Patents

Literature

123results about How to "High fracture toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer-and polymer blend-bioceramic composite implantable medical devices

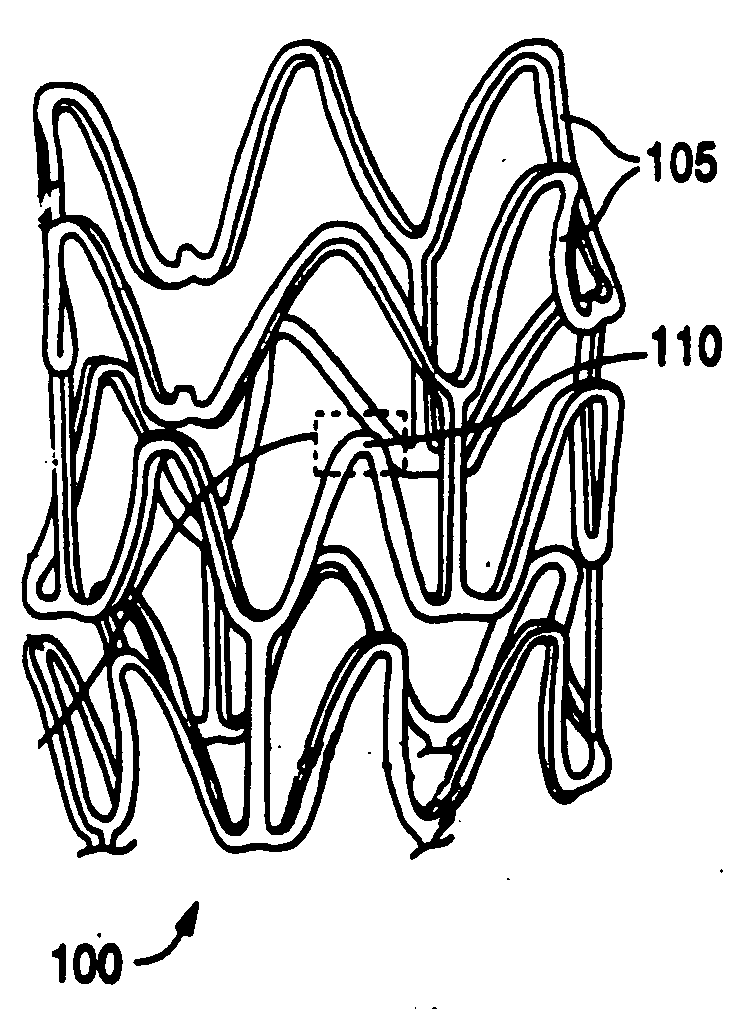

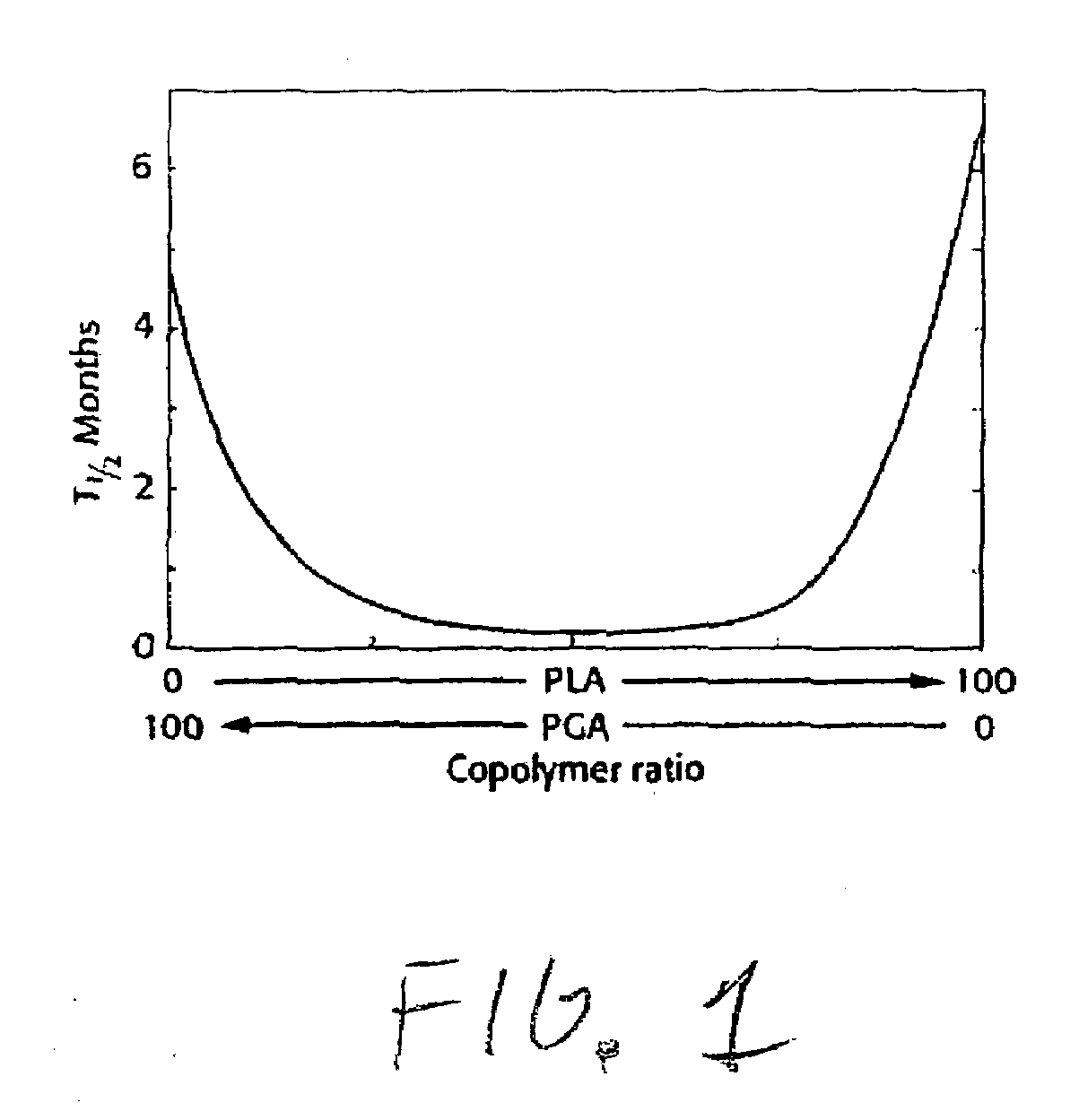

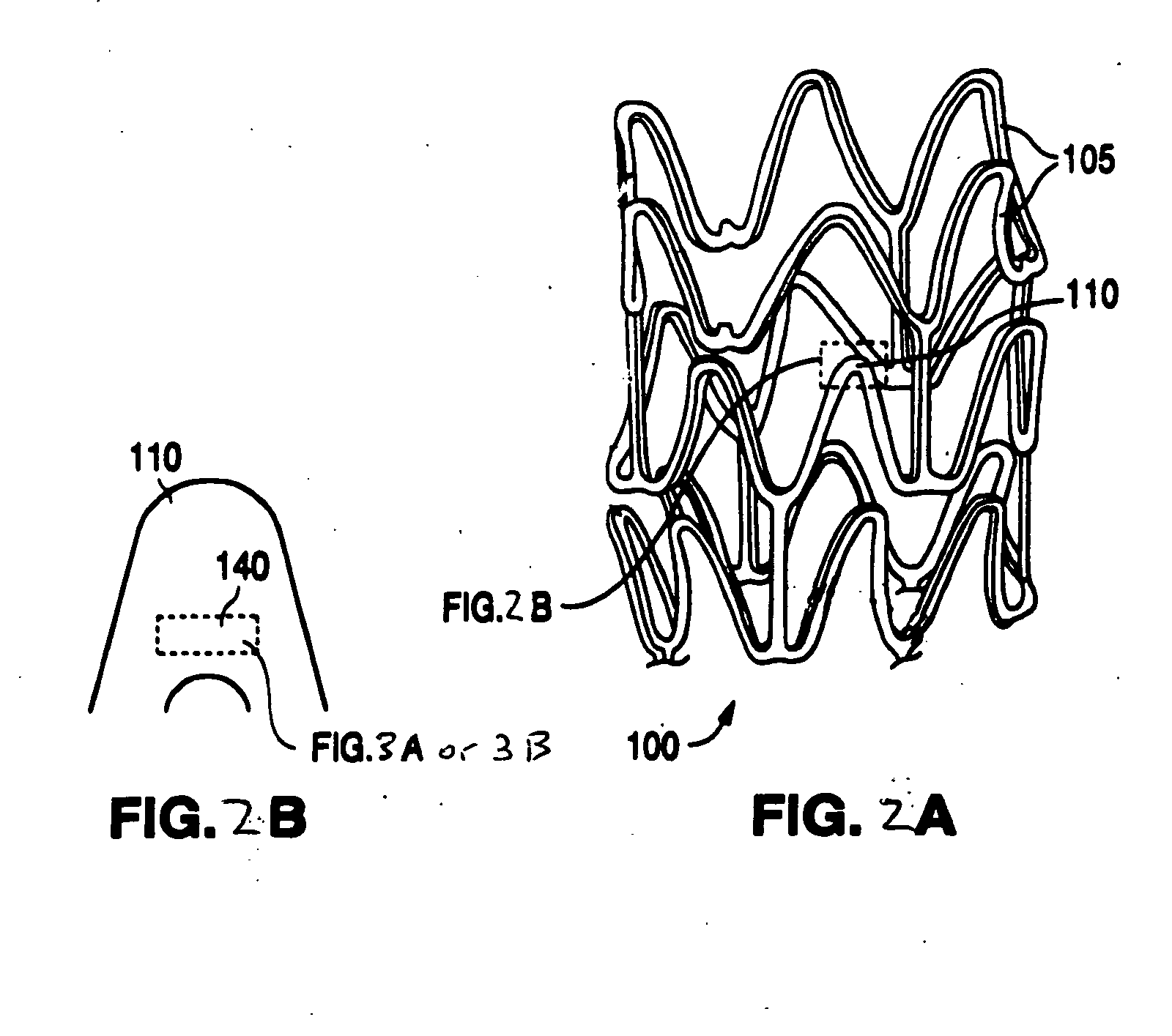

InactiveUS20070282426A1High fracture toughnessHigh degradation rateSurgeryBlood vesselsBioceramicBiomedical engineering

Implantable medical devices fabricated from polymer / bioceramic composites and polymer blend / bioceramic composites are disclosed.

Owner:ABBOTT CARDIOVASCULAR

Diamond-silicon carbide combination drill teeth for petroleum probe boring and manufacture method thereof

The invention relates to a diamond-silicon carbide composite drilling tooth used for oil drilling, the material of a substrate is hard alloy, and the material of a tooth crown is a diamond-silicon carbide compound in nano-structure. The microstructure of the diamond-silicon carbide compound in the nano-structure is formed by the direct combination of micron-sized diamond grains, and nano-silicon carbide binder and nano-diamond grains are filled in the slits of the micron-sized diamond grains. The preparation method of the composite drilling tooth comprises the steps that: diamond powder and silica powder are ground by a ball grinder after being mixed, then ground mixed powder material is mixed with carbon nanotube fiber to form diamond-amorphous silicon-carbon nanotube fiber mixed powder material which is put into a die, and the substrate is covered and treated with pressure forming to form a blank; high pressure sintering is carried out to the blank. The product greatly improves the fracture toughness and the anti-impact strength of the material on the premise of keeping the high hardness, high wearing resistance and high heat stability of the diamond-silicon carbide composite.

Owner:贺端威 +1

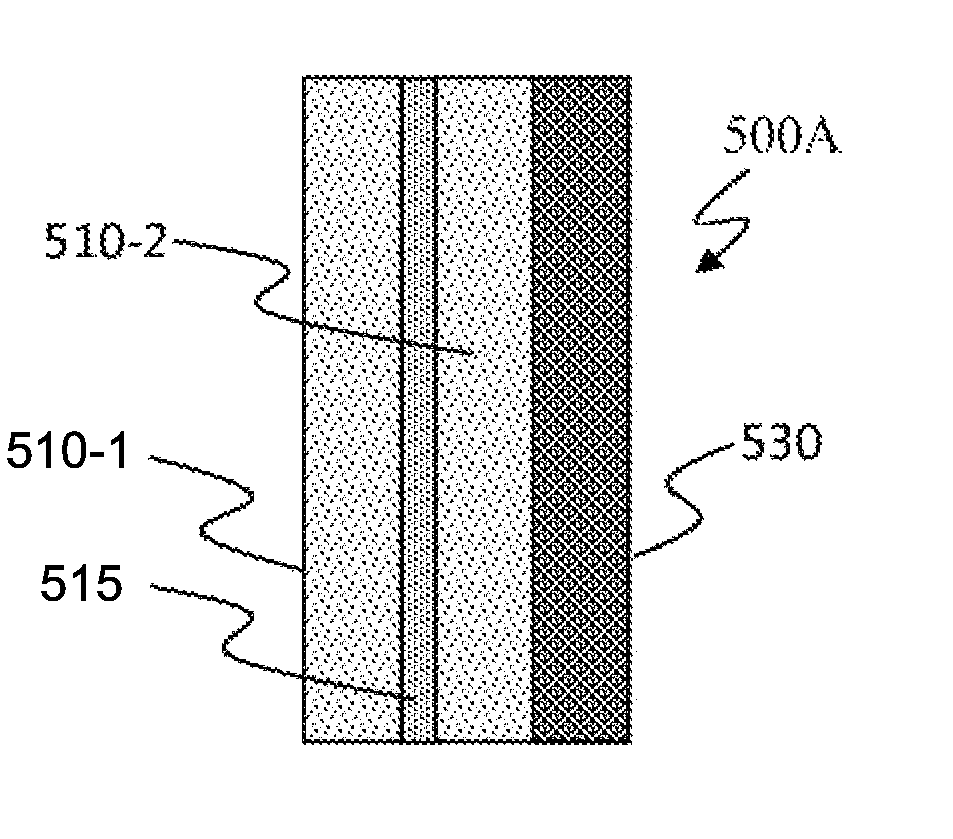

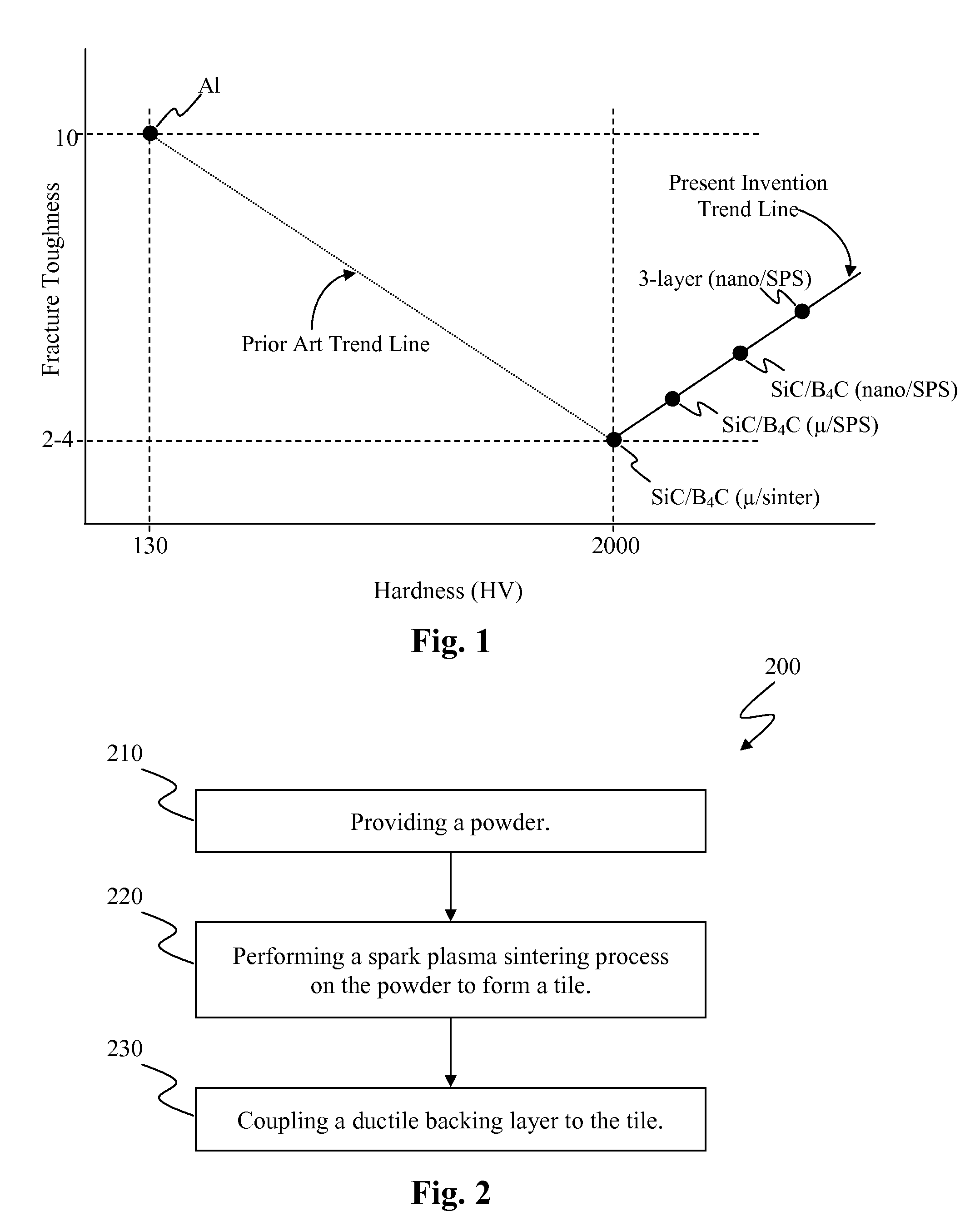

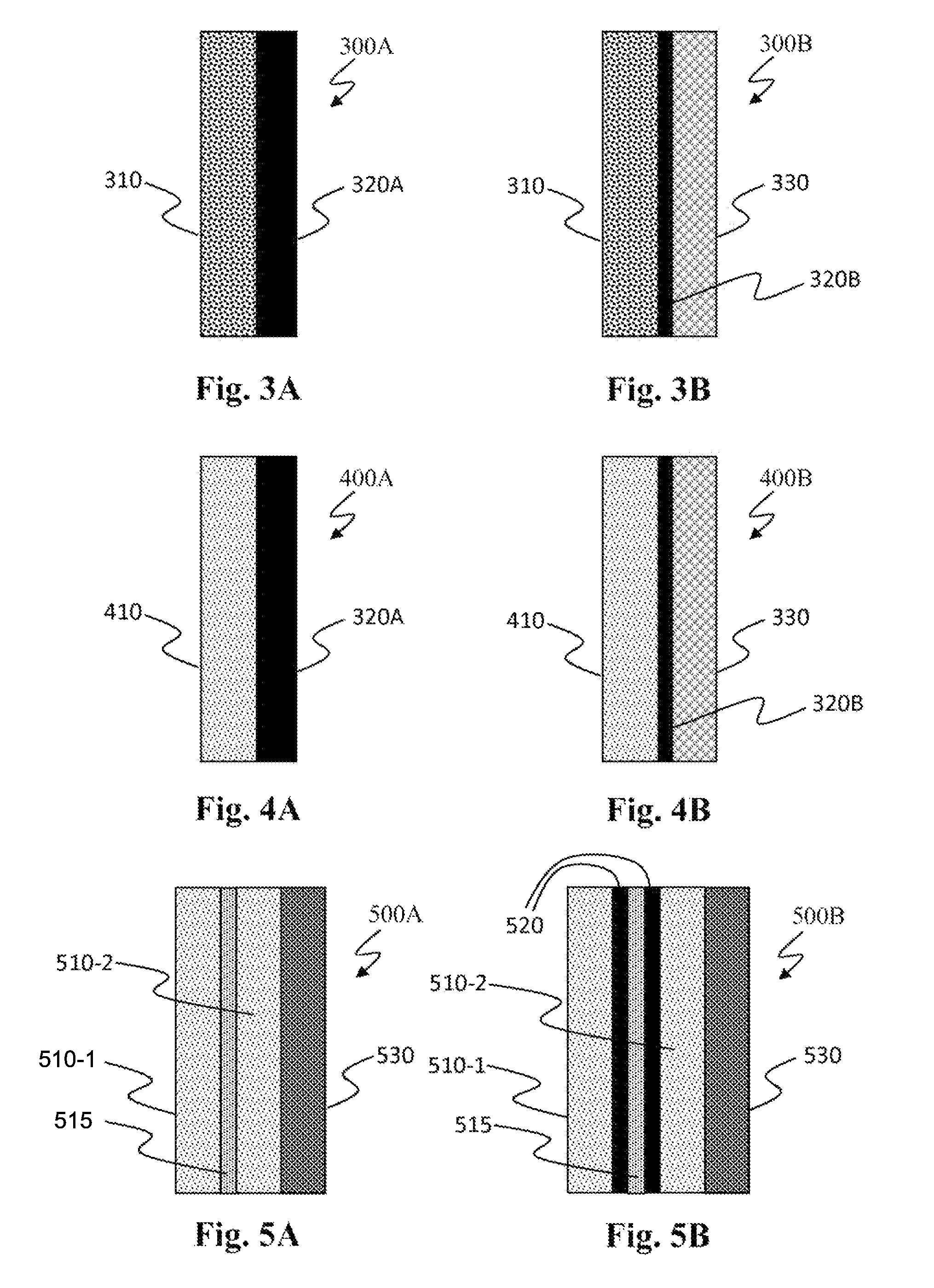

Sandwich of impact resistant material

InactiveUS8668803B1High fracture toughnessHigh hardnessMaterial nanotechnologyMolten spray coatingNanometreHardness

Owner:UMICORE AG & CO KG +1

Tough cordierite glass-ceramics

An internally nucleated, toughened cordierite glass-ceramic is disclosed. The cordierite glass-ceramic has good oxidation resistance and fracture toughness and coefficient of thermal expansion rivaling that of silicon nitride. The glass-ceramic may be cast as a liquid. Annealing produces a material of high crystallinity combining high hardness, high Young's modulus, good thermal stability, high strength, low density and good dielectric properties. The glass-ceramic comprises interlocking crystalline phases dominated by cordierite and a second phase having an elongated or acicular structure. A third phase may comprise a crystalline ceramic that promotes acicularity of the second phase. The third phase is preferably capable of twinning.

