pallet mechanism is hinged at the tail end of a lifting platform, the tray mechanism comprises a pallet rack formed by combining a support frame and a tray at a bottom end, and a shifting rod group capable of shifting out the traffic cones stacked on the tray is further arranged on the tray rack. According to the invention, the problems in the prior art can be solved; the distance consistency of the stacked traffic cones (road cones) is good; and the stacking distance of the traffic cones (road cones) can be conveniently adjusted according to different project needs.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method for hydrotreatment catalyst

ActiveCN103801312AExtended service lifeLarge hole volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationResidual oil

The invention discloses a preparation method for a hydrotreatment catalyst. The method comprises the following steps: in the process of gel formation by cocurrent flow of an alkaline solution containing aluminum and an acidic solution containing aluminum, adding an additive and an organic template agent in the manner of cocurrent flow at the same time, controlling proper reaction conditions and carrying out gel formation; then adding an alkaline solution to adjust a pH value; then carrying out filtering, washing and drying so as to obtain alumina dry gel; carrying out molding, drying and calcining so as to obtain an alumina carrier; and loading active metal components. The catalyst prepared by using the method has the advantages of a large specific surface area, a great pore volume and a reasonable pore structure and is particularly applicable as a catalyst for hydrodesulfurization or hydro-conversion of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slotted game board and gaming table

A gaming table for supporting cards and gaming pieces such as dominos. The gaming table has game boards that include first and second major surfaces and first and second sets of slots. The first set of slots is sized and configured for supporting gaming pieces like dominos and is disposed within the first major surface of the game board. The second set of slots is sized and configured for supporting playing cards. The second set of slots is disposed on the first major surface of the game board but within the first set of slots to form a set of compound slots.

Owner:BRAUN LOUIS F

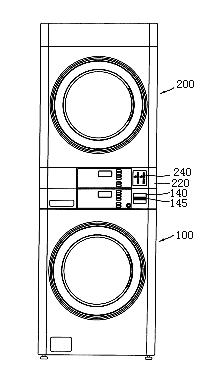

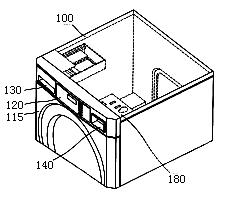

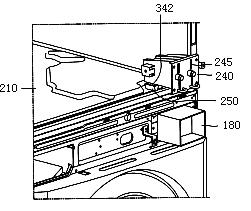

Clothing processing device with coin guiding device

InactiveCN102605587AEvenly stackedEasy to set upOther washing machinesApparatus for meter-controlled dispensingEngineeringInput device

The invention refers to a clothing processing device with a coin guiding device, comprising the following components: a lower part clothing processing device with a coin box for keeping coins; an upper clothing processing device located on the upper part of the lower part clothing processing device and provided with a coin input device; a lower part coin guiding device and an upper coin guiding device which are used for guiding the coins inputted into the coin input device into the coin box and are respectively arranged on the lower part clothing processing device and the upper clothing processing device, the lower coin guiding device comprising a lower part coin output which is used for outputting the inputted coins in a direction parallel with or in a inclined direction with the bottom of the coin box. According to the invention, owing to the effects of the coin guiding device, the coins does not fall in a vertical direction but in a horizontal or inclined direction relative to the coin box, thus the coins can uniformly distributed in the coin box and the coin box does not need to be cleaned usually, which is convenient to manage the coin box.

Owner:NANJING LG PANDA APPLIANCES

Wadding removing device for non-woven fabric processing

ActiveCN111874633AConvenient for centralized processingSo as not to damageBulk conveyorsConveyor partsElectric machineryWoven fabric

The invention discloses a wadding removing device for non-woven fabric processing. The device comprises a base, a baffle, a first motor, an air draft pipeline, a bearing cylinder and a battery pack, agroove is formed in the left end face of the base, a first electric telescopic rod is fixed to the right side wall of the groove, and a rotating box is rotatably connected to the top of the base; andthe air draft pipeline penetrates through a top cover to be connected with a filter net, the top of the bearing cylinder penetrates through the bottom of a support and is in threaded connection witha fastener, a sliding rail is fixed to the upper end face of the base, a roller is rotatably connected to the front side of a sliding block, a hydraulic cylinder is fixed to the right side of the front end face of the sliding block, and a top plate is fixed to the left side of the top of the sliding rail. According to the wadding removing device for non-woven fabric processing, after broken wadding in a side face hole of the rotating box is ejected out, the roller and a wadding sticking barrel can move downwards along with the sliding block, meanwhile, the wadding sticking barrel can rotate along with the roller, the wadding sticking barrel and the outer side wall of the rotating box are attached together, and the ejected broken wadding can be conveniently stuck down.

