Drying device for wood

A drying device and wood technology, applied in the directions of drying, drying machine, heating device, etc., can solve the problems of unsatisfactory drying effect of products, uneven heat dissipation of wood, poor air flow, etc., to improve drying effect, Simple structure and uniform stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

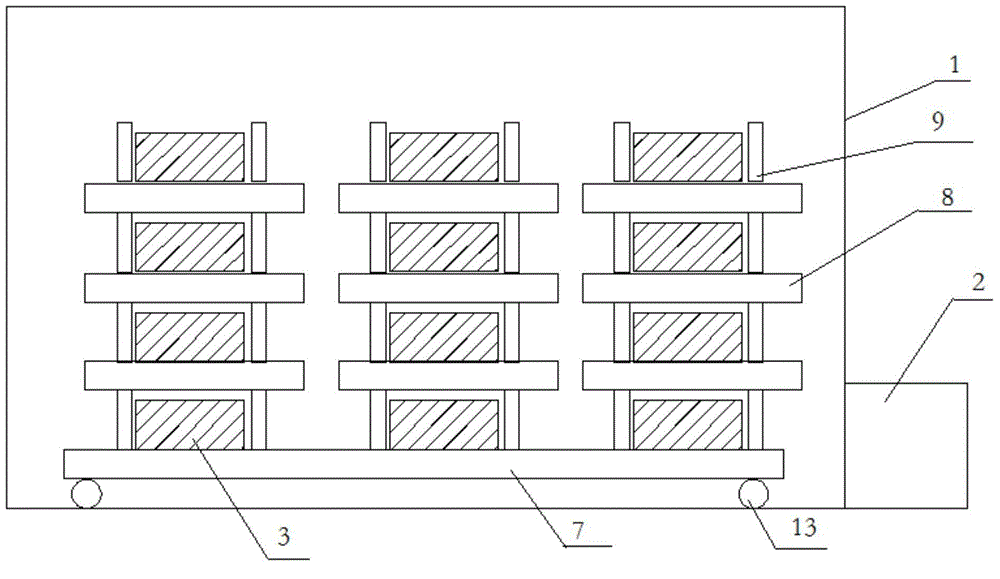

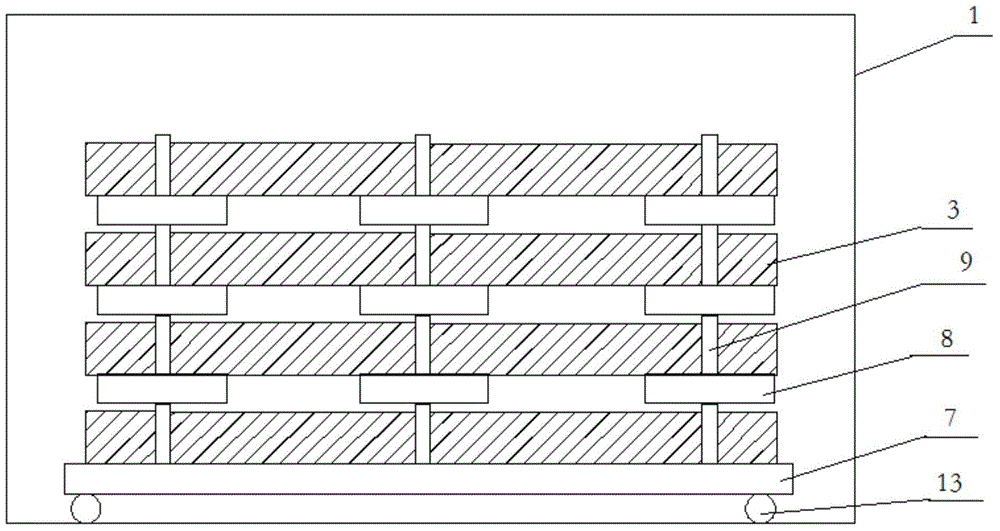

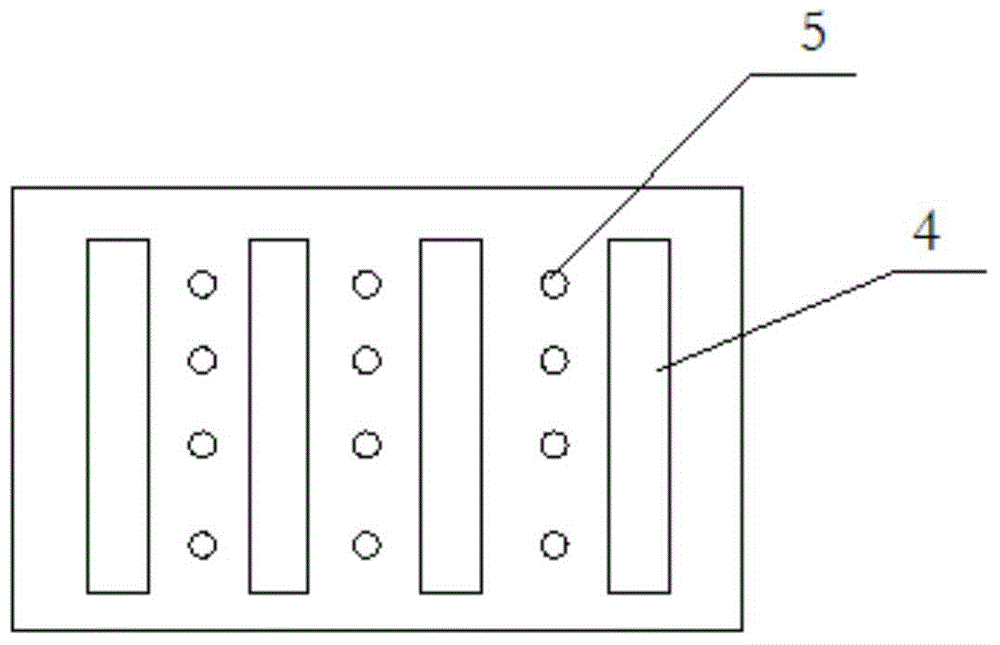

[0024] Such as Figures 1 to 6 As shown, a drying device for wood includes a drying box 1, a water tank 2 and a wood support, the water tank 2 is arranged beside the drying box 1, and a heating device is arranged in the water tank 2, The heating device heats the water in the water tank 2 into water vapor and sends it into the drying box 1. There is an air outlet on the top of the water tank 2, and the air outlets are evenly distributed on the front side wall and the rear side wall of the drying box 1. There are several steam inlets, the steam inlets are connected to the air outlet of the water tank 2 through the air inlet pipe, and the wood 3 is humidified before drying the wood 3 to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com