Owner:CORNING INC

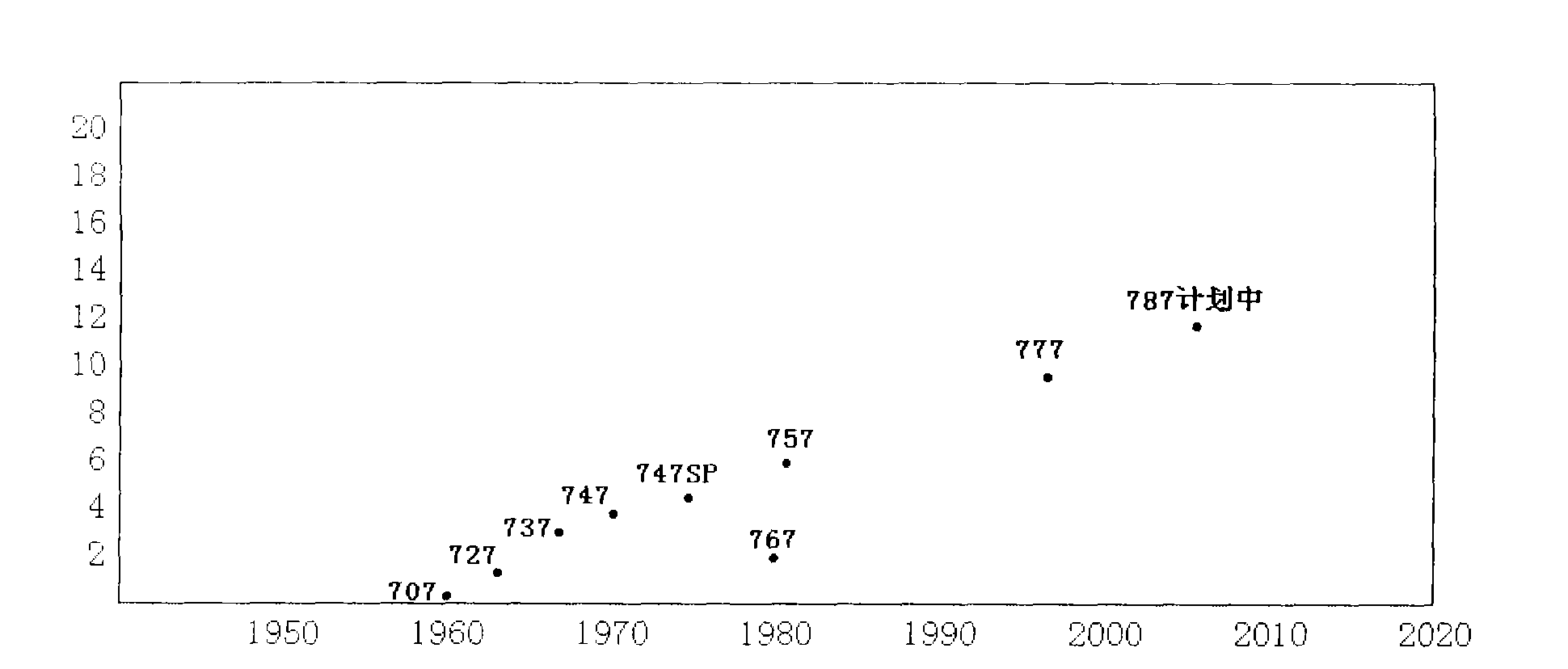

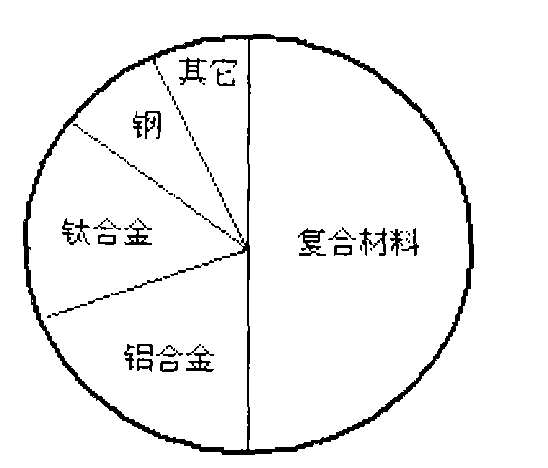

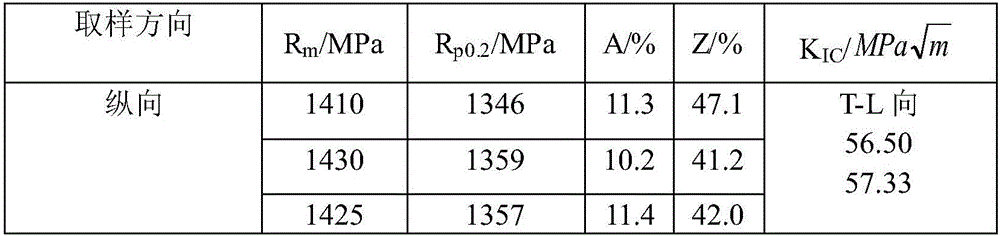

Ti alloy with high performance

The invention relates to a Ti alloy new material with high performance. The alloy has the chemical components by weight percent: 3-7 percent of Al, 1-6 percent of Mo, 0.5-6 percent of V, 1-4 percent of Sn, 1-4 percent of Zr, 0.5-3 percent of Cr, 0.5-3 percent of Nb, 0.01-0.3 percent of Si, and the balance of Ti. The high performance Ti alloy has favorable comprehensive performance, is in the leadin the worldwide and has the breakthrough points that the strength and the plasticity are kept at the highest level, the fracture toughness of the Ti alloy are greatly enhanced, the use performance ofTi alloy parts is improved, and the comprehensive performance of planes of the country is further improved.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

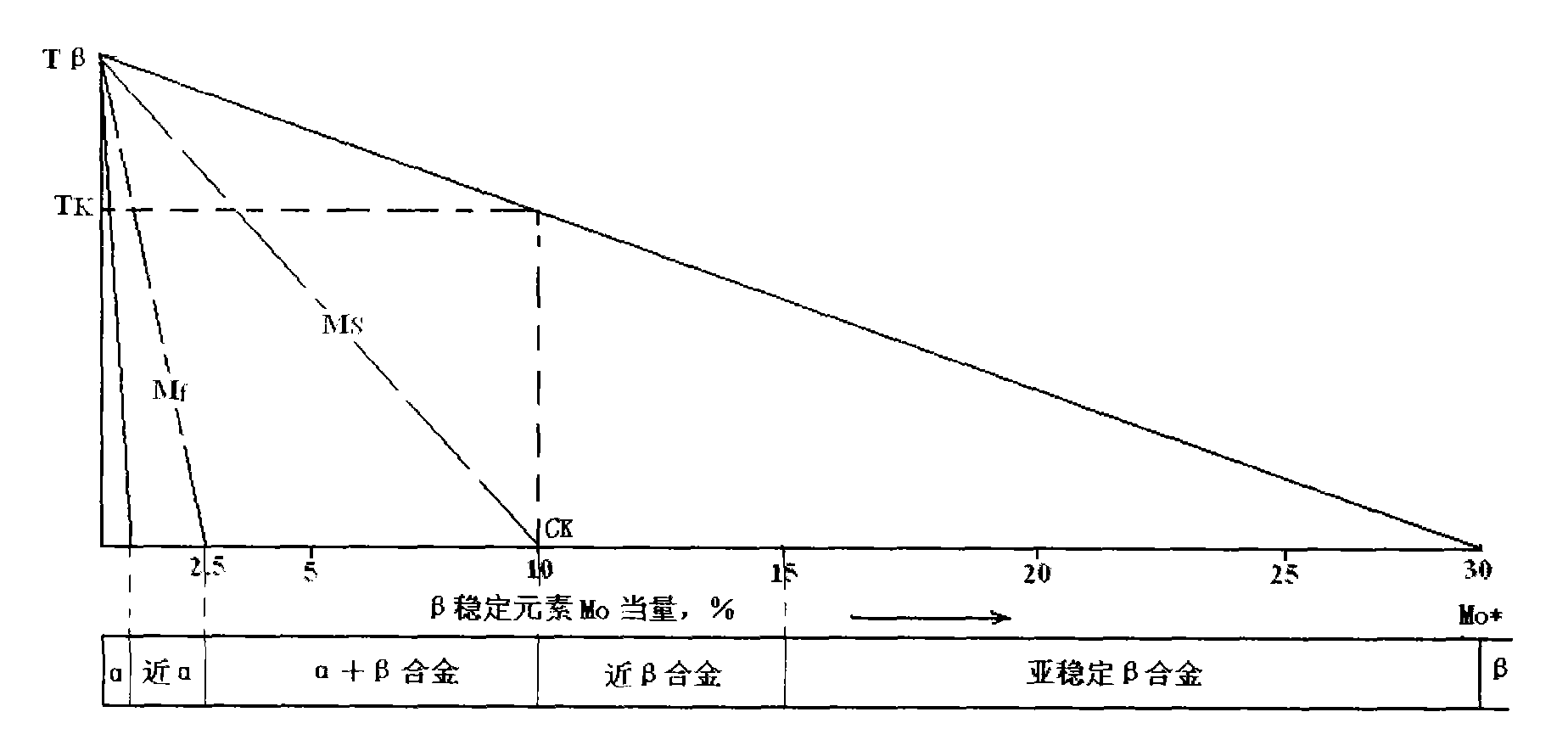

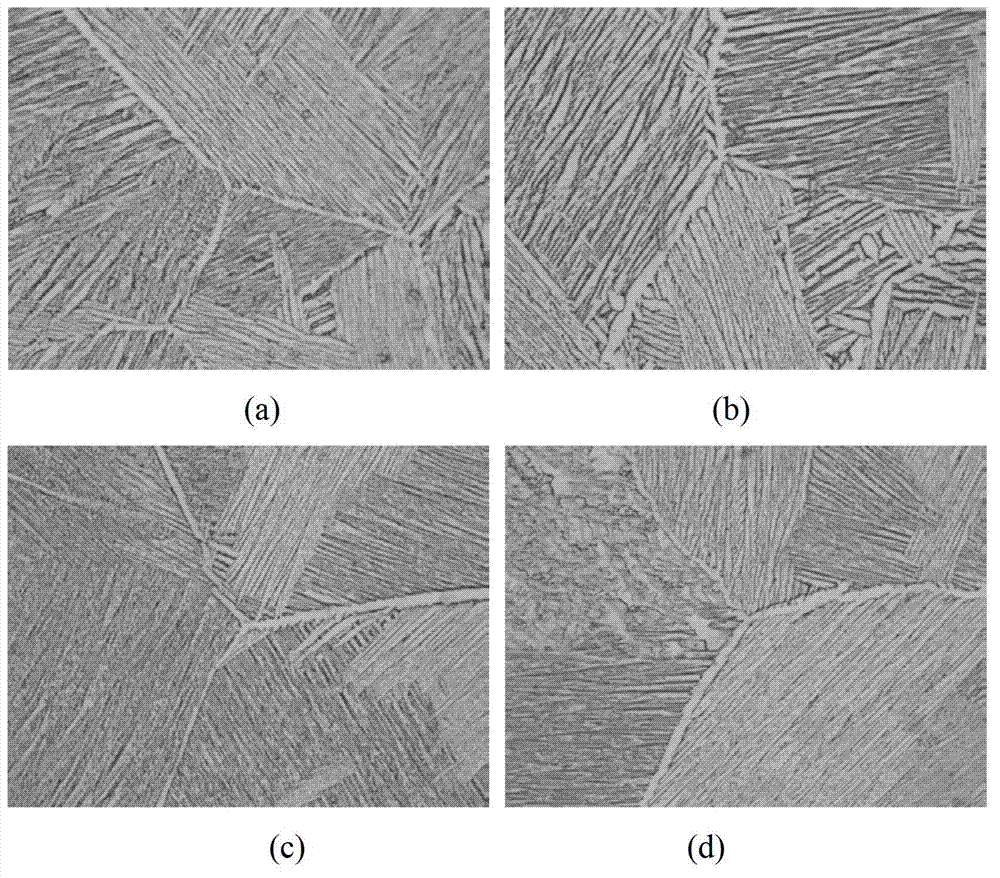

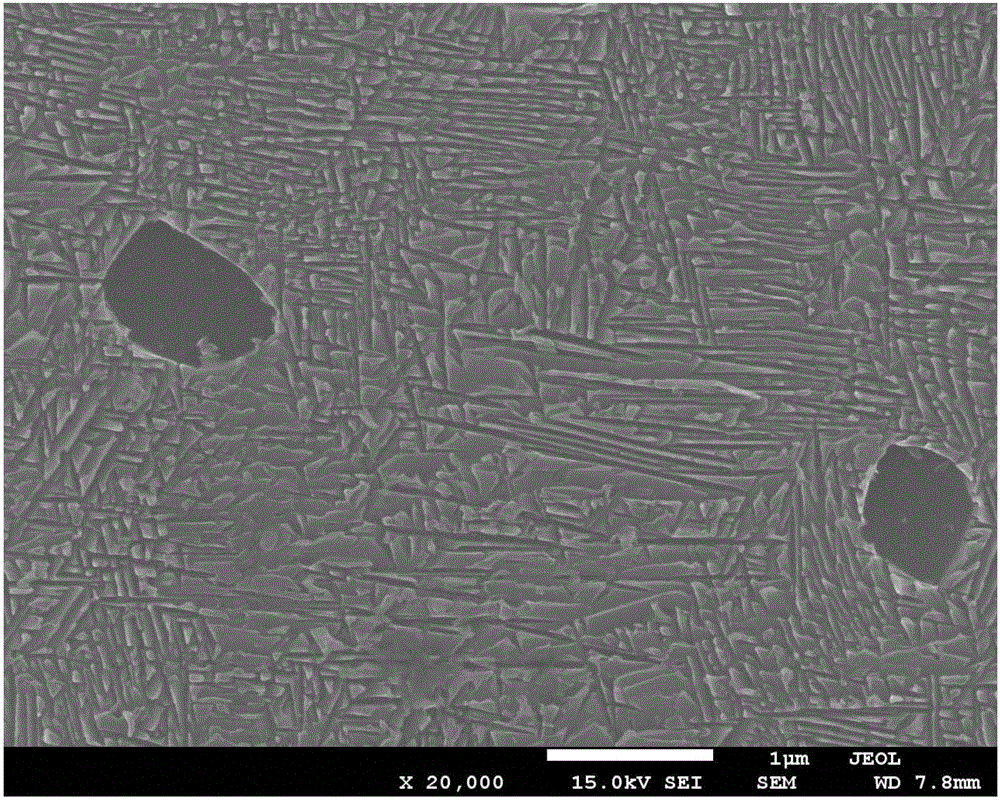

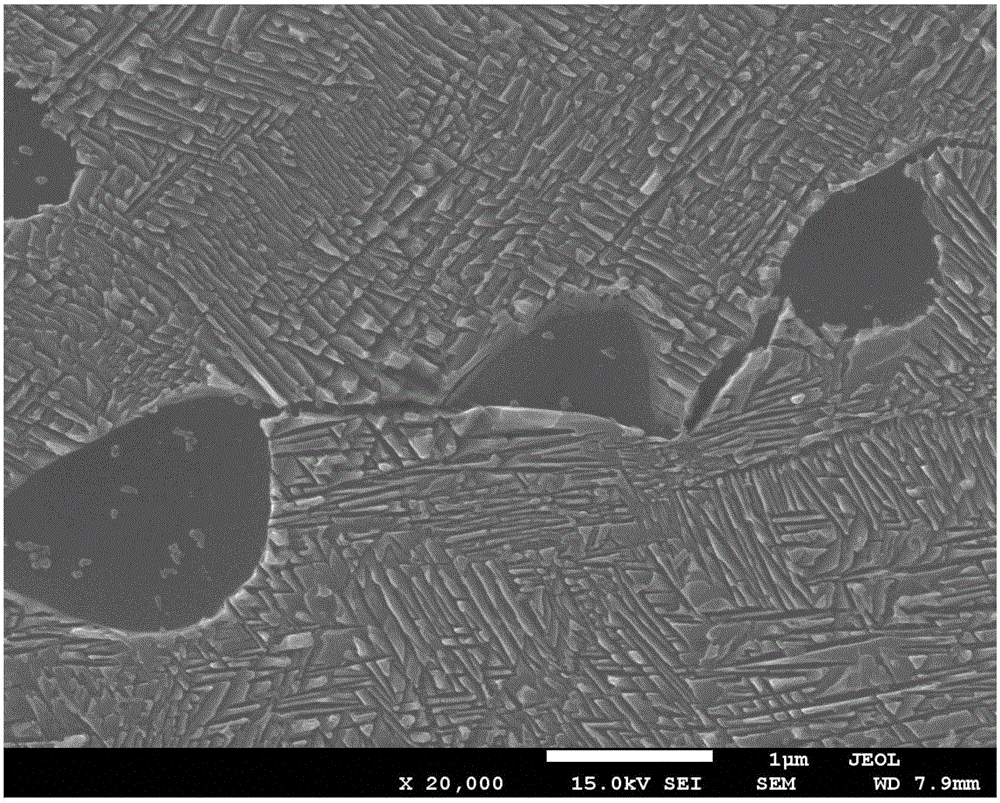

Novel titanium alloy partitioned beta heat treatment process

ActiveCN102851627AGuaranteed uniformityPrecise control of primary alpha phase contentTitaniumTitanium alloy

The invention discloses an accuracy control-based novel titanium alloy partitioned beta heat treatment process. The process includes: first subjecting alpha+beta area forged alpha type and alpha-beta type titanium alloys to preheating at Tbeta-(20DEG C-40DEG C), calculating the heat preservation time according to t(min)=eta*delta max, with the delta max being the largest section thickness of a forged piece and the heating coefficient eta ranging from 0.5 to 0.8; then raising the temperature to (Tbeta-5DEG C)-(Tbeta+5DEG C) along with a furnace, and calculating the heat preservation time t(min) according to the above calculation formula, with the heating coefficient eta ranging from 0.2 to 0.6; and then raising the temperature to (Tbeta+5DEG C)-(Tbeta+30DEG C) along with the furnace again, and calculating the heat preservation time t(min) according to the above calculation formula, with the heating coefficient eta ranging from 0.2 to 0.5; and subjecting the forged piece discharged from the furnace to air cooling or cooling at certain cooling rate. The process is suitable for heat treatment of large, complex, variable section alpha type and alpha-beta type titanium alloy forged pieces, so that required high comprehensive performance lamellar structures with high ductility, high toughness and low fatigue crack propagation ability can be obtained, thus meeting the requirements of airplane and aero-engine manufacturing for large and complex variable section forged pieces or parts with uniform structure performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