Owner:昆山洁宏无纺布制品有限公司

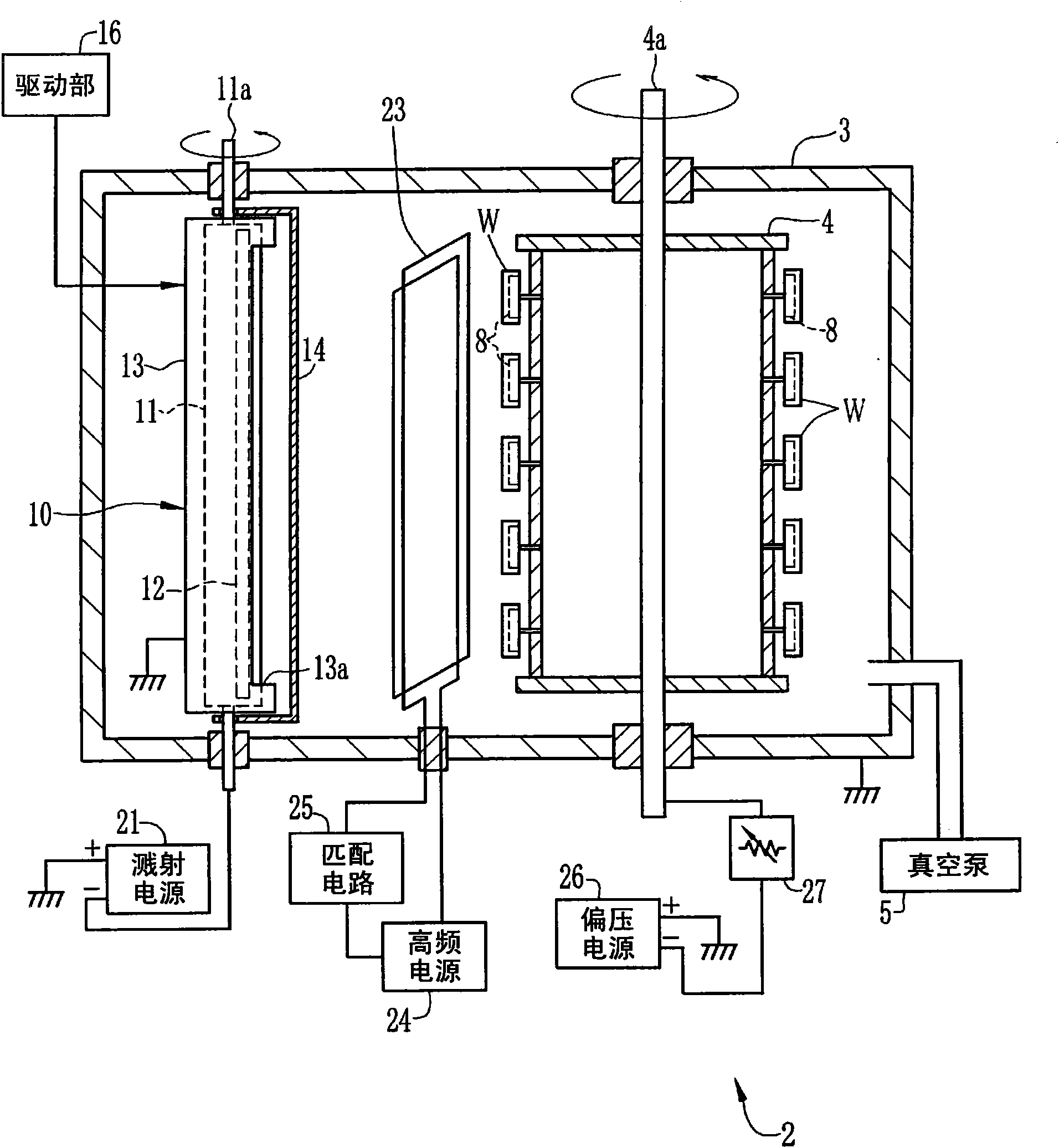

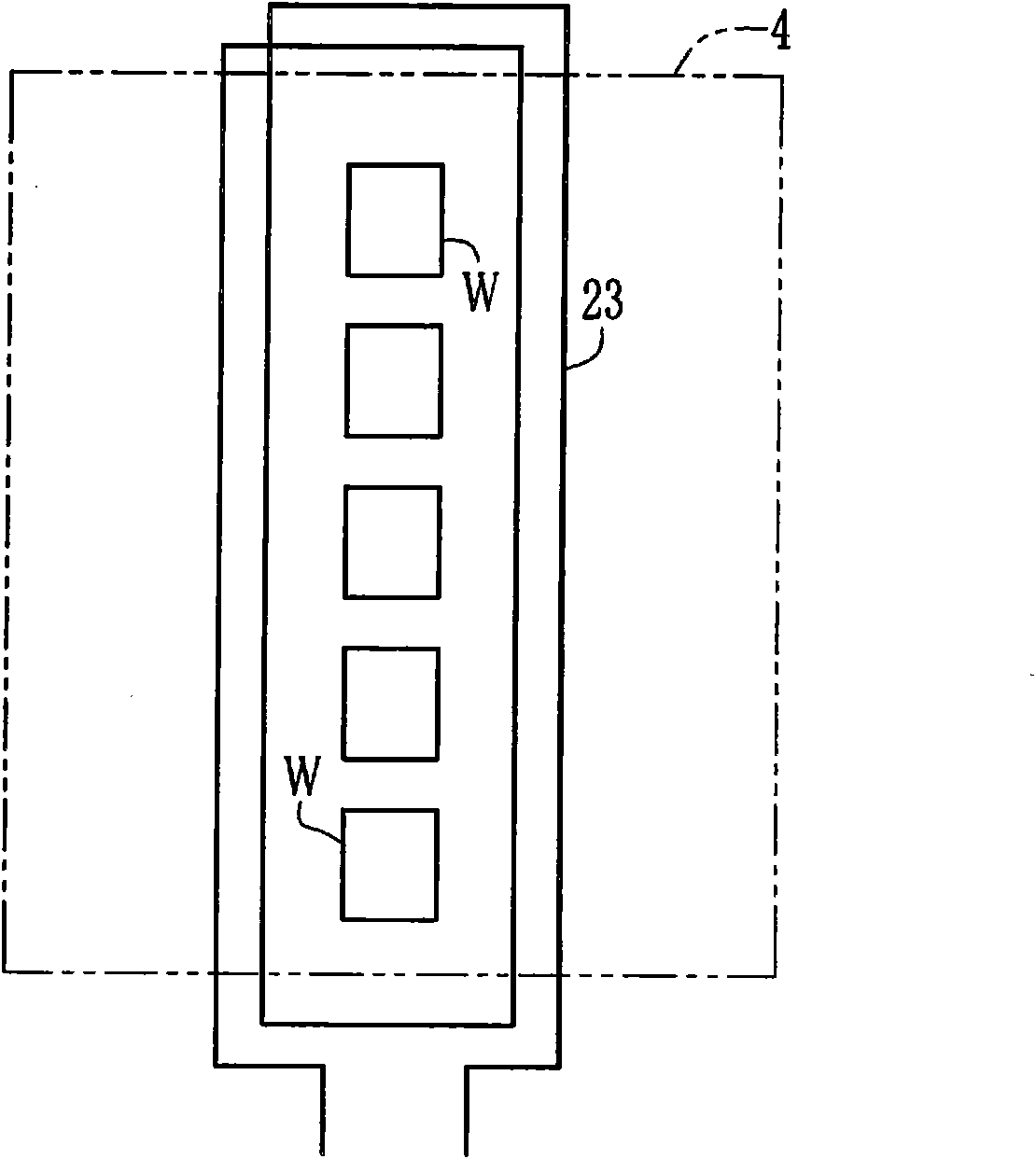

Sputtering apparatus and film forming method

InactiveCN101861409AEvenly stackedImprove uniformityVacuum evaporation coatingSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

An RF coil (23) is arranged between a target (11) and a work (W), and sputtering particles scattering from the target (11) toward the work (W) are ionized to positive ions when the RF coil (23) is supplied with high frequency power. The work (W) or the work holder (8) holding the work (W) are negatively biased by a bias power supply (26), and the ionized sputtering particles are attracted. A current flowing in the bias power supply (26) is controlled not to have the adhered sputtering particles immediately become electrically neutral.

Owner:EBARA-UDYLITE CO LTD

Automatic processing equipment for gastrodia elata traditional Chinese medicinal material planting fungus-growing material

InactiveCN106818219AEffective incisionShort cutCultivating equipmentsMushroom cultivationAutomatic processingEngineering

The invention relates to an automatic processing equipment for planting fungus material of Gastrodia elata, which includes a bottom plate, and the top surface of the bottom plate is sequentially installed with a placement device, a moving device, a support frame, and a pushing device. The support frame is located above the mobile device, and the support frame Two incision devices are symmetrically installed on the upper end, and two conversion devices are symmetrically located on both sides of the rear end of the bottom plate. The push device, two conversion devices, two incision devices, placement devices and moving devices cooperate to complete the automatic processing process of Gastrodia elata planting fungi. . The present invention can solve the problems existing in the process of processing the fungus materials for planting Gastrodia elata, such as the need to manually use tools such as axes to process the fungus materials, the existence of safety hazards, the low efficiency of fungus treatment, the labor intensity of manually stacking the fungus materials, and the long time-consuming and Low work efficiency and other problems can realize the integrated automatic processing function of the fungus materials used for Gastrodia elata planting.

Owner:谢秋晨

Special gabion box construction equipment for hydraulic engineering dam scouring preventing protection

InactiveCN108035309AImprove work efficiencyReduce labor intensitySievingScreeningEngineeringMechanical engineering

The invention relates to special gabion box construction equipment for hydraulic engineering dam scouring preventing protection. The special gabion box construction equipment comprises a screening device, a supporting bottom plate and a leveling device. The screening device is arranged at the left end of the top of the supporting bottom plate, and the leveling device is arranged at the right end of the top of the supporting bottom plate. The screening device comprises two screening connecting columns, a screening vibration column, a vibrator, a discharging mechanism, a material outlet mechanism, a first screening mechanism, a second screening mechanism, a conveying belt, a recycling mechanism, a first discharging plate, a second discharging plate, a discharging barrel, a material pulverizing box and a material pulverizing table. The special gabion box construction equipment can solve the problems that during existing gabion box stone filling, the work efficiency is low, the labor intensity is large, stone needs to be manually screened and carried, effective support does not exist during gabion box filling, and gabion box stone filling is not dense through manual work.

