Repeated solid solution aging thermal treatment process of titanium alloy

A technology of solution aging and titanium alloy, applied in the field of multiple solution aging heat treatment process of titanium alloy, can solve the problem of difficulty in obtaining high-plasticity and high fracture toughness forgings, high-strength/ultra-high-strength-high-plasticity-high-toughness of titanium alloys at the same time The best matching is difficult to break through and other problems, so as to achieve the effect of improving plasticity, high toughness matching, and improving fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

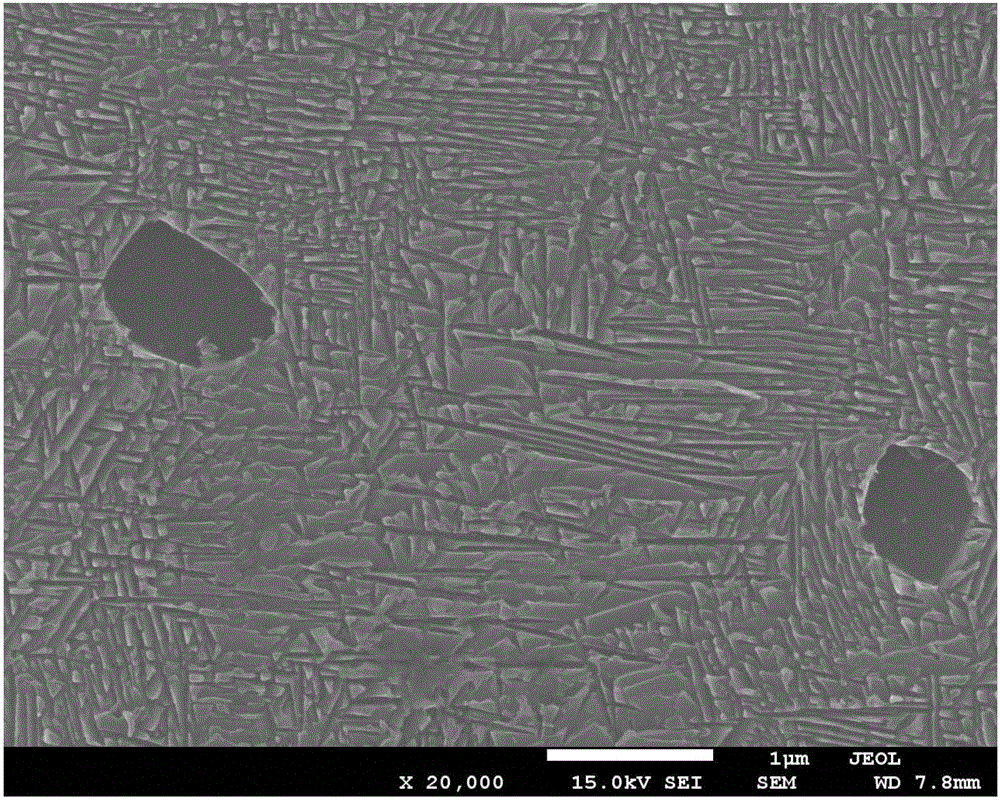

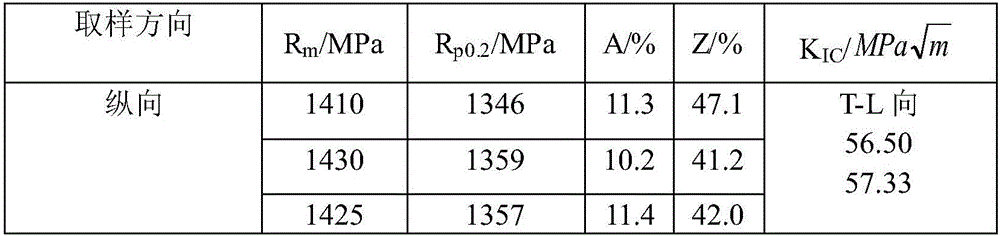

[0029] Example 1: The microstructure of the TB17 titanium alloy forging after adopting the above-mentioned multiple solution aging heat treatment process has spherical α phase, lamellar α phase, and nano- and micron-level α phases, which is a mixed multi-scale microstructure ( figure 1 ). The mechanical properties have ultra-high strength-high plasticity-high toughness matching (Table 1).

[0030] Table 1 Mechanical properties of TB17 titanium alloy forgings

[0031]

Embodiment 2

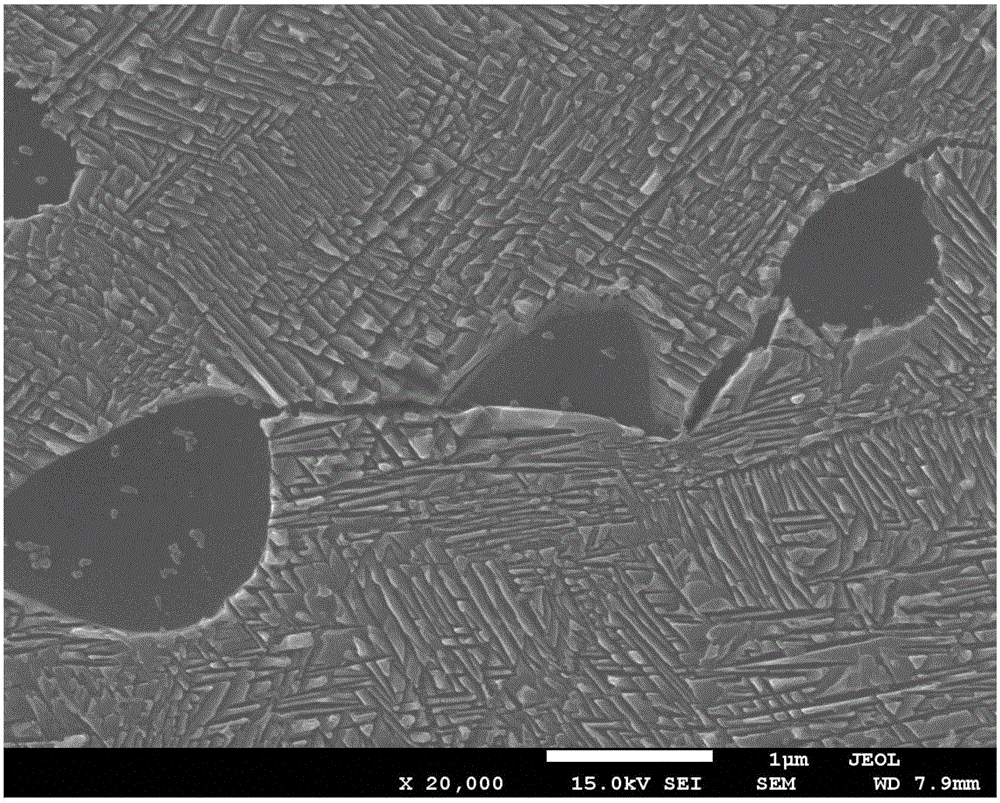

[0032] Example 2: The microstructure of TB8 titanium alloy forgings after adopting the above-mentioned multiple solution aging heat treatment process has spherical α phase, lamellar α phase, and nano- and micron-level α phases, which is a mixed multi-scale microstructure ( figure 2 ). The mechanical properties have ultra-high strength-high plasticity-high toughness matching (Table 2).

[0033] Table 2 Mechanical properties of TB8 titanium alloy forgings

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com