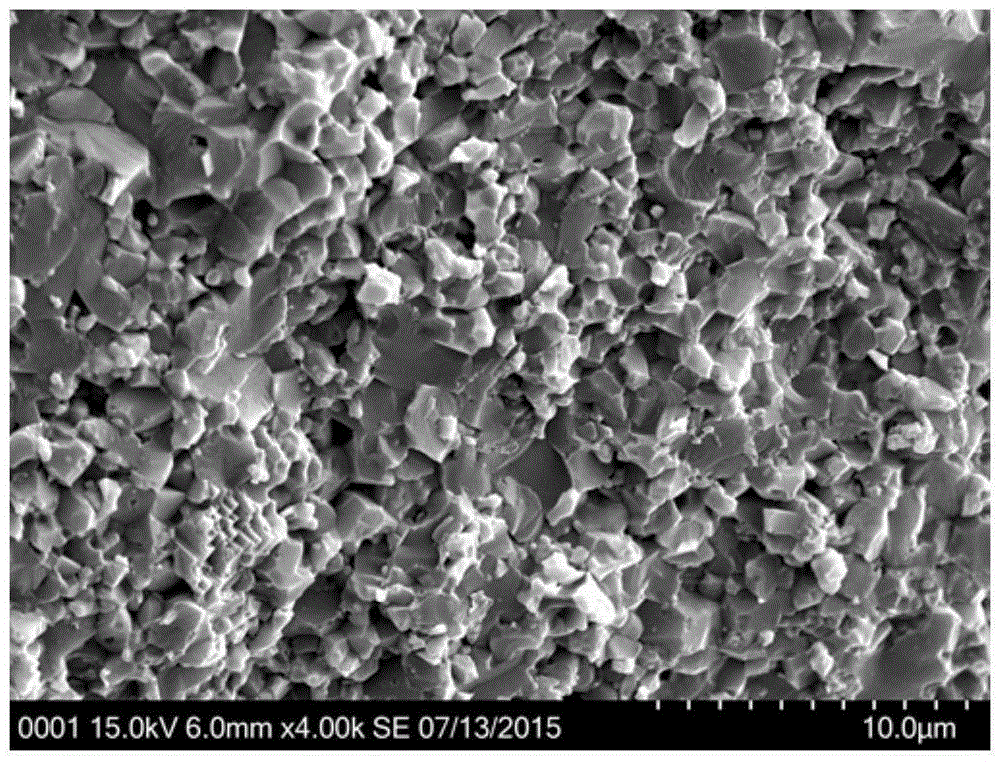

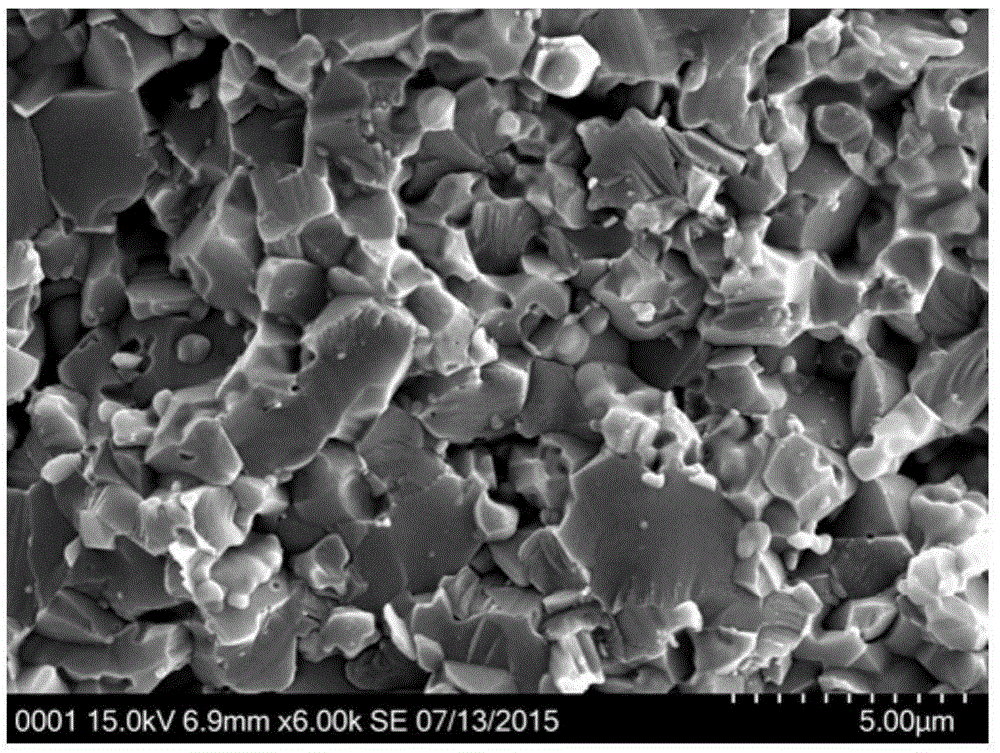

Al2O3/Ti(C,N) composite ceramic tool material and microwave sintering process thereof

The invention discloses an Al2O3 / Ti(C,N) composite ceramic tool material and a microwave sintering process thereof. The Al2O3 / Ti(C,N) composite ceramic tool material is prepared from, by mass, 61%-70% of alumina (Al2O3), 25%-35% of titanium carbonitride (Ti(C,N)), 2%-6% of nickel (Ni) and 1%-3% of molybdenum (Mo). Ceramic tool materials are sintered in a microwave sintering furnace with nitrogen as protection atmosphere through the characteristics that whole microwaves can conduct non-gradient heating, material compactness is promoted and environment friendliness is achieved, wherein the frequency of the microwave sintering furnace is 2.45 GHz. The prepared tool material is uniform in microstructure and small in crystalline grain, has high density, high fracture toughness and high harness, and the performance of the prepared tool material meets the use requirement of tools; meanwhile, the sintering process is advanced, the production efficiency is high, cost is low, large-scale production can be easily conducted, and popularization value is achieved.

Owner:NANJING UNIV OF SCI & TECH

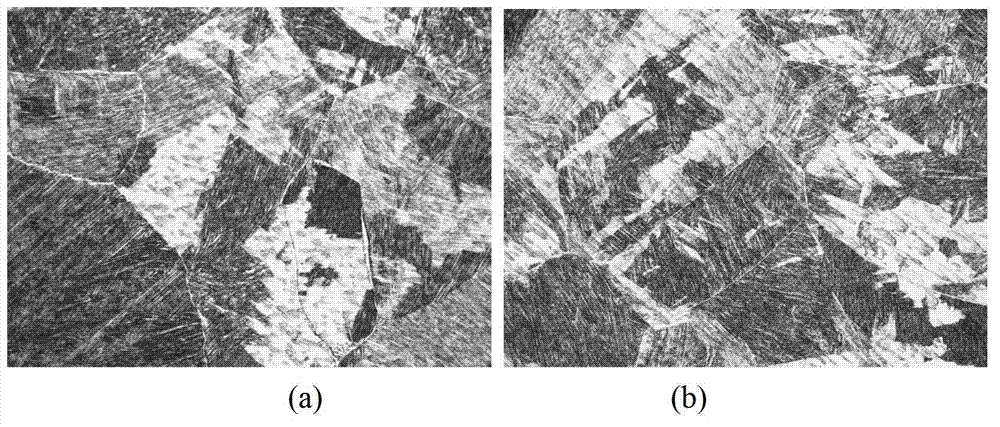

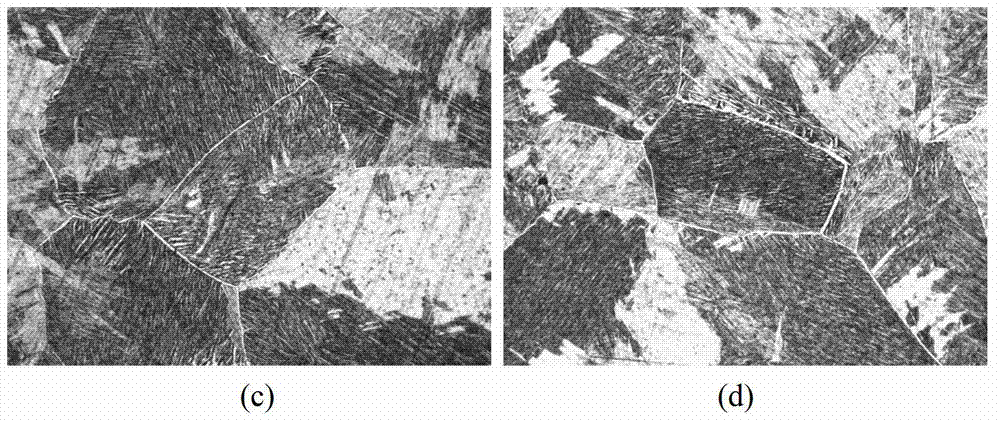

Repeated solid solution aging thermal treatment process of titanium alloy

The invention relates to a repeated solid solution aging thermal treatment process of titanium alloy. The process includes the steps that a titanium alloy forge is subjected to heat preservation at the temperature T for t minutes, wherein T is larger than or equal to Tbeta-15 DEG C but smaller than or equal to Tbeta+15 DEG C, t is equal to eta*delta max, delta max is the maximum section thickness of the forge and is shown in millimeters, and eta is the heating coefficient and ranges from 0.2 min / mm to 0.8 min / mm; then the forge is discharged out of a furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, then the cooled forge is subjected to heat preservation at the temperature of T for t minutes, wherein T is larger than or equal to Tbeta-25 DEG C but smaller than or equal to Tbeta-50 DEG C, the computational formula of t is as above, namely t=eta*delta max, and the heating coefficient eta ranges from 0.3 min / mm to 1.2 min / mm; then the forge is discharged out of the furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 540 DEG C to 600 DEG C, and the heat preservation time t ranges from 0.5 hour to 2 hours; the forge is discharged out of the furnace to be air-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 400 DEG C to 540 DEG C, and the heat preservation time t ranges from 4 hour to 24 hours; and then the forge is discharged out of the furnace to be air-cooled to be at the room temperature. The repeated solid solution aging thermal treatment process of the titanium alloy is suitable for thermal treatment of near-beta type, metastable beta type and steady beta type ultrahigh-toughness titanium alloy so as to obtain required microscopic structures with high overall performance and multi-scale precipitated phases mixed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

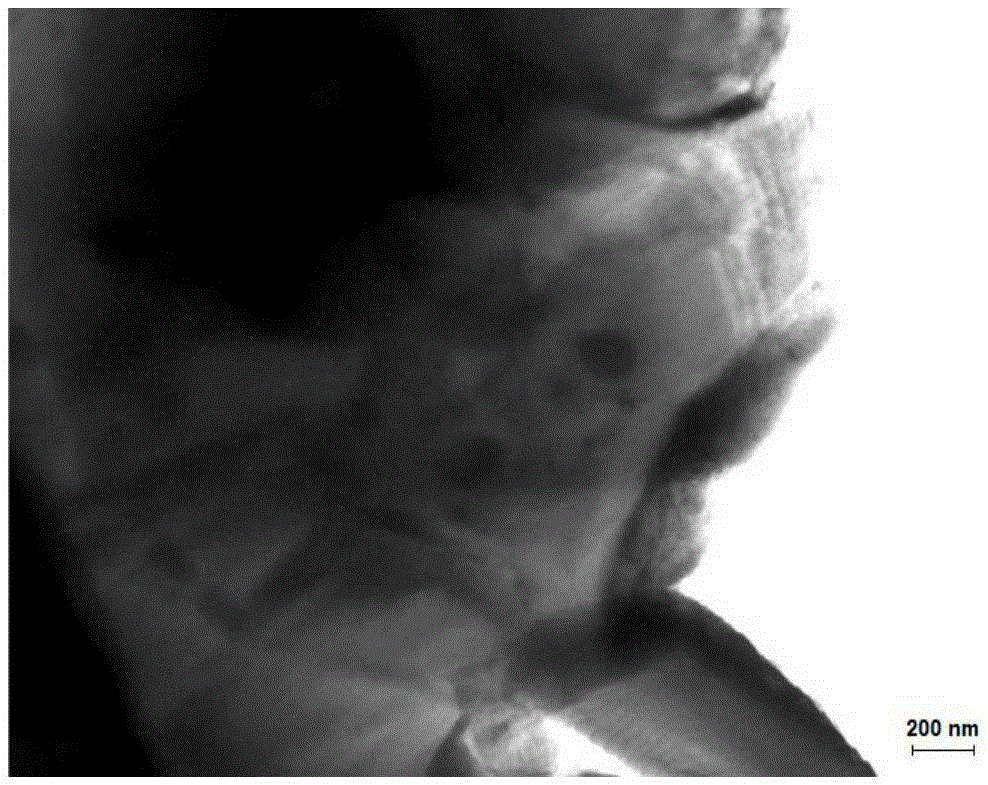

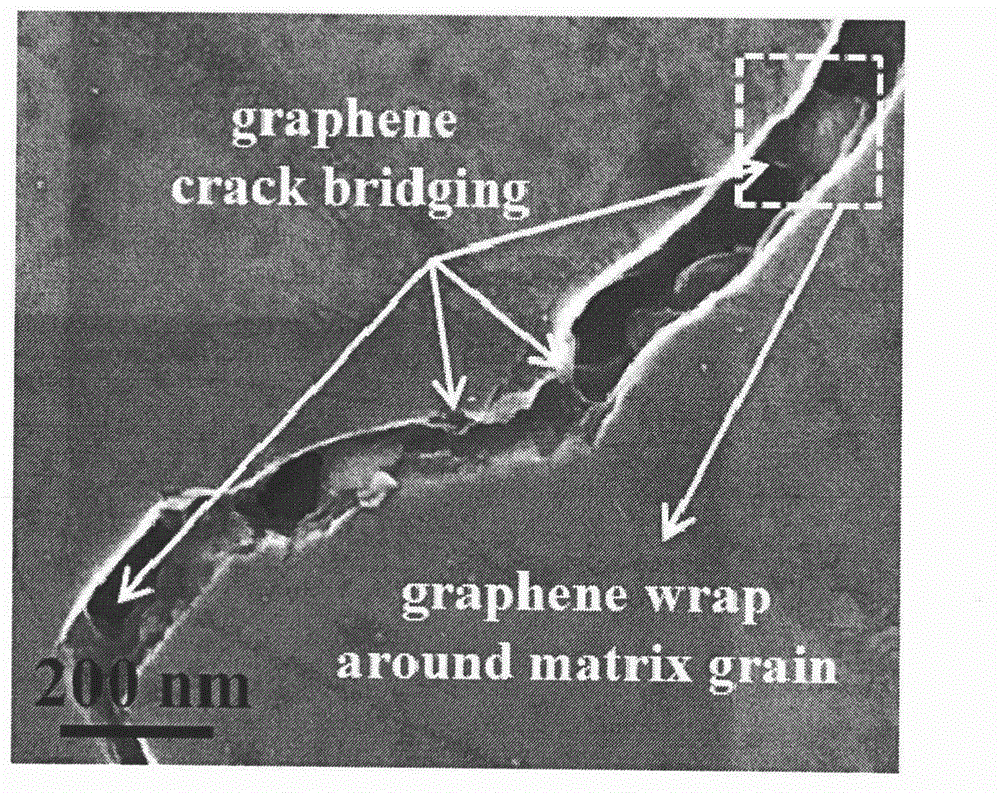

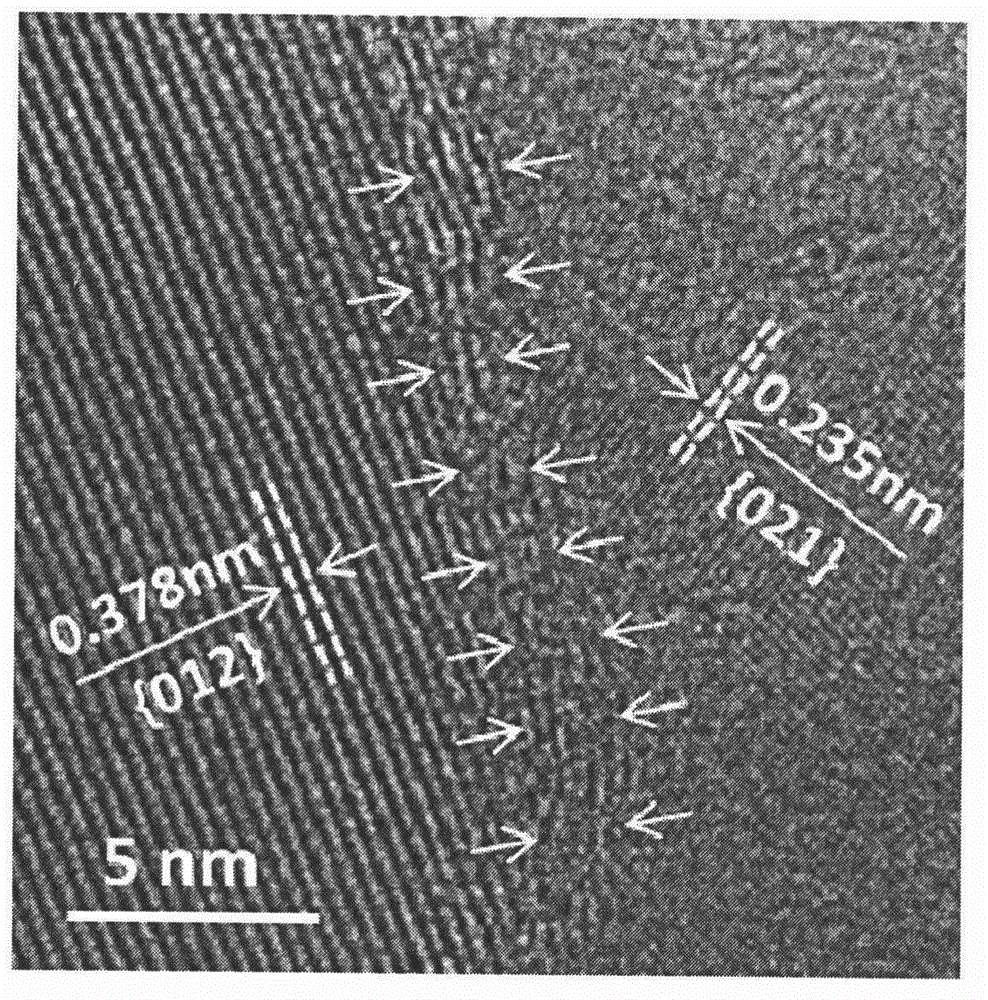

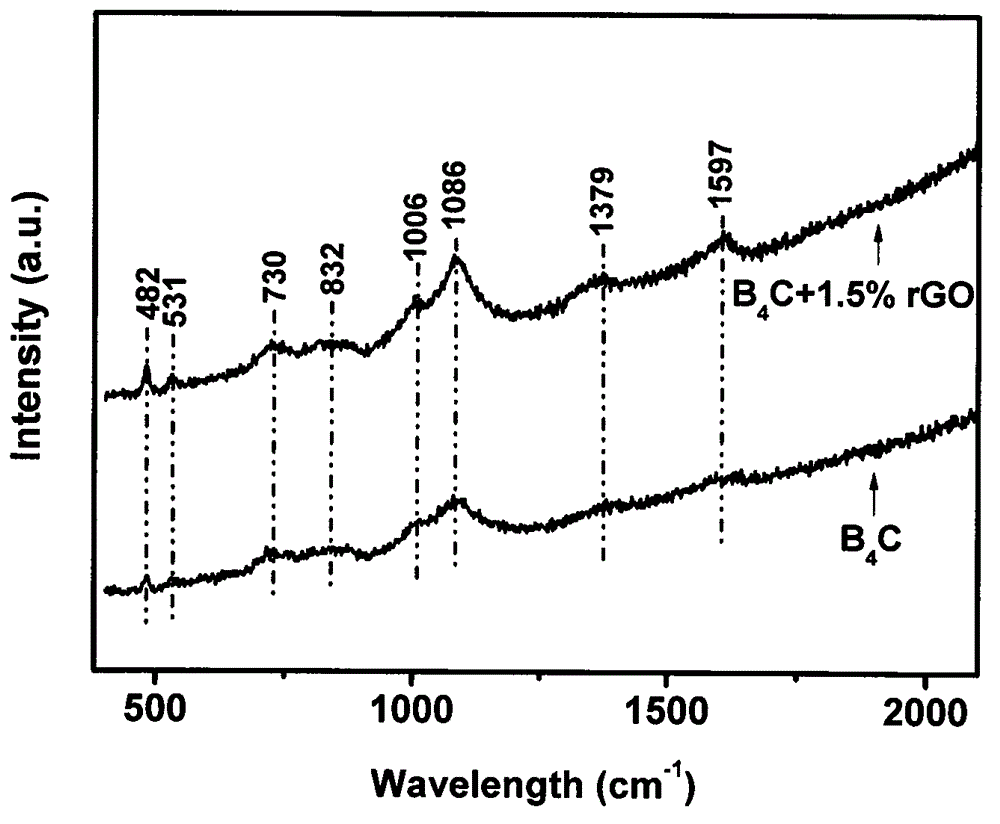

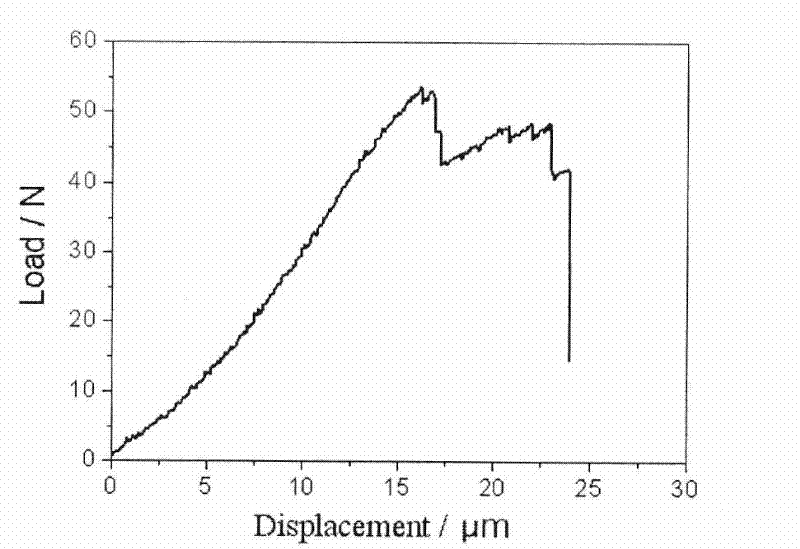

Graphene composite B4C superhard material preparation method

A graphene composite B4C superhard material preparation method is characterized by comprising the following steps: graphene oxide with the sheet diameter greater than 1mum and the layer number not more than five is mixed with B4C powder with the particle size not more than 3mum, the graphene oxide volume fraction is 0.3% -5%, water with the mass of 20-40 times of the mass of the B4C are added for ultrasonic treatment for 10-30min to obtain a graphene oxide / B4C mixture liquid, the graphene oxide / B4C mixture liquid is stirred for 2h more for more uniform mixing, and finally the graphene oxide / B4C mixture liquid is stirred and dried at a drying temperature below 100 DEG C at atmospheric pressure to obtain mixed powder; the mixed powder is pre-pressed into an initial blank in a molding apparatus; the initial blank is put into a high temperature and high pressure apparatus for high pressure sintering to obtain a graphene composite B4C superhard material, wherein the sintering temperature 1300-1600 DEG C, the sintering pressure is greater than 3GPa, and the sintering time is greater than 10min. The superhard material is harder than 19GPa, the fracture toughness reaches 8.76MPa. m1 / 2, and the fracture toughness of the graphene composite B4C superhard material is improved by more than 1 times compared with that of a pure B4C material.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