Owner:盛亚明

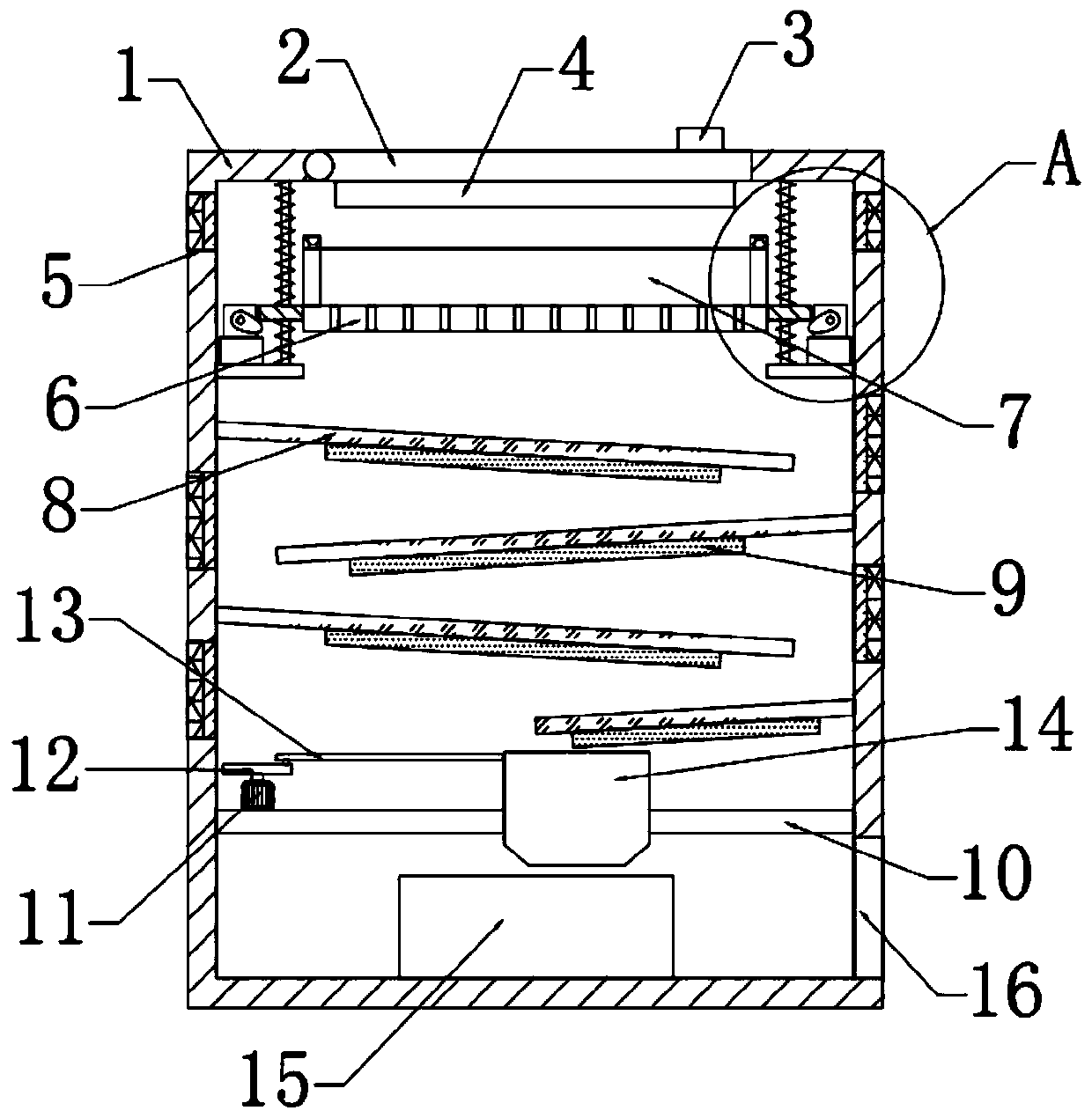

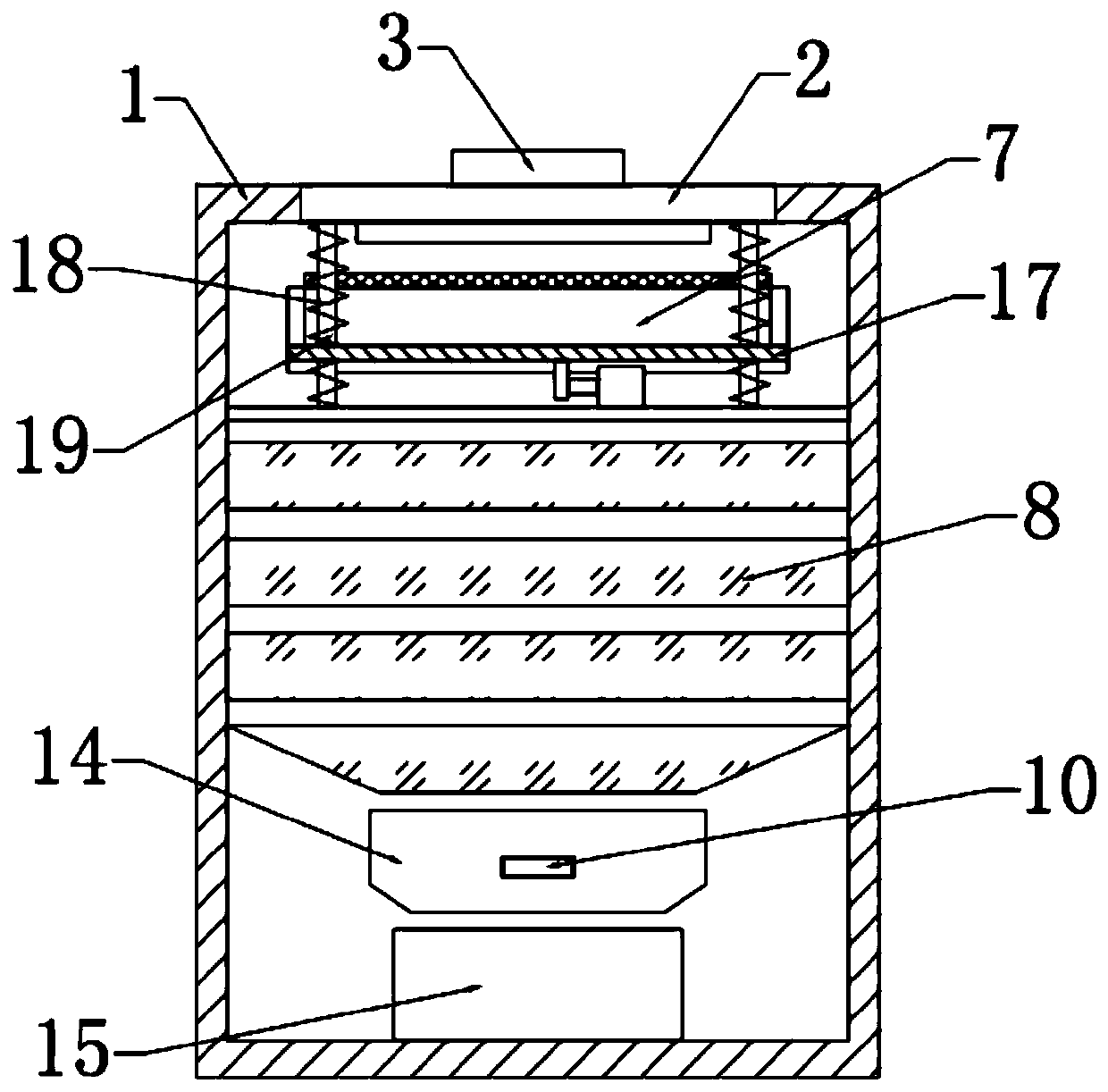

Agricultural grain drying device

InactiveCN110864539ADry evenlyAchieve orderly dryingSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, and particularly relates to an agricultural grain drying device. The agricultural grain drying device comprises a housing, wherein a top cover is hinged to the top of the housing; a first drying mechanism is arranged on the lower side of the top cover; a second drying mechanism is arranged on the lower side of the first drying mechanism; a discharging mechanism is arranged on the lower side of the second drying mechanism; a storage box movably connected with the housing is arranged on the lower side of the discharging mechanism; anda box door is arranged at the bottom end of the right side of the housing. According to the agricultural grain drying device, the first drying mechanism is arranged, so that grains can be preliminarily dried by utilizing a dryer; meanwhile, a driving mechanism is arranged, so that a filter plate can move up and down repeatedly, and the grains can be uniformly dried; in the process that the filterplate moves up and down repeatedly, the grains can be screened, and impurities are filtered; a plurality of drying plates are arranged, so that the drying time of the grains can be prolonged; and anexhaust window is arranged, so that moisture generated in the grain drying process can be discharged in time, and the grain drying effect is better.

Owner:长沙市天珍科技有限公司

Steel coil longitudinal shear printing management system and method based on big data

InactiveCN110802414AAvoid problems that delay downtimeEvenly stackedOther manufacturing equipments/toolsMaintainance and safety accessoriesElectric machineryProcess engineering

