Preparation technology of high-comprehensive-performance aluminum-lithium alloy plate

A technology of comprehensive performance and preparation process, which is applied in the field of preparation of high comprehensive performance aluminum-lithium alloy plates, can solve the problems of alloy fracture toughness reduction, high production cost, and long cycle, and achieve the goal of improving fracture toughness and alloy plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

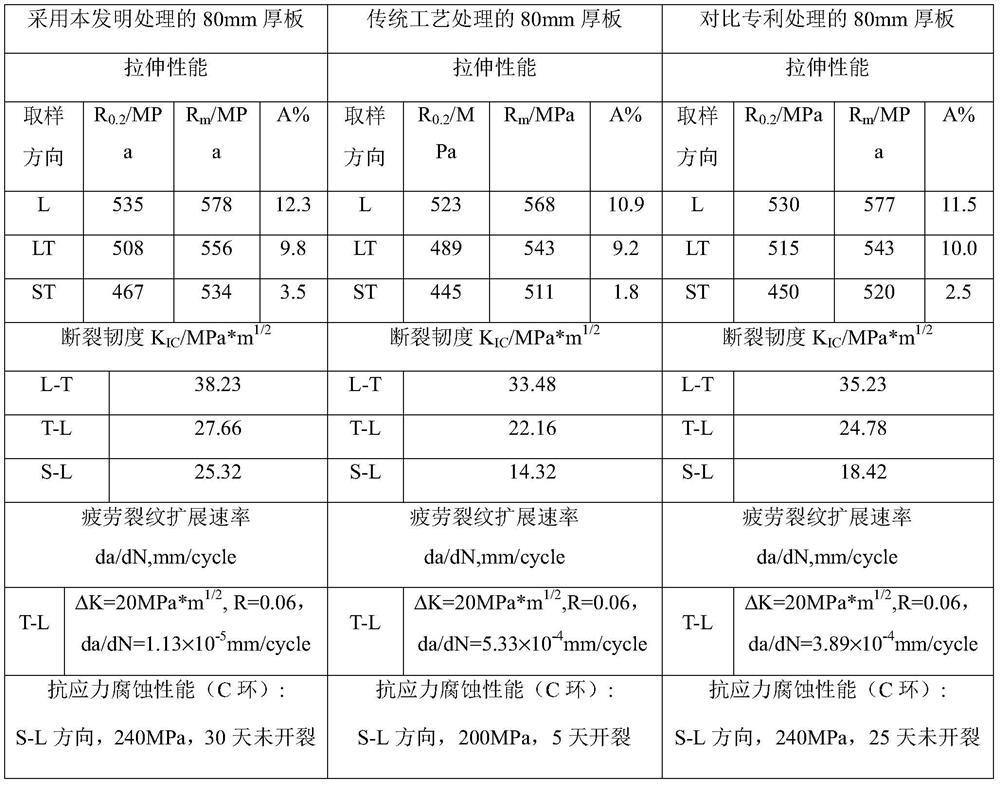

[0030] Adopting the preparation method of the high-comprehensive-performance aluminum-lithium alloy plate involved in the present invention, the corresponding alloy composition and weight percentage are: Cu 4.3%, Li 1.56%, Mg 0.28%, Zn 0.40%, Mn 0.41%, Ag 0.30% , Zr0.08%, Ti 0.02%, Si 0.08%, Fe 0.13%, the balance is Al, the slab with a thickness of 320mm is heated at a temperature of 420±10°C, and then hot rolled out of the furnace, temperature controlled and speed controlled Rolled to 100mm, the final rolling temperature is 401°C, and then cooled to 85°C within 5 minutes by emulsion cooling. Then, dry the surface, air-cool the plate to room temperature and put it into an air circulation heating furnace for heating at a heating temperature of 505°C. After reaching the temperature, keep it for 2 hours, and then air-cool it to 465°C for the second rolling, and stop when the rolling reaches 80mm , the final rolling temperature is 438°C, transfer to the horse rack for spray coolin...

Embodiment 2

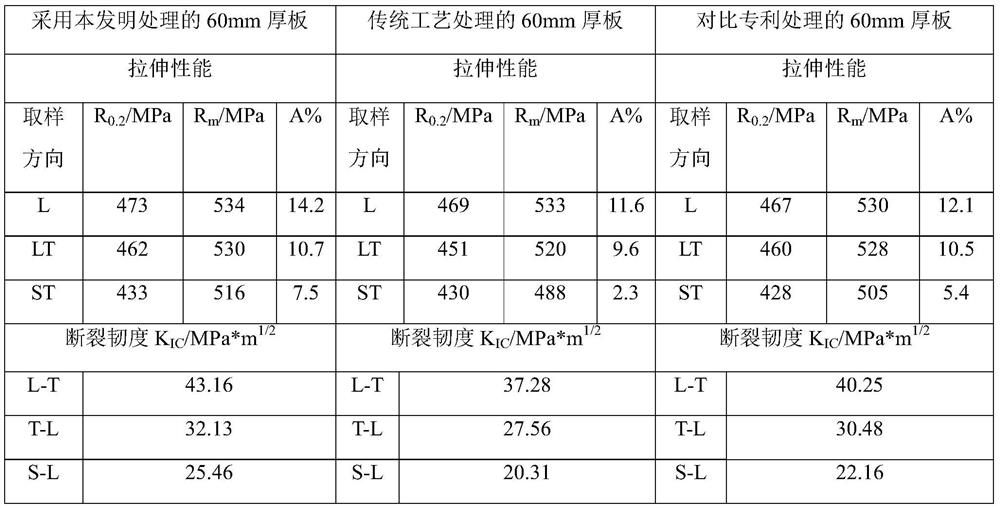

[0037] Adopting the preparation method of the high comprehensive performance aluminum-lithium alloy plate involved in the present invention, the alloy composition and weight percentage are: Cu 3.3%, Li 1.1%, Mg0.44%, Mn 0.42%, Zn0.55%, Zr 0.11% , Ag 0.32%, Ti0.02%, Sc 0.08%, Si 0.08%, Fe 0.13%, the balance is Al, the flat ingot with a thickness of 400mm after homogenization treatment is heated at 400±10℃, and then taken out of the furnace Hot rolling, temperature-controlled, controlled-speed rolling to 90mm, the final rolling temperature is 377°C, and then cooled to 50°C within 4 minutes by emulsion cooling. Then, dry the surface, air-cool the plate to room temperature and put it into the air circulation heating furnace for heating, the heating temperature is 520°C, keep it warm for 1.5h after reaching the temperature, and then air-cool the plate to 470°C for secondary rolling, when the rolling reaches 60mm Stop, the final rolling temperature is 445°C, transfer to the horse ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com