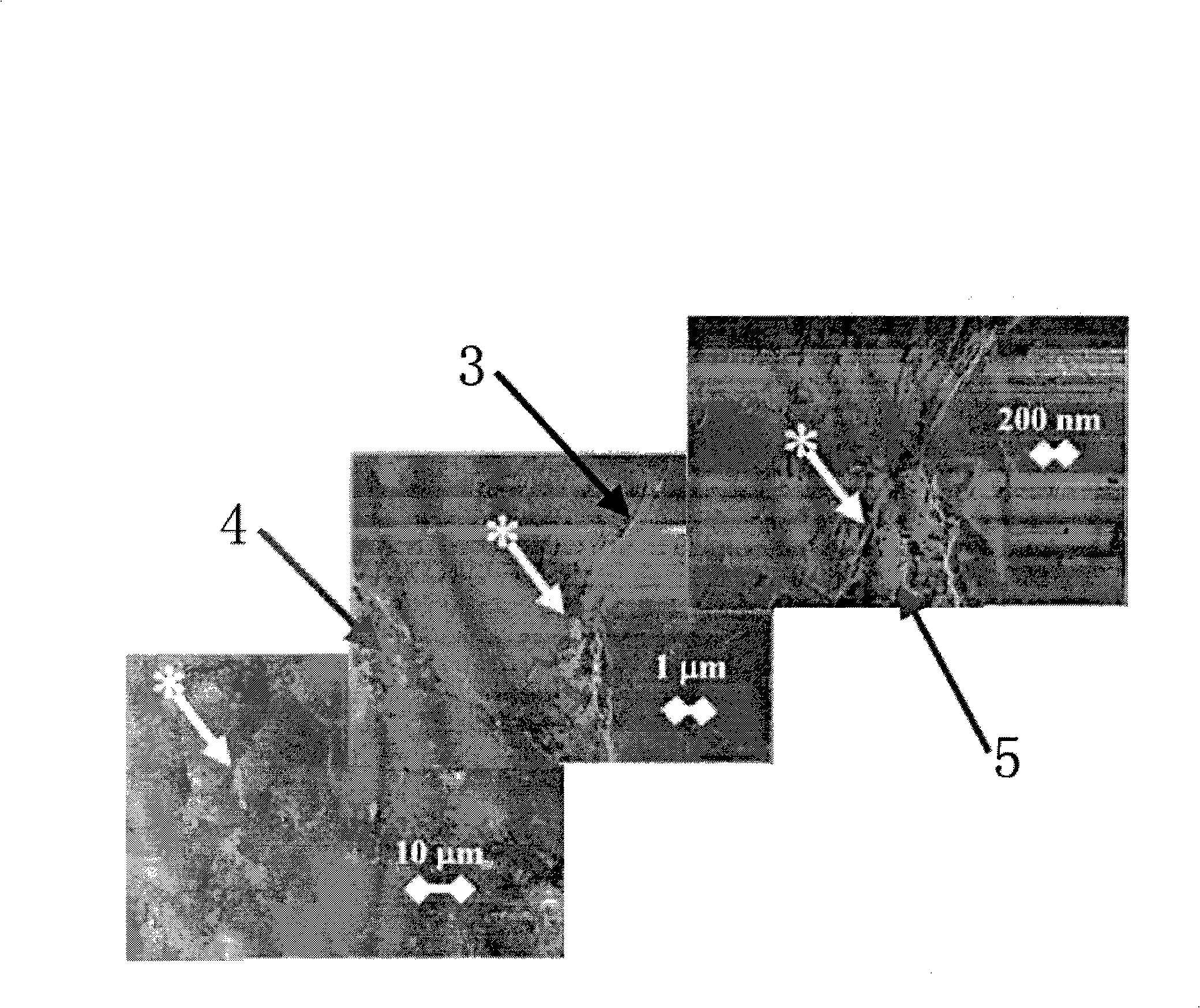

Ceramic Armor

InactiveUS20070105706A1High fracture toughnessImprove impact resistanceEfficient propulsion technologiesLiquid/solution decomposition chemical coatingBorideCarbide silicon

A dense, hard body having good fracture toughness, hardness and a high capacity to absorb impacts which is also useful as lightweight armor. The body is an eutectic of either (a) two carbides selected from boron carbide (B4C), silicon carbide (SiC), titanium carbide (TiC), tantalum carbide (TaC), tungsten carbide (WC), zirconium carbide (ZrC) and hafnium carbide (HfC); or (b) one of the above carbides and at least one boride of an element of group IVa, Va or VIa of the Periodic Table. The molten eutectic, e.g. a ternary composition of B4C, SiC and TiB2, may be generally directionally cooled so its lamellar microstructure is oriented relative to a large surface of the body.

Owner:GENERAL ATOMICS

Tough cordierite glass-ceramics

An internally nucleated, toughened cordierite glass-ceramic is disclosed. The cordierite glass-ceramic has good oxidation resistance and fracture toughness and coefficient of thermal expansion rivaling that of silicon nitride. The glass-ceramic may be cast as a liquid. Annealing produces a material of high crystallinity combining high hardness, high Young's modulus, good thermal stability, high strength, low density and good dielectric properties. The glass-ceramic comprises interlocking crystalline phases dominated by cordierite and a second phase having an elongated or acicular structure. A third phase may comprise a crystalline ceramic that promotes acicularity of the second phase. The third phase is preferably capable of twinning.

Owner:CORNING INC

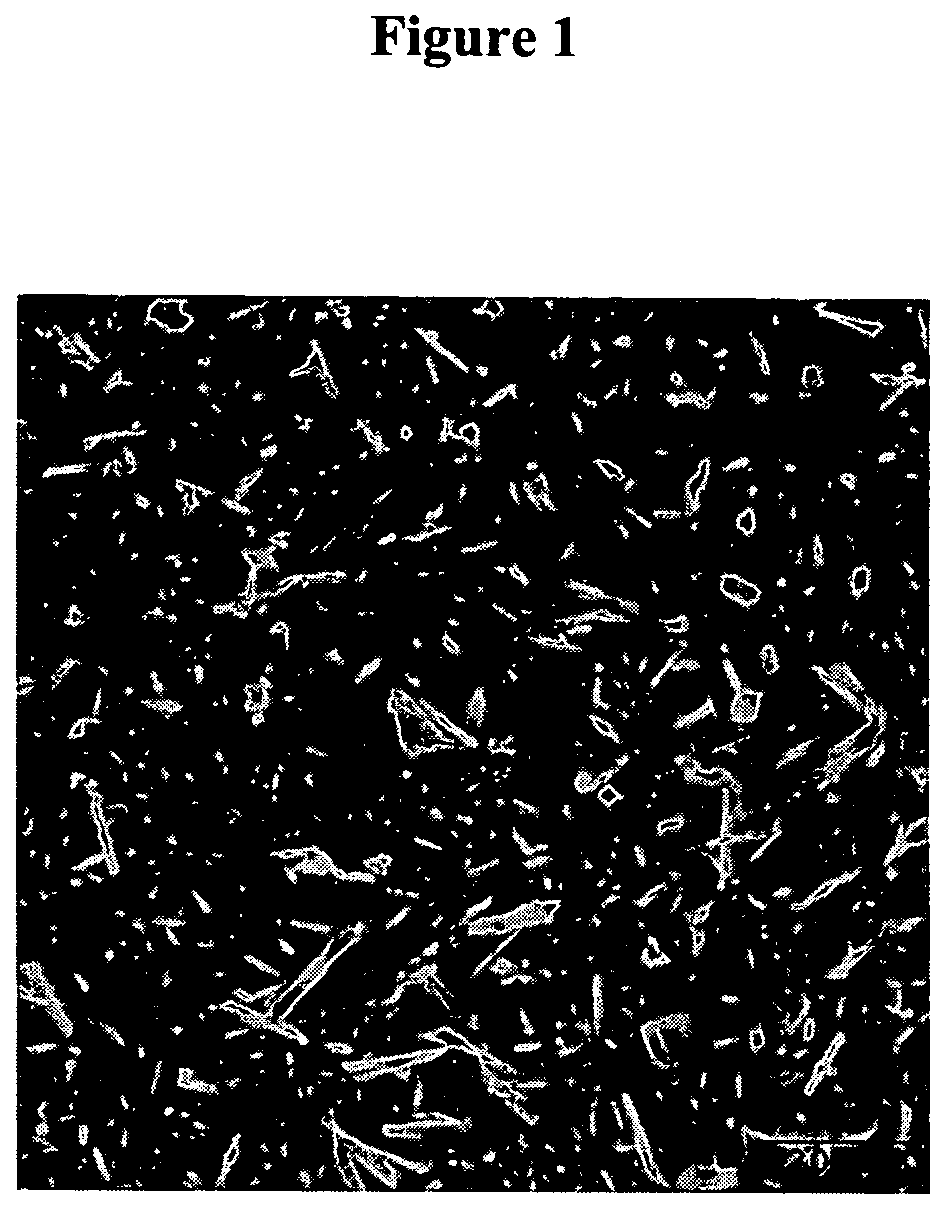

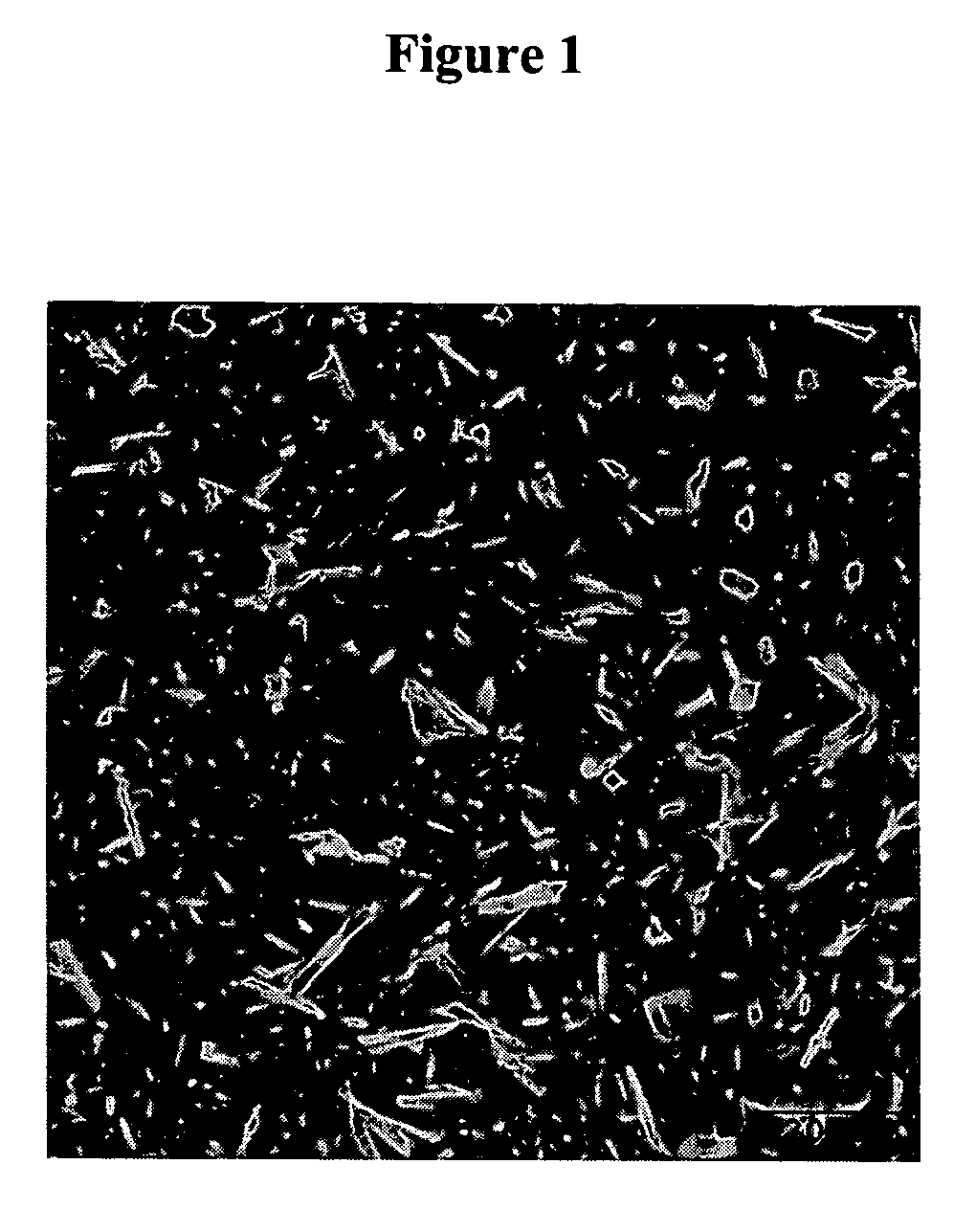

Filler for dental composite materials

InactiveUS20020193463A1High fracture toughnessImprove wear resistanceImpression capsOxygen/ozone/oxide/hydroxideFiller particleFilling materials

Ceramic filler compositions of customized shapes (FIGS. 1-30) according to the present invention, includes ceramic and glass-ceramic particles having a customized shape which provides mechanical locking within a resin matrix giving significantly improved fracture toughness performance for a resin / glass or ceramic composite system. The material has particular application as a tooth filling material with significantly improved wear resistance. The wide range of unique-shaped filler particles are produced using wet chemistry methods according to the invention of preparing the ceramic particles for use in a resin matrix composite material. Such composite materials have a very wide application, especially as a dental composite filling material for restoring a tooth.

Owner:NEW AGE BIOMATERIALS

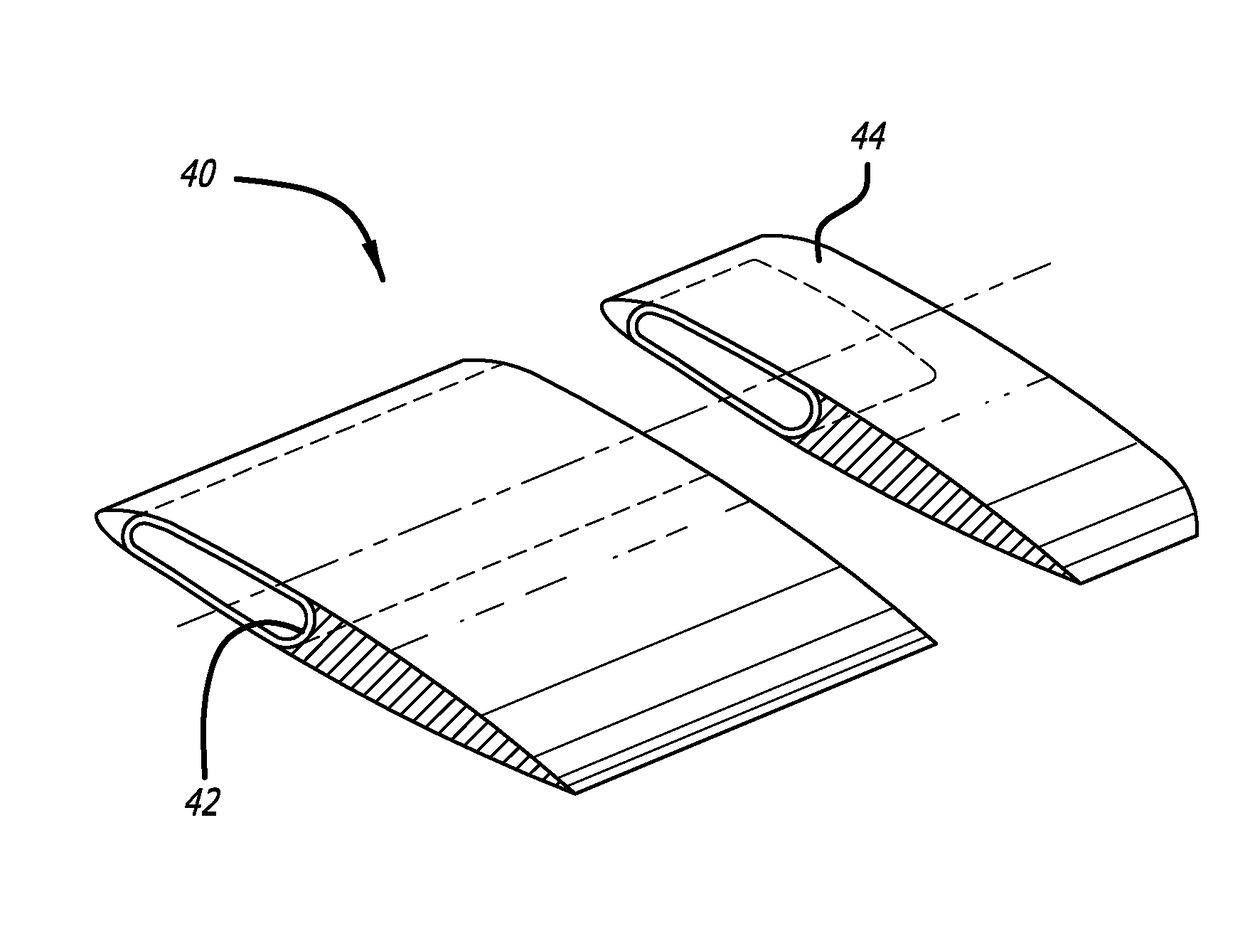

Composite material with thermoplastic toughened novolac-based epoxy resin matrix

ActiveUS20170369663A1High fracture toughnessEasily damagedSynthetic resin layered productsResin matrixPolyresin

Pre-impregnated composite material (prepreg) that can be cured / molded to form aerospace composite parts. The prepreg includes carbon reinforcing fibers and an uncured resin matrix. The resin matrix includes an epoxy component that is a combination of a hydrocarbon epoxy novolac resin and a trifunctional epoxy resin and optionally a tetrafunctional epoxy resin. The resin matrix includes polyethersulfone as a toughening agent and a thermoplastic particle component.