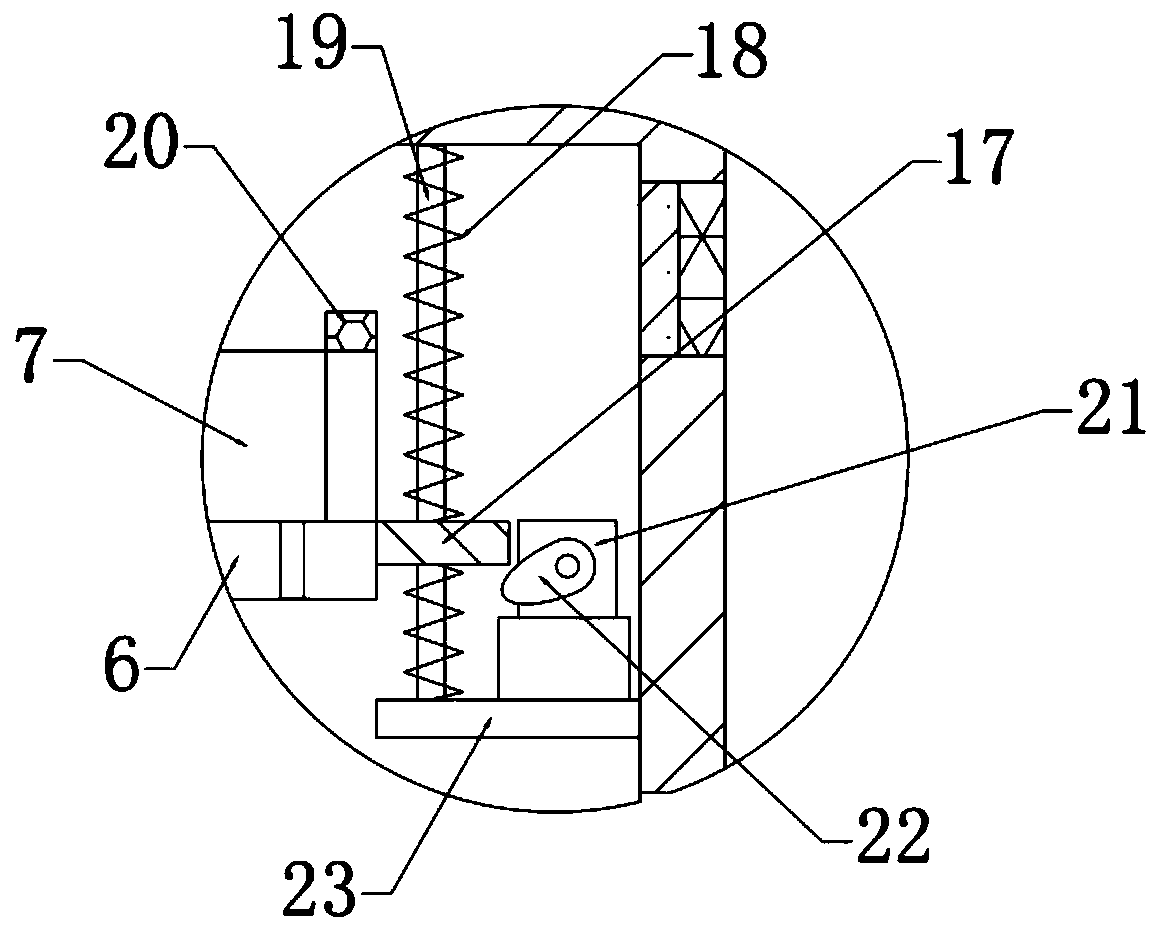

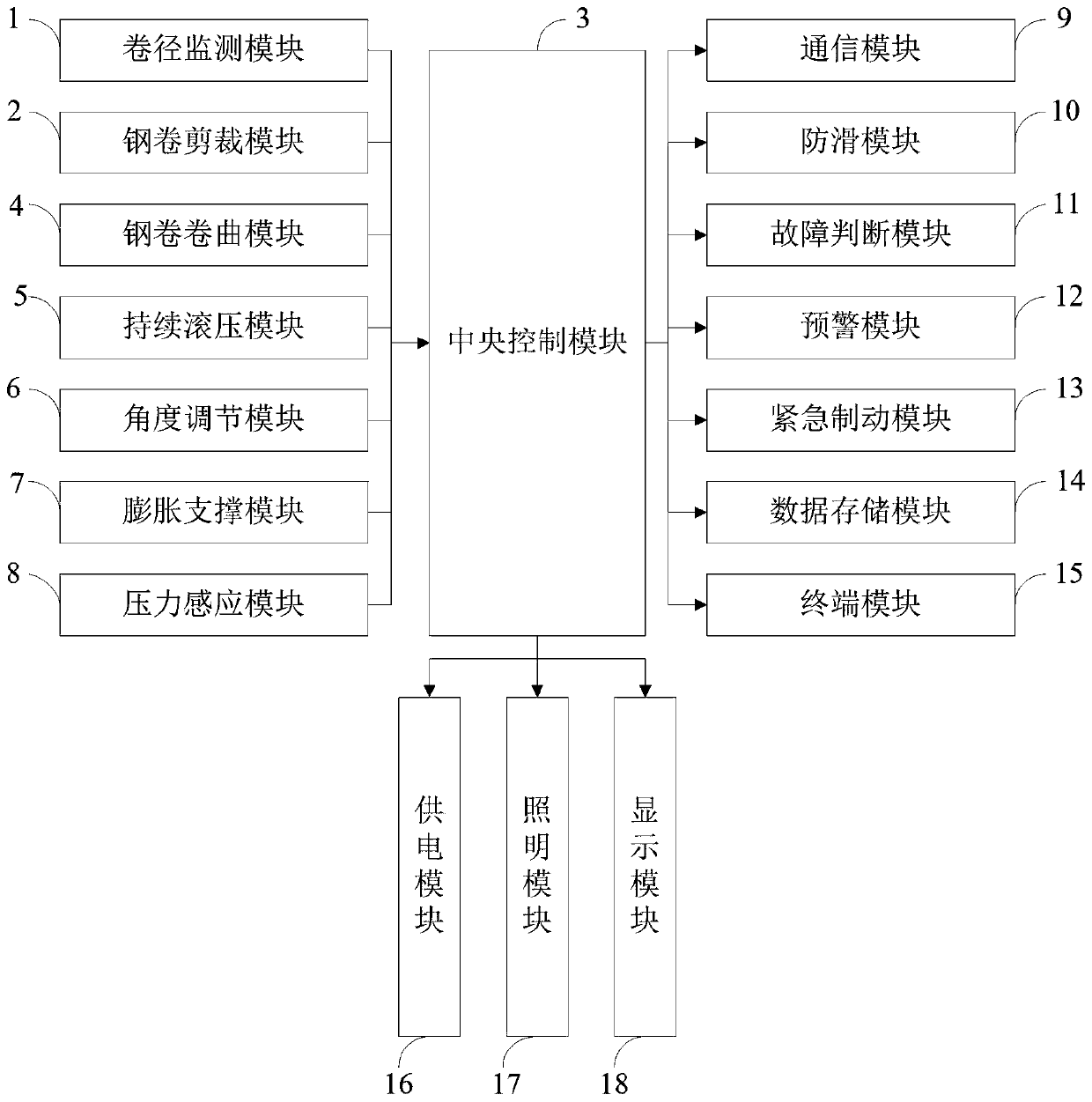

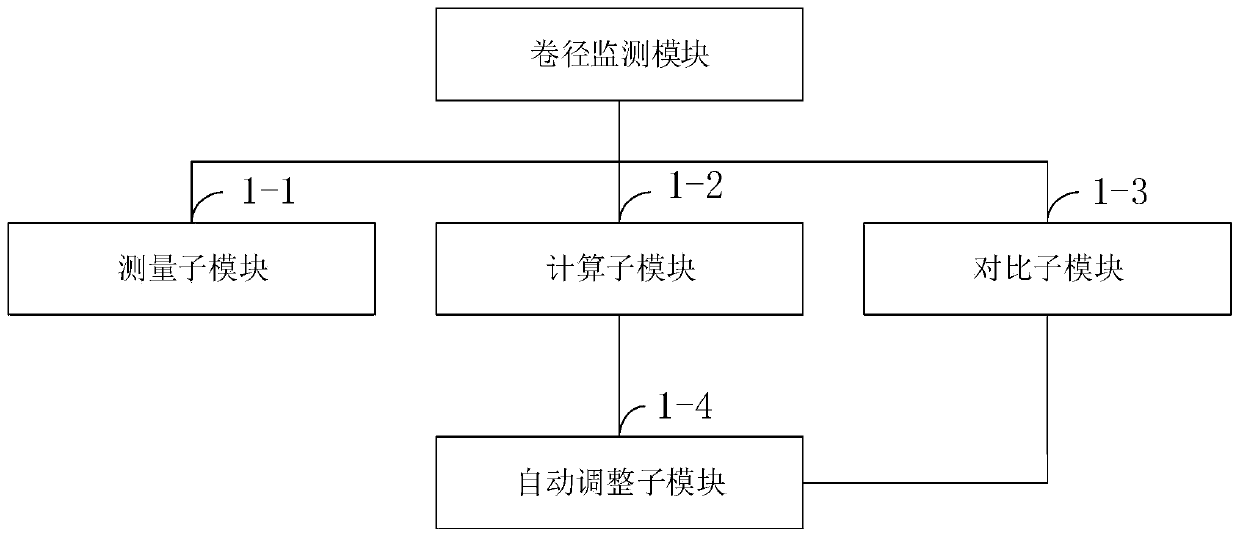

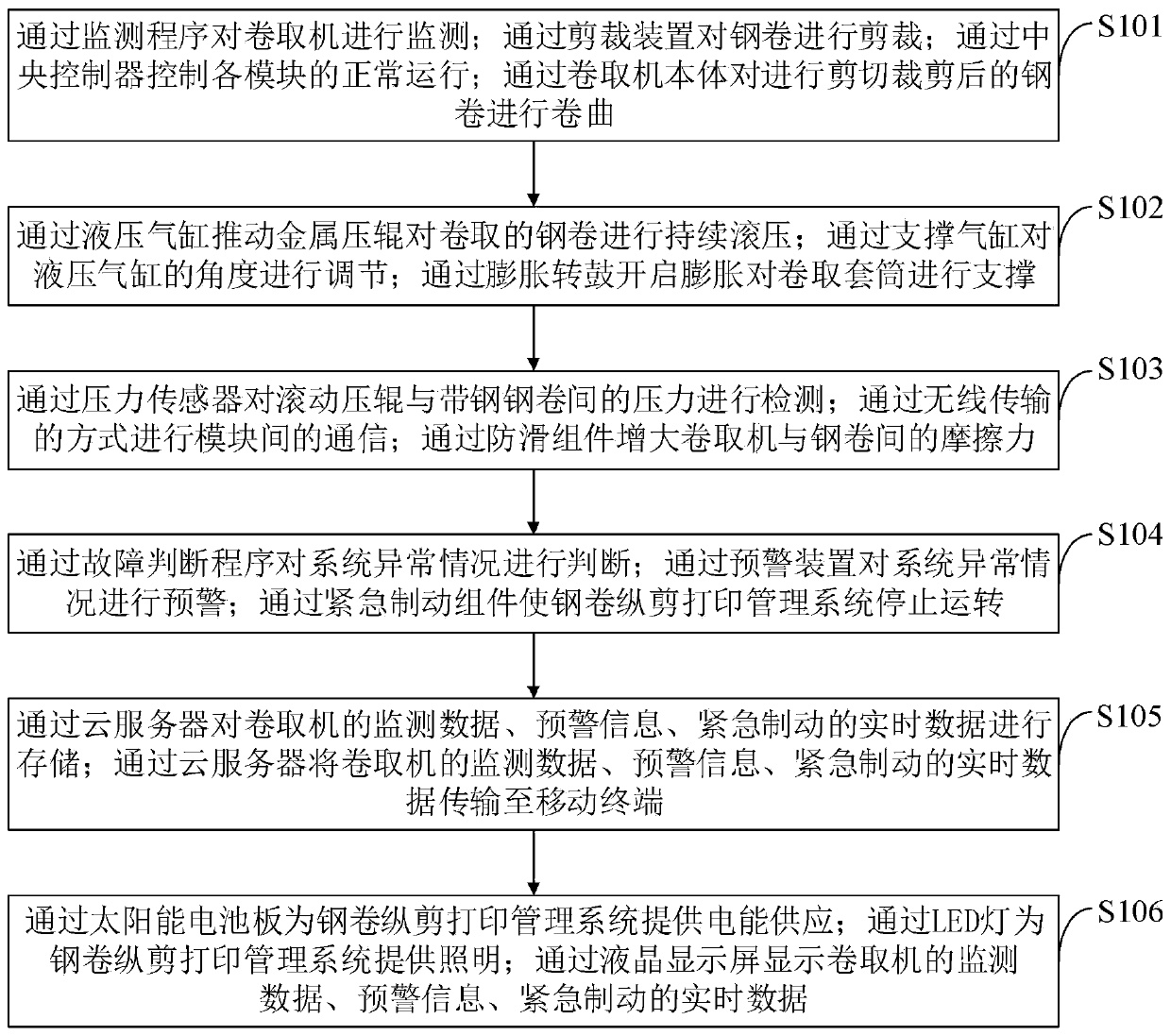

The invention belongs to the technical field of steel coil longitudinal shear printing, and discloses a steel coil longitudinal shear printing management system and method based on big data. The steelcoil longitudinal shear printing management system comprises a coil diameter monitoring module, a steel coil cutting module, a central control module, a steel coil crimping module, a continuous rolling module, an angle adjusting module, an expansion supporting module, a pressure sensing module, a communication module, an anti-skid module, a fault judgment module, an early warning module, an emergency braking module, a data storage module, a terminal module, a power supply module, an illumination module and a display module. According to the steel coil longitudinal shear printing management system, a coil diameter error monitoring module and an automatic adjusting sub-module are arranged in a rolling unit, the problem that the tension error between the two rolling machines is large so thatthe two rolling machines cannot normally run is avoided. According to the steel coil longitudinal shear printing management system, the scrap steel accident caused by the motor fault is automaticallyjudged, the scrap steel is guaranteed to be uniformly accumulated on a roller way, the scrap steel is prevented from tipping or twisting, and a good condition is created for subsequent scrap steel treatment.