Owner:HEXCEL

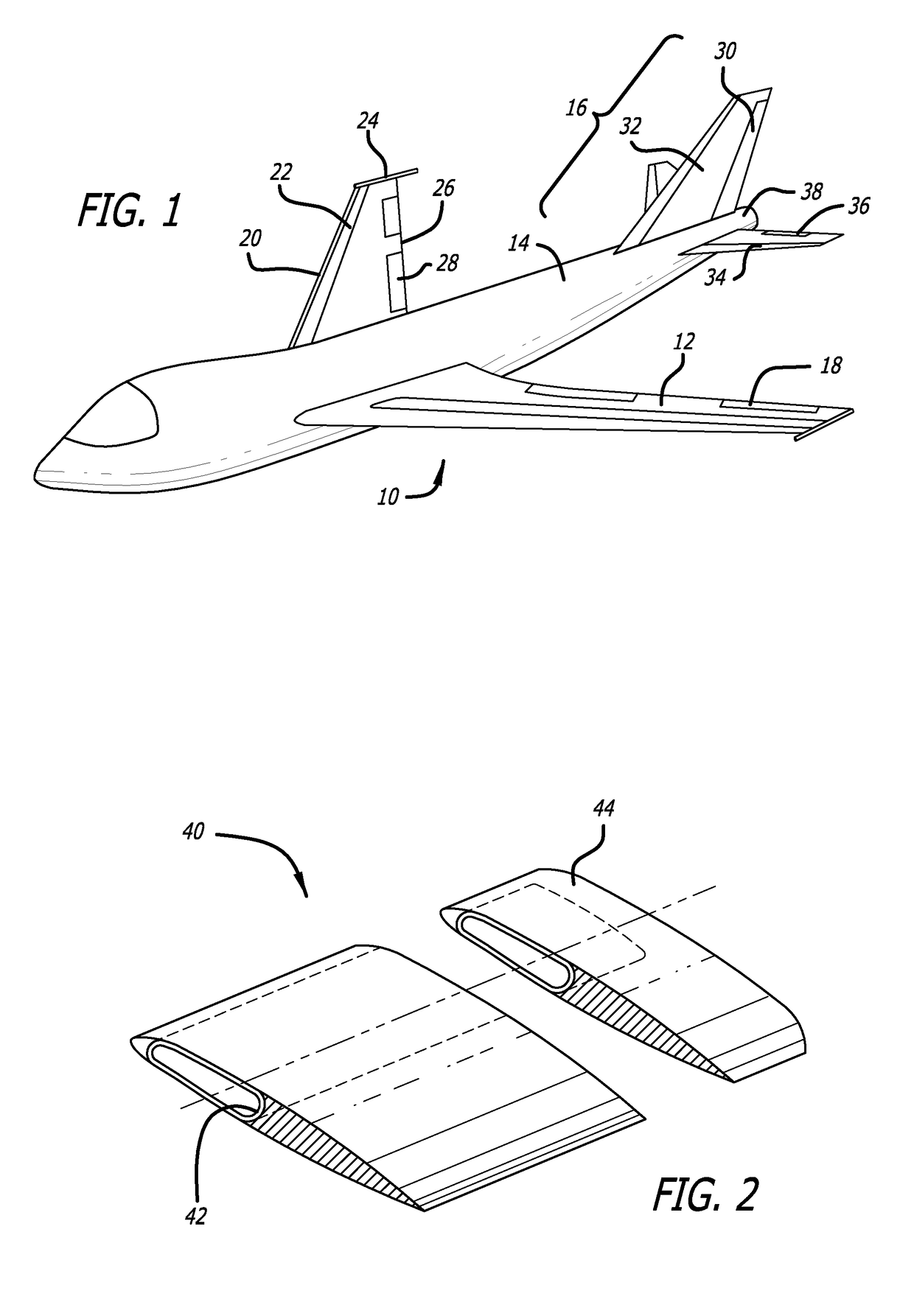

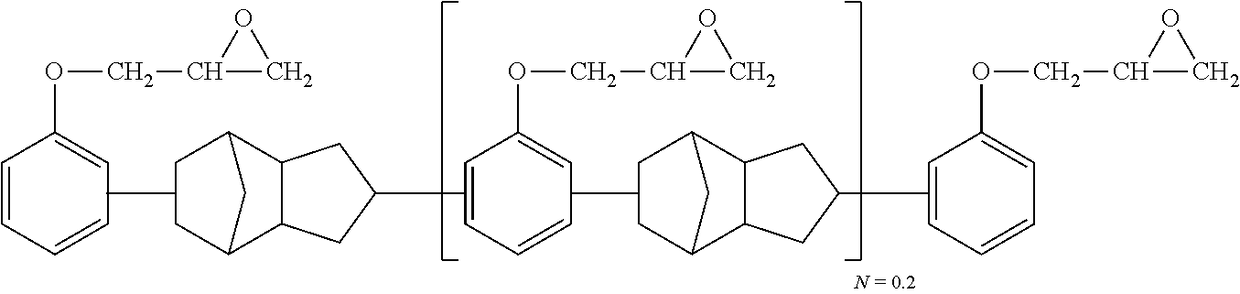

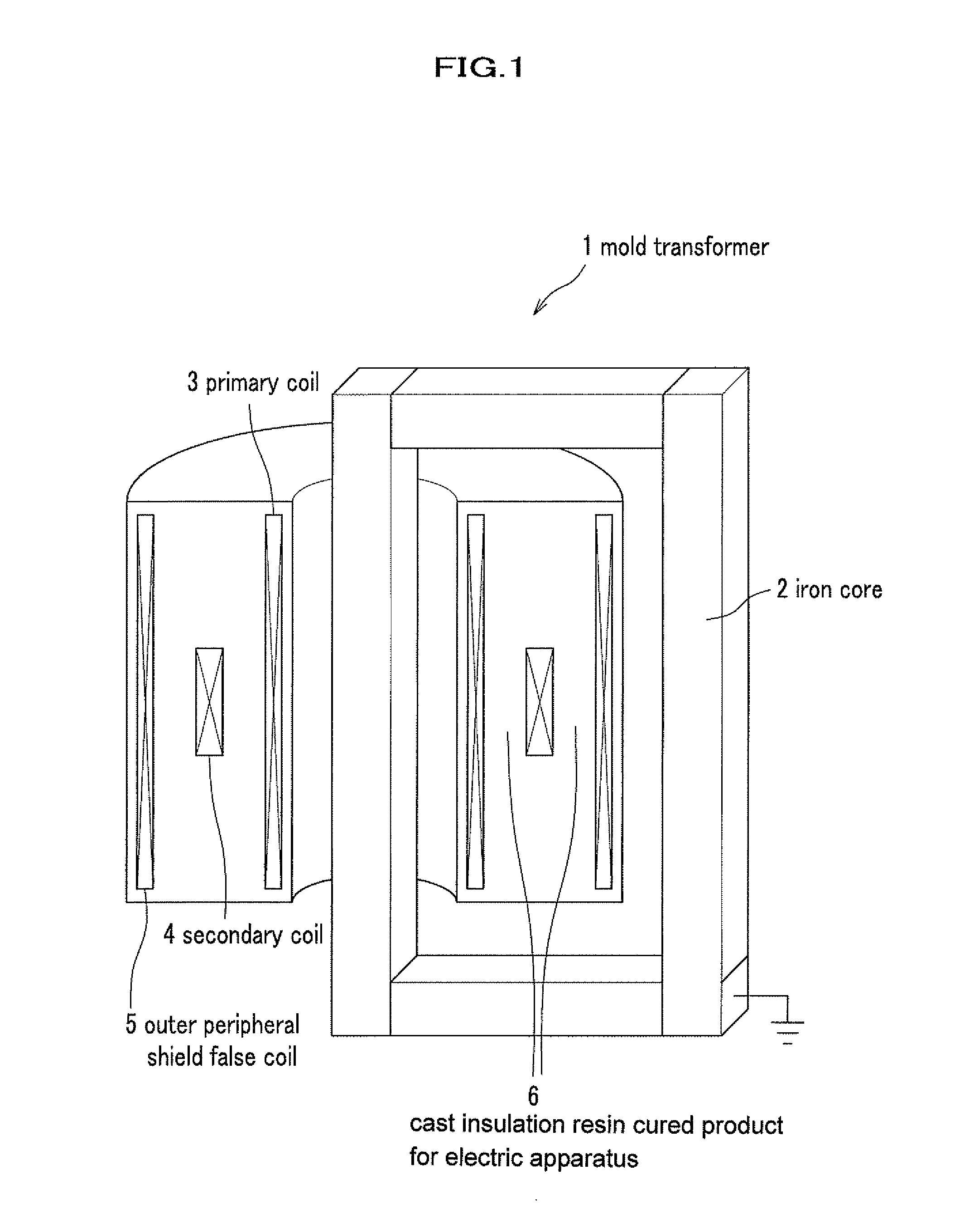

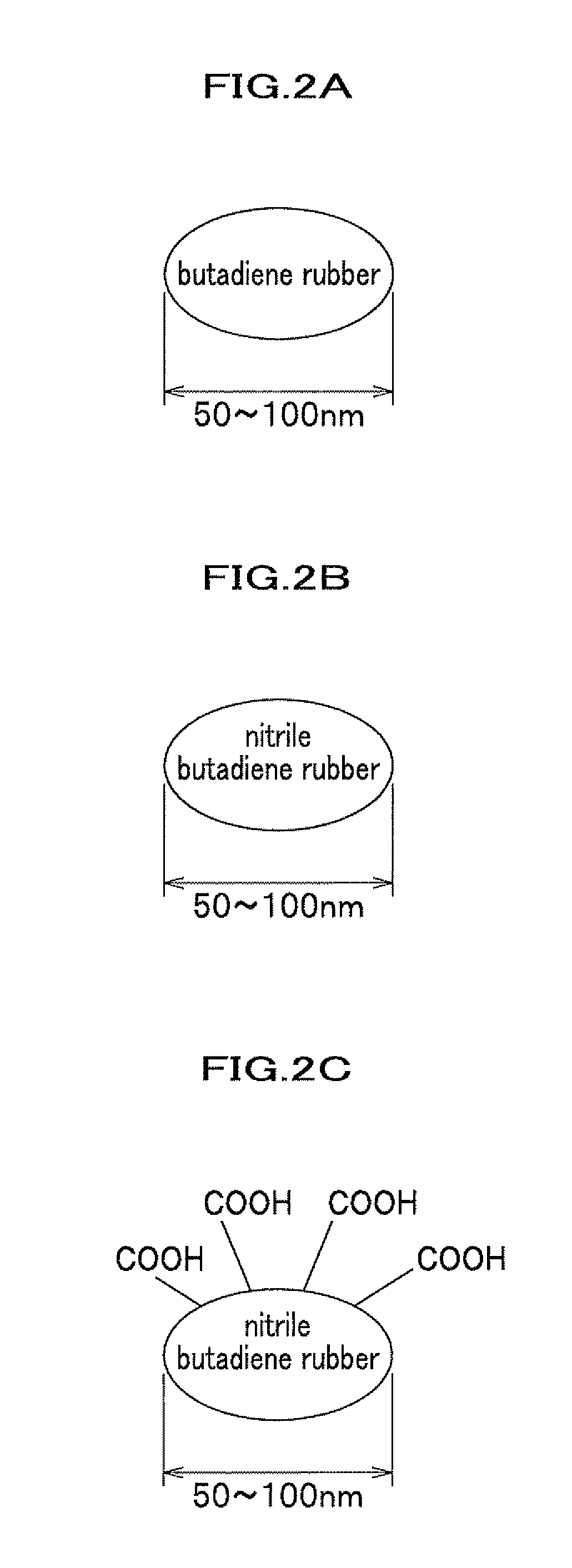

Cast insulation resin for electric apparatus and high voltage electric apparatus using the same

InactiveUS20100319964A1Improve compatibilityImprove fracture toughnessRubber insulatorsPlastic/resin/waxes insulatorsElastomerEpoxy

A cast insulation resin for an electric apparatus having an improved fracture toughness is provided. The cast insulation resin for an electric apparatus is a cast insulation resin used in an electric apparatus, comprising at least either a polar fine elastomer particle or a liquid elastomer having a polar molecule dispersed in an epoxy resin, and a filler formed of at least either an inorganic compound or an inorganic compound having a modified surface thereon with an organic compound.

Owner:HITACHI IND EQUIP SYST CO LTD

High-hardness Ti(C, N)-based metal-ceramic cutter composite

A high-hardness Ti(C, N)-based metal-ceramic cutter composite is characterized by comprising Ti, TiB2, WC, C, Ni and Mo, wherein the composite is a Ti(C, N)-TiB2-WC metal-ceramic cutter material or a Ti(C, N)-TiB2-(W, Ti)C metal-ceramic cutter material; Ti is Ti (C5, N5), the atomic ratio of C to N is 5:5, the average particle size of Ti is 1.5 microns, and the purity is 99.9%; powder TiB2 is a reinforcement phase, the average particle size is 2 microns, and the purity is 99%; the average particle size of WC is 2 microns, the purity of WC is 99.6%, C is (W0.7, Ti0.3)C, the average particle size of C is 1.5 microns, the purity of C is 99%, and the mass fraction of WC and C is 15%; Ni is nanometer Ni, the average particle size of Ni is 0.05 micron, and the purity of the Ni is 99.9%; Mo is nanometer Mo, the average purity is 0.06 micron, and the purity is 99%. The high-hardness Ti(C, N)-based metal-ceramic cutter composite improves the hardness and the bending strength, at the high temperature, of the Ti(C, N)-based metal-ceramic cutter, improves the mechanical properties of the cutter, saves noble rare metals such as Co, Ta and W, facilitates to improve national resource guarantee and pushes upgrading and updating of hard alloy materials in China.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

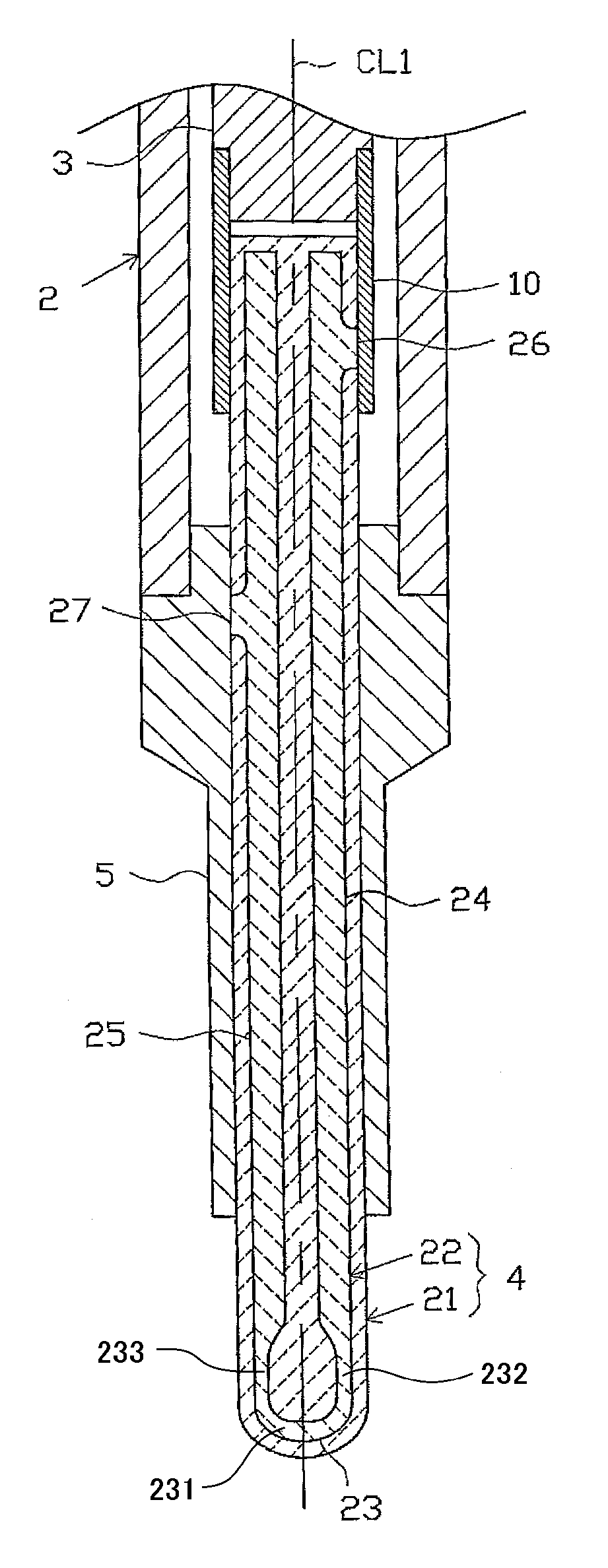

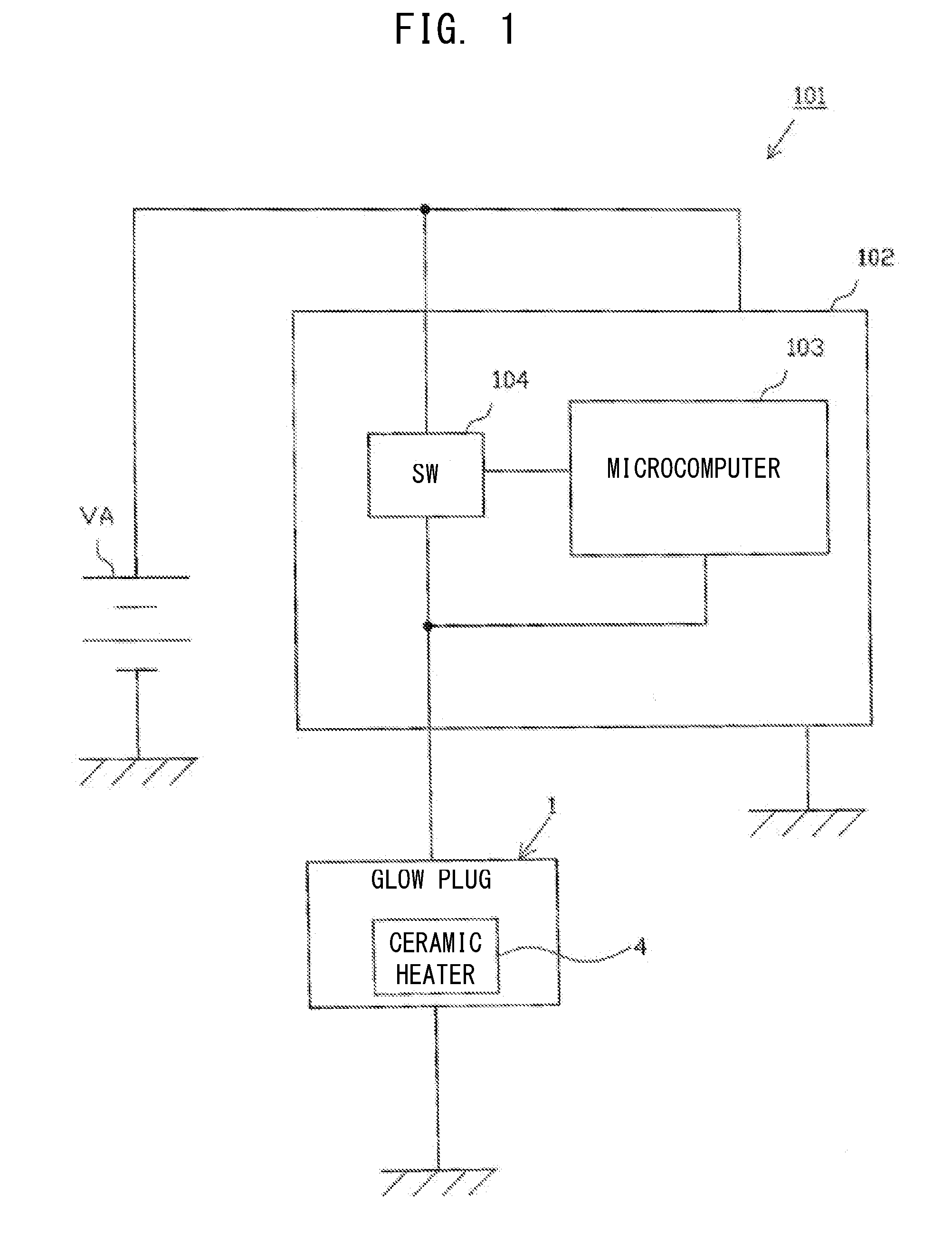

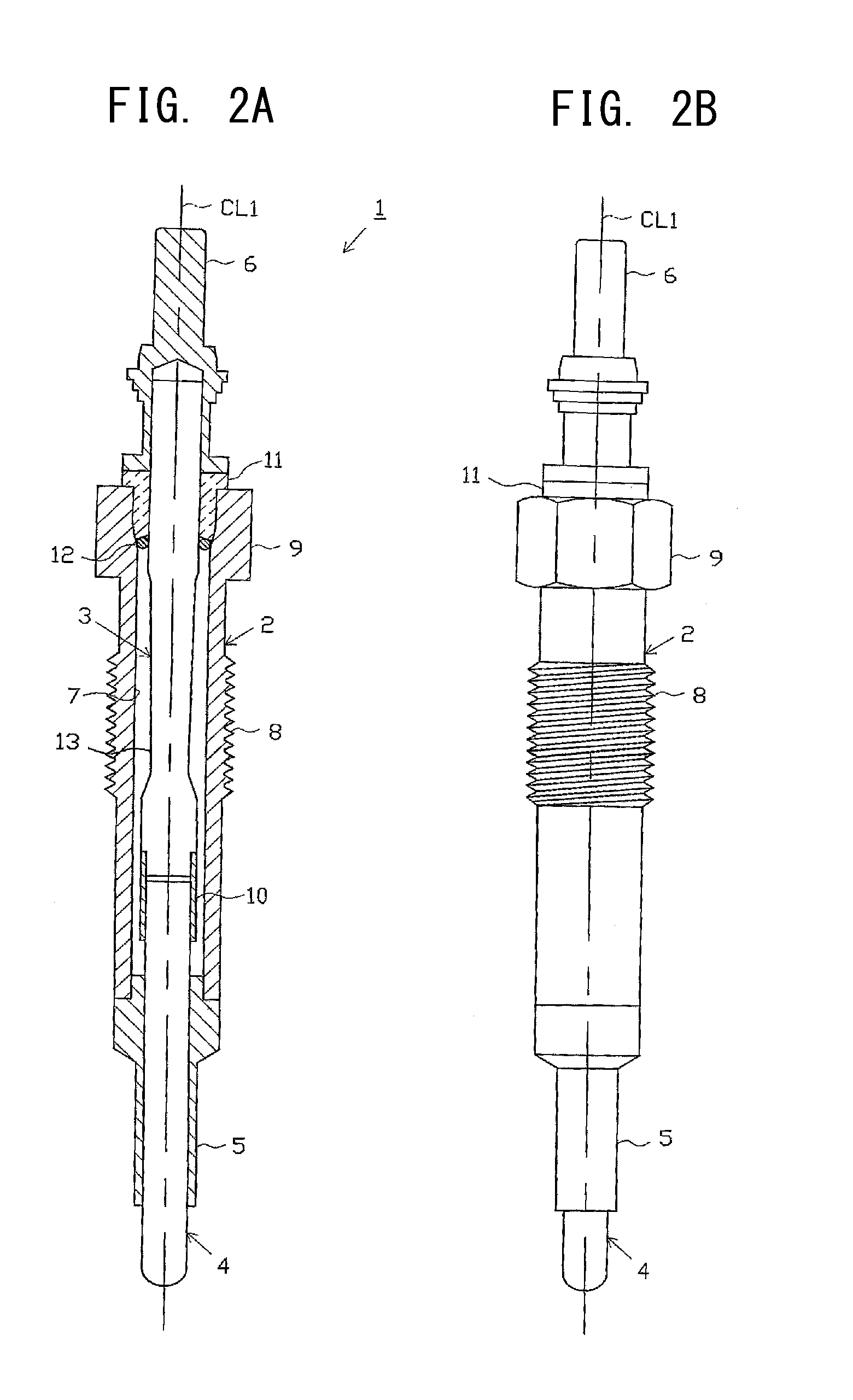

Ceramic heater and manufacturing method therefor, and heating apparatus

InactiveUS20130160730A1High fracture toughnessAvoid disconnectionIncandescent ignitionOhmic-resistance heatingElectrically conductiveSilicon nitride

A ceramic heater having a substrate and a heat-generating element. The substrate is formed from an electrically insulating ceramic and extends rearward from the forward end of the ceramic heater in the direction of the axis. The heat-generating element has a heat-generating portion formed from an electrically conductive ceramic which contains silicon nitride and an electrically conductive material, disposed in a forward end portion of the substrate, and having a shape resembling the letter U as viewed along the direction of the axis. The heat-generating portion has a fracture toughness of 4.3 MPa·m0.5 or more.

Owner:NGK SPARK PLUG CO LTD

Macromolecular compounds

InactiveUS6767934B1Increase conversion rateImprove stabilityImpression capsPharmaceutical delivery mechanismNetwork structureLength wave

Macromolecular photocrosslinkers have polymeric backbones of substituted siloxane groups carrying photoactive groups. When exposed to light of wavelength above 305 nm, the photocrosslinkers are adapted to generate radicals which are retained on the macromolecular photocrosslinker and react to form a crosslinked network structure. The photocrosslinkers may be used in the production of medical devices, including ophthalmic lenses.

Owner:AMO GRONINGEN

Method for producing long-life die casting die material

InactiveCN101781738AExtend your lifeOvercome the shortcoming of insufficient thermal fatigue lifeThermal fatigueDie casting

The invention relates to the technical field of the production process of a die casting die steel material, and specifically relates to a method for producing a long-fatigue life die casting die material. The method comprises the following steps: 1, selecting high-quality raw materials; 2, adopting the double refining of vacuum induction smelting and electroslag remelting; 3, six-side forging; 4, solution annealing; and 5, quality acceptance checking. The die casting material produced by the invention overcomes the disadvantage of the short thermal fatigue life of the traditional large hot die casting die, prolongs the service life of the die, and is mainly applicable to the die casting and extruding dies made of aluminum alloy, magnesium alloy and zinc alloy.

Owner:东莞市辰卓实业有限公司

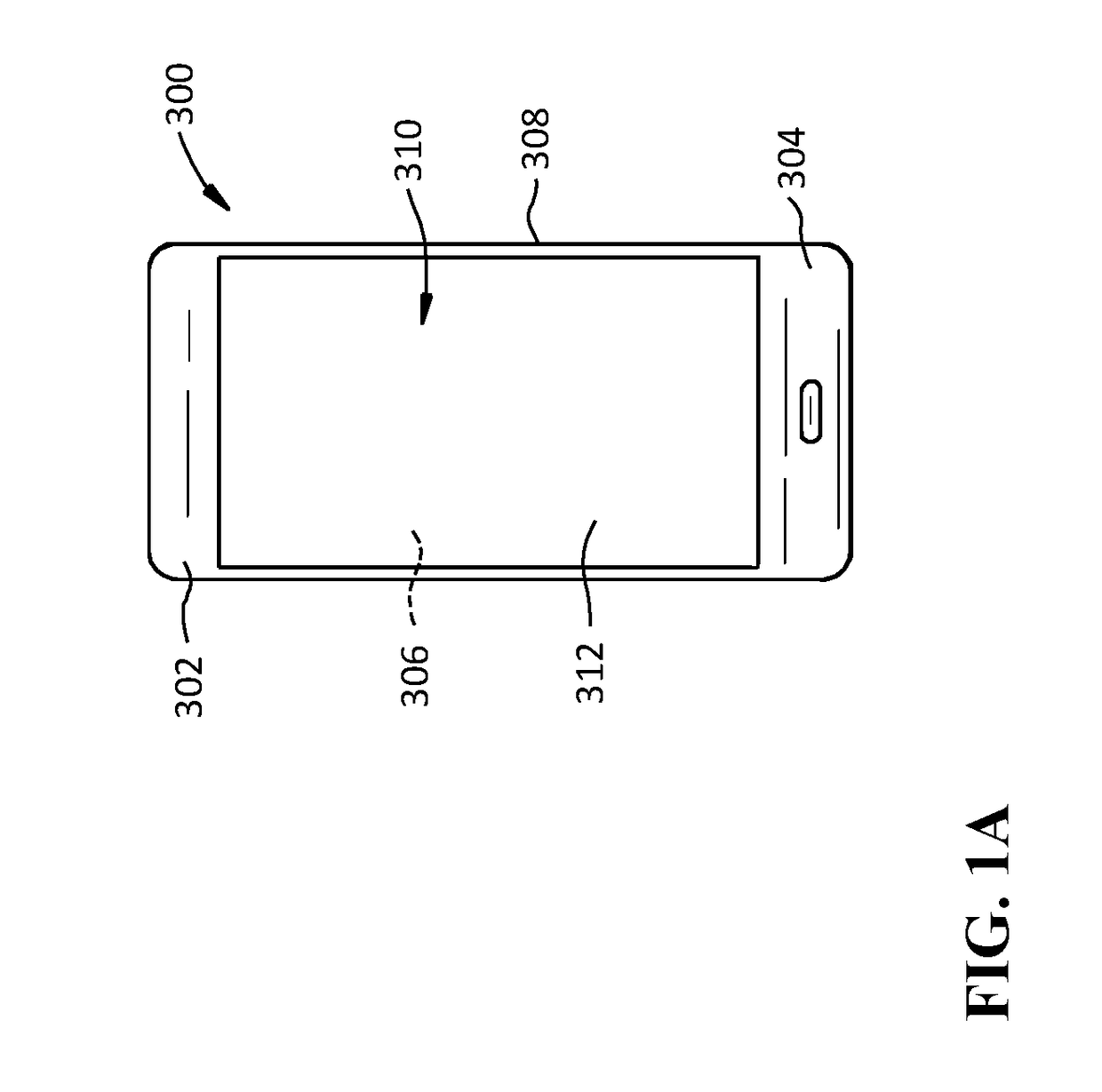

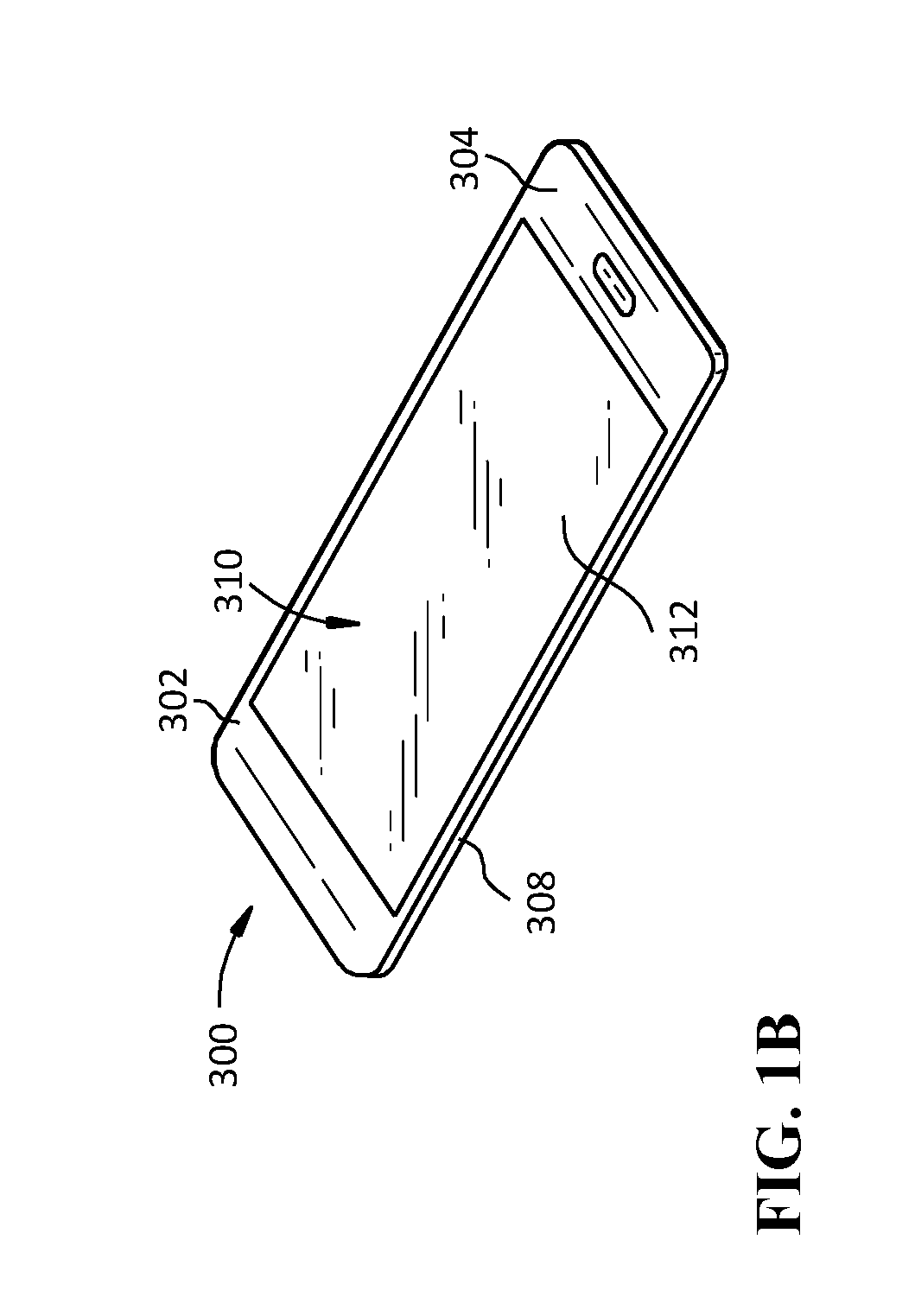

Transparent silicate glasses with high fracture toughness

ActiveUS20180022635A1High fracture toughnessCasings/cabinets/drawers detailsOxideOptical coefficient

Provided herein are glass based articles comprising SiO2, Al2O3, and two or more metal oxides selected from the group consisting of La2O3, BaO, Ta2O5, Y2O3, and HfO2. The glass based articles typically are characterized by a high fracture toughness (e.g., at least 0.86 MPa*m0.5), a high Young's modulus value (e.g., at least 85 GPa) and / or a stress optical coefficient (SOC) of not more than 3 Brewster (e.g., about 1.3 Brewster to about 2 Brewster). Also provided herein are glass based articles comprising SiO2 and two or more of MxOy, wherein M is Ba, La, Ta, Y, Al or Hf; wherein the total amount of SiO2 is the same or substantially the same as that of a reference glass based article comprising two or more binary compositions of MxOy—SiO2, wherein the reference glass based article has the same molar percentage of each MxOy, and the molar ratio of MxOy to SiO2 in each binary composition is 4 / (c*x), wherein c is the number of charges of M.

Owner:CORNING INC

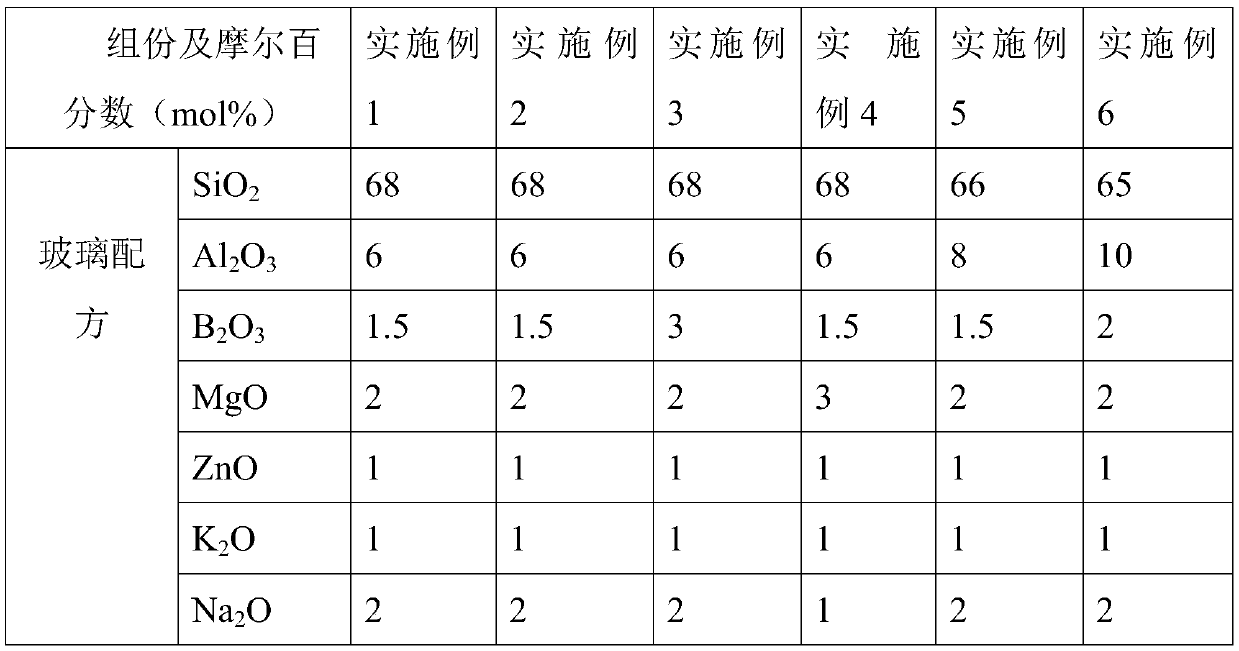

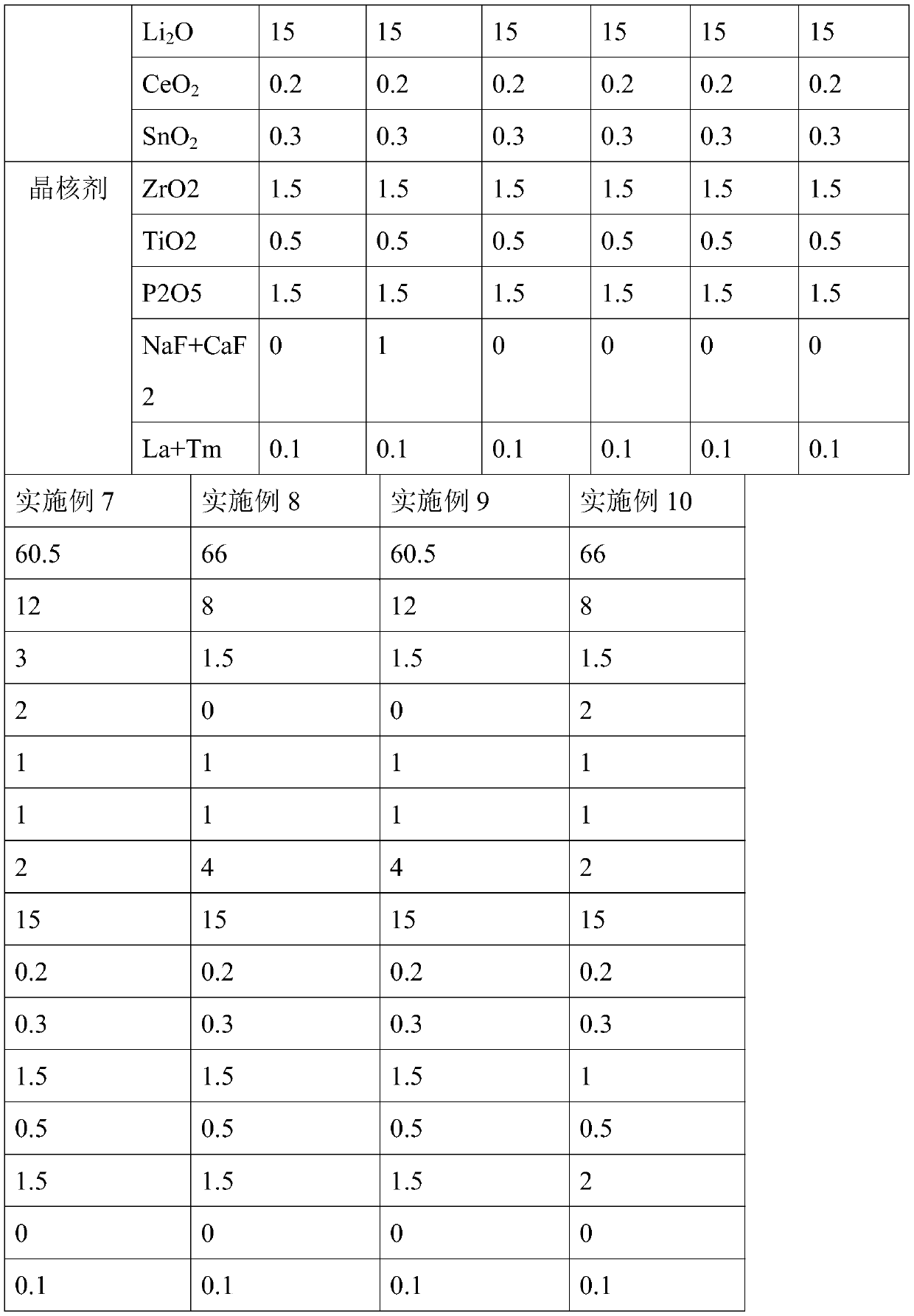

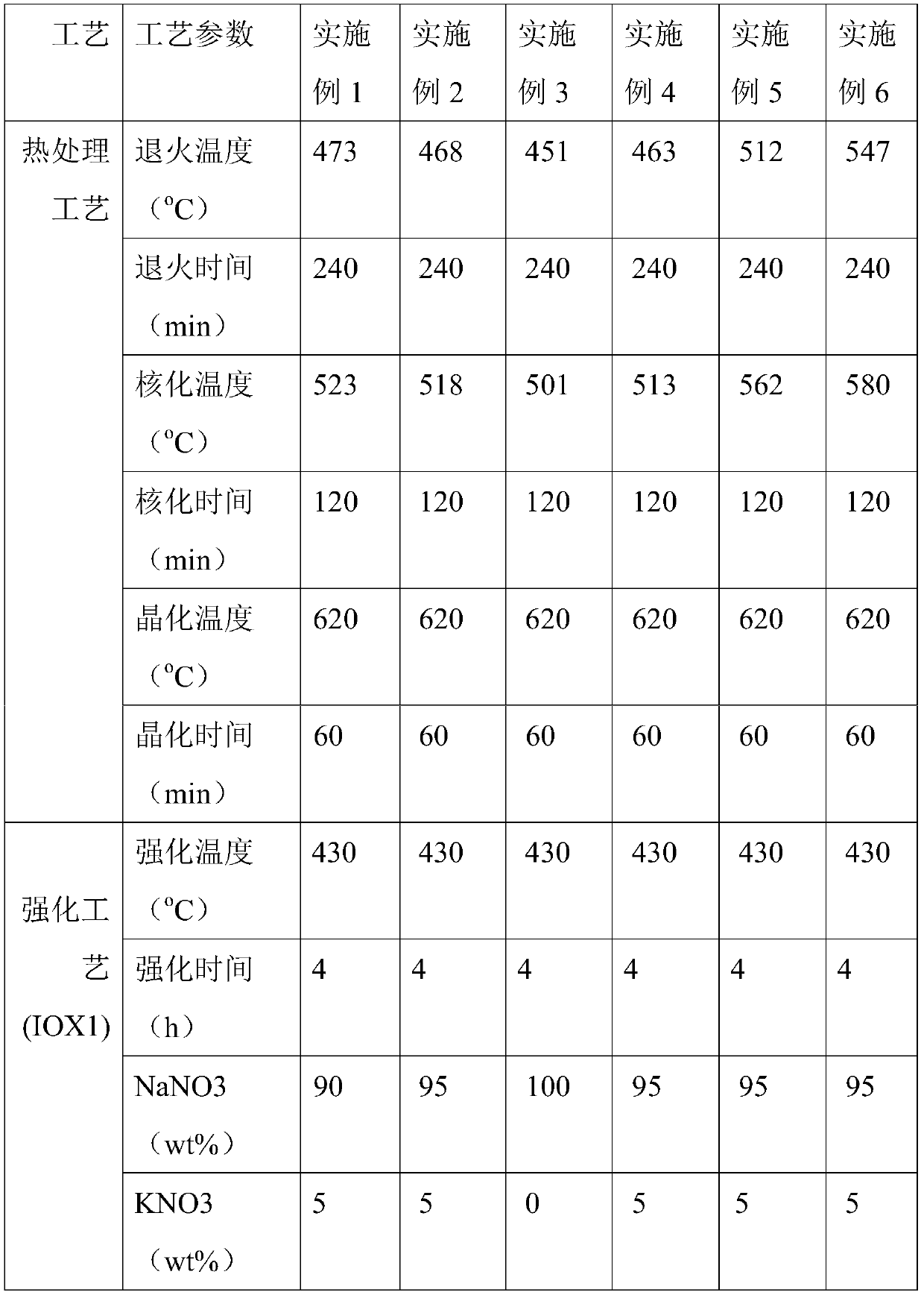

Multi-crystal-nucleus composite transparent glass ceramic and preparation method thereof

ActiveCN110981206AImprove resistance to damageHigh fracture toughnessMaterial nanotechnologyGlass meltingGlass-ceramic

The invention discloses multi-crystal-nucleus composite transparent glass ceramic and a preparation method thereof. The preparation method of the multi-crystal-nucleus composite transparent glass ceramic comprises the following steps that: S1, multiple nucleating agents are added during glass melting; S2, plain glass with a certain boundary dimension is obtained after processing; S3, the plain glass obtained in S2 is placed under the condition that the temperature is T1 and heated for 1-6 hours for annealing treatment, after annealing treatment is completed, the plain glass is placed under thecondition that the temperature is T2 and is heated for 1-6 hours and subjected to nucleation treatment, after nucleation treatment is completed, the plain glass is placed under the condition that thetemperature is T3 and heated for 0-3 hours for crystallization treatment, and T1 is smaller than T2. According to the invention, the glass ceramic containing various crystal nucleuses and crystal phases of lithium disilicate and petalite is prepared, the nucleation and crystallization energy required by the crystal precipitation is reduced through the multiple crystal nucleuses, the heat treatment temperature and the heat treatment time can be reduced, the crystal ratio can be adjusted, and the glass ceramic prepared through the preparation method has characteristics of enhanced damage resistance, good fracture toughness and wide application range.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