Owner:宁波兰羚钢铁实业有限公司

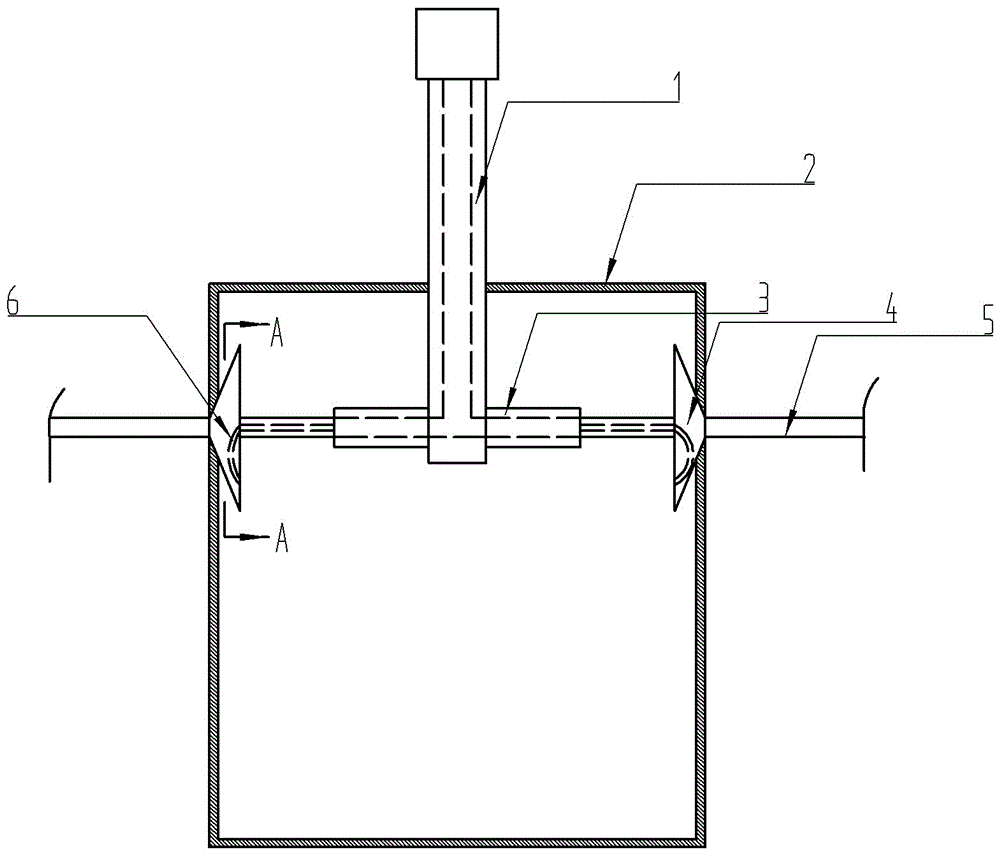

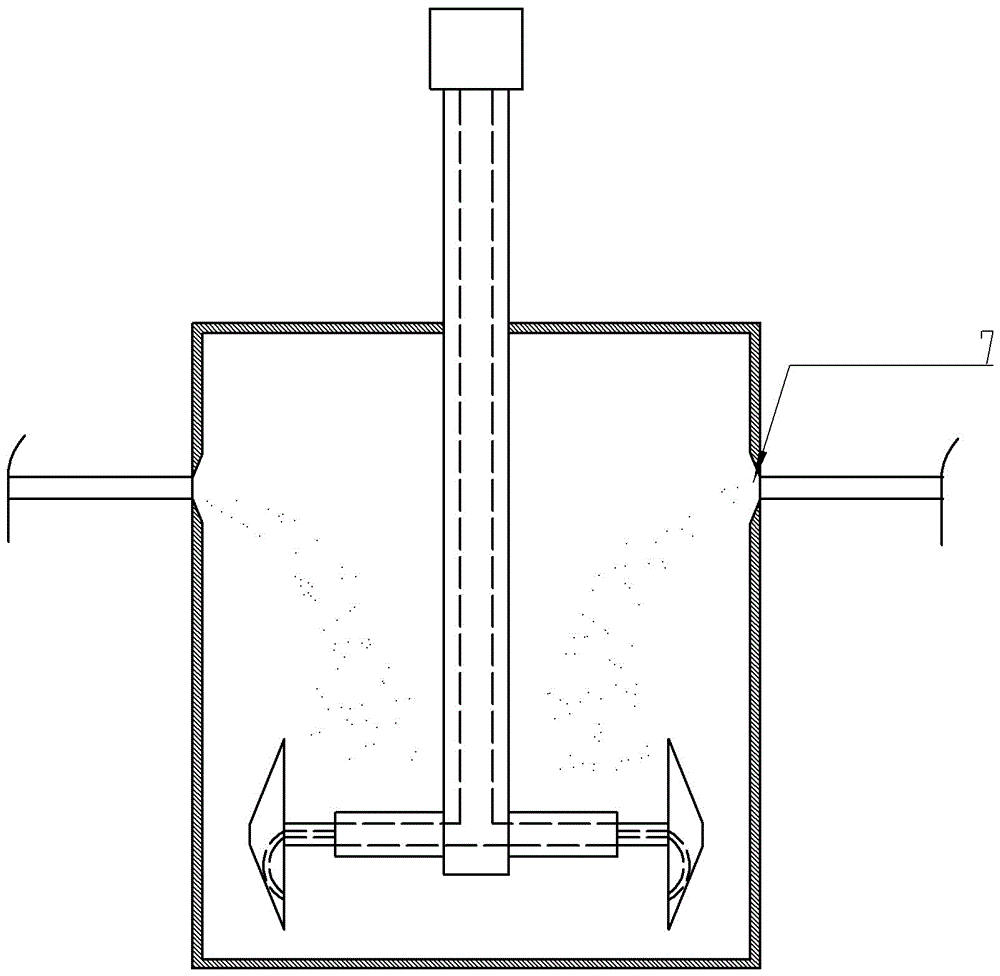

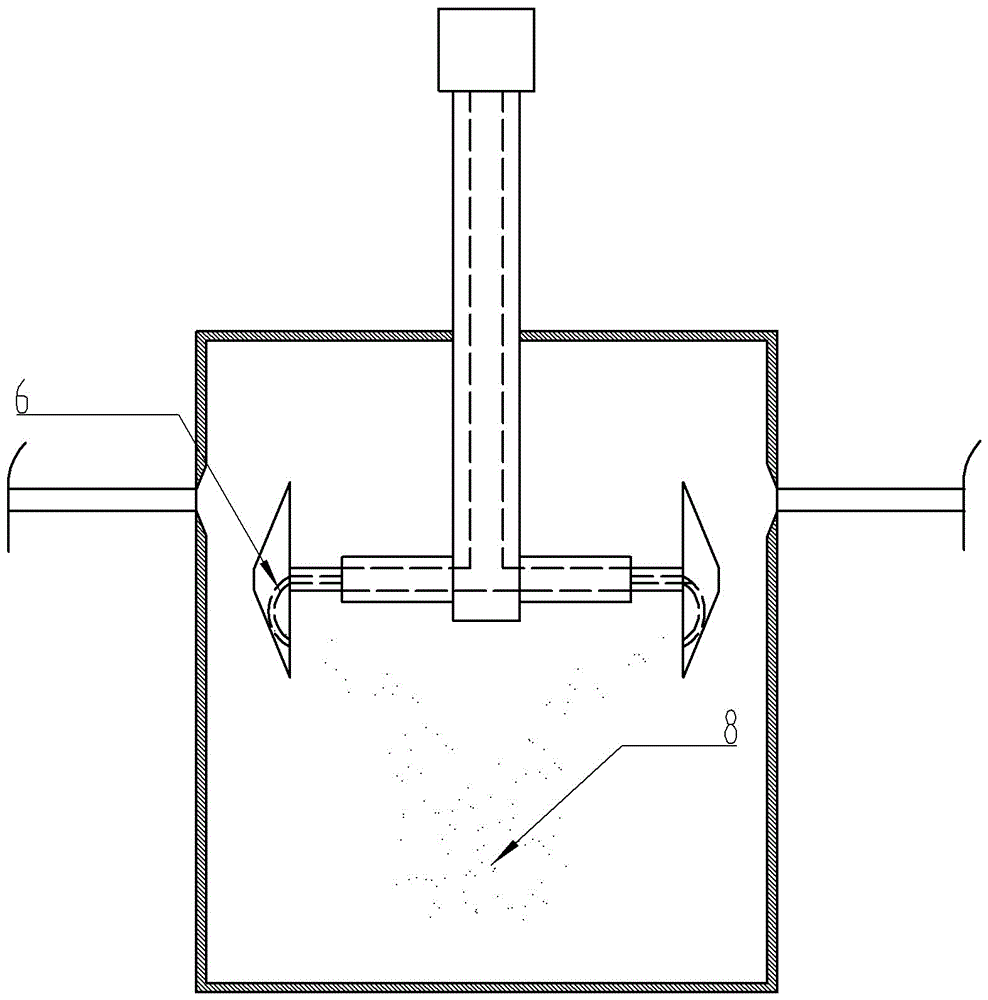

Stirring apparatus for producing coatings

PendingCN106492687AEvenly stackedImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringCoating

The invention discloses a stirring apparatus for producing coatings. The stirring apparatus comprises a housing and a stirring shaft extended into the housing, and also comprising a stirring cross beam perpendicularly fixed to the stirring shaft; the stirring cross beam is a hollow sleeve driven by a power mechanism to telescope; an end of the stirring cross beam is also provided with a stirring portion; the vertical section of the stirring portion is trapezoidal, one long side of the stirring portion is connected to the end of the stirring cross beam, the housing is provided with a through hole mating with one short side of the stirring portion, the stirring shaft is of hollow tubular structure and is communicated with the stirring cross beam that is also of hollow tubular structure, the stirring portion is also internally provided with a discharge passage, and the stirring shaft, the stirring cross beam and the discharge passage are communicated to form a passage allowing material to pass through; the discharge end of the discharge passage is positioned at the lower half of the long side of the stirring portion and is inclined close to the housing. The stirring apparatus has the advantages that material is pre-dispersed, stirring efficiency is improved, and coating production efficiency is improved.