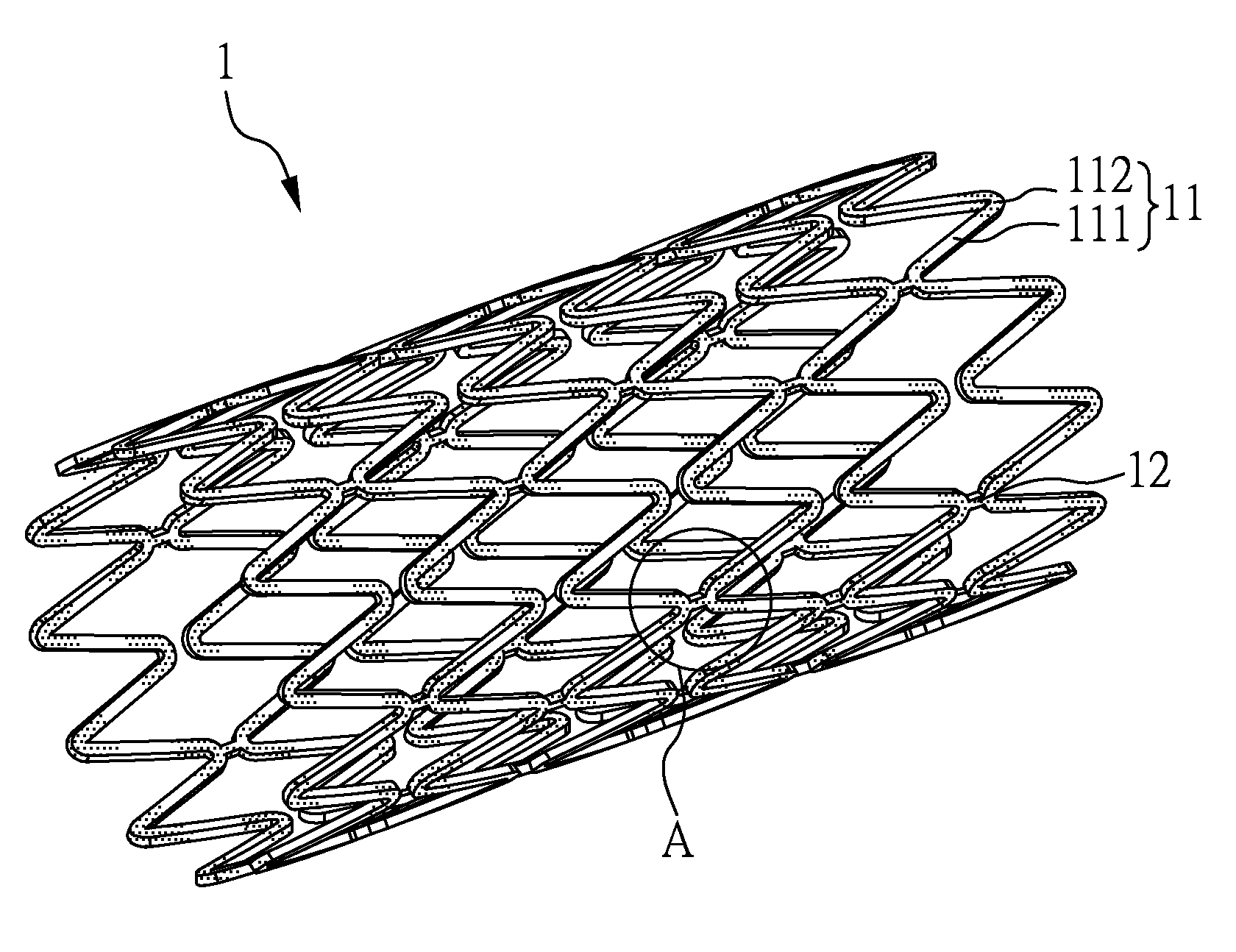

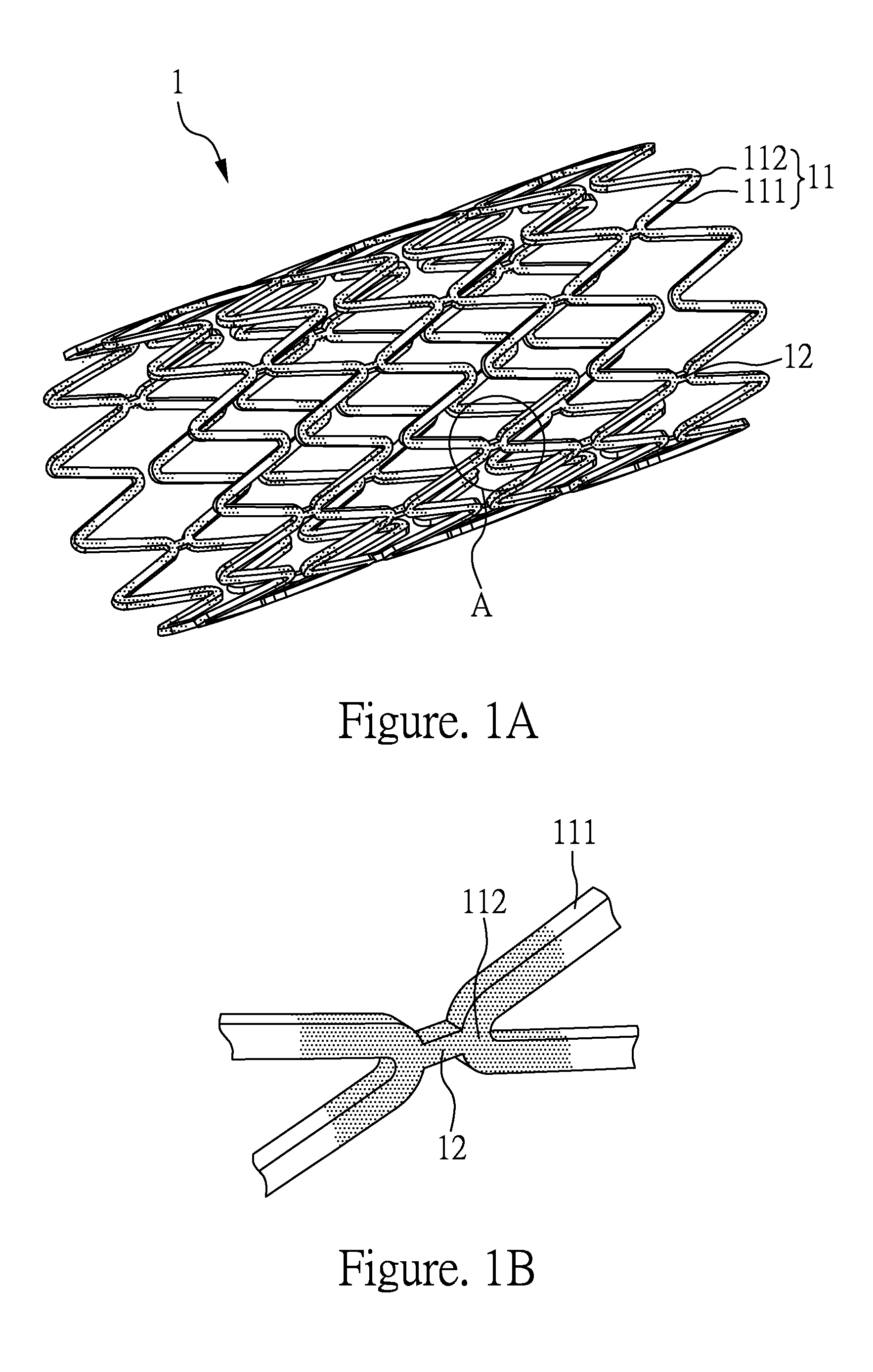

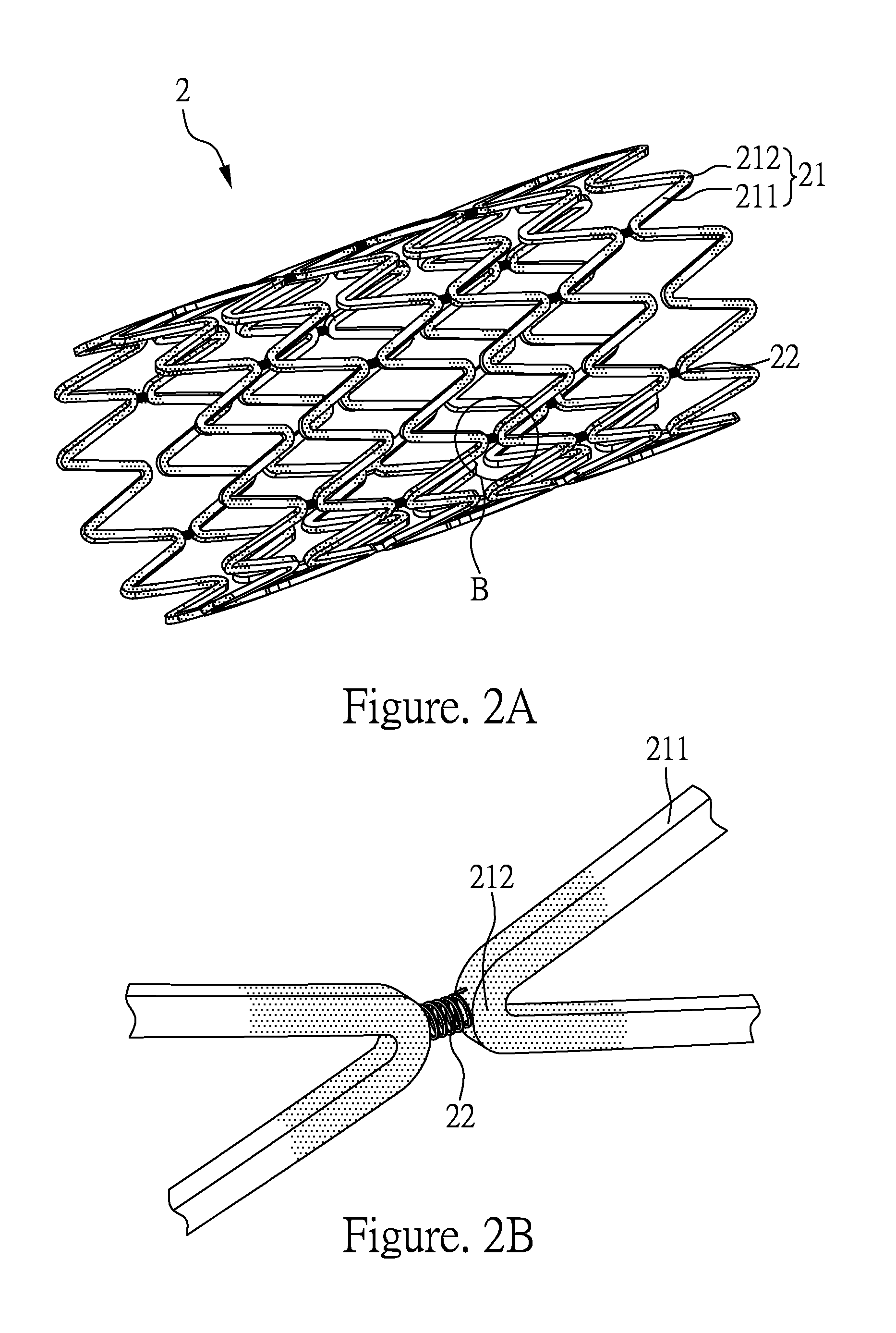

Intravascular stent with regio-selective materials and structures

InactiveUS20150342763A1High fatigue resistanceHigh fracture toughnessStentsAdditive manufacturing apparatusRegioselectivityInsertion stent

Owner:NAT TAIWAN UNIV

Explosion-suppressing material and preparation method thereof

InactiveCN102634703AImprove extrusion resistanceGood anti-collapseFire rescueBoring toolsChemical compositionPerformance index

The invention belongs to a preparation method of an explosion-suppressing material. The explosion-suppressing material comprises the following chemical compositions by weight percent: 0.3-0.5 percent of Si, 0.1-0.3 percent of Fe, 0.15-0.25 percent of Cu, 1.0-1.5 percent of Mn, 1.0-1.5 percent of Mg, 0.1-0.3 percent of Zn, 0.15-0.25 percent of Ti, 0.03-0.06 percent of La, 0.05-0.09 percent of Ce and the balance Al. A grain structure of the explosion-suppressing material is refined by adopting a repeated heating forging and pressing method. The explosion-suppressing material provided by the invention has excellent extrusion resistance, collapse prevention, zero dreg-falling and high-strength explosion-suppressing property. The performance indexes of the explosion-suppressing material, such as strength, plasticity, fracture toughness and fatigue resistance, are greatly increased according to the preparation method; the technology is simple and is easily performed; and the service life of the explosion-suppressing material is prolonged.

Owner:王季庄

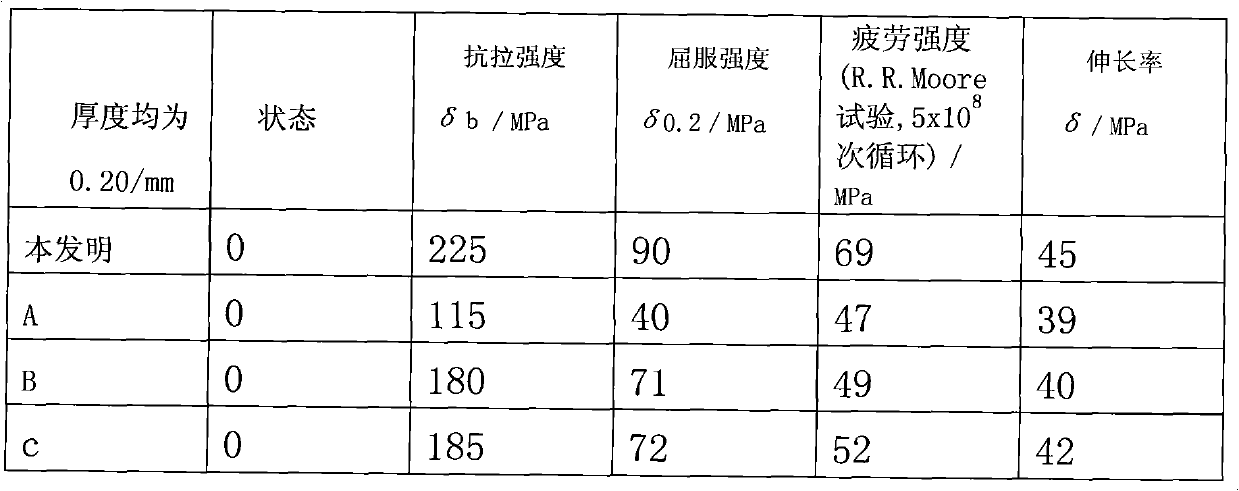

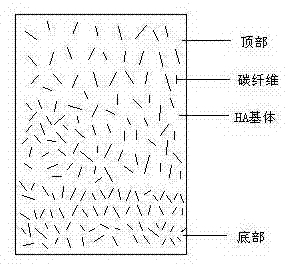

Preparation method of gradient carbon fiber/hydroxyapatite (HA) composite material

The invention relates to a preparation method of a gradient carbon fiber / hydroxyapatite (HA) composite material. The method comprises the following steps: performing compound modification on carbon fibers via low-temperature oxidation and a HA membrane layer pulling and drawing method; dispersing nanometer HA powder, an organic monomer acrylamide, a cross-linking agent N, N-methylene bisacrylamide, a dispersant sodium hexametaphosphate, an initiator ammonium persulfate, a catalyst N,N,N',N'-tetramethylethylenediamine and ammonium hydroxide into deionized water so as to prepare modified carbon fiber-HA duplex ceramic slurry; performing centrifugal molding on the duplex ceramic slurry; then taking out a centrifugal barrel and putting the centrifugal barrel into a water bath kettle so as to realize the curing molding of modified carbon fiber-HA gel; demolding a green body and then drying the green body in a drying box; and sintering the green body under the argon atmosphere in a tubular furnace so as to obtain the gradient carbon fiber-HA composite material. The method has the advantages that the content of carbon fibers at the bottom of the composite material is high, so that the strength and the toughness of the composite material can be improved during the load bearing; the content of HA at the top of the composite material is high, so that the osteoinduction and the biocompatibility of the composite material can be improved when the composite material is implanted into a human body; the centrifugal molding technology is adopted, so that the problem of stress concentration caused by the reason that the carbon fibers are likely to agglomerate during the dry pressing is solved, and thus the mechanical property of the composite material is improved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

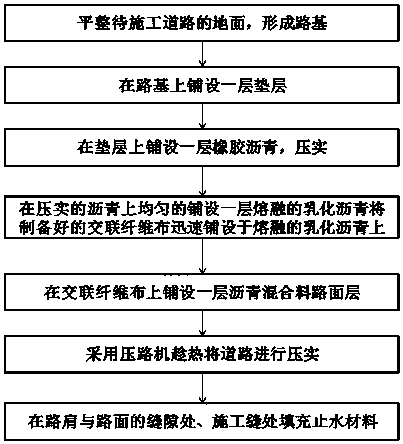

A road construction method

The invention discloses a road construction method. The road construction method comprises the following steps: firstly, forming a roadbed; secondly, paving a cushion layer on the roadbed; thirdly, paving rubber asphalt on the cushion layer, and compacting the cushion layer on which the rubber asphalt is paved; fourthly, uniformly paving a layer of molten emulsified asphalt on the compacted asphalt, and quickly paving prepared crosslinking fiber cloth on the molten emulsified asphalt, wherein the crosslinking fiber cloth is prepared by cross linking polystyrene fibers, ammonium aluminum carbonate hydroxide fibers and polypropylene fibers; fifthly, paving an asphalt mixture pavement layer on the crosslinking fiber cloth; sixthly, compacting a road while hot by adopting a road roller. According to the road construction method disclosed by the invention, the crosslinking fiber cloth is used, has higher tensile strength and can be well combined with asphalt, so that the fracture toughness of the road is enhanced. The road construction method disclosed by the invention is novel and is very suitable for high-quality road surfaces and road surfaces with soft roadbeds; the service life of the road surface can be greatly prolonged.

Owner:天津亚平市政工程集团有限公司

Method for preparing ceramic biological material with abrasion self-remediation function in in-vivo environment

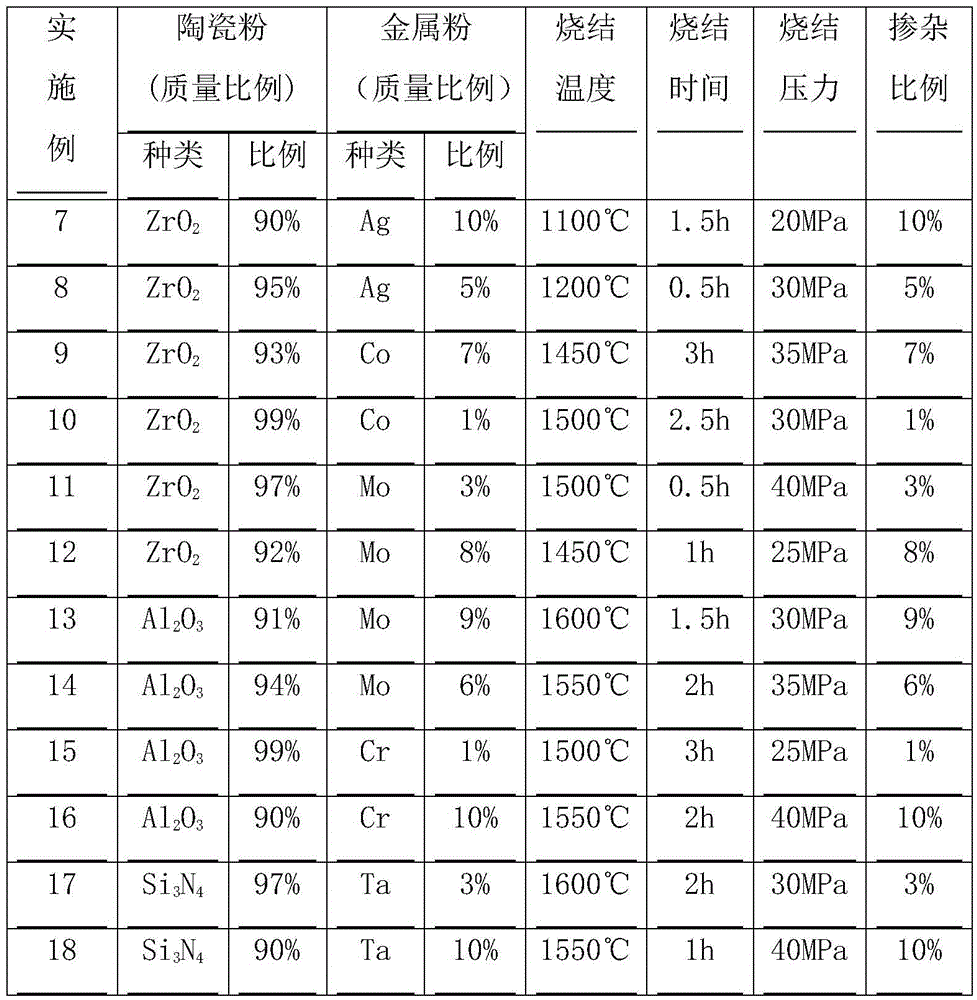

The invention discloses a method for preparing a ceramic biological material with an abrasion self-remediation function in an in-vivo environment. The ceramic biological material comprises the following raw materials in percentage by mass: 90-99% of zirconia powder (alumina powder) and 1-10% of metal powder. The method comprises the following steps: putting the raw materials into a planet ball mill, uniformly mixing according to a wet method, drying, and performing hot-pressing sintering at 1100-1800 DEG C for 0.5-3 hours in the presence of an inert atmosphere. The metal doping mass ratio in the prepared ceramic biological material is within 1-10%; when the ceramic biological material is used as a friction accessory (such as an artificial joint and an artificial intervertebral disc) in a human body, because of fiction abrasion and corrosion, a layer of protein biological membrane can be formed on a friction interface, along with friction, the protein biological membrane can be converted into a graphite layer, and friction and abrasion of the ceramic biological material can be effectively reduced. Abrasion remediation of the ceramic biological material can be achieved, and the ceramic biological material is good in abrasion self-remediation function in the human body.

Owner:SOUTHWEST JIAOTONG UNIV

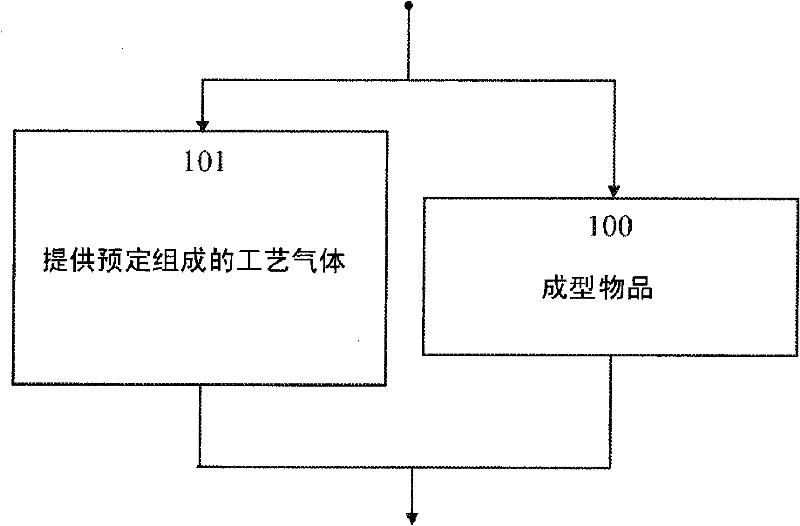

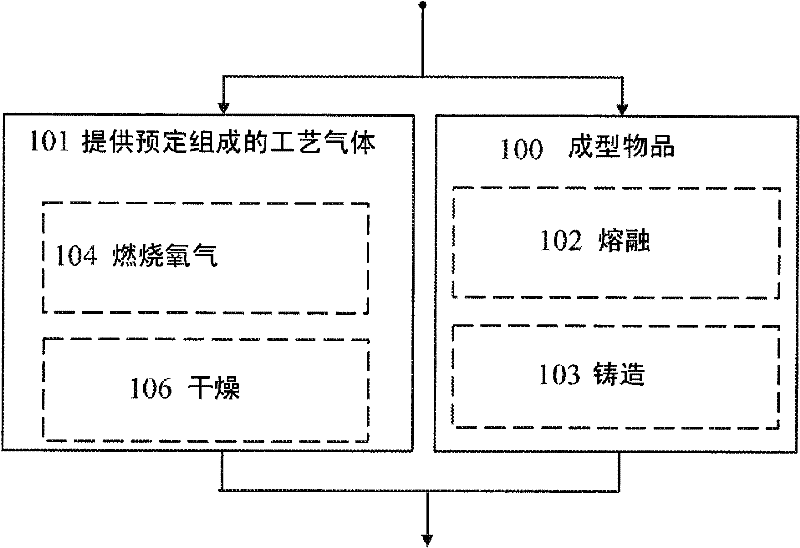

Method of producing precious metal alloy objects

InactiveCN102057067AImprove material propertiesHigh fracture toughnessWelding/cutting media/materialsSoldering mediaMetal alloyBiocompatibility

The present invention provides a method for manufacturing a biocompatible precious metal alloy object. According to a first aspect melting of alloying elements and casting of the biocompatible precious metal alloy are carried out in a process chamber (11) being provided with a process gas of predetermined composition. A burning flame (19) of a hydrocarbon-containing gas provides low oxygen and water content. According to a second aspect post-processing of a precious metal alloy is made in atmosphere provided by the process gas to form the biocompatible precious metal alloy object. The biocompatible precious metal alloy object manufactured according to the invention has a low probability of causing sensitisation when in contact with the human body.

Owner:BIOPM AB

Process for preparing laminar zirconium boride superhigh-temperature ceramic by casting-impregnation method

InactiveCN102173830AAdd extension pathImprove fracture toughnessCeramic layered productsBorideArgon atmosphere

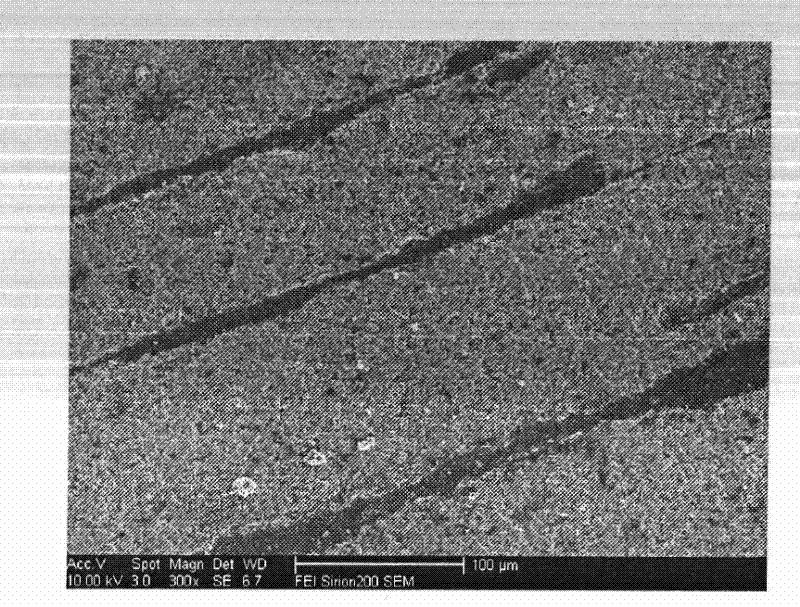

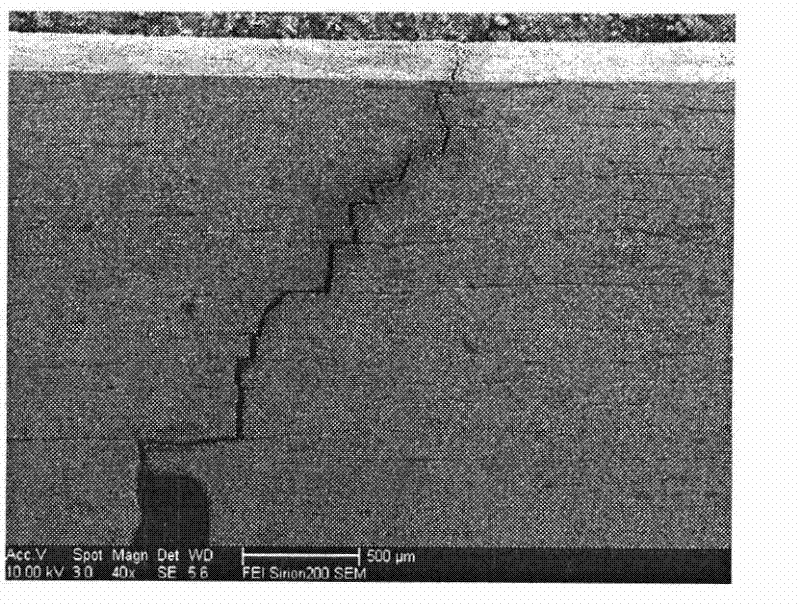

The invention provides a process for preparing laminar zirconium boride superhigh-temperature ceramic by a casting-impregnation method, which is characterized by comprising the following steps: (1) preparing a zirconium boride casting sheet by a casting method: evenly stirring adhesive, plasticizer and solvent, adding zirconium boride ceramic powder to form a casting material, carrying out casting molding, drying at room temperature, and demolding to obtain the casting sheet which is 200-1000 mu m thick; (2) impregnating the casting sheet in graphite or boron nitride slurry by an impregnationmethod so as to impregnate the casting sheet; (3) slicing the casting sheet according to the size of a mold; (4) superposing the sliced casting sheets into the mold, and degreasing in vacuum; and (5)carrying out hot pressed sintering in an argon atmosphere to obtain the laminar zirconium boride superhigh-temperature ceramic of which the fracture toughness is up to 8.3 MPa.m<1 / 2>. The fracture mode of the laminar zirconium boride ceramic is non-brittle fracture, i.e. the laminar zirconium boride ceramic gradually fractures while having certain tolerance to cracking damage, and has favorable performance.

Owner:SHANDONG UNIV OF TECH

Preparation technology of high-comprehensive-performance aluminum-lithium alloy plate

PendingCN113718096AReduce intensityImprove plasticityTemperature control deviceHeat treatment process controlStored energyIngot

The invention relates to a preparation technology of a high-comprehensive-performance aluminum-lithium alloy plate. The technology comprises the following steps that a cast ingot is subjected to temperature-controlled primary rolling, is rapidly cooled to the room temperature and then is placed into a high-temperature air circulation furnace to be heated, after heat preservation is performed for a period of time, the temperature is reduced to the specific temperature, the cast ingot is discharged from the furnace, secondary hot rolling is performed, and the cast ingot is rapidly cooled to the room temperature after being subjected to hot rolling to the specified size; and then the rolled plate is subjected to solid solution quenching, cold deformation and artificial aging treatment. By means of temperature-controlled hot primary rolling and rapid cooling after rolling, a Widmanstatten structure can be fully broken, appropriate deformation stored energy is reserved, the plate is recrystallized to a certain degree in the subsequent high-temperature heating process, flat and straight grain boundaries among grains in the hot-rolled plate are eliminated, and part of nested morphology is formed; through secondary rolling and rapid cooling at the specific temperature, a recrystallized structure can be transformed into a deformed structure again, and precipitation of large-size Widmanstatten is inhibited, so that the aluminum-lithium alloy treated to be in a final use state has excellent comprehensive performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

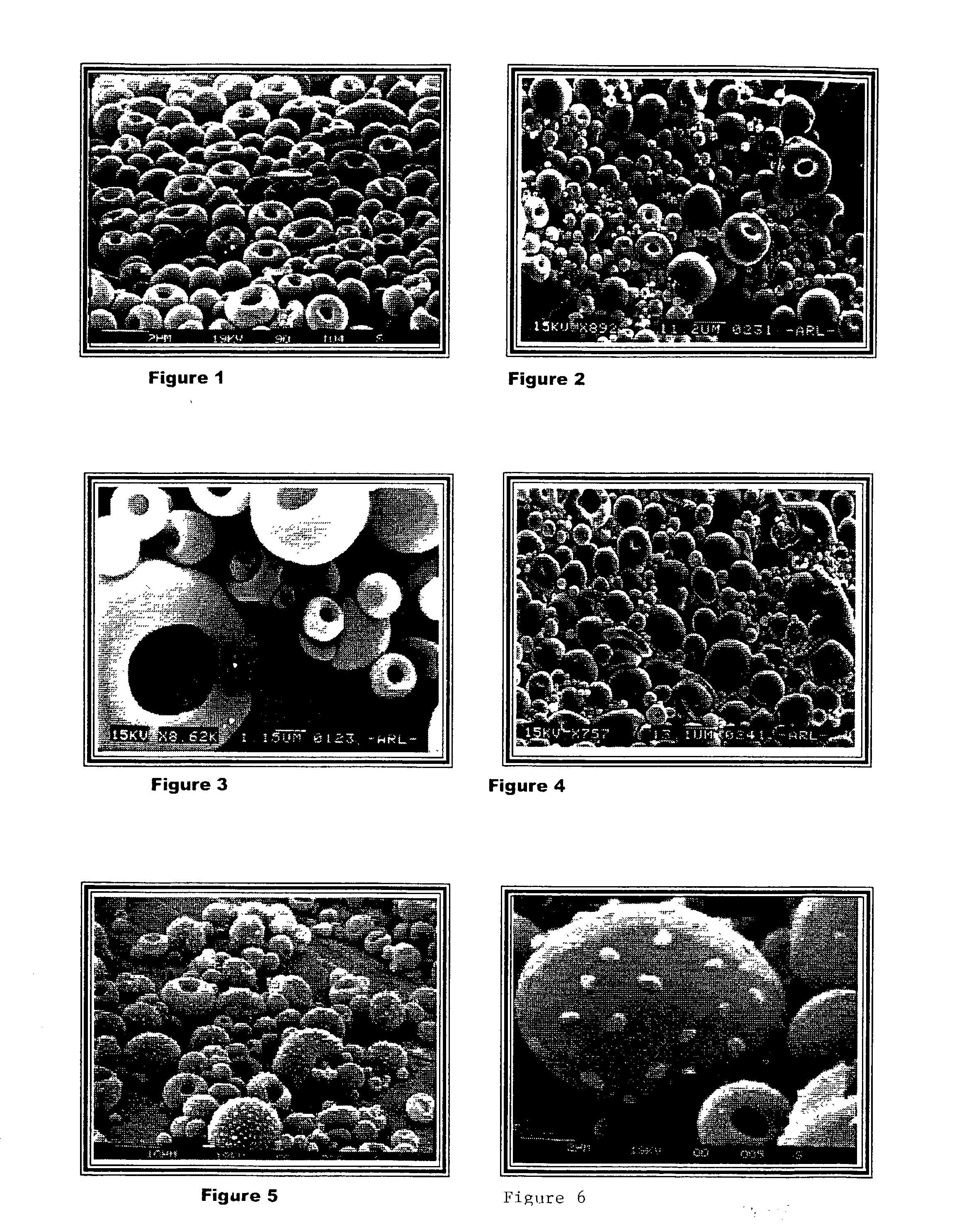

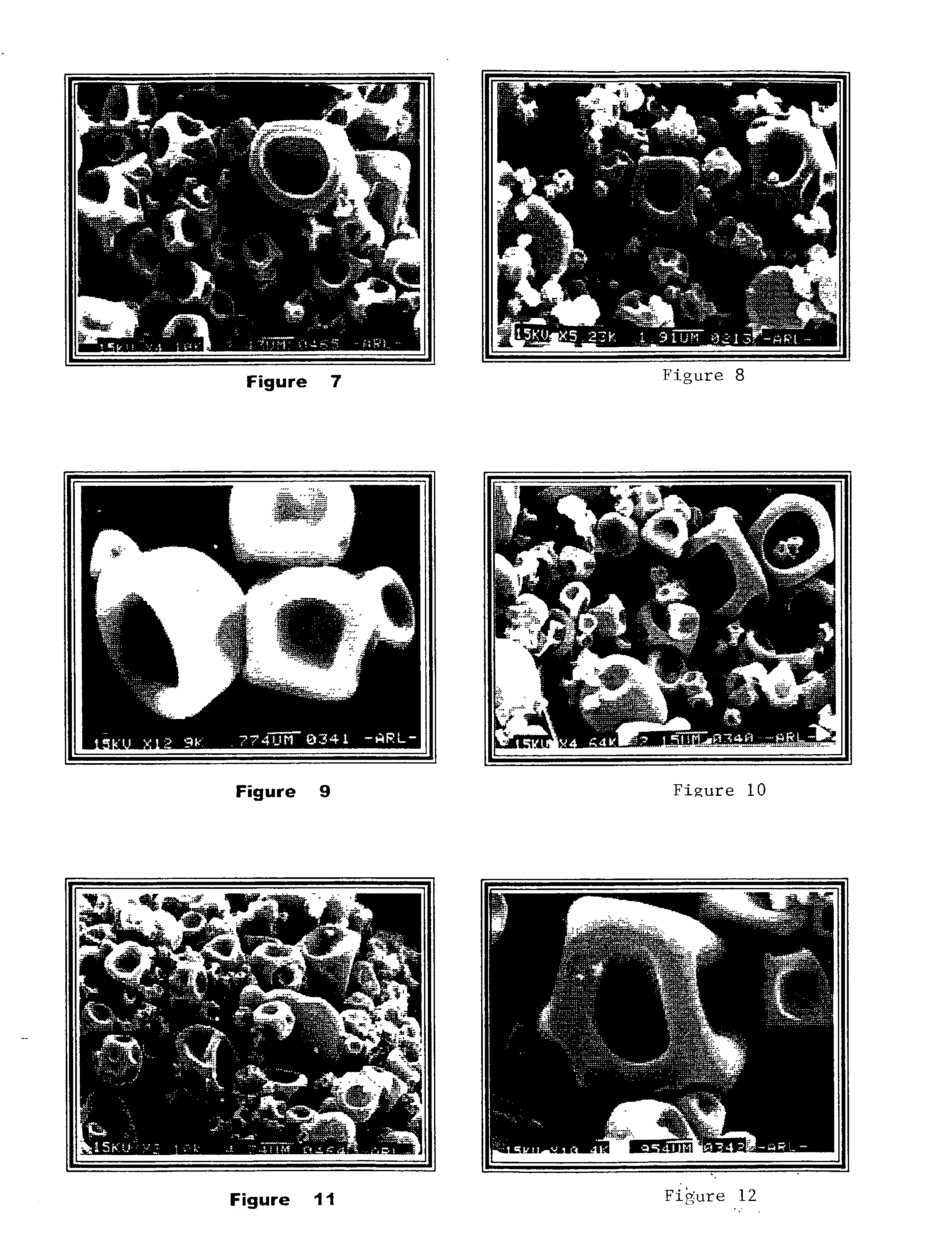

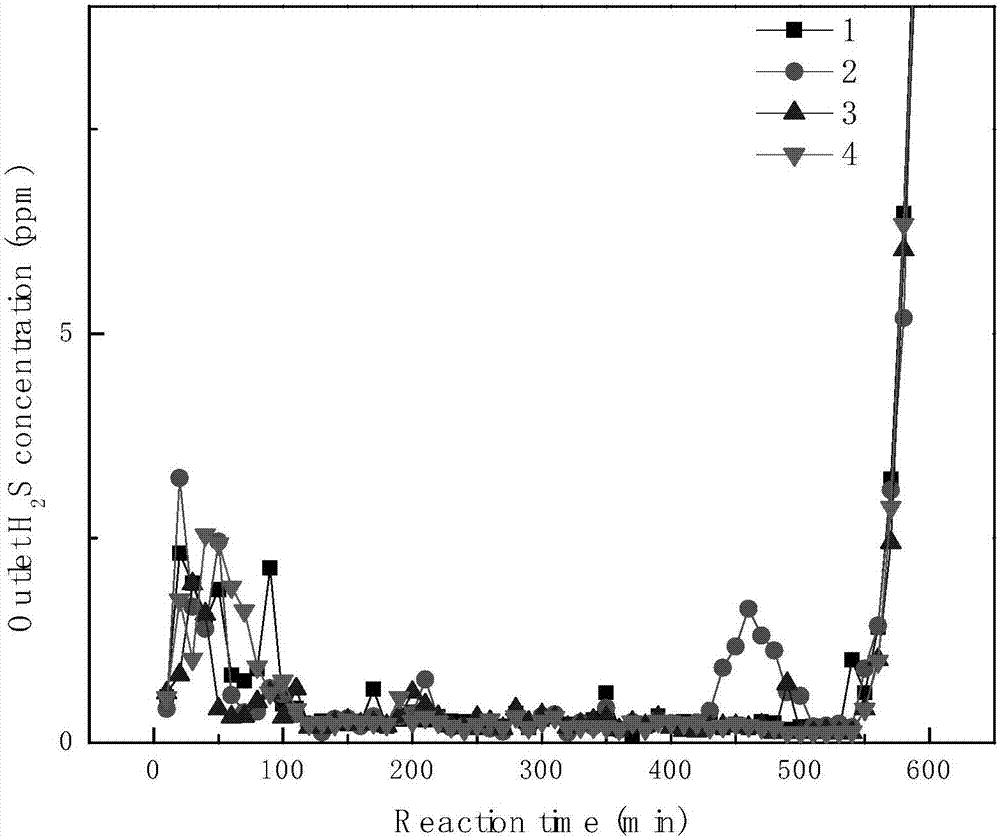

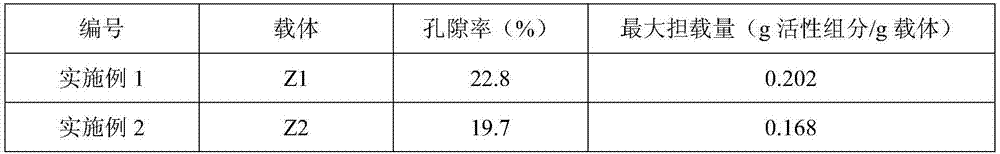

Preparation method of zirconium ball carrier, and application of zirconium ball carrier to manganese-based desulfurizing agent

ActiveCN107213918AHigh fracture toughnessImprove toughnessCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHigh energyWear resistant

The invention discloses a preparation method of a zirconium ball carrier, and application of the zirconium ball carrier to a manganese-based desulfurizing agent. During the preparation, zirconia is used as a carrier support body; polyether sulfone is used as a bonding agent; polyvinylpyrrolidone is used as a dispersing agent; through two-way substitution of N-methyl pyrrolidone and water, a sphere is formed by a wet process in water; after high-temperature sintering, a spherical wear-resistant carrier of a porous structure is formed, i.e., the zirconium ball carrier is obtained. A bran-new carrier preparation method is used; the porous wear-resistant spherical carrier is prepared by a phase inversion method; the spherical carrier is suitable for the preparation of all impregnated catalysts; the problems that the air resistance of a conventional powder catalyst is great, so that the spherical carrier can be swept and taken away by airflow during experiment, and the like are solved. When the carrier is used for preparing a high-temperature manganese-based desulfurizing agent, a high-precision renewable desulfurizing agent is obtained; the desulfurizing agent can be used for removing H2S in an IGCC (Integrated Gasification Combined Cycle); the technical support is provided for electric field electricity generation of an SOFC (Solid Oxide Fuel Cell) with high energy utilization efficiency.

Owner:CHINA UNIV OF MINING & TECH

Explosion suppression material

The invention relates to an explosion suppression material. The explosion suppression material comprises the following chemical components in percentage by weight: 0.05-0.1% of Si, 0.03-0.035% of Cu, 1.0-1.1% of Mn, 1.0-1.1% of Mg, 0.2-0.3% of Cr, 0.05-0.08% of Ti, 0.08-0.12% of Fe, 0.08-0.1% of Zn and the balancing amount of Al. The explosion suppression material has an excellent corrosion-resistant property and is high ductility; in addition, the explosion suppression material is relatively high in strength and can completely meet the needs.

Owner:BEIJING PHOENIX TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com