Owner:CHONGQING ALL COLOR WORLD COATING CO LTD

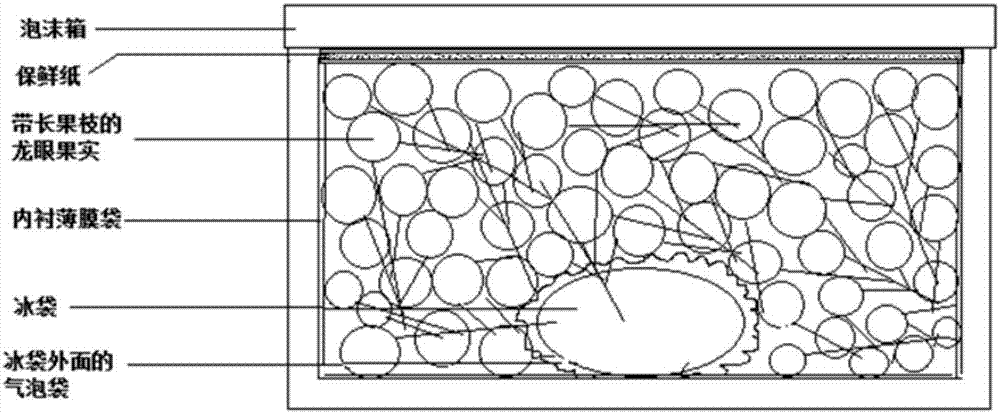

Longan-preserving method applicable for e-commerce logistics

PendingCN107347978AImprove product appearanceResidue reductionFruit and vegetables preservationIsolation effectLogistics management

The invention discloses a longan-preserving method applicable for e-commerce logistics. The method is described as follows: adopting a common foam box with an internally lined polyethylene film preservation bag to form outer packing; placing ice packs sleeved by bubble wrap which has an isolation effect in the central position of the bottom of the foam box; evenly placing longan fruits with fruit spurs around the ice packs and on the ice packs; after the ice packs are fully surrounded by the longan fruits, laying a piece of longan-preserving paper having the same area with the opening of the internal foam box on the longan fruits; laying a piece of isolation paper having the effects of insulating air and resisting humidity on the longan-preserving paper; and finally, folding the upper extra part of the preservation bag flatly, performing sealing, covering the foam box with a lid and sealing tightly around the lid with box-sealing tapes to prevent air leakage and cool leakage. The preservation method provided by the invention can not only increase a good-quality fruit rate and extend the shelf life and the subsequent refrigeration life of the longan fruits but also reduce the residual amount of SO2 in the fruits and improve the uniformity of the SO2 content of the piled fruits.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

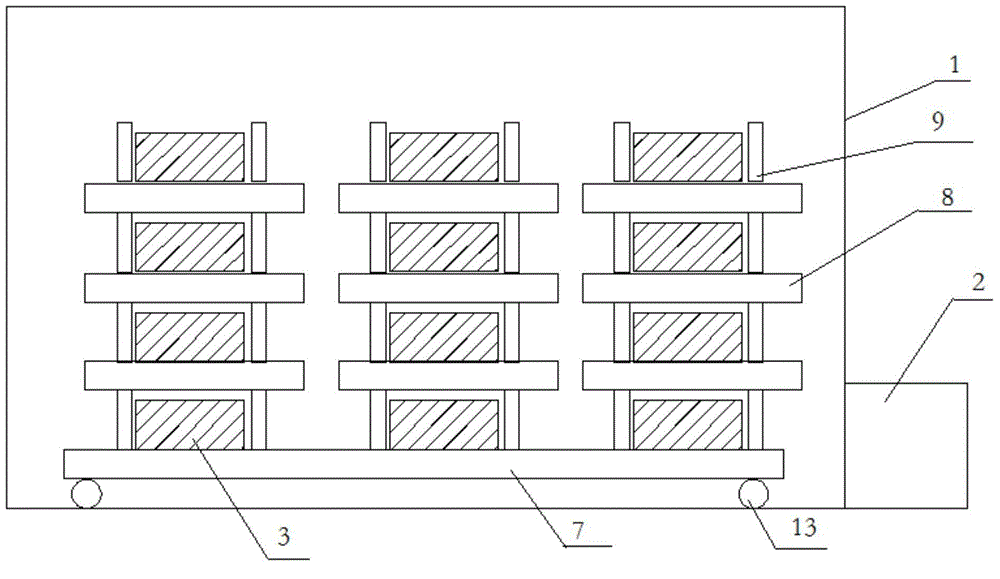

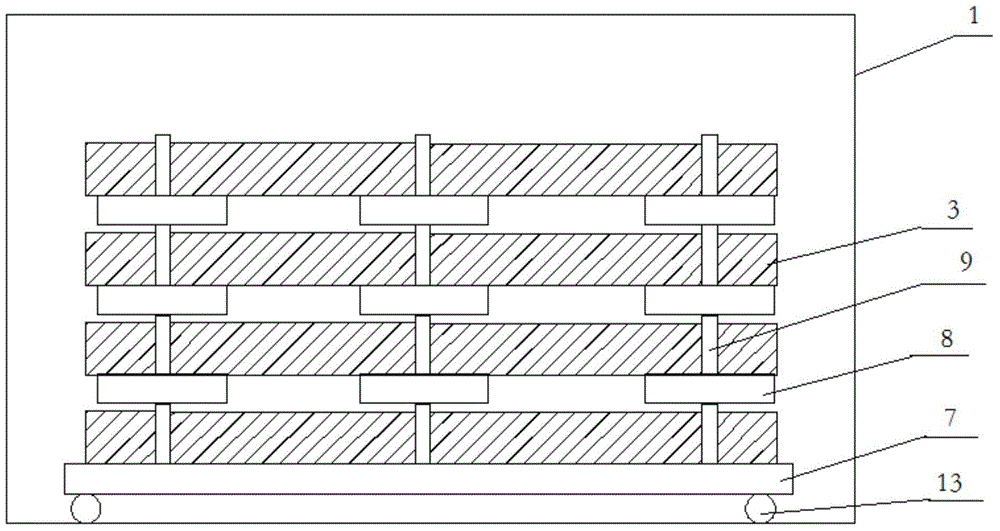

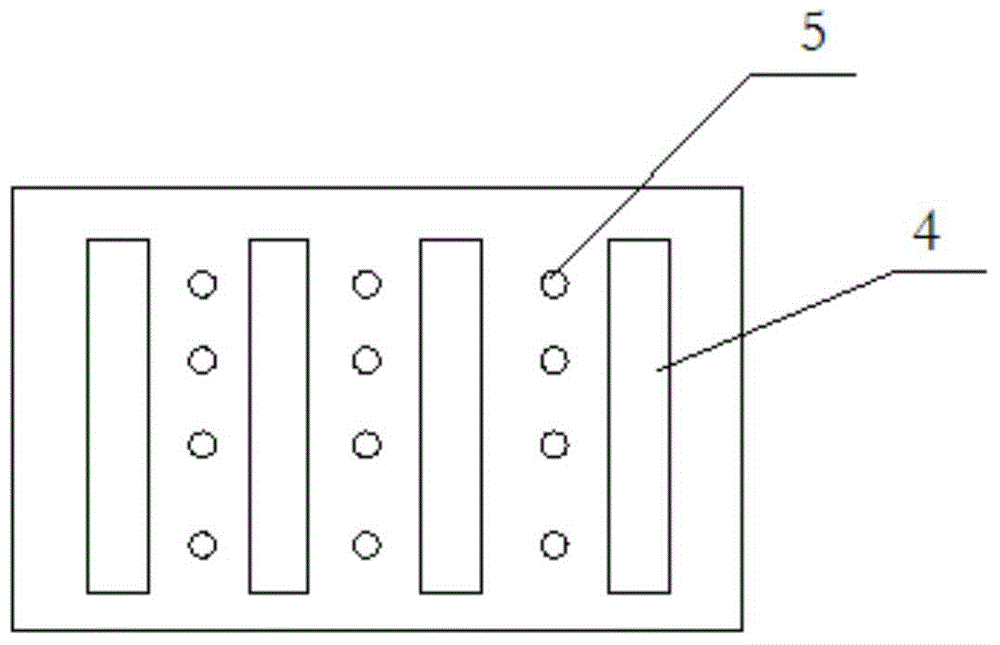

Drying device for wood

InactiveCN105020980AImprove drying efficiencyEvenly stackedDrying chambers/containersDrying machines with local agitationPulp and paper industryAir convection

The invention provides a drying device for wood. The drying device comprises a drying box, a water box and a wood support. The water box is arranged beside the drying box. A heating device is arranged in the water box. Steam inlets are formed in the front side wall and the rear side wall of the drying box. The wood support comprises a bottom plate and a plurality of wood separation devices used for separating the wood when the wood is stacked. The wood separation devices are arranged on the bottom plate side by side. Each wood separation device comprises at least two wood supporting devices. Through the wood support, the wood can be stacked more uniformly and separated sufficiently, and thus air in the drying box can be in sufficient contact with the wood, and the drying effect on the wood is enhanced. Due to the fact that air inlets and air outlets of the drying box are arranged oppositely, the wood is heated and dried by means of air convection, the flowing air can bring water evaporated from the wood in time, and the wood drying efficiency is improved.

Owner:TIANJIN HEYUAN FURNITURE

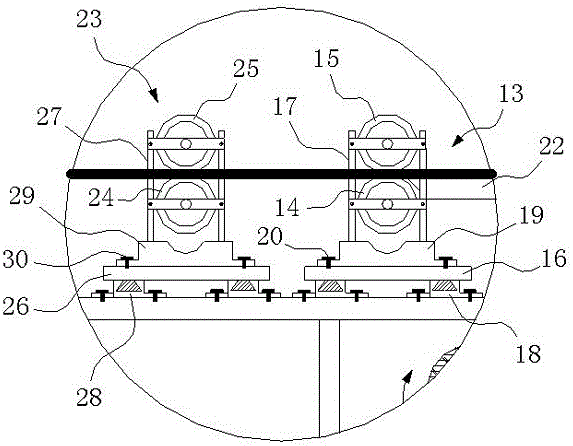

Web spreading method and device for preparation of filament non-woven fabric through wet spinning technique

The invention discloses a web spreading method for preparation of a filament non-woven fabric through a wet spinning technique. The method comprises steps as follows: (1), preparation of filament fiber bundles; (2), drafting of the filament fiber bundles; (3), forming of uniform flaky fiber bundles; (4), conveying of the uniform flaky fiber bundles; (5), inclination compensation treatment on the uniform flaky fiber bundles; (6), spreading of a filament fiber web. The invention further discloses a web spreading device. A fiber web forming mechanism used for crossing and stacking the uniform flaky fiber bundles which are to fall on a web curtain in the breadth direction of the web curtain is arranged at an output end of a conveying roller, an inclination compensation mechanism used for transversely drafting the uniform flaky fiber bundles in an inclined state back and forth in the direction opposite to the fiber web forming mechanism when the fiber web forming mechanism moves is arranged between the conveying roller and the fiber web forming mechanism. With the adoption of the method and device, the wet fiber bundles can form a uniform flaky fiber web on the web curtain, wet-process web forming is realized, and the quality of the filament non-woven fabric is effectively improved.

Owner:YANGZHOU JIYUAN TEXTILE

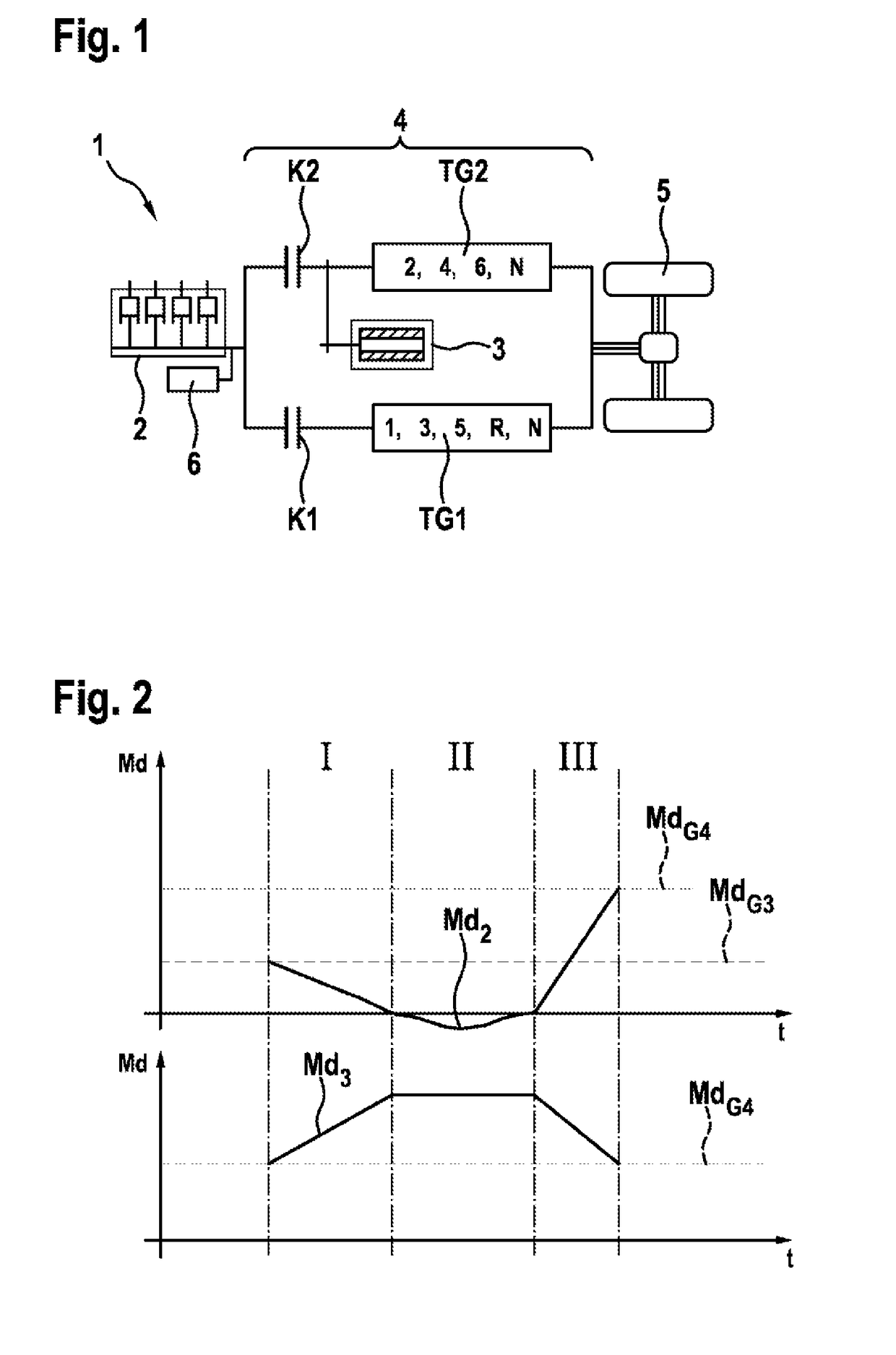

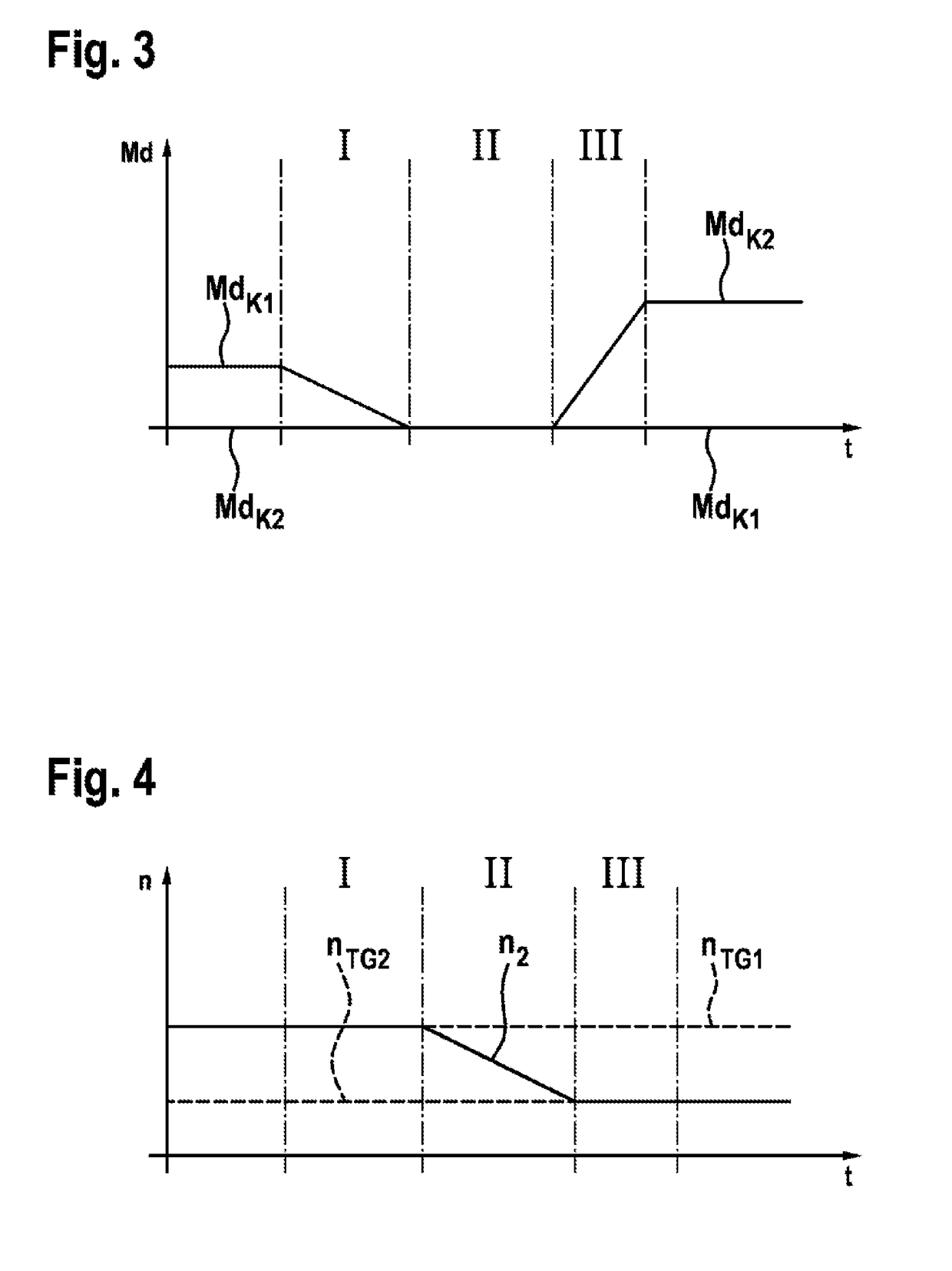

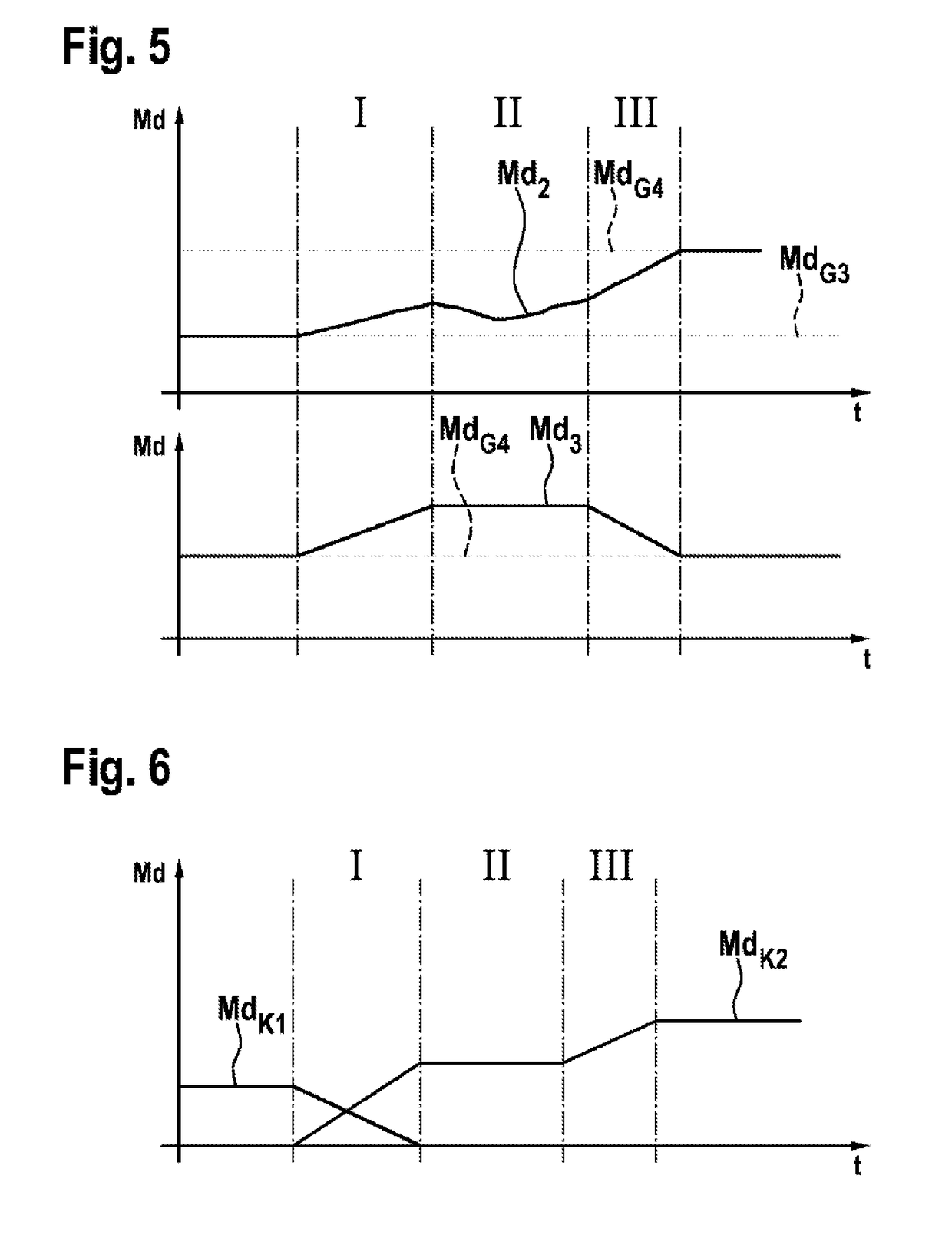

Method and device for operating a drive device, drive device

ActiveUS20190084575A1Security advantageEvenly stackedHybrid vehiclesGas pressure propulsion mountingElectric machineInternal combustion engine

The invention relates to a method for operating a drive device (1) of a motor vehicle, having an internal combustion engine (2), an electric machine (3), and a dual-clutch transmission (4). The dual-clutch transmission (4) has two clutches (K1, K2), by means of which the transmission can be connected to the internal combustion engine (2). At least the internal combustion engine (2) is actuated in a driving operation in order to generate a target drive torque, and the clutches (K1, K2) are actuated in opposite directions for a gear shift. During a gear shift, the electric machine (3) which is connected to the dual-clutch transmission (4) without a clutch is actuated such that the electric machine completely or partly generates the target torque at least temporarily.

Owner:ROBERT BOSCH GMBH

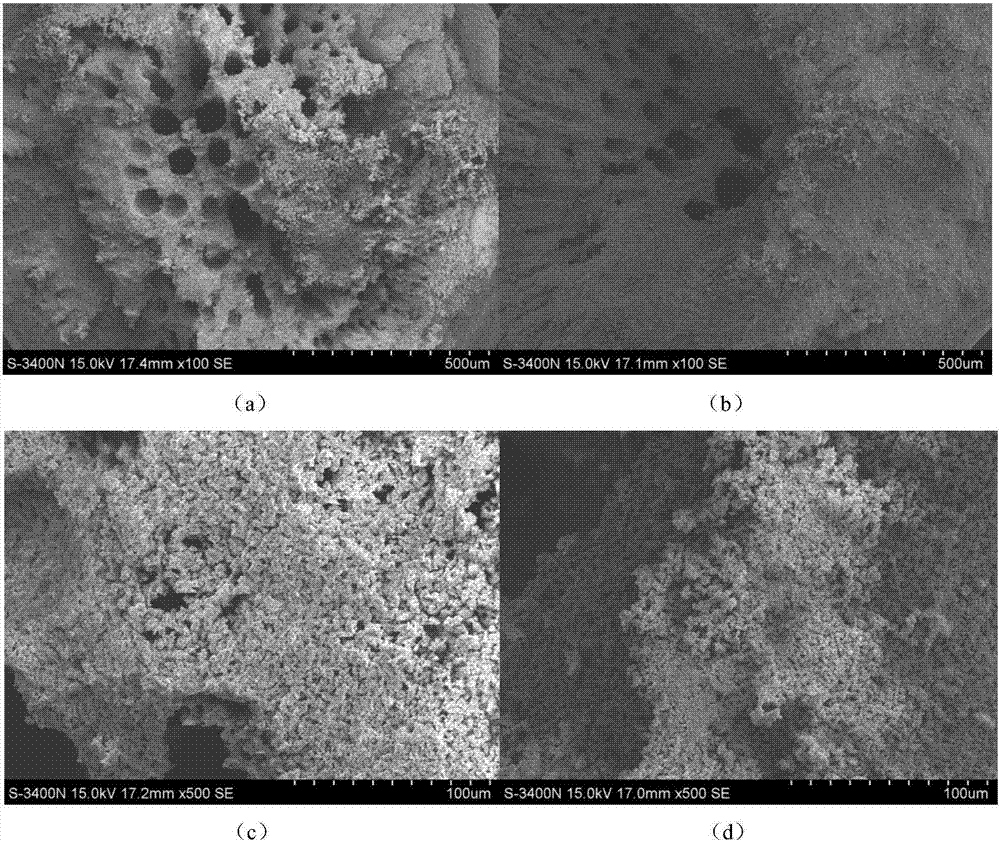

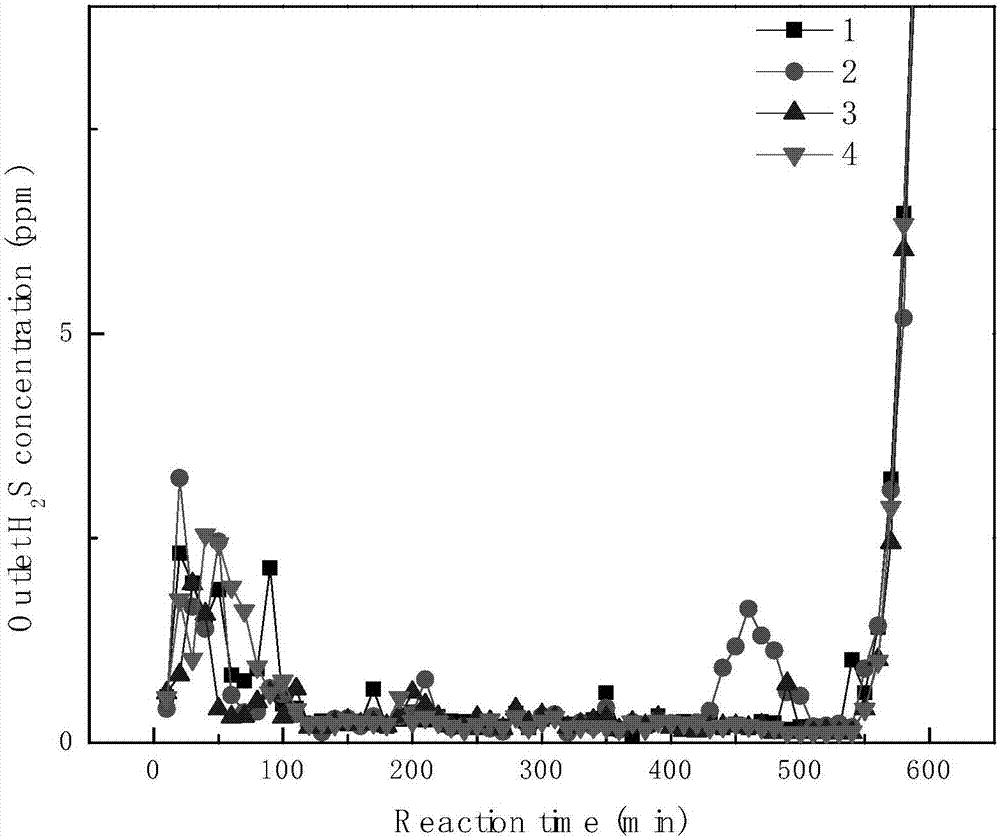

Preparation method of zirconium ball carrier, and application of zirconium ball carrier to manganese-based desulfurizing agent

ActiveCN107213918AHigh fracture toughnessImprove toughnessCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHigh energyWear resistant

The invention discloses a preparation method of a zirconium ball carrier, and application of the zirconium ball carrier to a manganese-based desulfurizing agent. During the preparation, zirconia is used as a carrier support body; polyether sulfone is used as a bonding agent; polyvinylpyrrolidone is used as a dispersing agent; through two-way substitution of N-methyl pyrrolidone and water, a sphere is formed by a wet process in water; after high-temperature sintering, a spherical wear-resistant carrier of a porous structure is formed, i.e., the zirconium ball carrier is obtained. A bran-new carrier preparation method is used; the porous wear-resistant spherical carrier is prepared by a phase inversion method; the spherical carrier is suitable for the preparation of all impregnated catalysts; the problems that the air resistance of a conventional powder catalyst is great, so that the spherical carrier can be swept and taken away by airflow during experiment, and the like are solved. When the carrier is used for preparing a high-temperature manganese-based desulfurizing agent, a high-precision renewable desulfurizing agent is obtained; the desulfurizing agent can be used for removing H2S in an IGCC (Integrated Gasification Combined Cycle); the technical support is provided for electric field electricity generation of an SOFC (Solid Oxide Fuel Cell) with high energy utilization efficiency.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com